Patents

Literature

41results about How to "Guaranteed non-stop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air-conditioner internal and external unit cleaning method

ActiveCN106152413AFrosting evenlyImprove defrosting efficiencyMechanical apparatusSpace heating and ventilation safety systemsFour-way valveEngineering

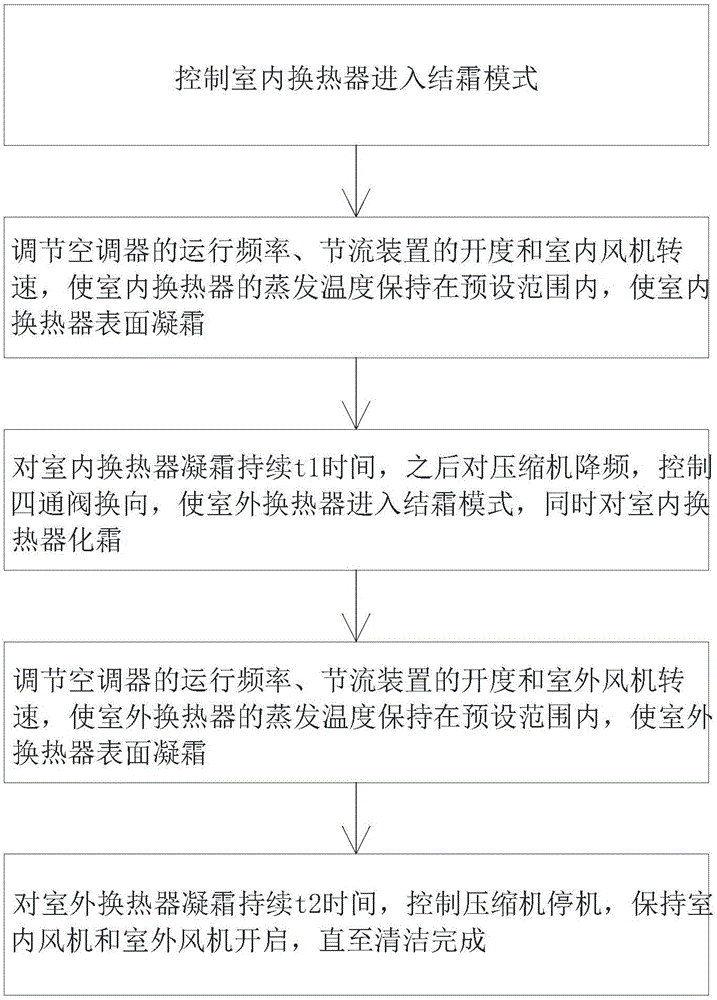

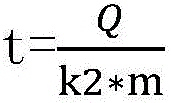

The invention discloses an air-conditioner internal and external unit cleaning method. The method comprises the steps that an indoor heat exchanger is controlled to enter a frosting mode; operation frequency of an air-conditioner, the opening degree of a throttling device and the rotating speed of an indoor fan are adjusted to enable evaporating temperature of the indoor heat exchanger to be kept within the preset range and the surface of the indoor heat exchanger to be frosted; frosting of the indoor heat exchanger lasts for time t1, later, frequency of a compressor is reduced, a four-way valve is controlled to be reversed, an outdoor heat exchanger enters a frosting mode, and meanwhile, the indoor heat exchanger is defrosted; the operation frequency of the air-conditioner, the opening degree of the throttling device and the rotating speed of an outdoor fan are adjusted, the evaporation temperature of the outdoor heat exchanger is kept within the preset range, and the surface of the outdoor heat exchanger is frosted; frosting of the outdoor heat exchanger lasts for time t2, the compressor is controlled to be shut down, and the indoor fan and the outdoor fan are kept starting until cleaning is completed. According to the air-conditioner internal and external unit cleaning method, the problem that in the prior art, the surface of the heat exchanger is cleaned through condensate water, and the effect is poor can be solved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

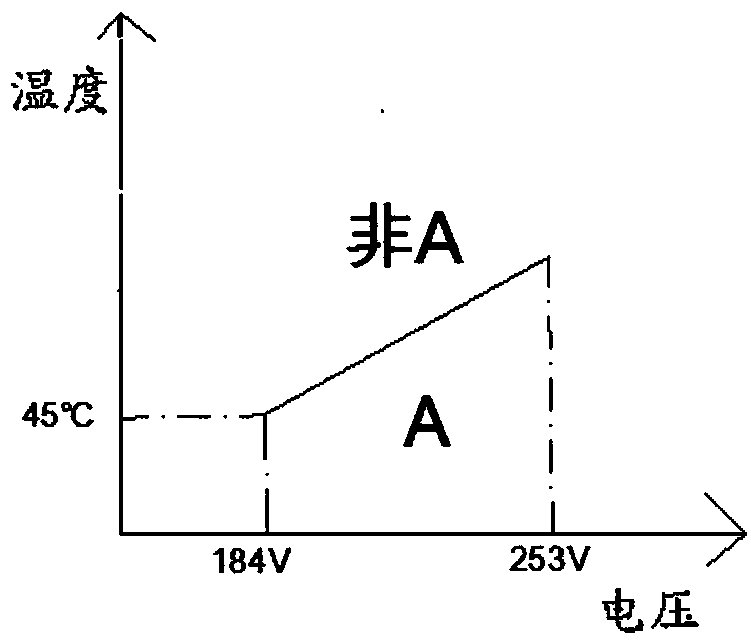

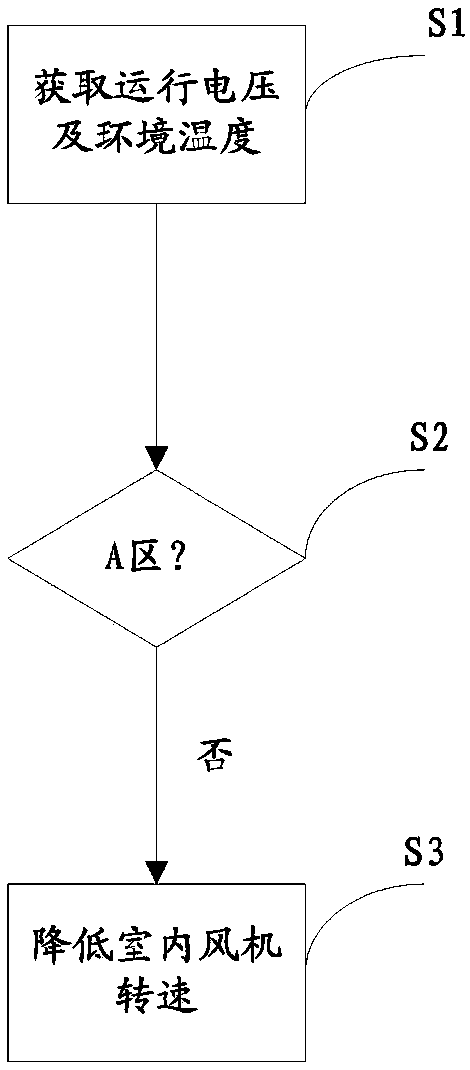

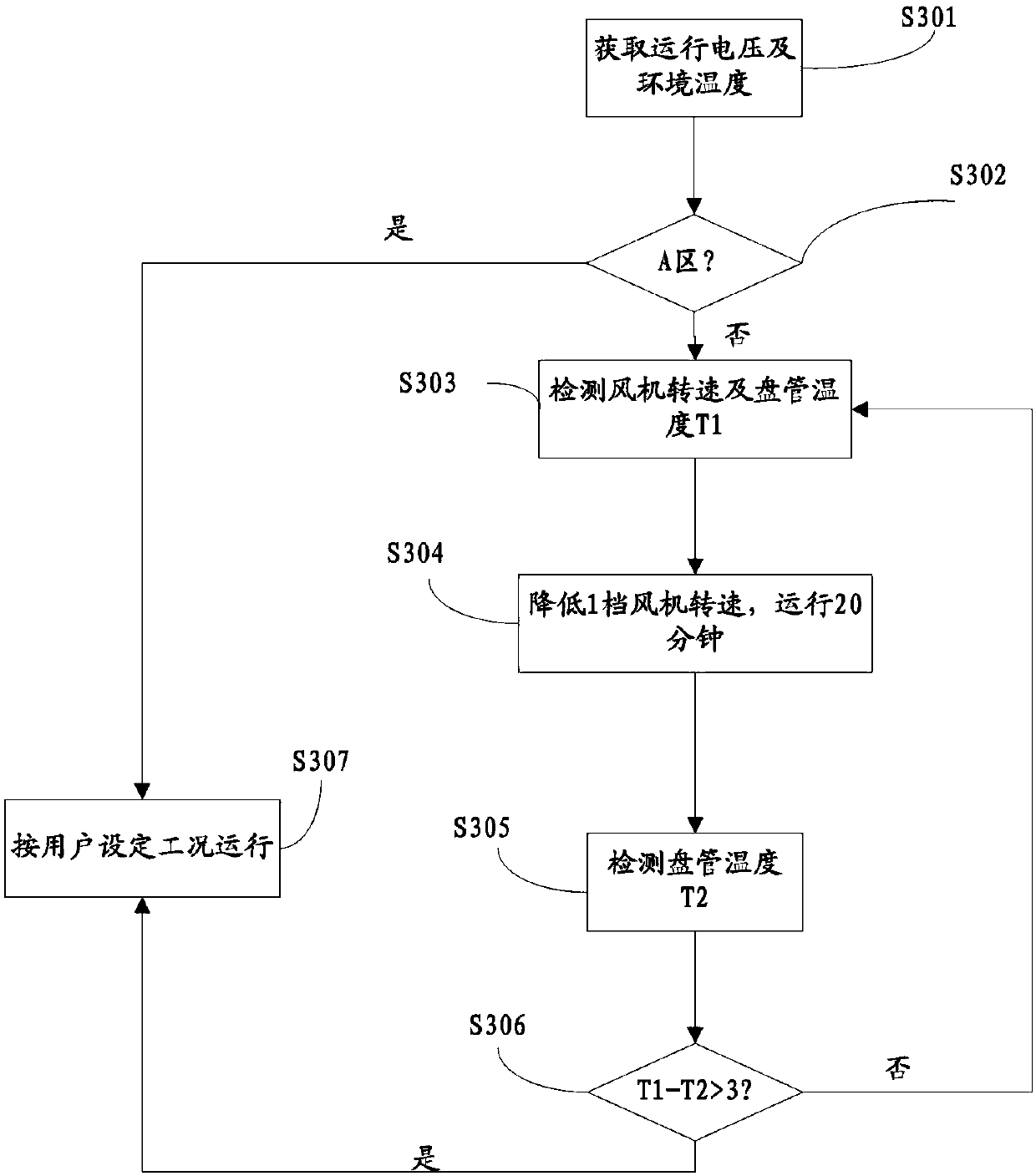

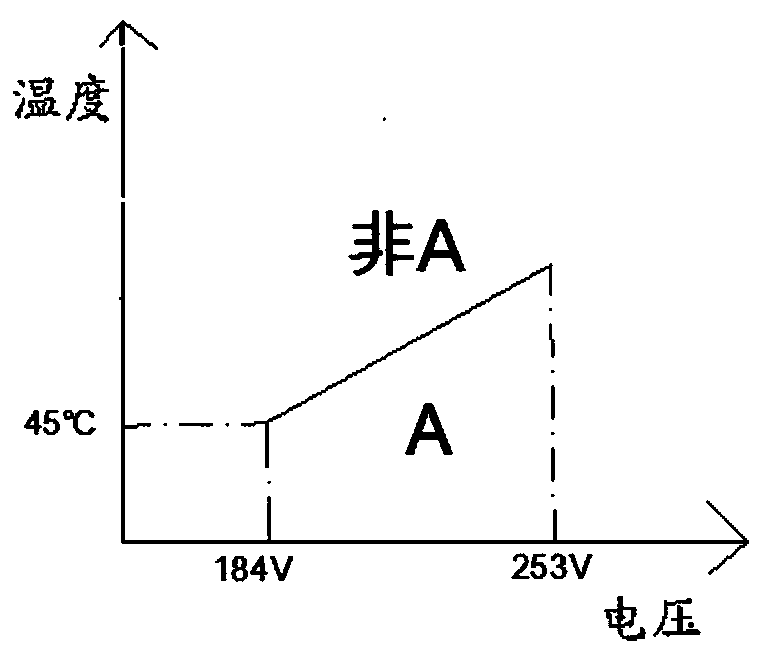

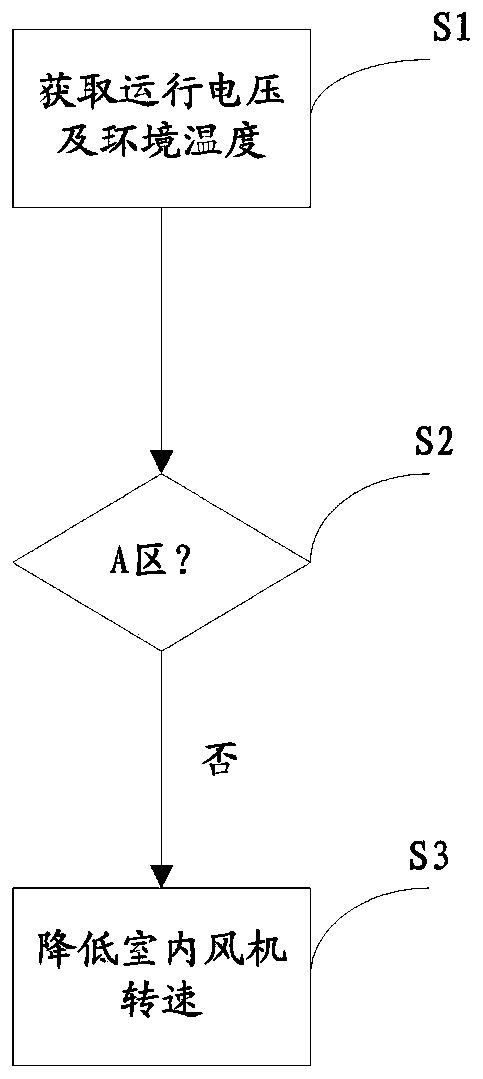

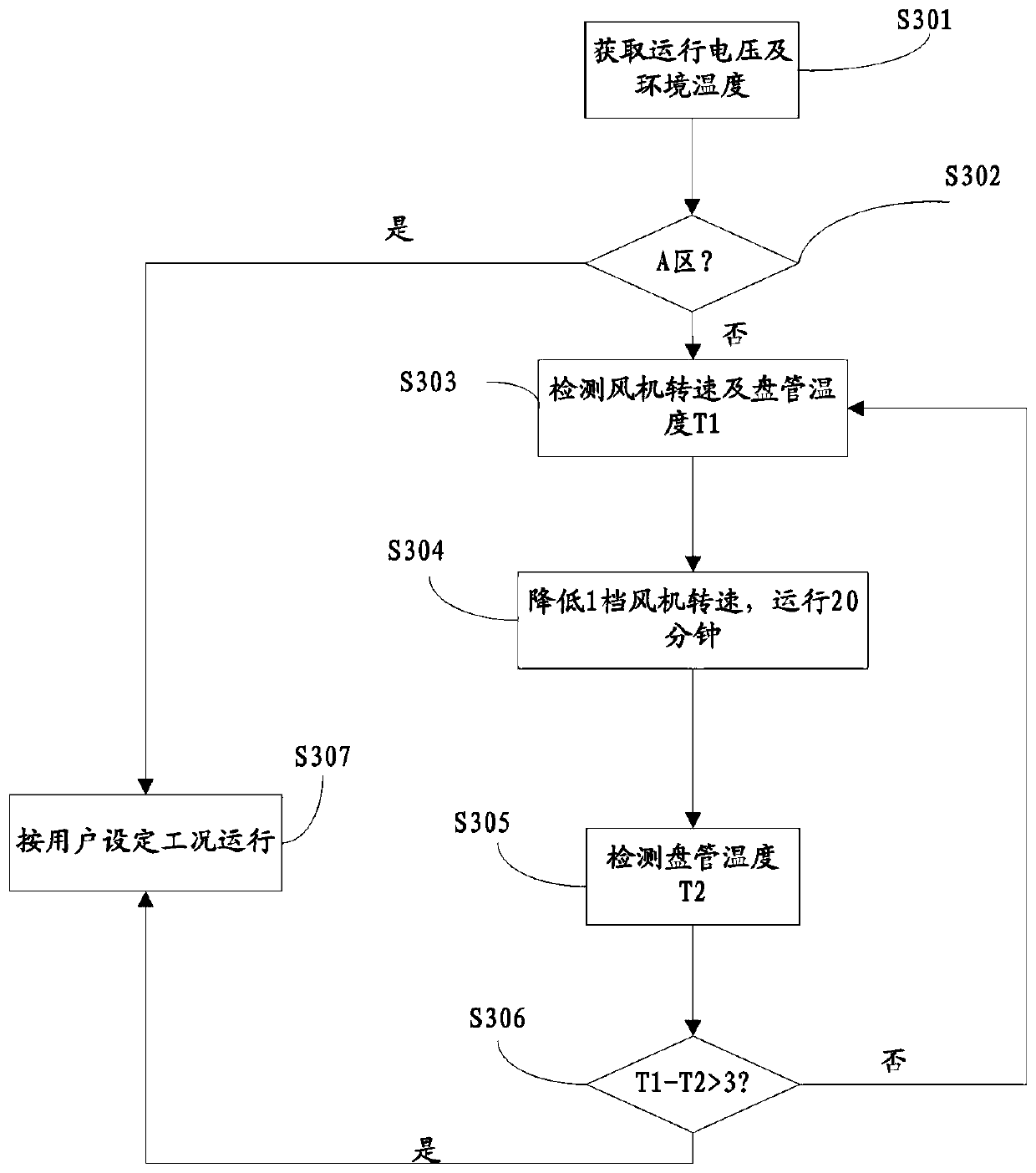

Protection control method and device for air conditioner

ActiveCN107747790AShort maintenance periodAvoid actionMechanical apparatusSpace heating and ventilation safety systemsLow voltageControl theory

