Patents

Literature

44results about How to "Frosting evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

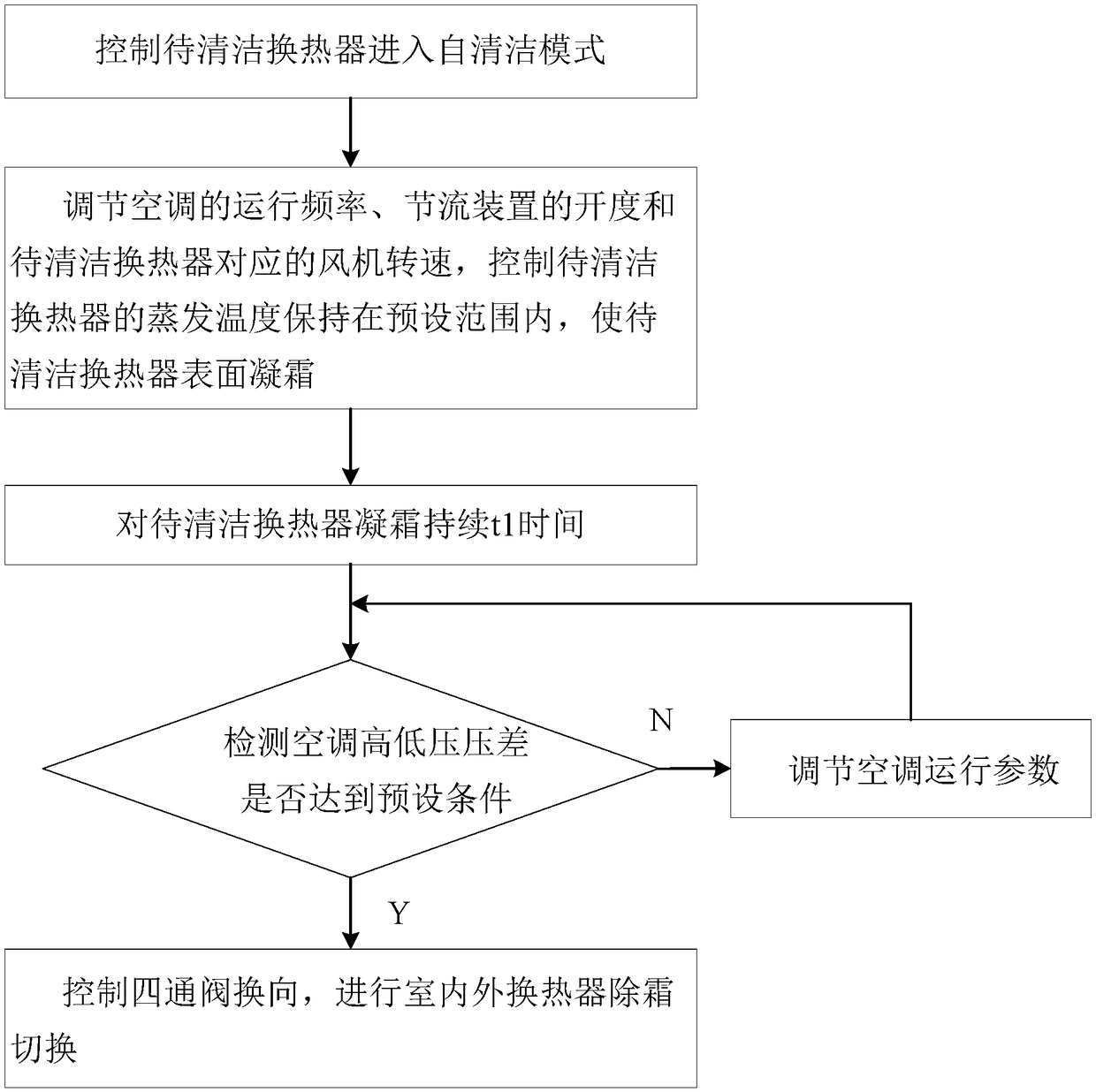

Air conditioner indoor/outdoor unit cleaning method

ActiveCN106594976AGuaranteed uptimeFrosting evenlyMechanical apparatusSpace heating and ventilation safety systemsFour-way valveEngineering

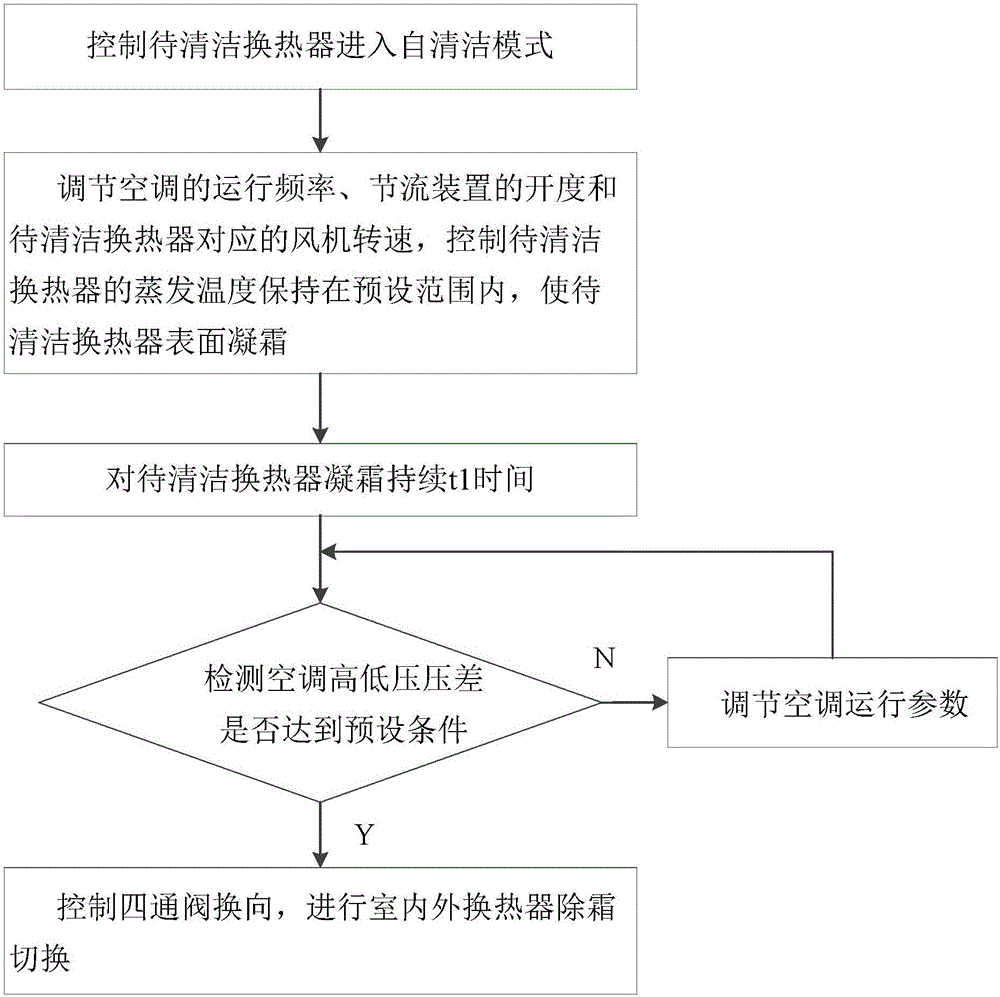

The invention discloses an air conditioner indoor / outdoor unit cleaning method. The method comprises the steps of: controlling a heat exchanger to be cleaned to enter a self-cleaning mode; adjusting the operation frequency of an air conditioner, the openness of a throttling device and the rotating speed of a fan corresponding to the heat exchanger to be cleaned, and controlling the evaporation temperature of the heat exchanger to be cleaned to keep in a preset range to condense the surface of the heat exchanger to be cleaned; condensing the heat exchanger to be cleaned by t1 time; detecting if the high / low pressure difference of the air conditioner reaches preset conditions; controlling a four-way valve to change the direction to perform the defrosting switching of indoor and outdoor heat exchangers when the high / low pressure difference of the air conditioner reaches the preset conditions; and adjusting air conditioner operation parameters when the high / low pressure difference of the air conditioner dose not reach the preset conditions, and then, controlling the four-way valve to change the direction to perform the defrosting switching of the indoor and outdoor heat exchangers when the high / low pressure difference of the air conditioner reaches the preset conditions. As the direction change of the four-way valve can be controlled through detecting if the high / low pressure difference of the air conditioner reaches the preset conditions, the higher shock on the compressor caused by excessive high / low pressure difference of the air conditioner can be prevented.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

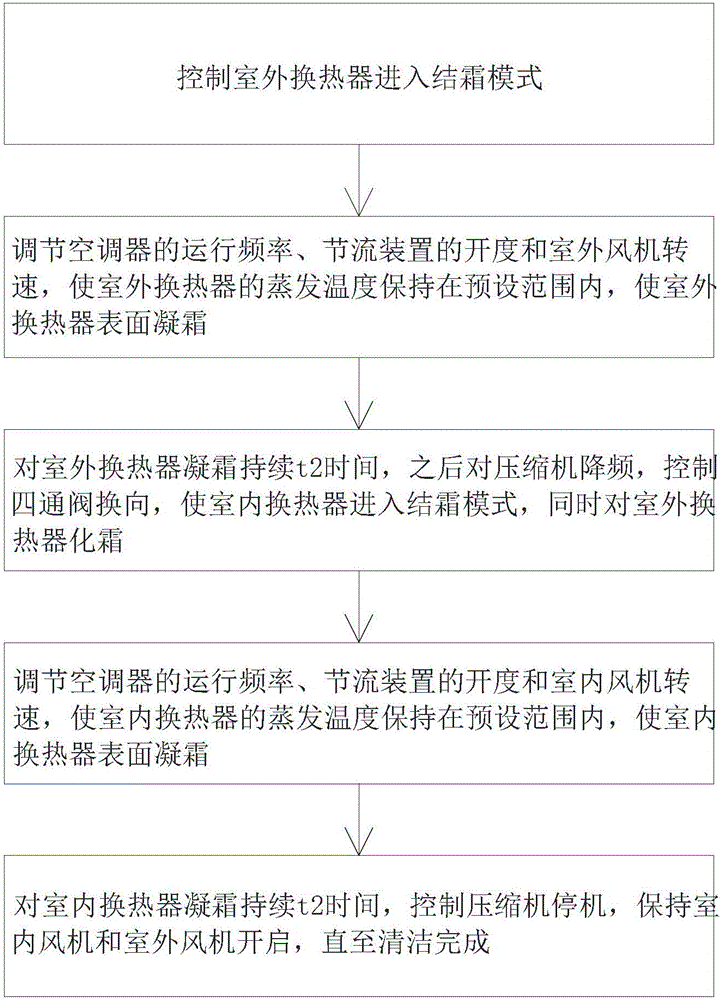

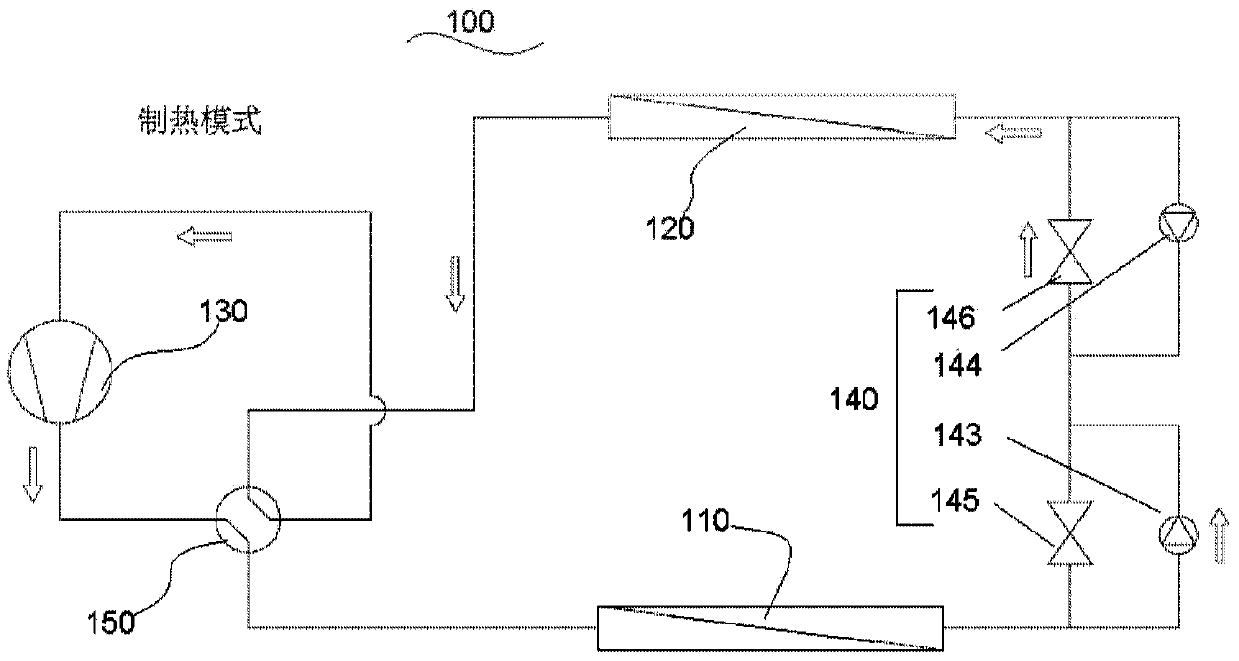

Air-conditioner internal and external unit cleaning method

ActiveCN106152413AFrosting evenlyImprove defrosting efficiencyMechanical apparatusSpace heating and ventilation safety systemsFour-way valveEngineering

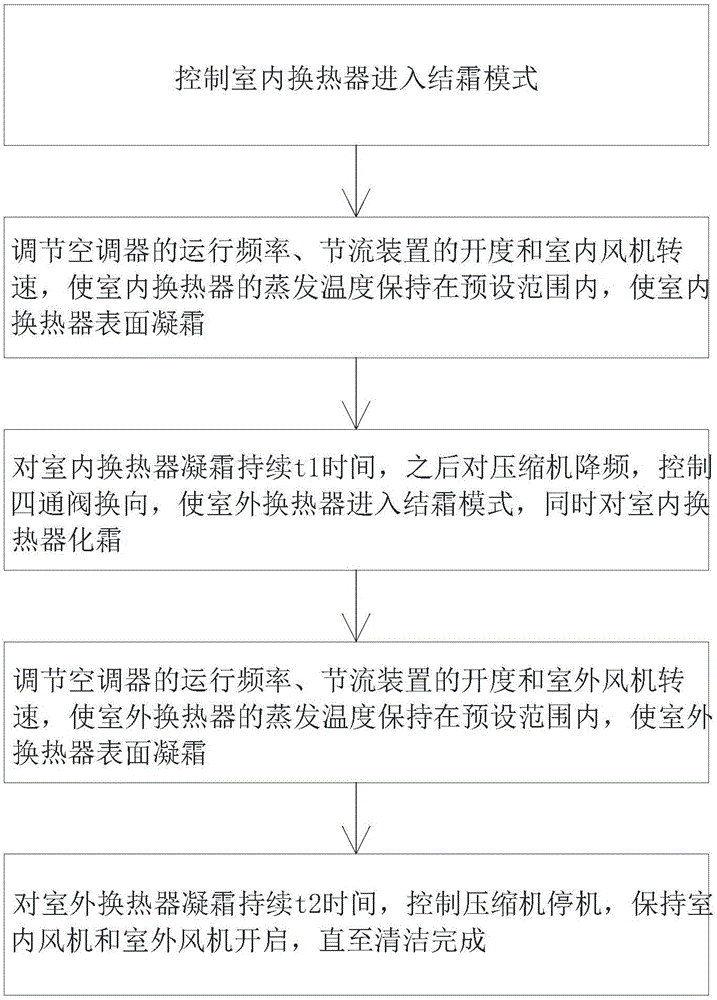

The invention discloses an air-conditioner internal and external unit cleaning method. The method comprises the steps that an indoor heat exchanger is controlled to enter a frosting mode; operation frequency of an air-conditioner, the opening degree of a throttling device and the rotating speed of an indoor fan are adjusted to enable evaporating temperature of the indoor heat exchanger to be kept within the preset range and the surface of the indoor heat exchanger to be frosted; frosting of the indoor heat exchanger lasts for time t1, later, frequency of a compressor is reduced, a four-way valve is controlled to be reversed, an outdoor heat exchanger enters a frosting mode, and meanwhile, the indoor heat exchanger is defrosted; the operation frequency of the air-conditioner, the opening degree of the throttling device and the rotating speed of an outdoor fan are adjusted, the evaporation temperature of the outdoor heat exchanger is kept within the preset range, and the surface of the outdoor heat exchanger is frosted; frosting of the outdoor heat exchanger lasts for time t2, the compressor is controlled to be shut down, and the indoor fan and the outdoor fan are kept starting until cleaning is completed. According to the air-conditioner internal and external unit cleaning method, the problem that in the prior art, the surface of the heat exchanger is cleaned through condensate water, and the effect is poor can be solved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

