Patents

Literature

60results about How to "Easy to return oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

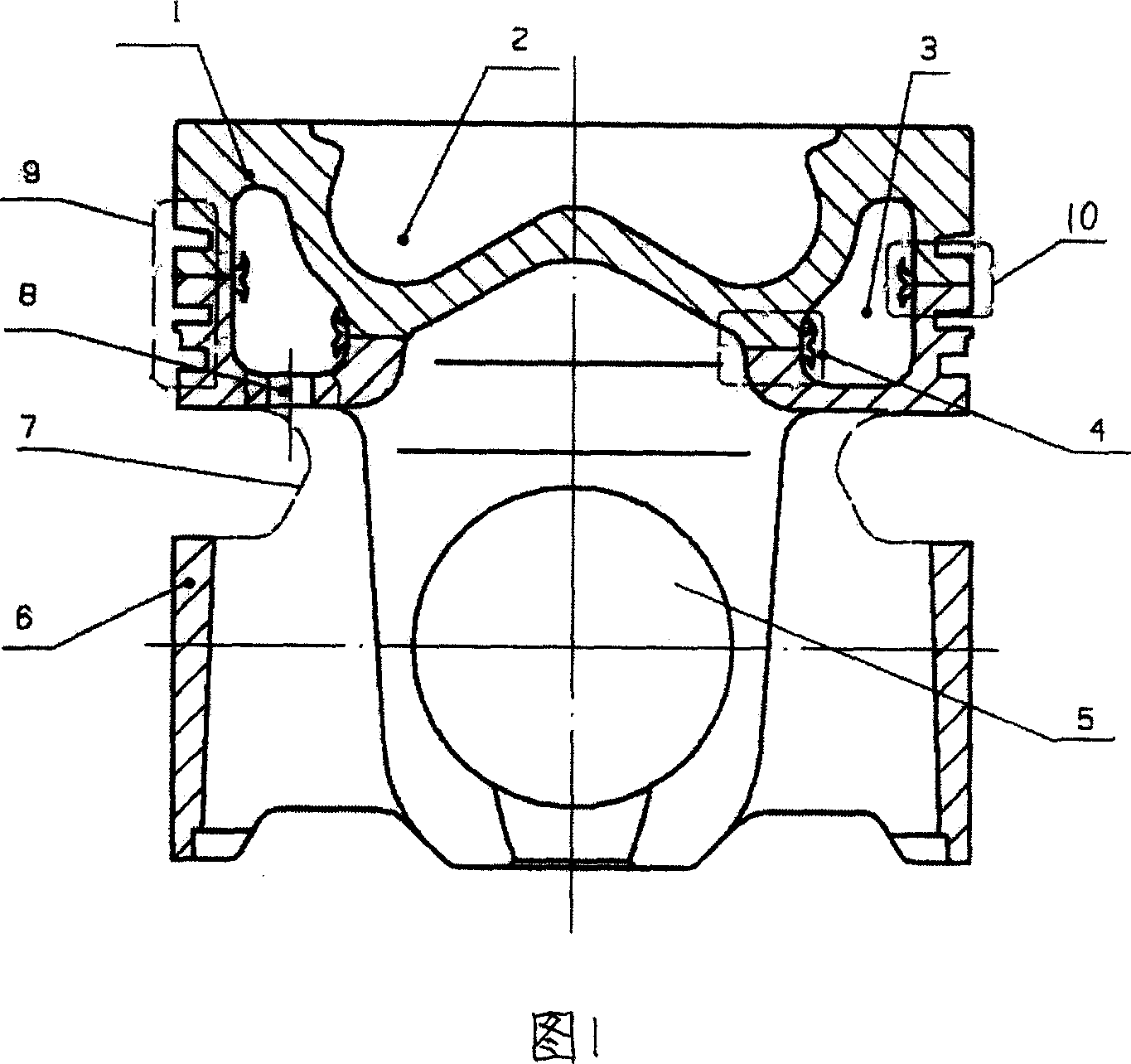

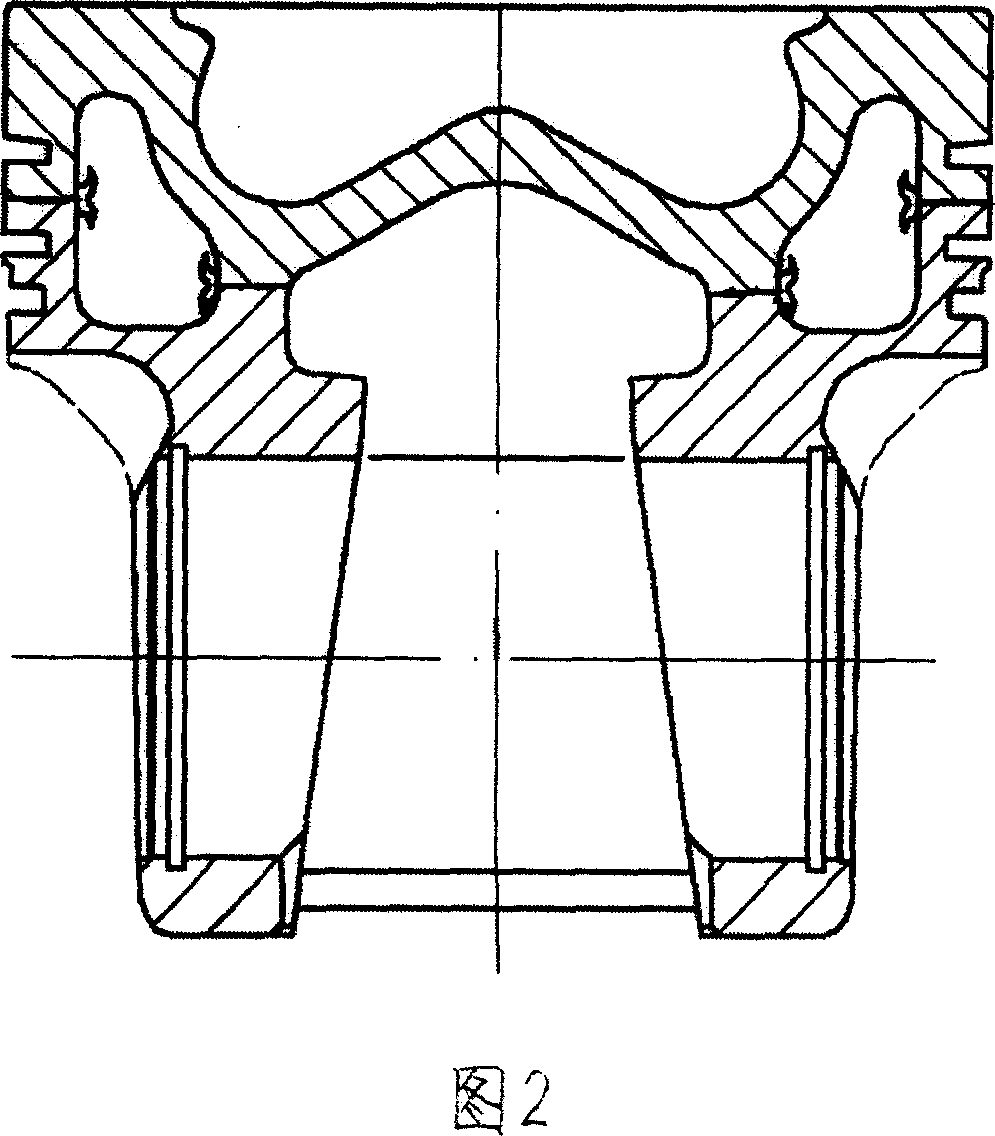

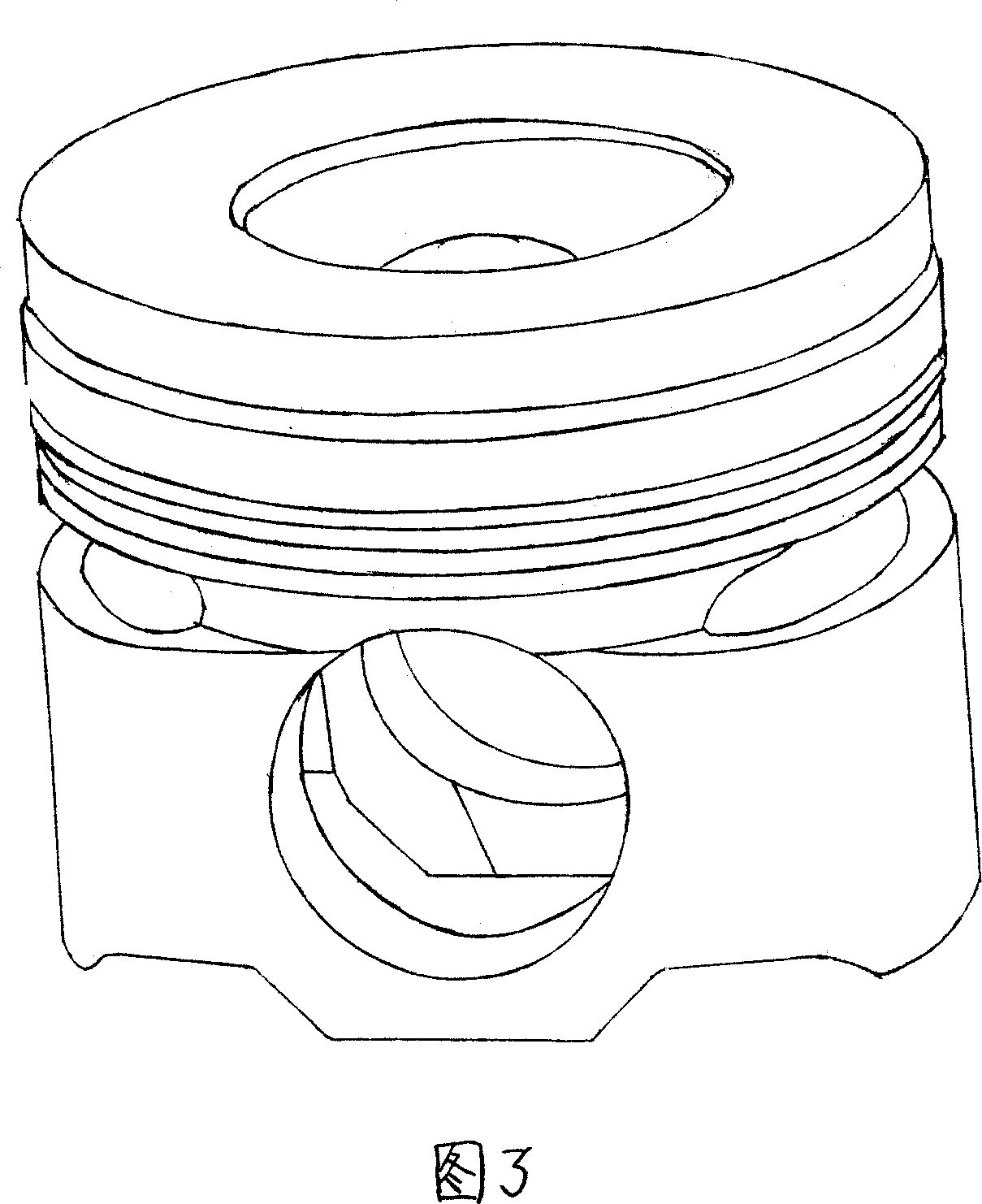

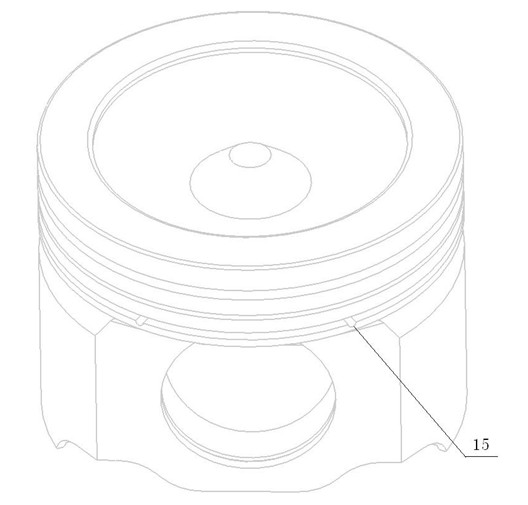

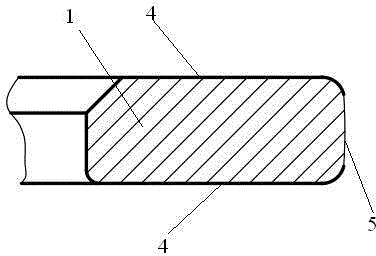

Welded forged steel integrated piston and its producing method

InactiveCN1944994AImprove structural rigidityReduce weightMachines/enginesPistonsFriction weldingCombustor

The present invention is welded integral forged steel piston and its manufacturing process. The manufacturing process includes the following steps: forging the head blank and the skirt blank; separate heat treatment of the head blank and the skirt blank; coarse machining the head blank and the skirt blank; friction welding the head and the skirt together; machining the ring slot, combustor, pin hole, excircle and oil outlet in the piston; and final surface phosphorizing or graphitizing treatment of the piston. The present invention has raised manufacturability, high integral structural rigidity, lowered weight and low machine oil consumption compared with available integrally cast piston.

Owner:SHANDONG BINZHOU BOHAI PISTON

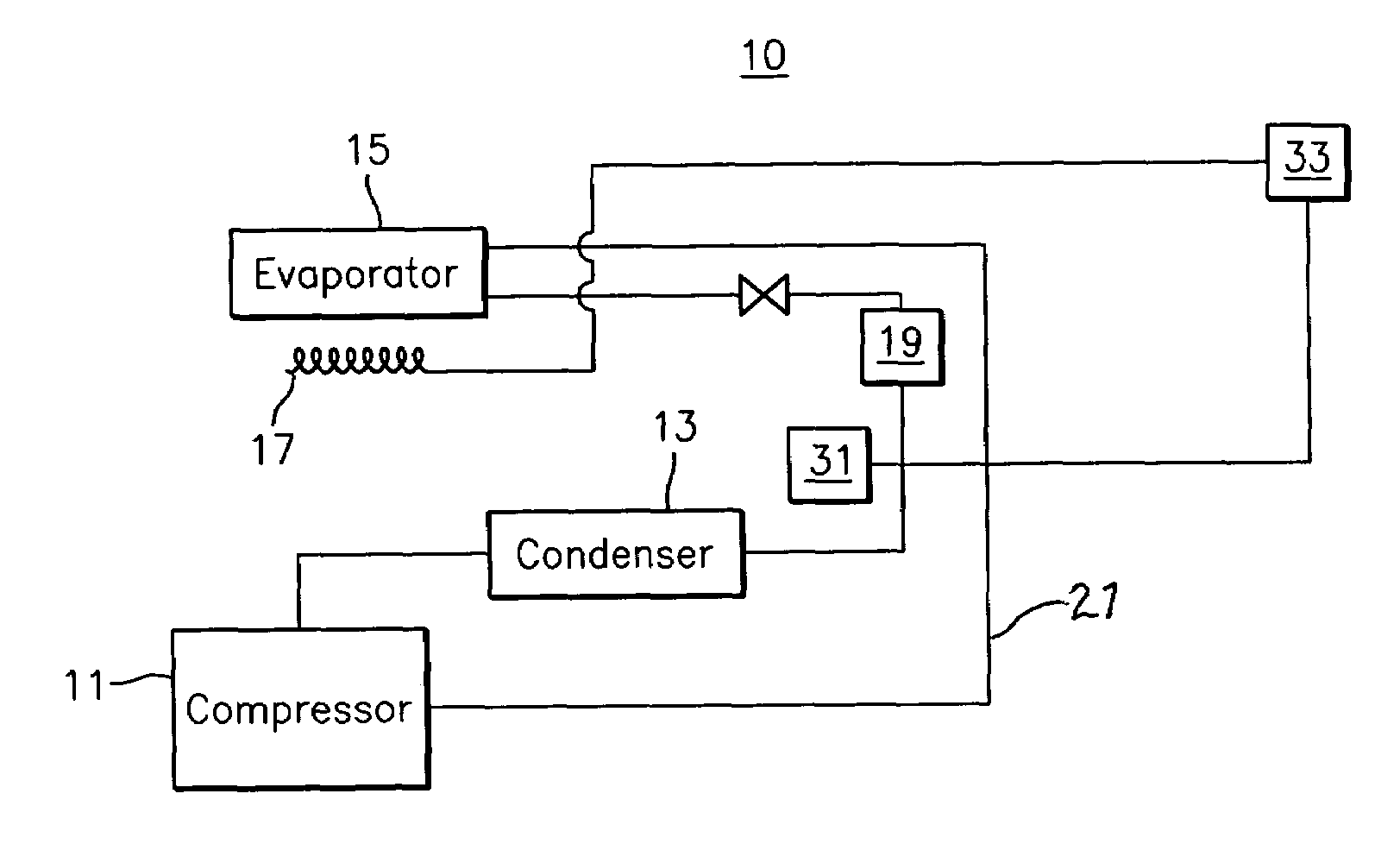

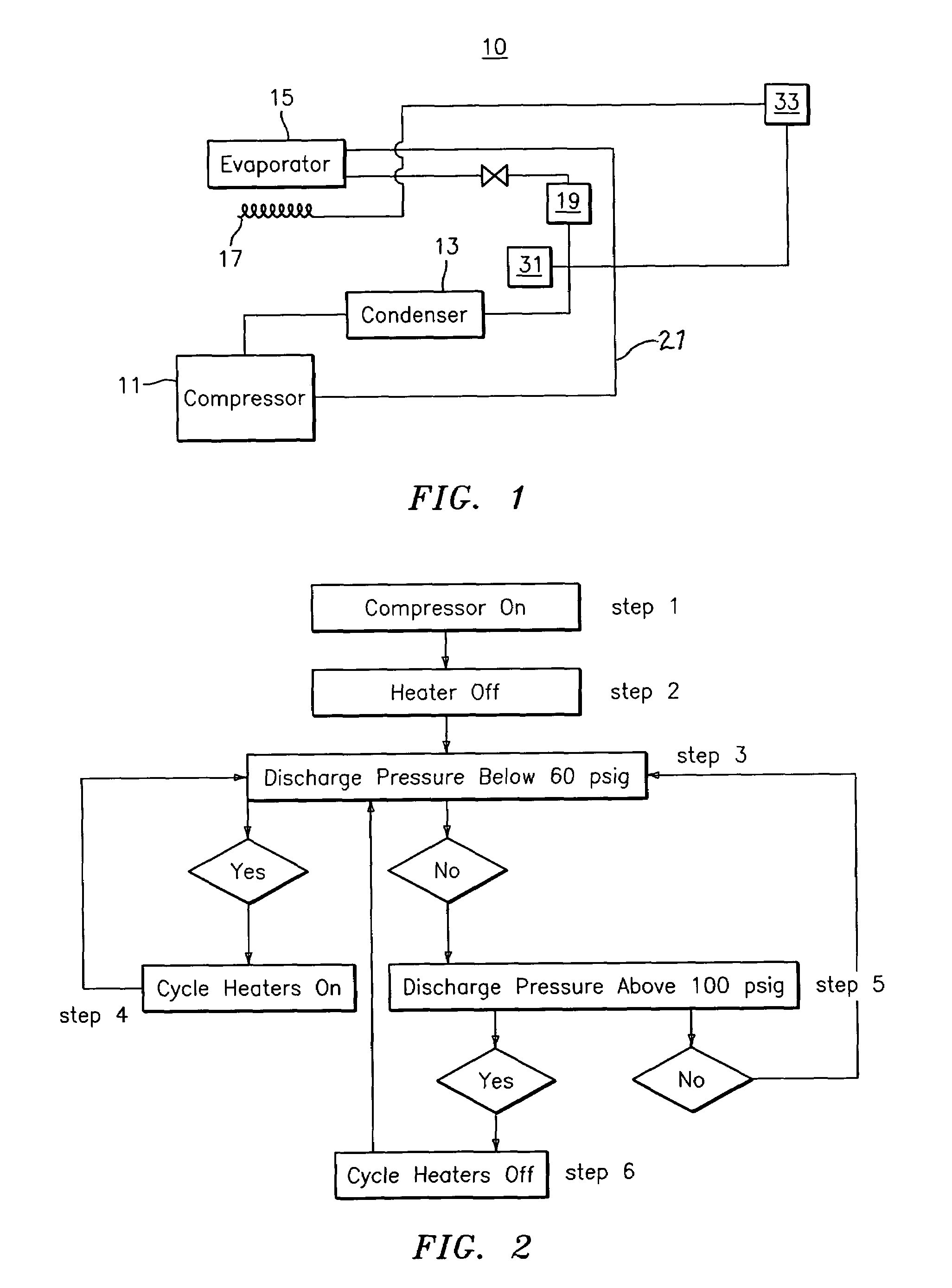

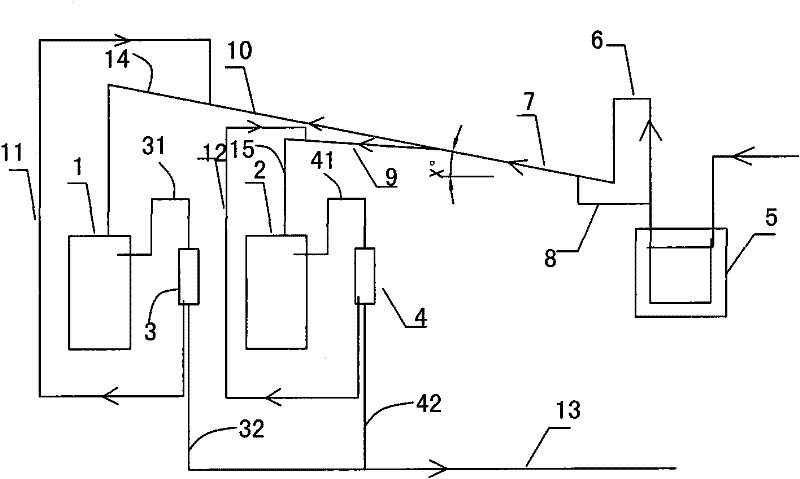

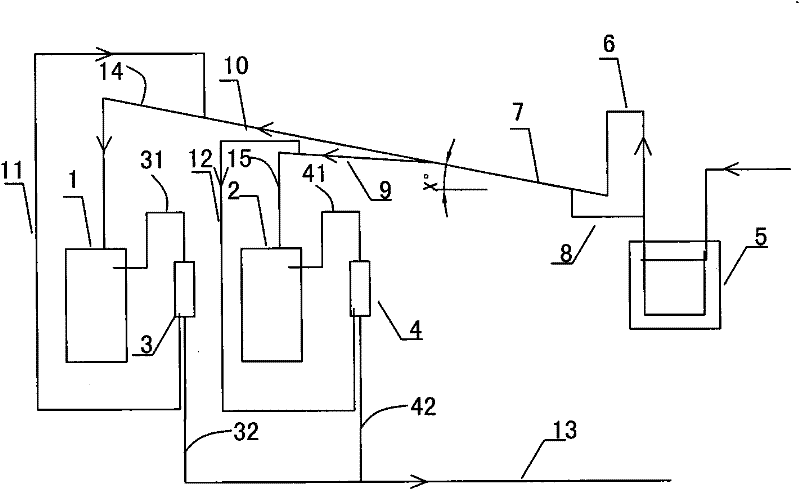

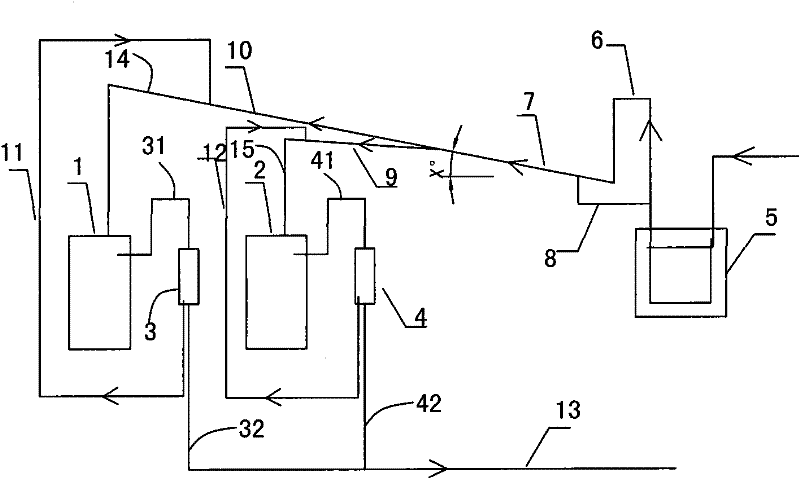

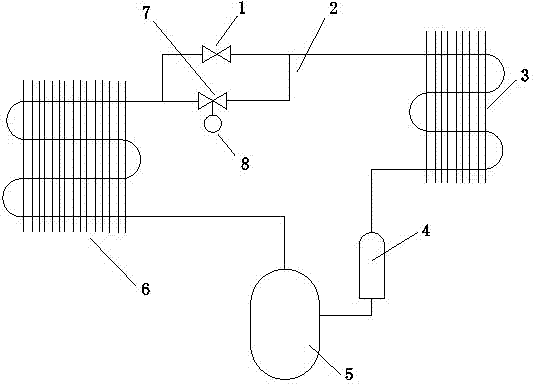

Heater cycling for improved oil return

ActiveUS6993920B2Easy to return oilMaintaining tight temperature controlCompressorHeat pumpsEngineeringRefrigerant

A method comprises the steps of (a) providing a refrigeration unit having a refrigerated or heated space and at least one measured operating parameter, (b) providing heat to the refrigerated space when the at least one measured operating parameter exceeds a first threshold, (c) terminating provision of heat when the at least one measured operating parameter exceeds a second threshold, and repeating steps b–c when the at least one operating parameter falls below the first threshold. In using this method, the unit can be operated continuously, with substantially higher refrigerant mass flow and evaporator pressure then in the prior art. Higher refrigerant mass flow rate and higher evaporator pressure improve oil return to the compressor, thus reducing the like hood of compressor damage due to oil pump out.

