Insulation enhanced grid system resistant to sputtering pollution

A sputter-resistant and enhanced technology, applied in the direction of using plasma, machine/engine, thrust reverser, etc., can solve the problems of grid system insulation failure, difficult processing, neutral gas accumulation, etc. Risk of breakdown short circuit, simplified insulation connection structure, effect of reducing cost and difficulty

Pending Publication Date: 2022-05-31

BEIHANG UNIV

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The miniature ion source of the ion optical system with the above settings has high insulation performance", this design is suitable for micro-miniature ion thrusters, but this design uses a planar acceleration grid, considering the small grid spacing, the thickness of the insulator is very small Small, it is difficult to process and use such a thin insulating structure in actual manufacturing, and there are problems of mechanical strength and dielectric strength of the structure

After a long time of use, due to sputtering pollution, the thinner metal particle blocking protrusions are easily covered by sputtering pollution, resulting in early insulation failure of the grid system

[0008] For the grid system insulation design of the ion thruster, especially for the micro-miniature ion thruster that will consider the structural size limitation, the shortcomings and problems of the prior art are as follows: first, the existing grid system is for the fixed structure of the double grid, Requires more complex insulation connection design, more parts

For micro-small ion thrusters, the overall size is small. If the grid system structure design of medium and large ion thrusters is continued, the cost and difficulty of processing and assembling small-sized parts will be high, and the reliability will be reduced.

At present, there is a lack of structural design of compact grid systems to reduce the cost and difficulty of processing and assembly of grid systems

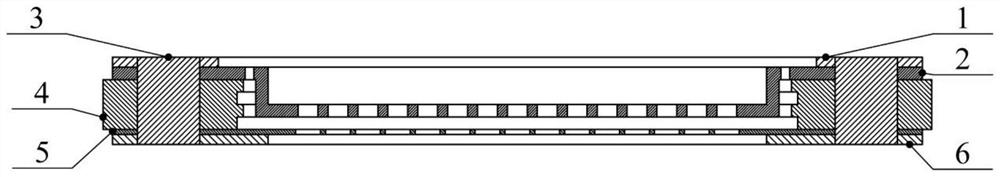

Secondly, due to the small distance between the double grids of the ion thruster, which is on the order of millimeters or submillimeters, when the structure design of the planar accelerating grid is adopted, the thickness of the insulating part between the grids is small, and the processing is difficult. The path distance on the surface of the insulator is short, resulting in poor anti-creepage and sparking ability of the grid system

At the same time, due to the small thickness and small surface area of the inter-gate insulator, it can accommodate less sputtering pollutants, resulting in poor sputtering pollution resistance of the inter-gate insulator, and the sputtering products are easy to adhere to its surface, which is easy to cause gate short circuit

The above problems will cause the insulation failure of the grid system

Third, the existing design cannot discharge the neutral gas between the grids in a directional manner, and the neutral gas is easy to accumulate between the grids, resulting in high air pressure between the grids, and it is easy to cause the grid to break at the place where the double grids and the insulating parts between the grids are in contact. Fire short circuit, especially near the surface attached by sputtered contaminants, which will affect the working stability of the ion thruster

The high air pressure between the grids will limit the voltage applied to the grid at the same time, limiting the velocity of the ion beam accelerated by the voltage, thus limiting the ion thruster to achieve higher specific impulse performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0041] In the following description, numerous specific details are set forth in order to facilitate a full understanding of the present invention, however, the present invention may also be

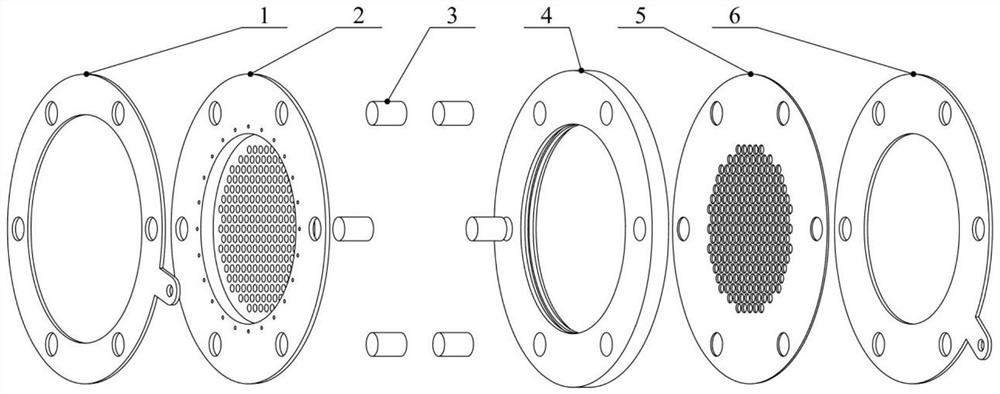

[0055] In some embodiments, the overall diameter of the system is 10.0-200.0 mm, the acceleration grid electrode 1, the acceleration grid 2, the screen