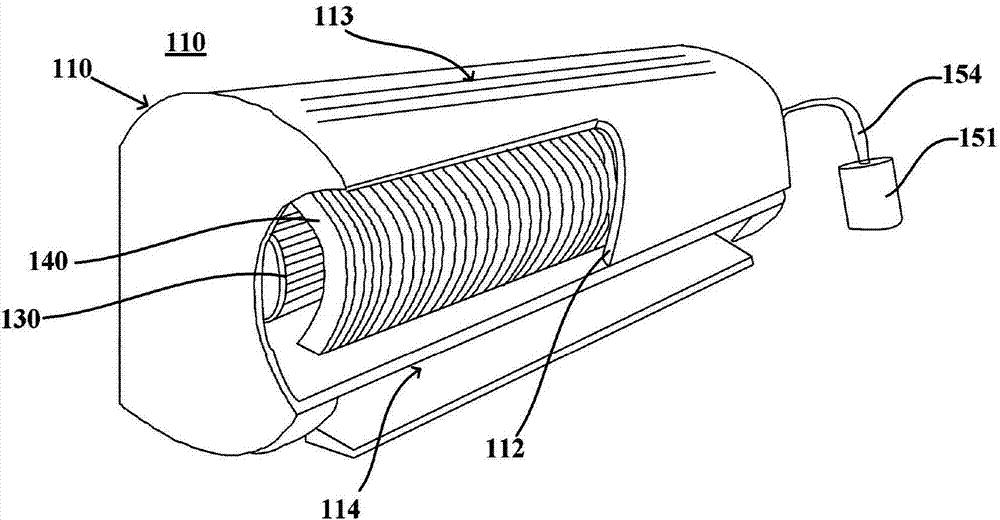

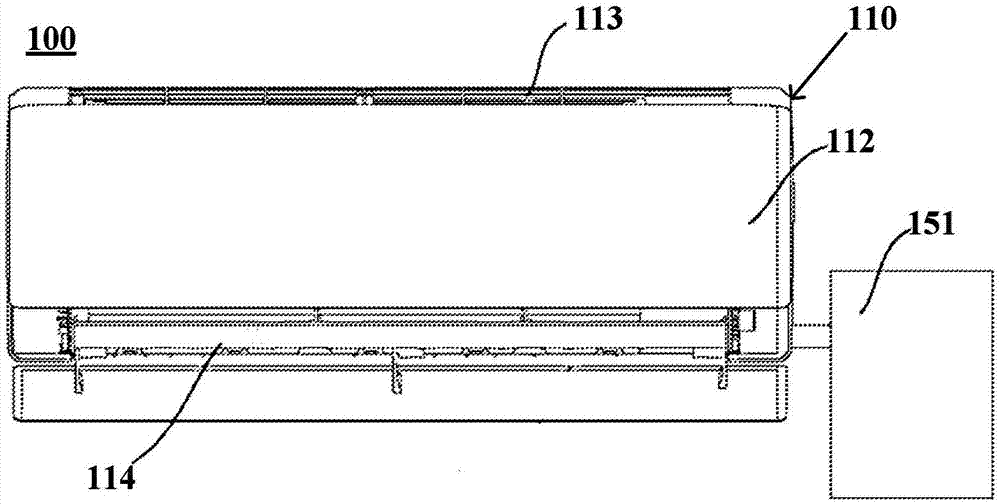

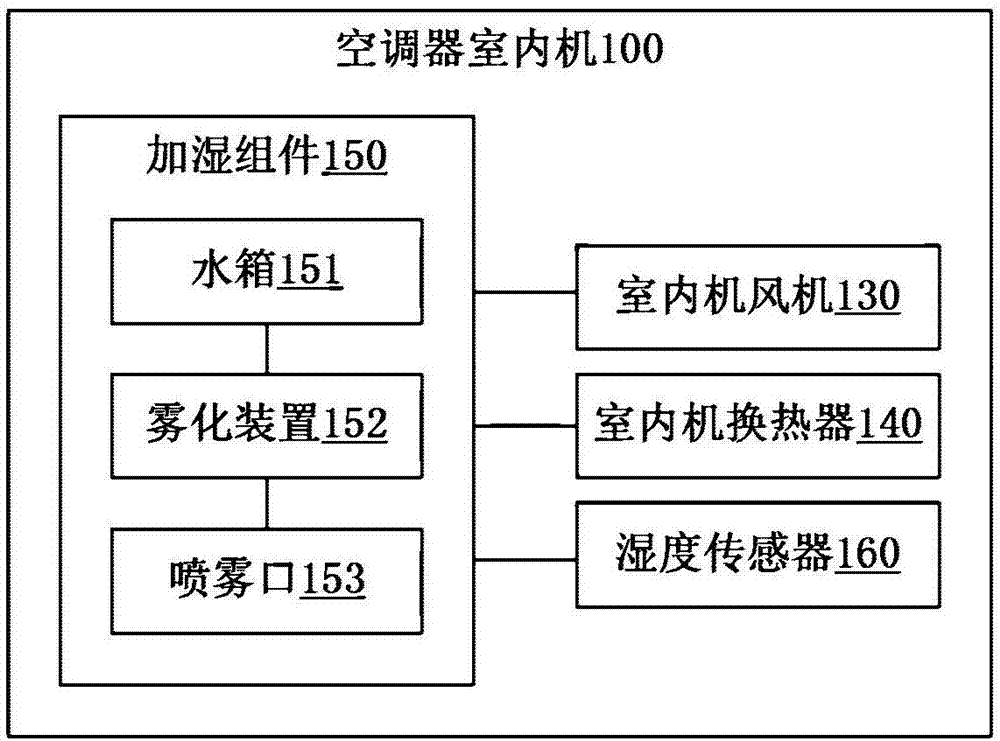

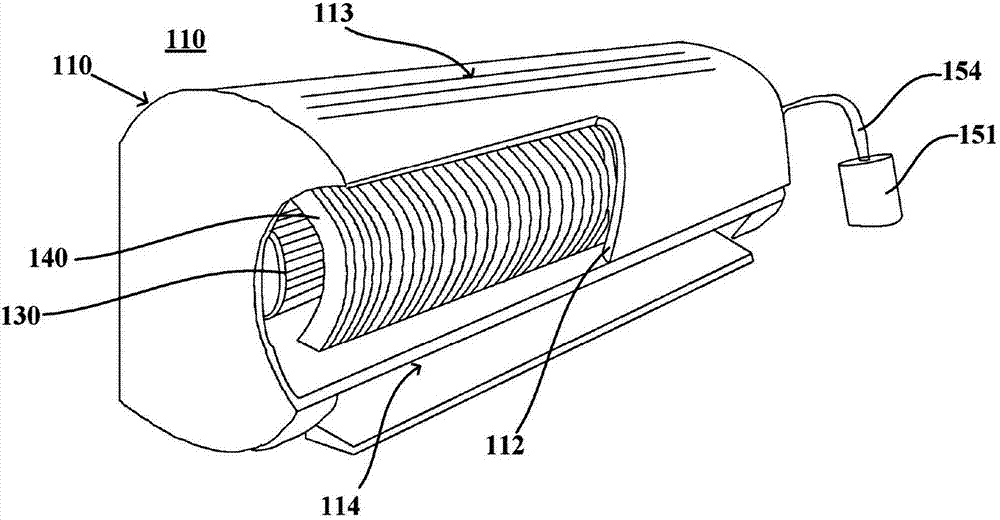

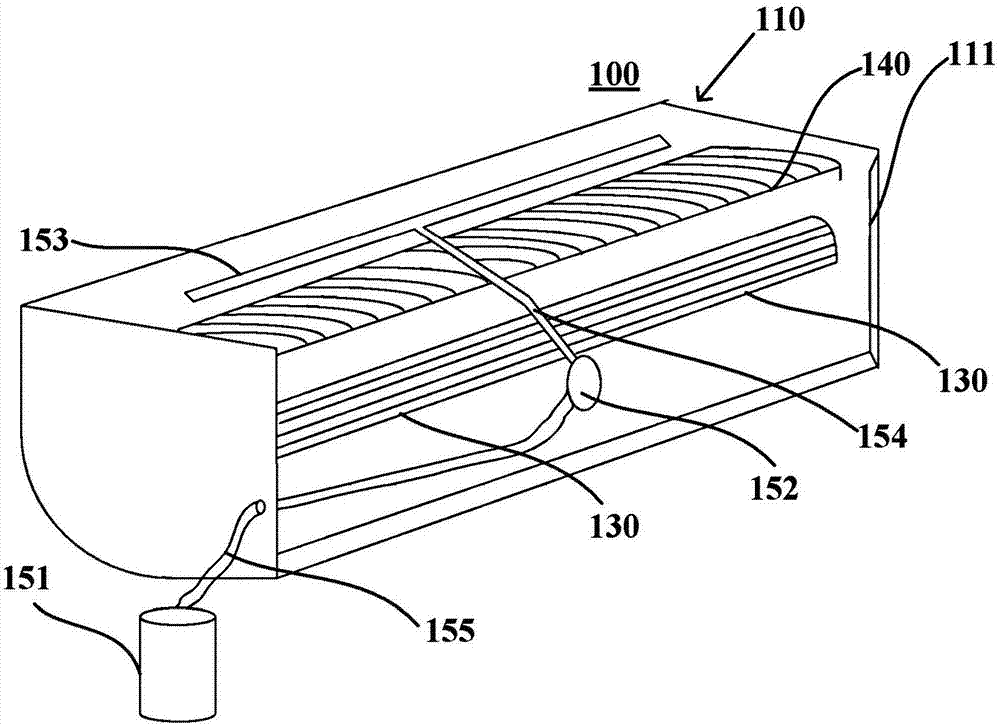

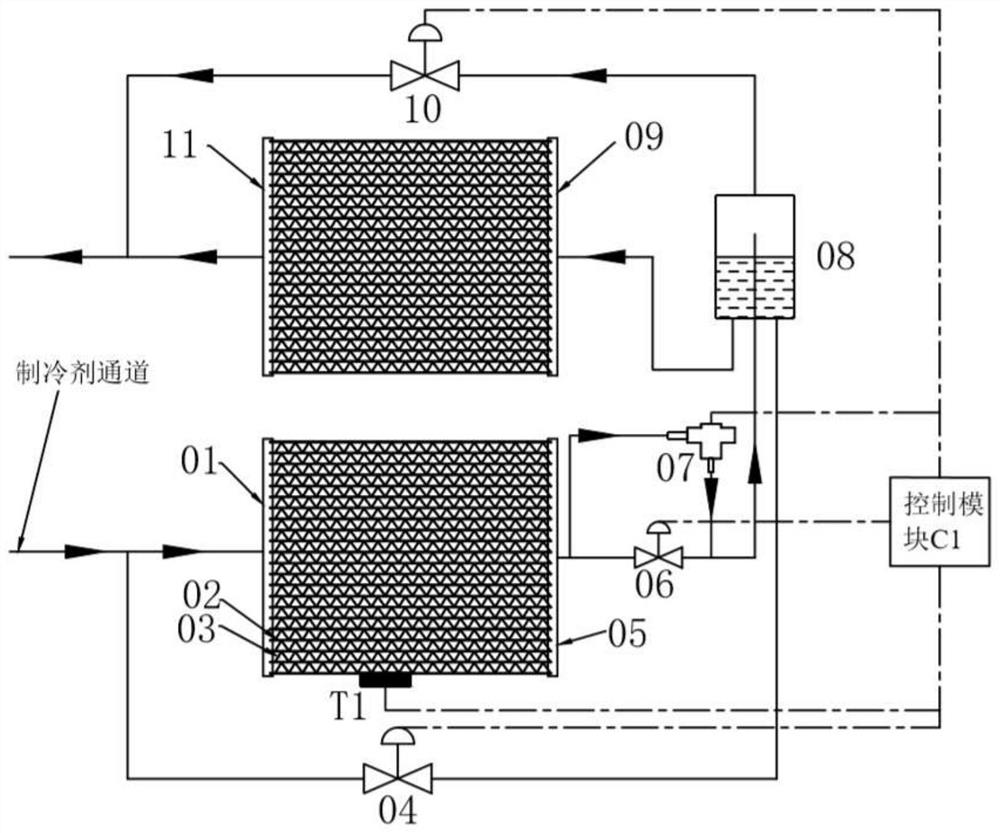

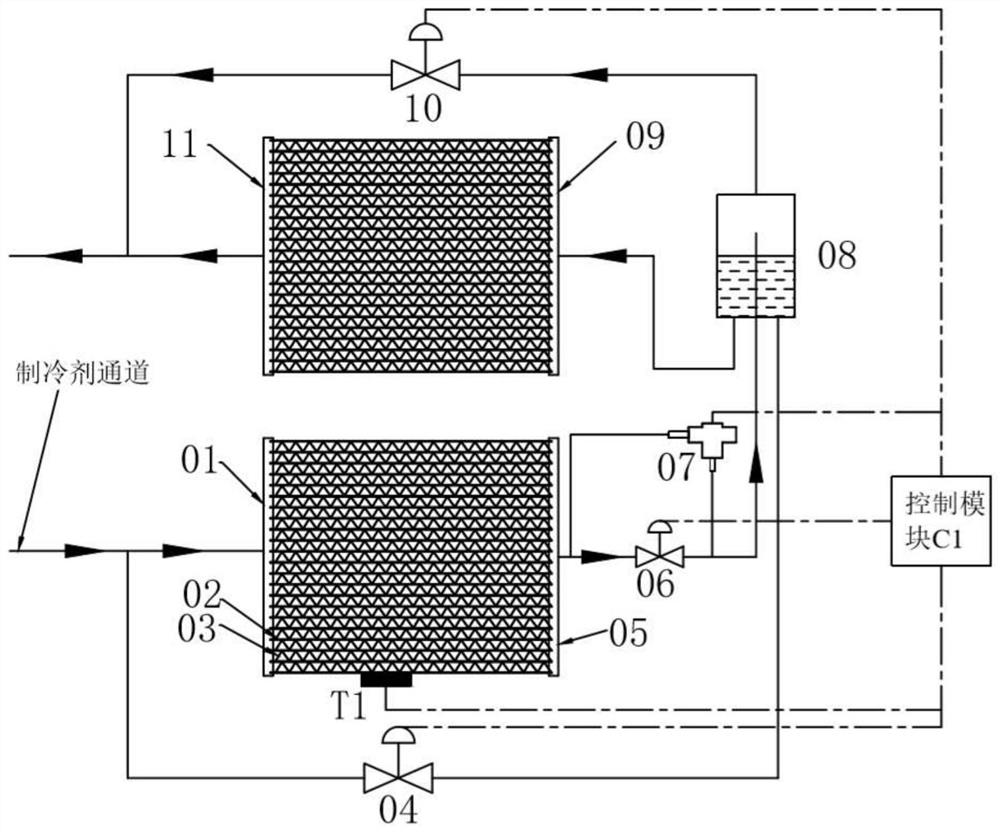

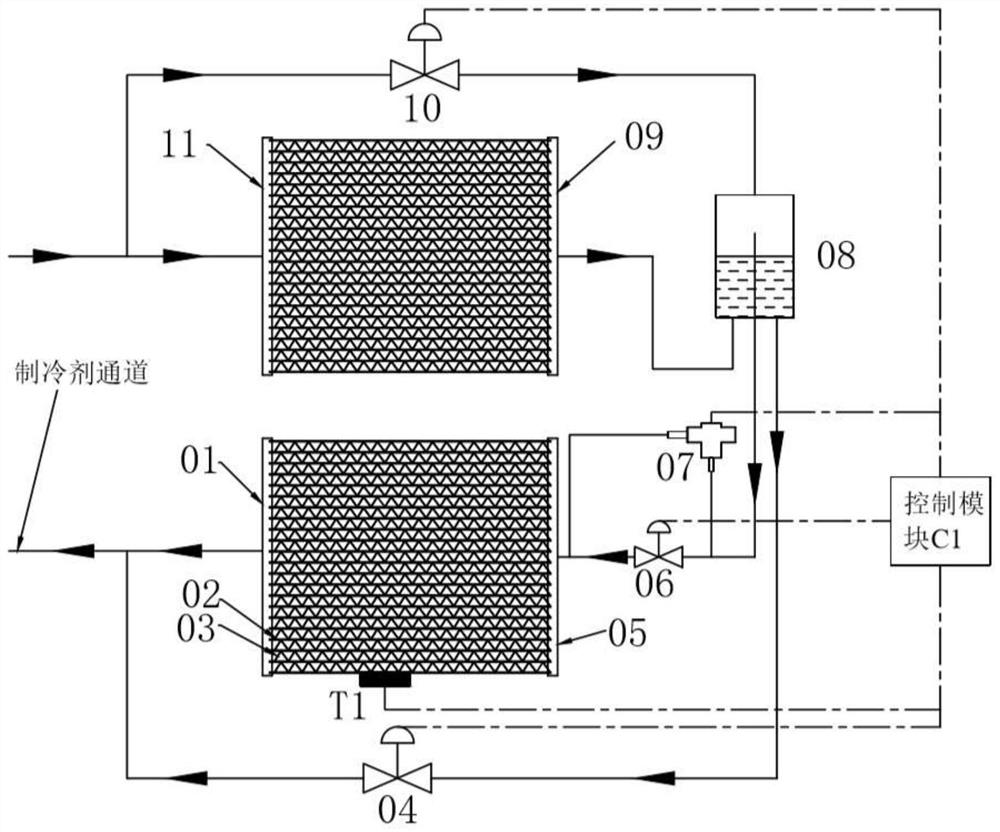

Air conditioner indoor unit with self-cleaning function

InactiveCN107514682AWith self-cleaning functionIncrease the degree of frost condensationCondensate preventionFlush cleaningEngineeringHeat exchanger

The invention provides an air conditioner indoor unit with a self-cleaning function. The air conditioner indoor unit comprises a case, a humidifying assembly, a spray opening and a heat exchanger of the indoor unit. The case comprises a skeleton and a housing, wherein the skeleton is used for supporting a fan and the heat exchanger of the indoor unit, and the housing covers the skeleton and is provided with an air inlet and an air outlet. The humidifying assembly comprises a water tank and an atomization device used for atomizing water in the water tank. The spray opening is formed in the case and located in the air inlet upstream position of the heat exchanger of the indoor unit and used for outputting water mist formed by the atomization device. The humidifying assembly starts the atomization device when the air conditioner indoor unit executes the self-cleaning function, so that the spray opening is utilized to spray out the water mist to flow through the heat exchanger of the indoor unit, and accordingly the frosting degree at the heat exchanger of the indoor unit is improved. The heat exchanger of the indoor unit operates a condenser mode after frosting, and accordingly attached contaminants are taken away by water formed by defrosting. According to the scheme, the problem that a self-cleaning air conditioner cannot generate enough condensed water in the dry environment, and consequently the self-cleaning effect is affected is solved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

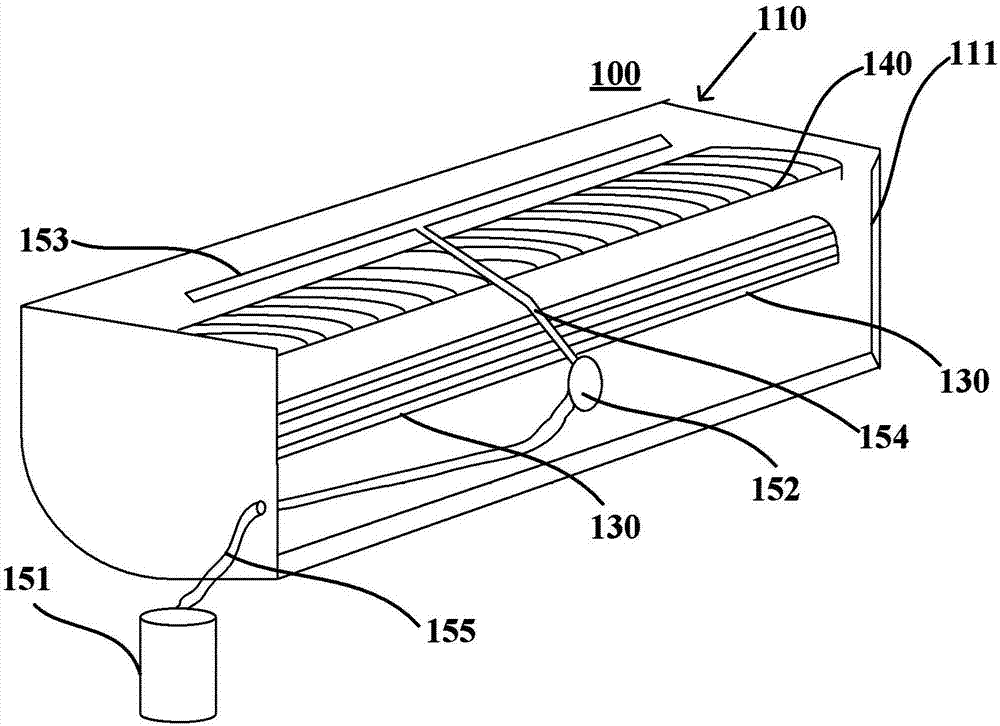

Air conditioner indoor unit

InactiveCN107514681AIntegrated humidification functionIncrease the degree of frost condensationSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringMoisture sensor

The invention provides an air conditioner indoor unit which comprises a unit shell, a humidity sensor and a humidifying assembly. The unit shell comprises a framework for supporting an indoor unit fan and an indoor unit heat exchanger, and a housing which is arranged on the framework in a covering manner and is provided with an air inlet and an air outlet. The humidity sensor is arranged for measuring the humidity of the working environment of the indoor unit. The humidifying assembly is provided with a mist spray opening arranged in the unit shell and arranged to be started when the humidity of the working environment is lower than a preset first humidity threshold value, so that the mist spray opening is used for spraying out water mist to humidify the working environment. According to the scheme, the water mist is sprayed out through the mist spray opening to humidify the working environment, and the integrated humidifying function is achieved in the air conditioner indoor unit.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

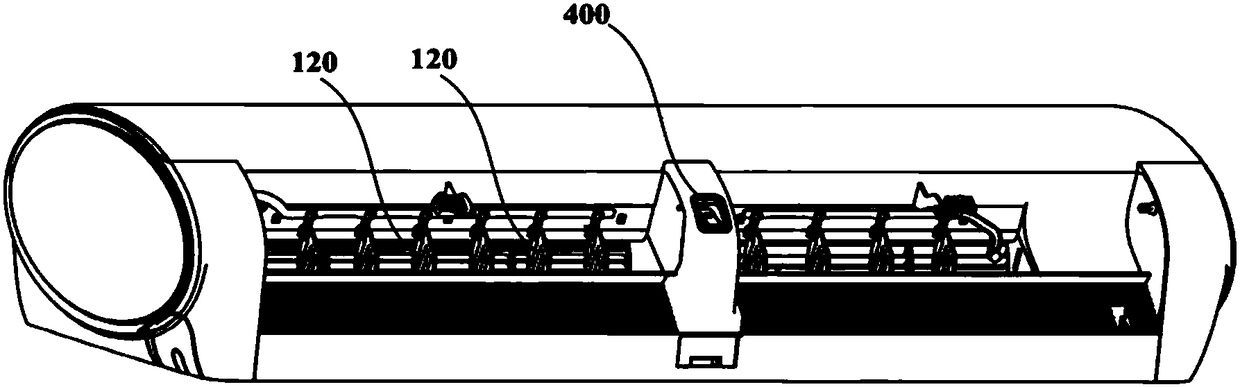

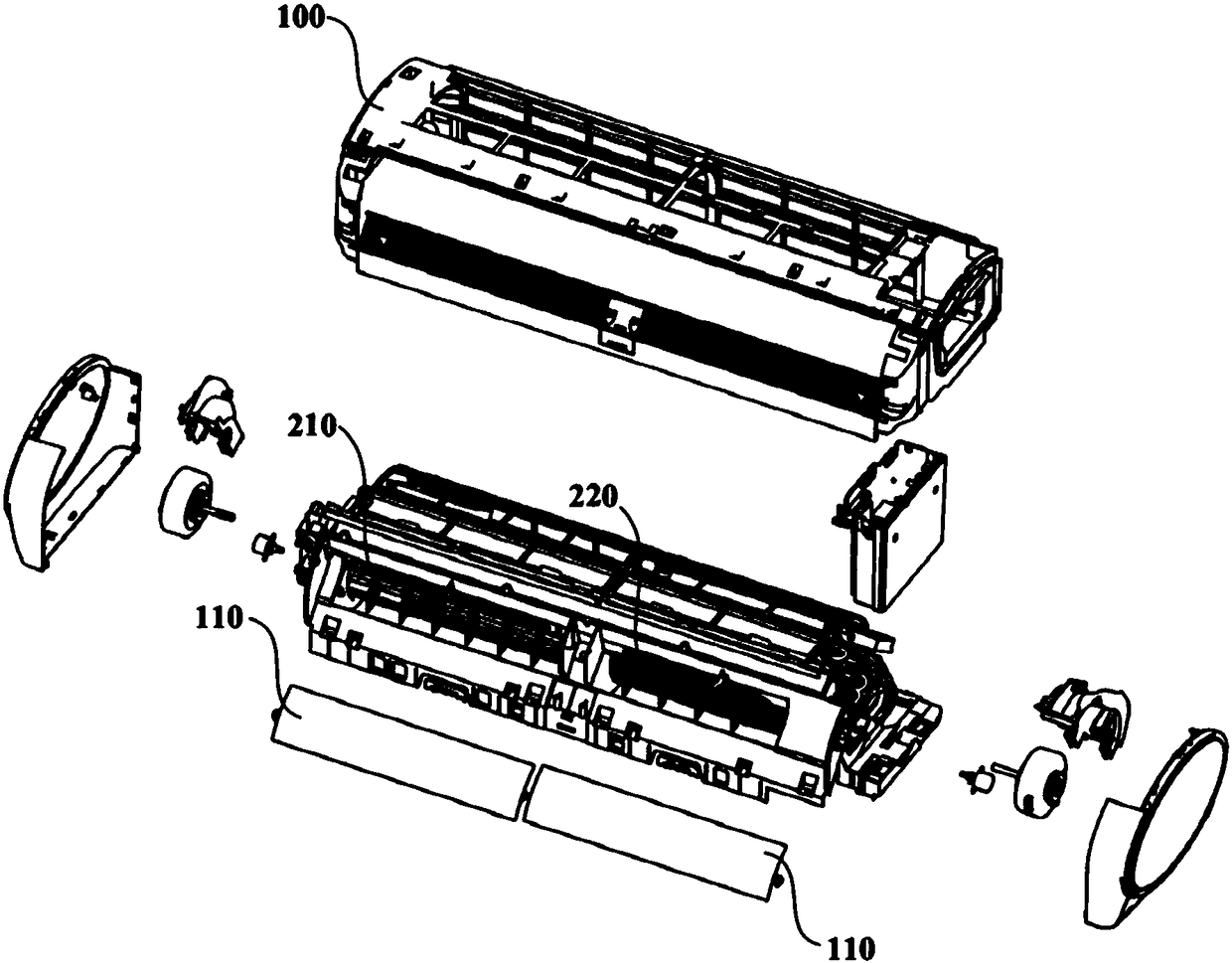

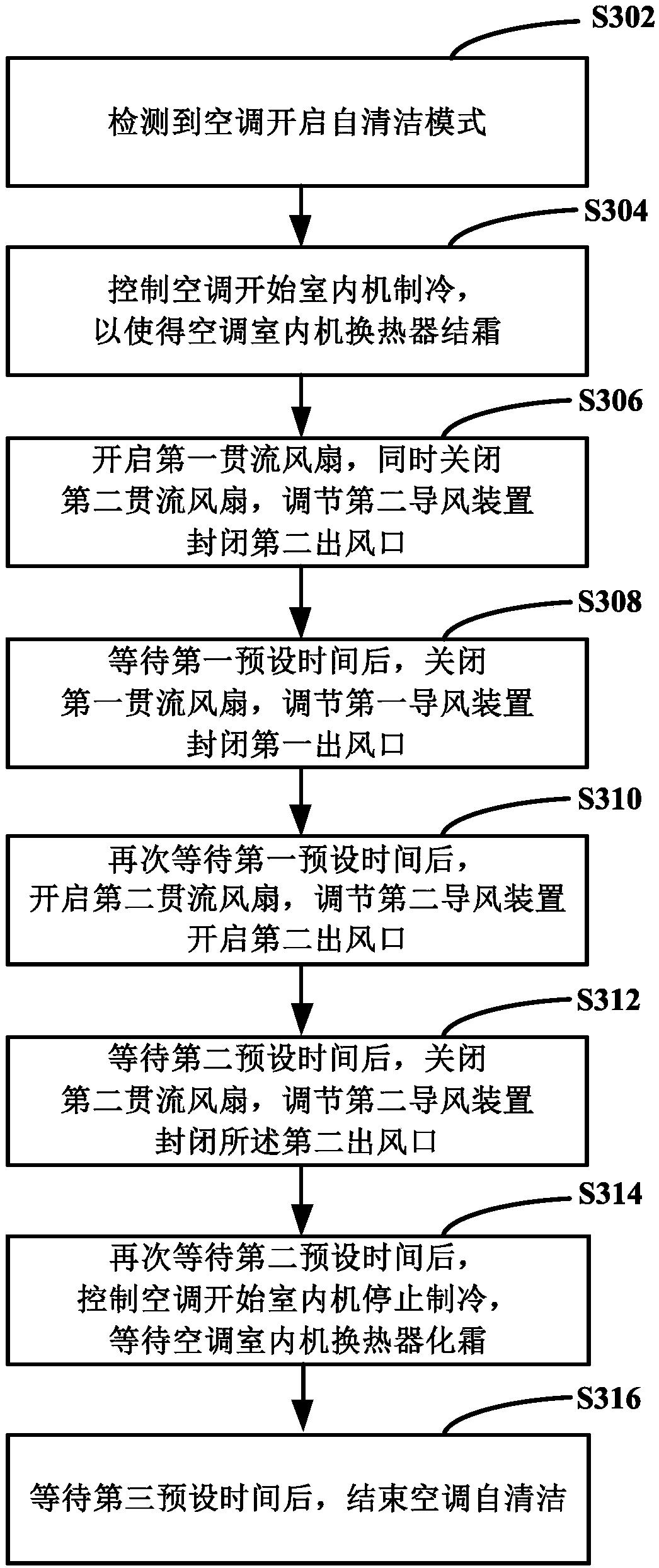

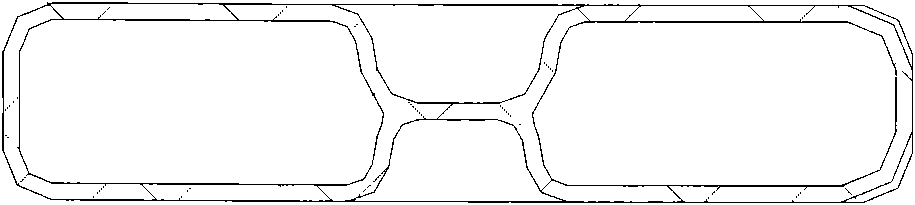

Wall-mounted air conditioner and self-cleaning control method thereof

ActiveCN108397818AFrosting evenlyImprove self-cleaning effectMechanical apparatusSpace heating and ventilation safety systemsEngineeringWall mount

The invention provides a wall-mounted air conditioner and a self-cleaning control method thereof. The self-cleaning control method is characterized in that according to the structure characteristic ofthe air conditioner with two cross-flow fans, in the self-cleaning refrigerating process, a left air area and a right air area are frosted separately, that is, the first cross-flow fan is started firstly, and a heat exchanger corresponding to the second cross-flow fan is frosted firstly; and then the first cross-flow fan is turned off, the second cross-flow fan is turned on, and at the moment, aheat exchanger corresponding to the first cross-flow fan is frosted then. In the self-cleaning process of the method, at most one air outlet discharges air, so that the cold amount output by an indoorunit in the refrigerating process is reduced, a user is prevented from feeling cold, and the use experience of the user is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