The invention discloses a protection control method for an air conditioner, and belongs to the technical field of air conditioners. The method comprises the following steps: acquiring a running voltage of the air conditioner and an environment temperature; and when the running voltage and the environment temperature are out of a set area, lowering the rotational speed of an indoor fan. The invention further discloses a protection control device for an air conditioner. The invention solves the problem that a compressor of a fixed-frequency air conditioner is liable to stop due to the action ofan overload protector of the compressor in a high-temperature and low-voltage environment.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

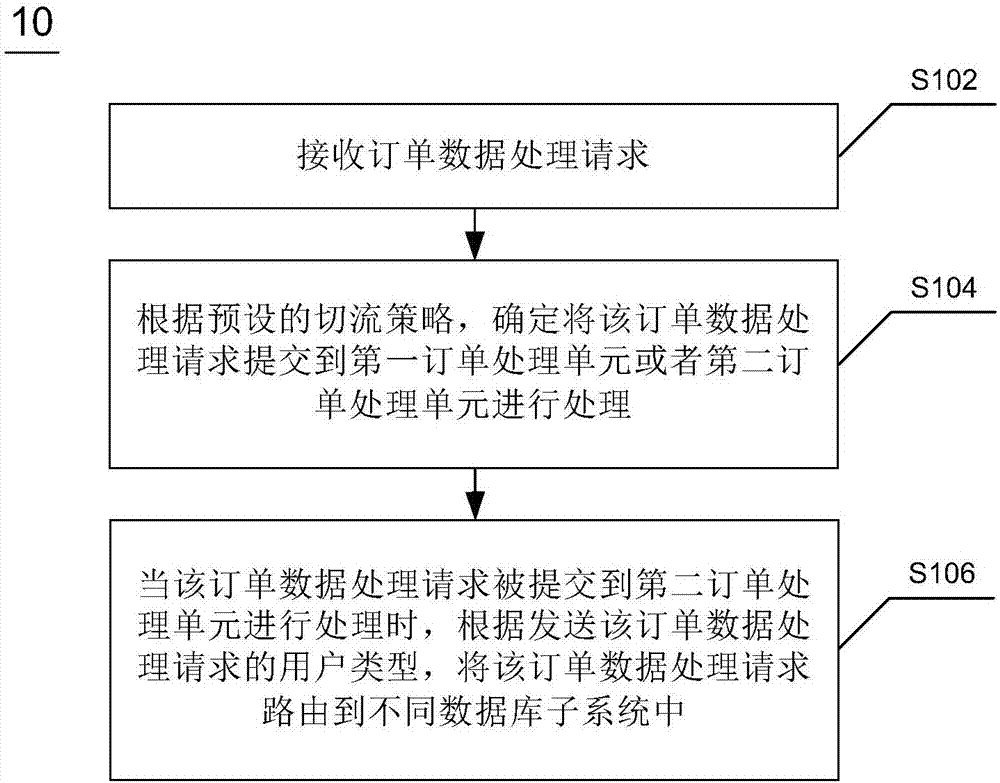

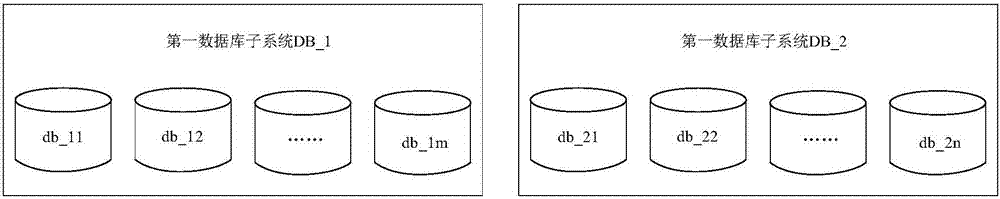

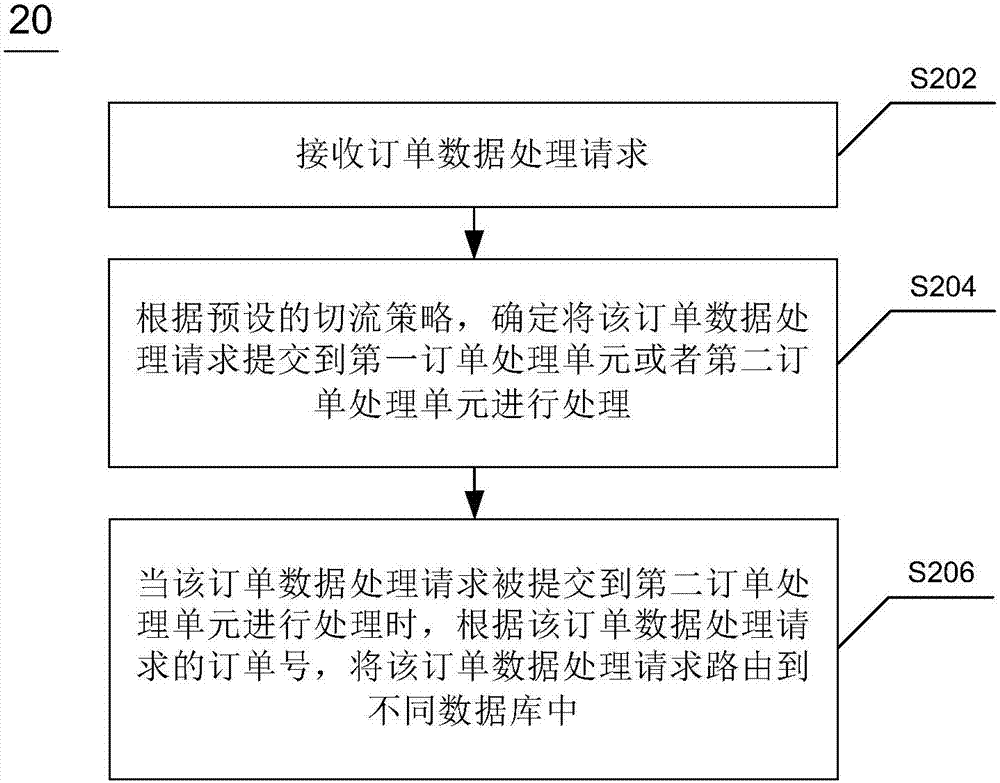

Method and device for processing order data of high-concurrency businesses

ActiveCN107464151AEasy to handleGuaranteed non-stopBuying/selling/leasing transactionsSpecial data processing applicationsOrder formDatabase schema

The invention discloses a method and device for processing order data of high-concurrency businesses. The method comprises the following steps of: receiving an order data processing request; determining to submit the order data processing request to a first order processing unit or a second order processing unit to be processed according to a preset flow shearing strategy; and when the order data processing request is submitted to the second order processing unit to be processed, routing the order data processing request into different database subsystems according to the type of a user for sending the order data processing request. According to the method, business services are stopped in database architecture upgrading processes, so that the satisfaction degrees of users are enhanced; and moreover, the order processing amount and concurrent order processing amount can be effectively enhanced.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

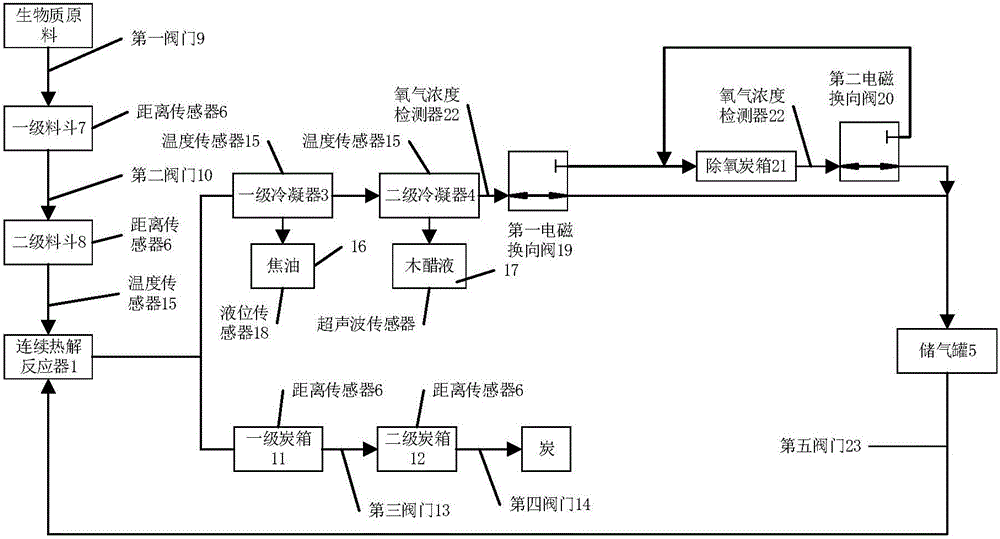

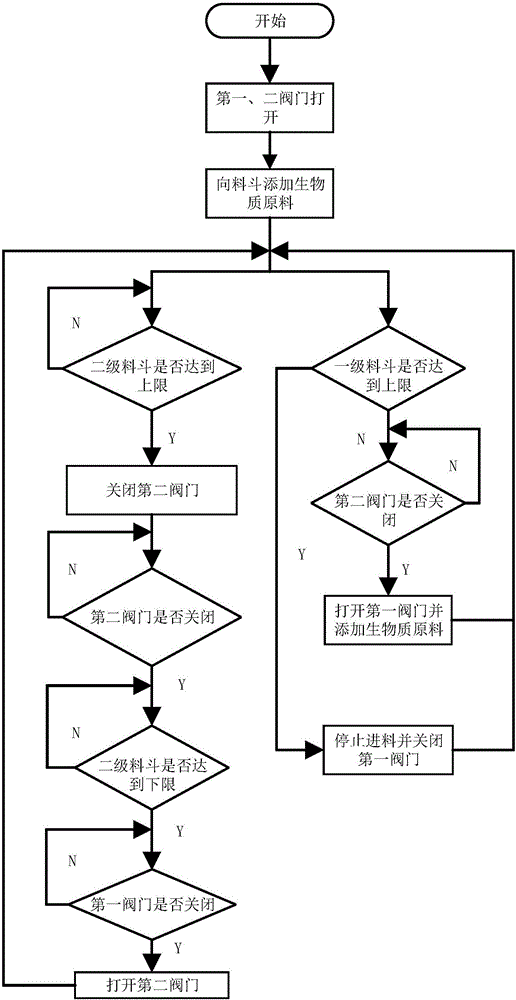

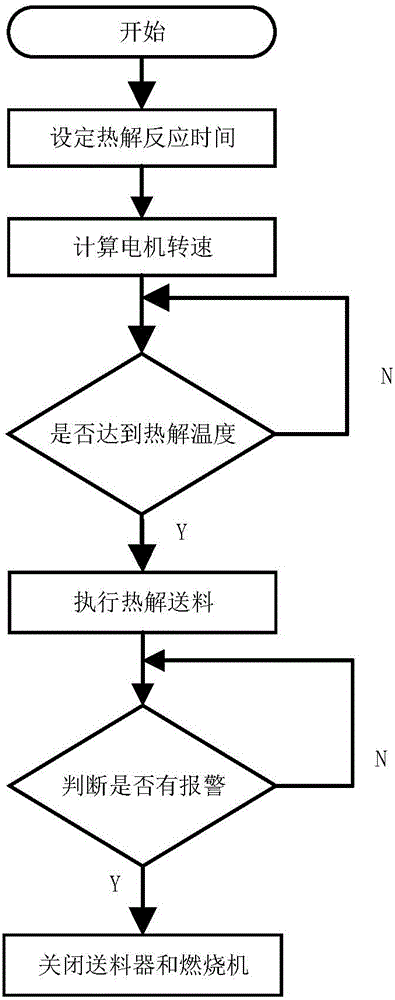

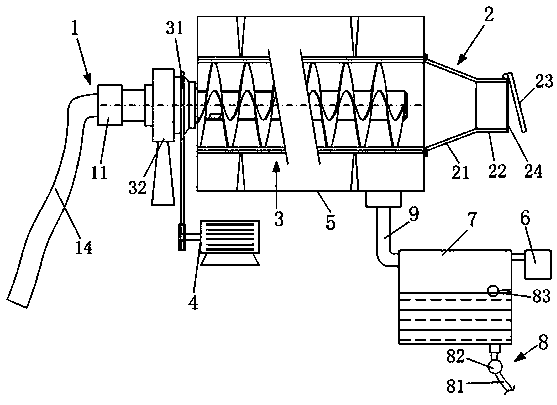

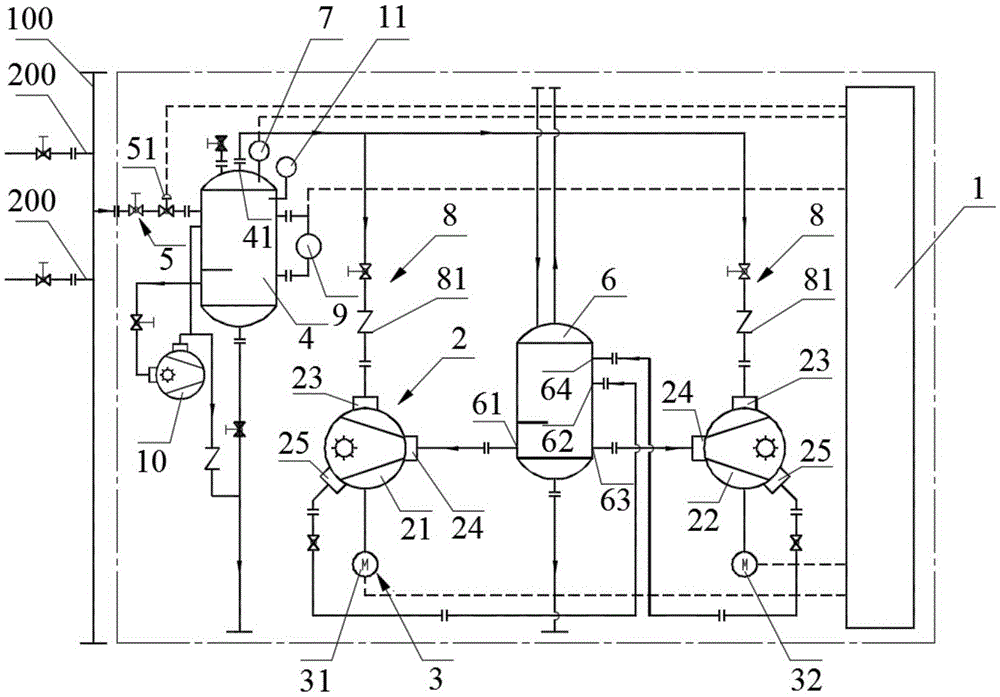

Biomass continuous pyrolysis control system and biomass continuous pyrolysis control method

ActiveCN105005275AEasy to controlSmooth feedingEnergy industryTotal factory controlControl systemProcess engineering

The present invention relates to a biomass continuous pyrolysis control system and a biomass continuous pyrolysis control method. The system comprises hoppers, a continuous pyrolysis reactor and charcoal boxes which are connected orderly, a first-grade condenser communicated with the continuous pyrolysis reactor and the charcoal box simultaneously, a second-grade condenser communicated with the first-grade condenser, and an air storage tank connected with the second-grade condenser and communicated with the continuous pyrolysis reactor. The hoppers comprise a first-grade hopper and a second-grade hopper in which the distance sensors are arranged respectively, a feeding port of the first-grade hopper is equipped with a first valve, and a second valve is arranged at the communication position of the second-grade hopper and the first-grade hopper. The charcoal boxes comprise a first-grade charcoal box and a second-grade charcoal box in which the distance sensors are arranged respectively, the first-grade condenser is communicated with the first-grade charcoal box, and a third valve is arranged at the communication position of the first-grade charcoal box and the second-grade charcoal box. A fourth valve is arranged at a discharging port of the second-grade charcoal box, the distance sensors are all connected with a controller, and the first to fourth valves are all connected with the controller. According to the present invention, the accurate control of feeding and discharging is realized.

