Welded forged steel integrated piston and its producing method

An integral piston, welded technology, applied in the direction of pistons, engine components, machines/engines, etc., can solve the problems of complex formation process of closed oil cavity and low structural strength of piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

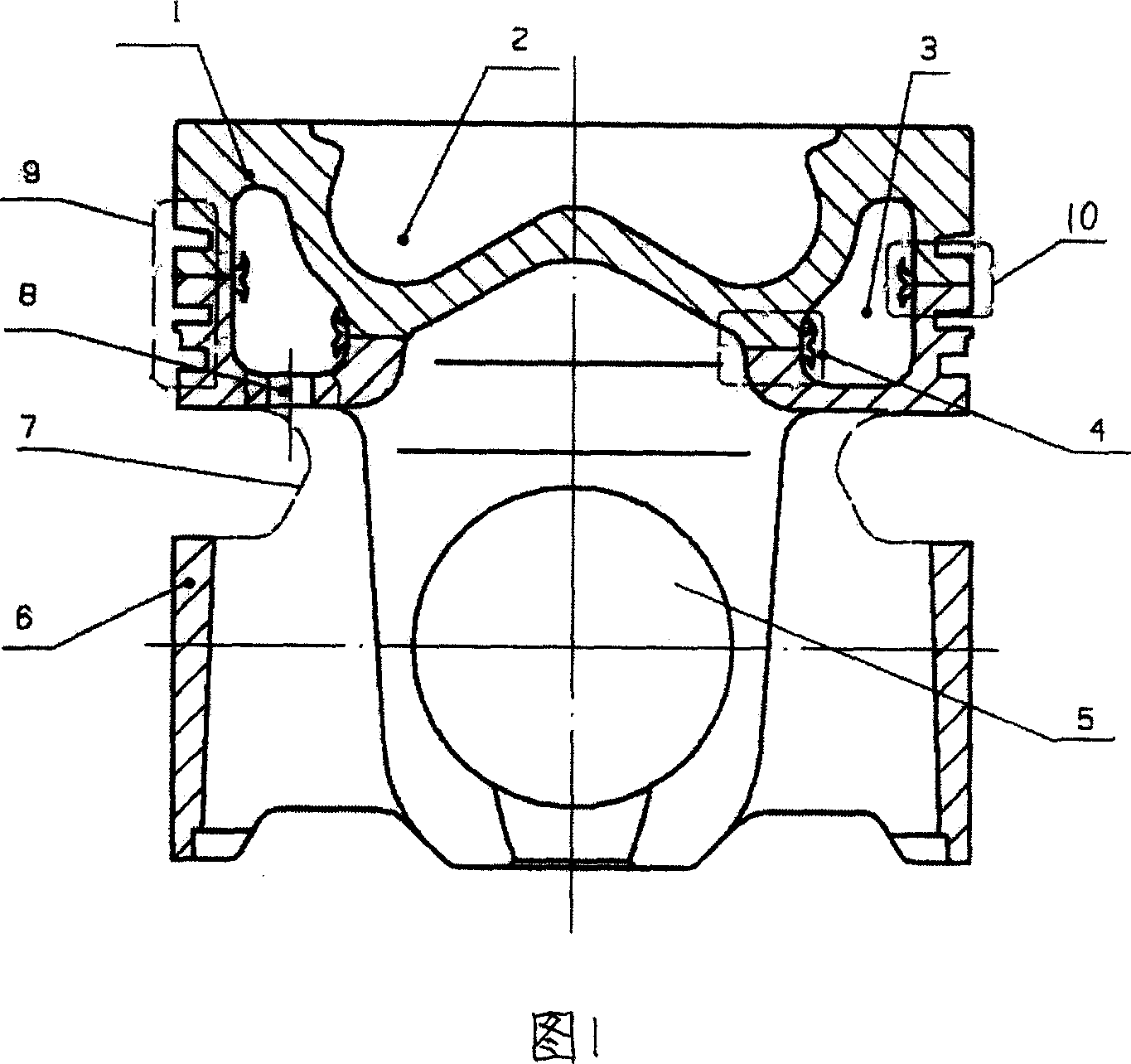

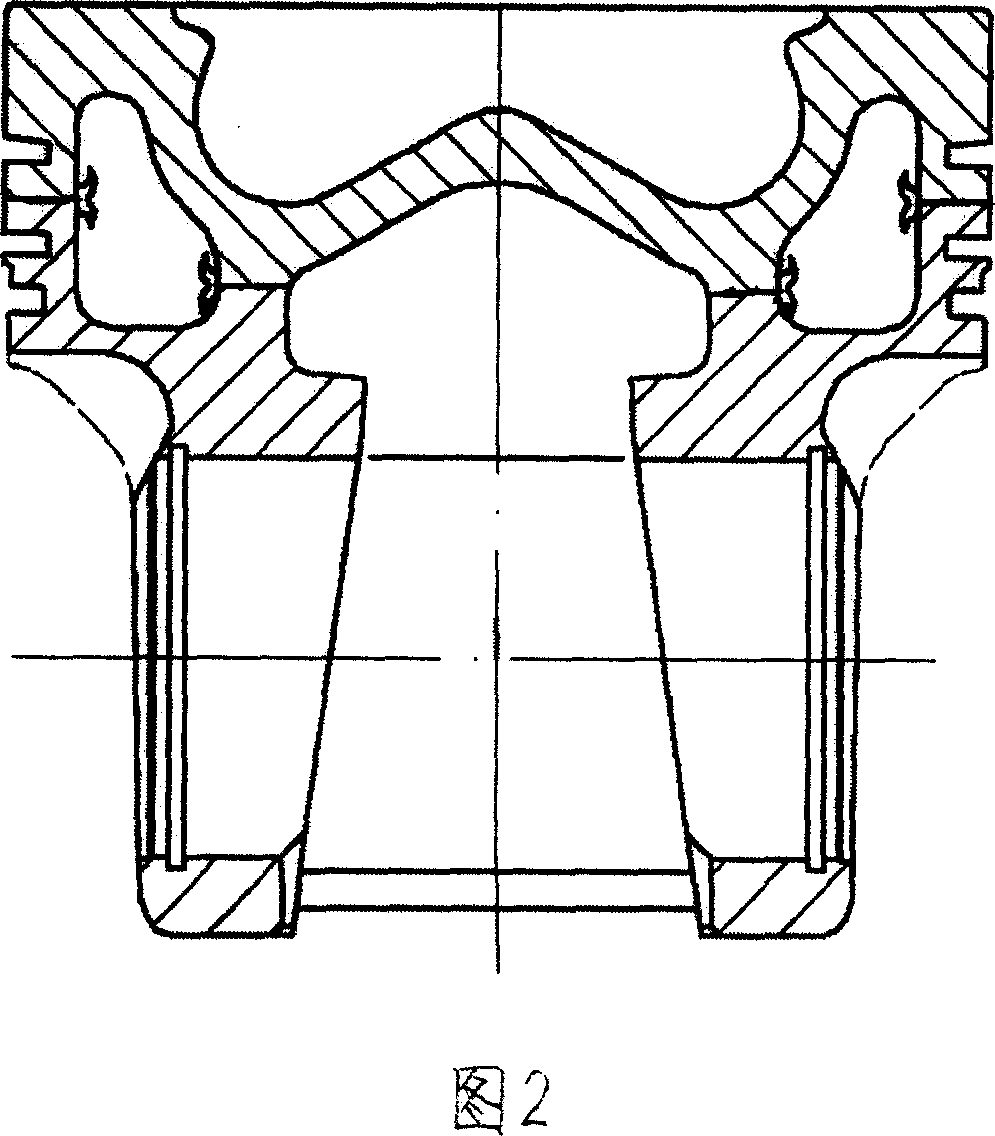

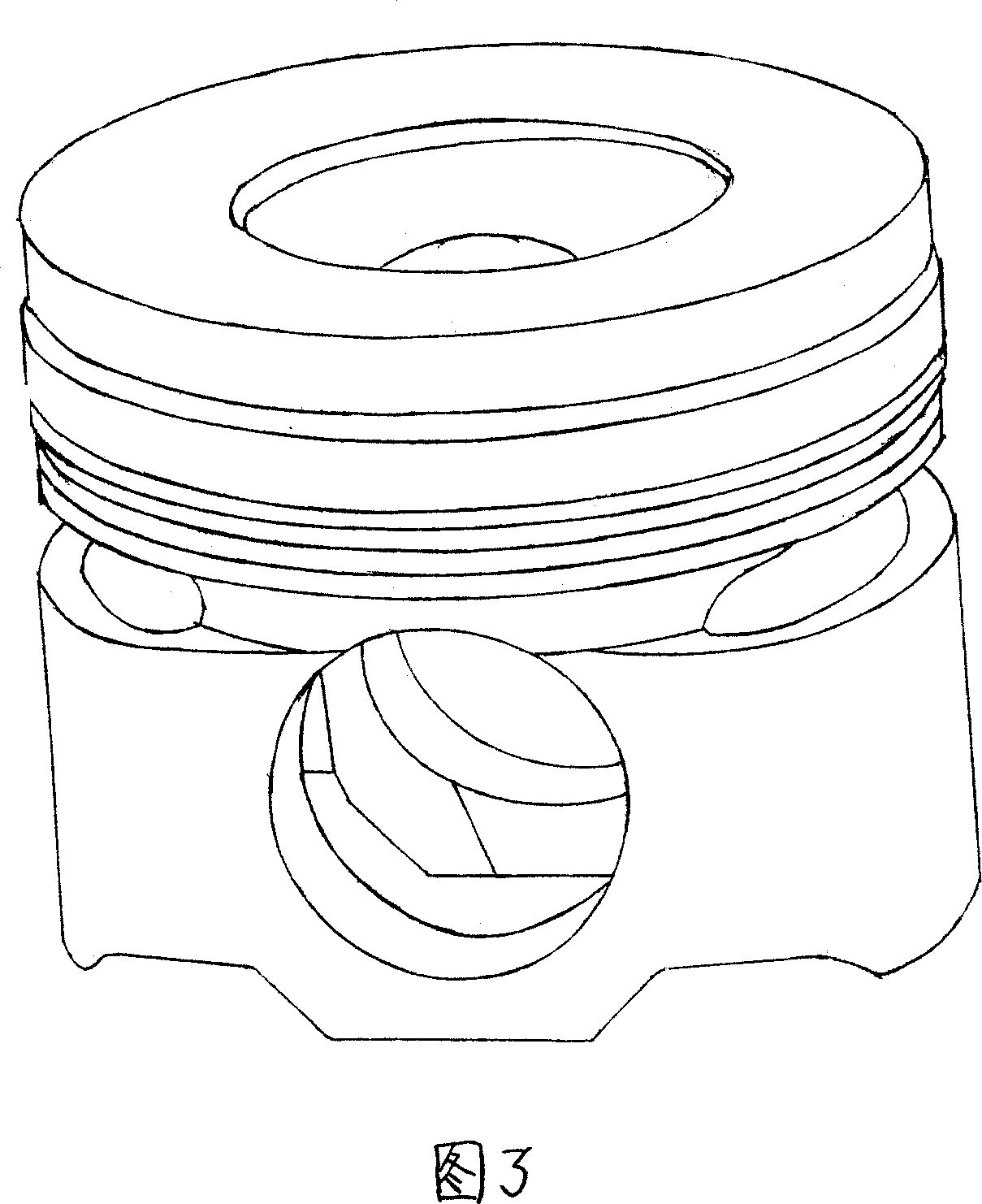

[0019] The specific structure and manufacturing method of the present invention are further described below in conjunction with the embodiments given with accompanying drawings.

[0020] As shown in the accompanying drawings, the welded forged steel integral piston of the present invention has a forged head (1) and a forged skirt (6), the head and the skirt are welded and fixed into a piston body, and the ring groove ( 9) There is a cooling oil chamber (3) on the piston body between the combustion chamber (2), and the cooling oil chamber communicates with the inner cavity of the piston body through the oil inlet and outlet holes (8), and there is an annular groove on the skirt below the ring groove ( 7), the annular groove communicates with the inner cavity of the piston body in the long axis direction.

[0021] The head (1) and skirt (6) are welded together through the welding surface (4) below the combustion chamber and the welding surface (10) in the middle of two adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com