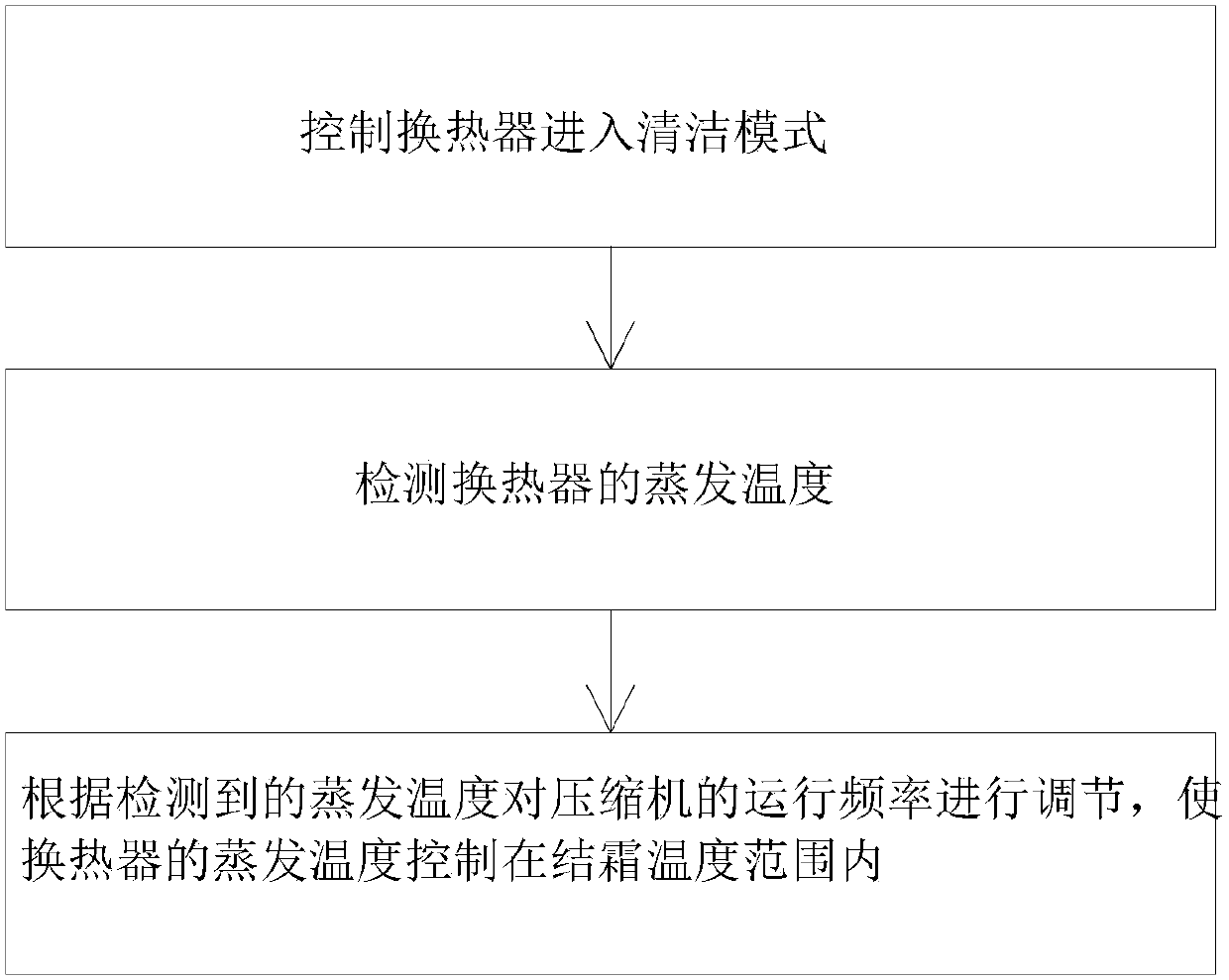

Cleaning method for indoor unit and outdoor unit of air conditioner

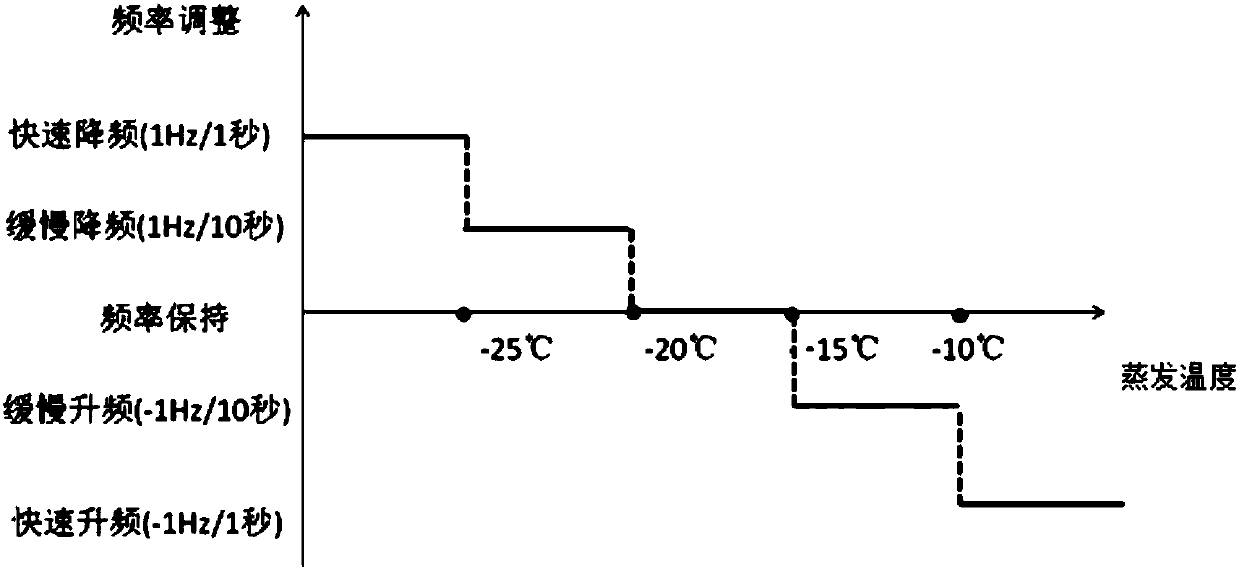

InactiveCN106196476AFrosting evenlyEasy to cleanMechanical apparatusSpace heating and ventilation safety systemsEngineeringCleaning methods

The invention discloses a cleaning method for an air conditioner. The cleaning method includes the steps of controlling a heat exchanger to operate in a cleaning mode; detecting the evaporation temperature of the heat exchanger; and adjusting the operation frequency of a compressor according to the detected evaporation temperature so as to control the evaporation temperature of the heat exchanger within a frosting temperature range. According to the cleaning method for an indoor unit and an outdoor unit of the air conditioner, the problem that in the prior art, the effect is poor when condensate water is used for cleaning the surface of the heat exchanger can be solved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

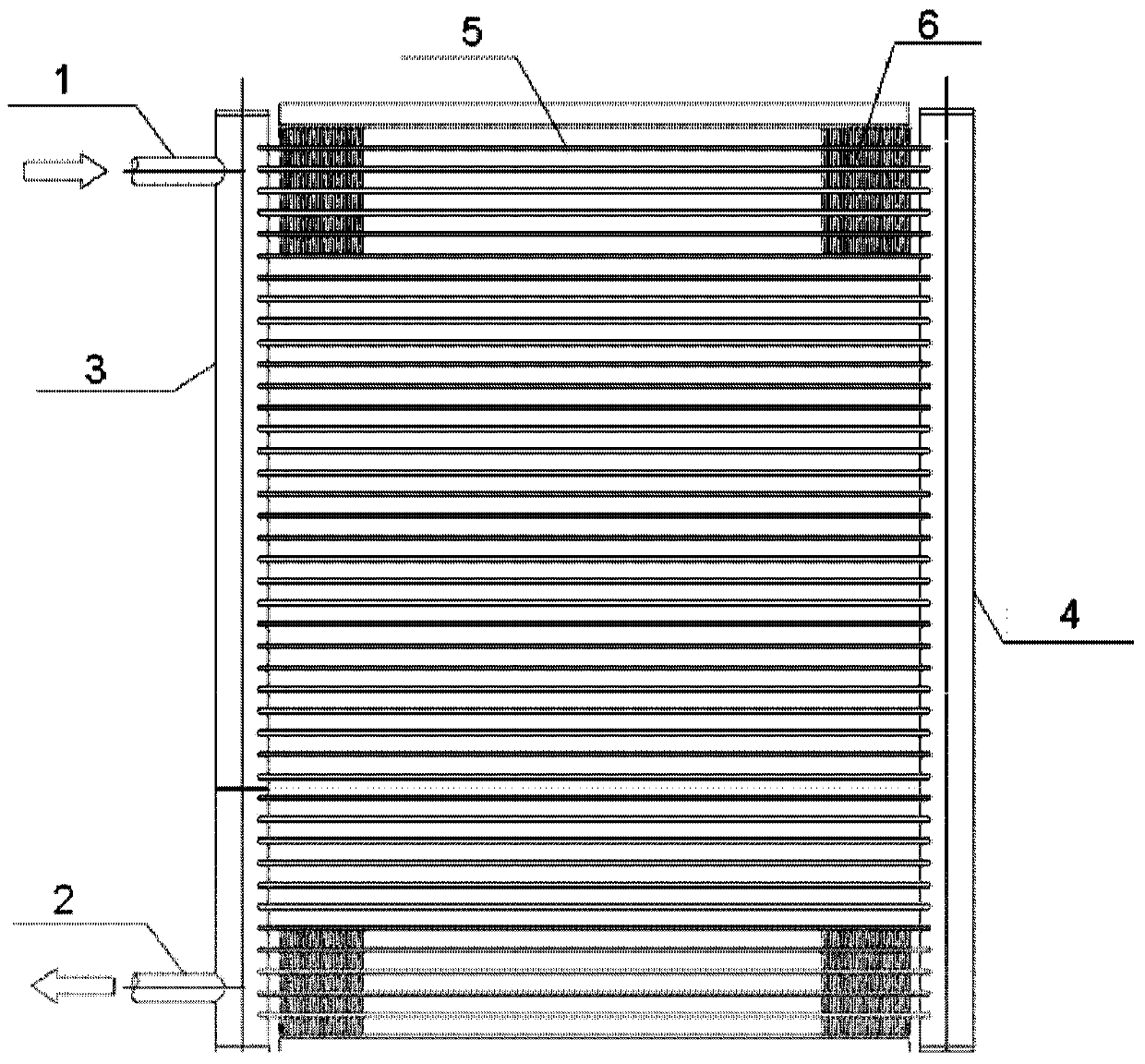

Heat pump system

ActiveCN103743156AExtended run timeShorten defrosting timeMechanical apparatusHeat pumpsWork patternEngineering

The invention provides a heat pump system. The heat pump system comprises at least one reversing valve, a compressor, at least one indoor heat exchanger, at least one outdoor heat exchanger and at least one throttling device. The outdoor heat exchanger comprises at least two independent flow paths and has three alternative work patterns, wherein the at least two independent flow paths in the outdoor heat exchanger respectively run as an evaporator when the first work pattern is selected, at least one of the at least two independent flow paths in the outdoor heat exchanger is at least partly used for defrosting and the rest of the at least two independent flow paths respectively run as the evaporator when the second work pattern is selected, and the at least two independent flow paths in the outdoor heat exchanger respectively run as a condenser when the third work pattern is selected.

Owner:DANFOSS MICRO CHANNEL HEAT EXCHANGER JIAXING

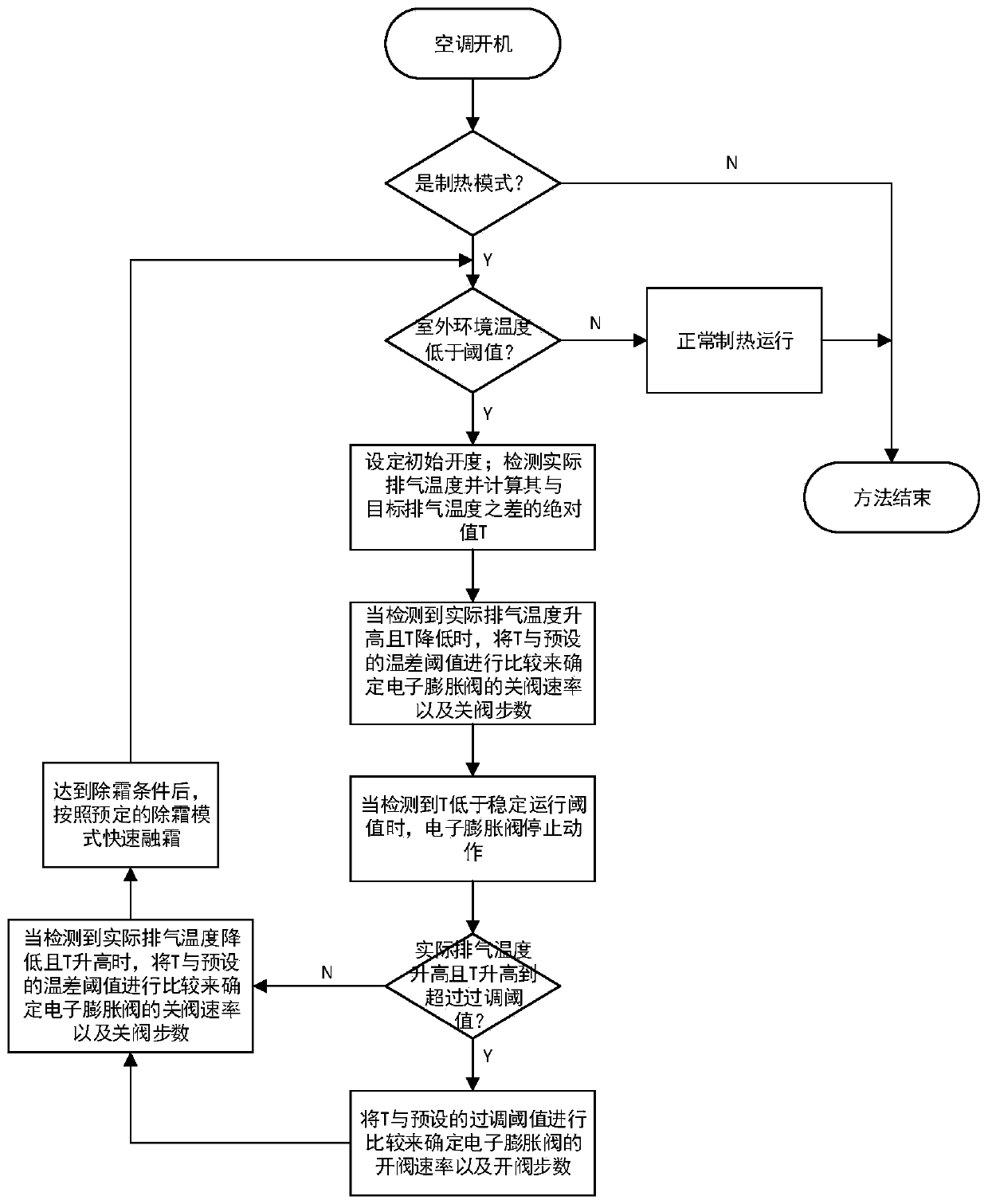

Electronic expansion valve control method for prolonging frosting period and air conditioner

ActiveCN111023458ASpeed up the flowFrosting evenlyMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsEngineering

The invention discloses an electronic expansion valve control method for prolonging the frosting period and an air conditioner. When the air conditioner is in a heating mode and the outdoor environment temperature is lower than a preset temperature threshold value, the air conditioner operates according to the following modes: the initial opening degree is set, the actual exhaust temperature is detected in real time, and the absolute value T of the difference between the actual exhaust temperature and the preset target exhaust temperature is calculated; when it is detected that the actual exhaust temperature is increased and T is decreased, T is compared with a preset temperature difference threshold value to determine the valve closing speed and the valve closing step number of an electronic expansion valve; when it is detected that T is lower than a stable operation threshold value, the electronic expansion valve stops acting; and when it is detected that the actual exhaust temperature is reduced and T is increased, T is compared with the preset temperature difference threshold value to determine the valve closing speed and the valve closing step number of the electronic expansion valve. Judgment and adjustment are conducted according to the actual exhaust temperature and the change condition of the absolute value of the difference between the actual exhaust temperature and the target exhaust temperature, and the low-temperature heating capacity can be effectively improved.

Owner:四川长虹空调有限公司

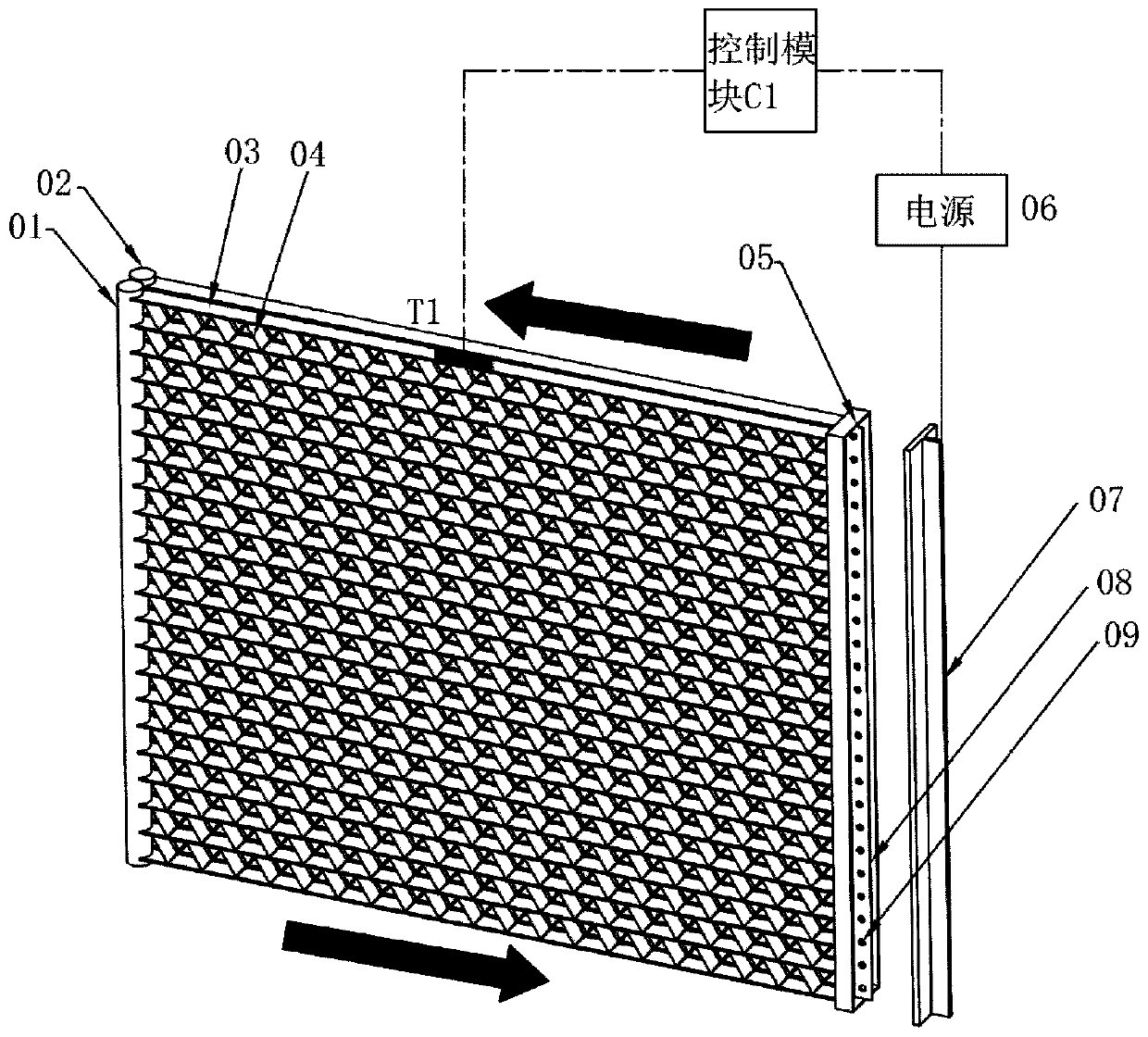

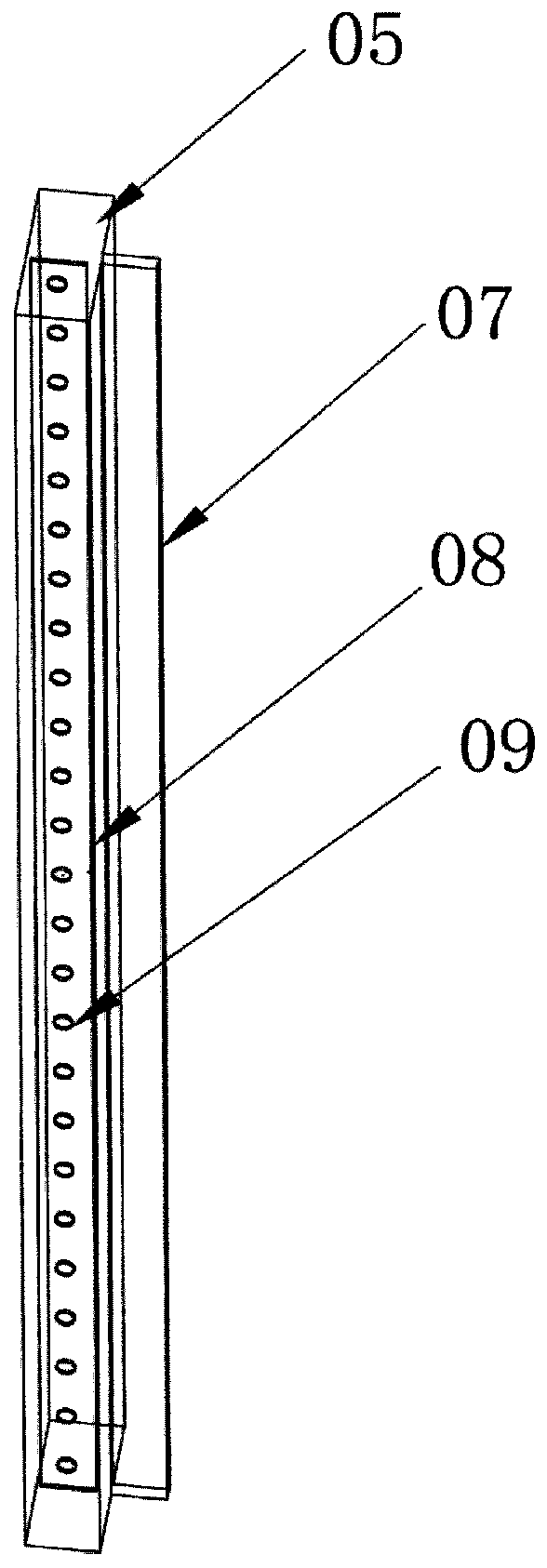

Micro-channel evaporator and control method thereof

ActiveCN111238090ASmall pressure dropStrong frosting abilityMechanical apparatusEvaporators/condensersPhysicsRefrigerant

The invention discloses a micro-channel evaporator and a control method thereof. The micro-channel evaporator comprises three liquid collecting pipes, flat pipes, fins, an electromagnet, a power supply and a throttle plate, wherein the throttling plate is added in the middle of the third liquid collecting pipe, throttling holes are formed in the throttling plate, the throttling plate is made of amagnetic material, the third liquid collecting pipe is provided with a protruding channel, and the electromagnet is arranged in the protruding channel. According to the evaporator, when the micro-channel evaporator works under a frosting working condition, the power supply is powered on, and the throttling plate can throttle a refrigerant flowing from a front-row heat exchanger, so that the temperature of a rear-row heat exchanger of the micro-channel evaporator is lower, the frosting capacity of the rear-row heat exchanger is higher, frosting performs towards the rear-row heat exchanger, uniform frosting of the micro-channel evaporator is achieved, and the performance of the micro-channel evaporator under the frosting working condition is improved; and when the micro-channel heat exchangeevaporator works under a non-frosting working condition, the power supply is cut off, and the throttling plate does not play a throttling role at the moment, so that the resistance of the micro-channel evaporator is reduced, and the improvement of the energy efficiency of the micro-channel evaporator is facilitated.