Owner:SOUTH CHINA AGRI UNIV

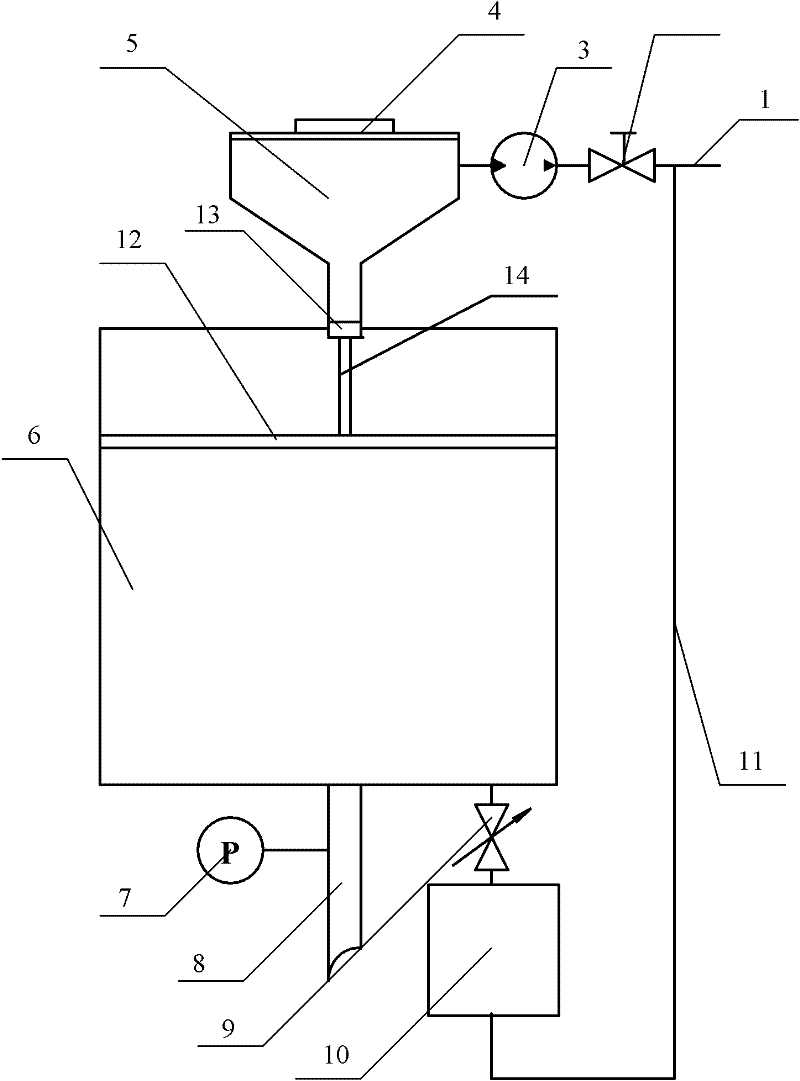

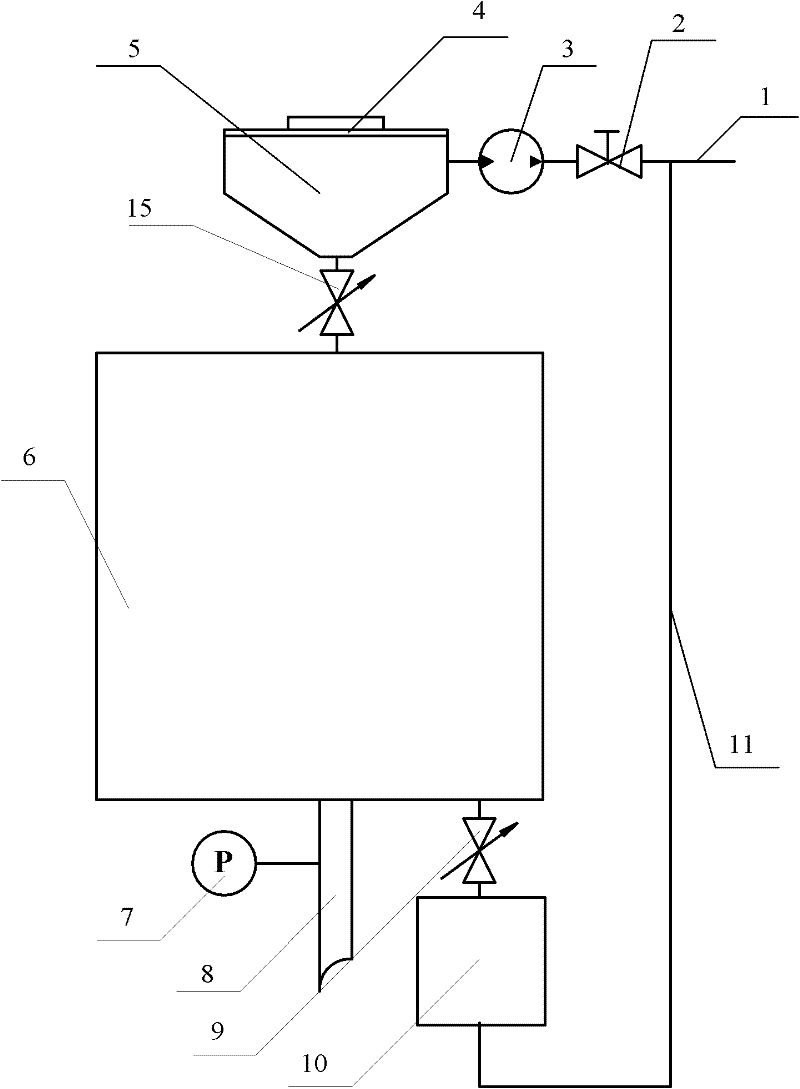

Expansion tank liquid level pressure stabilization device in closed water-cooling circulating system

InactiveCN102251842ALess equipmentSimplify expansion tank voltage stabilization systemMachines/enginesEngine cooling apparatusPipingExpansion tank

The invention aims to provide an expansion tank liquid level pressure stabilization system in a closed water-cooling circulating system. The expansion liquid level pressure stabilization system comprises an expansion tank, an outer water replenishing pipeline, an internal water replenishing pipeline and a container which is a funneled container; a sealing cover is arranged on the funneled container; the outer water replenishing pipeline is connected with the funneled container and the internal water replenishing pipeline respectively; the funneled container is connected with the expansion tank which is connected with a main water pipeline and an auxiliary pipeline respectively; and the auxiliary pipeline is connected with a small water storage tank which is communicated with the internal water replenishing pipeline. The equipment of the conventional nitrogen pressure stabilization system is reduced, the expansion tank pressure stabilization system in the closed water-cooling system is simplified, the problem of small change range and unstability of the expansion tank liquid level pressure is solved, the closed water-cooling system does not stop when the condition of environment is changed, and the reliability of long-term running of the closed water-cooling system is improved.

Owner:HARBIN ENG UNIV

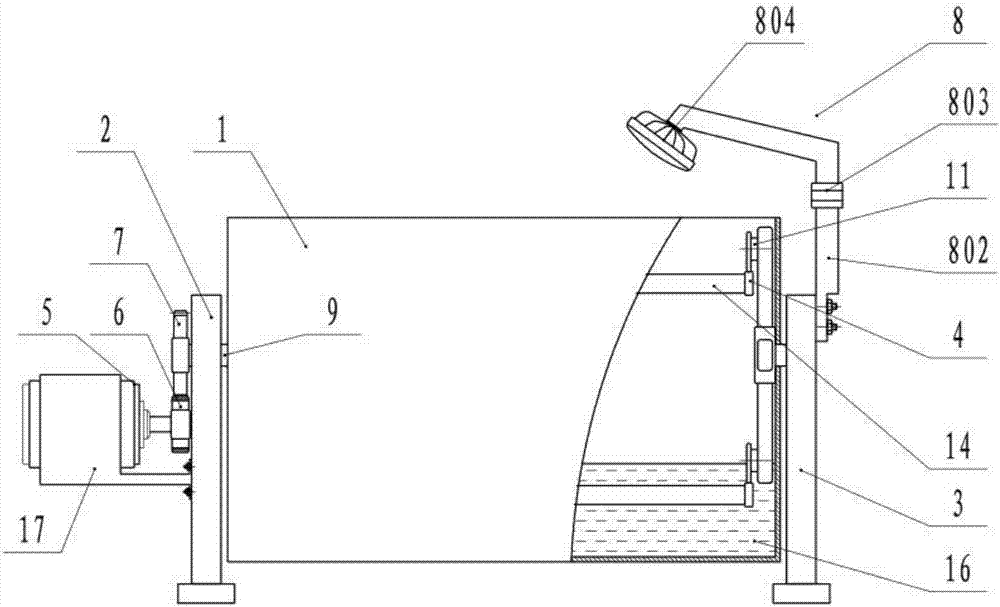

Vacuum suction-type screw-extrusion solid-liquid separation system

ActiveCN103641289AReduce processing timeSave time and costSludge treatment by de-watering/drying/thickeningSuction forceSlag

The invention discloses a vacuum suction-type screw-extrusion solid-liquid separation system. The vacuum suction-type screw-extrusion solid-liquid separation system comprises a screw extruding mechanism, a driving mechanism, a sealing box body, a vacuumizing machine, an airtight water tank and a continuous liquid discharging mechanism, wherein the screw extruding mechanism is connected with a continuous feeding mechanism and a continuous solid discharging mechanism, the driving mechanism is used for providing the rotation power, the screw extruding mechanism is sealed inside the sealing box body, the vacuumizing machine is communicated with the sealing box body through a pipeline and used for providing vacuum suction force to the vacuum suction-type screw-extrusion solid-liquid separation system, the airtight water tank is connected onto a pipeline between the sealing box body and the vacuumizing machine and used for collecting the liquid discharged from the screw extruding mechanism, and the continuous liquid discharging mechanism is arranged on the airtight water tank. By utilizing the integral vacuum suction principle, the vacuumizing machine which is arranged at the rear end is used for providing the vacuum suction force to the entire internal space, the reliability is high, the flow is optimized, the continuous suction function, the continuous solid / slag discharging function and the continuous liquid discharging function can be realized, the sewage waste treatment time is effectively saved, and the time cost and the labor cost can be greatly saved.