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

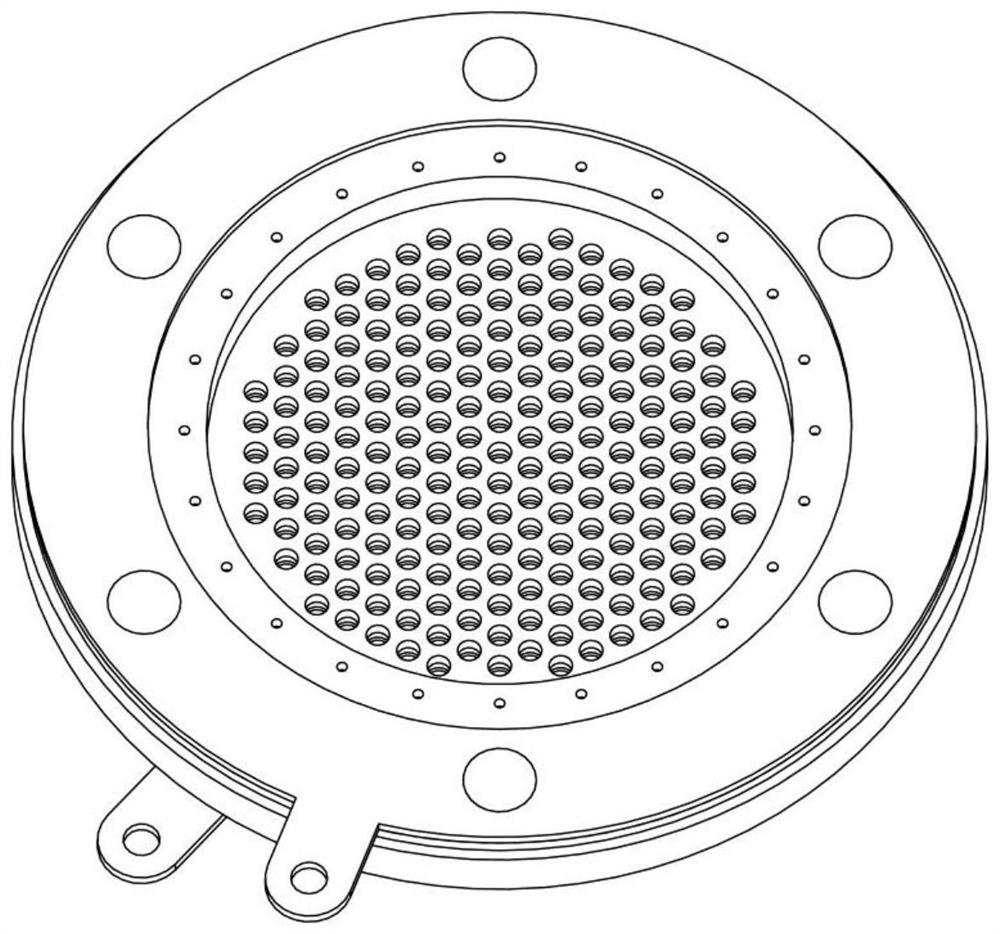

The invention discloses an insulation enhancement type grid system resistant to sputtering pollution. The insulation enhancement type grid system comprises an acceleration grid structure, an inter-grid insulation structure and a screen grid structure which are sequentially and coaxially installed through positioning holes. The compact structural design is adopted, the structure is simplified, the number of parts is reduced, and the machining and assembling cost and difficulty are reduced; according to the bowl-shaped acceleration grid, under the condition that the grid distance is not changed, the thickness of an inter-grid insulating part is increased, and the insulating performance of a grid system is enhanced; the stepped sputtering-resistant groove of the inter-gate insulator effectively increases the creepage distance, enhances the insulating property, can capture sputtering pollutants, is not easy to cause short circuit of the gate, enhances the insulating property, and prolongs the service life of the gate system; and the risk of inter-gate breakdown short circuit caused by inter-gate gas accumulation is reduced through the acceleration gate exhaust holes.

Description

An Insulation Enhanced Gate System Resistant to Sputtering Contamination technical field The invention belongs to the technical field of high-speed ion beam extraction in the technical field of space electric propulsion and ion source, and particularly relates to the technical field of high-speed ion beam extraction. And an insulation-enhanced grid system for microminiature ion thrusters with vent holes and sputter contamination resistance. Background technique [0002] Ion thruster is a kind of electric thruster, used for space electric propulsion (or called aerospace plasma propulsion, electric rocket), It has the advantages of specific impulse, wide range of thrust variation, and mature technology. It has been widely used in the attitude and orbit of spacecraft. control. The ion thruster has a high similarity with the ion source in structure and principle, and is a special kind of space electric propulsion [0003] The advanced ion source is characterized by the use...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F03H1/00

CPCF03H1/0006

Inventor 王伟宗付宸聪李亦非刘伟王海波董宜承程玉峰

Owner BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com