A method for forming a composite ceramic film on the surface of a lead-silver alloy anode

A lead-silver alloy and ceramic film layer technology is applied in the field of electrochemical film formation, which can solve the problems of limited widespread use and increased anode corrosion rate, and achieves the effects of strong corrosion resistance, reduced cell voltage, and easy washing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

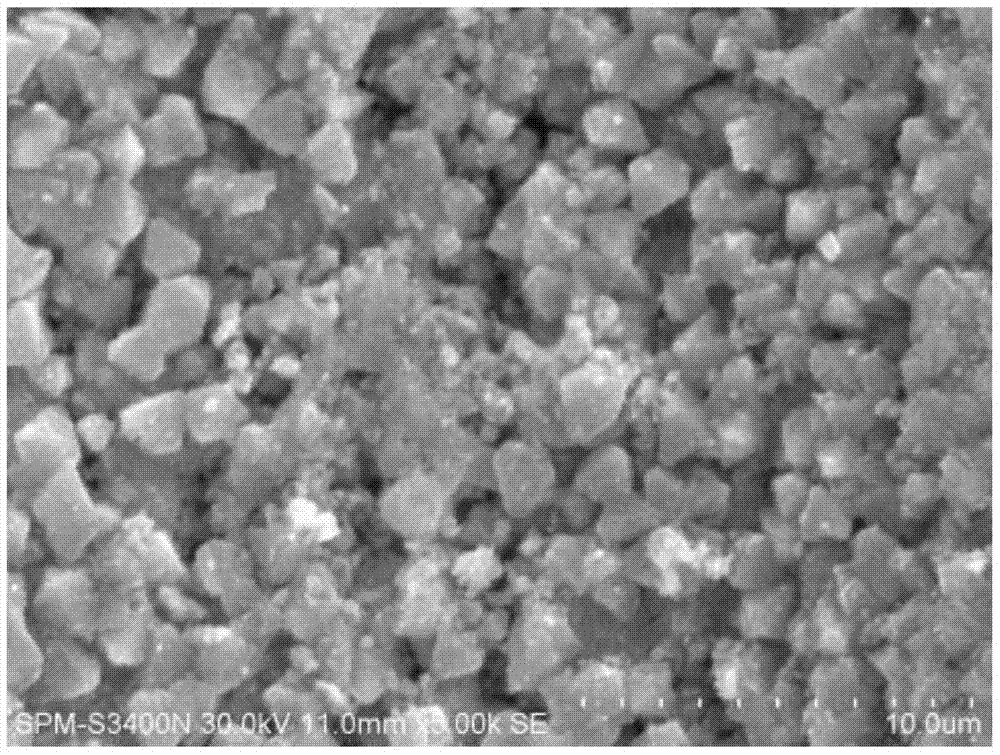

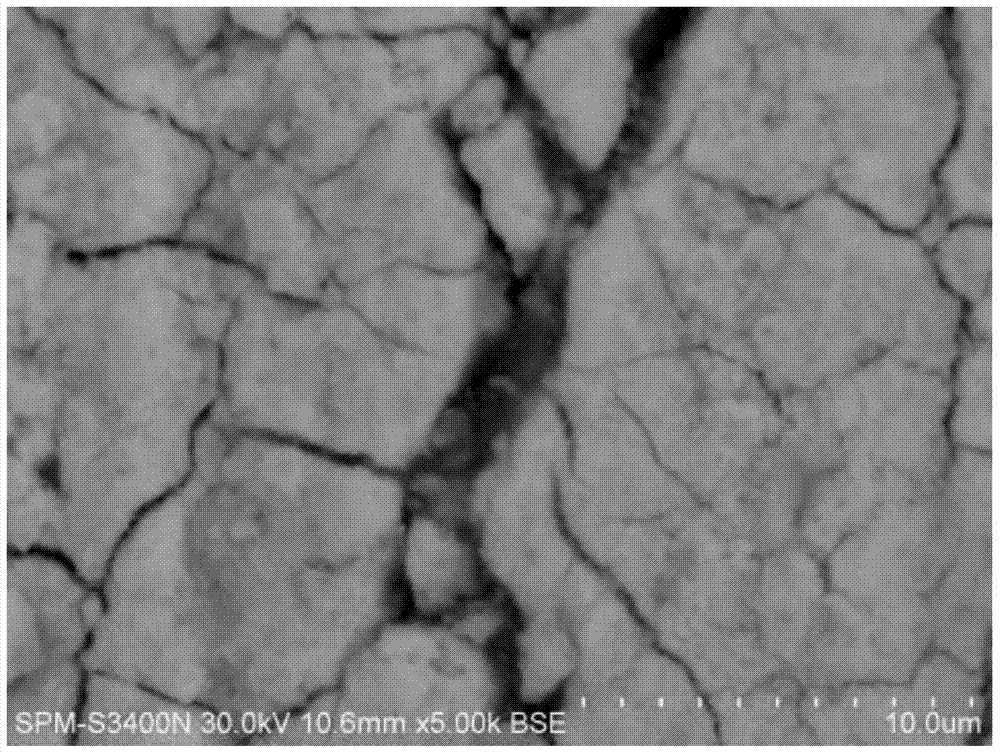

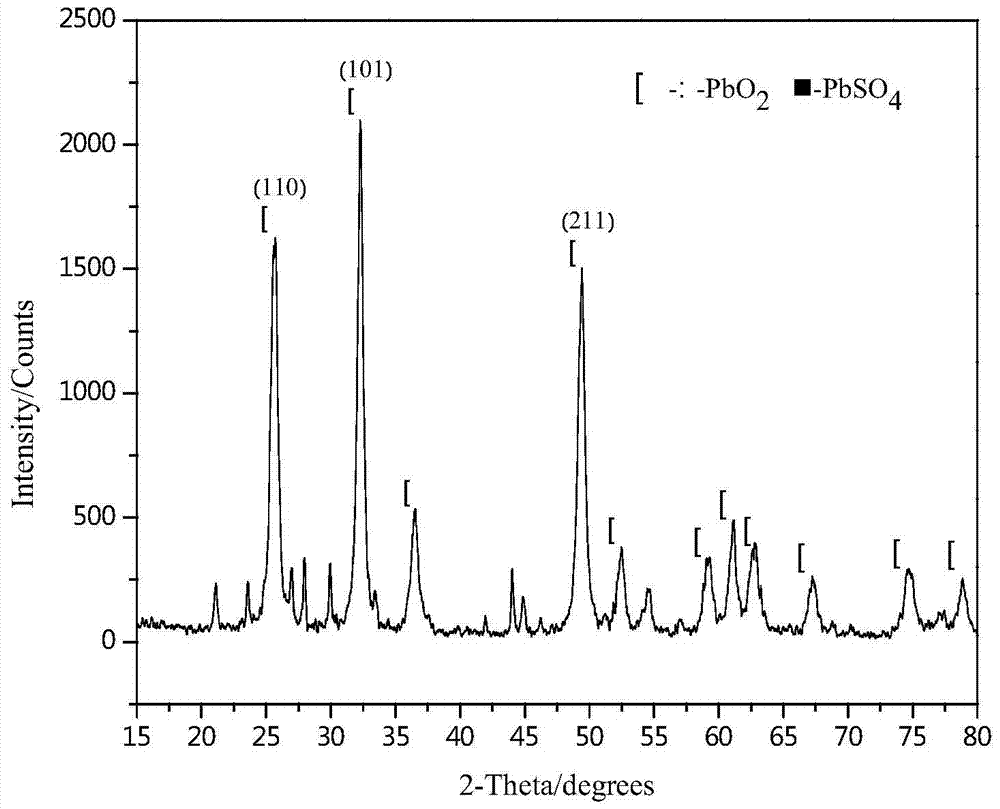

[0028] A method for forming a composite ceramic membrane on the surface of a lead-silver alloy anode, wherein the composite ceramic membrane on the surface of the lead-silver alloy anode consists of an intermediate membrane and an outer membrane. In the method of the invention, an intermediate film layer is first compounded on the surface of the lead-silver alloy anode, and then an outer film layer is compounded on the surface of the intermediate film layer. Wherein, the film forming steps of the intermediate film layer are as follows:

[0029] (1) Use a rod-shaped aluminum-based lead-silver alloy with a diameter of 12 to 14 mm as a pretreatment anode, remove the oil stain on the surface of the pretreatment anode by chemical method, and then rinse the anode surface with water;

[0030] (2) After the supporting electrolyte and water are mixed evenly, it is configured into an intermediate membrane layer film-forming electrolyte, the sulfuric acid concentration of the supporting ...

Embodiment 2

[0037] In the method for forming a composite ceramic film on the surface of the lead-silver alloy anode, an intermediate film layer is first compounded on the surface of the lead-silver alloy anode, and then an outer film layer is compounded on the surface of the intermediate film layer. Wherein, the film forming steps of the intermediate film layer are as follows:

[0038] (1) A section of aluminum-based lead-silver alloy with a width of 15mm and a thickness of 7mm is used as a pretreatment anode, and the oil stain on the surface of the pretreatment anode is removed by a chemical method, and then the surface of the anode is washed with water;

[0039] (2) After the supporting electrolyte and water are mixed evenly, it is configured into an intermediate membrane layer film-forming electrolyte, the sulfuric acid concentration of the supporting electrolyte is 150g / L, and the cerium sulfate concentration is 30g / L;

[0040] (3) With pure lead or pure aluminum plate as the negative...

Embodiment 3

[0046] In the method for forming a composite ceramic film on the surface of the lead-silver alloy anode, an intermediate film layer is first compounded on the surface of the lead-silver alloy anode, and then an outer film layer is compounded on the surface of the intermediate film layer. Wherein, the film forming steps of the intermediate film layer are as follows:

[0047] (1) the rod-shaped aluminum-based lead-silver alloy with a diameter of 12mm is used as the pretreatment anode, removes the oil stain on the surface of the pretreatment anode by chemical method, and then rinses the anode surface with water;

[0048] (2) After the supporting electrolyte and water are mixed uniformly, it is configured into an intermediate membrane layer film-forming electrolyte, the concentration of the sulfuric acid of the supporting electrolyte is 200g / L, and the concentration of cerium sulfate is 50g / L;

[0049] (3) With pure lead or pure aluminum plate as the negative electrode, the lead-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com