Owner:XI AN JIAOTONG UNIV

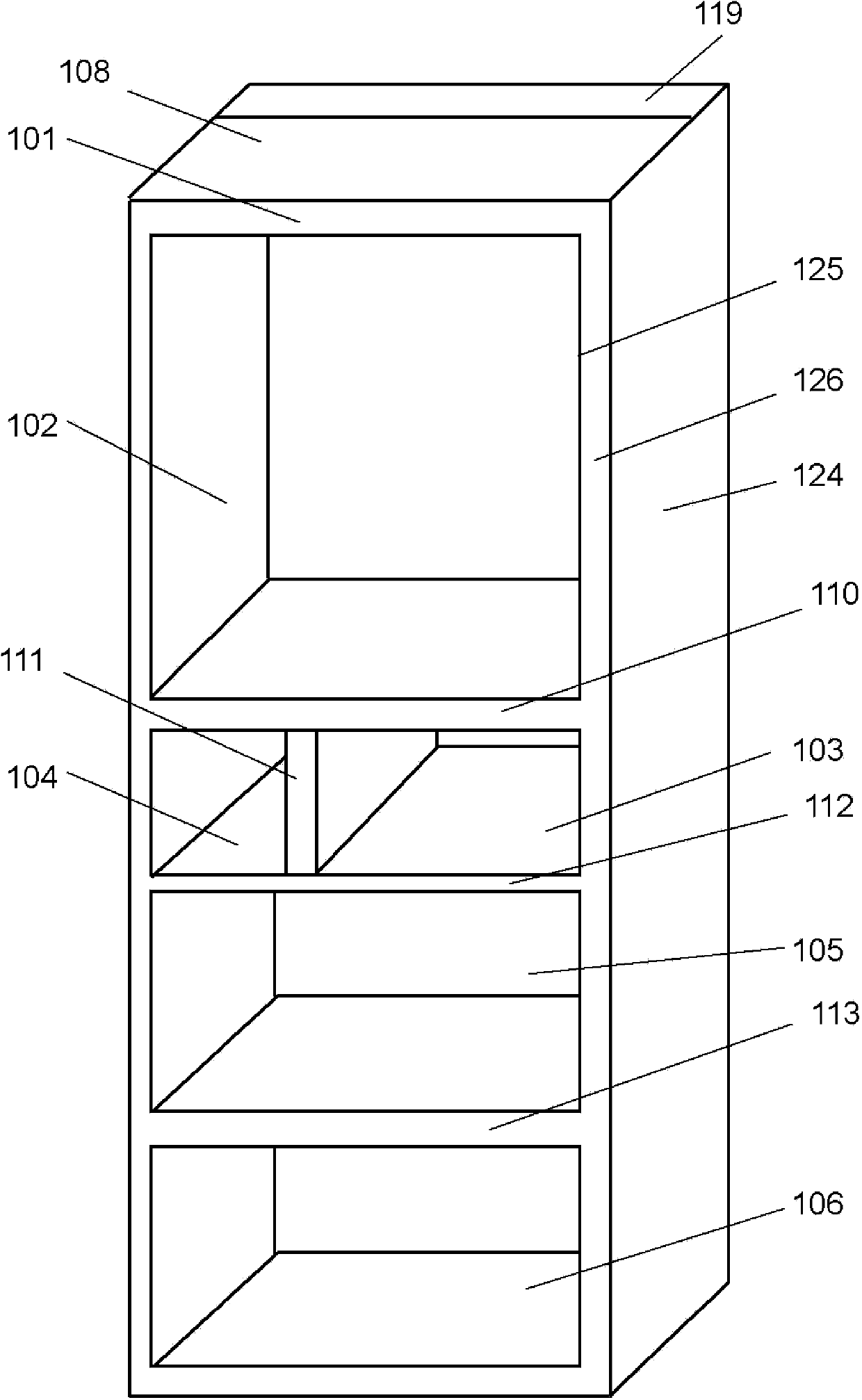

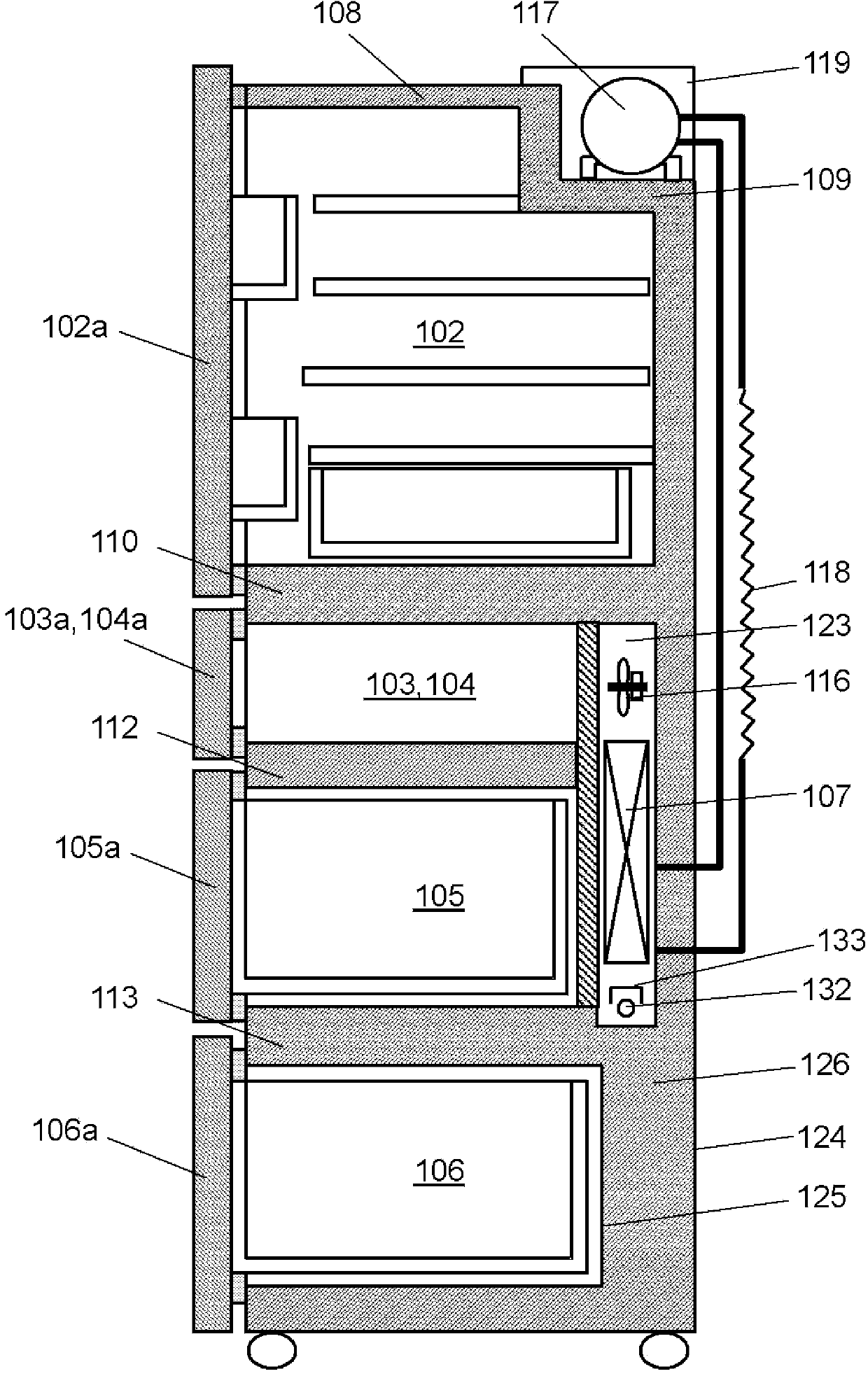

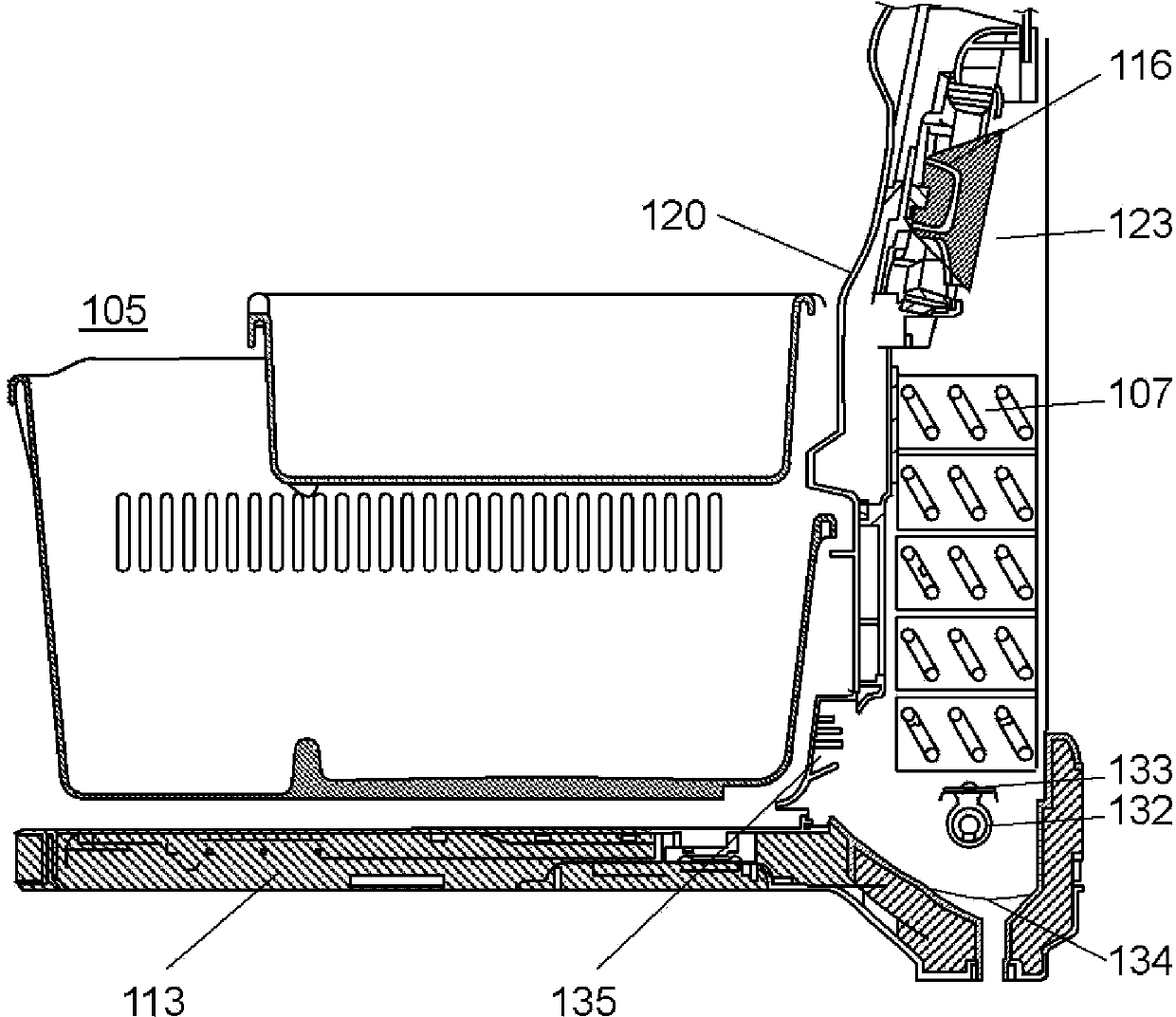

Refrigerator

InactiveCN103975207AShorten the timeLess typingLighting and heating apparatusCooling fluid circulationEngineeringRefrigerated temperature

Cooler (107) provided on the back surface side of a refrigerator, the cooler for generating cool air, defrosting heater (132) provided below cooler (107), and cooler cover (120) having cool air return port (135) are provided. Center of defrosting heater (132) is set on the upper side of a lower surface of a freezing compartment, projection member (136) protruding into the interior side is arranged on the lower surface of the freezing compartment, and a lower end of cool air return port (135) and an upper end of projection member (136) are overlapped with each other in the height direction.

Owner:PANASONIC CORP

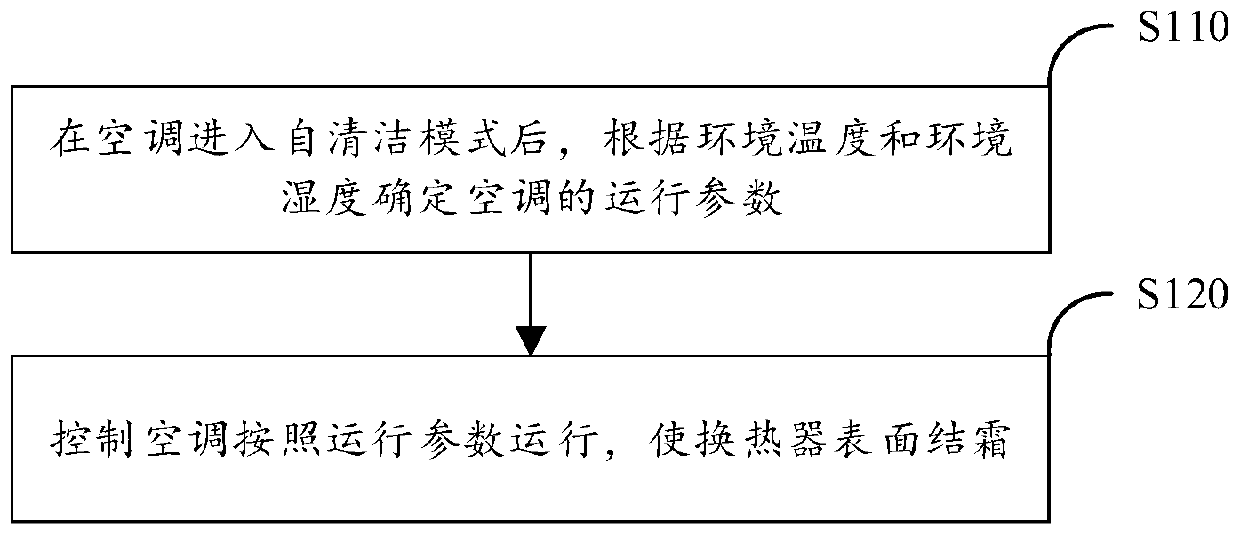

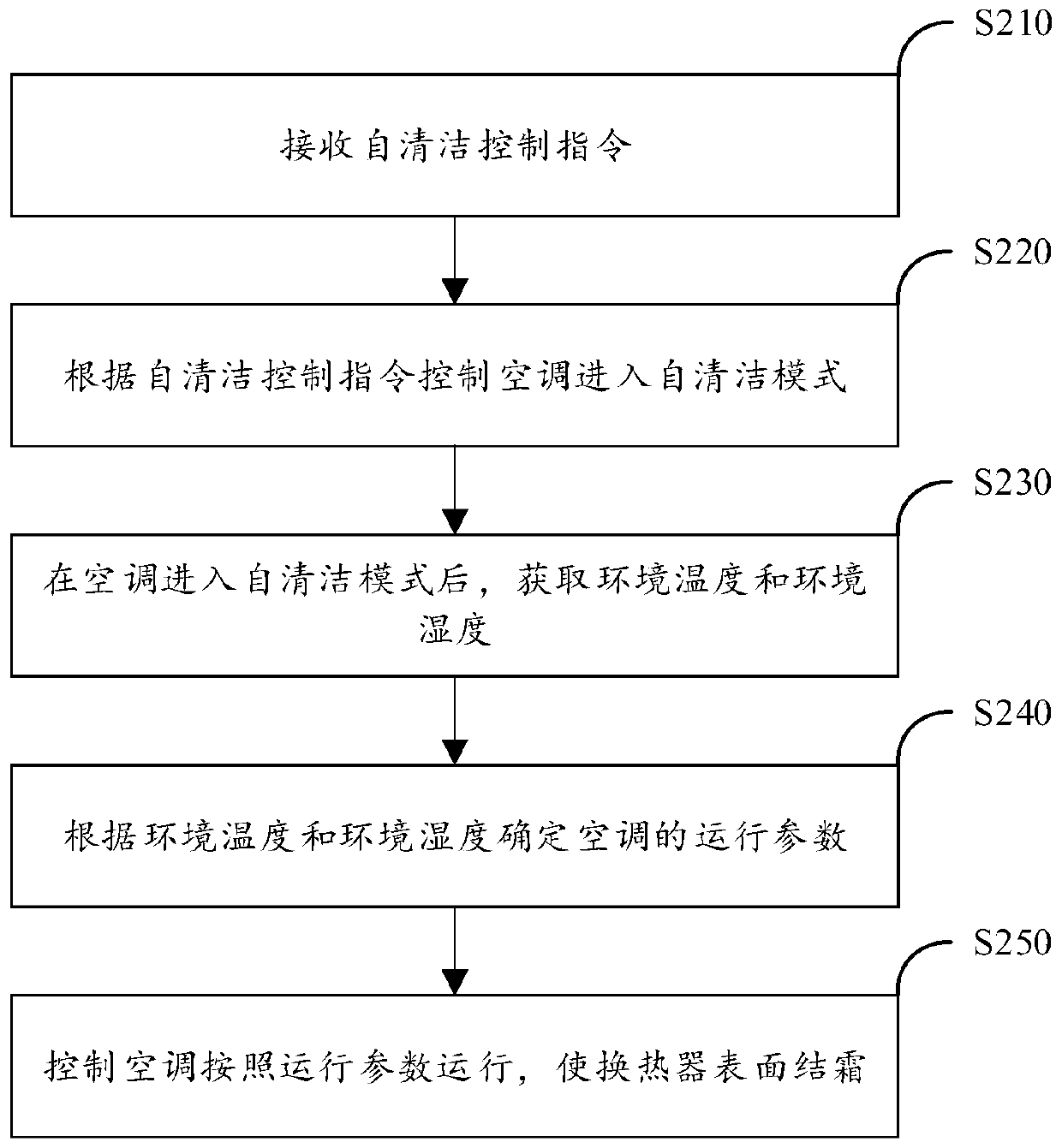

Method and device for self-clean control of air conditioner, as well as air conditioner

InactiveCN110986280APrecise control of self-cleaning functionImprove experienceMechanical apparatusSpace heating and ventilation safety systemsAmbient humidityProcess engineering

The application relates to the technical field of air conditioners, and discloses a method for self-clean control of an air conditioner. The method for self-clean control of the air conditioner comprises the following steps of after the air conditioner enters a self-clean mode, determining operation parameters of the air conditioner according to environment temperature and environment humidity; and controlling the air conditioner to operate according to the operation parameters to enable the surface of a heat exchanger to frost. According to the method disclosed by the invention, the operationparameters of the air conditioner can be subjected to self-adaption adjustment according to the environment temperature and the environment humidity, so that the accurate control of the self-clean function of the air conditioner is realized, frosting is more uniform, and the user experience is improved. The application also discloses a device for self-clean control of the air conditioner and theair conditioner.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

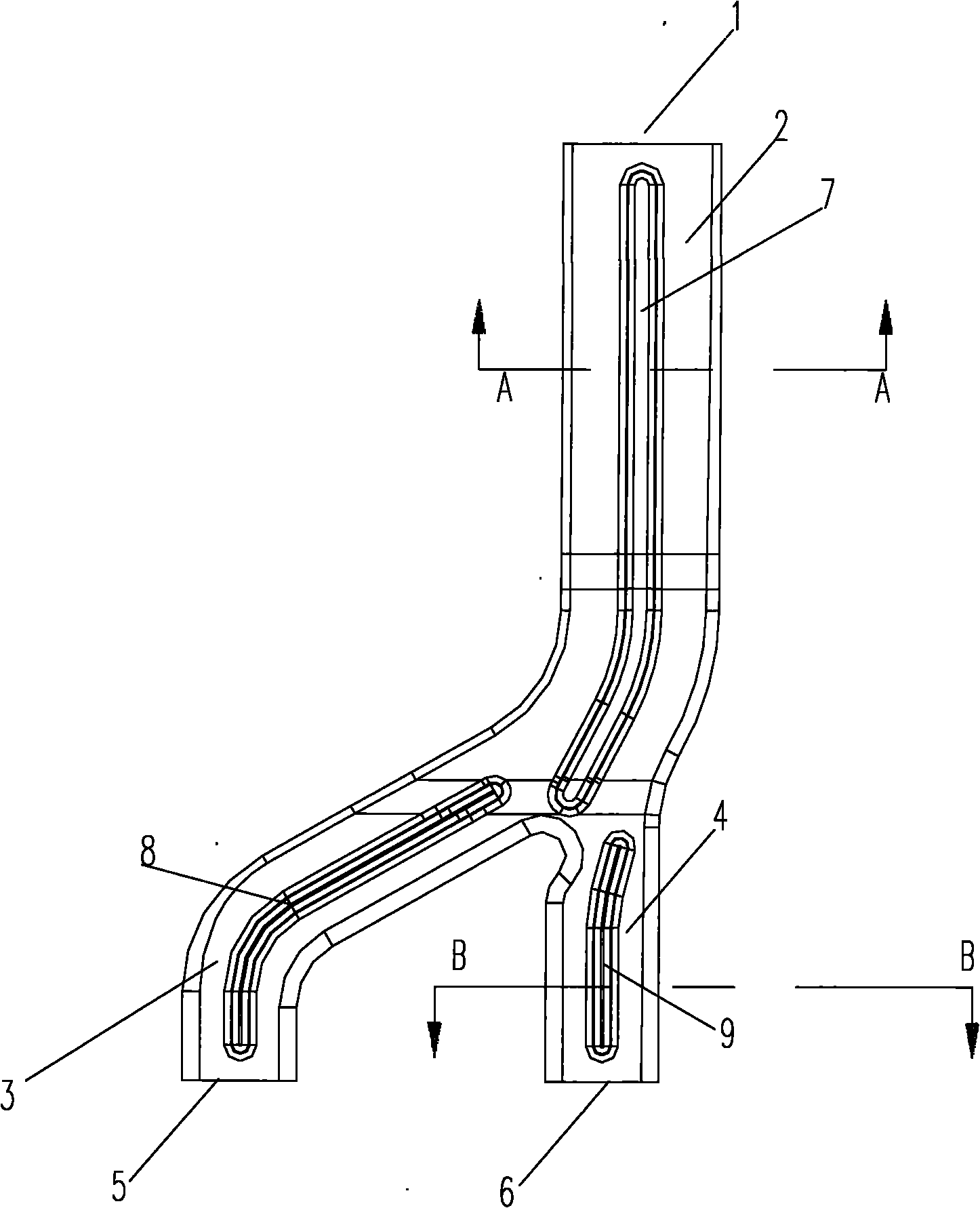

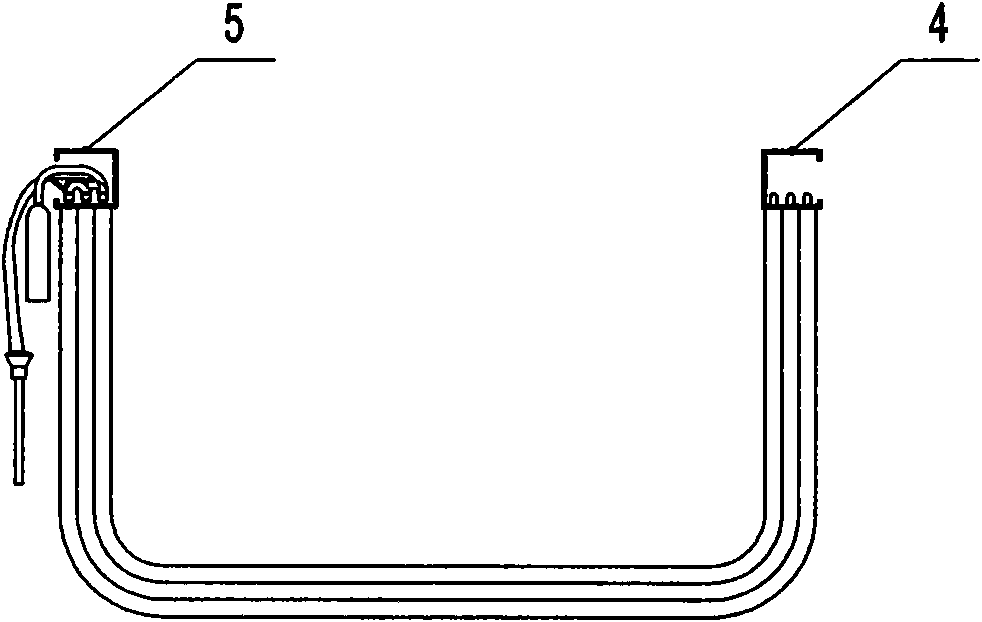

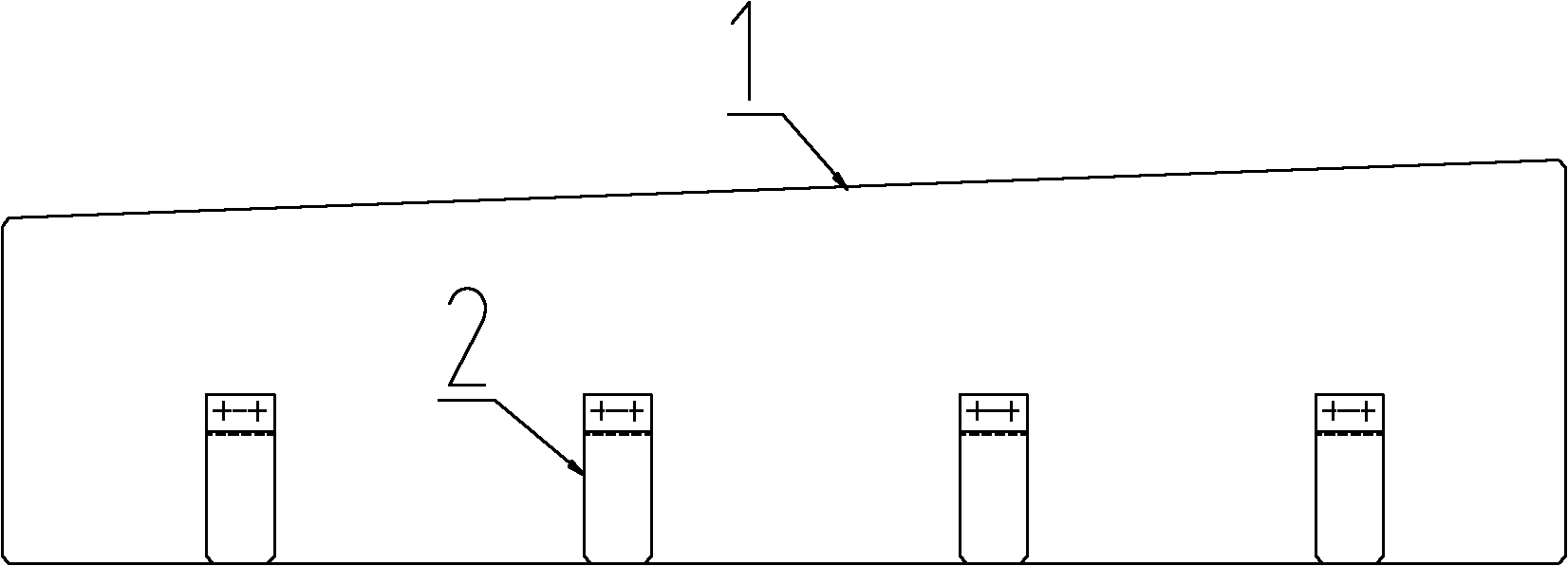

Return air duct and refrigerator with same

ActiveCN101886867AFrosting evenlyImprove work efficiencyLighting and heating apparatusCooling fluid circulationFrostEngineering