Owner:CARRIER CORP

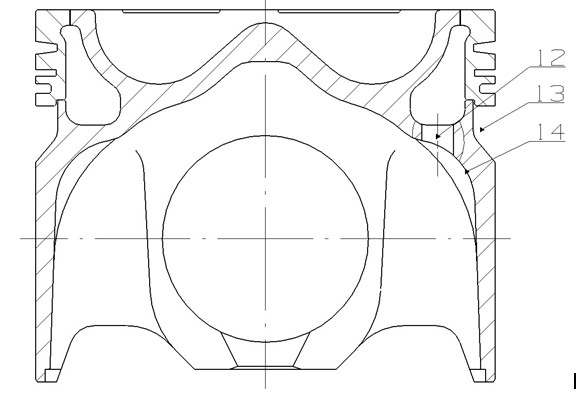

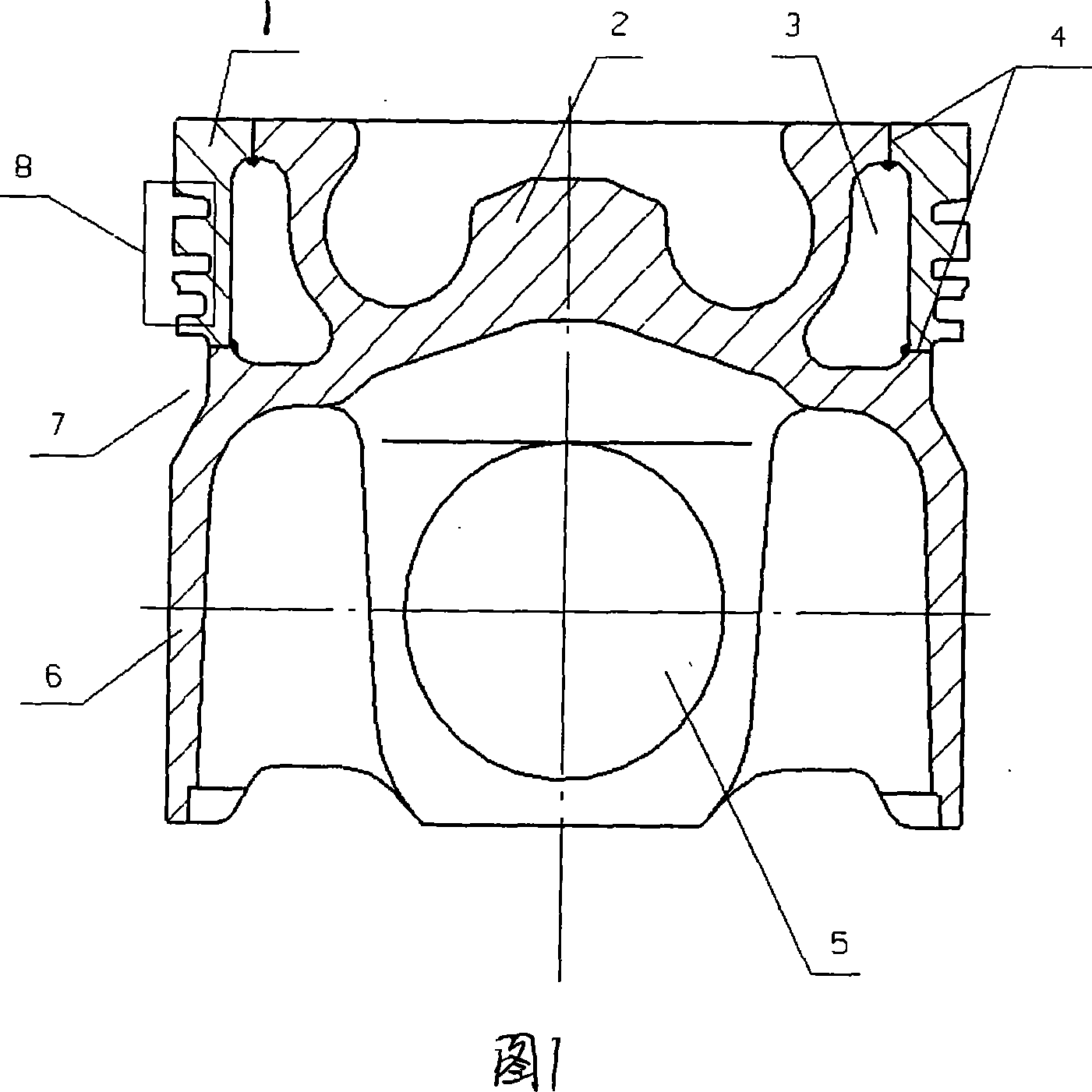

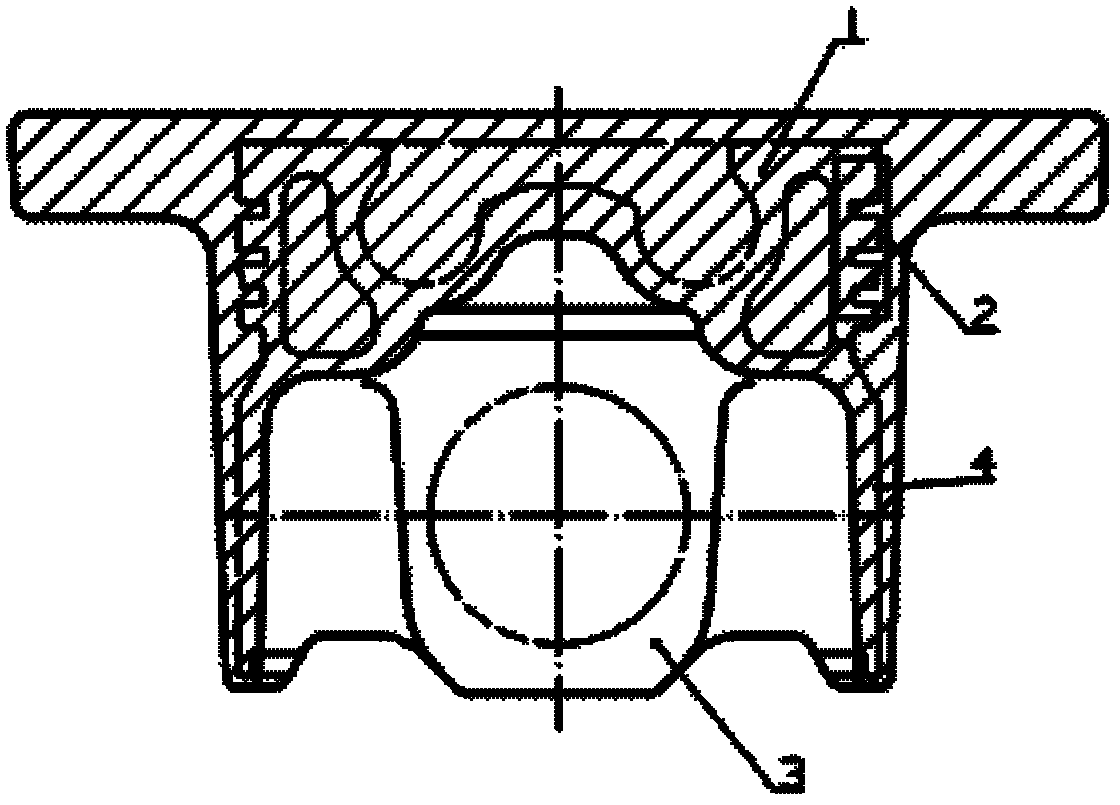

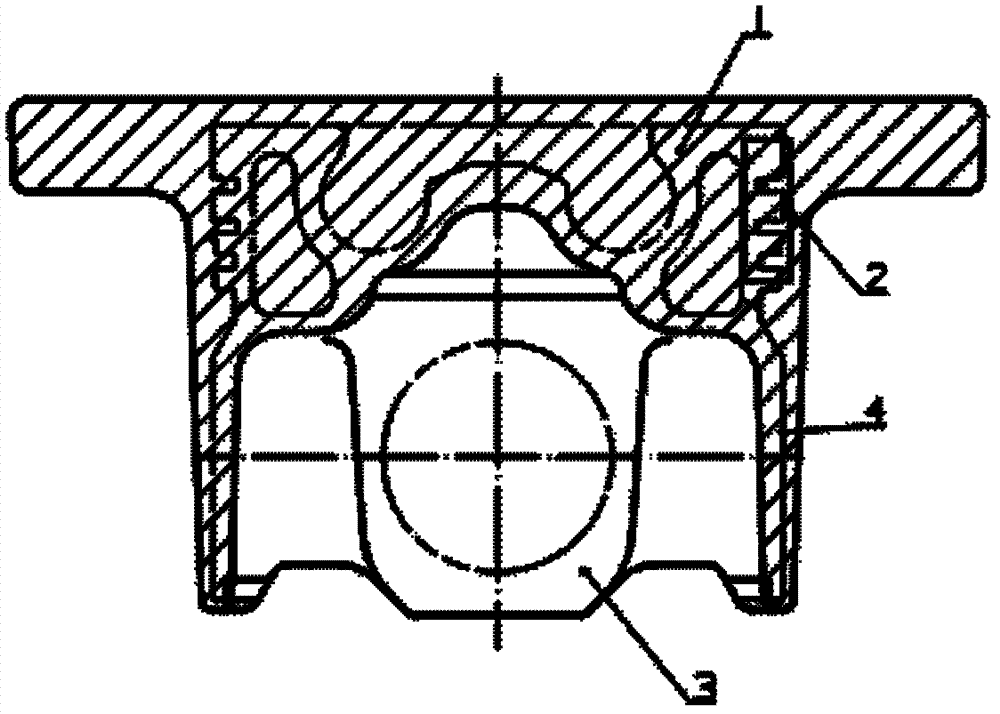

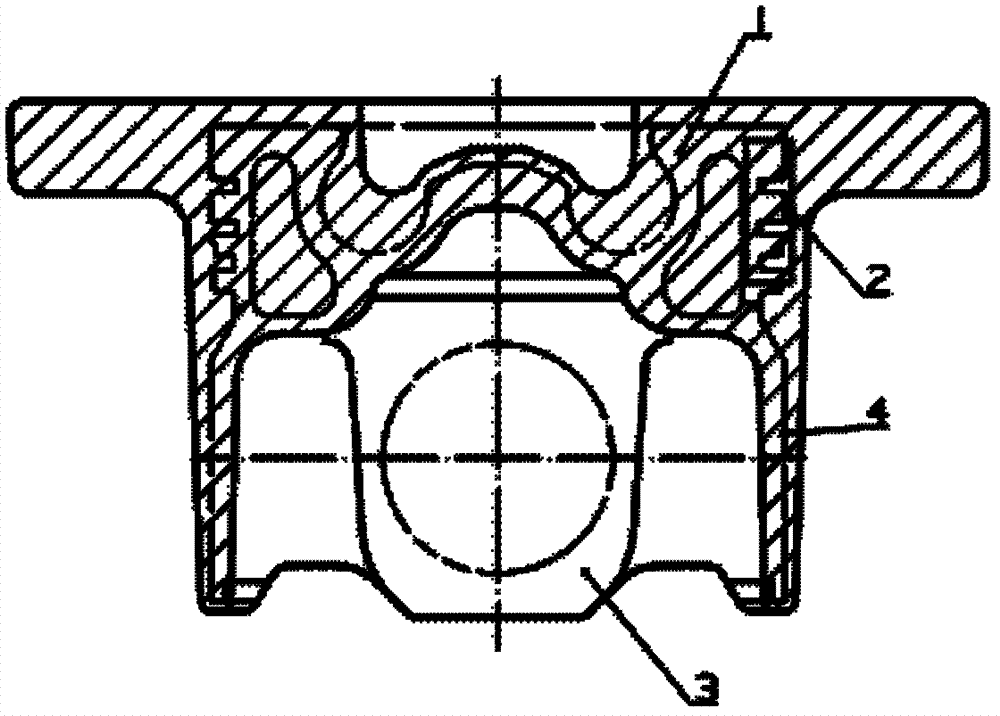

Novel laser welding piston with forged steel structure

InactiveCN101793205AImprove structural rigidityImprove flexibilityMachines/enginesPistonsPiston ringHigh pressure

The invention relates to a novel laser welding piston with a forged steel structure. The piston comprises a forged piston ring body and a piston body, wherein the piston ring body and the piston body are welded by laser; a closed cooling oil chamber is formed between the piston ring body and the piston body and is communicated with the external through an oil inlet hole and an oil outlet hole; the lower part of the piston ring body is provided with an oil ring groove; the piston body corresponding to the position of the oil ring groove is provided with an annular groove; a girdle band is arranged between the oil ring groove and the annular groove; the girdle band is provided with a plurality of oil return holes communicating the oil ring groove and the annular groove; or the lower side of the oil ring groove is provided with a plurality of level oil return blind holes. The piston reduces weight of the piston, and increases flexibility of the piston body; and the oil return holes or the level oil return blind holes are favorable for back flow of machine oil of the oil ring groove, particularly the machine oil at the bottom of the oil ring groove so as to prevent the spilling of the machine oil caused by high pressure of the machine oil, and contribute to reducing machine oil consumption and harmful emissions of motors.

Owner:SHANDONG BINZHOU BOHAI PISTON

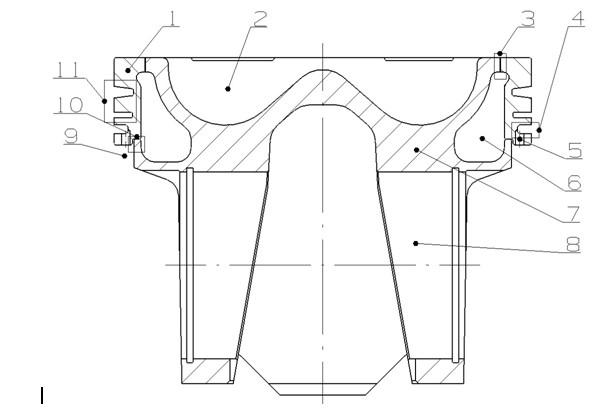

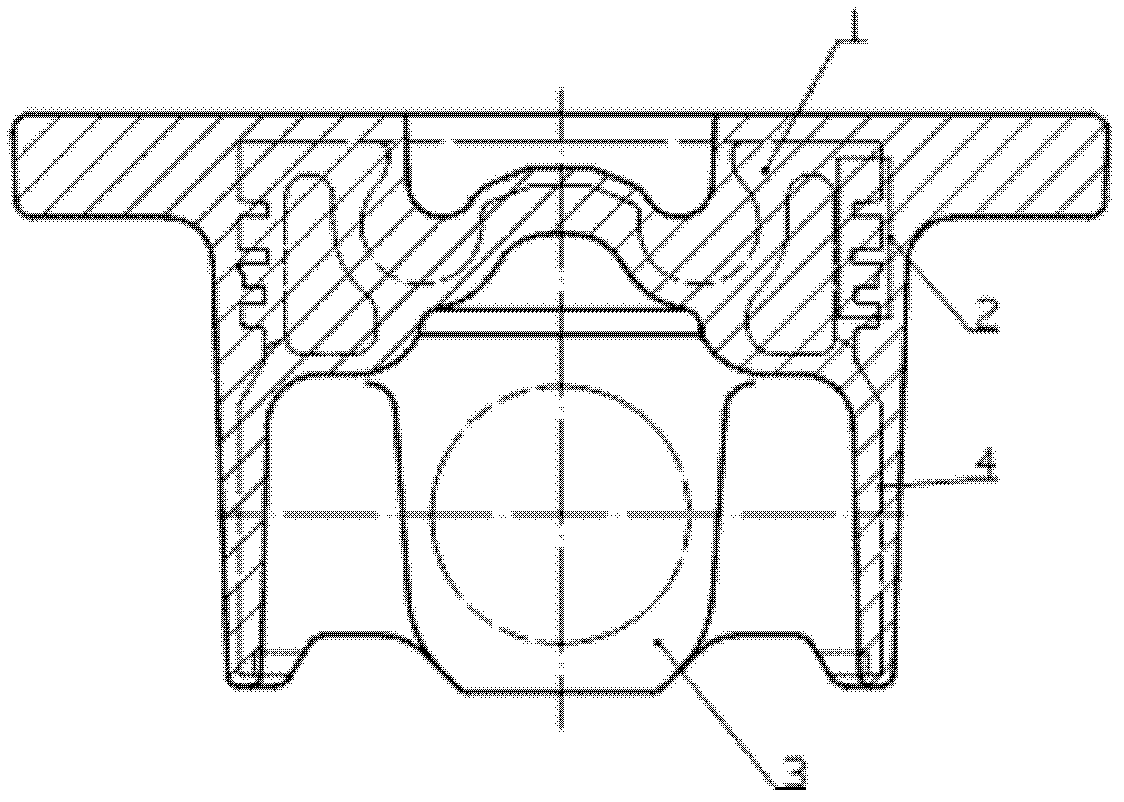

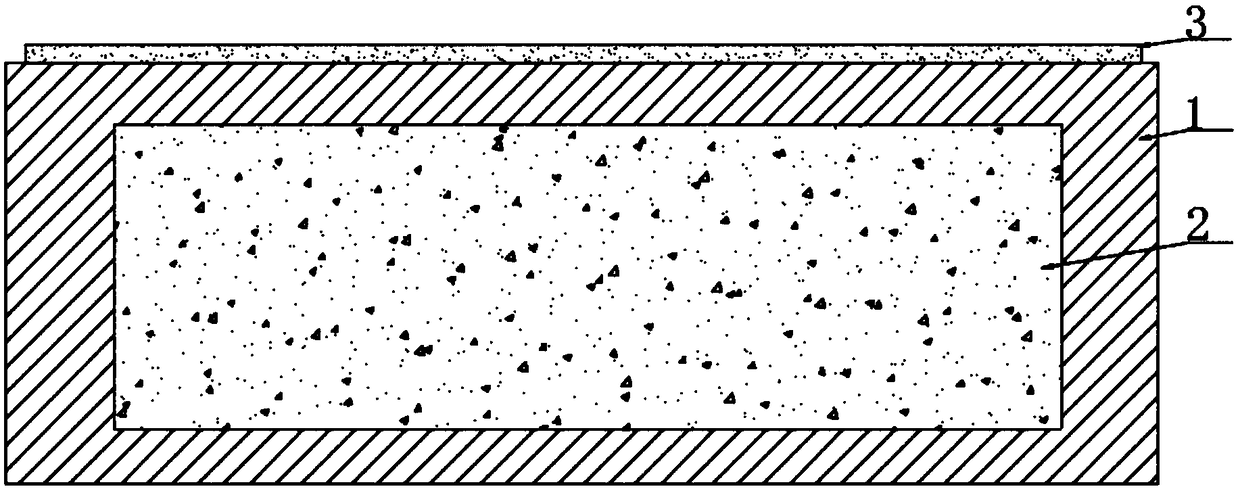

Welding type single piece piston in forged steel with close internal cooling oil pocket and fabricating method

InactiveCN101092914ALower working temperatureImprove structural rigidityMachines/enginesPistonsPiston ringLaser

This invention discloses a weld forging steel single-piece piston and its manufacturing method meeting the requirement of high power, high intensification and low discharge including: a piston body containing a piston ring welded to one unit with the piston by laser, an internal cool oil cavity set between them to connect with the internal cavity of the piston by at least two inlet and outlet holes and a bolt hole under the piston.

Owner:SHANDONG BINZHOU BOHAI PISTON

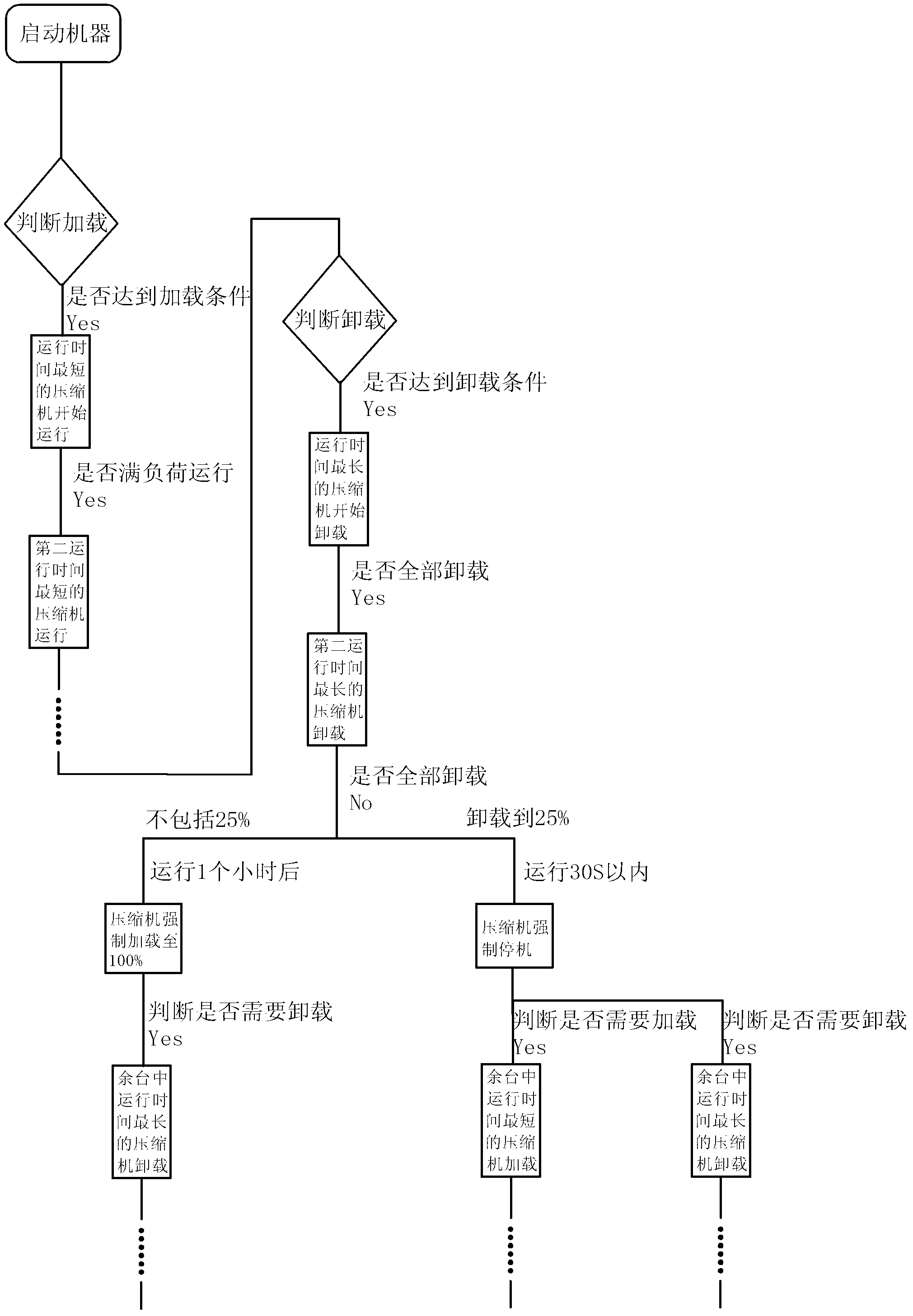

Capacity adjusting control method of multi-nose screw compressor

ActiveCN103233893AEasy to return oilImprove the quality of operationRotary/oscillating piston pump componentsLiquid fuel engine componentsOperation modeEngineering

The invention provides a capacity adjusting control method of a multi-nose screw compressor. The capacity adjusting control method solves the problem that the existing multi-nose screw compressor unit in an operation mode is poor in lubrication. The capacity adjusting control method of the multi-nose screw compressor comprises the following steps of 1, starting up and judging whether loading is required; 2, detecting the running time of each compressor before the loading; 3, loading the compressor with the shortest running time; 4, loading the compressor with the second shortest running time; 5, loading gradually and sequentially till the load requirement is met; 6, judging whether unloading is required; 7, detecting the running time of each compressor before the unloading; 8, unloading the compressor with the longest running time; 9, unloading the compressor with the second shortest running time; and 10, unloading gradually and sequentially till the load requirement is met. According to the capacity adjusting control method, for a condition that poor lubrication can occur when the compressor runs in a partial load state for a long time, a controller controls each compressor to act sequentially and adjacently according to the running time, so that oil return of the compressor is good, and the operation quality of the compressor can be improved.