Owner:CHENGDU XINCHAOSHUN ENVIRONMENTAL TECH

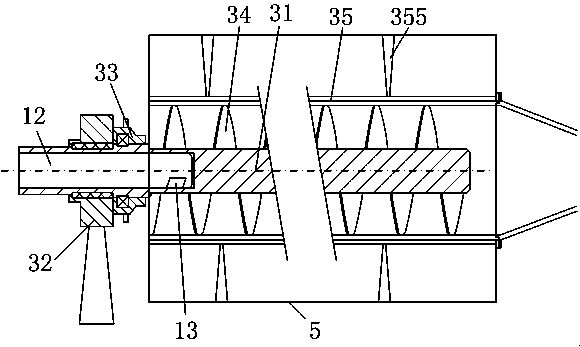

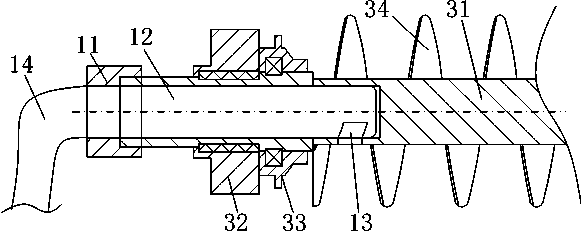

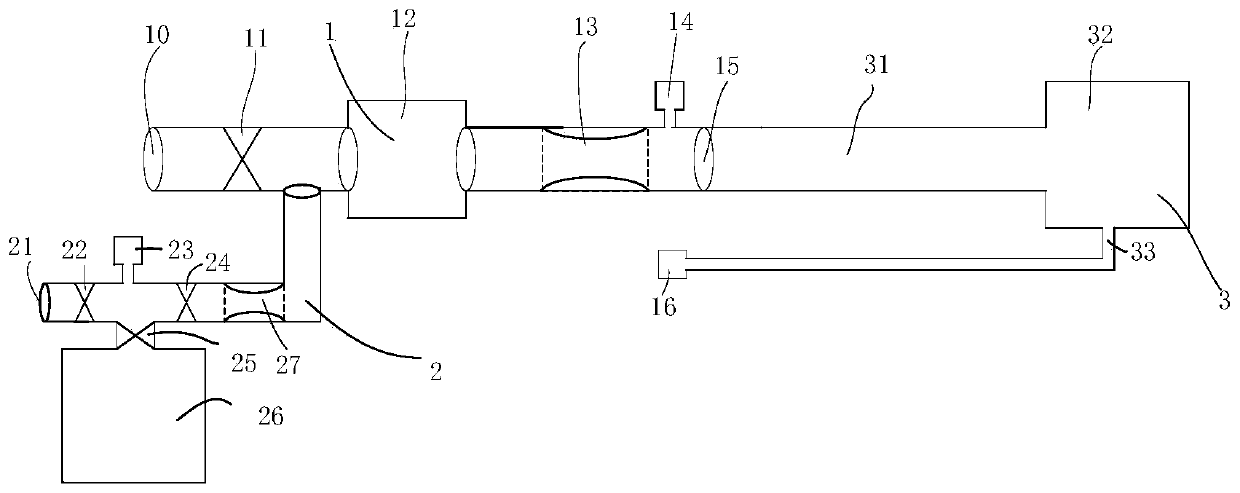

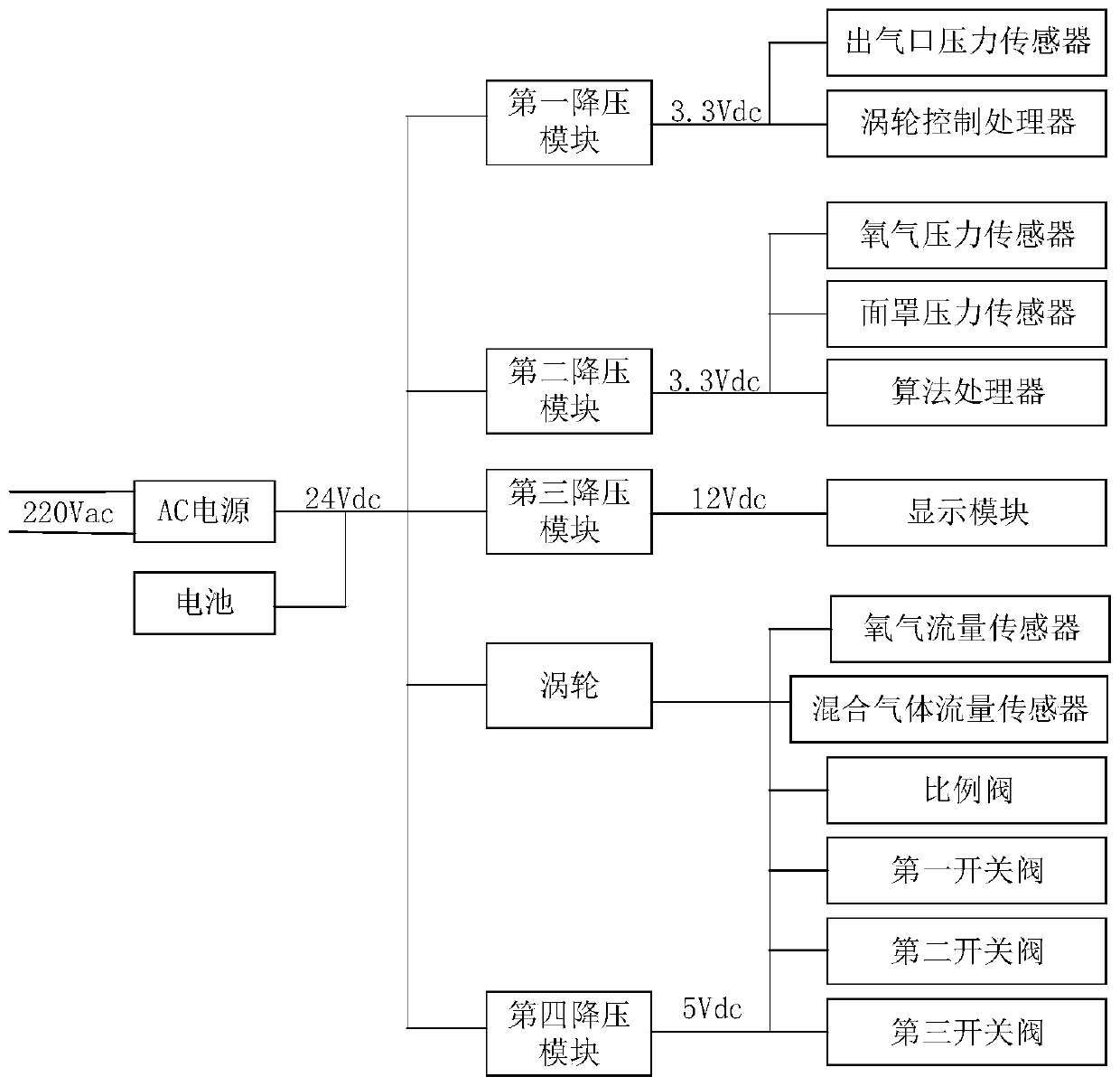

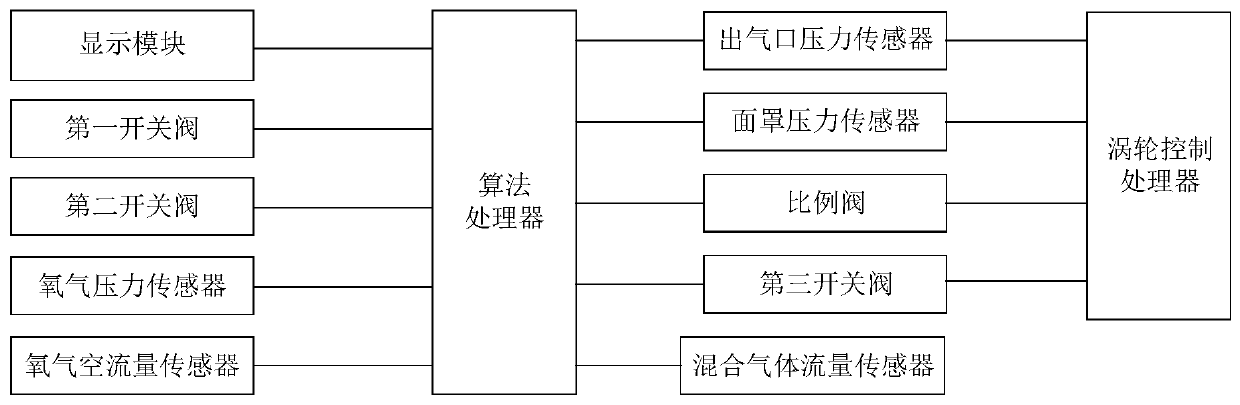

Breathing support equipment airway and safety control system and control method

PendingCN110464933AReduce riskAvoid failureRespiratory masksMedical devicesEngineeringEquipment Safety

The invention provides a breathing support equipment airway and a safety control system and a control method. The breathing support equipment airway comprises: a main air inlet passage, a reserve airinlet passage and a breathing mask, wherein the main air inlet passage is connected with the reserve air inlet passage in parallel and is respectively connected with the breathing mask; a front end ofan air outlet of the main air inlet passage is provided with an air outlet pressure sensor; the breathing mask comprises a mask body, the mask body is provided with a pressure collecting port, and the pressure collecting port is provided with a mask pressure sensor. The control method of the breathing support equipment safety control system is also provided. A processor module, a turbine module,a pressure sensor and a power module of the breathing support equipment safety control system are respectively provided with a backup module, so that the processor module, the turbine module, the pressure sensor and the power module not only can work jointly, but also can work independently to complete an air supply function. When one of the modules fails, the other module can replace the work ofthe current module, maintain an output pressure of the breathing support equipment, maintain a user's normal breathing, and ensure the user's life safety.

Owner:HUNAN MICOME ZHONGJIN MEDICAL SCI & TECH DEV CO LTD

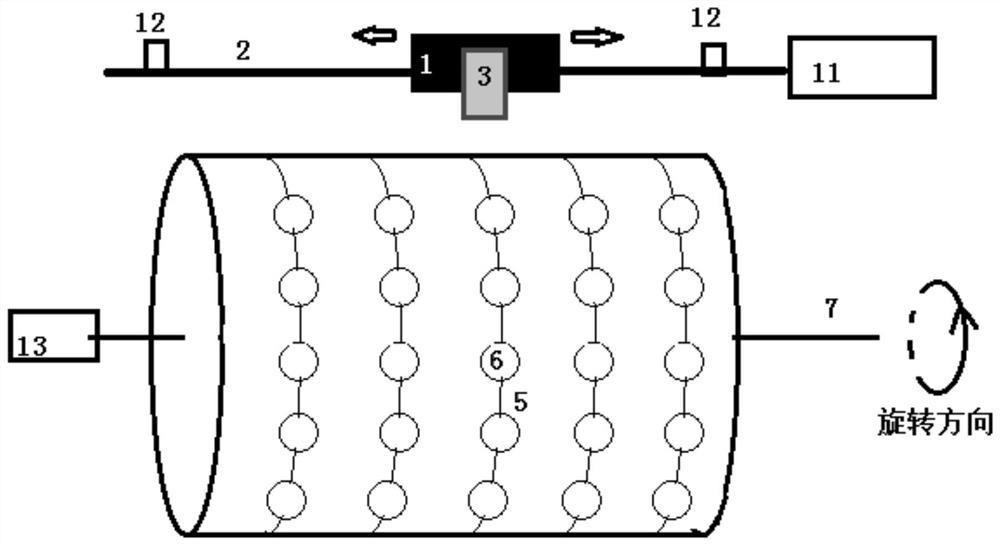

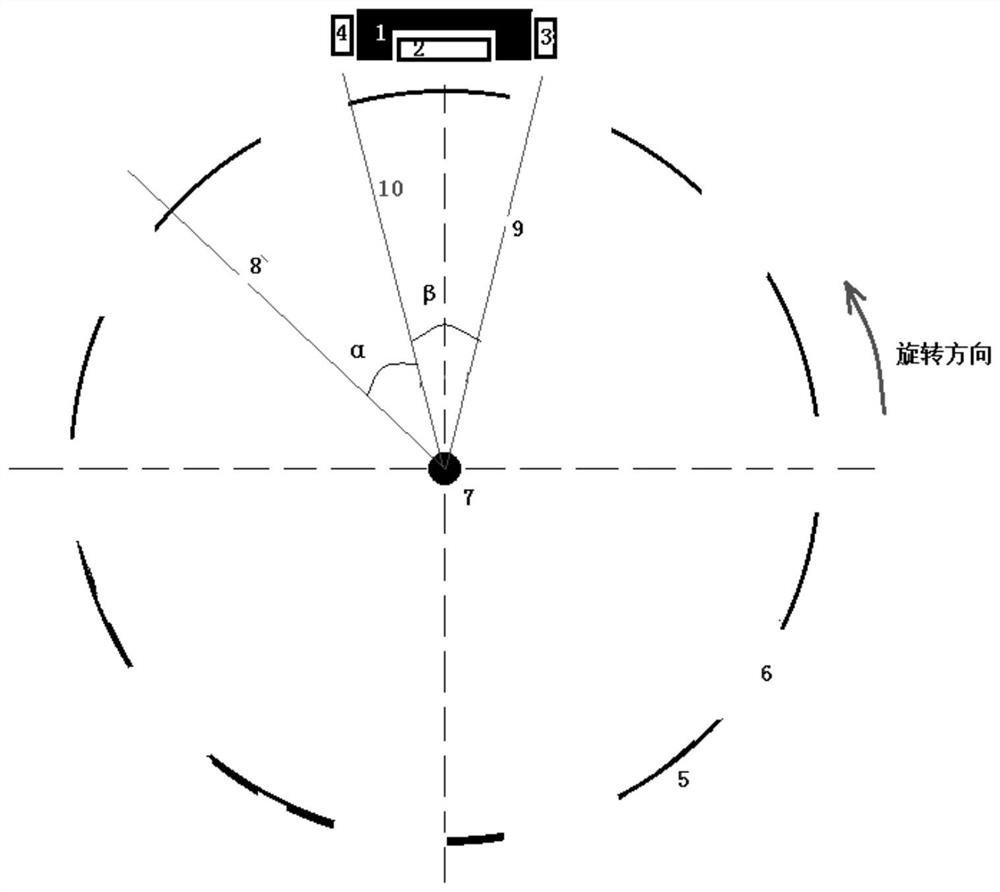

Drum screen mesh unblocking device and drum screen mesh unblocking method

ActiveCN113070200AImprove detection accuracyQuick responseSievingScreeningLaser rangingRotational axis

The invention further discloses a drum screen mesh unblocking device. A stepping motor drives a sliding block to move on a sliding rail in a reciprocating mode, and a laser ranging system and a gas nozzle of an unblocking system are fixed to the two sides of the sliding block, right face the drum curved surface of the drum screen and move along with the sliding block. the laser ranging system measures the laser irradiation distance, an angle encoding system determines the rotating angle of the drum around a rotating shaft relative to the 0 position, a control system judges whether the screen meshes are blocked or not, and a gas spray head of the unblocking system is used for flushing the blocked screen meshes. The invention further discloses a drum screen mesh unblocking method. The device and a drum screen system work synchronously, the drum is not required to rotate at a constant speed, each screen mesh can be scanned, the state of the screen meshes can be automatically detected, and unblocking operation can be automatically carried out; and positioning, distance measurement, recognition and unblocking are conducted in a reciprocating mode, it is guaranteed that the drum screen equipment is not stopped in the using process, and therefore the equipment using efficiency is improved, and the labor intensity of workers is reduced.

Owner:NANJING UNIV

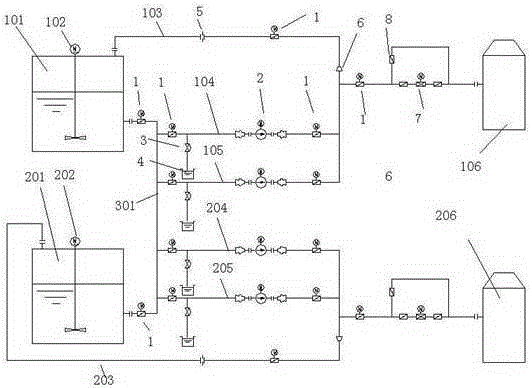

Slurry feed system of desulfurized limestone

The invention discloses a slurry feed system of desulfurized limestone, comprising a plurality of limestone slurry boxes, wherein the limestone slurry boxes are connected in series though a communicating pipeline, the communicating pipeline is connected with a plurality of slurry pumping pipelines, the slurry pumping pipelines are connected with desulfurizing towers by slurry pumps, and each limestone slurry box is internally provided with a stirrer. By using the arrangement of the plurality of limestone slurry boxes and a mode of operation of the plurality of desulfurizing towers, non-stop can be guaranteed when overhauling, and the plurality of limestone slurry boxes are connected in series, so that when a part of the limestone slurry boxes is overhauled, the overhauled part can use the adjacent limestone slurry boxes to operate.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