The invention provides a return air duct which comprises a return air inlet, a first return air part, at least two branch return air parts and two return air outlets, wherein the return air inlet is positioned on a refrigeration box bladder; the top end of the first return air part is connected with the return air inlet; the at least two branch return air parts are respectively connected with the bottom end of the first return air part; and the two return air outlets correspond to the at least two branch return air parts and are spaced by a preset distance to ensure that an evaporator of a refrigerator uniformly frosts. Through the return air duct, return air can be guided to both sides of the refrigerator so as to ensure that the evaporator uniformly frosts, thereby the working efficiency of a frost melting heater is greatly improved, and the energy consumption is reduced.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

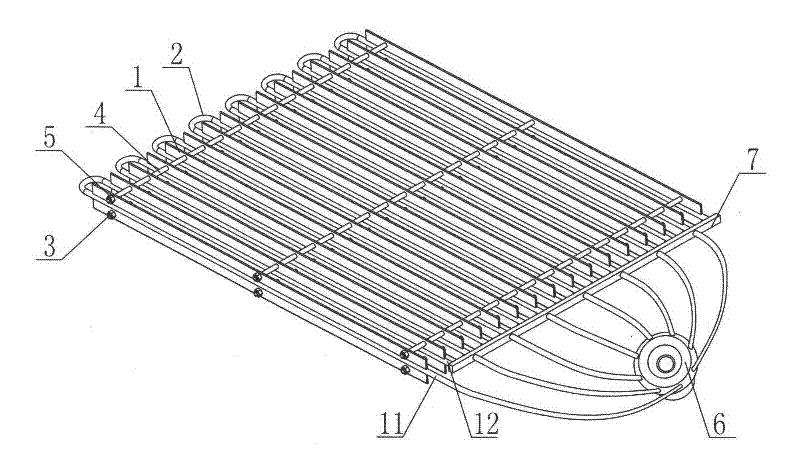

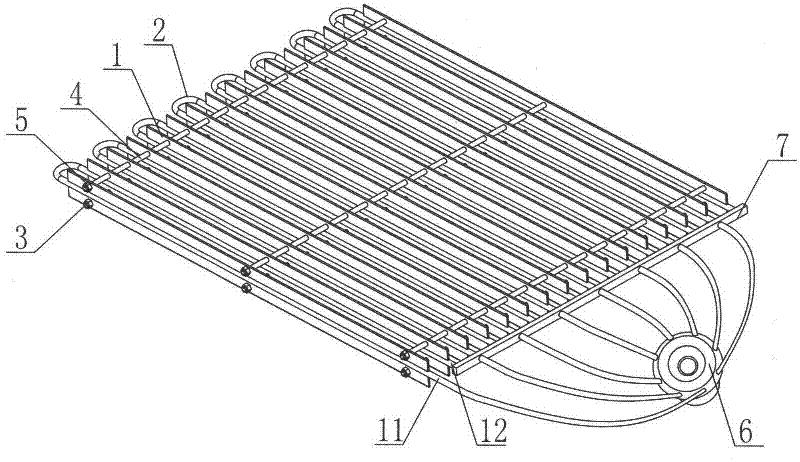

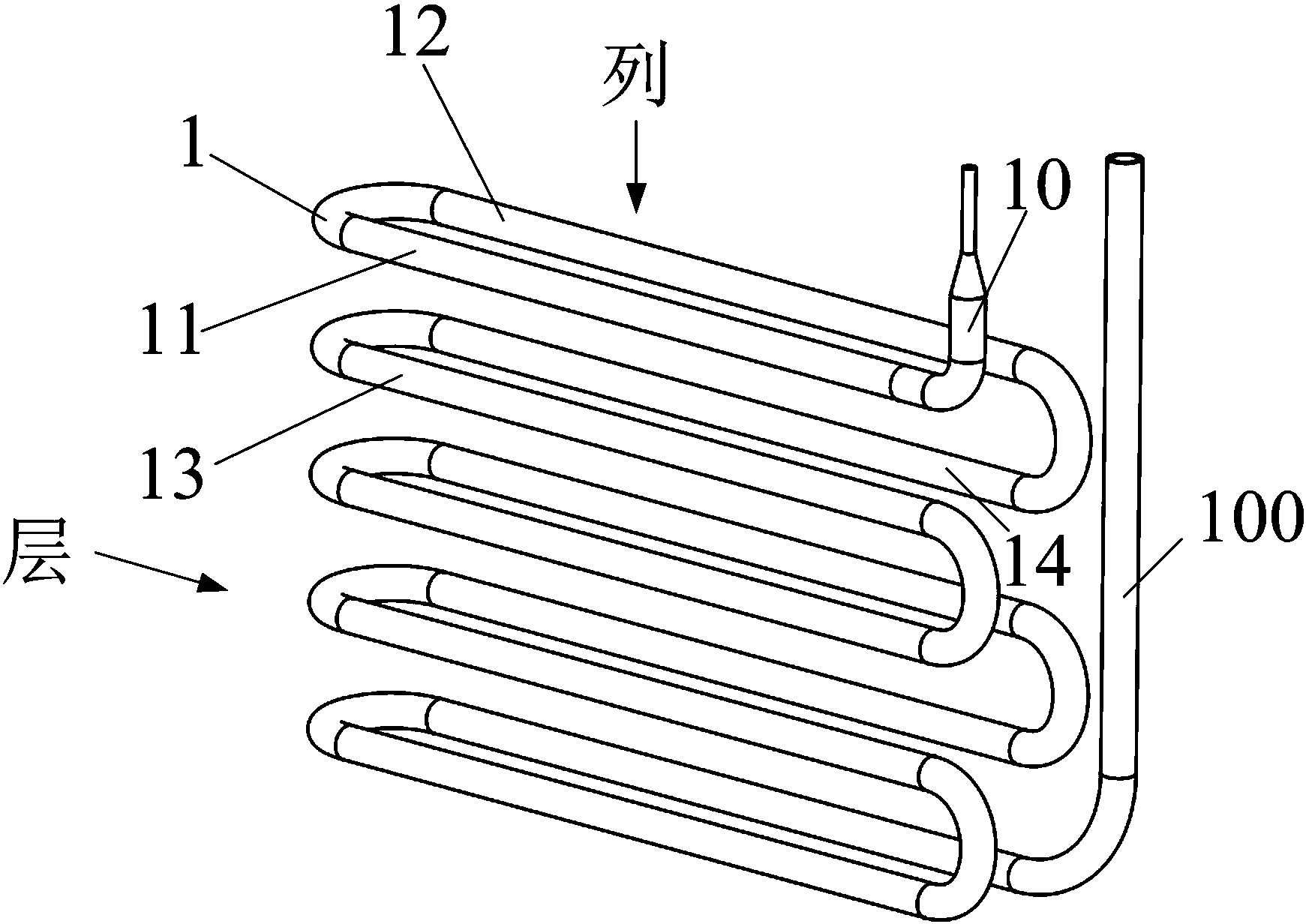

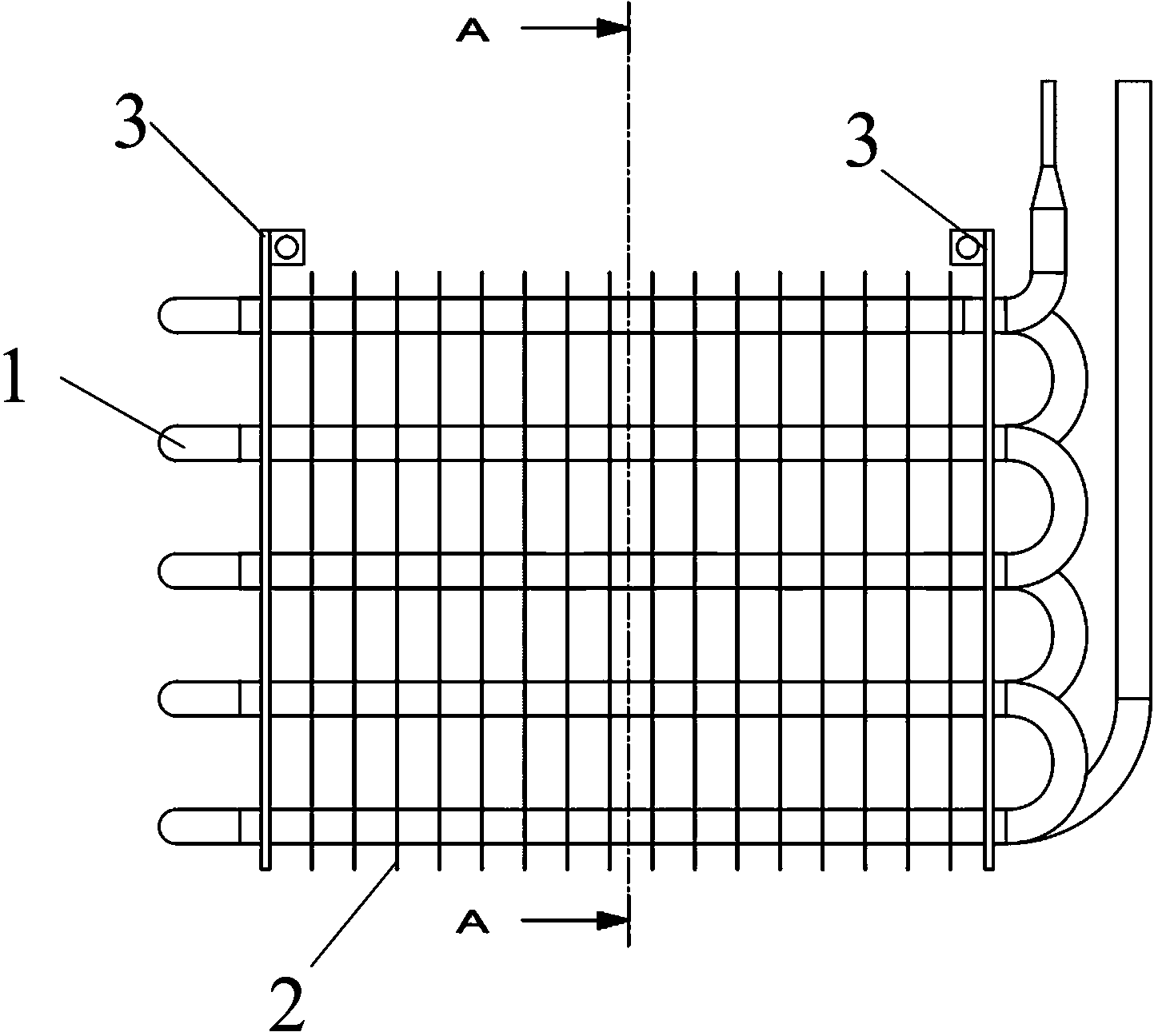

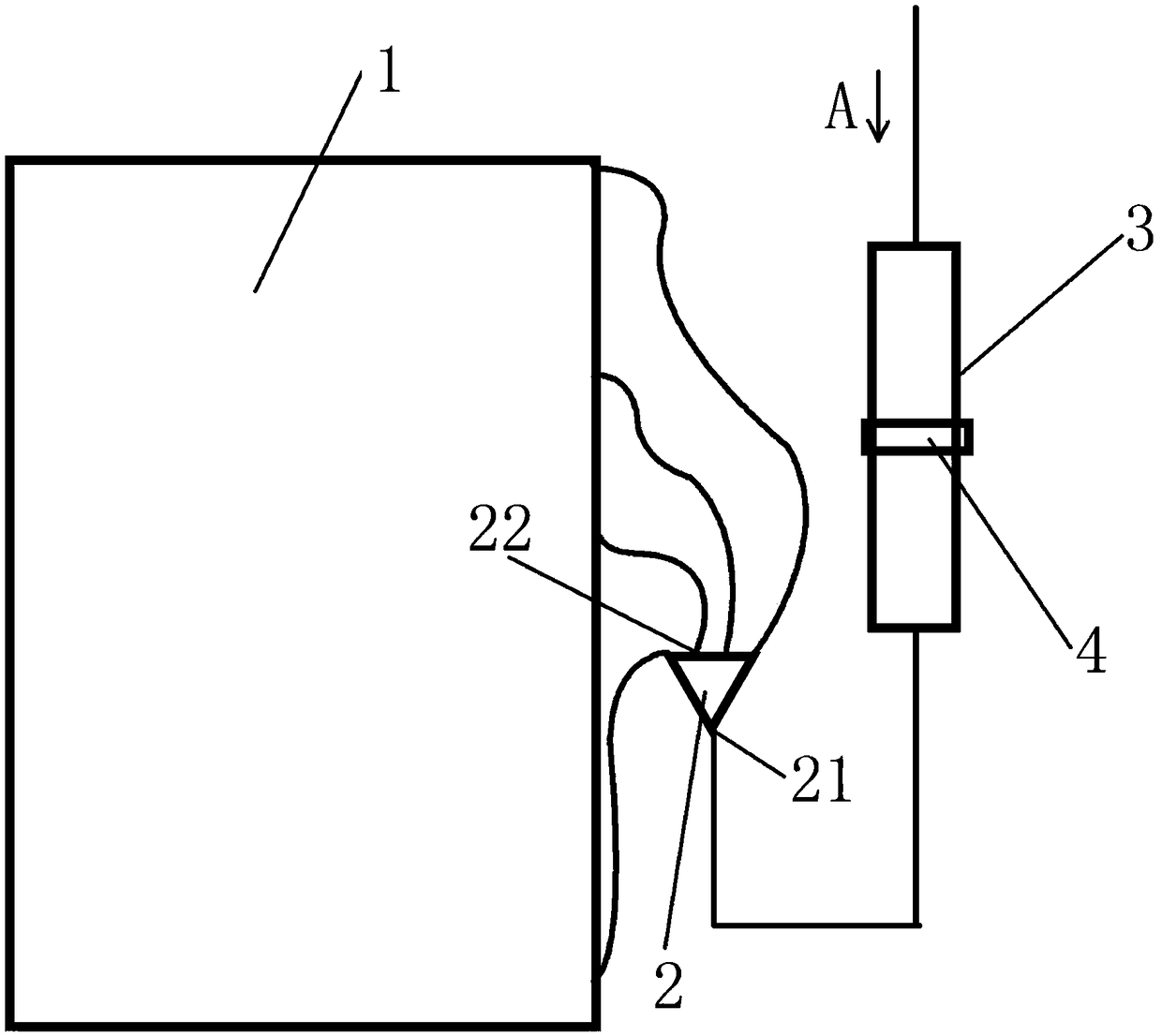

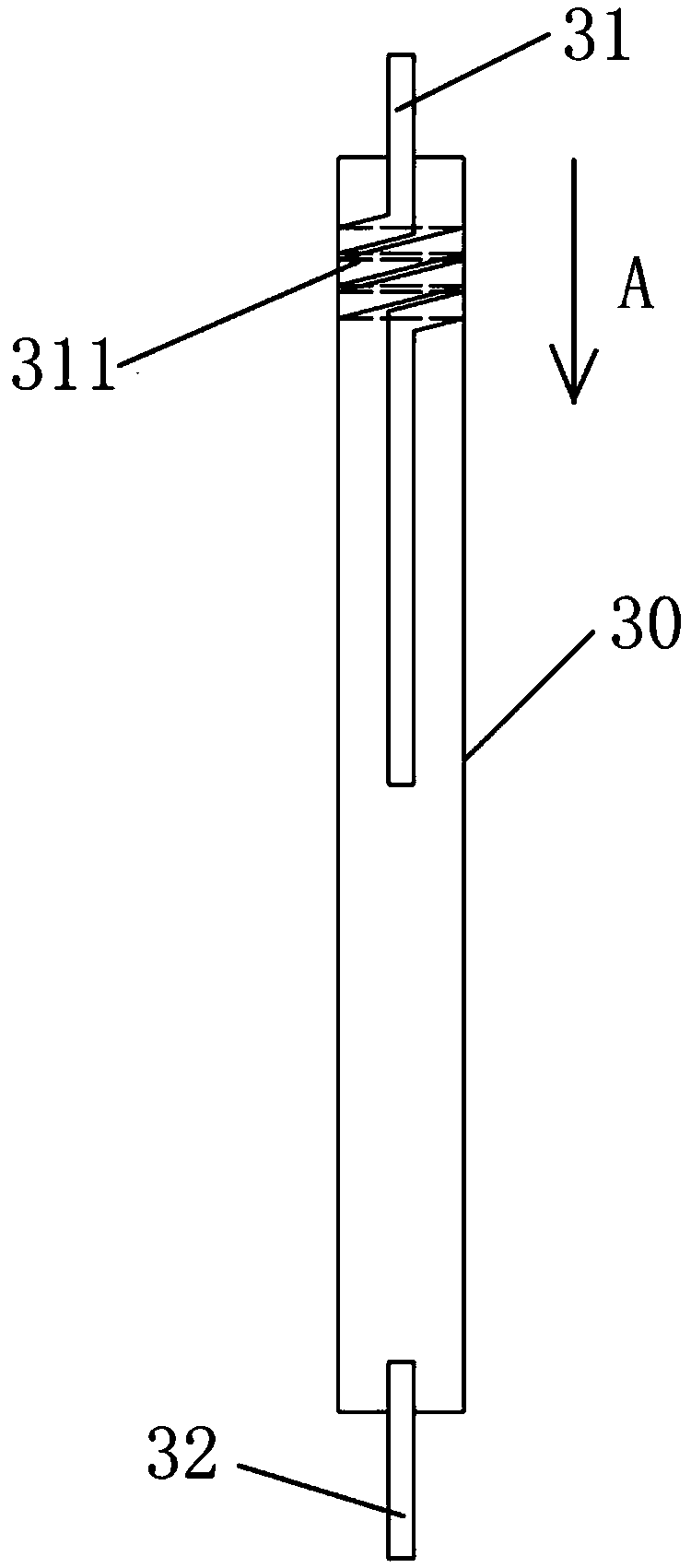

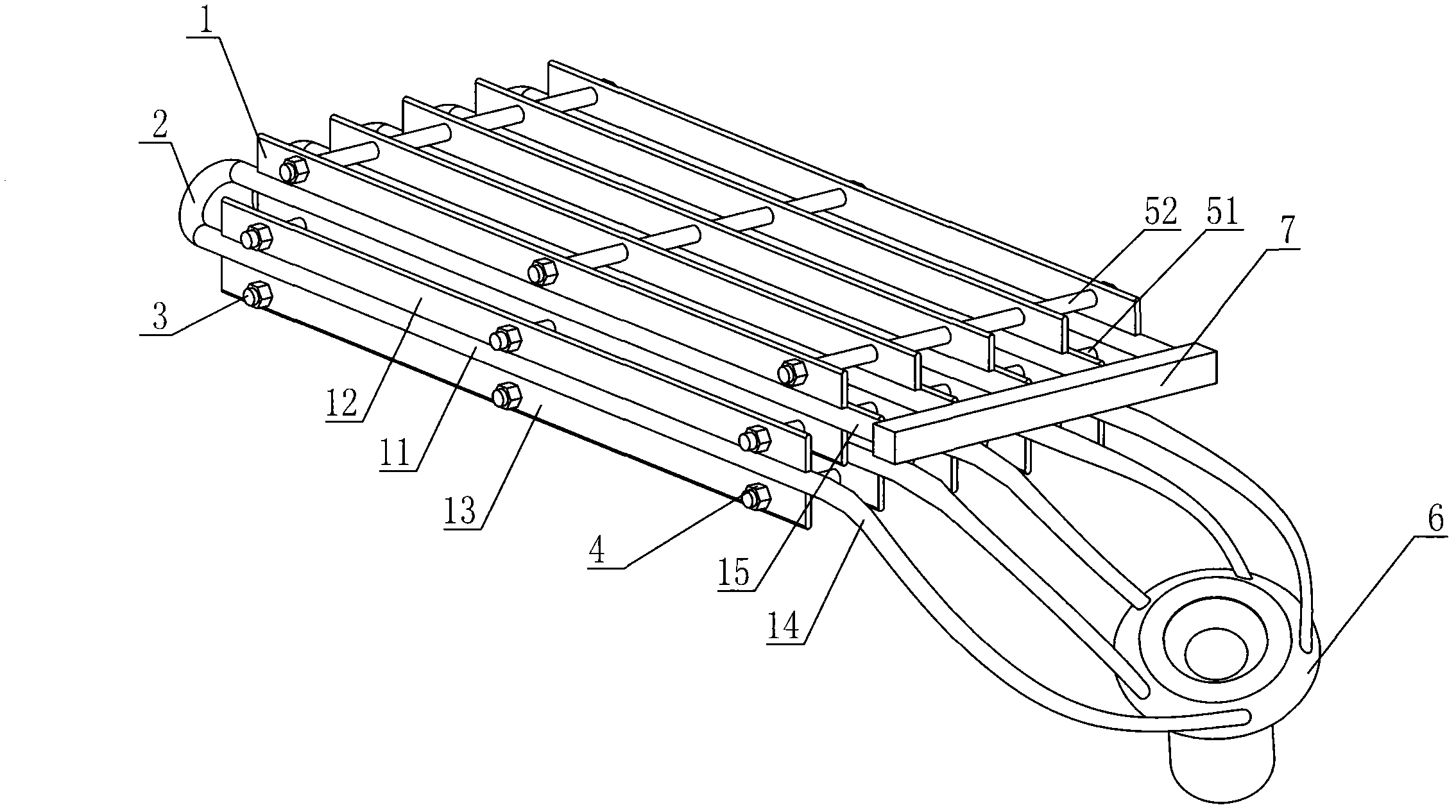

Horizontal U-shaped fin tube heat exchanger of air source heat pump and fixing mode thereof

InactiveCN102042718AUniform thermal dynamicsFrosting evenlyEvaporators/condensersSpace heating and ventilation detailsGas collecting tubePlate heat exchanger

The invention discloses a novel U-shaped fin tube heat exchanger and a fixing mode thereof. A common U-shaped fin tube heat exchanger is designed into a horizontal U-shaped heat exchanger with an upward opening, a gas collecting tube assembly is horizontally arranged, the gas collecting tube assembly and a dispenser assembly are respectively assembled outside one side of the fin tube heat exchanger, and an end plate I and an end plate II are respectively shaped into a U-shaped structure. The invention has the advantages of ensuring that pressure drops of refrigerants of all refrigerant loops are consistent and wind circulation of each refrigerating system is more uniform, effectively solving the problem of nonuniform defrosting of heat exchangers adopting other fixing modes, and reducing the height of the whole set because an outdoor condensing fan blade and a motor are installed in a space in the U-shaped fin tube heat exchanger.