Owner:青岛奥利凯中央空调有限公司

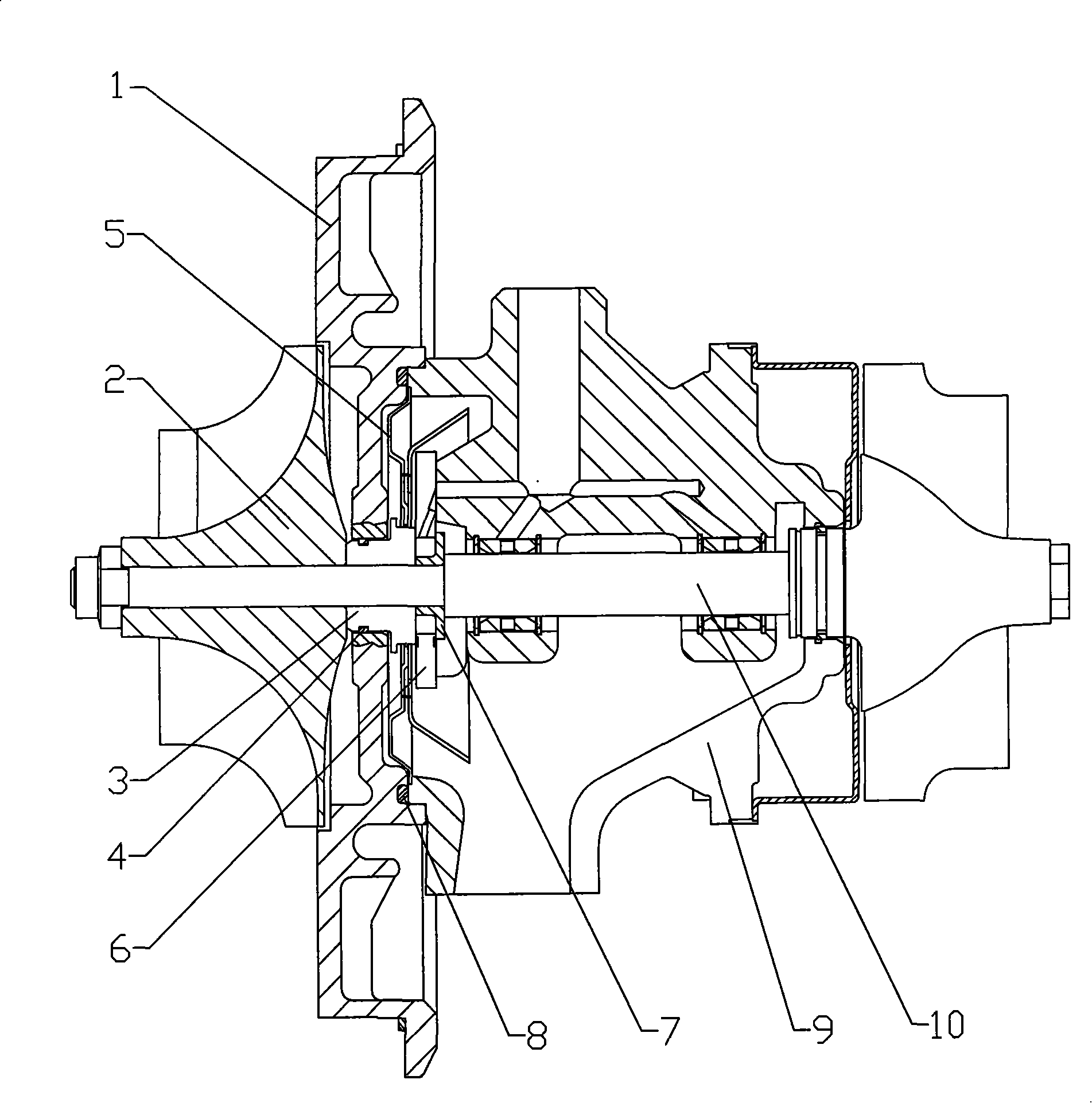

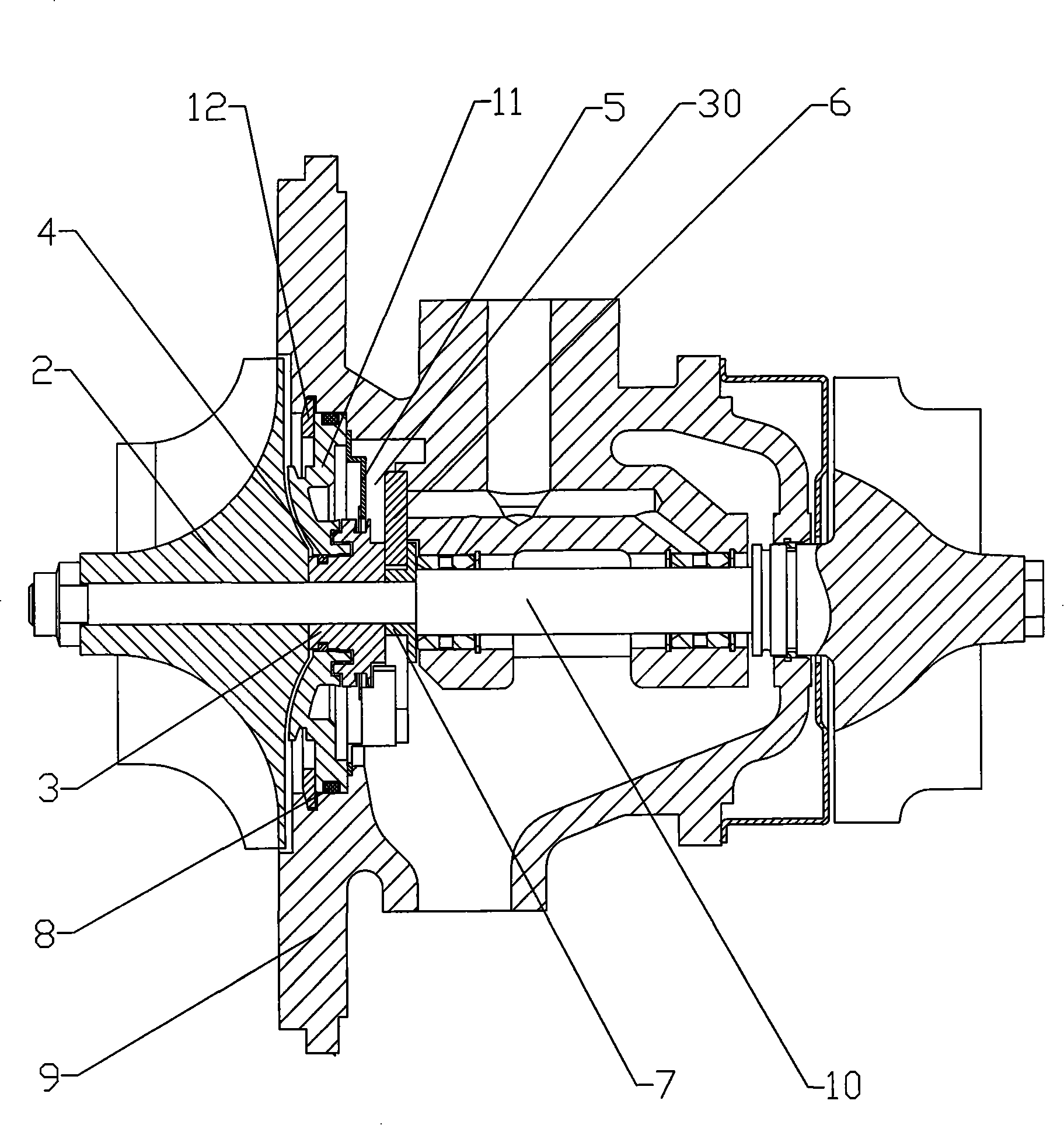

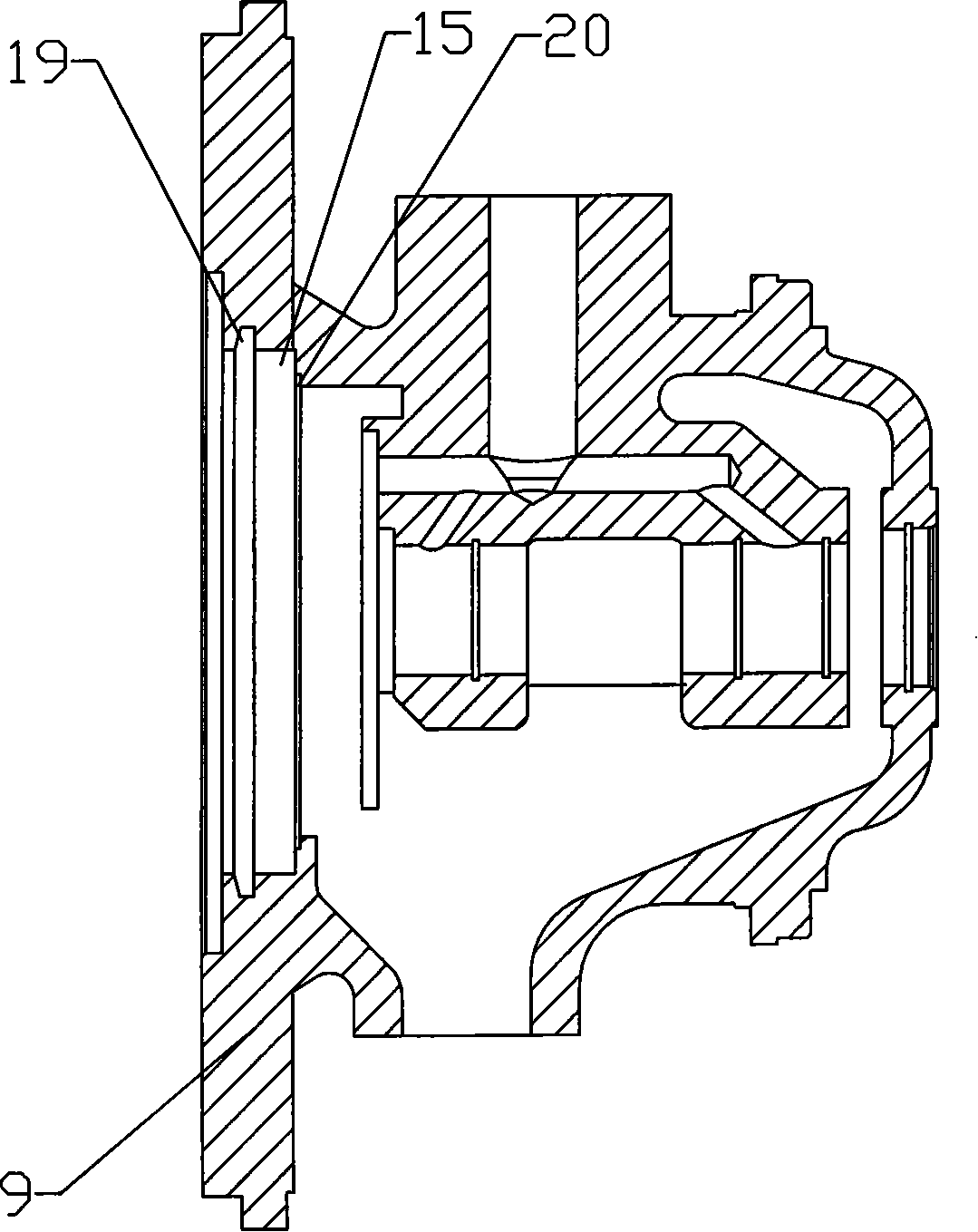

Exhaust-driven turbo-charger central rotor device

InactiveCN101187333AEfficient use ofAvoid deformationEngine sealsMachines/enginesImpellerTurbocharger

The invention discloses a kernel rotor device of an exhaust-gas turbocharger, comprising a middle casing, a thrust sleeve, a thrust bearing, an oil baffle, and a shaft gland, wherein a blade wheel is arranged on a turbine shaft on one end of the shaft gland, the middle casing on the one end of the blade wheel is provided with a chamber, a sealing ring sleeve base is arranged in the chamber, and the sealing ring sleeve base comprises a ring-shaped component which is sealed with the inner walls of the chamber and a lantern ring which is dynamically sealed by the shaft gland and is arranged on the turbine shaft. A ring-shaped connecting member is fixedly connected between the ring-shaped component and the lantern ring, one lateral side of the ring-shaped connecting member which faces the blade wheel is provided with an arc-shaped end face which is relative to the shape of the blade wheel. The original connection between a linking disk and the middle casing is changed into the connection of the middle casing and the sealing ring sleeve to remove the linking disk with large size, thereby avoiding deformation of the product. The original projection sealing is changed into notch sealing to enlarge the oil return space of the product, and the original screw pressing is changed into a circlip pressing, thereby providing conveniences for assembly, easily adopting an automatic assembly line, and reducing the cost of the product.

Owner:KANGYUE TECH

Novel packer based on ambient pressure

The invention discloses a novel packer based on the ambient pressure. A rear hydraulic cylinder, a front hydraulic cylinder and a vacuum oil tank are arranged on a spindle; a vacuum cavity is arranged in the vacuum oil tank; four oil circuits are arranged on the spindle; an oil return cavity of the front hydraulic cylinder is communicated with rodless cavities of the rear hydraulic cylinder through the oil circuits respectively; a rod cavity of the rear hydraulic cylinder is communicated with the vacuum oil tank; the oil return cavity of the front hydraulic cylinder is communicated with the rod cavity of the rear hydraulic cylinder; the rodless cavity of the rear hydraulic cylinder is communicated with the vacuum oil tank; solenoid valves are respectively arranged on the oil circuits; under the condition of starting setting, ambient pressure oil enters an oil inlet cavity of the front hydraulilc cylinder, pressure oil in the oil return cavity of the front hydraulic cylinder enters the rodless cavity of the rear hydraulic cylinder, oil liquid in the rod cavity of the rear hydraulic cylinder returns to the vacuum oil tank, a push rod compresses a rubber sleeve seat under the action of pressure so as to force a rubber sleeve to be stressed to deform, expand and compress a sleeve pipe, and the setting action is finished. The novel packer based on the ambient pressure provided by the invention adopts the ambient pressure under a petroleum well as a drive source, and no extra drive equipment is required, so that the cost is reduced, and the usage is more energy-saving.