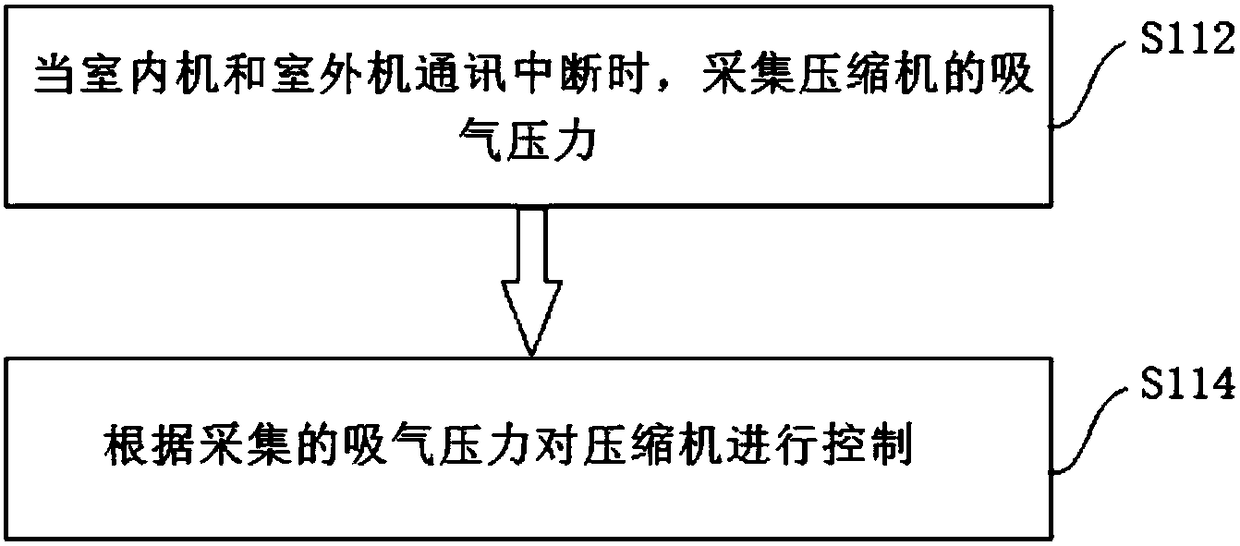

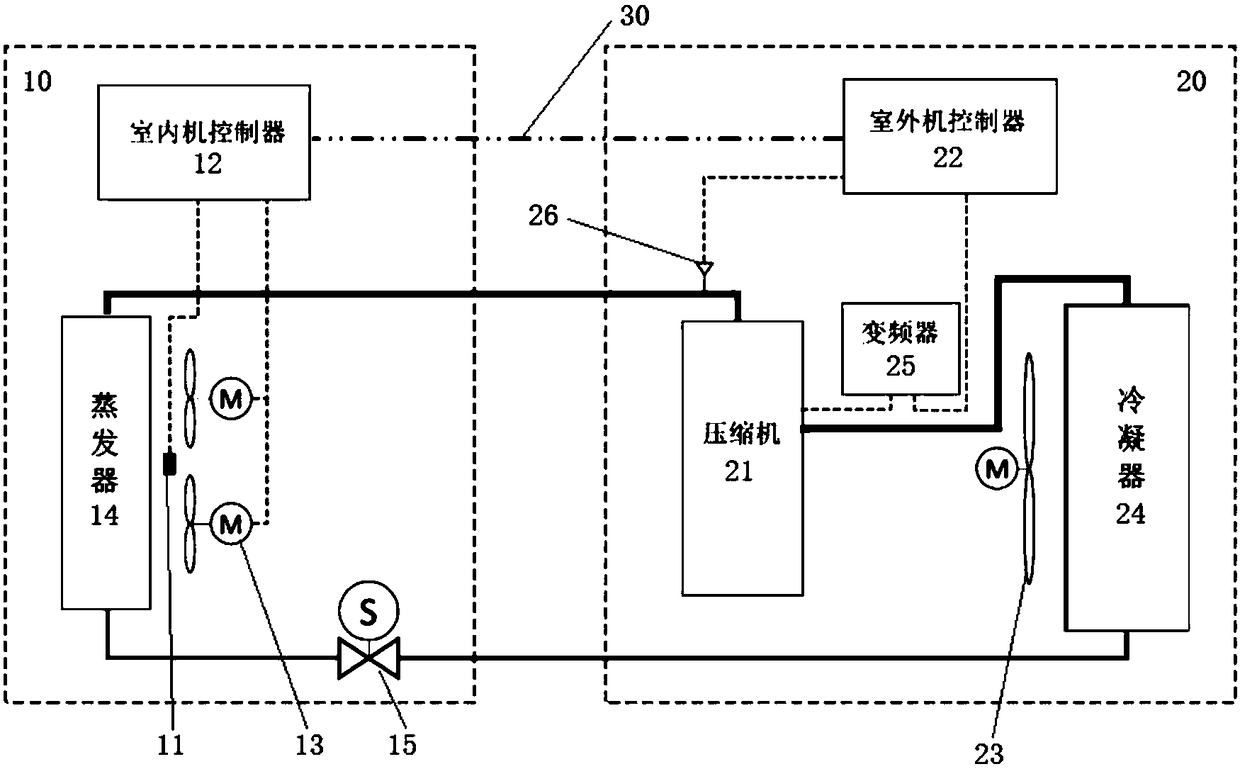

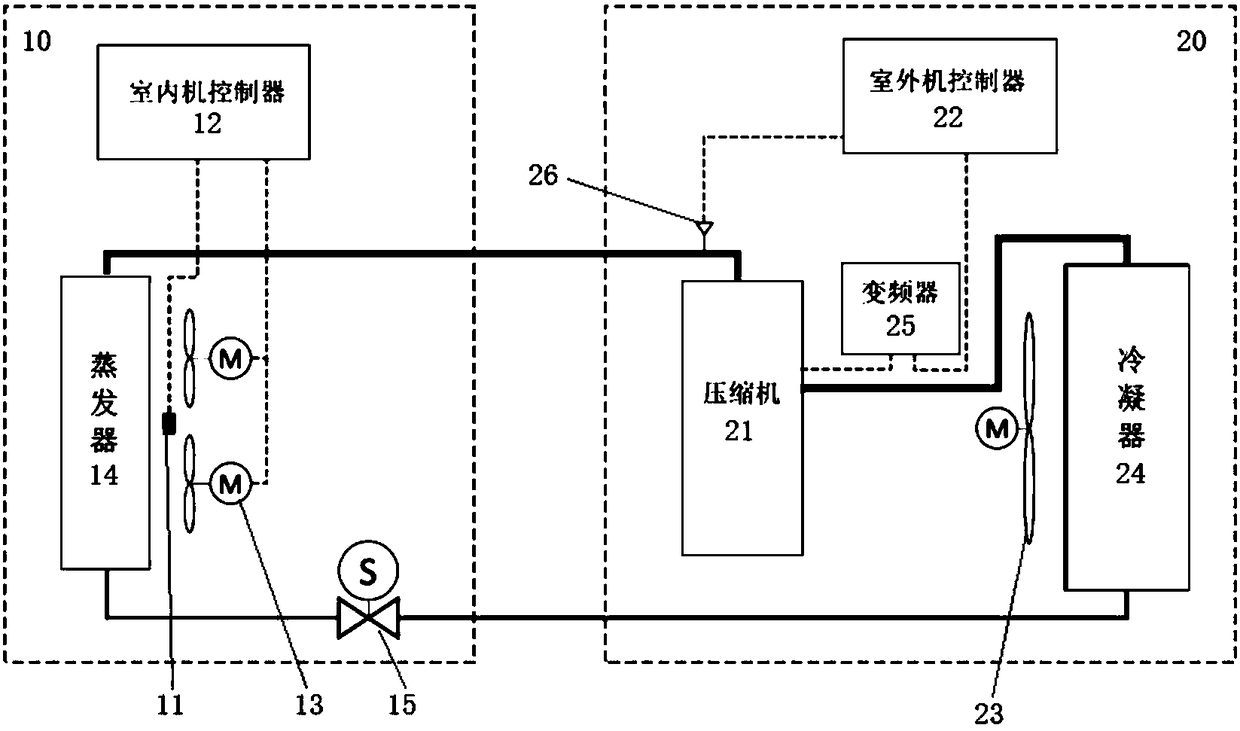

Control method and device of air conditioning system

InactiveCN108180540AGuaranteed non-stopMechanical apparatusLighting and heating apparatusAir conditioningEmergency control

The invention discloses a control method and device of an air conditioning system. The control method comprises the following steps: when communication between an indoor unit and an outdoor unit is cut off, suction pressure of a compressor is acquired; and the compressor is controlled according to the acquired suction pressure. The invention provides an emergency control logic when communication between the indoor unit and the outdoor unit is cut off, and can guarantee no stop of the air conditioning system when communication between the indoor unit and the outdoor unit is cut off.