Owner:劳特斯空调(江苏)有限公司

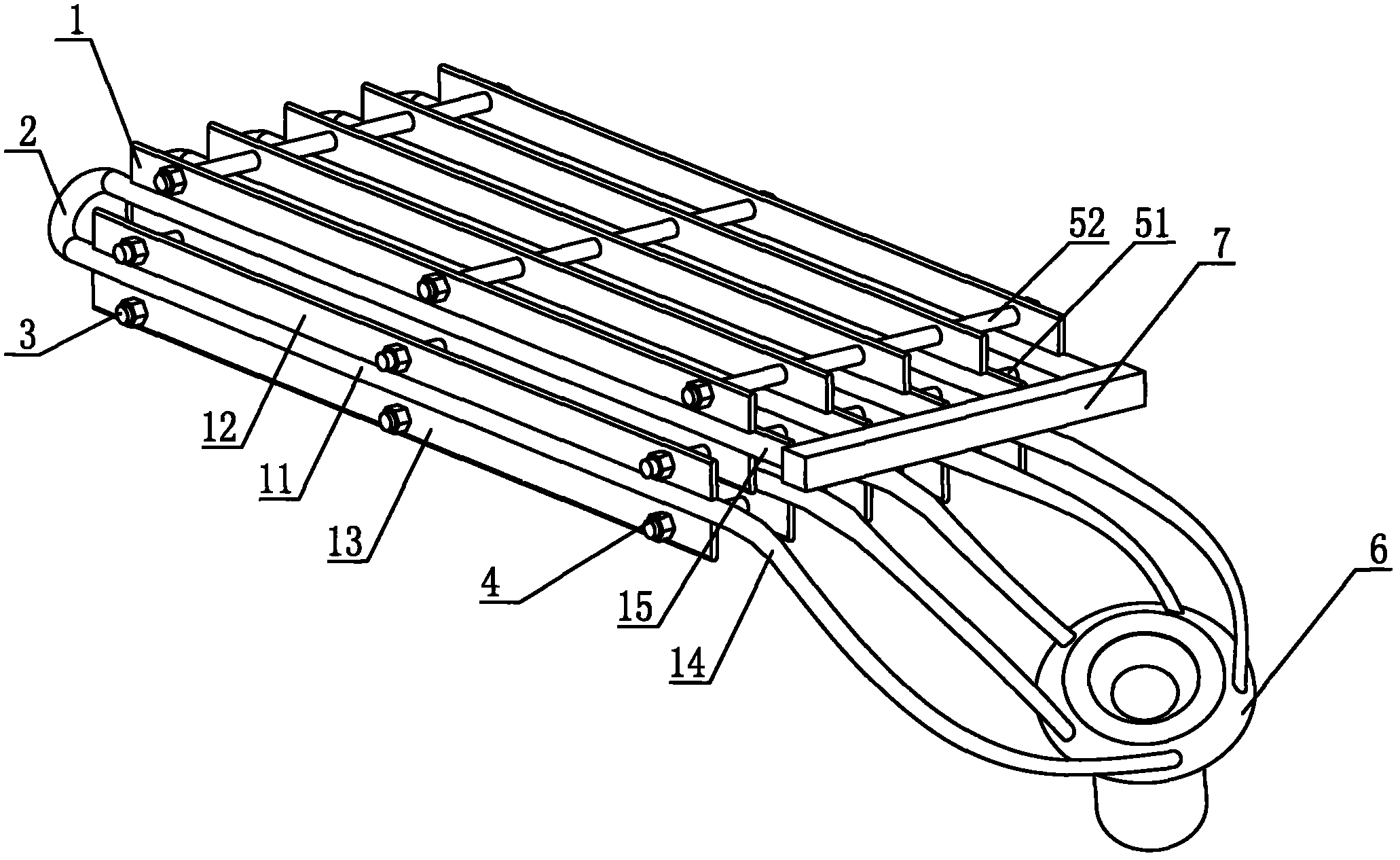

Spliced aluminum alloy fin calandria evaporator

The invention relates to a spliced aluminum alloy fin calandria evaporator which comprises a plurality of parallelly arranged aluminum alloy fin tubes, elbows, guide screws, partition tubes and holding nuts, wherein every two adjacent aluminum alloy fin tubes and one elbow are connected to form a U-shaped parallel unit, the two aluminum alloy fin tubes of each parallel unit respectively serve as a liquid inlet tube and a liquid outlet tube; the calandria evaporator provided by the invention is also provided with a liquid distributor; and the liquid distributor is provided with a liquid inlet and liquid outlets the quantity of which is same as that of the liquid inlet tubes, the liquid inlet tube of each parallel unit is communicated with a refrigerating fluid inlet tube through the liquid distributor, and the liquid outlet tube of each parallel unit is communicated with a refrigerating fluid outlet tube. The spliced aluminum alloy fin calandria evaporator provided by the invention has the advantages of adopting a parallel connection method to realize more uniform refrigeration, avoiding the problem that the temperature of a refrigerating fluid is increased along with the increment of the length of the passed distance, meeting the requirement of a large cold storage, ensuring the temperature in the large cold storage to be uniform, adopting the aluminum alloy fin tubes, ensuring good heat exchange effect, and ensuring uniformly frosting on fins.

Owner:贾凤华

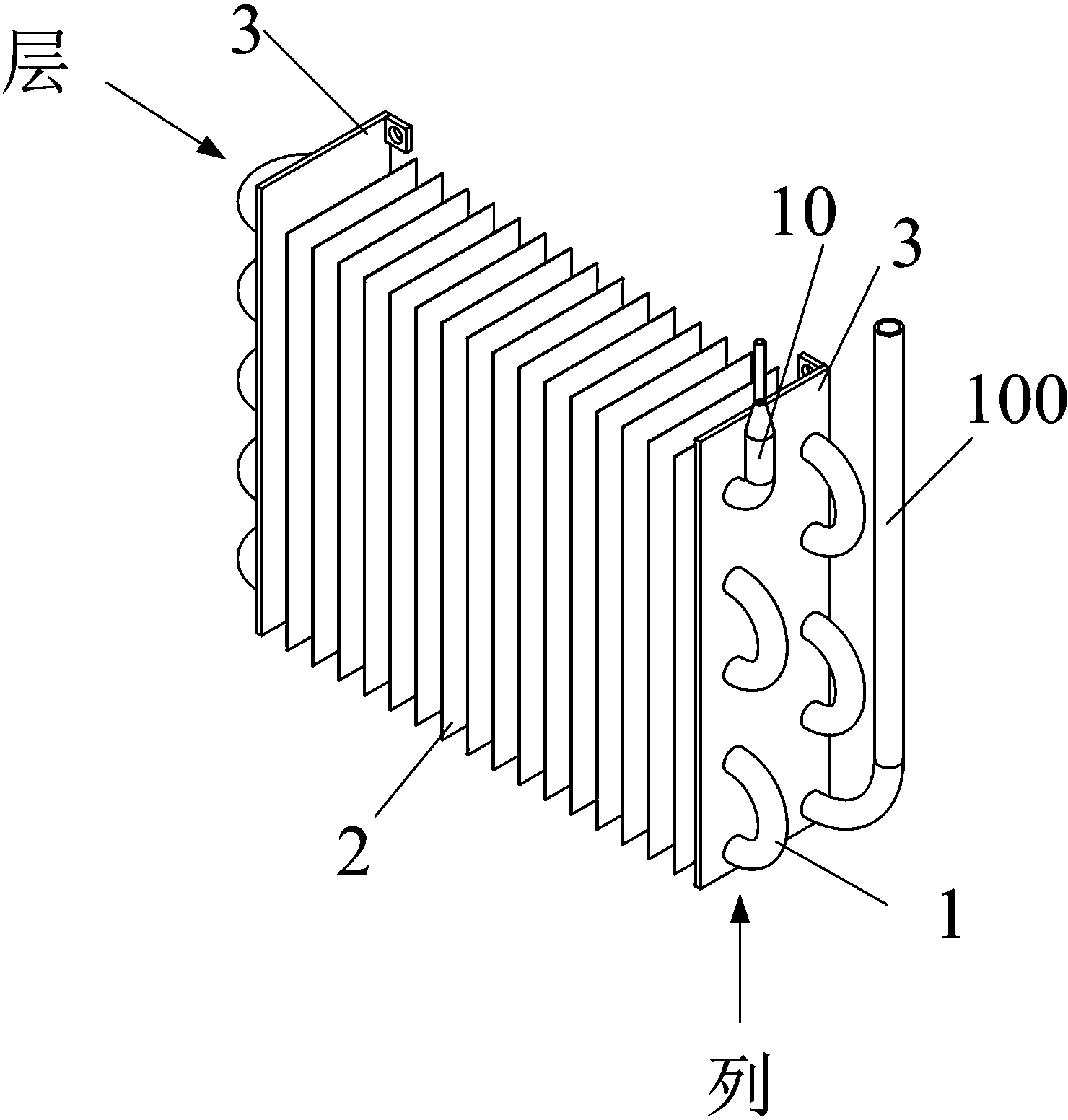

Fin evaporator and electric refrigerator adopting fin evaporator

InactiveCN104101136AAvoid direct connectionAvoid cooling grade reductionEvaporators/condensersEngineeringEvaporation duct

The invention relates to the technical field of an electric refrigerator in household appliances, in particular to a fin evaporator, which comprises a fixing plate, two lines or a plurality of lines of evaporation pipes and a plurality of fins, wherein the evaporation pipes are arranged on the fixing plate, the fins are sheathed on the evaporation pipes, and the evaporation pipes enter the evaporator from the top layer, spirally go downwards in a snake shape at each layer, and are sent out of the evaporator at the bottom layer. The air supply direction is upward from the bottom, the flowing direction of refrigerants in a pipeline is generally opposite to the air supply direction, through adopting the convection mode, the heat exchange is enhanced, and the cooling capacity transfer efficiency is improved. The refrigerant pipeline direction is integrally downward from the top, and the distance between an inlet section and an outlet section of each evaporation pipe reaches the maximum value. The temperature differences of the inlet section and the outlet section of each evaporation pipe are great, the heat exchange of the traditional evaporator through the fins since the inlet section and the outlet section of the evaporation pipe are adjacent is avoided, i.e., the cooling capacity grade reduction is avoided, and the cooling capacity utilization rate is improved. The frosting non-uniformity of the fins on the air supply cross section of the traditional evaporator, and the air supply non-uniformity and the heat exchange efficiency reduction due to the frosting non-uniformity are avoided.

Owner:孙卫华

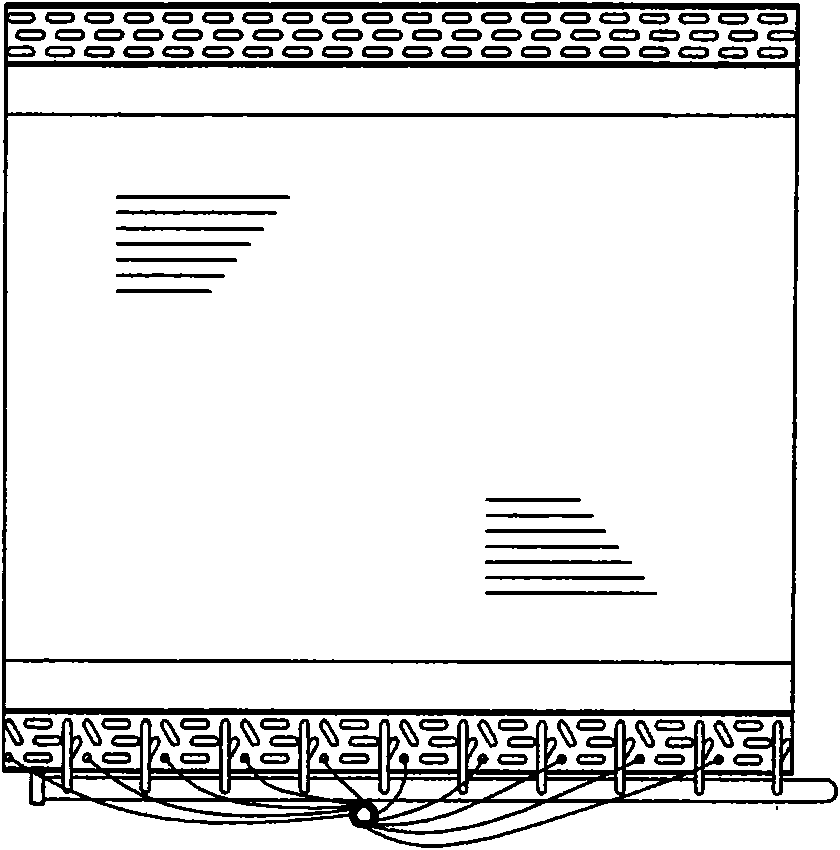

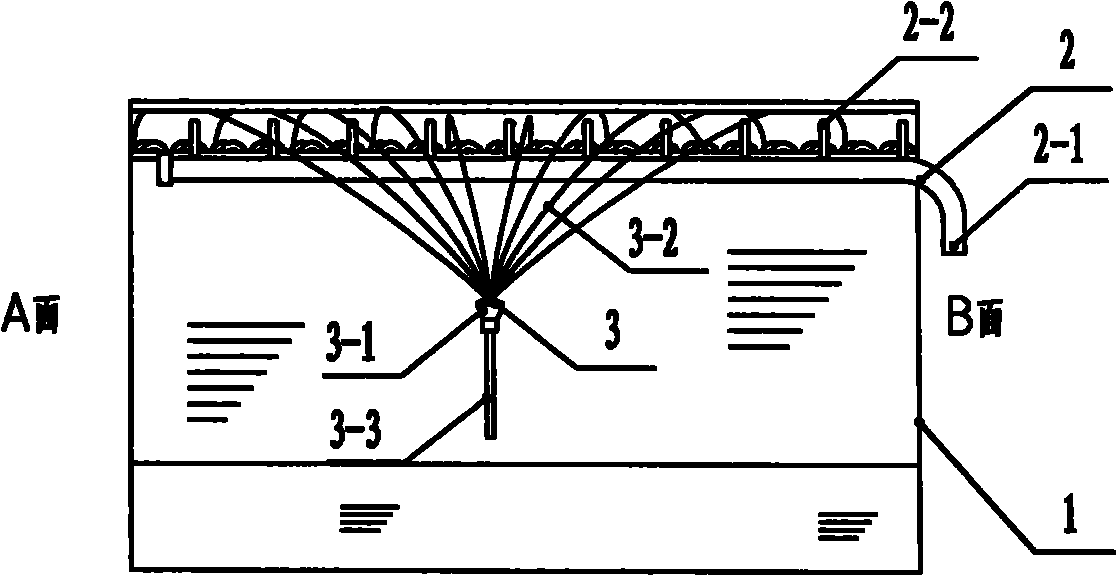

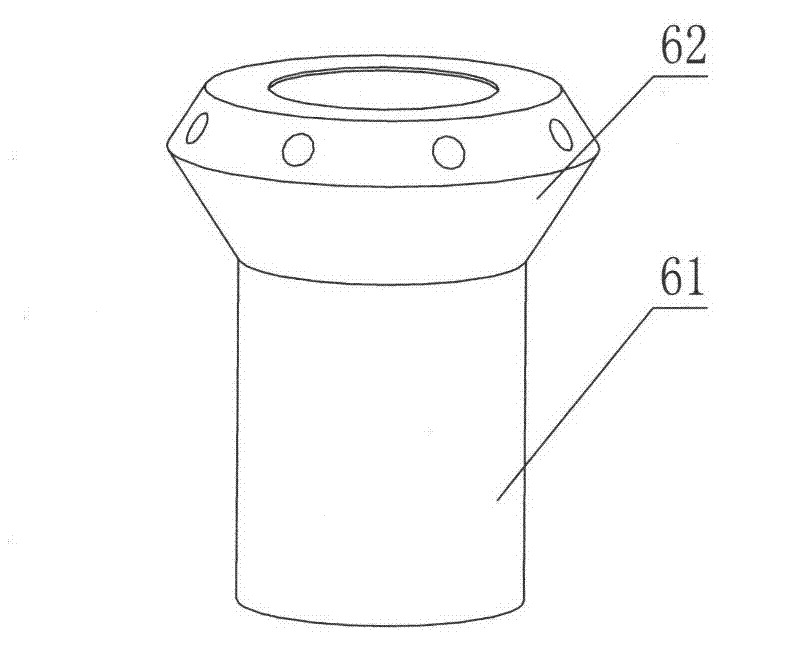

A liquid separator assembly and its air conditioner

ActiveCN107062713BFrosting evenlyEven defrostingMechanical apparatusFluid circulation arrangementVapor–liquid separatorHeating effect

The invention relates to the field of air conditioners. Specifically relates to a liquid distributor assembly and its air conditioner, wherein a liquid distributor assembly includes a liquid distribution head, one end of the liquid distribution head has a liquid collection port, the other end has a number of liquid distribution ports, the liquid distribution head The port is used to communicate with the liquid distribution pipe of the heat exchanger; a gas-liquid separator with a refrigerant outlet is arranged on the upstream side of the liquid collection port, and the refrigerant outlet communicates with the liquid collection port. The technical problem to be solved by the present invention is that in the prior art, the ratio of the gas-liquid mixture entering the liquid pipes of the heat exchanger from the liquid separator is inconsistent, resulting in uneven frosting and defrosting, and poor heating effect. The liquid separator assembly and its air conditioner with more uniform frost and defrost and better heating effect.

Owner:GREE ELECTRIC APPLIANCES INC

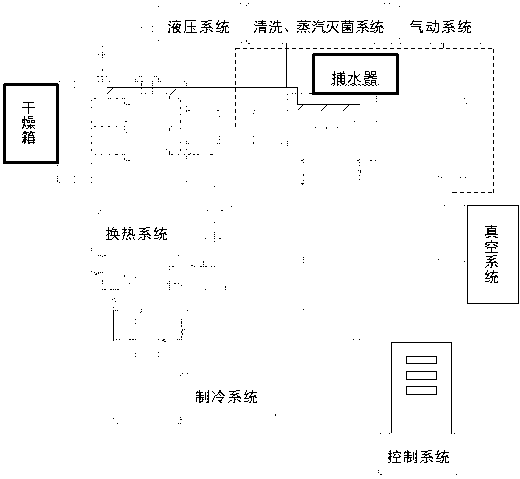

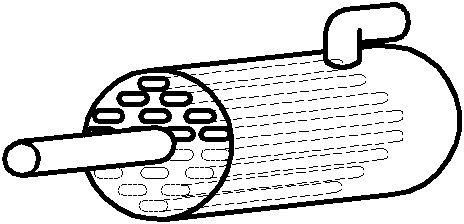

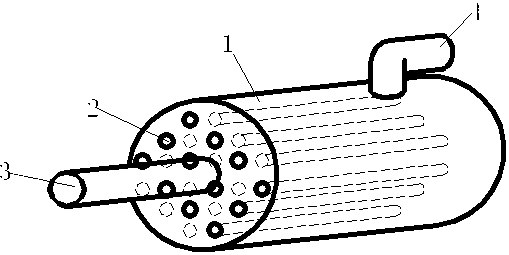

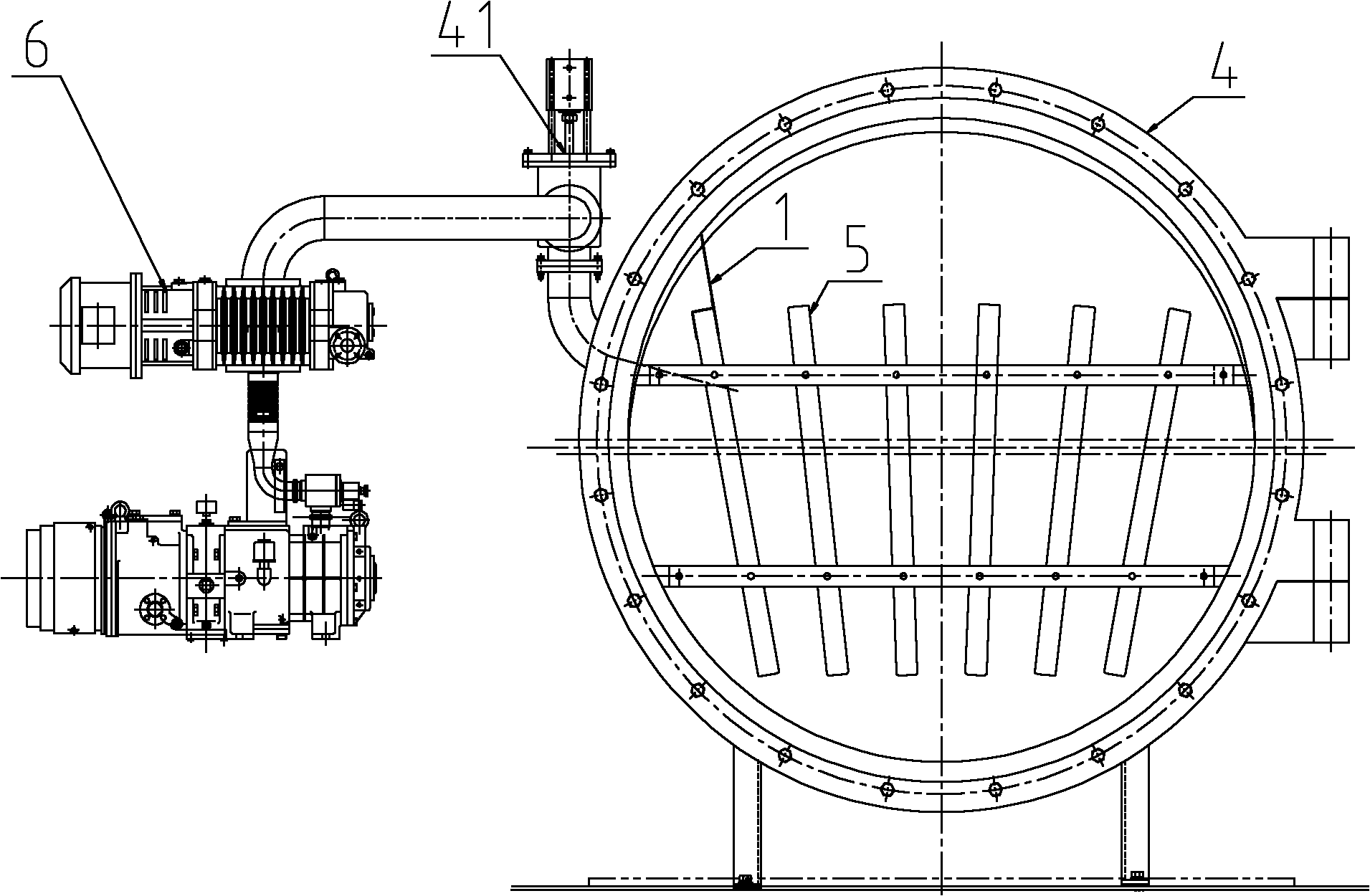

Freeze dryer water catcher

InactiveCN103344096ANot easy to cause short circuitNot easy to accumulateDrying solid materials without heatRefrigeration compressorEngineering

The invention relates to a freeze dryer water catcher which comprises a water catcher shell and two sets of coil pipes, wherein the two sets of coil pipes are evenly distributed in the water catcher shell, vapor inlets of the two sets of coil pipes are formed in the upper portion of the water catcher shell, and vapor outlets of the two sets of coil pipes are formed in the lower portion of the water catcher shell. The vapor inlets of the two sets of coil pipes are connected with a drying box, and the vapor outlets of the two sets of coil pipes are connected with a refrigerating unit. The two sets of coil pipes are evenly distributed in the water catcher shell, vapor enters each set of coil pipe from the upper portion and leaves each set of coil pipe from the lower portion, therefore, frosting is even when the two sets of units are started, frosting is also even when one set of unit is started, the short circuit phenomenon of a vapor channel is not easy to occur, and the water catching effect is good. Due to the fact that the vapor enters each set of coil pipe from the upper portion and leaves each set of coil pipe from the lower portion, refrigerant oil is not easily stored in the coil pipes, oil can be well returned, and accidents do not easily occur to a refrigeration compressor. The improved water catcher coil pipes can obtain a satisfactory effect after running for a long time, and the expected aim is achieved.