Owner:MUDANJIANG XINXIANG PETROLEUM MASCH CO LTD

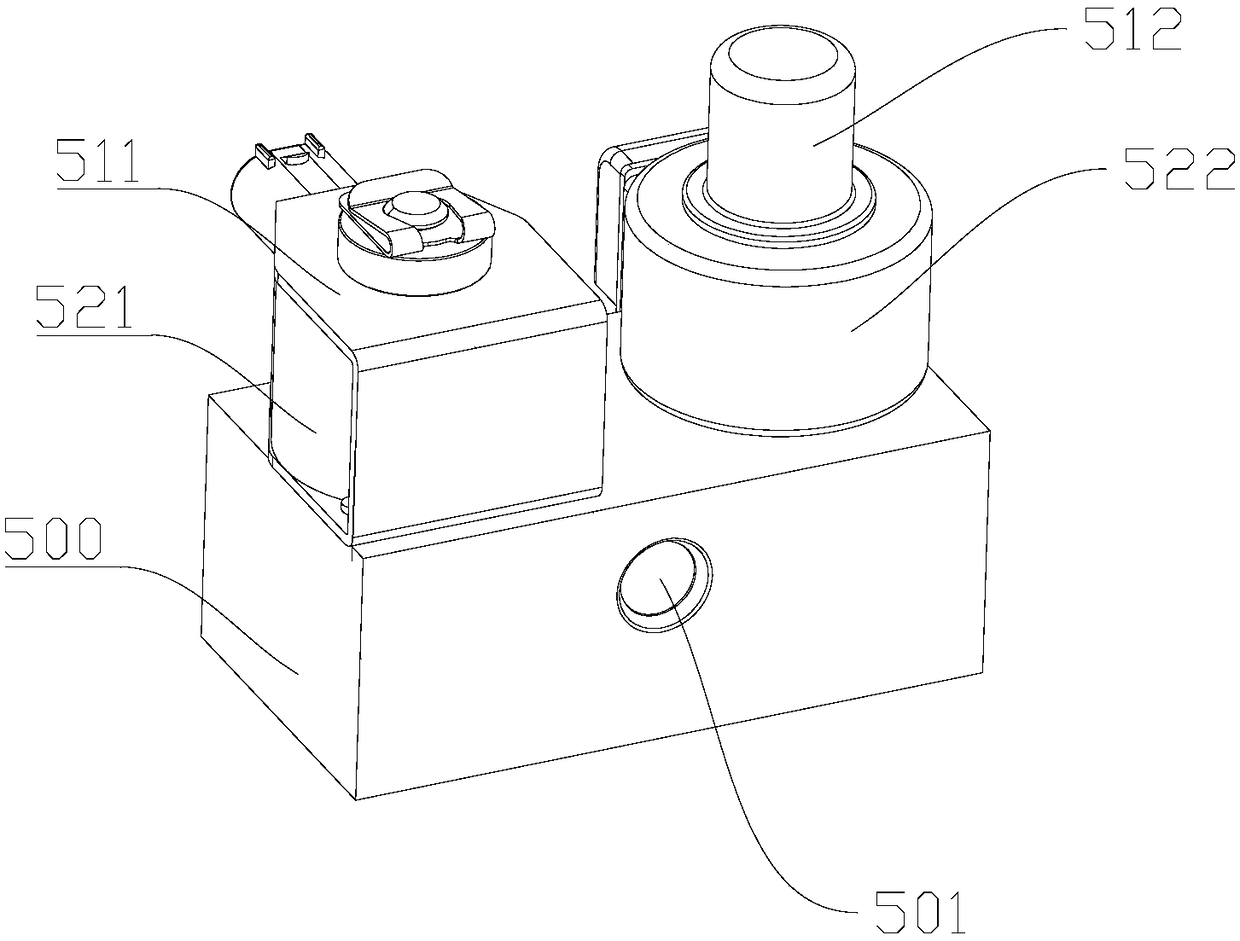

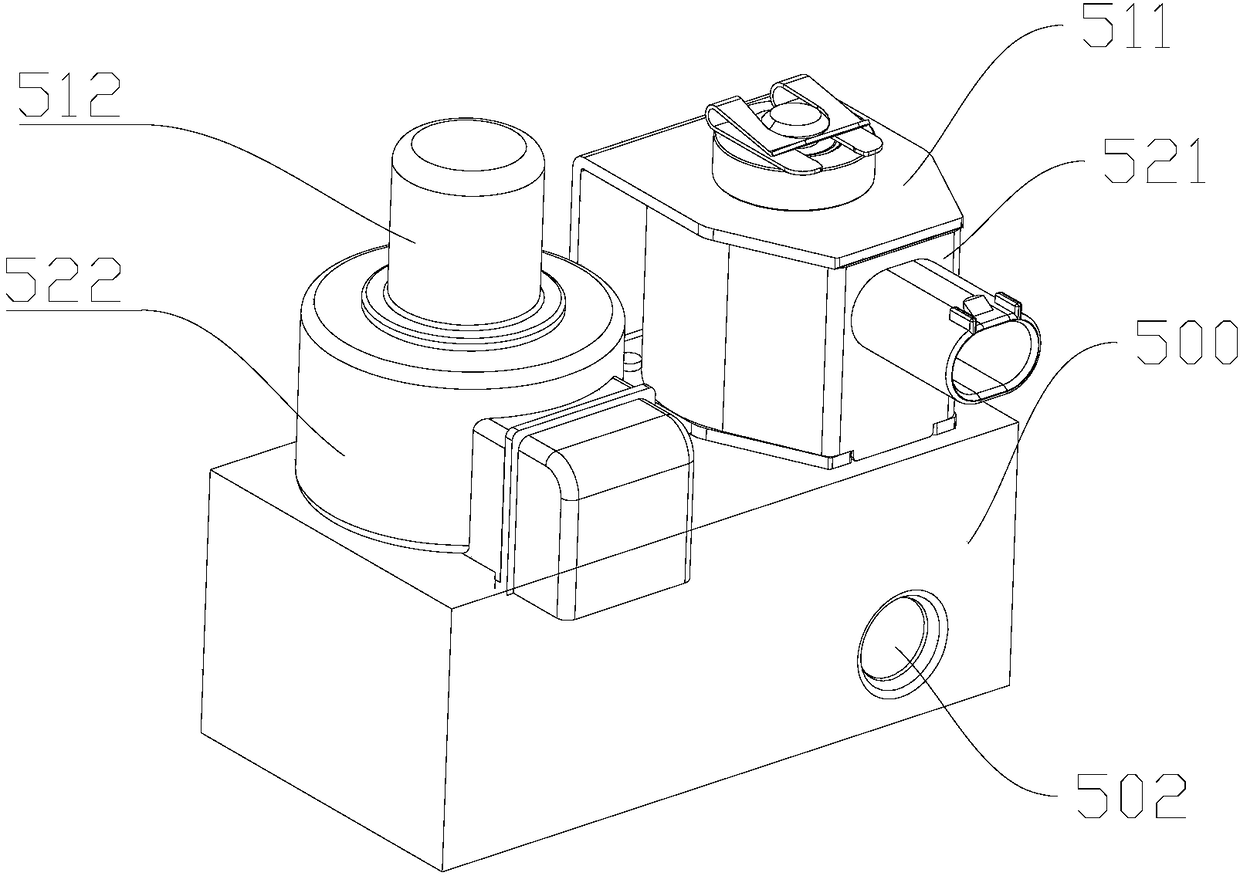

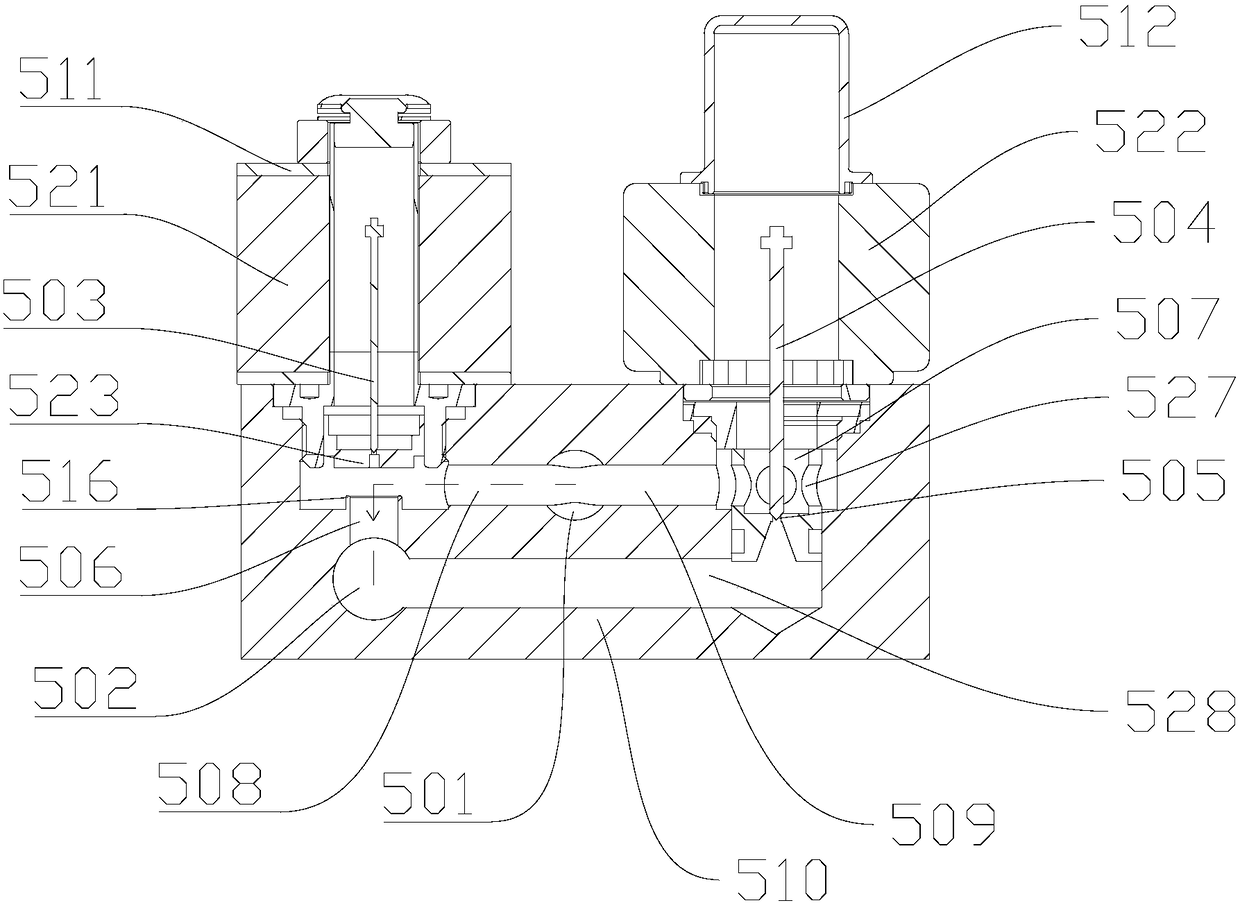

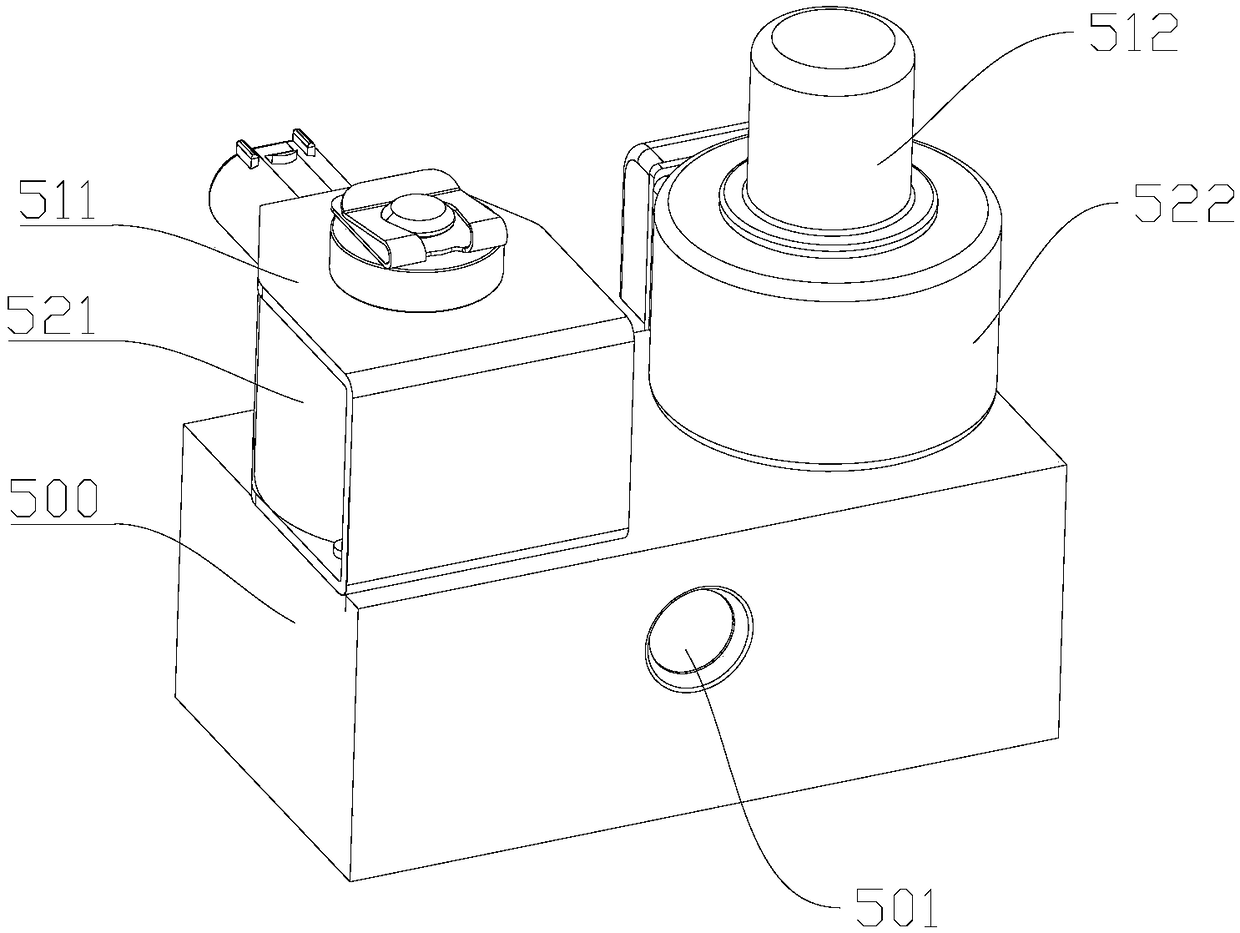

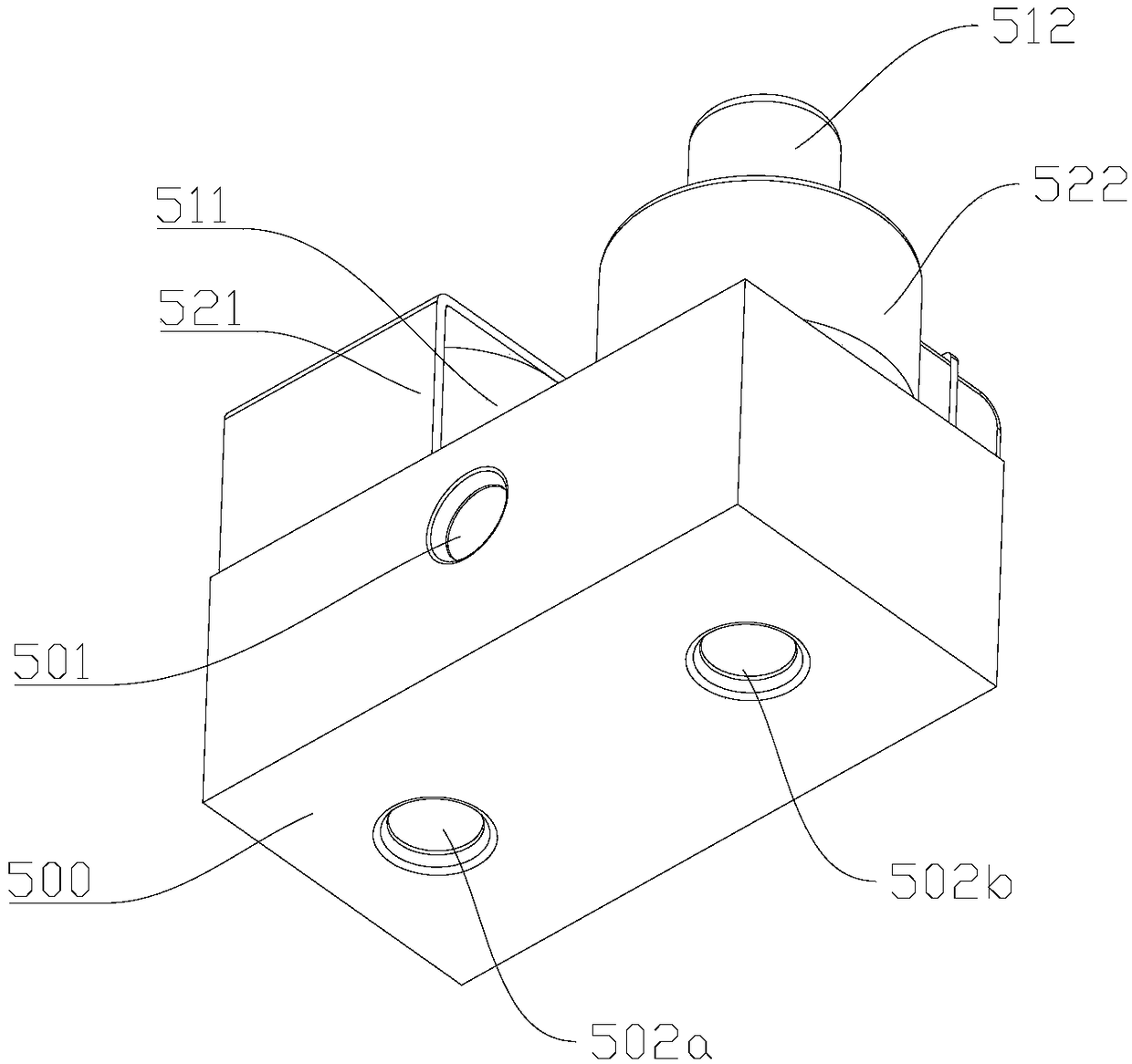

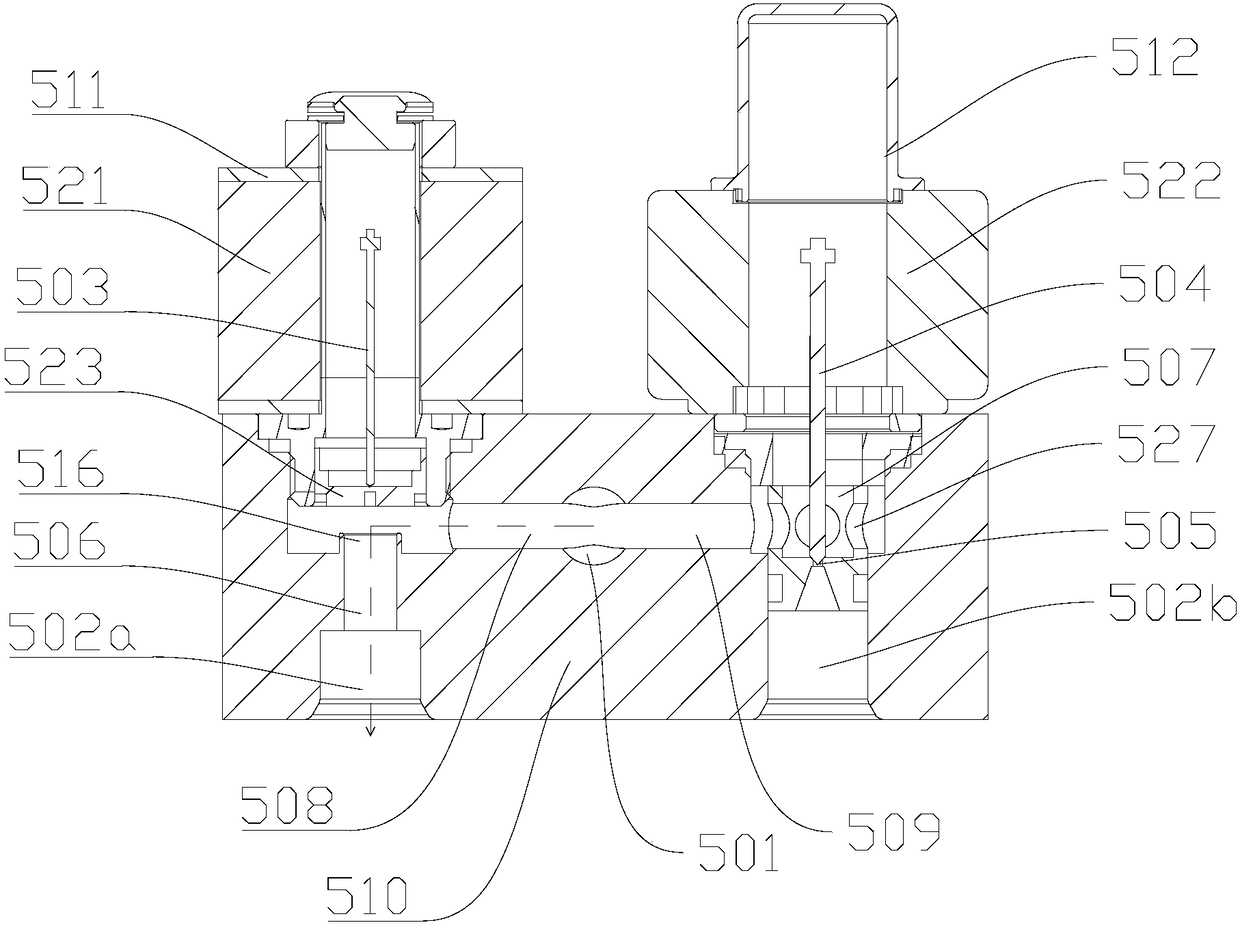

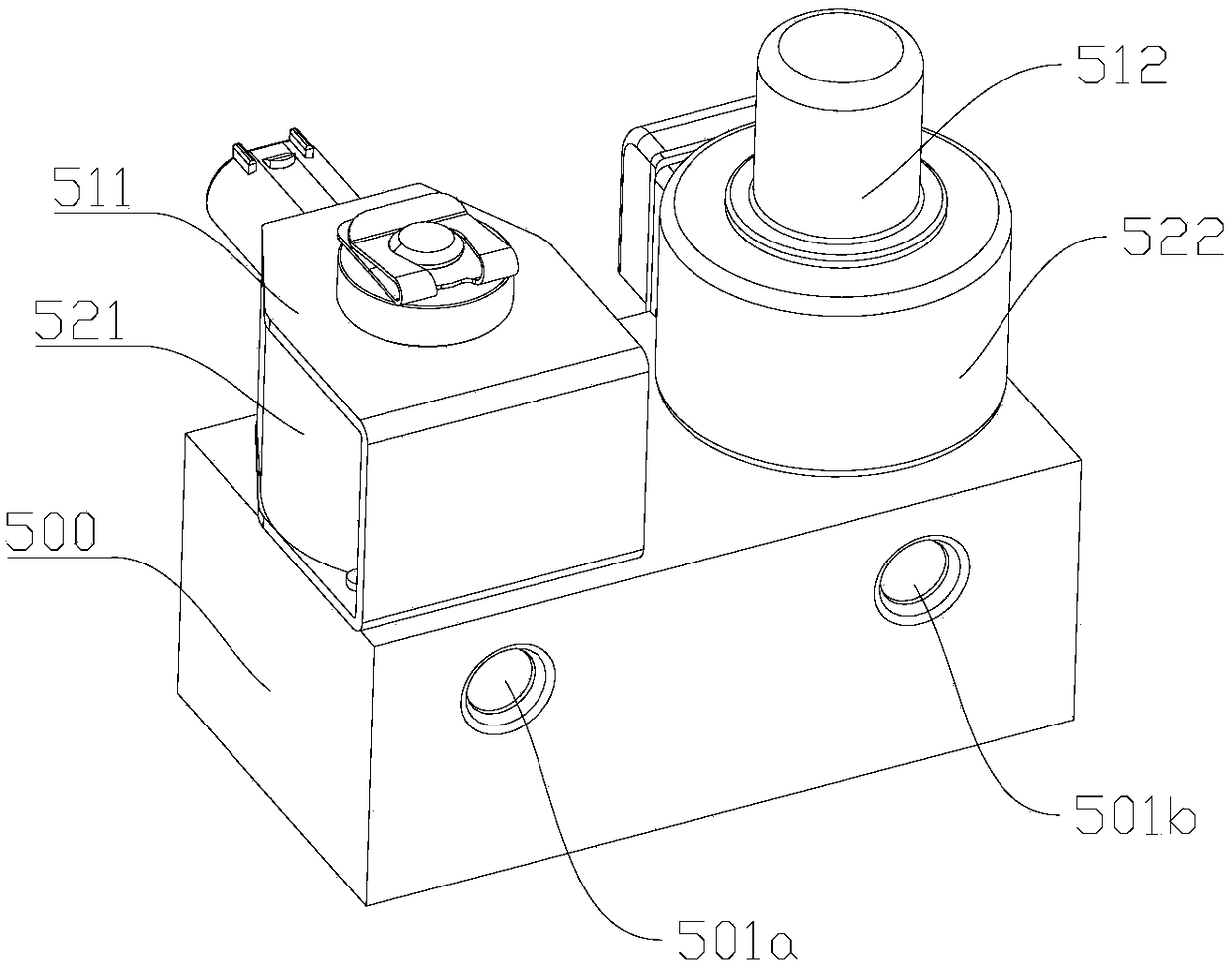

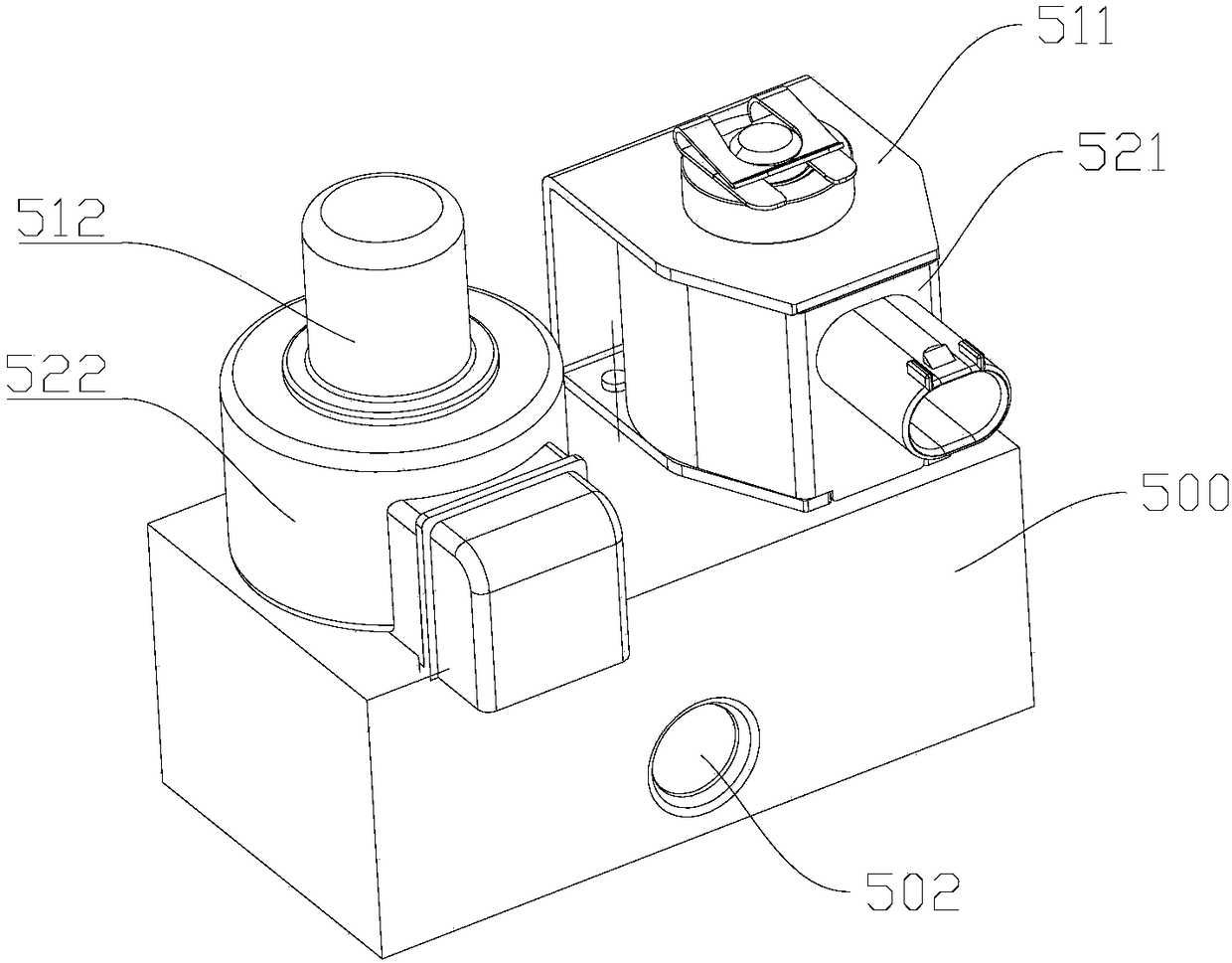

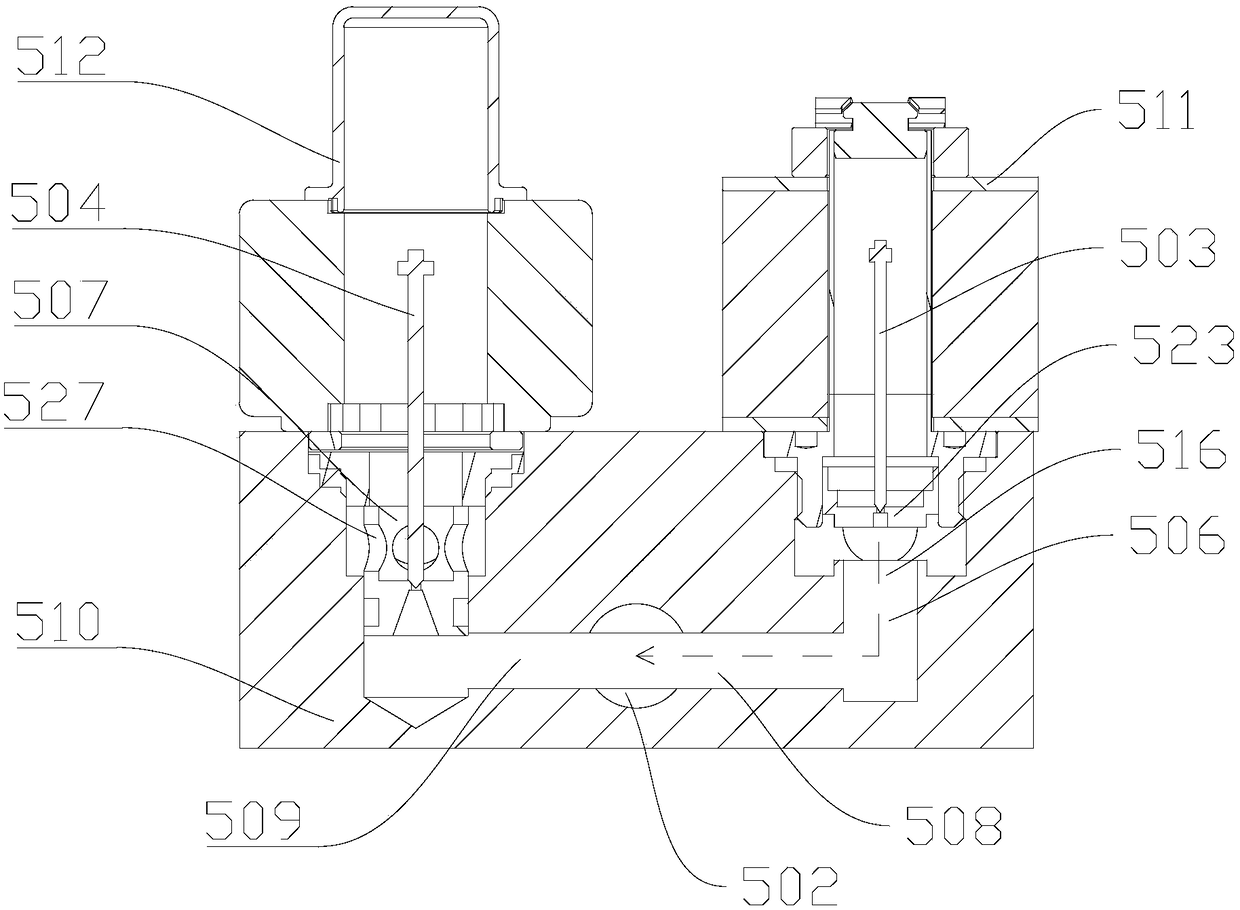

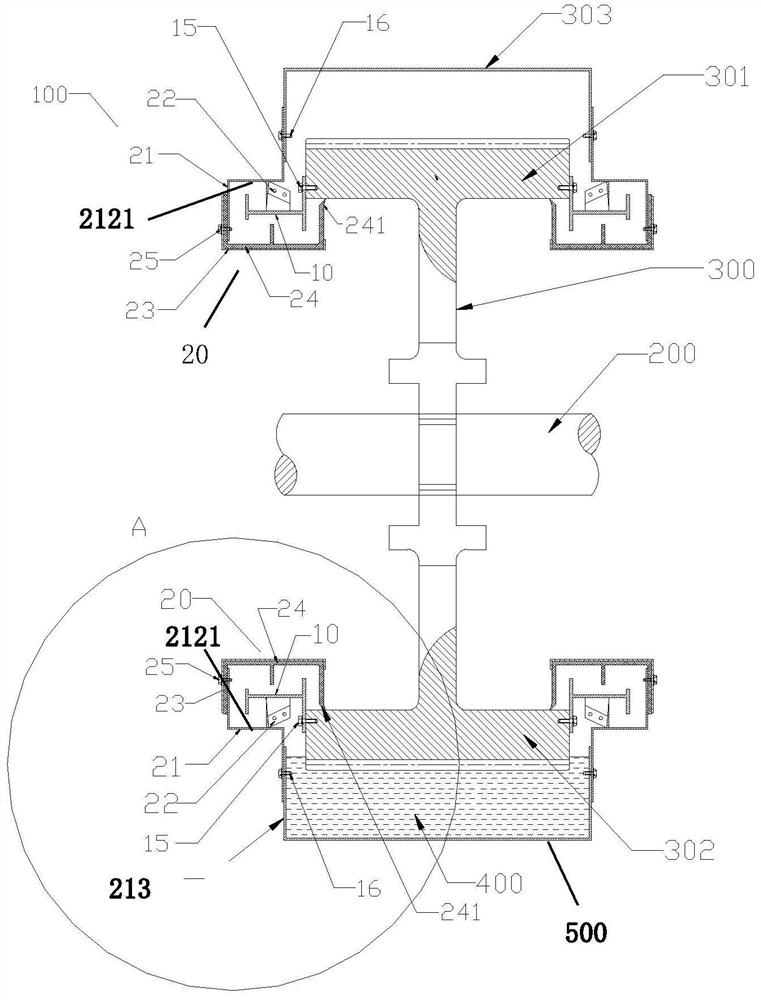

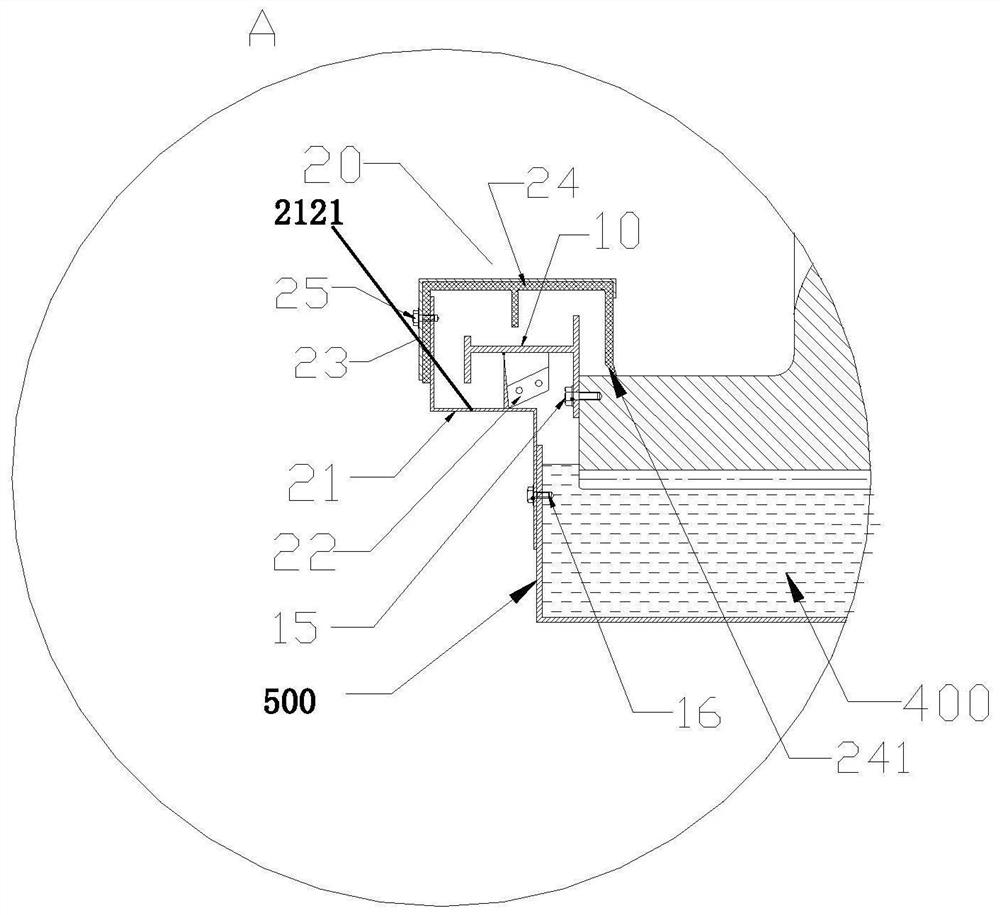

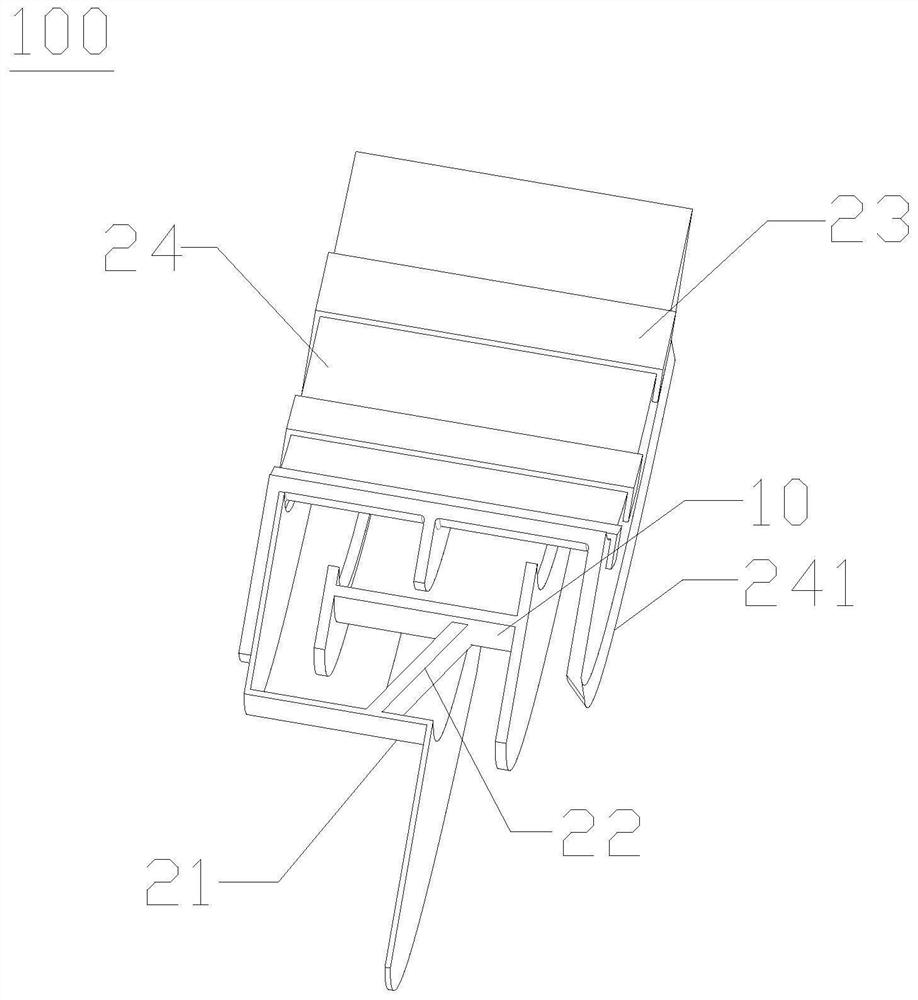

Expansion switch valve

InactiveCN108253161ARealize functionFirmly connectedMultiple way valvesEfficient regulation technologiesEngineeringRefrigerant

The invention provides an expansion switch valve. The expansion switch valve comprises a valve body (500), wherein an inlet (501), an outlet (502) and an inner flow passage communicating between the inlet and the outlet are formed in the valve body (500), a first valve element (503) and a second valve element (504) which are parallel to each other are installed on the inner flow passage, and the first valve element (503) enables the inlet and the outlet to directly communicate or be disconnected; and the second valve element (504) enables the inlet and the outlet to communicate or be disconnected through a throttling hole (505). In this way, the first valve element and the second valve element are integrally installed on the inner flow passage of the same valve body, so that the on-off control function or the throttling expansion control function of a refrigerant can be realized, the structure is simple, and the production and the installation are easy. When the expansion switch valveis applied to a heat pump system, the pipeline connection can be simplified, the cost can be reduced, the refrigerant filling amount of the whole heat pump system is reduced, and the oil return of a compressor is facilitated.

Owner:BYD CO LTD

Parallel system of multiple high-pressure cavity compressors

The invention discloses a parallel system of multiple high-pressure cavity compressors. Due to the design of an inverse U-shaped pipe, an overflow pipe and an oblique main pipe, the refrigerating machine oil reflowing from an oil separator is prevented from flowing back to compressors when all the compressors stop running, and more oil reflowing from the oil separator can be stored in a vapor-liquid separator through the overflow pipe so as to prevent liquid blockage; when the compressors run in low loads and the coolant flow rate of an air suction pipe is low, the oil can be prevented from flowing back to the vapor-liquid separator; after a certain oil quantity is accumulated in the oblique main pipe, the oil is directly recycled to the compressors, so that the oil supply of the compressors is ensured; and the system can avoid liquid compression or liquid blockage of the compressors in each state of the compressors, so that the reliability of the compressor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