Owner:SUGON DATAENERGYBEIJING CO LTD

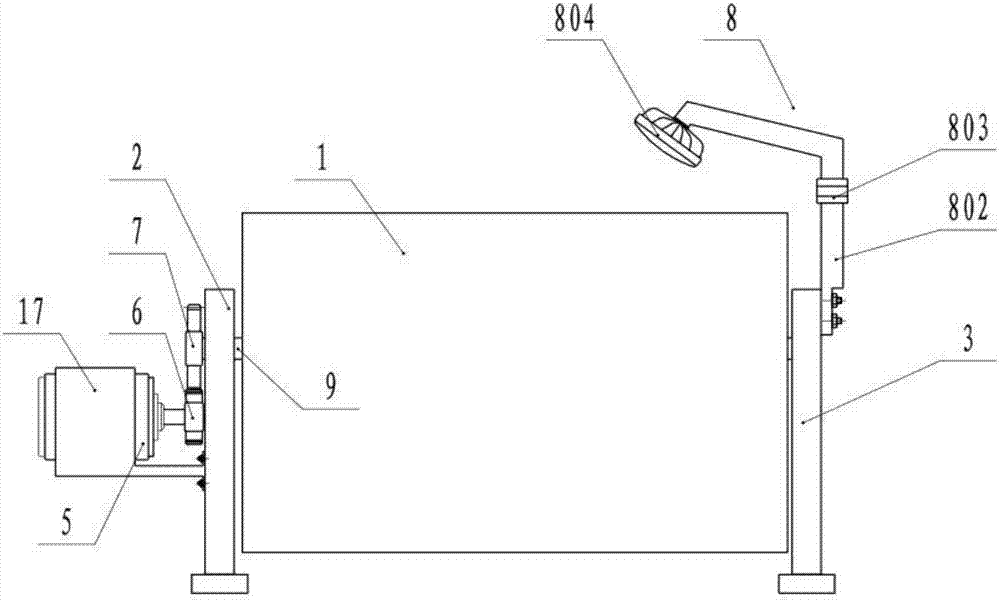

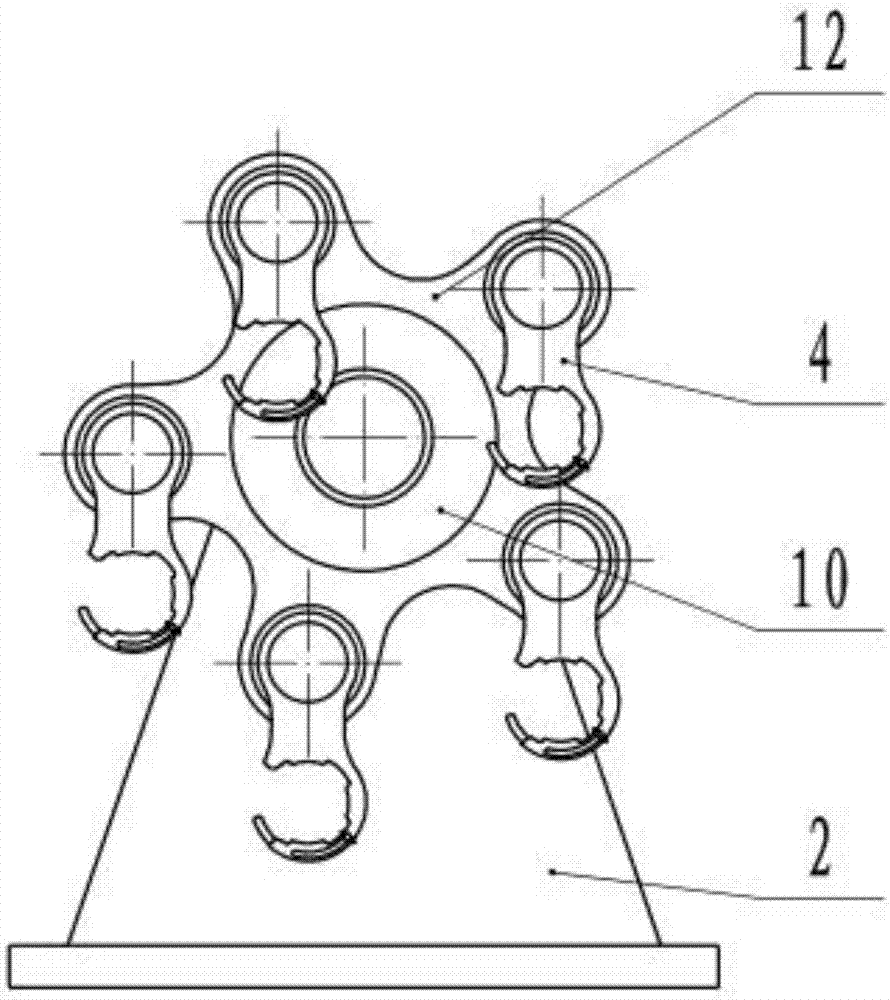

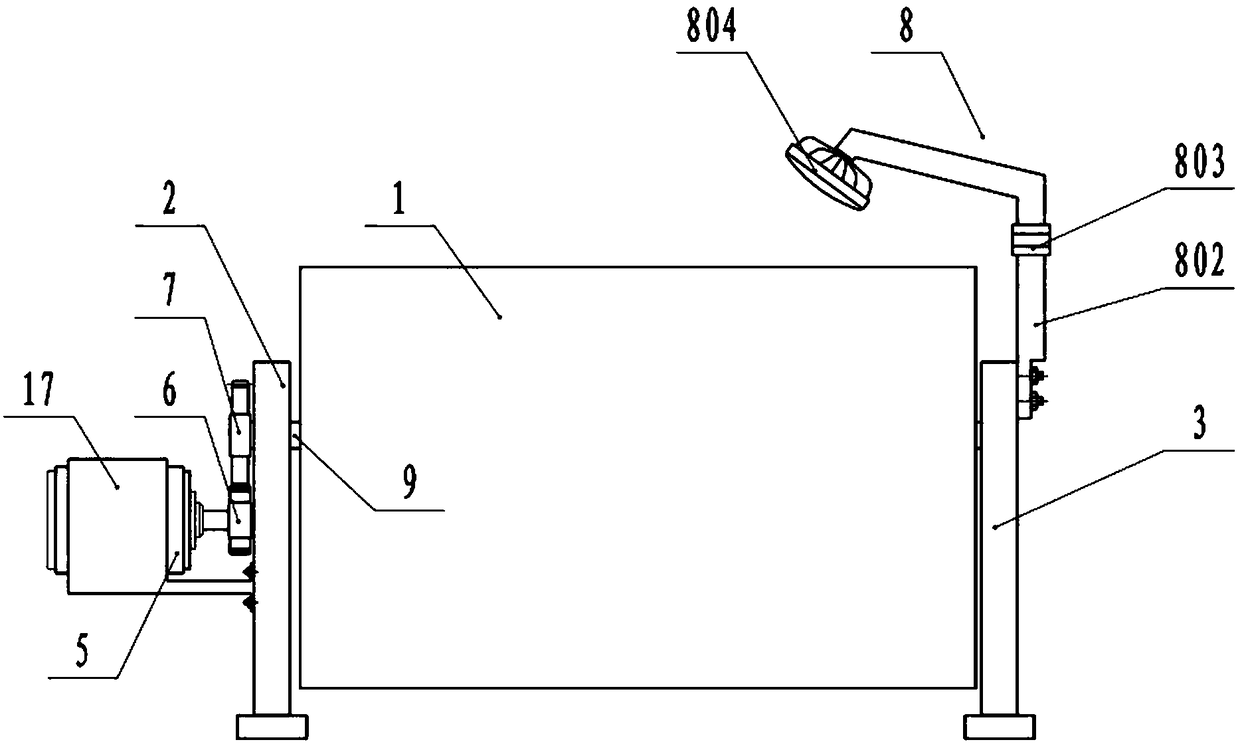

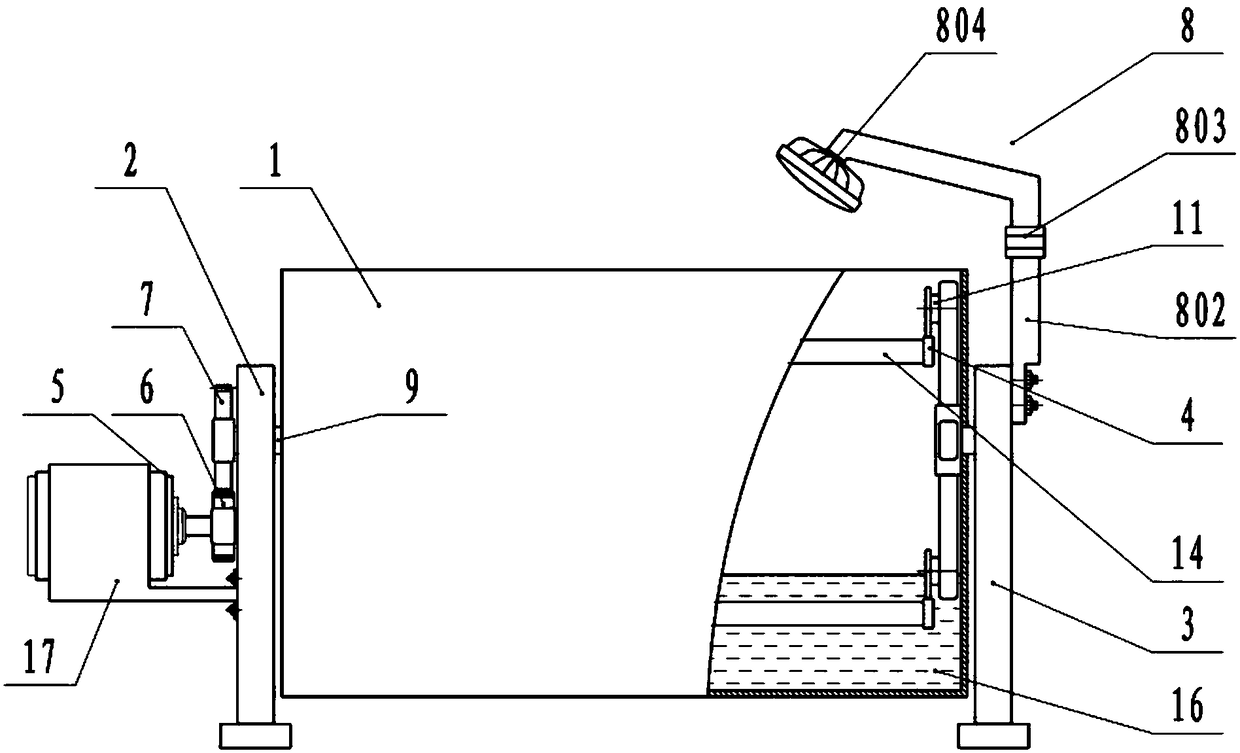

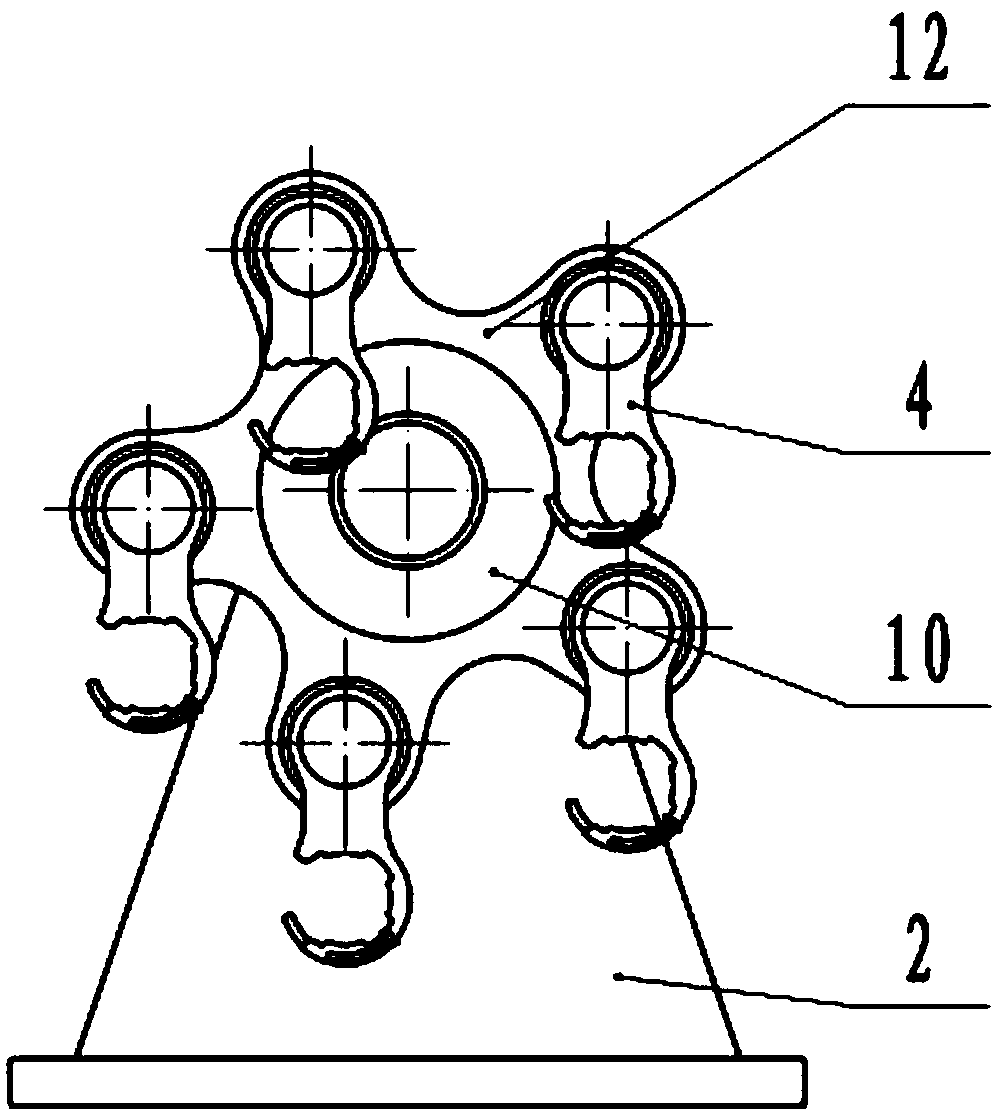

Pipe welding outward galvanization device

The invention discloses a pipe welding outward galvanization device, and belongs to the technical field of pipe welding outward galvanization. A first fixing base and a second fixing base are arranged on the two sides of a zinc pot correspondingly, an electric motor is arranged on the outer side of the first fixing base, a driving gear is arranged at the power output end of the electric motor, and is engaged with a driven gear, the driven gear is arranged on the outer side of the first fixing base through a connecting shaft, the connecting shaft transversely penetrates the first fixing base and extends to the interior of the zinc pot, a gear disc is arranged at the end of the connecting shaft, five outwards-extending wheel teeth are at least arranged on the peripheral edge of the gear disc evenly, a hanging pipe device is rotatably connected to the outer side of each wheel tooth through a rotating shaft, and a zinc blowing device is fixedly connected to the outer side of the second fixing base. The device has the beneficial effects that manual labor force is reduced, and the welding pipe galvanization work efficiency is greatly improved.

Owner:桐乡乐维新材料有限公司

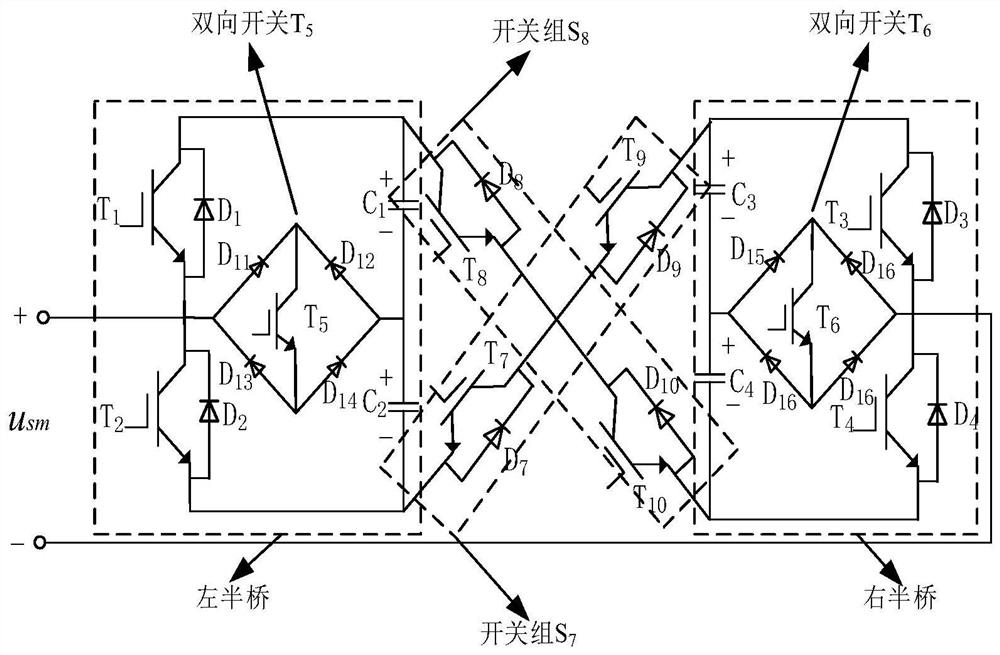

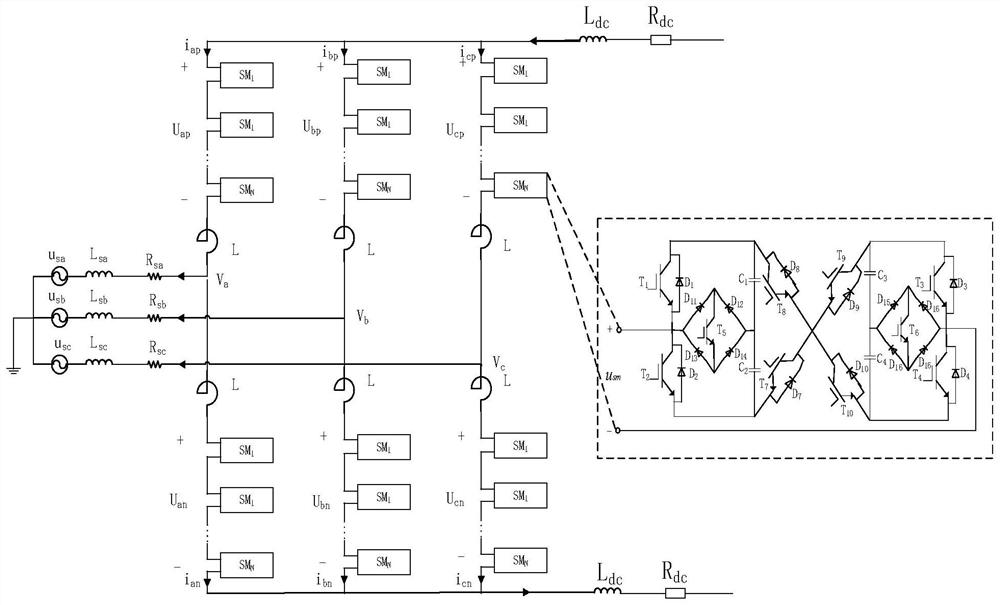

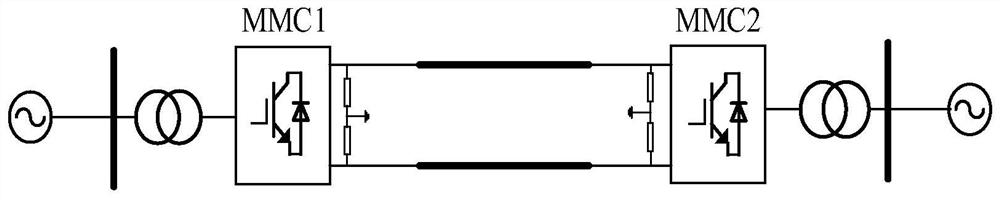

Five-level clamping cross type sub-module topological structure of modular multi-level converter

PendingCN113300622AAvoid capacitor voltage divergenceFast troubleshootingAc-dc conversionElectric power transfer ac networkDc faultAc circuit

The invention relates to a five-level clamping cross type sub-module topological structure of a modular multilevel converter, and belongs to the technical field of flexible direct-current power transmission. The MMC sub-module topology comprises an MMC sub-module topology, the MMC sub-module topology comprises sub-module output ends, the sub-module output ends are a voltage anode output end and a voltage cathode output end, the MMC sub-module topology further comprises a left half-bridge and a right half-bridge which are the same in structure, and the two half-bridges are connected through a power switch group S7 and a power switch group S8 which are crossed. The method has the rapid DC fault clearing capability, an AC switch does not need to be tripped off, the problems of capacitor voltage divergence possibly caused by long-time locking and action of an AC circuit breaker are avoided, and the non-locking mode is beneficial to rapid recovery of stable operation after the MMC breaks down.

Owner:KUNMING UNIV OF SCI & TECH

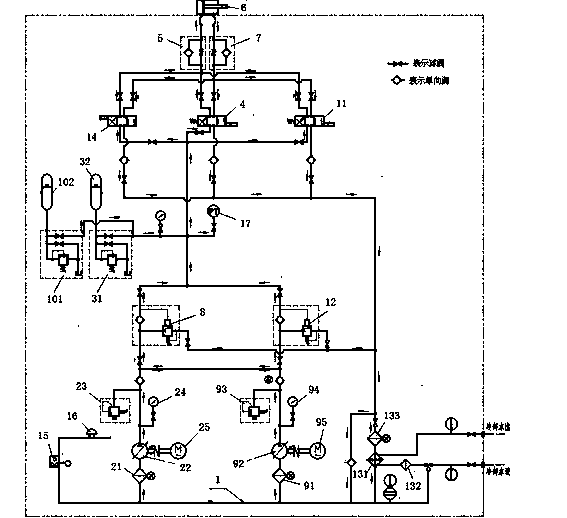

Multistage-protection hydraulic device

The invention discloses a multistage-protection hydraulic device which comprises an oil tank, a first oil pumping assembly, a first energy storage control assembly, a first electromagnetic reversing valve, an oil feeding throttling valve, an oil cylinder and an oil return throttling valve which are connected through a pipeline. The device further comprises a second oil pumping assembly, a second energy storage control assembly, a second electromagnetic reversing valve and a second unloading valve. An inlet of the second oil pumping assembly is connected with the oil tank, and an outlet of the second oil pumping assembly is connected with an outlet of the first oil pumping assembly. The second energy storage control assembly is connected onto an oil feeding pipeline between the second oil pumping assembly and the first electromagnetic reversing valve. The device adopts two hydraulic sources, one is operated, and the other is for hot spare onsite. Once one hydraulic source breaks down, the source is switched immediately onsite, greater damage to the device and caused by the fact that a worker needs to move from a control chamber to the site of the device is avoided, and the hydraulic device does not shut down. Further, energy storage devices, unloading valves, overflowing valves and electromagnetic valves are all arranged in two sets and can be optionally switched in use, and multistage protection can be achieved by means of combination use.