Owner:上海千山远东制药机械有限公司

Staggered-parallel-type aluminum alloy finned tube evaporator

The invention relates to a staggered-parallel-type aluminum alloy finned tube evaporator which comprises a plurality of finned tubes and a bend tube; the plurality of finned tubes are arrayed in parallel; the two adjacent finned tubes are staggered up and down; the upper fins of the lower finned tubes are corresponding to the lower fins of the upper finned tubes; two finned tubes at intervals are at the same level; two ends of the bend tube are respectively connected with two finned tubes, thus a parallel unit is formed; two finned tubes of each parallel unit are respectively a liquid inlet tube and a liquid outlet tube, and are provided with a liquid distributor; the liquid distributor is provided with a liquid inlet and liquid outlets the number of which is corresponding to the number of the liquid inlet tubes; the liquid inlet tubes of each parallel unit are communicated with a refrigerant liquid inlet pipeline through a liquid distributor; and the liquid outlet tubes of each parallel unit are communicated with the refrigerant liquid inlet pipeline. According to the invention, through adopting the up and down staggered array mode of the finned tubes, the mutual influence between the adjacent finned tubes is reduced, the refrigeration speed is accelerated, more uniform refrigeration is realized through the parallel connection mode, the frosting on the fins is uniform.

Owner:贾凤华

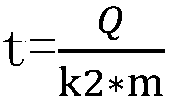

Cleaning method of air conditioner inside and outside unit

ActiveCN106594976BGuaranteed uptimeFrosting evenlyMechanical apparatusSpace heating and ventilation safety systemsFour-way valveDifferential pressure

The invention discloses a method for cleaning the inner and outer units of an air conditioner. The method includes: controlling the heat exchanger to be cleaned to enter a self-cleaning mode; adjusting the operating frequency of the air conditioner, the opening of the throttling device and the fan speed corresponding to the heat exchanger to be cleaned, and controlling the evaporation temperature of the heat exchanger to be cleaned to maintain a predetermined Within the set range, make frost on the surface of the heat exchanger to be cleaned; frost on the heat exchanger to be cleaned lasts for t1 time; detect whether the high and low pressure difference of the air conditioner reaches the preset condition; when the high and low pressure difference of the air conditioner reaches the preset condition, control The four-way valve changes direction to switch between indoor and outdoor heat exchangers for defrosting; when the high and low pressure difference of the air conditioner does not meet the preset conditions, adjust the operating parameters of the air conditioner to make the high and low pressure difference of the air conditioner reach the preset conditions, and then control the four-way The valve is reversed to switch between indoor and outdoor heat exchanger defrosting. Since the reversing of the four-way valve can be controlled by detecting whether the pressure difference between the high and low pressures of the air conditioner reaches a preset condition, it is possible to avoid a large impact on the compressor caused by an excessive high and low pressure difference of the air conditioner.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

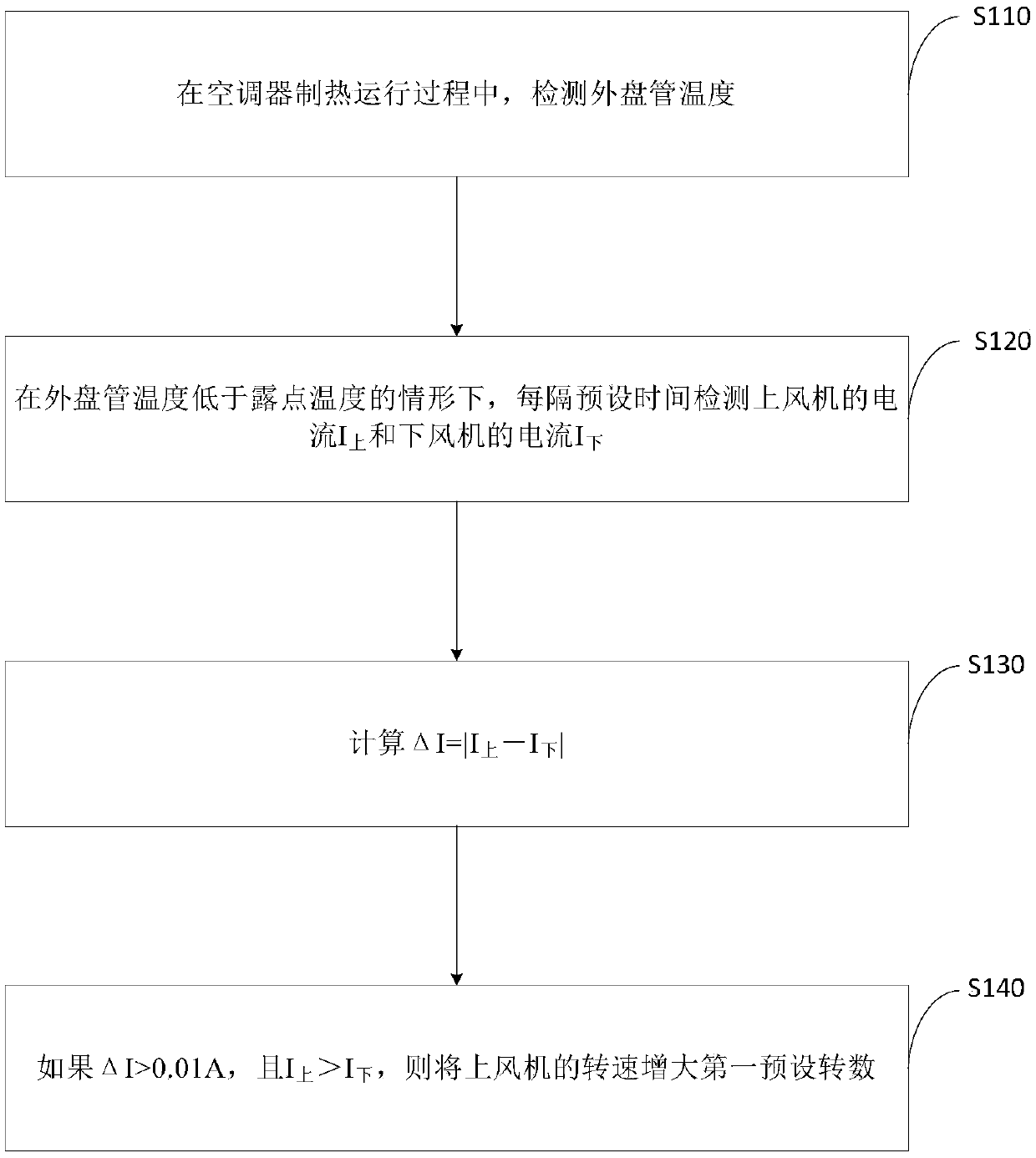

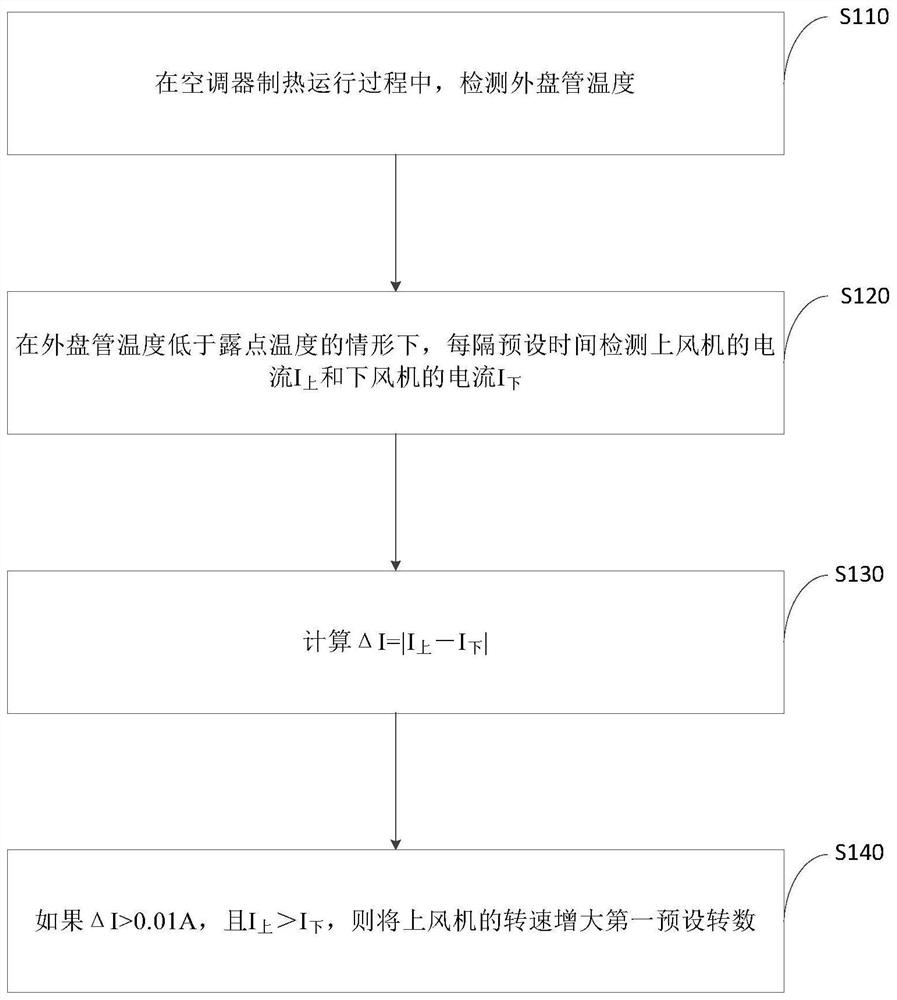

Air conditioner frost control method

ActiveCN110836461AFrosting evenlyImprove defrostingMechanical apparatusSpace heating and ventilation safety systemsAir velocityEngineering

The invention belongs to the technical field of air conditioners, and particularly relates to an air conditioner frosting control method. In order to ensure frosting uniformity of an air conditioner to improve the defrosting efficiency, a provided air conditioner defrosting control method is directed to an air conditioner provided with dual fans on an outdoor unit. The method includes the following steps that during heating operation of the air conditioner, the temperature of an outer coil is detected; in the case where the temperature of the outer coil is lower than a dew point temperature, the current of the upper fan and the current of the lower fan are detected every preset time; calculating is conducted according to a formula of delta I=|I upper-I lower|; if deltaI is greater than 0.01 A, and I upper> I lower, the rotation speed of the upper fan is increased by a first preset number of revolutions. Non-uniformity of temperature points of the outer coil of an outdoor heat exchanger is balanced by controlling magnitudes of wind speeds in different regions of the outer coil, and frosting uniformity is further rationally controlled, so that frosting of the outdoor unit is more uniform, and frosting uniformity is conducive to defrosting, that is, the defrosting efficiency is improved.

Owner:CHONGQING HAIER AIR CONDITIONER CO LTD +2

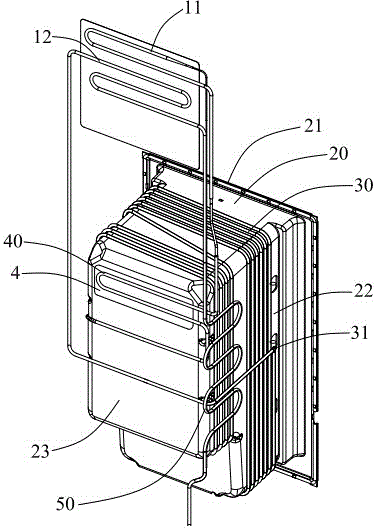

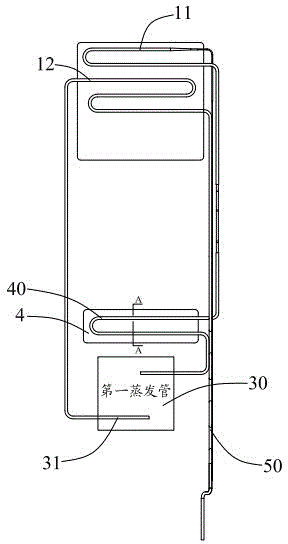

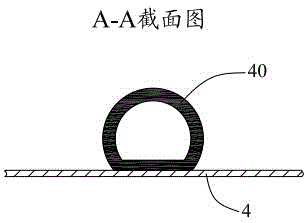

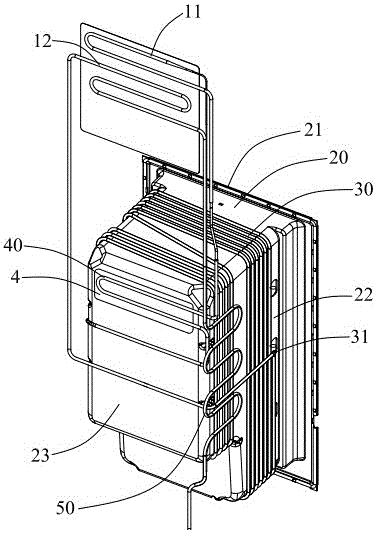

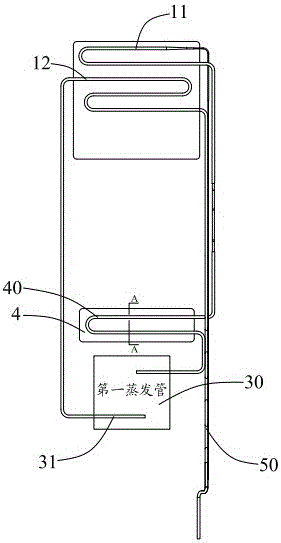

Direct cooling refrigerator and refrigerating method thereof

ActiveCN104034114AFrosting evenlyPlay the role of energy savingDomestic refrigeratorsEvaporators/condensersEvaporationEngineering

The invention provides a direct cooling refrigerator. The direct cooling refrigerator comprises an inner container, wherein an evaporation tube stack is arranged between the inner container and a direct cooling refrigerator shell; the evaporation tube stack at least comprises a first evaporation tube and a second evaporation tube; at least one of the first evaporation tube and the second evaporation tube is a container-winding evaporation tube. By adopting the direct cooling refrigerator, the effect of saving energy can be achieved.

Owner:HAIER GRP CORP +1

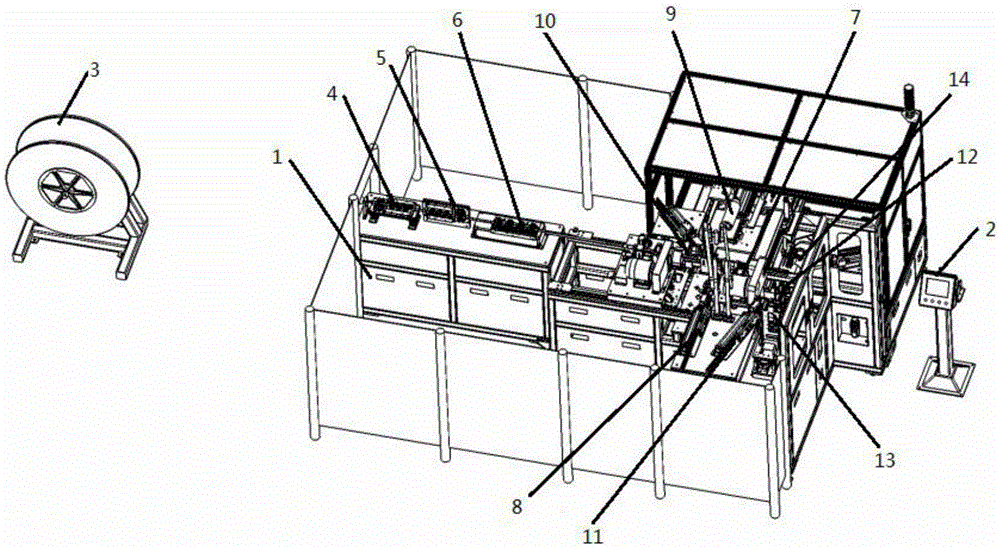

Automatic tube coiling and assembly machine for evaporator of snow melting machine

The invention relates to an automatic tube coiling and assembly machine for an evaporator of a snow melting machine. The automatic tube coiling and assembly machine comprises a rack, a controller arranged at one side of the rack, and an automatic discharge frame arranged at the other side of the rack, wherein a straightening mechanism controlled by the controller, a tube coiling mechanism used for coiling a copper tube, an assembly mechanism used for assembling the copper tube with an evaporator cover, and a material retreating mechanism are sequentially arranged on the rack; and the tube coiling mechanism comprises a necking assembly, a first bending assembly, an automatic tube coiling assembly, an automatic paste coating assembly, a chipless cutting assembly, a second bending assembly and a third bending assembly which are sequentially connected. According to the invention, the traditional manual operation is replaced by automatic control, thus the production efficiency is increased; and meanwhile, the copper tube is in close fit with the inner wall of the evaporator cover through automatic necking, multiple bending, and reversing expansion, so that frosting of the evaporator of the snow melting machine is more uniform.

Owner:SUZHOUSCON AUTOMATION TECH

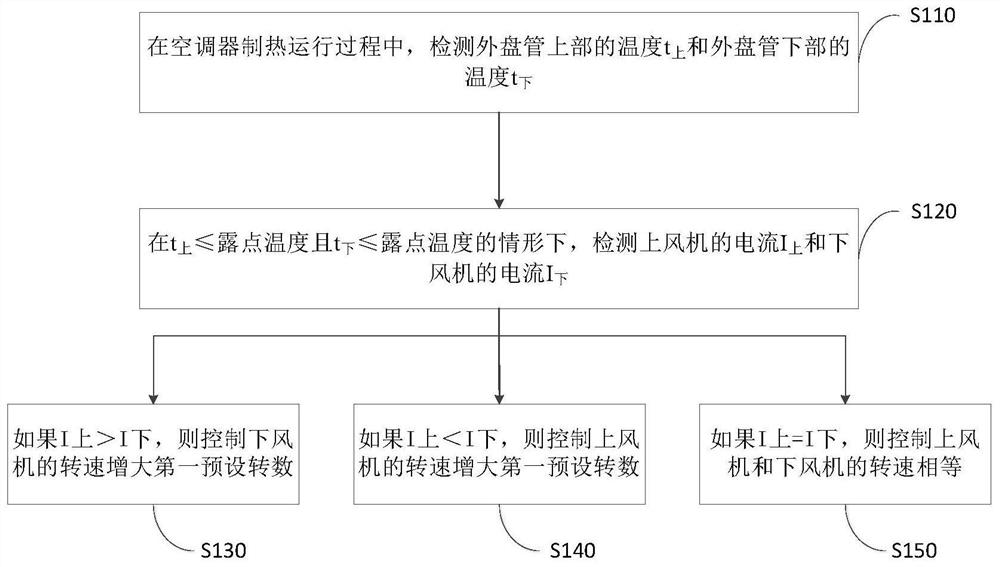

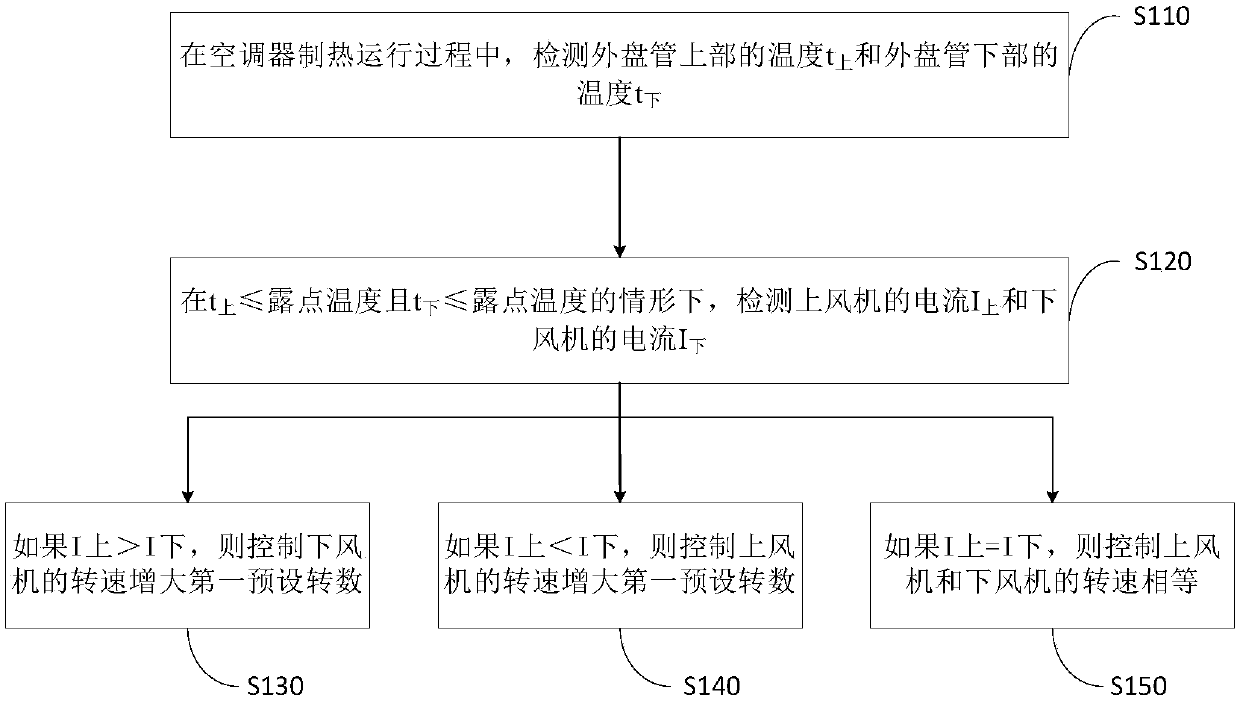

Air Conditioner Frosting Control Method

ActiveCN110836495BFrosting evenlyImprove defrostingMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsEngineering

The invention belongs to the technical field of air conditioners, and in particular relates to a frosting control method for an air conditioner. In order to ensure the uniformity of frosting of the air conditioner and improve the defrosting efficiency, the air conditioner defrosting control method proposed in the present invention is aimed at the air conditioner with dual fans on the outdoor unit. The method includes: during the heating operation of the air conditioner, detecting The temperature of the upper part of the coil t 上 and the temperature t of the lower part of the outer coil 下 ; at t 上 ≤ dew point temperature and t 下 ≤ dew point temperature, detect the current I of the upper fan 上 and the current I of the lower fan 下 ; if I 上 >I 下 , then the speed of the fan under control increases the first preset number of revolutions; if I 上 <I 下 , then control the speed of the fan to increase the first preset number of revolutions; if I 上 = I 下 , then control the speed of the upper fan and the lower fan to be equal. The invention can reasonably control the uniformity of frosting, so that the frosting of the external machine is more uniform, and the uniformity of frosting is beneficial to defrosting, that is, the defrosting efficiency is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Direct cooling refrigerator and refrigeration method thereof

ActiveCN104034114BFrosting evenlyPlay the role of energy savingDomestic refrigeratorsEvaporators/condensersEvaporationEngineering

Disclosed is a direct-cooling refrigerator, comprising a freezing liner (20), wherein an evaporation tube group is arranged between the freezing liner (20) and a shell of the direct-cooling refrigerator. The evaporation tube group comprises a first evaporation tube (30) and a second evaporation tube (40), the first evaporation tube (30) being of a liner winding type.