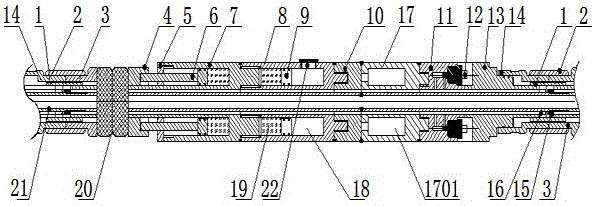

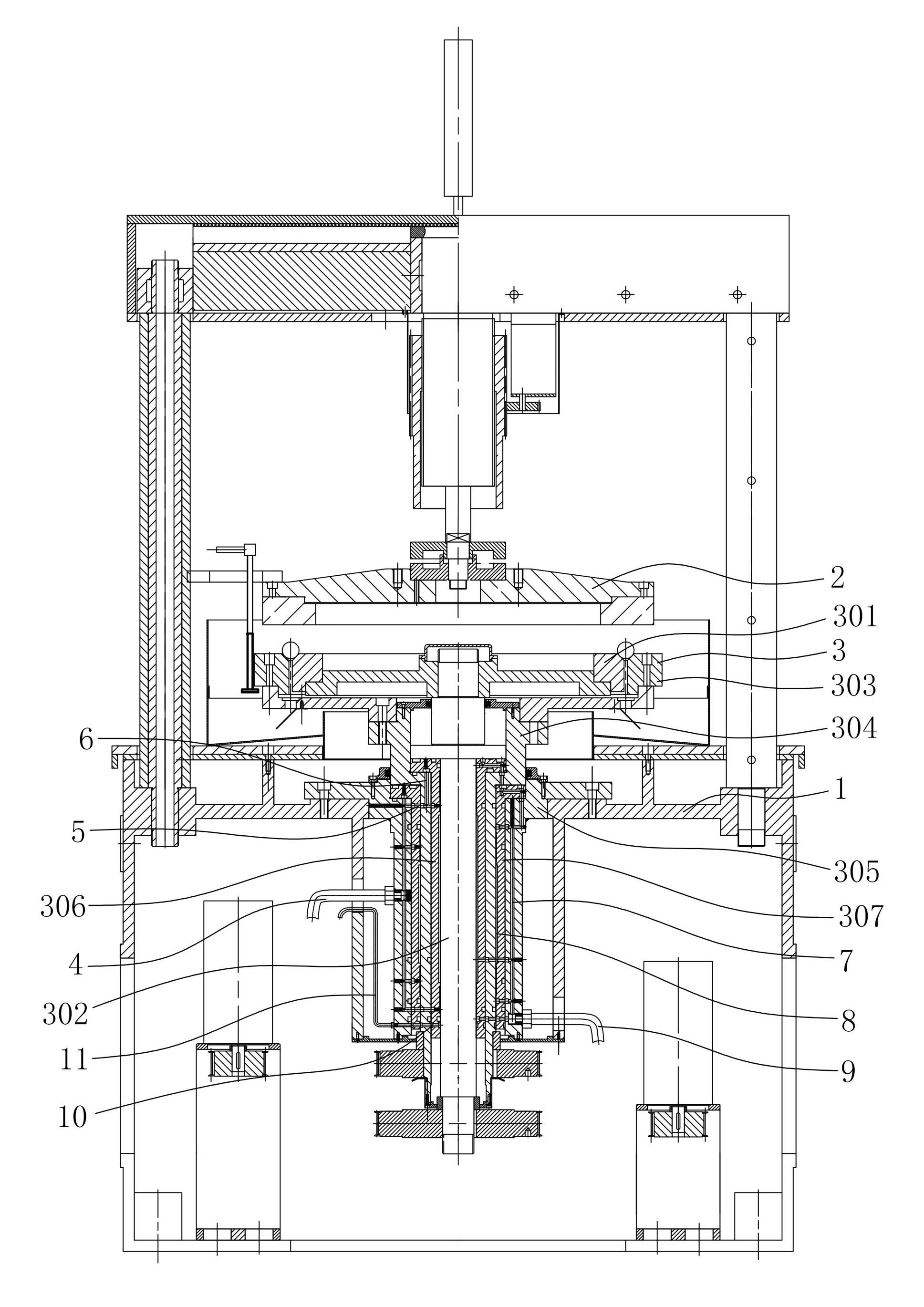

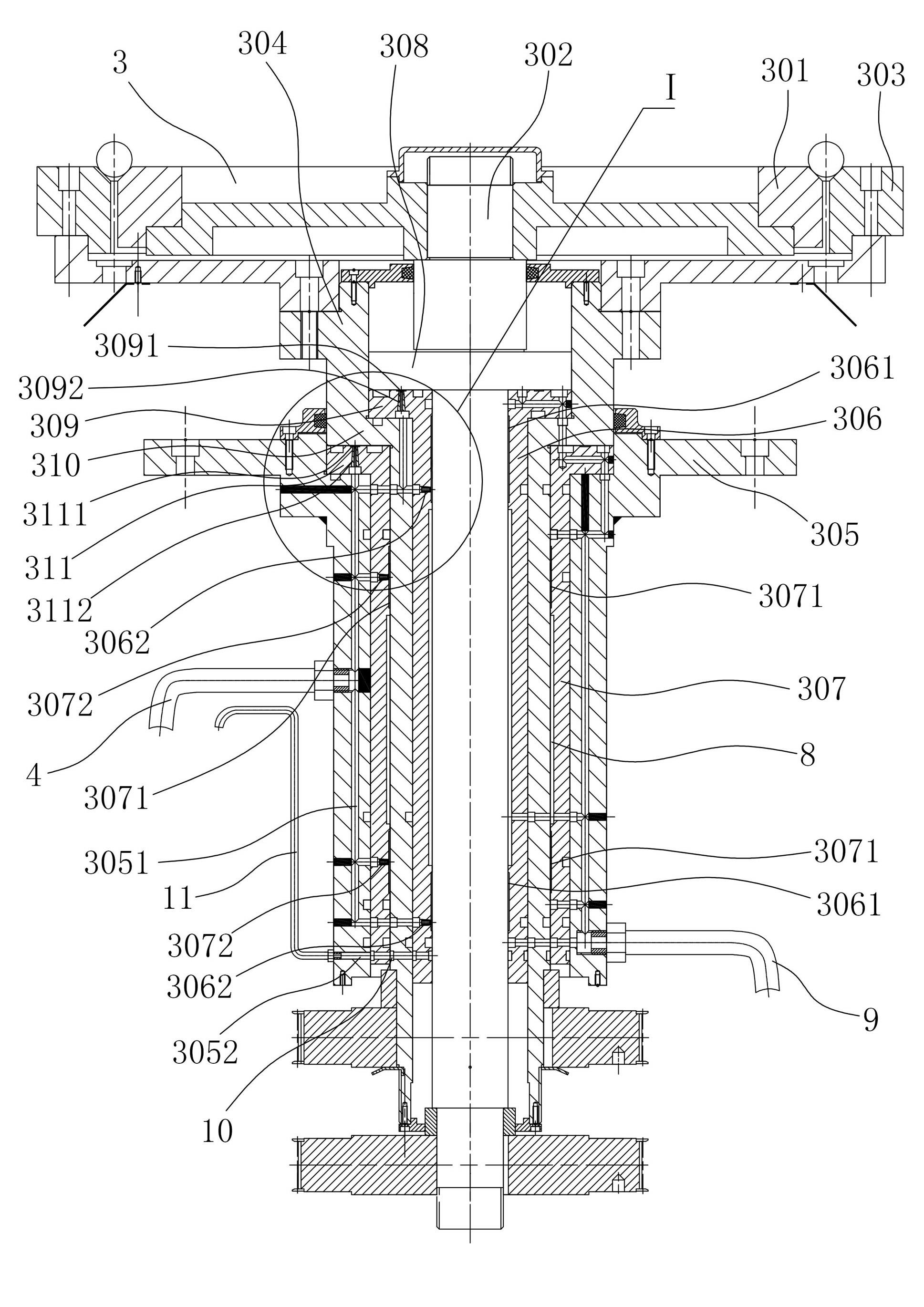

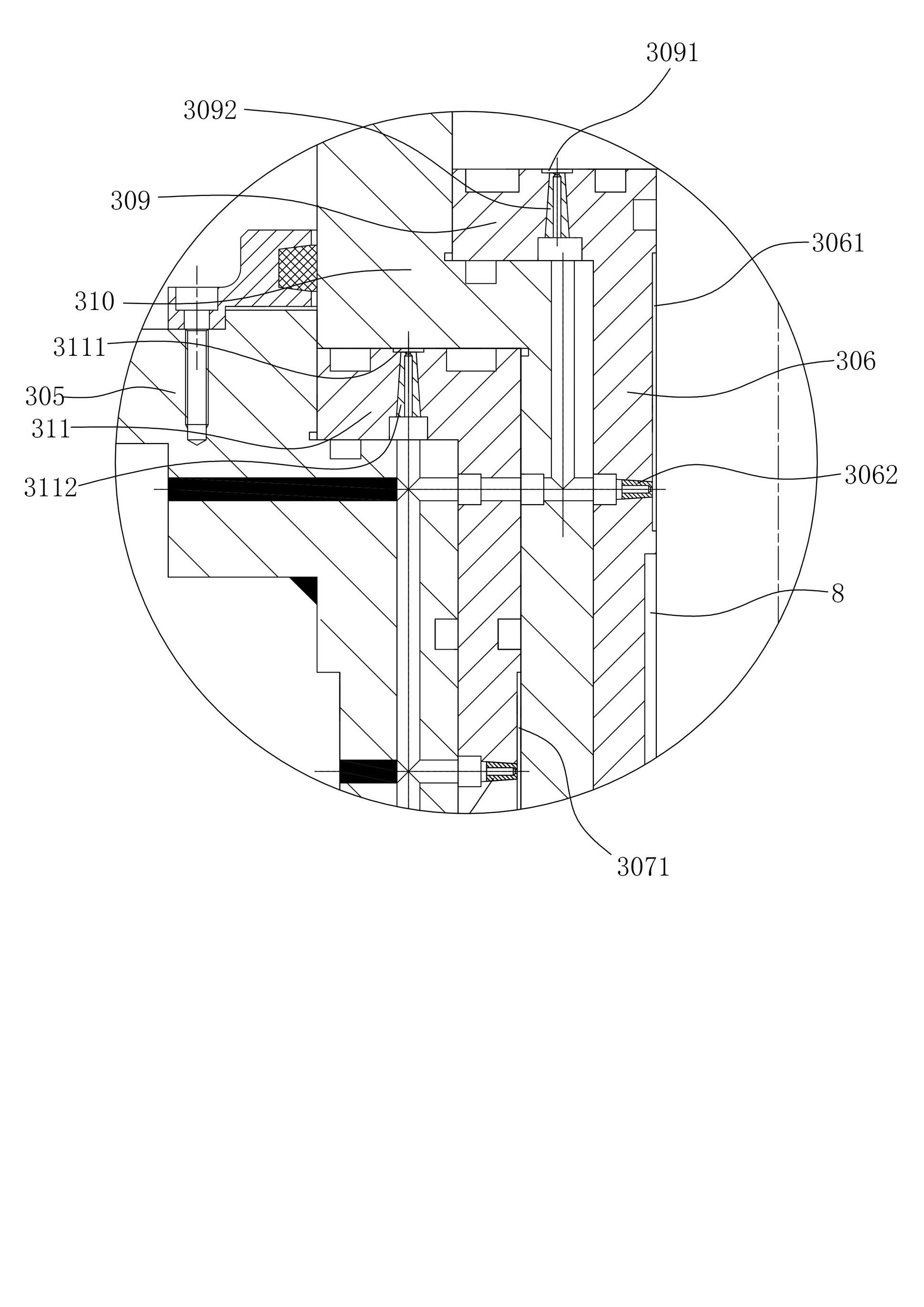

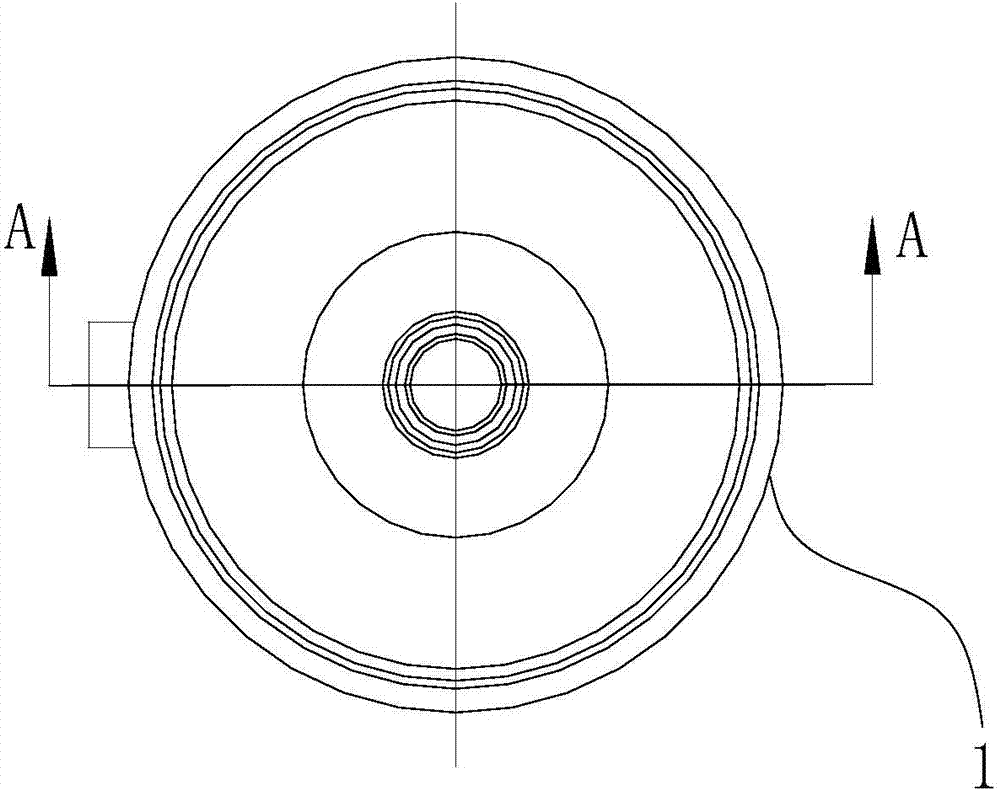

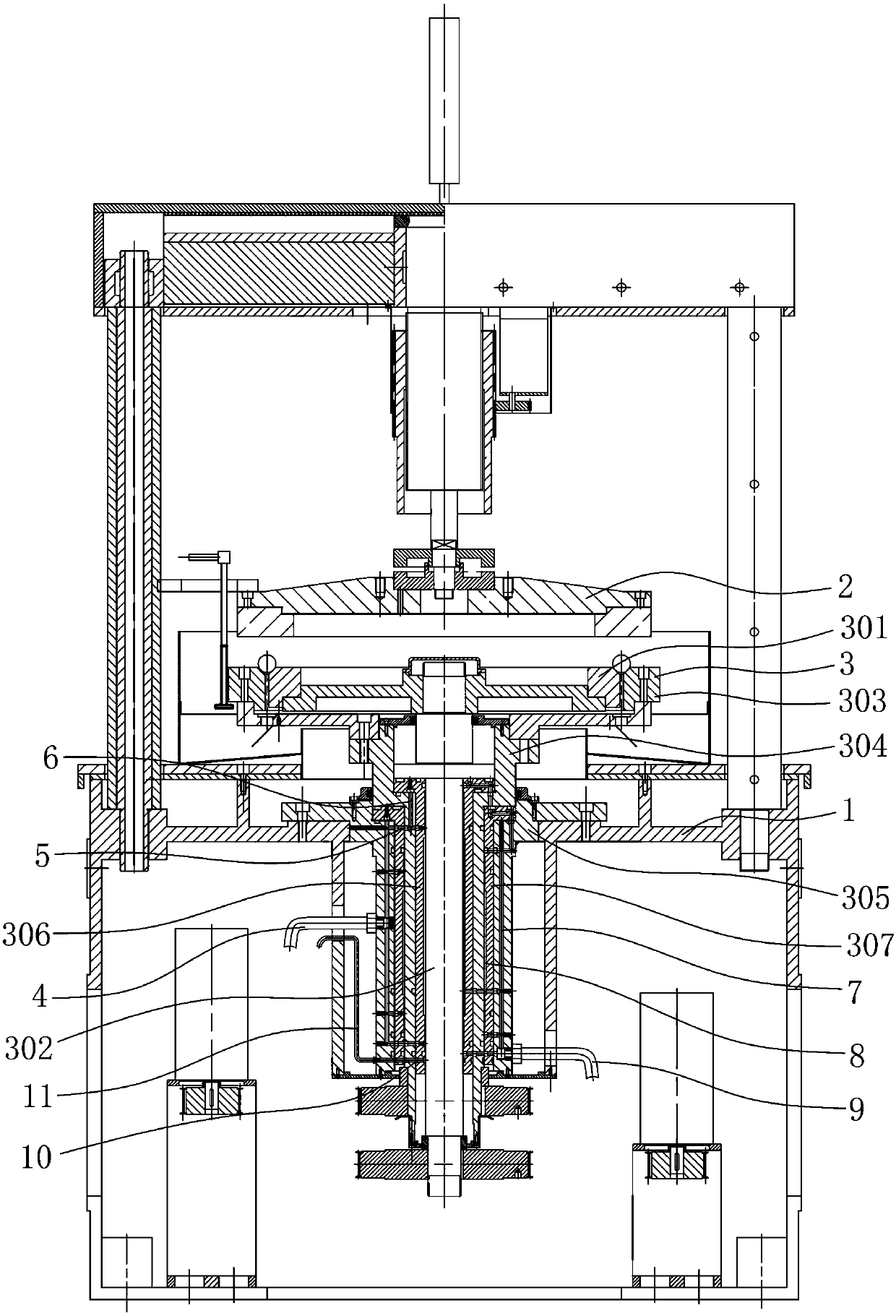

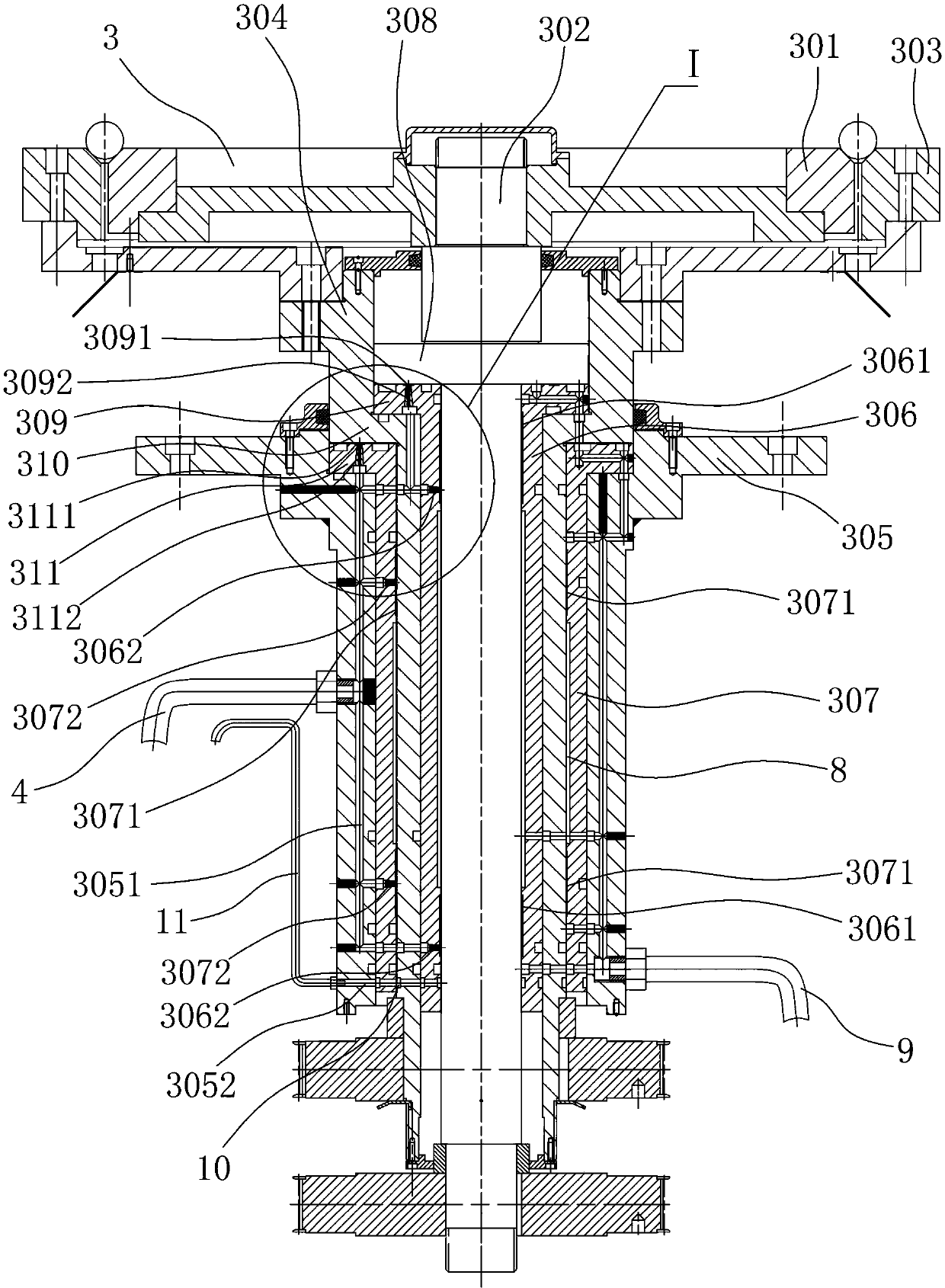

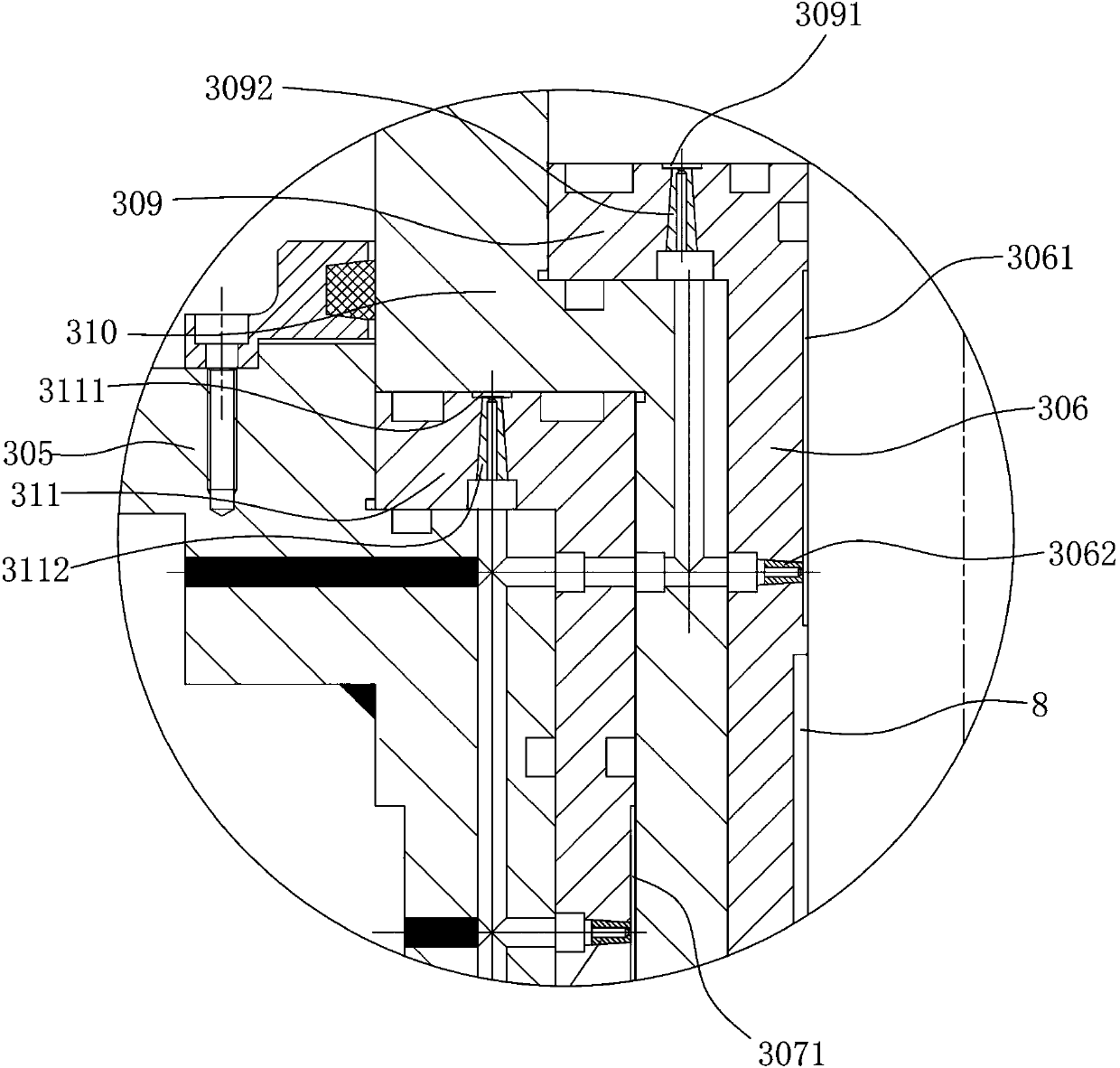

Ball crusher with double-rotor hydrostatic bearing structure

The invention discloses a ball crusher with a double-rotor hydrostatic bearing structure, which comprises a frame and a lower grinding disc. The lower grinding disc comprises an inner disc, an inner disc spindle, an outer disc, an outer disc spindle and an outer disc spindle bearing block fixed on the frame. The inner disc spindle is fixedly connected with the inner disc. The outer disc spindle is fixedly connected with the outer disc. The inner disc is sleeved in the outer disc. The inner disc spindle is sleeved in the outer disc spindle. The outer disc spindle is sleeved in the outer disc spindle bearing block. An inner disc liquid hydrostatic bearing is arranged between the inner disc spindle and the outer disc spindle. An outer disc liquid hydrostatic bearing is arranged between the outer disc spindle and the outer disc spindle bearing block. The ball crusher with the double-rotor hydrostatic bearing structure has the advantages of high rotary precision and simple and compact structure, is very suitable for precise and ultraprecise grinding machining and is convenient to disassemble and assemble.

Owner:江苏智邦精工科技有限公司

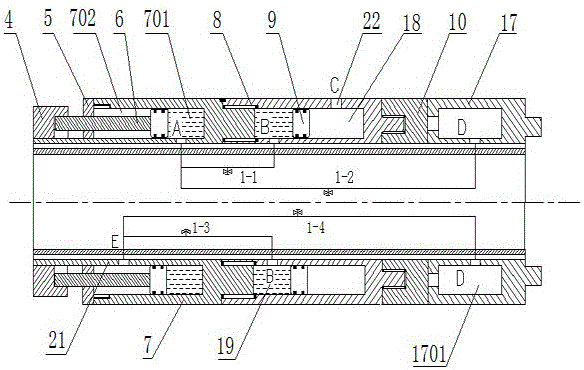

Lubricating oil return mode of supercharger of turbocharged engine

InactiveCN102705073AGood oil return effectMeet lubrication requirementsMachines/enginesLubrication temperature controlHeat balanceControl valves

The invention relates to a lubricating oil return mode of a supercharger of a turbocharged engine, and aims to lubricate the supercharger. An oil return channel A which accords with the cold operating condition of an engine, an oil return channel B which accords with the normal operating condition of the engine, oil return channels C and D which accord with the operating condition of the engine in high temperature environment, and a supercharger oil return control valve are arranged on a cylinder body of the engine, so that oil return lines of lubricating oil in the supercharger of the engine in different operating states are cyclically switched. The operating efficiency of the engine is improved; the high temperature characteristic of the lubricating oil in the supercharger is reasonably utilized, so that the heat balance of the engine is realized; and meanwhile, the oil return performance of the supercharger of the engine is improved, the probability that the oil in the supercharger leaks is reduced, and the power performance and economy of the engine are effectively improved.

Owner:GREAT WALL MOTOR CO LTD

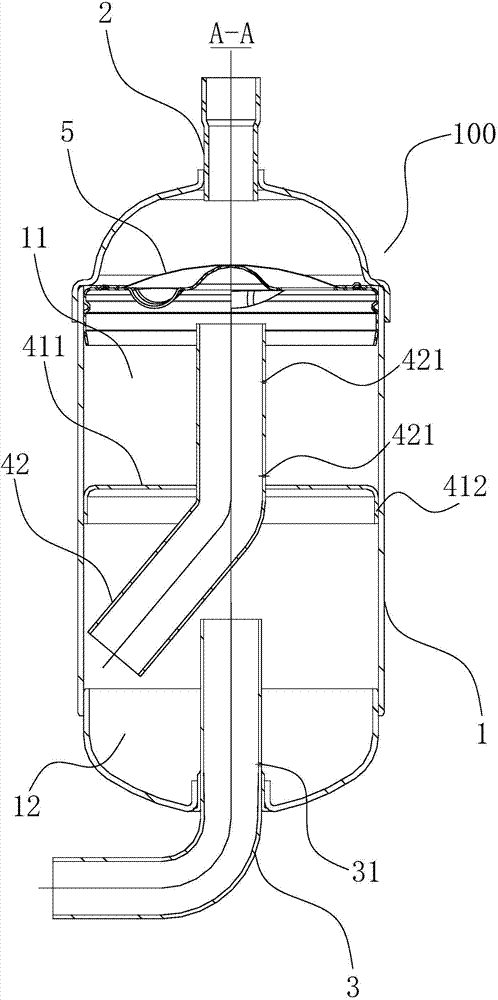

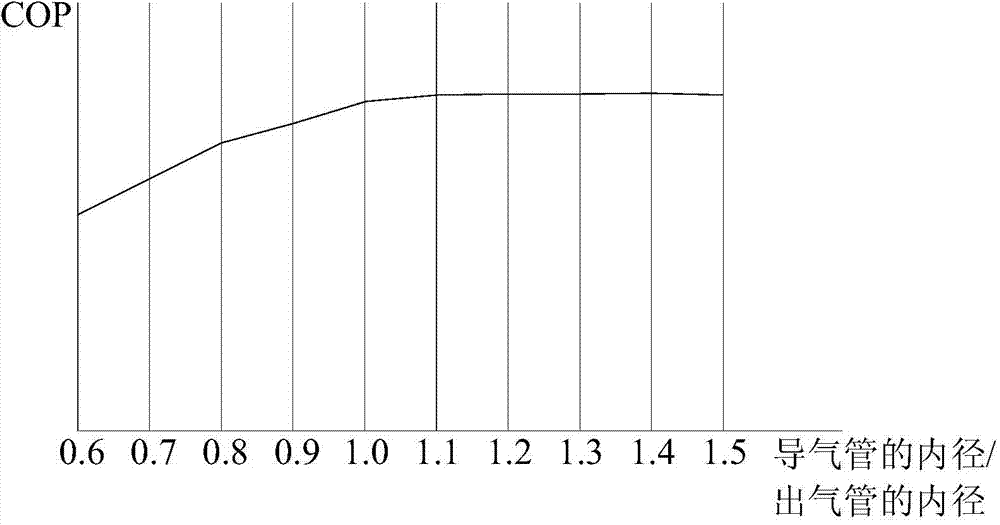

Liquid accumulator

InactiveCN103940160AReduce the amount of liquid refrigerantImprove reliabilityRefrigeration componentsRefrigerantEngineering

The invention discloses a liquid accumulator which comprises a shell, an air inlet pipe, an air outlet pipe and at least one separating device. The air inlet pipe and the air outlet pipe are arranged on the shell in a spaced mode, the air inlet pipe and the air outlet pipe are both communicated with the interior of the shell, and the separating device is arranged in the shell and is located between the air inlet pipe and the air outlet pipe so as to conduct air and liquid separation on a air-liquid refrigerant mixture entering the shell from the air inlet pipe. According to the liquid accumulator, the separating device is arranged in the liquid accumulator, the separating device can conduct air and liquid separation on the air-liquid refrigerant mixture entering the liquid accumulator, and therefore the air-liquid refrigerant mixture in the liquid accumulator at least passes through two-time air-liquid separation, the number of liquid refrigerants absorbed by a compressor is reduced, and the reliability of the compressor is improved.