Owner:SHANGHAI PUDONG HANWEI VALVE

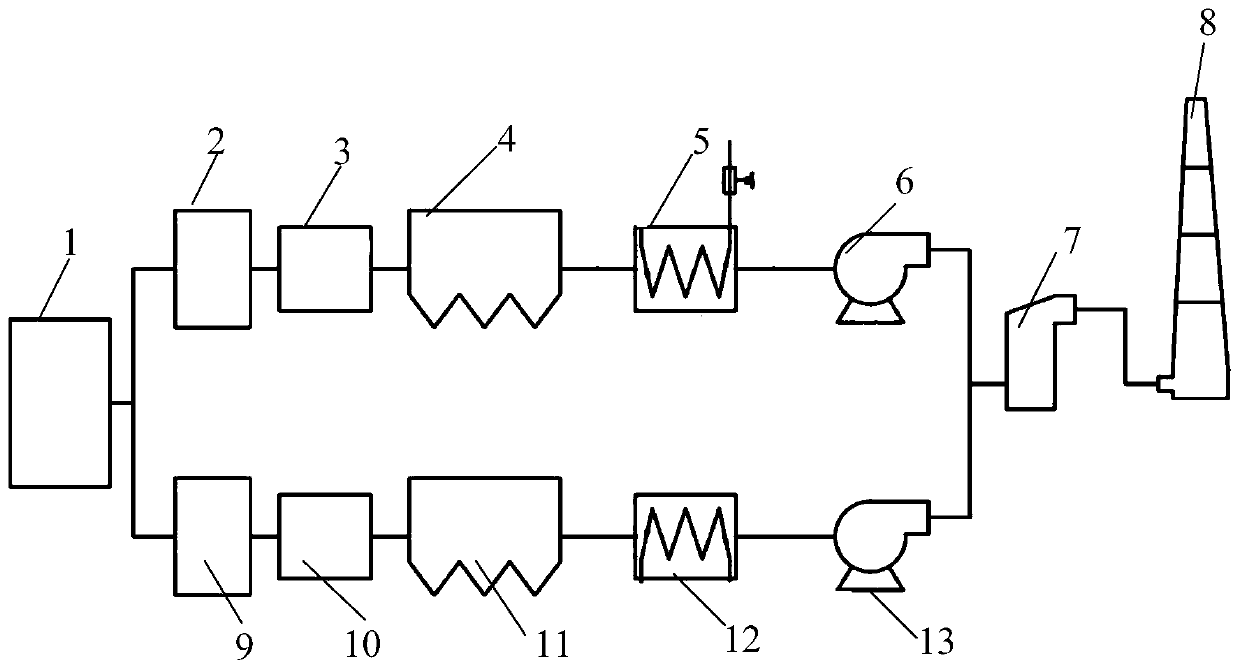

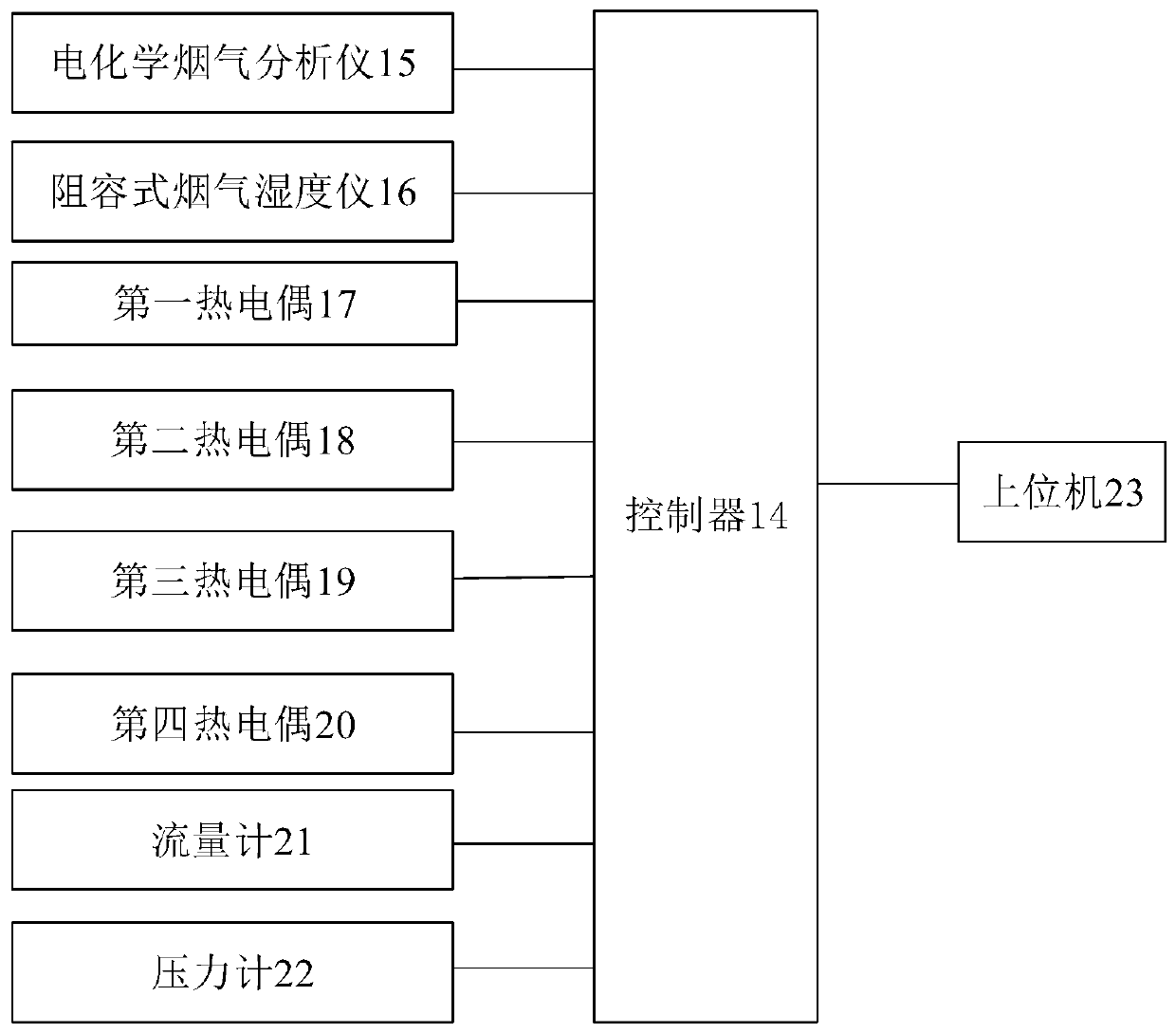

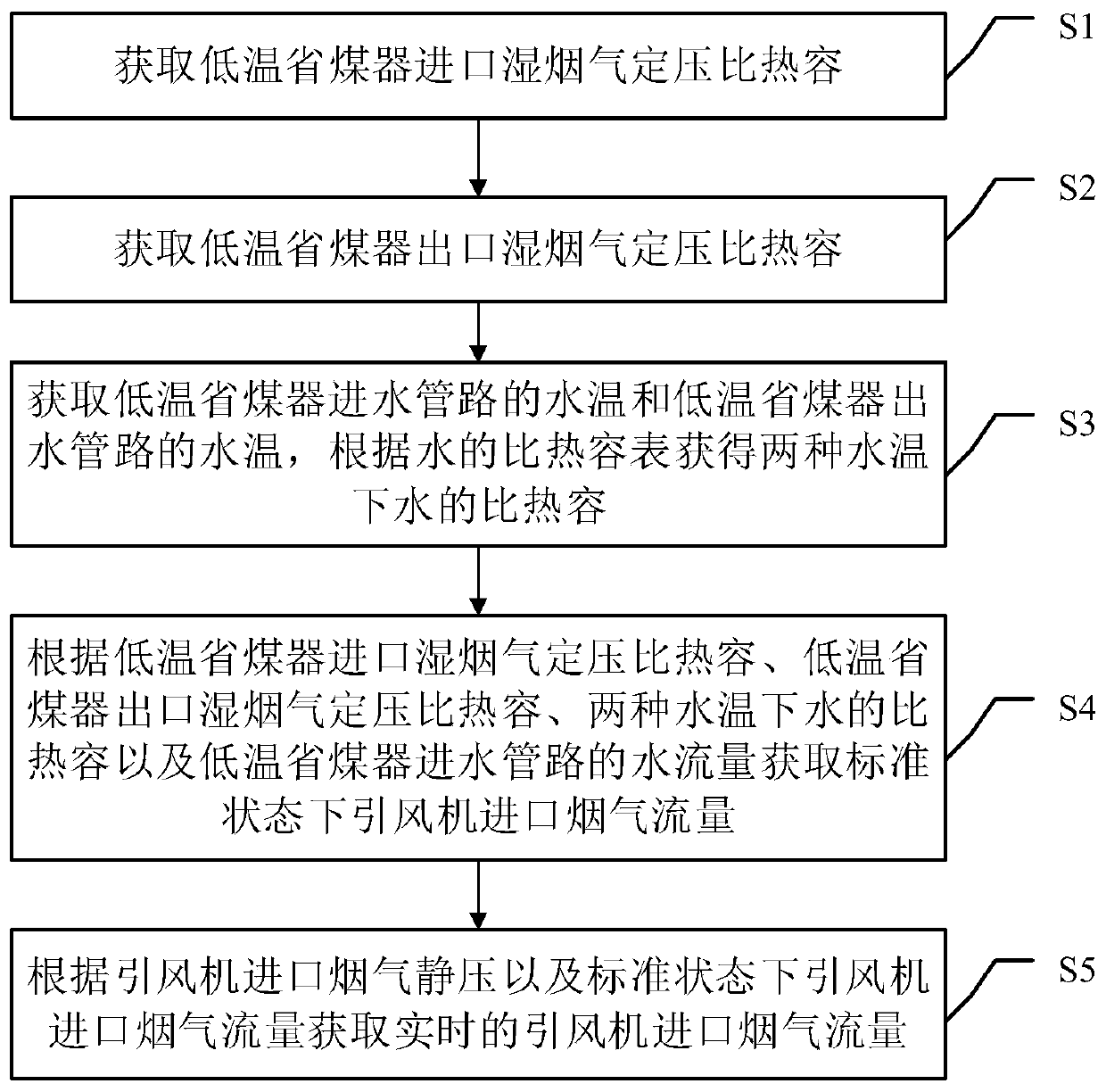

Induced draft fan inlet flue gas flow measuring device and method

PendingCN111521226AEasy to measureShort timeVolume/mass flow by thermal effectsMaterial heat developmentAir preheaterCapacitance

The invention discloses an induced draft fan inlet flue gas flow measuring device and method. The device comprises a boiler, a first SCR denitration device, a first air preheater, a first dust remover, a first low-temperature economizer, a first induced draft fan, a desulfurizing tower and a chimney which are sequentially connected through a pipeline. An electrochemical flue gas analyzer, a resistance-capacitance type flue gas hygrometer, a first thermocouple and a second thermocouple which are electrically connected with the controller are arranged on a pipeline in front of the first low-temperature economizer. A third thermocouple, a fourth thermocouple, a flow meter and a pressure meter which are electrically connected with the controller are arranged on a pipeline behind the first low-temperature economizer. The device has the advantages that the flue gas flow at the inlet of the induced draft fan is measured, the flue gas flow does not need to be indirectly obtained from slag, slag component extraction does not need to be quantitatively analyzed, the measurement method is simple, and consumed time is short.

Owner:CHINA DATANG CORP SCI & TECH RES INST CO LTD EAST CHINA BRANCH +1

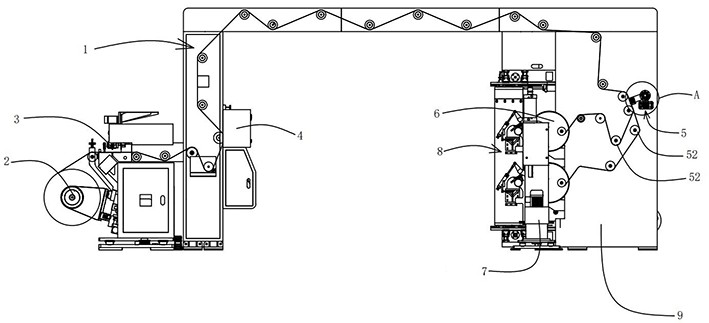

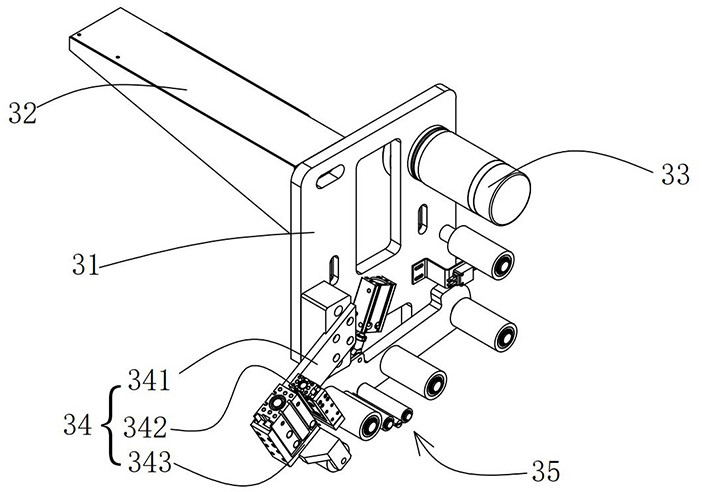

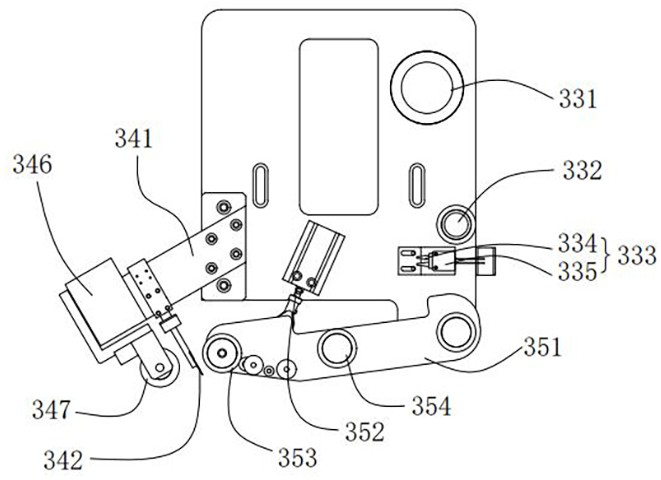

Viscous material slitting and rolling system

PendingCN114476768AWill not affect slitting and windingGuaranteed non-stopWebs handlingEngineeringPipe

The invention relates to the technical field of slitting and rolling, in particular to a viscous material slitting and rolling system which comprises a guide assembly feeding mechanism, a pipe moving mechanism, a material receiving mechanism, a labeling mechanism, a slitting mechanism, a rolling mechanism and a discharging mechanism. The guiding mechanism is used for guiding viscous materials to pass through the material receiving mechanism, the labeling mechanism and the slitting mechanism in sequence and then conveying the viscous materials to the winding mechanism, and the pipe moving mechanism is used for feeding a coiled pipe to the winding mechanism and transferring the coiled pipe to the discharging mechanism. The material receiving mechanism is arranged and used for flatly cutting and then connecting the tail ends of the viscous materials, it is guaranteed that follow-up slitting and winding of the materials are not affected due to the fact that the connecting positions of the materials are not tidy, and it is guaranteed that automatic slitting and winding are carried out without shutdown.

Owner:DONGGUAN TURUI MECHANICS

An external galvanizing device for welded pipes

The invention discloses a pipe welding outward galvanization device, and belongs to the technical field of pipe welding outward galvanization. A first fixing base and a second fixing base are arranged on the two sides of a zinc pot correspondingly, an electric motor is arranged on the outer side of the first fixing base, a driving gear is arranged at the power output end of the electric motor, and is engaged with a driven gear, the driven gear is arranged on the outer side of the first fixing base through a connecting shaft, the connecting shaft transversely penetrates the first fixing base and extends to the interior of the zinc pot, a gear disc is arranged at the end of the connecting shaft, five outwards-extending wheel teeth are at least arranged on the peripheral edge of the gear disc evenly, a hanging pipe device is rotatably connected to the outer side of each wheel tooth through a rotating shaft, and a zinc blowing device is fixedly connected to the outer side of the second fixing base. The device has the beneficial effects that manual labor force is reduced, and the welding pipe galvanization work efficiency is greatly improved.

Owner:桐乡乐维新材料有限公司

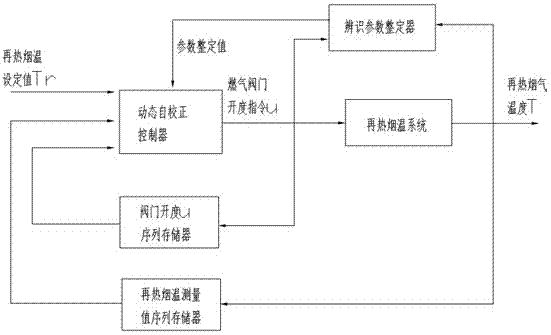

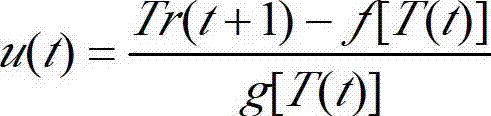

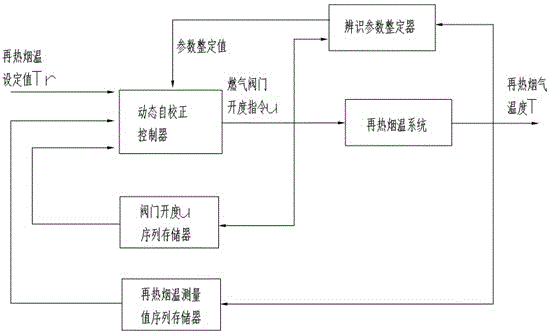

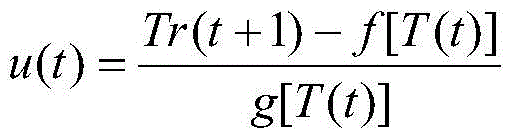

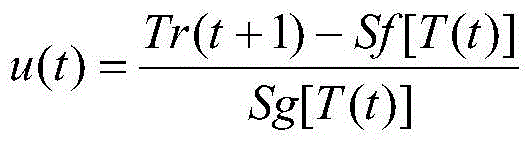

Dynamic self-correction control method of reheating smoke temperature of waste heat boiler

ActiveCN103076742ASimplify structural complexityQuick responseAdaptive controlHysteresisAutomatic control

The invention discloses a dynamic self-correction control method of reheating smoke temperature of a waste heat boiler. The method comprises the following steps of according to a dynamic self-correction control model of a controlled object obtained by a step response test of reheating smoke temperature settings, enabling an automatic control system of the reheating smoke temperature of the waste heat boiler to record a gas valve opening instruction sequence and a reheating smoke temperature measuring value sequence in a real-time way; and dynamically setting each parameter by a controller, so as to obtain the current gas valve opening increment instruction. The method has the advantages that the dynamic performance of the reheating smoke temperature control system of the waste heat boiler is improved, and the problems of large hysteresis and slow response speed of the reheating smoke temperature control system are effectively solved; the offset range between the reheating smoke temperature and the specified value is ensured, and the stability of the reheating smoke temperature control system is improved; and meanwhile, the stop of the waste heat boiler is avoided under the accident working conditions of great change of a waste heat source, no waste heat source, and the like.