Owner:HAIER GRP CORP +1

Frosting control method of air conditioner

ActiveCN110836495AFrosting evenlyImprove defrosting efficiencyMechanical apparatusSpace heating and ventilation safety systemsEngineeringElectrical and Electronics engineering

The invention belongs to the technical field of air conditioners, and particularly relates to a frosting control method of an air conditioner. In order to guarantee frosting uniformity of the air conditioner to improve defrosting efficiency, the defrosting control method of the air conditioner is provided for the air conditioner provided with double fans on an outdoor unit. The method comprises steps as follows: detecting a temperature t(upper) of the upper part of an outer coil pipe and a temperature t(lower) of the lower part of the outer coil pipe in a heating operation process of the air conditioner; detecting current I(upper) of an upper fan and current I(lower) of a lower fan under the conditions that t(upper) is lower than or equal to a dew point temperature and t(lower) is lower than or equal to the dew point temperature; controlling the revolution speed of the lower fan to be increased by first preset number of revolution if I(upper) is larger than I(lower); controlling the revolution speed of the upper fan to be increased by first preset number of revolution if I(upper) is smaller than I(lower); and controlling revolution speeds of the upper fan and the lower fan to be equal if I(upper) is equal to I(lower). According to the method, frosting uniformity can be controlled reasonably, frosting of the outdoor unit is more uniform, defrosting is facilitated by the aid of uniform frosting, and the defrosting efficiency is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

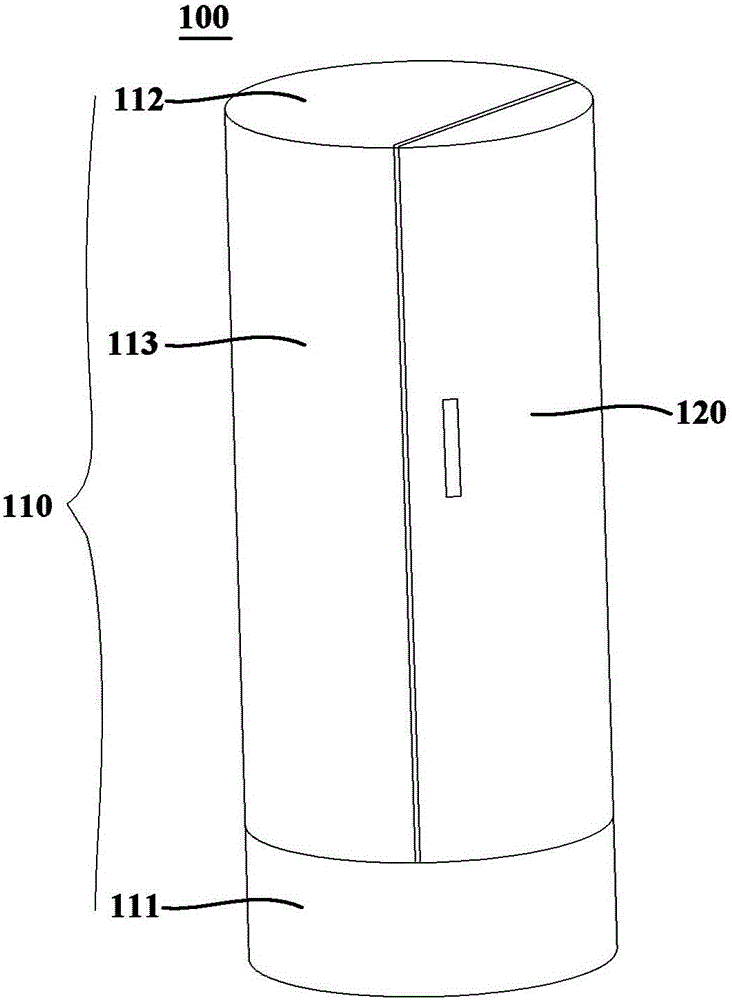

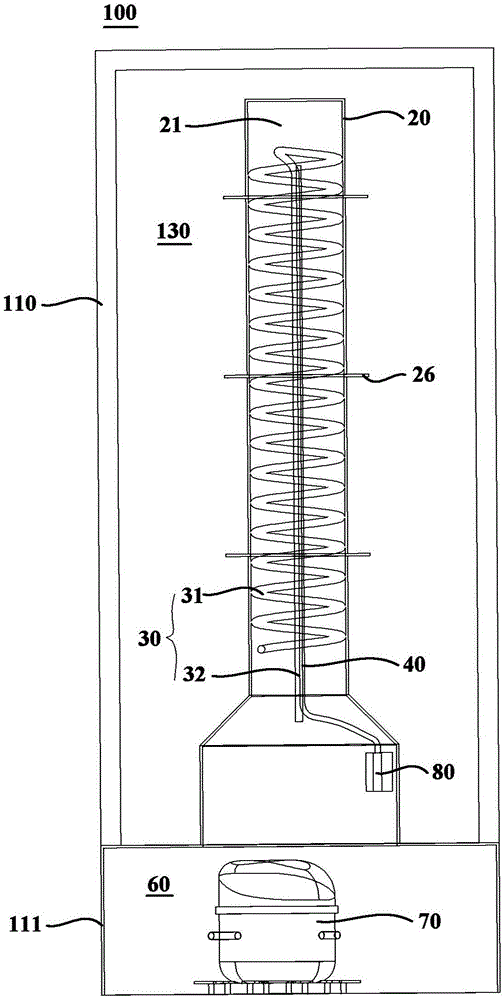

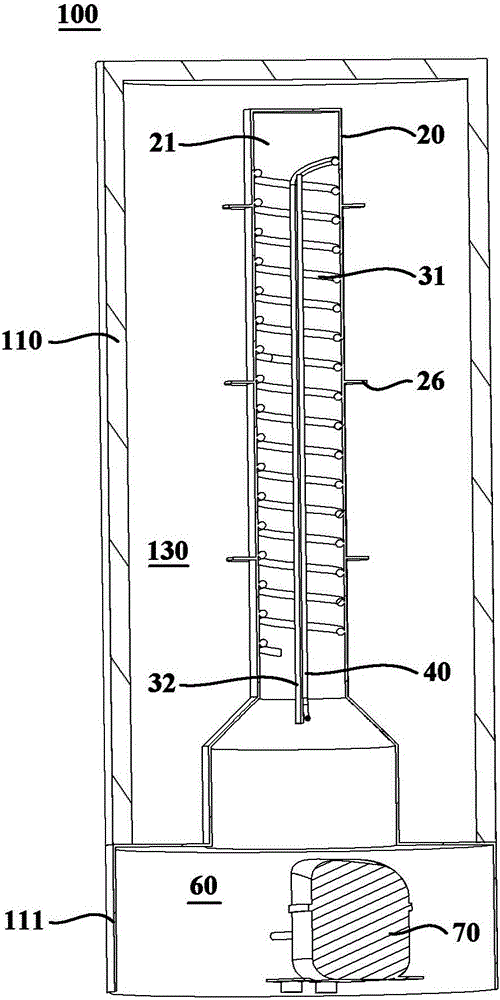

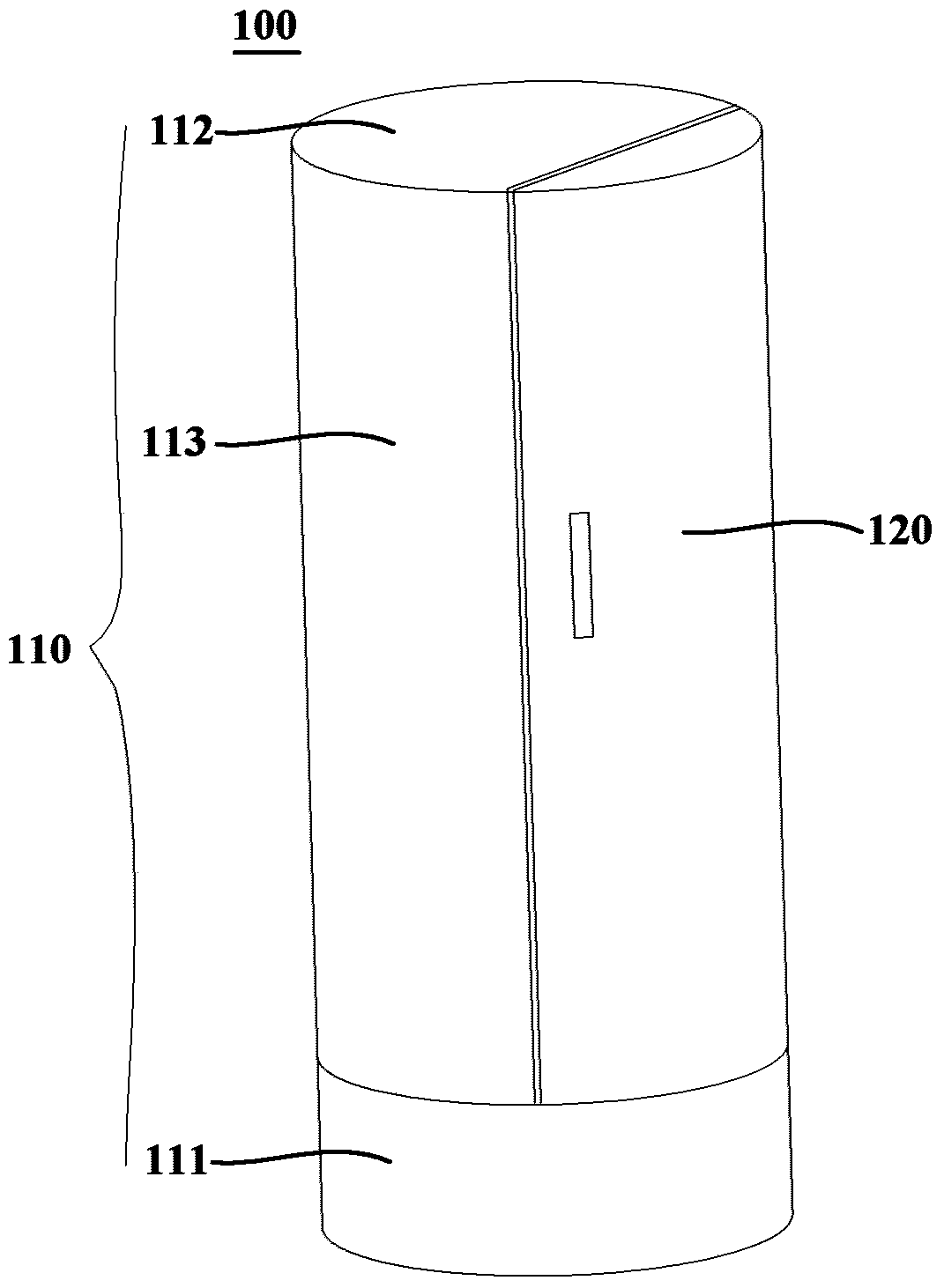

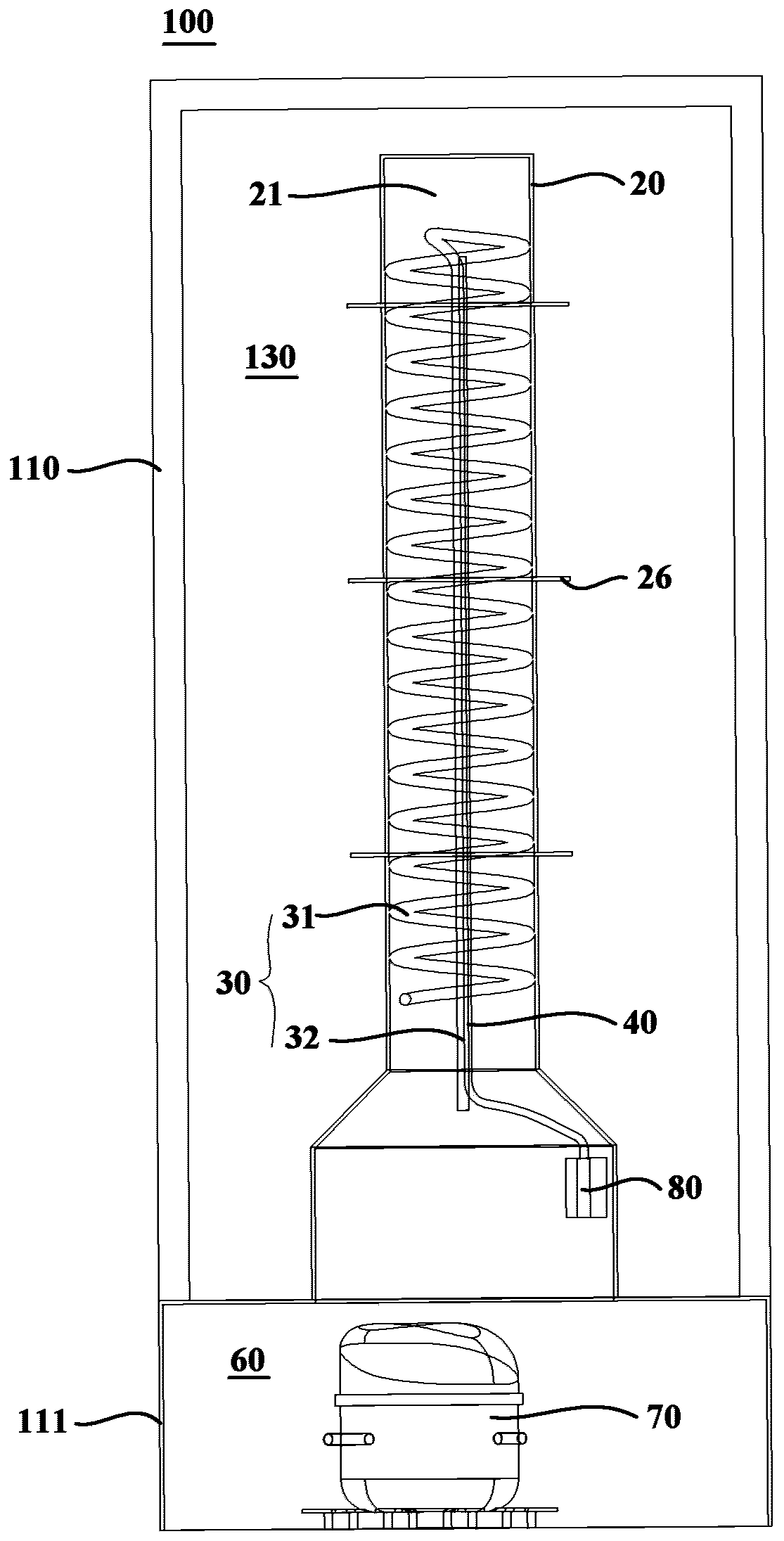

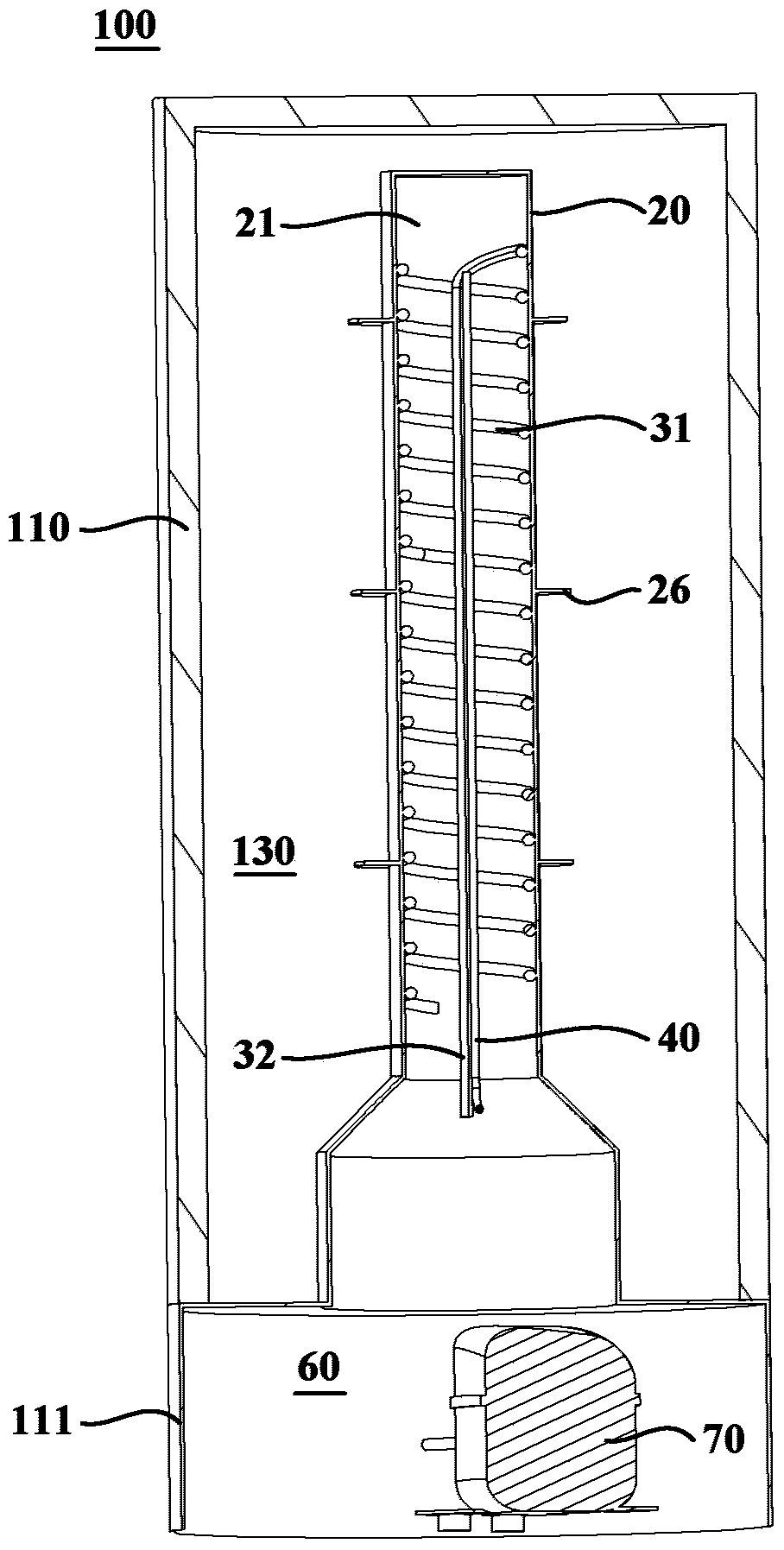

Refrigerator

ActiveCN105737474ARapid coolingIncrease cooling rateLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigeration

The invention provides a refrigerator. The refrigerator comprises a refrigerator body with a storage compartment in a defined manner and further comprises a refrigeration column and an evaporator; the refrigeration column extends upwards in the vertical direction and is arranged in the center of the storage compartment, and a refrigeration cavity is arranged in the refrigeration column in a defined manner; the evaporator is arranged in the refrigeration cavity, at least part of pipeline of the evaporator is tightly attached to the inner surface of the refrigeration column, and therefore cold of the evaporator is transmitted to the refrigeration column, so that cold of the evaporator is sent out with the refrigeration column as the center; and compared with the manner that the cold of the evaporator is transmitted to the refrigeration column through air, the manner that the cold of the evaporator is directly transmitted to the refrigeration column is adopted, the cold transmission time is short, refrigeration is rapid, and the refrigeration efficiency of the refrigerator is improved.

Owner:HAIER SMART HOME CO LTD

Air Conditioner Frosting Control Method

ActiveCN110836461BFrosting evenlyImprove defrostingMechanical apparatusSpace heating and ventilation safety systemsAir velocityEngineering

The invention belongs to the technical field of air conditioners, and in particular relates to a frosting control method for an air conditioner. In order to ensure the uniformity of frosting of the air conditioner to improve the defrosting efficiency, the air conditioner defrosting control method proposed by the present invention is aimed at an air conditioner with dual fans installed on the outdoor unit. The method includes the following steps: During the heating operation of the air conditioner, Detect the temperature of the outer coil; when the temperature of the outer coil is lower than the dew point temperature, detect the current I of the upper fan every preset time 上 and the current I of the lower fan 下 ;calculate ΔI=|I 上 -I 下 |; if ΔI>0.01A, and I 上 >I 下 , then increase the rotation speed of the upper fan by a first preset number of rotations. The invention balances the unevenness of the temperature points of the outer coil of the outdoor heat exchanger by controlling the wind speed in different areas of the outer coil, and then reasonably controls the uniformity of frosting, so that the frosting of the external unit is more uniform, and the frosting Uniformity is conducive to defrosting, that is, improving the defrosting efficiency.

Owner:CHONGQING HAIER AIR CONDITIONER CO LTD +2

refrigerator

ActiveCN105737474BRapid coolingIncrease cooling rateLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigeration

The invention provides a refrigerator. The refrigerator comprises a refrigerator body with a storage compartment in a defined manner and further comprises a refrigeration column and an evaporator; the refrigeration column extends upwards in the vertical direction and is arranged in the center of the storage compartment, and a refrigeration cavity is arranged in the refrigeration column in a defined manner; the evaporator is arranged in the refrigeration cavity, at least part of pipeline of the evaporator is tightly attached to the inner surface of the refrigeration column, and therefore cold of the evaporator is transmitted to the refrigeration column, so that cold of the evaporator is sent out with the refrigeration column as the center; and compared with the manner that the cold of the evaporator is transmitted to the refrigeration column through air, the manner that the cold of the evaporator is directly transmitted to the refrigeration column is adopted, the cold transmission time is short, refrigeration is rapid, and the refrigeration efficiency of the refrigerator is improved.

Owner:HAIER SMART HOME CO LTD

Gas guide device used for freeze dryer condenser

InactiveCN102022899AEvenly distributedFrosting evenlyDrying solid materials without heatEvaporators/condensersThree stageEngineering

The invention relates to a gas guide device used for a freeze dryer condenser which comprises a cylinder body and a plurality of three-stage heat exchange plates that are arranged in the cylinder body in a fan shape, wherein the cylinder body is connected with an external vacuum pump through a pipeline, the pipeline is provided with a vacuum aspirating hole, the gas guide device comprises a guide plate and a plurality of bent fixing plates connected to one side surface of the guide plate at intervals, a clamping structure is formed to be clamped and fixed on the three-stage heat exchange plate close to the vacuum aspirating hole, the guide plate supports against one side surface of the three-stage heat exchange plat, and the top edge of the guide plate supports against the inner wall of the cylinder body. The invention effectively ensures that airflow is uniformly distributed on the periphery of the three-stage heat exchange plates so as to play a role of uniformly guiding to make the surfaces of the three-stage heat exchange plates frost uniformly, thereby avoiding reducing the condensing capacity of the condenser.

Owner:上海共和真空技术有限公司

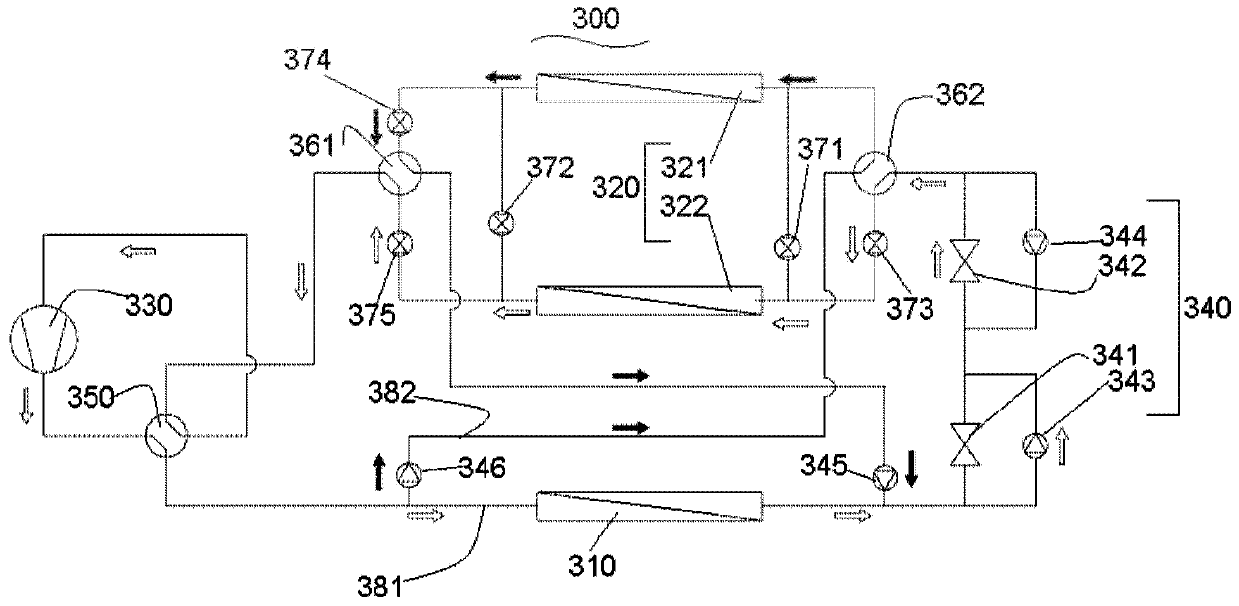

A double-row microchannel heat exchanger and its working method

ActiveCN111306846BImprove heat transfer effectFrosting evenlyEvaporators/condensersHeat exchanger casingsVapor–liquid separatorEngineering

The invention discloses a double-row microchannel heat exchanger and a working method thereof. The double-row microchannel heat exchanger comprises four liquid collecting tubes, flat tubes, fins, three ball valves, an electromagnetic expansion valve and a gas-liquid separator. When the double-row microchannel heat exchanger is used as an evaporator and works under the frosting condition, a refrigerant coming out of a front-row microchannel heat exchanger is throttled, so that the double-row microchannel heat exchanger can frost evenly; when the double-row microchannel heat exchanger works under the non-frosting condition, the refrigerant does not pass through the electromagnetic expansion valve; when the double-row microchannel heat exchanger is used as a condenser, the flow of the refrigerant entering the front-row microchannel heat exchanger is increased through adjustment of the opening degrees of the ball valves; the gas-liquid separator is mounted between the front-row microchannel heat exchanger and a back-row microchannel heat exchanger, the gas and the liquid which are produced by the double-row microchannel heat exchanger used as the evaporator and the condenser can be connected in a bypass manner, and thus the performance of the second half of the microchannel heat exchanger can be improved.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com