Owner:ANHUI MEIZHI PRECISION MFG

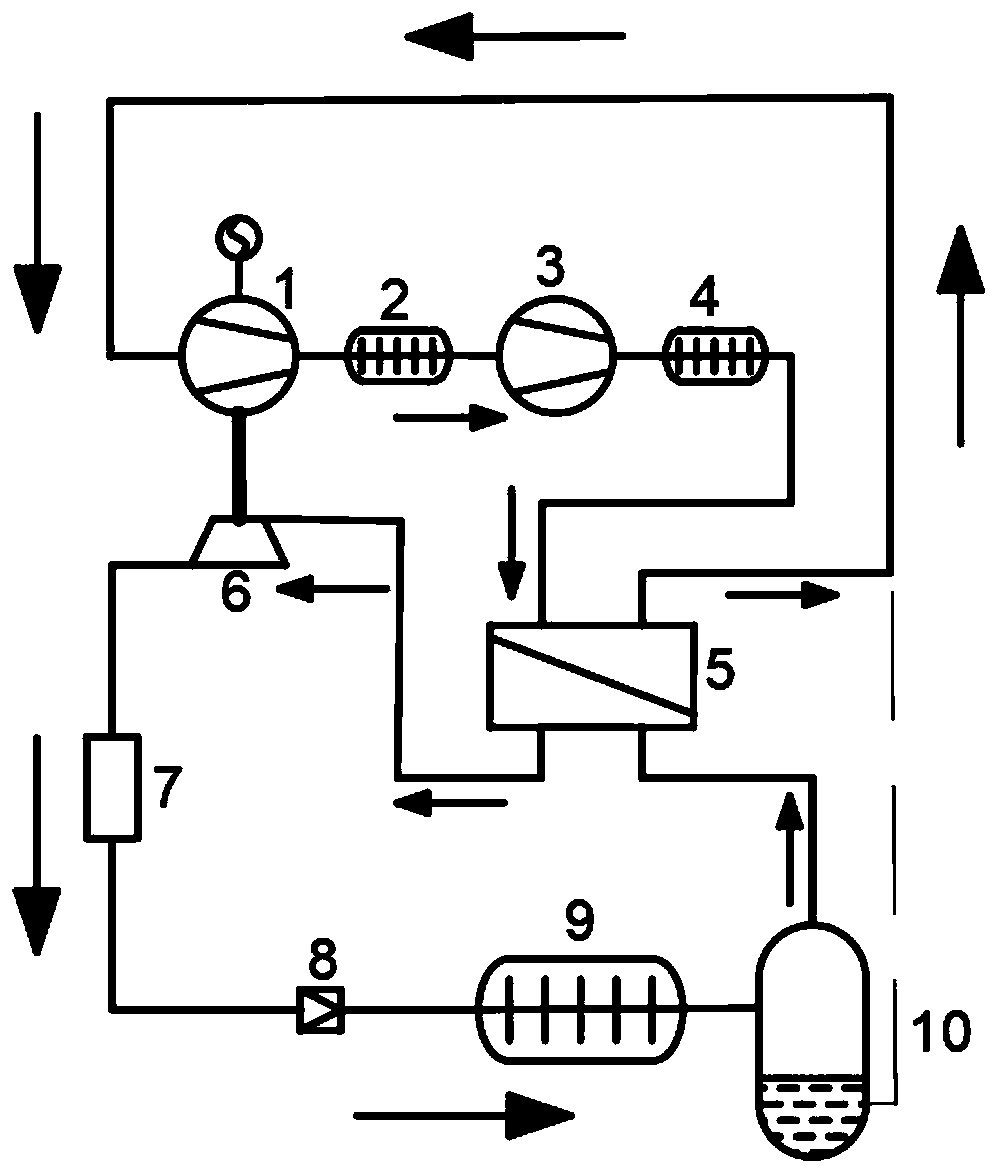

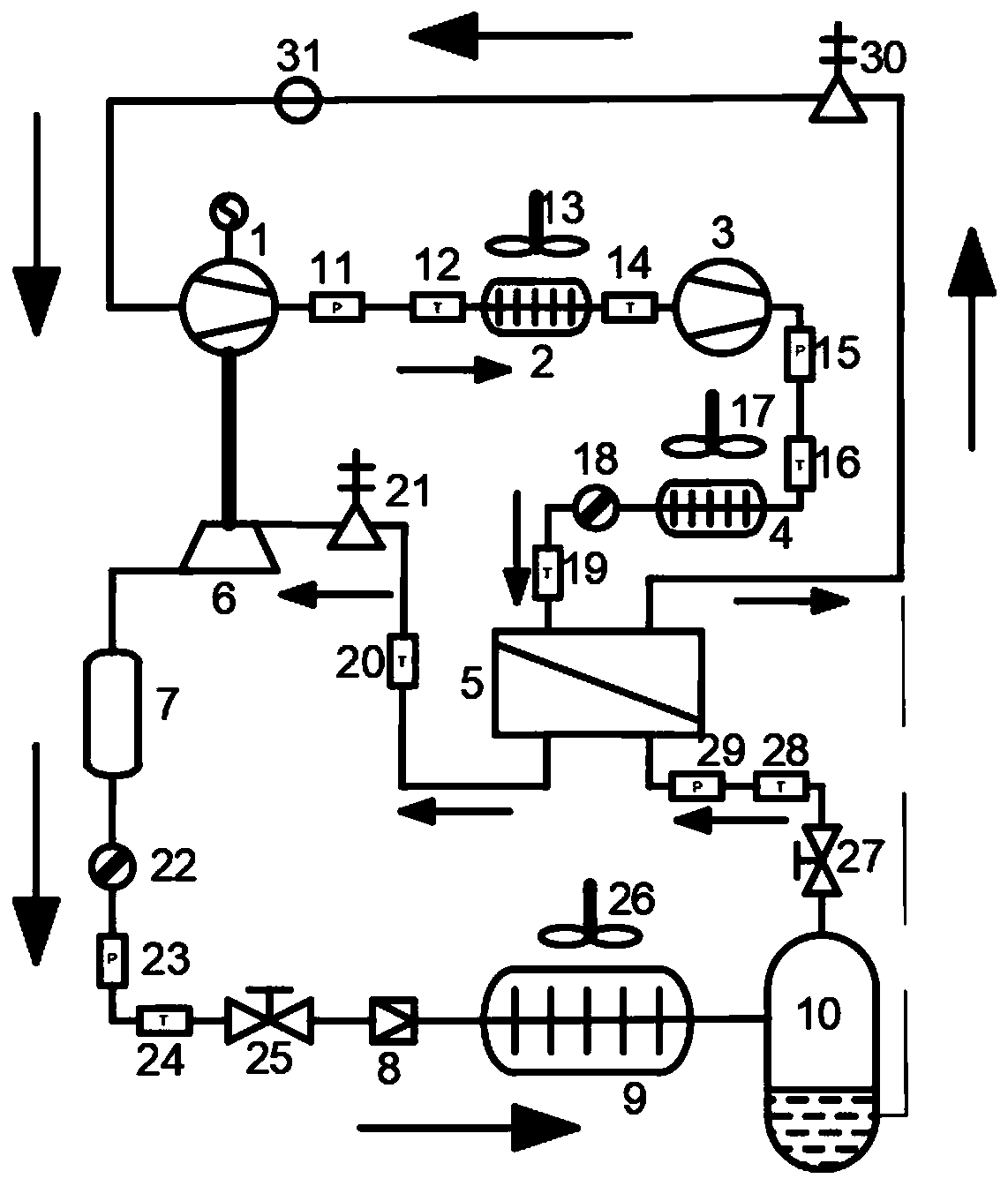

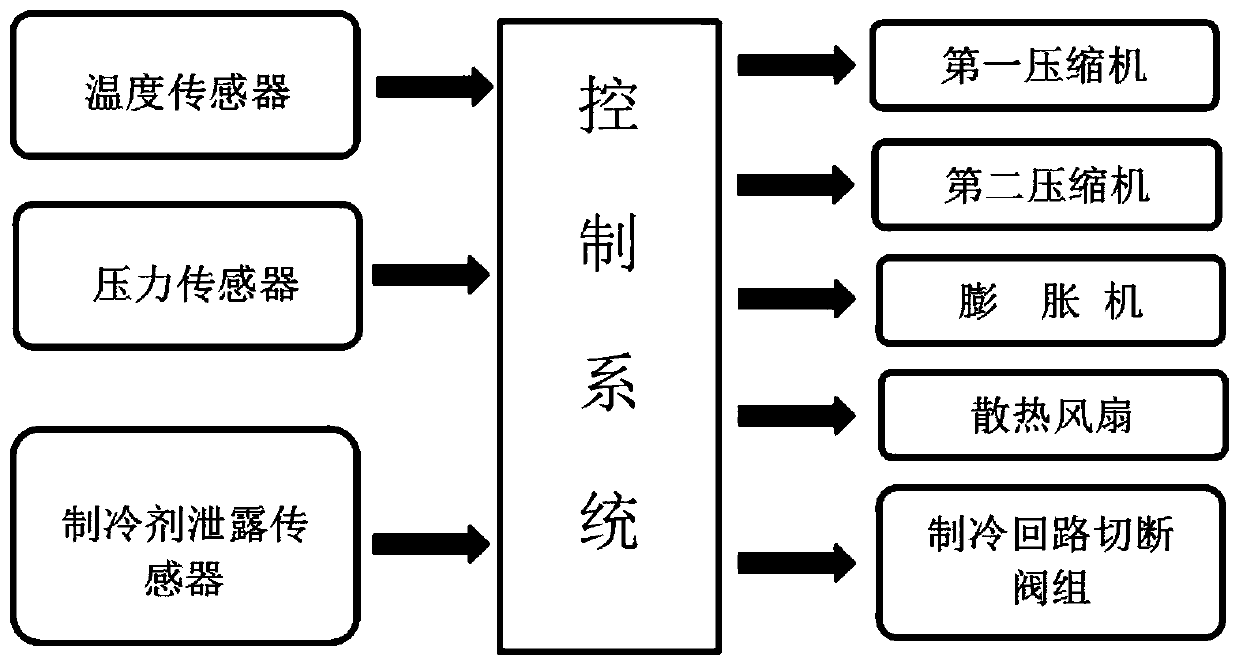

Trans-critical carbon dioxide refrigeration method and device thereof

PendingCN110806035AGood chemical stabilityLarge latent heat of evaporationCompression machinesSuperheatersPhysical chemistryGas cooler

The invention discloses a trans-critical carbon dioxide refrigeration method and a device thereof. The method comprises the following steps that (1) superheated carbon dioxide steam is pressurized forprimary compression and primary cooling; (2) subcritical carbon dioxide is subjected to secondary compression and secondary cooling; (3) after supercritical carbon dioxide is cooled again, the supercritical carbon dioxide is throttled to be low-temperature subcritical carbon dioxide; (4) the throttled low-temperature subcritical carbon dioxide is sent to an evaporation tank to be evaporated intohigh-temperature low-pressure carbon dioxide gas; and (5) the high-temperature low-pressure carbon dioxide gas absorbs heat and then is converted into superheated carbon dioxide steam, and is fed intoa first compressor for boosting for cyclic utilization. According to the trans-critical carbon dioxide refrigeration method and the device thereof, an expansion machine is used for recycling and outputting mechanical energy to drive a compressor to complete compression, a double-compressor is used for improving the compression performance of the supercritical carbon dioxide, and a double-gas cooler and an internal regenerator are used for cooling the carbon dioxide gas so as to improve the cycle energy efficiency of the carbon dioxide.

Owner:SHANGHAI FULUDI FLUID TECH CO LTD

Technology for manufacturing hotly-spun pressed forged steel single-piece piston with inner cooling oil cavity

The invention discloses a technology for manufacturing a hotly-spun pressed forged steel single-piece piston with an inner cooling oil cavity, which comprises the following steps of: forging piston blanks; mechanically processing the piston blanks to obtain the piston as a semi-finished product with an inside part of the inner cooling oil cavity and a covering part for blocking the inner cooling oil cavity, heating the covering part and downwardly spinning the covering part of the inner cooling oil cavity in the piston by the hot spinning technology to contact the inside part of the inner cooling oil cavity to form a complete inner cooling oil cavity; and not processing gaps of the inside part and the covering part of the inner cooling oil cavity, remaining the gaps or simply sealing by the general welding technology, such as argon arc welding and the like, and precisely processing into the piston as a finished product. The hotly-spun pressed forged steel single-piece piston with the inner cooling oil cavity manufactured by the technology disclosed by the invention is simple in structure, relatively easy and convenient to manufacture, high in production efficiency and low in manufacturing cost, and can meet the requirements of an engine on high power, high strength, and low emission, and the like.

Owner:BINZHOU BOHAI PISTON CO LTD

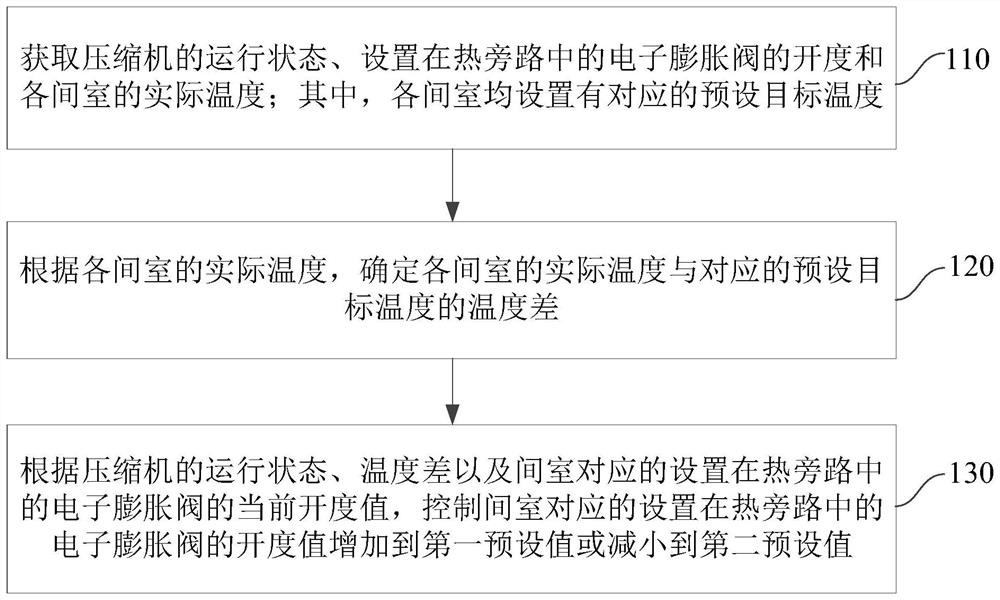

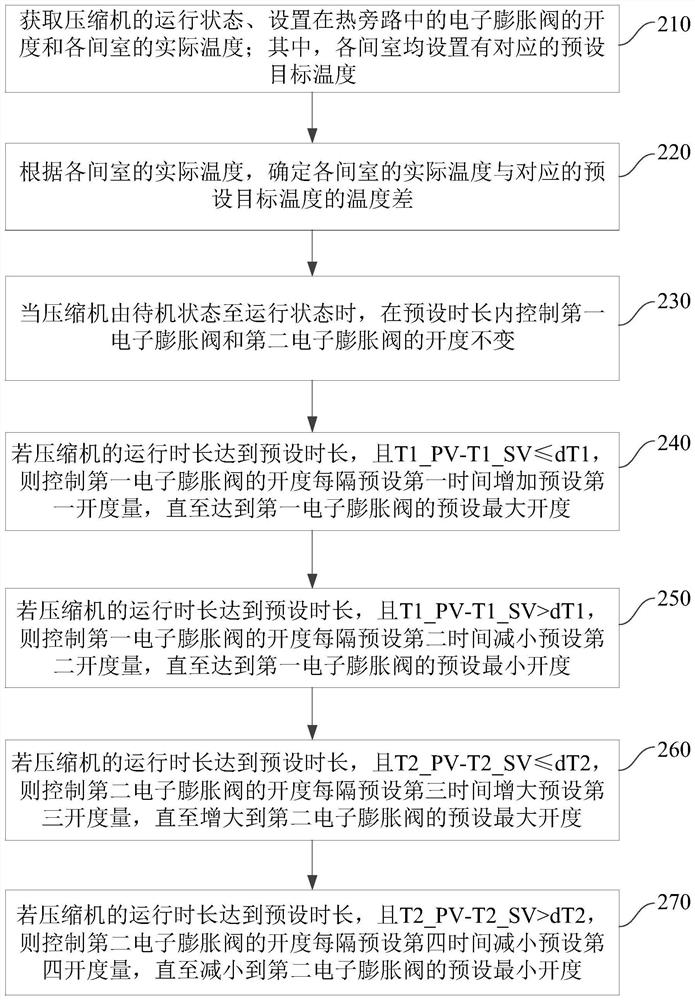

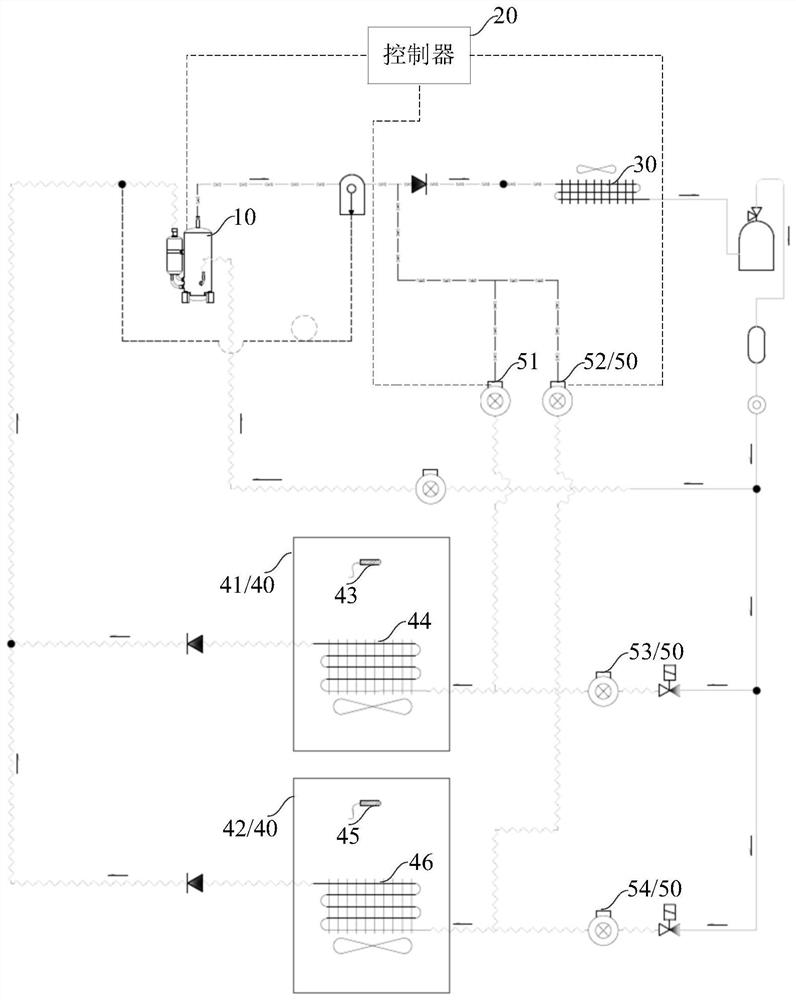

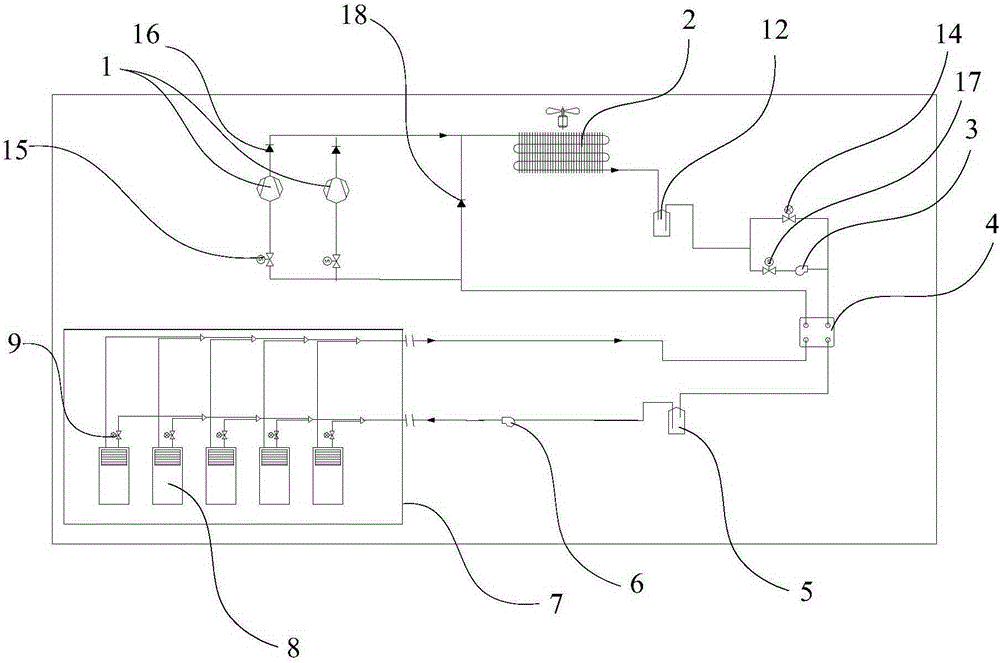

Control method and device for electronic expansion valves of multiple chambers of refrigerating system and refrigerating system

ActiveCN113280541ARaise the evaporation temperatureGuaranteed uptimeMechanical apparatusEfficient regulation technologiesThermodynamicsEngineering

The invention discloses a control method and device for electronic expansion valves of multiple chambers of a refrigerating system and the refrigerating system. The control method comprises the following steps that 1, the running state of a compressor, the opening degree of the electronic expansion valves arranged in a thermal bypass and the actual temperature of each chamber are obtained, wherein each chamber is provided with a corresponding preset target temperature; 2, according to the actual temperature of each chamber, the temperature difference between the actual temperature of each chamber and the corresponding preset target temperature is determined; and 3, according to the running state of the compressor, the temperature difference and the current opening values of the electronic expansion valves which correspond to the chambers and are arranged in the thermal bypass, the opening values of the electronic expansion valves which correspond to the chambers and are arranged in the thermal bypass are controlled to be increased to a first preset value or decreased to a second preset value. According to the control method and device for the electronic expansion valves of the multiple chambers of the refrigerating system and the refrigerating system, heating output can be reduced, the purpose of saving energy is achieved, oil return of the compressor is easy, and the compressor is protected.

Owner:JIANGSU TUOMILUO ENVIRONMENTAL TEST EQUIP CO LTD

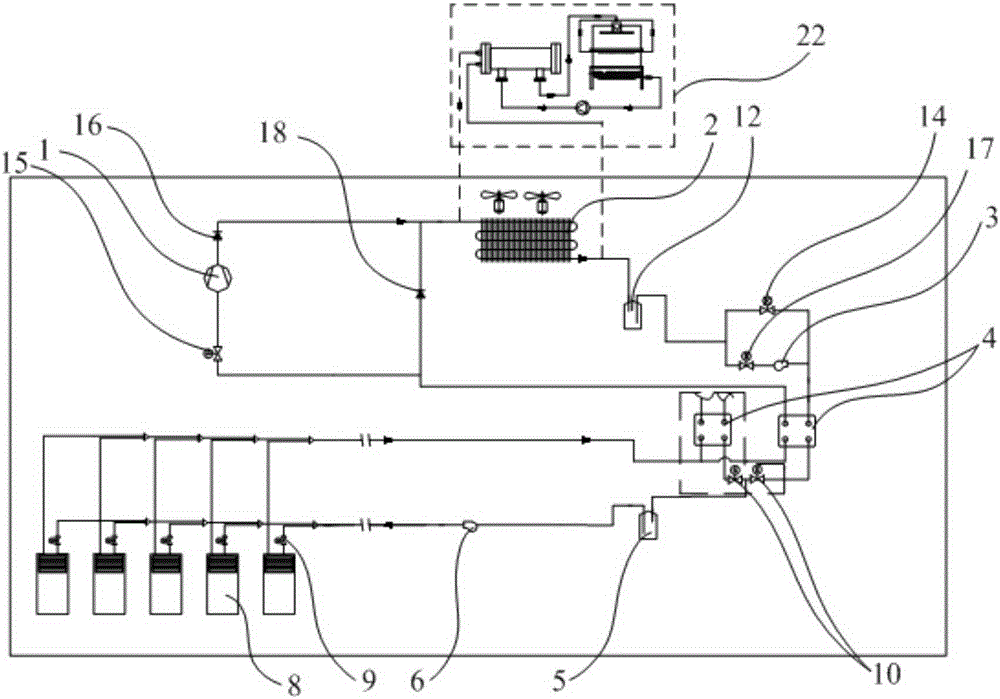

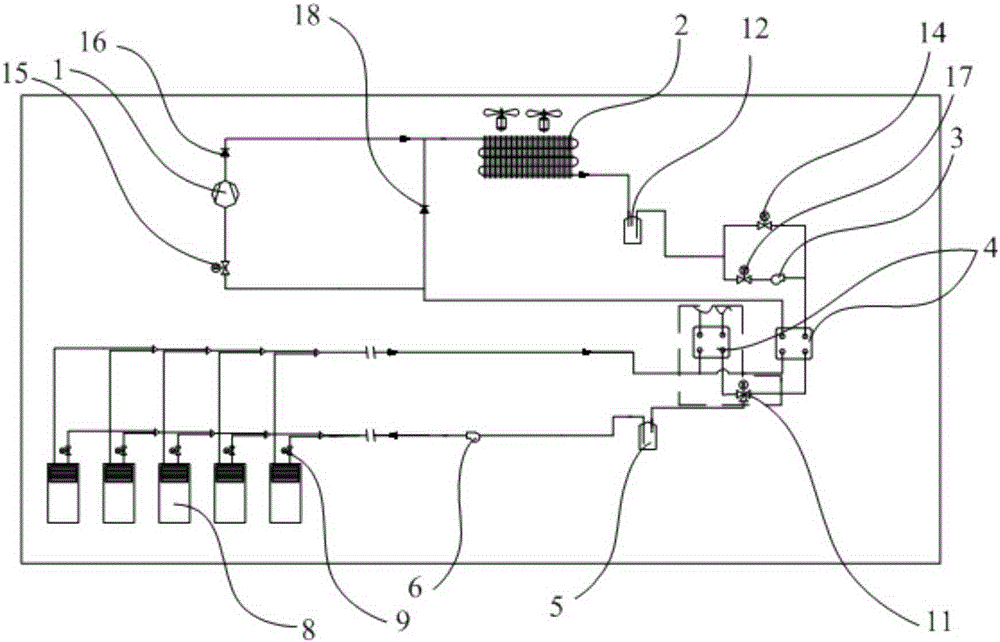

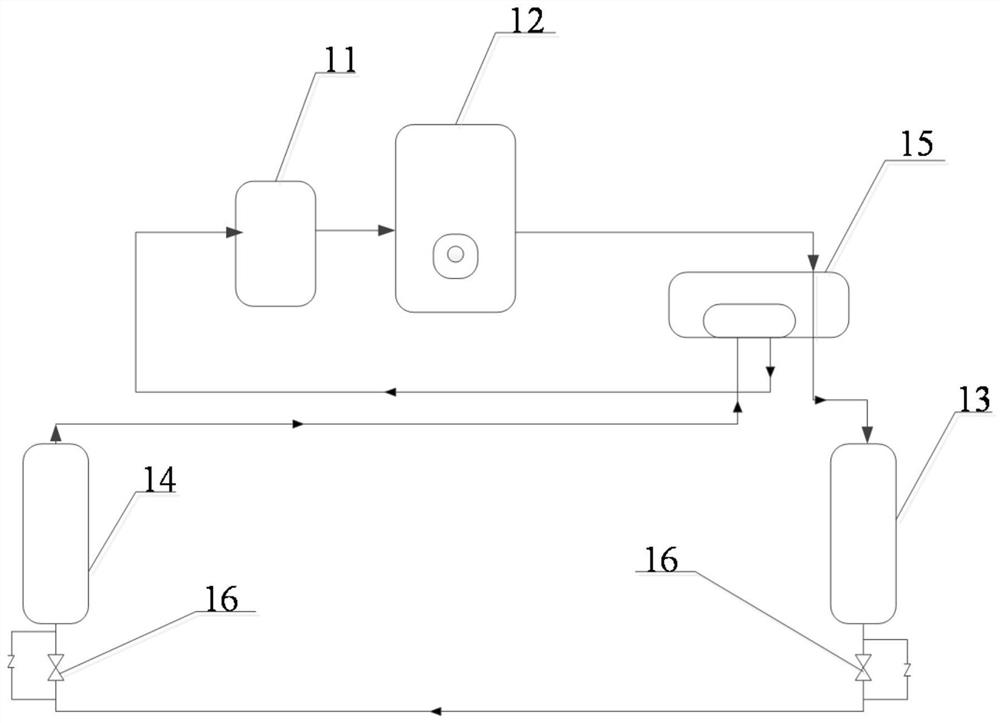

Air conditioning system

InactiveCN106642768AImprove reliabilityAchieve waterless coolingCompressorCompression machines with non-reversible cycleWater leakageIntermediate heat exchanger

The invention discloses an air conditioning system. The air conditioning system comprises a refrigeration module, a first intermediate heat exchanger, a first liquid storage tank, a first circulation pump and a tail end module, wherein the first intermediate heat exchanger comprises a first cold source side and a first hot source side; a first closed cycle is formed by the first cold source side and the refrigeration module; and the first hot source side, first liquid storage tank, first circulation pump and tail end module communicate in succession via a refrigerant pipeline to form a second closed cycle. Through application of the air conditioning system provided by the invention, problems of water leakage and oil returning existing in large air conditioning systems could be solved, and reliability of the air conditioning system could be enhanced in comparison with the prior art.

Owner:EMERSON NETWORK POWER CO LTD

Expansion switch valve

InactiveCN108253159ARealize on-off controlRealize functionOperating means/releasing devices for valvesMultiple way valvesEngineeringVALVE PORT

The invention provides an expansion switch valve which comprises a valve body. An inlet, a first outlet, a second outlet and an inner runner communicating among the inlet, the first outlet and the second outlet are formed in the valve body. The inner runner is provided with a first valve element (503) and a second valve element (504), the inlet and the first outlet communicate directly or are isolated through the first valve element (503), and the inlet and the second outlet communicate through a throttling hole (505) or are isolated through the second valve element (504). Thus, by integrallyinstalling the first valve element and the second valve element on the inner runner of the same valve body, the refrigerant circulation and cut-off control and / or throttling expansion control functioncan be achieved, the structure is simple, and production and installation are easy; and when the expansion switch valve provided by the invention is applied to a heat pump system, pipe connection canbe simplified, the cost is reduced, the refrigerant filling amount of the whole heat pump system is reduced, and oil return of a compressor is facilitated.

