Freeze dryer water catcher

A machine water catcher and water catcher technology, applied in drying, drying solid materials, drying solid materials without heating, etc., can solve the problems of refrigeration oil accumulation, inconsistent frosting, and lack of oil in refrigeration compressors. The frosting is uniform, the accident is not easy to occur, and the water capture effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

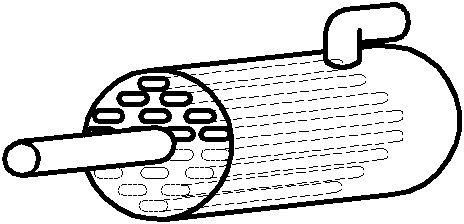

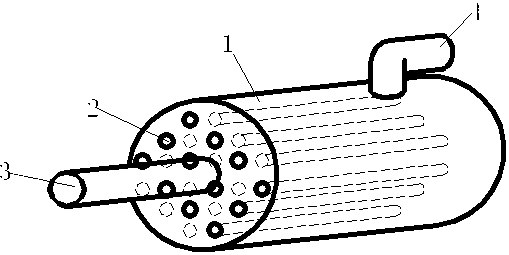

[0026] Such as image 3 As shown, the freeze dryer water catcher of the present invention includes a water catcher shell 1 and two sets of coil pipes 2 .

[0027] The two sets of coils 2 are evenly distributed in the water catcher shell 1 , and the inlets of the two sets of coils 2 are set above the water catcher shell 1 , and the outlets are set below the water catcher shell 1 .

[0028] One end of the water catcher shell 1 is provided with a water vapor inlet 3, and the other end is provided with a water vapor outlet 4. The water vapor inlet 3 and the water vapor outlet 4 on the water catcher shell 1 are respectively connected to a drying box and a refrigeration unit.

[0029] The improved water catcher solves the problem of the traditional water catcher: when one refrigeration unit is turned on, since only one group of coils is in the cooling state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com