Owner:BYD CO LTD

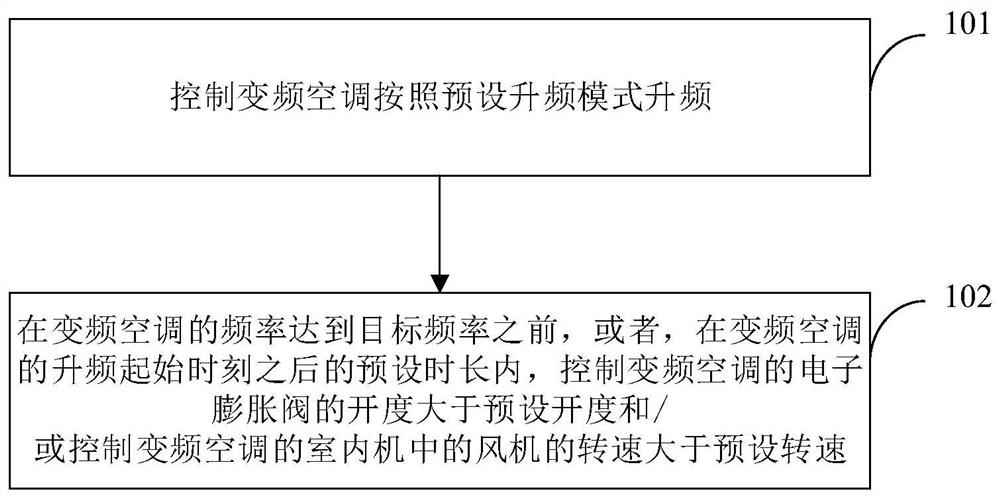

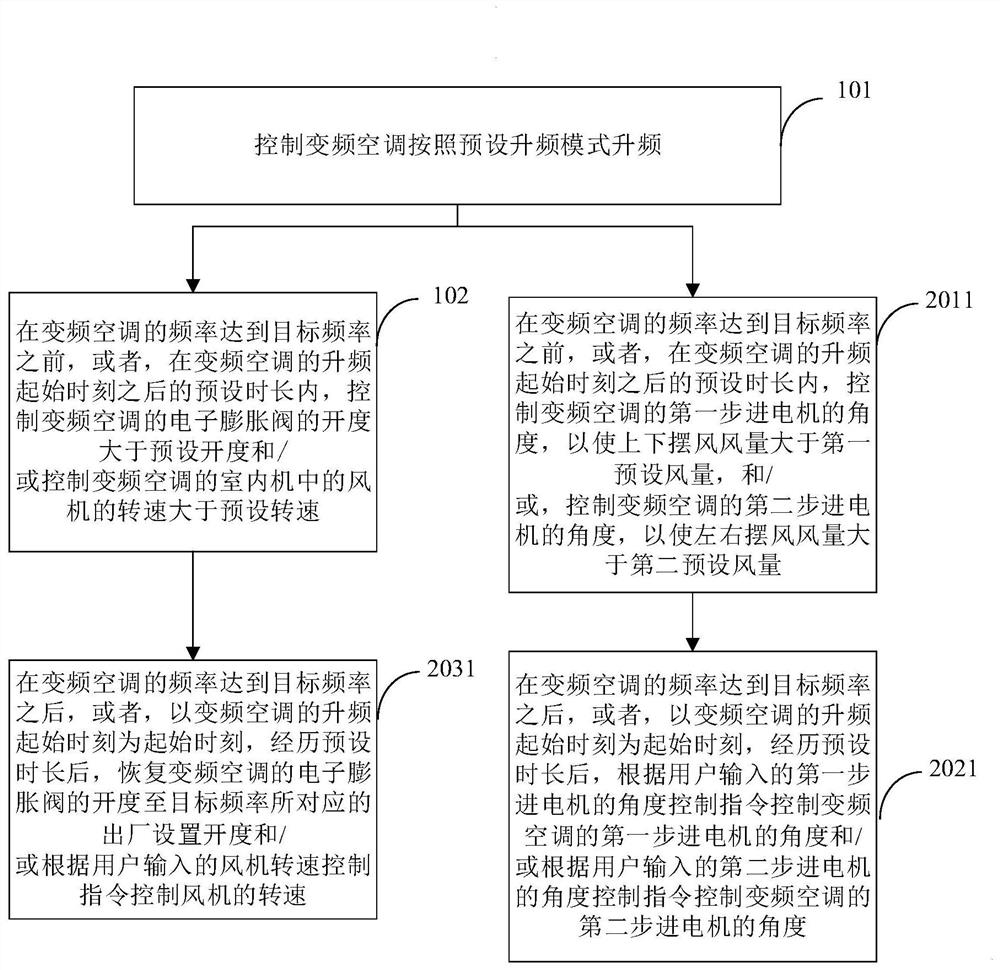

Variable frequency air conditioner control method and device, air conditioner and storage medium

PendingCN112413837AGood oil return effectIncrease return air temperatureMechanical apparatusEfficient regulation technologiesThermodynamicsEngineering

The invention provides a variable frequency air conditioner control method and device, an air conditioner and a storage medium. The variable frequency air conditioner control method comprises the steps that a variable frequency air conditioner is controlled to increase frequency according to a preset frequency increasing mode; and before the frequency of the variable frequency air conditioner reaches the target frequency or within the preset duration after the frequency rising starting moment of the variable frequency air conditioner, the opening degree of an electronic expansion valve of thevariable frequency air conditioner is controlled to be larger than the preset opening degree, and / or the rotating speed of a draught fan in an indoor unit of the variable frequency air conditioner iscontrolled to be larger than the preset rotating speed. The air return temperature can be effectively increased, oil return is optimized, and the oil return performance of the compressor is improved.

Owner:ZHENGZHOU HAIER AIR CONDITIONER CO LTD

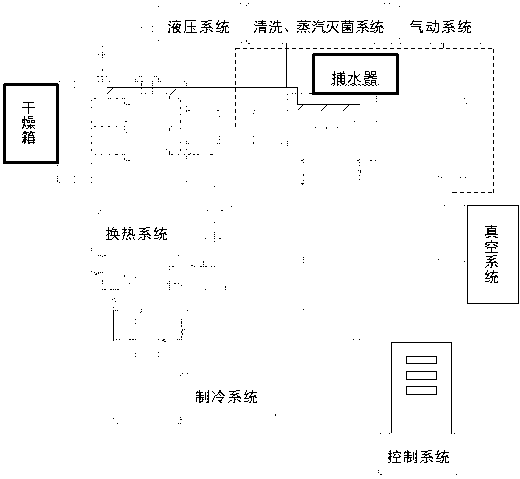

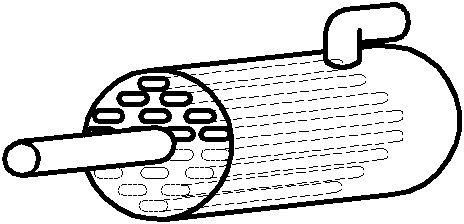

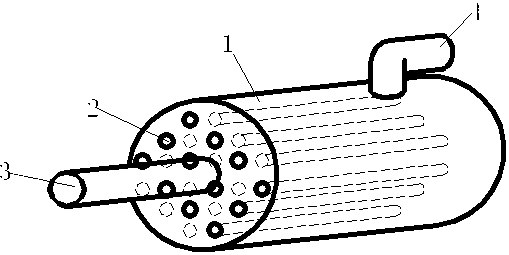

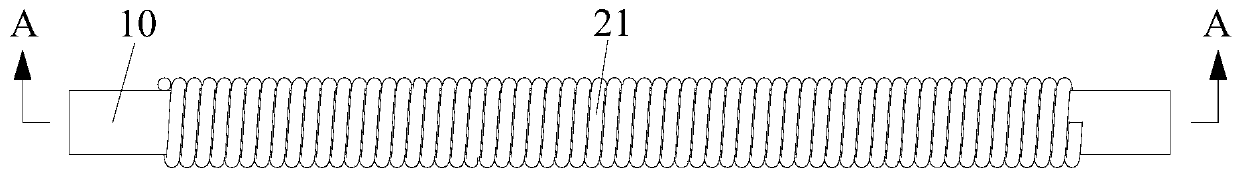

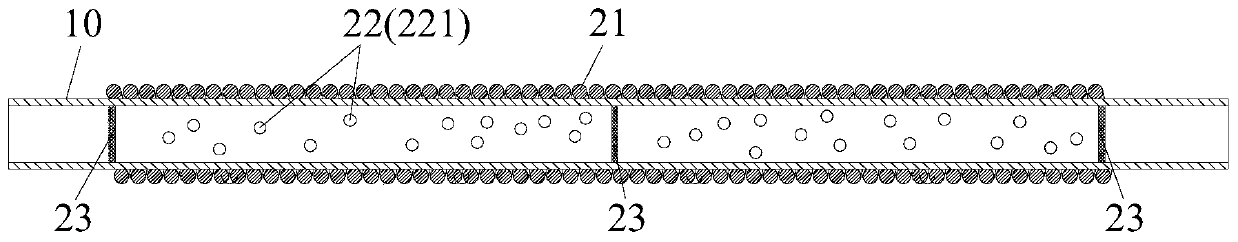

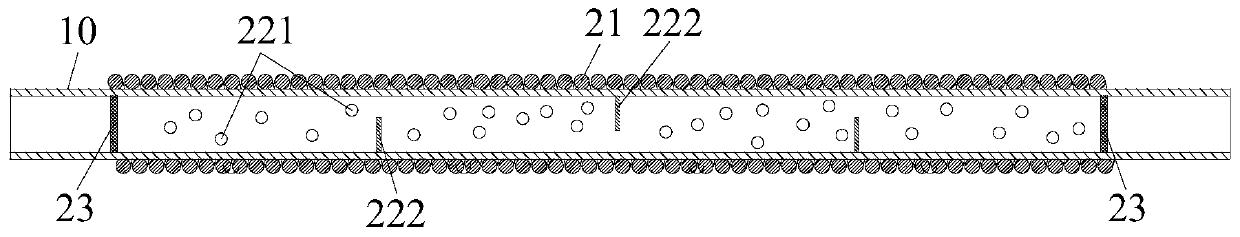

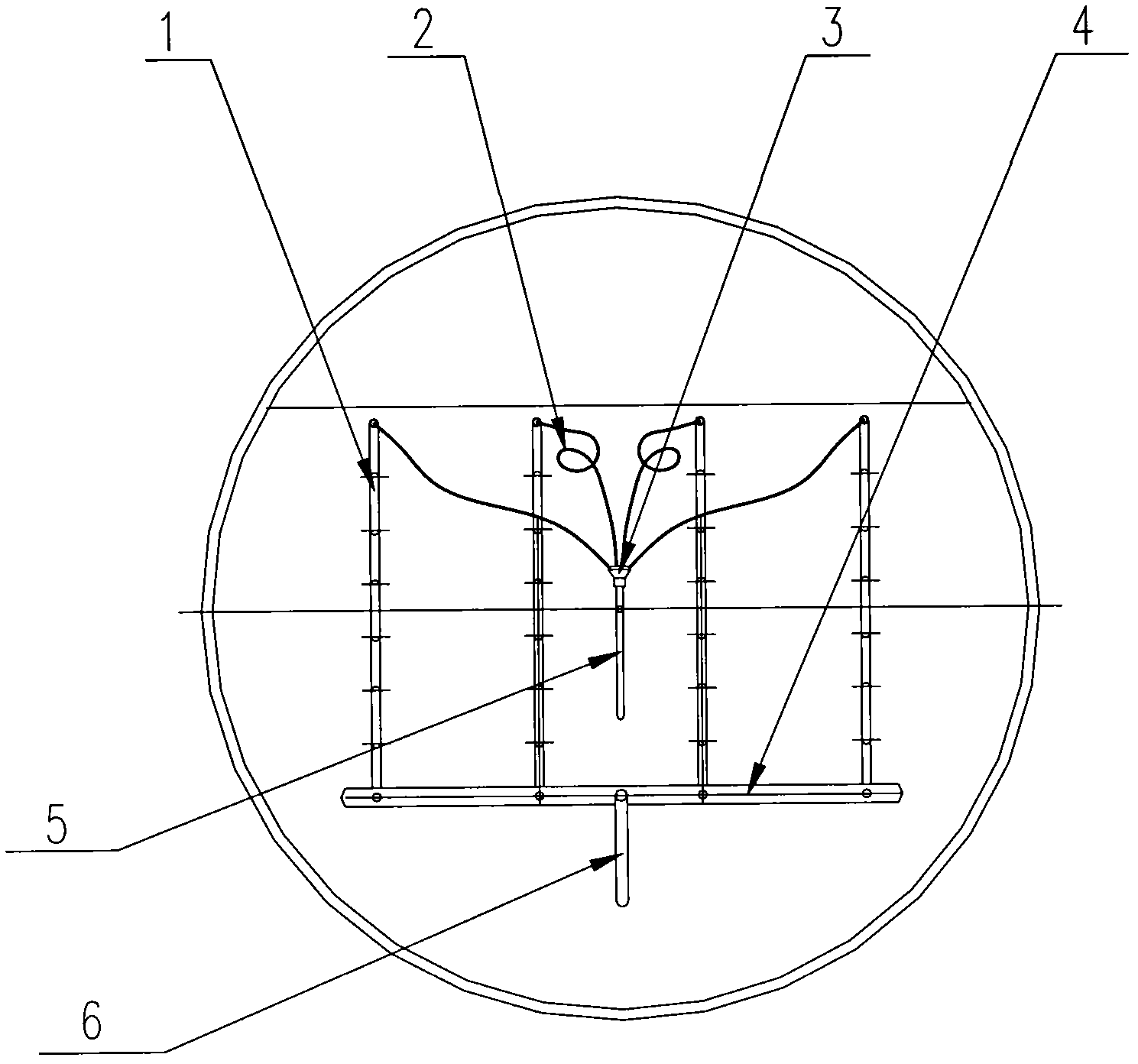

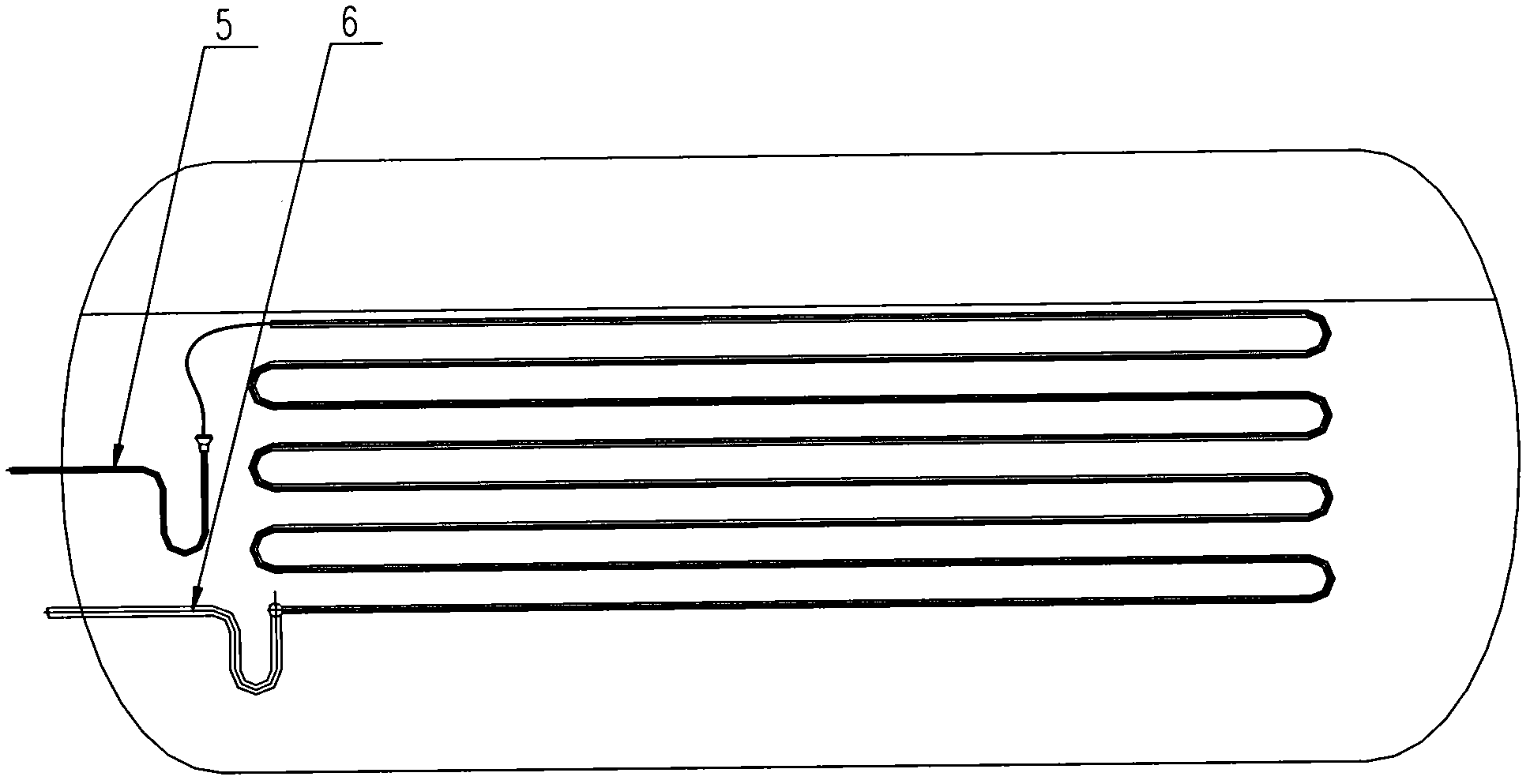

Freeze dryer water catcher

InactiveCN103344096ANot easy to cause short circuitNot easy to accumulateDrying solid materials without heatRefrigeration compressorEngineering

The invention relates to a freeze dryer water catcher which comprises a water catcher shell and two sets of coil pipes, wherein the two sets of coil pipes are evenly distributed in the water catcher shell, vapor inlets of the two sets of coil pipes are formed in the upper portion of the water catcher shell, and vapor outlets of the two sets of coil pipes are formed in the lower portion of the water catcher shell. The vapor inlets of the two sets of coil pipes are connected with a drying box, and the vapor outlets of the two sets of coil pipes are connected with a refrigerating unit. The two sets of coil pipes are evenly distributed in the water catcher shell, vapor enters each set of coil pipe from the upper portion and leaves each set of coil pipe from the lower portion, therefore, frosting is even when the two sets of units are started, frosting is also even when one set of unit is started, the short circuit phenomenon of a vapor channel is not easy to occur, and the water catching effect is good. Due to the fact that the vapor enters each set of coil pipe from the upper portion and leaves each set of coil pipe from the lower portion, refrigerant oil is not easily stored in the coil pipes, oil can be well returned, and accidents do not easily occur to a refrigeration compressor. The improved water catcher coil pipes can obtain a satisfactory effect after running for a long time, and the expected aim is achieved.

Owner:上海千山远东制药机械有限公司

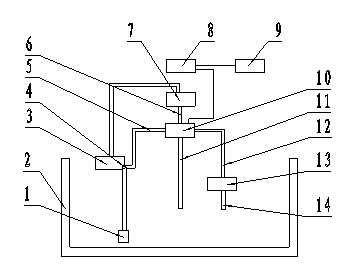

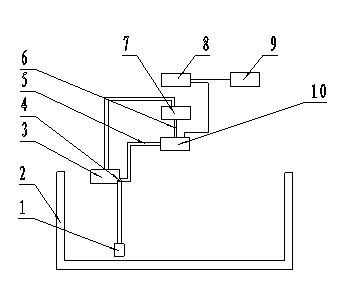

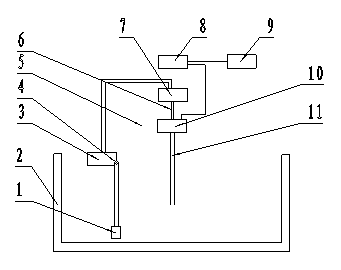

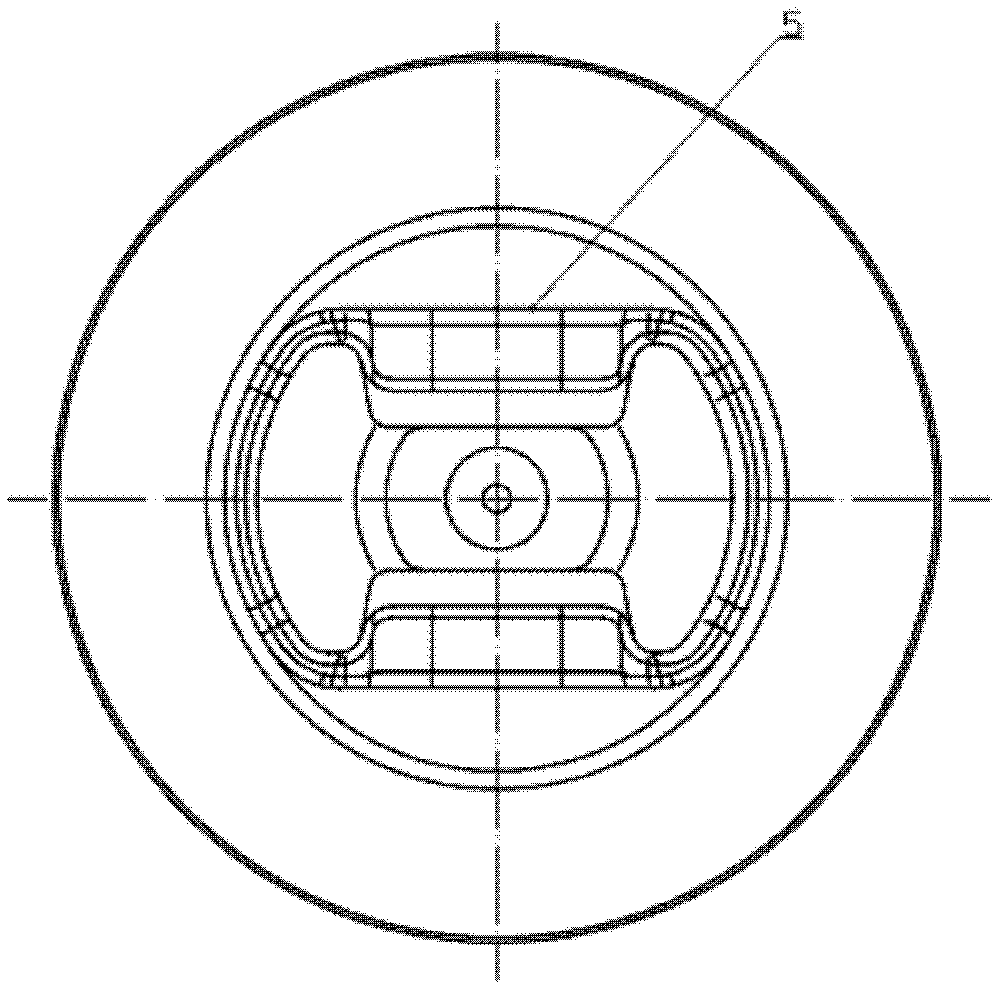

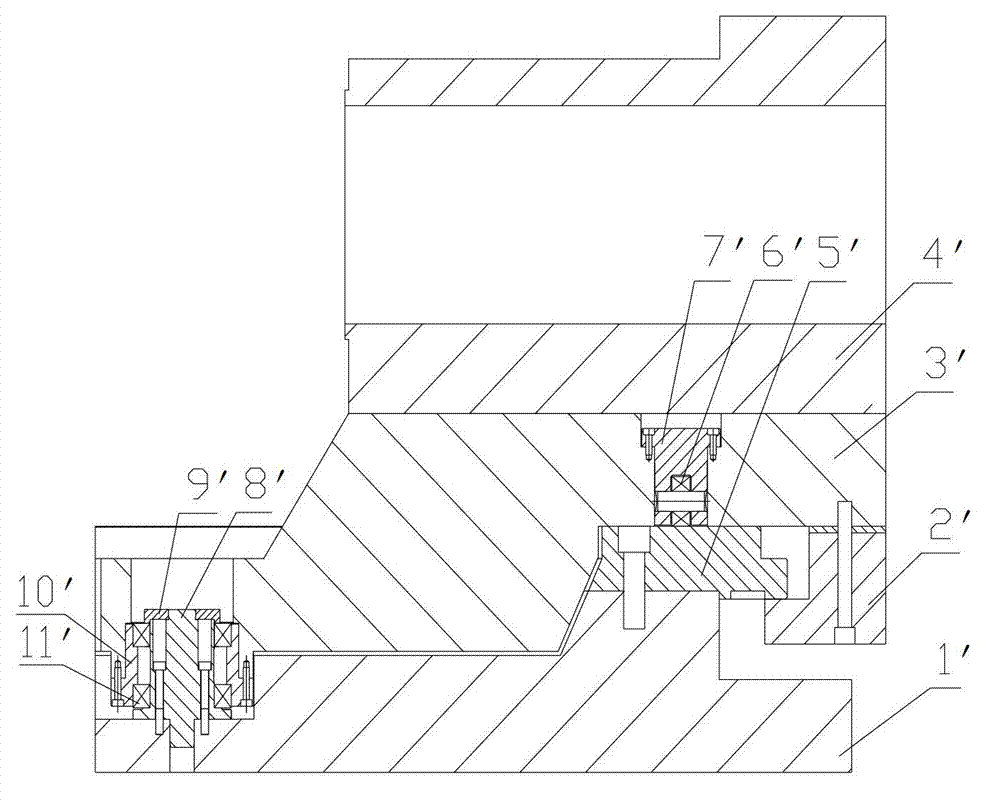

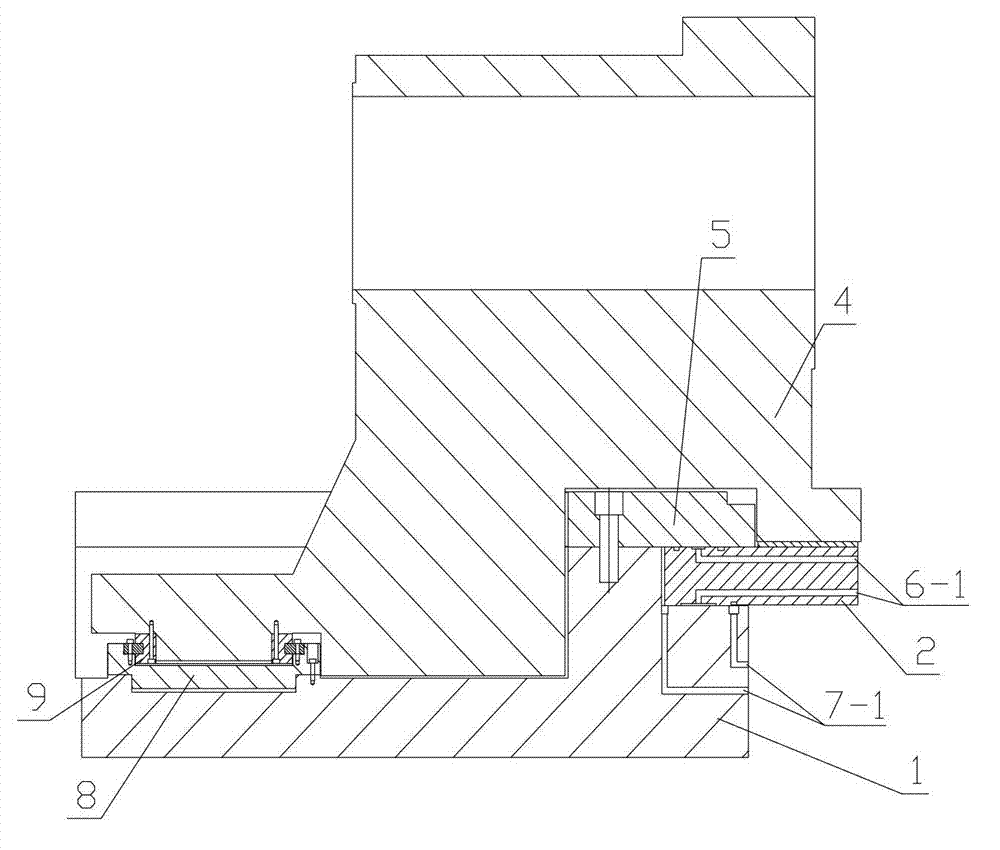

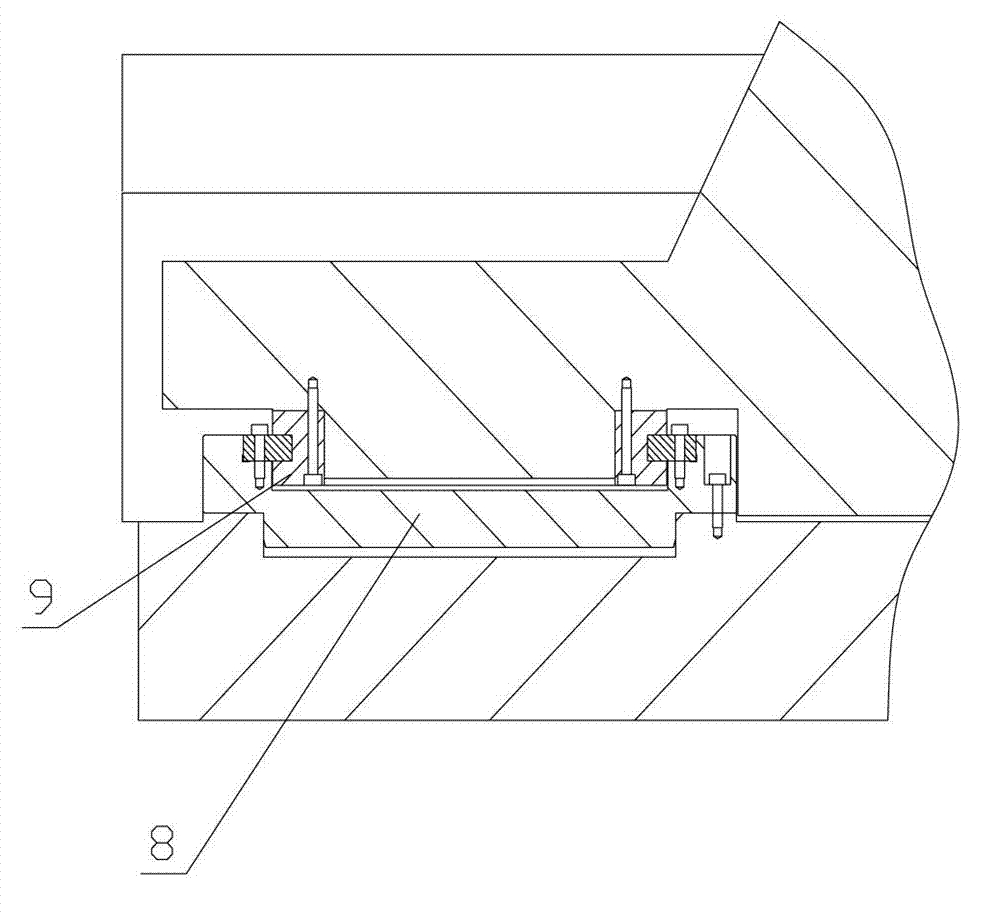

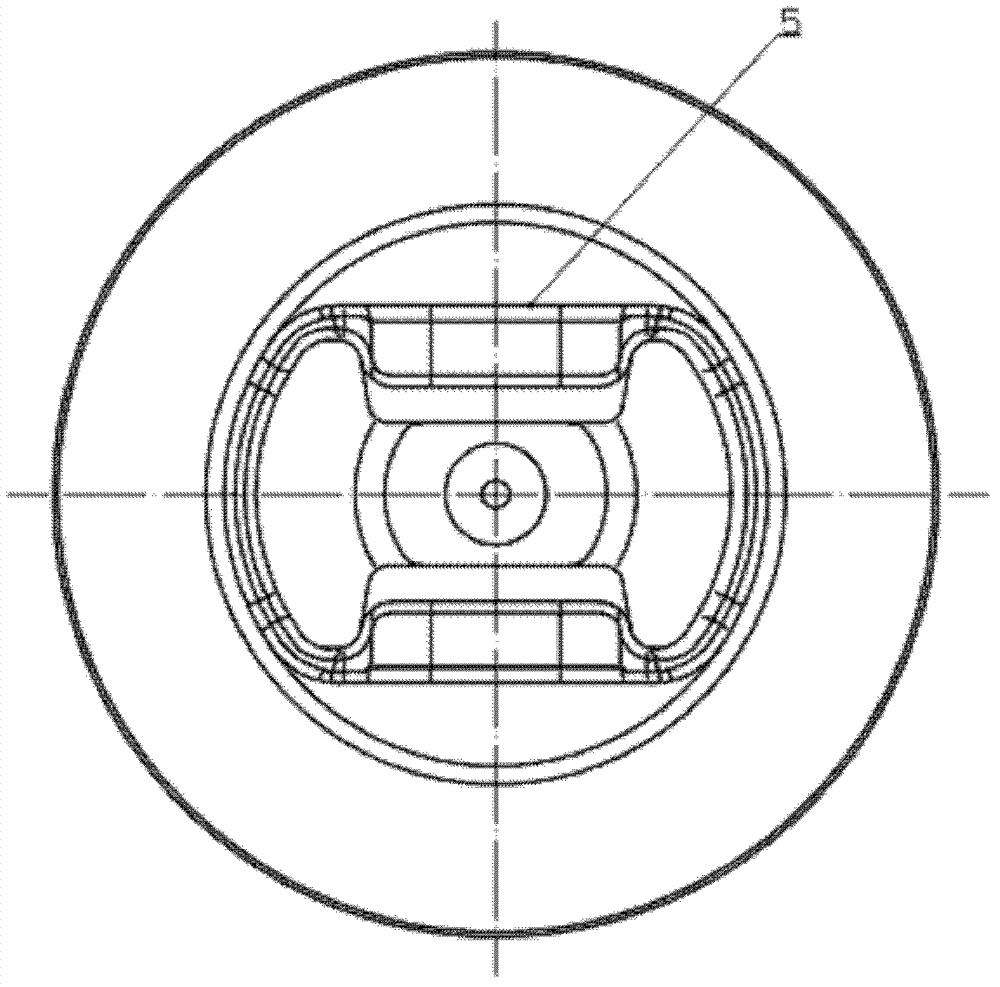

Sector static pressure rotary work table and gear cutting machine

ActiveCN103192141AHigh running precisionImprove running stabilityLarge fixed membersGear-cutting machinesMachine toolGear cutting

The invention discloses a sector static pressure rotary work table and a gear cutting machine. A big friction wheel (5) of the sector static pressure rotary work table is fixed on the upper end face of a sliding table (1), a pressing plate (2) is arranged between the sliding table (1) and the big friction wheel (5), the pressing plate (2) is fixed on the lower end face of a workpiece box body (4), an upper friction pair surface is formed between the upper end face of the pressing plate (2) and the big friction wheel (5), a lower friction pair surface is formed between the lower end face of the pressing plate (2) and the sliding table (1), an upper oil cavity (2-1) and a lower oil cavity (2-2) are arranged on the upper friction pair surface and the lower friction pair surface respectively, and the area of the lower oil cavity (2-2) is larger than that of the upper oil cavity (2-1). The big friction wheel of the rotary work table is free of abrasion during operation, stable in movement, good in rigidity, high in precision, simple and reasonable in structure, easy to machine and manufacture and convenient during oil return and can effectively guarantee the whole machine cutting precision of the gear cutting machine.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

Expansion switch valve

InactiveCN108253162ARealize on-off controlRealize functionOperating means/releasing devices for valvesMultiple way valvesEngineeringRefrigerant

The invention provides an expansion switch valve. The expansion switch valve comprises a valve body (500), wherein an inlet (501), an outlet (502) and an inner flow passage communicating between the inlet and the outlet are formed in the valve body (500), a first valve element (503) and a second valve element (504) which are parallel to each other are installed on the inner flow passage, and the first valve element (503) enables the inlet and the outlet to directly communicate or be disconnected; and the second valve element (504) enables the inlet and the outlet to communicate or be disconnected through a throttling hole (505). In this way, the first valve element and the second valve element are integrally installed on the inner flow passage of the same valve body, so that the on-off control function or the throttling expansion control function of a refrigerant can be realized, the structure is simple, and the production and the installation are easy. When the expansion switch valveis applied to a heat pump system, the pipeline connection can be simplified, the cost can be reduced, the refrigerant filling amount of the whole heat pump system is reduced, and the oil return of a compressor is facilitated.

Owner:BYD CO LTD

Labyrinth seal with oil scraping structure and oil scraping method

PendingCN111927953APrevent leakageImprove sealingEngine sealsLubrication elementsGear wheelLubrication

The invention relates to a labyrinth seal with an oil scraping structure and an oil scraping method. The labyrinth seal comprises a dynamic ring which is fixed on a gear and a static ring which is fixed on a gear shield; the dynamic ring is accommodated in the static ring; at least one oil scraping plate which is resisted against the surface of the dynamic ring is arranged on one side inner wall of the static ring; and the oil scraping plate is used for scraping lubrication oil which flows into a dynamic gear socket from a gear edge into an oil storage tank which is arranged below the gear shield. According to the labyrinth seal with the oil scraping structure, the oil scraping plate which is resisted against the dynamic ring is arranged on one side inner wall of the static ring; when thedynamic ring rotates along with the gear, the oil scraping plate scrapes lubrication oil between the dynamic ring and the static ring into the oil storage tank which is arranged below the gear shield;and in a heavy-load high-stickness lubrication medium working condition, the labyrinth seal also has good sealing performance when being applied to a main shaft gear stand, and the lubrication oil iseffectively prevented from being leaked out of the main shaft gear stand.

Owner:童春国

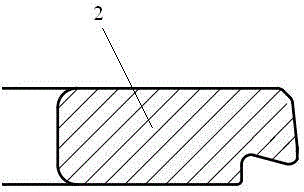

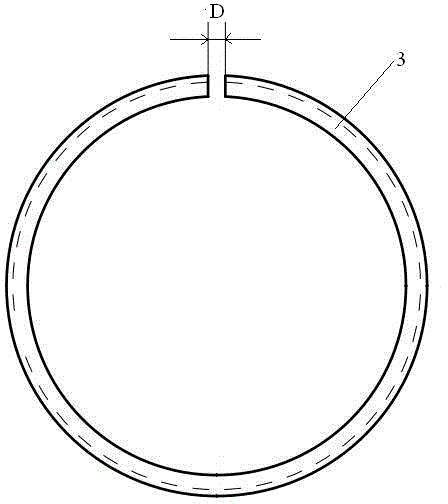

Supercharged gasoline direct-injection engine piston ring set

InactiveCN105179101AImprove wear resistanceReduce wearPiston ringsMachines/enginesGasoline direct injectionPiston ring

The invention relates to the field of engine parts, in particular to a supercharged gasoline direct-injection engine piston ring set. The supercharged gasoline direct-injection engine piston ring set comprises a first air ring, a second air ring and an oil ring closure part, wherein the cross section of the first air ring is in a shape of a cylindrical ring, the cross section of the second air ring is in a shape of a nose-shaped conical-surface ring, and oil return holes formed in a ciruclar ring of the oil ring closure part are in shapes of elongated holes. The closure gap D of the second air ring is 0.5-0.65 mm. Ten oil return holes of the oil ring closure part are evenly distributed in the circular ring, and the area of each oil return hole is 7 square milimeters. An oil scraping blade of the oil ring closure part is plated with chromium, and the surface of a circular ring body of the oil ring closure part is subjected to parkerizing treatment. The abrasion-resisting performance of the piston ring set is improved by 2-3 times, and the abrasion degree of a cast iron cylinder hole is reduced by 2-3 times. The frictional power consumption of the piston rings is reduced, so that the fuel consumption of an engine is reduced. The supercharged gasoline direct-injection engine piston ring set has very good oil return and self-cleaning capacities.

Owner:JIANGLING MOTORS

Air conditioning system with pressure relief function

InactiveCN103712382AAvoid pressure differenceImprove heat transfer effectFluid circulation arrangementRefrigeration safety arrangementRefrigerantEngineering

The invention discloses an air conditioning system with a pressure relief function. The air conditioning system comprises a compressor, a condenser, an expansion valve, an evaporator and a gas-liquid separator. A pressure relief branch is arranged between an inlet pipe of the condenser and an inlet pipe of the evaporator, an electromagnetic valve is serially connected in the pressure relief branch, and turning on and turning off of the electromagnetic valve are staggered and synchronized with turning on and turning off of the compressor. Since the pressure relief branch is arranged between the inlet pipe of the condenser and the inlet pipe of the evaporator, a high-pressure refrigerant in the condenser can be quickly released into low-pressure refrigerant of the evaporator, pressure balance of a refrigerating system is quickly established, and pressure difference is prevented from existing in the system when the compressor is started again; meanwhile, diameter of the pressure relief branch is large, so that oil return of the refrigerating system is well guaranteed, and heat exchange effect of the system is improved; moreover, a pressure sensor is further arranged at the position of the electromagnetic valve, pressure relief information can be fed back to an air conditioning control system by the pressure sensor, and accordingly convenience is brought to the control system to adjust states of an air conditioner.

Owner:ZHONGSHAN LANSHUI ENERGY TECH DEV

Manufacturing process of solid cold-spun forged steel piston with internal cooling oil chamber

The invention discloses a manufacturing process of a solid cold-spun forged steel piston with an internal cooling oil chamber. The manufacturing process comprises the following steps: performing solid forging to obtain a piston blank; machining a semi-finished piston product with an inside part of the internal cooling oil chamber and a shielding part for blocking off the internal cooling oil chamber; then heating the shielding part, and spinning downwards the shielding part of the internal cooling oil chamber of the piston by adopting the hot spinning process so that the shielding part contacts with the inside part of the internal cooling oil chamber so as to form the complete internal cooling oil chamber; and reserving the gap between the inside part and the shielding part of the internal cooling oil chamber and the shielding part without disposal or simply closing the gap by argon-arc welding and other common welding processes, and then performing precision machining to finally obtain the finished piston. The manufacturing process has the advantages of simple structure, more simple and convenient manufacturing procedures, high production efficiency, low manufacturing cost and the like, and can meet the requirements of an engine on high power, high strength and low emission.

Owner:BINZHOU BOHAI PISTON CO LTD

Functional moon cake containing astaxanthin and preparation method thereof

The invention discloses a functional moon cake containing astaxanthin. The moon cake comprises cake skin and cake filling, the cake skin wraps the cake filling, the main material of the cake skin is prepared from, by weight, 60-75 parts of plant powder, 3-5 parts of edible oil and fat, 1-2 parts of honey and 10-15 parts of egg white, and the main material of the cake filling is prepared from, by weight, 20-30 parts of plant powder, 4-6 parts of edible oil and fat, 4-6 parts of high fructose syrup, 5-8 parts of egg white, 60-75 parts of main filling and 1-5 parts of astaxanthin. The invention further provides a preparation method of the functional moon cake containing astaxanthin. According to the functional moon cake containing astaxanthin, by adding astaxanthin, the health care treatmenteffect is achieved, the oxidation resistance is conveniently improved, tumors and cancers can be resisted, and the immunity and vision are improved; honey and egg white are added to the cake filling,high fructose syrup and egg yolk are added to the cake filling, the flavor of the moon cake is sweeter, the exterior of the moon cake is crispy, the interior of the moon cake is soft, and the food therapy effect of the moon cake is improved.

Owner:GUANGDONG ZHANYANG CAKE IND CO LTD

Electromagnetic heating device, fluid pipeline and temperature adjusting equipment

PendingCN110360689AThermal resistance ratio is smallThe thermal resistance is smaller than the thermal resistance from outside to insideMechanical apparatusCorrosion preventionSolubilityEngineering

The invention relates to the technical field of air conditioning equipment, and discloses an electromagnetic heating device, a fluid pipeline and temperature adjusting equipment. The electromagnetic heating device comprises an alternating current body and a magnet receiving body, wherein the alternating current body is arranged to generate an alternating magnetic field when alternating current ispassed through the alternating current body; the magnet is arranged inside a heated member and positioned in the alternating magnetic field; and the magnet receiving body generates an induced currentunder the action of the alternating magnetic field, and simultaneously generates a Lorentz force. The alternating magnetic field generated by the alternating current body directly acts on the magnet receiving body inside the heated member, and the induced current generated by the magnet receiving body under the action of the alternating magnetic field is the alternating current (i.e. eddy current), so that the Joule heat is generated on the magnet receiving body, the heating is from inside to outside of the heated member, the heat resistance is small, and the heat transfer efficiency is high;and when the electromagnetic heating device is applied to the temperature adjusting equipment, heating for a refrigerant is realized, the specific volume of the refrigerant is effectively improved, the solubility of lubricating oil is effectively increased, the viscosity of the lubricating oil is reduced, the lubricating oil is advantageously returned, and the heating effect is improved, so that the system reliability is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

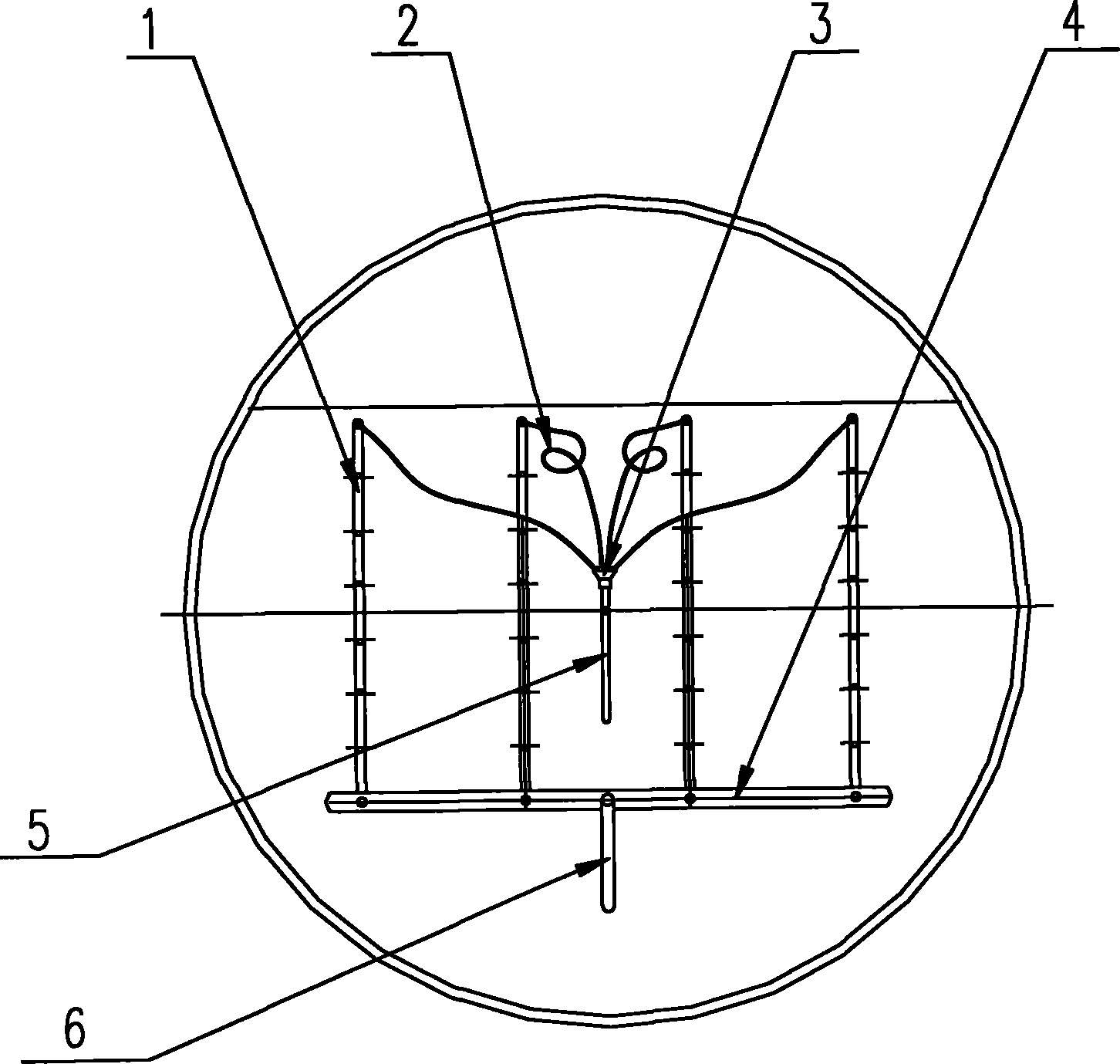

Low-pressure carbon dioxide extinguishing agent storage device

InactiveCN102155603AShorten the lengthSmall pressure lossContainer filling methodsFire rescueFire protectionEngineering

The invention relates to a fire-protection fire-extinguishing device and discloses a low-pressure carbon dioxide extinguishing agent storage device, comprising a built-in evaporator. The low-pressure carbon dioxide extinguishing agent storage device is characterized in that the evaporator comprises a shunt, a collecting pipe and a plurality of groups of snakelike coils which are connected in parallel between the shunt and the collecting pipe and are vertically arranged. For the device, the structure of the built-in evaporator is reasonable, the pressure loss is small, the installation is simple and the cold exchange efficiency is high.

Owner:XIAN XINZHU FIRE & RESCUE EQUIP

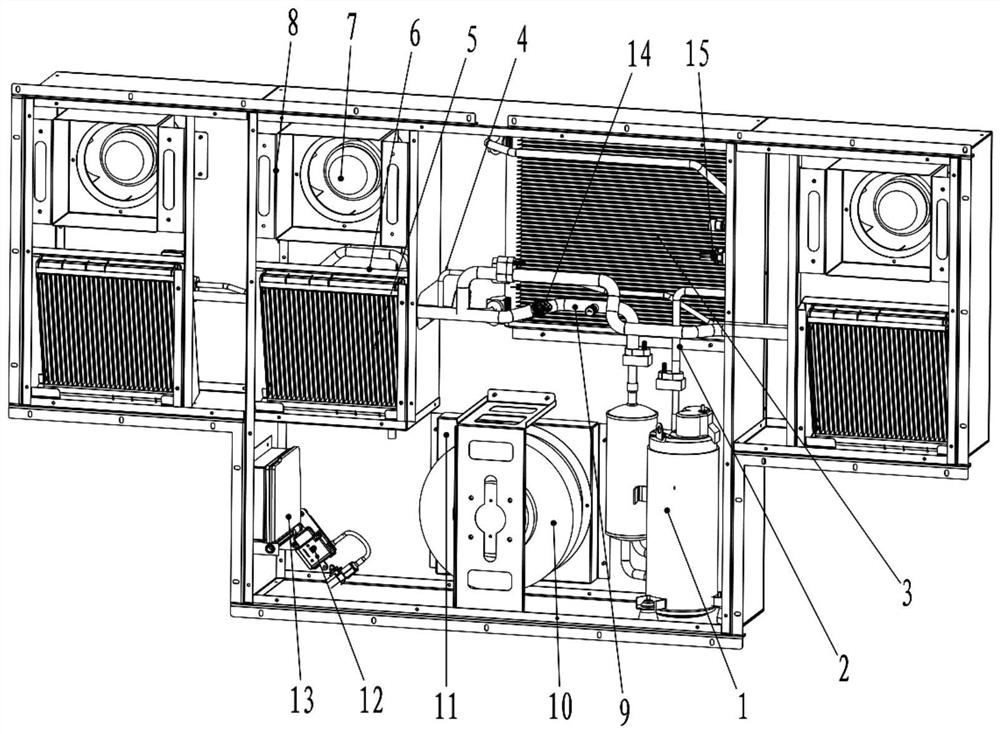

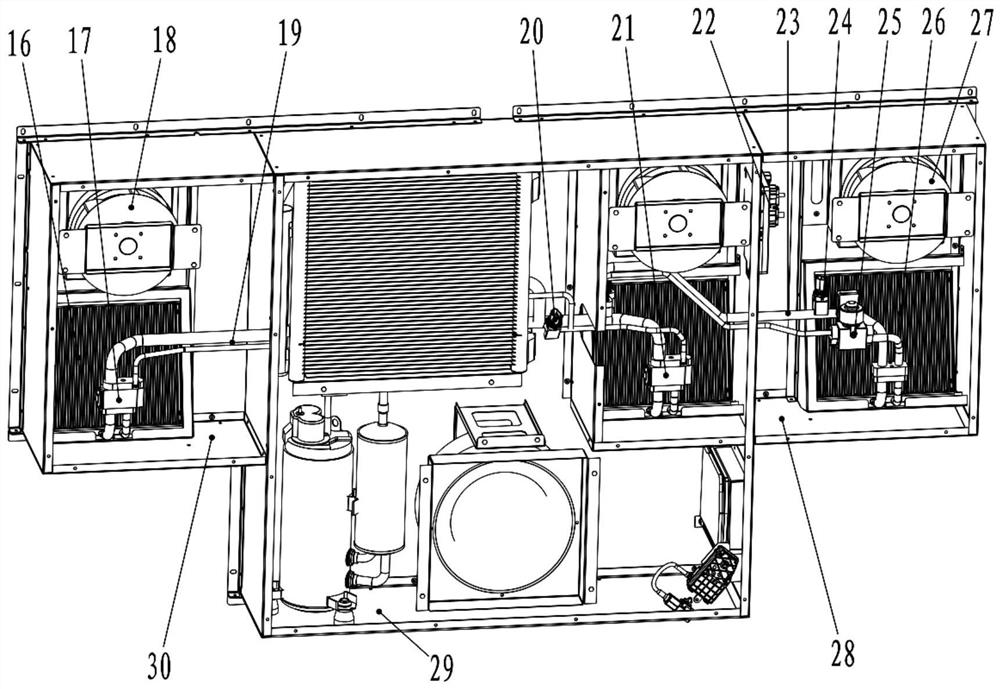

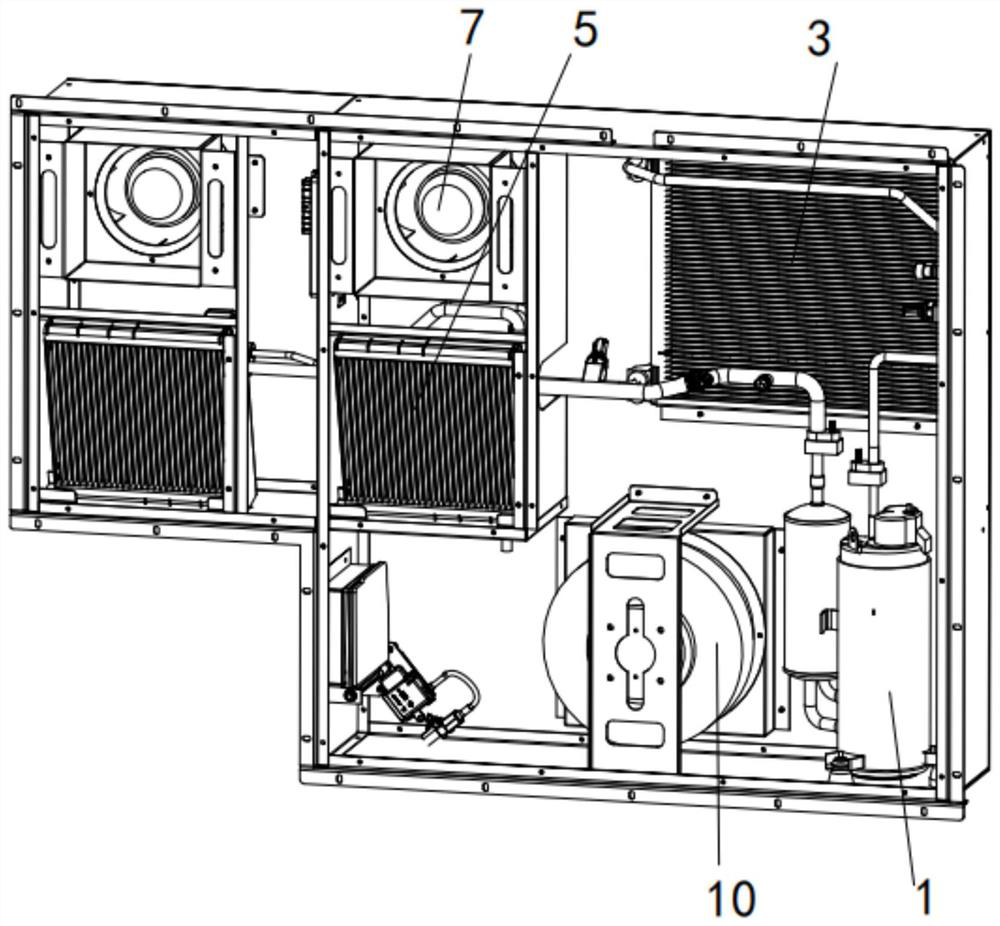

Double-cabinet and multi-connected-cabinet base station air conditioner

PendingCN113099702AReduce air temperatureStable deliveryCooling/ventilation/heating modificationsElectric machineAir blower

The invention relates to a double-cabinet and multi-connected-cabinet base station air conditioner which comprises a cabinet body serving as a shell of the connected-cabinet base station air conditioner and comprising a main cabinet body and an auxiliary cabinet; and a refrigerant subsystem which is located in the main cabinet body and comprises an electric compressor, a compressor exhaust pipe, a condenser assembly, a main cold steam pipeline and a first evaporator core body in the flowing direction of a refrigerant; the refrigerant flows through the first evaporator core body and then is connected through a compressor air suction pipe to realize circulating work; wherein a first air blowing motor and a first air blowing motor air inlet cover are arranged above the first evaporator core body; a condensation fan and a condensation fan air inlet cover are arranged below the condenser assembly; the at least one auxiliary cabinet is connected to the side of the main cabinet body, and an evaporator core body, an air blowing motor and an air blowing motor air inlet cover are arranged in each auxiliary cabinet; a controller and a sensor are arranged in the main cabinet body, the controller is electrically connected with the sensor, the electric compressor, the condensate fan and an air blower, and the intelligent control over the base station air conditioner is achieved.

Owner:JIANGXI XINDIAN AUTOMOBILE AIR CONDITIONING SYST

Ball crusher with double-rotor hydrostatic bearing structure

Owner:江苏智邦精工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com