Owner:南京博纳能源环保科技有限公司

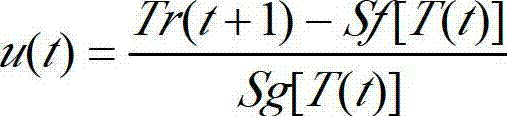

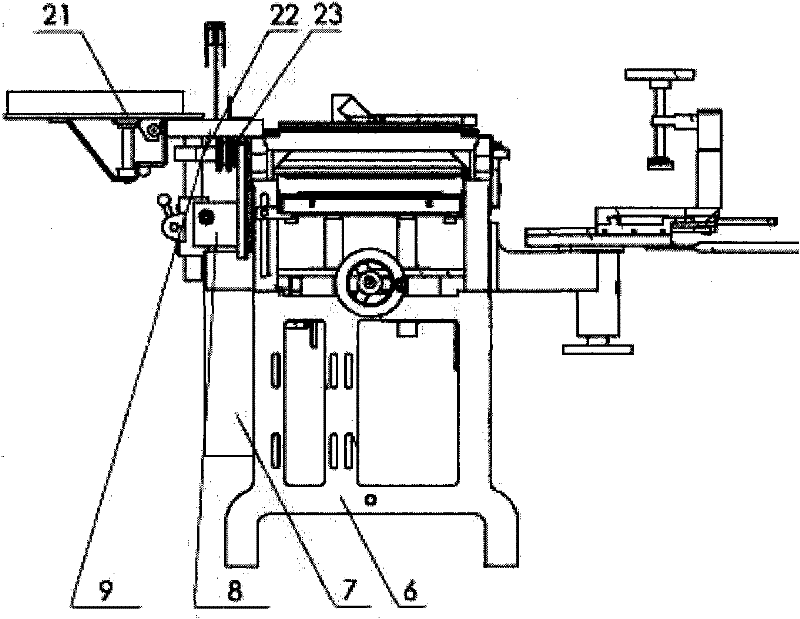

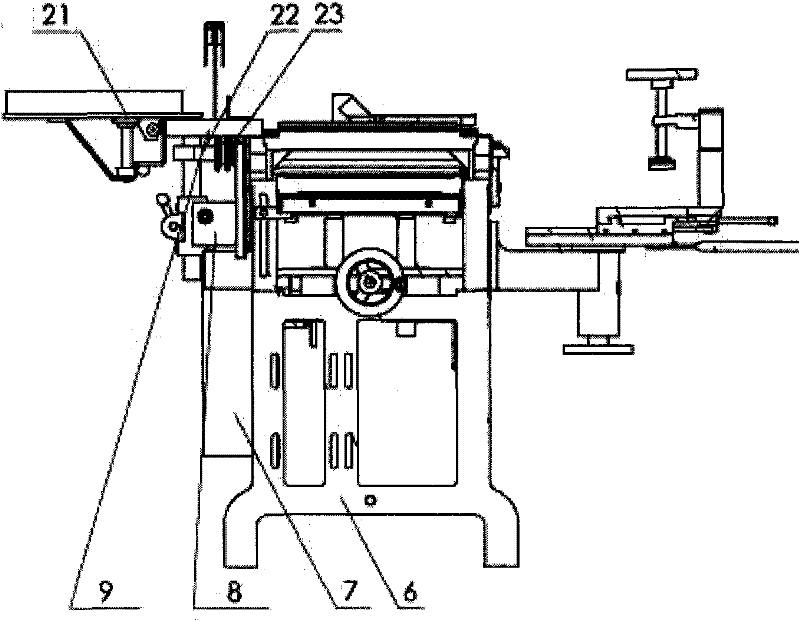

A multifunctional woodworking machine tool sawing mechanism

InactiveCN102259359AIncreased strength and service lifeLow costMulti-purpose machinesAgricultural engineeringWoodworking machine

The invention provides a sawing mechanism of a multifunctional woodworking machine tool, comprising a sawing mechanism, a main cutter shaft, a main cutter shaft pulley, a motor, a left bracket, a right bracket and a bracket connecting rod, and the sawing mechanism is installed on the left bracket and the right bracket , a bracket connecting rod is installed between the left side of the bracket and the right side of the bracket, the motor is connected to the main cutter shaft pulley, the main cutter shaft pulley is connected to the main cutter shaft, and the main cutter shaft pulley is provided with a pulley guard. The invention improves the strength and service life of the woodworking machine tool, and can reduce the cost and improve the economic benefit.

Owner:吴廷飞

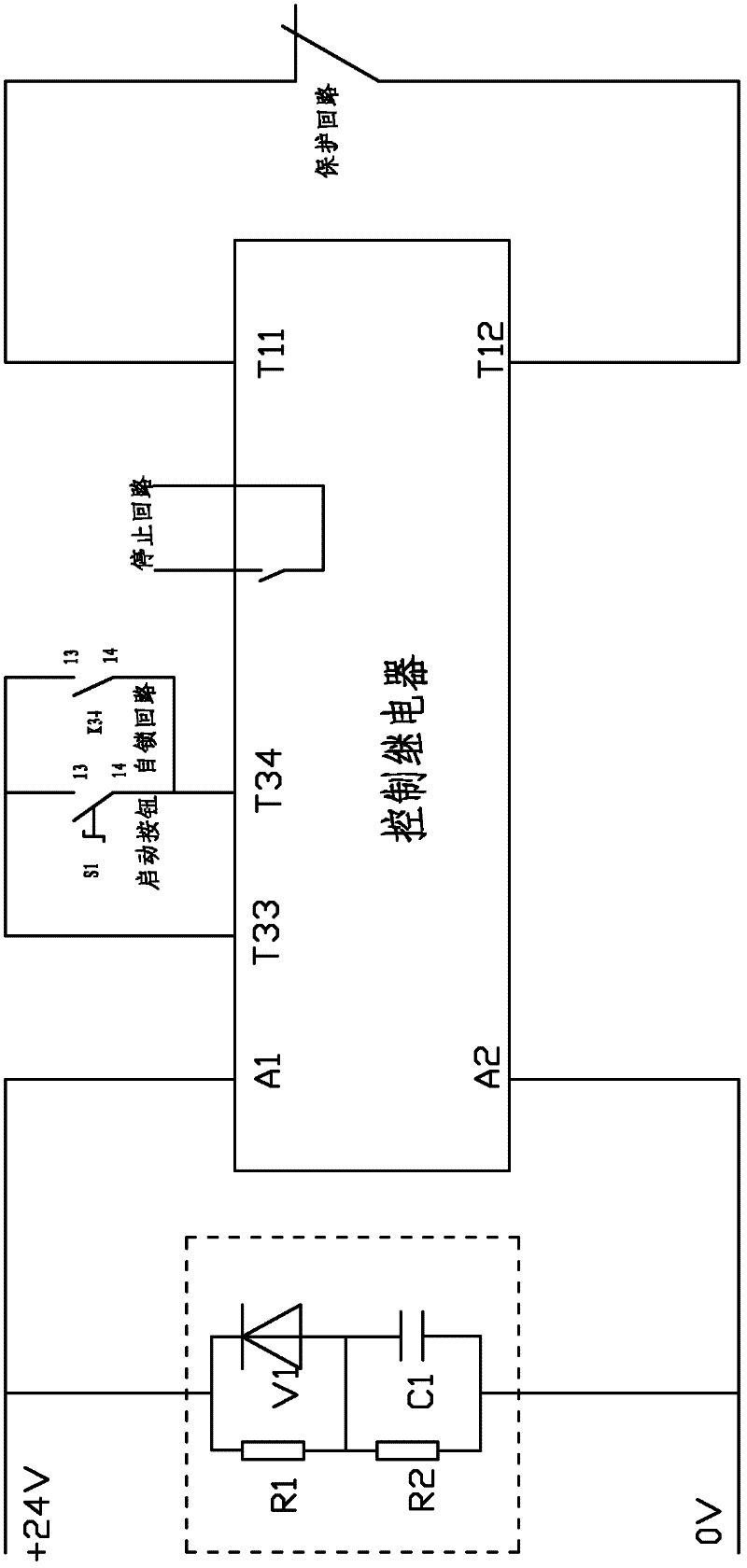

Voltage instantaneous fluctuation prevention protector for elasticizer

The invention discloses a voltage instantaneous fluctuation prevention protector for an elasticizer. The voltage instantaneous fluctuation prevention protector comprises a charging / discharging circuit, wherein the charging / discharging circuit is connected between a direct current power supply of the elasticizer and a load and comprises a current-limiting resistor R1, a charging / discharging capacitor C1 and a discharging diode V1, one end of the current-limiting resistor R1 and the output end of the discharging diode V1 are connected with the positive electrode of the direct current power supply of the elasticizer, the other end of the current-limiting resistor R1 and the input end of the discharging diode V1 are connected with the one end of the charging / discharging capacitor C1, and the other end of the charging / discharging capacitor C1 is grounded. The voltage instantaneous fluctuation prevention protector for the elasticizer has the advantages of simple structure, very low cost and subsequent maintenance cost and very strong practicability.

Owner:烟台华润锦纶有限公司

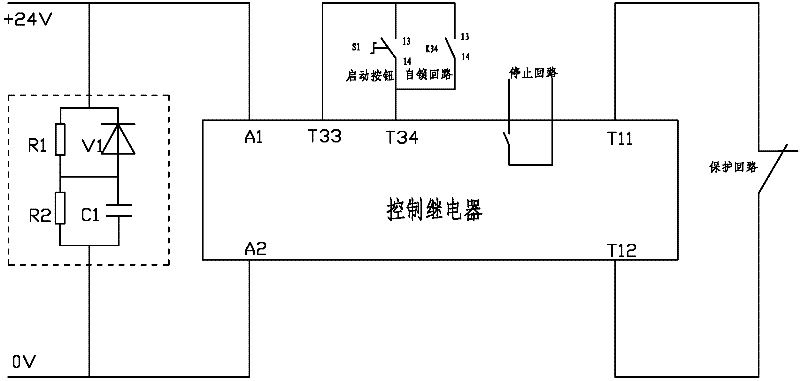

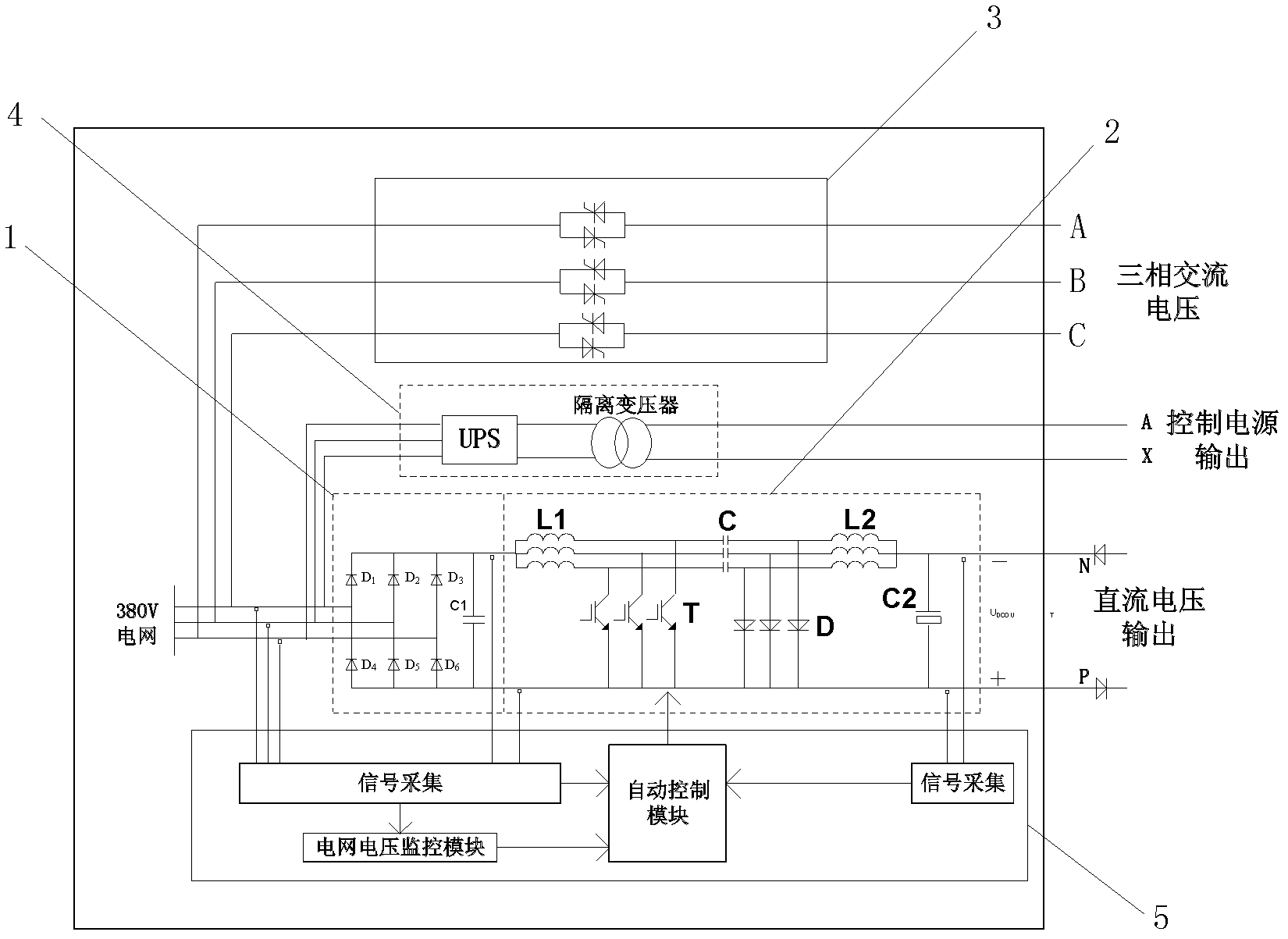

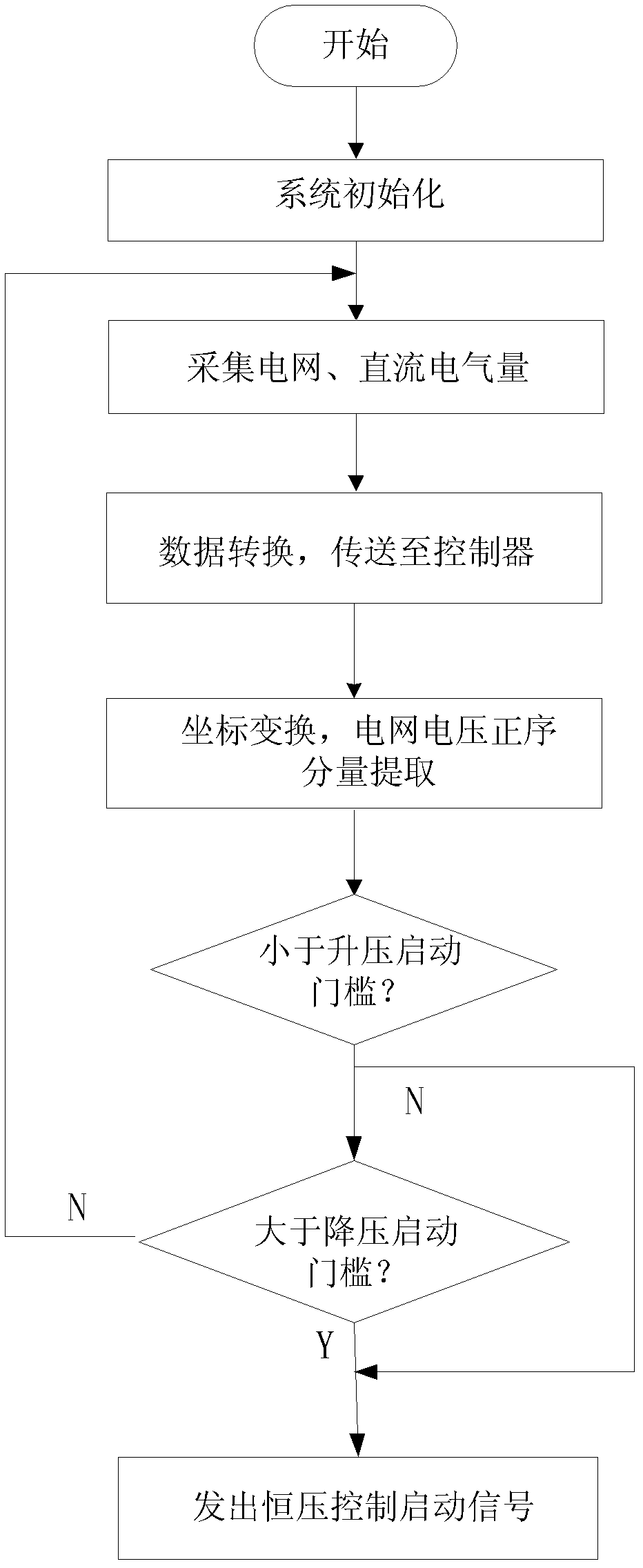

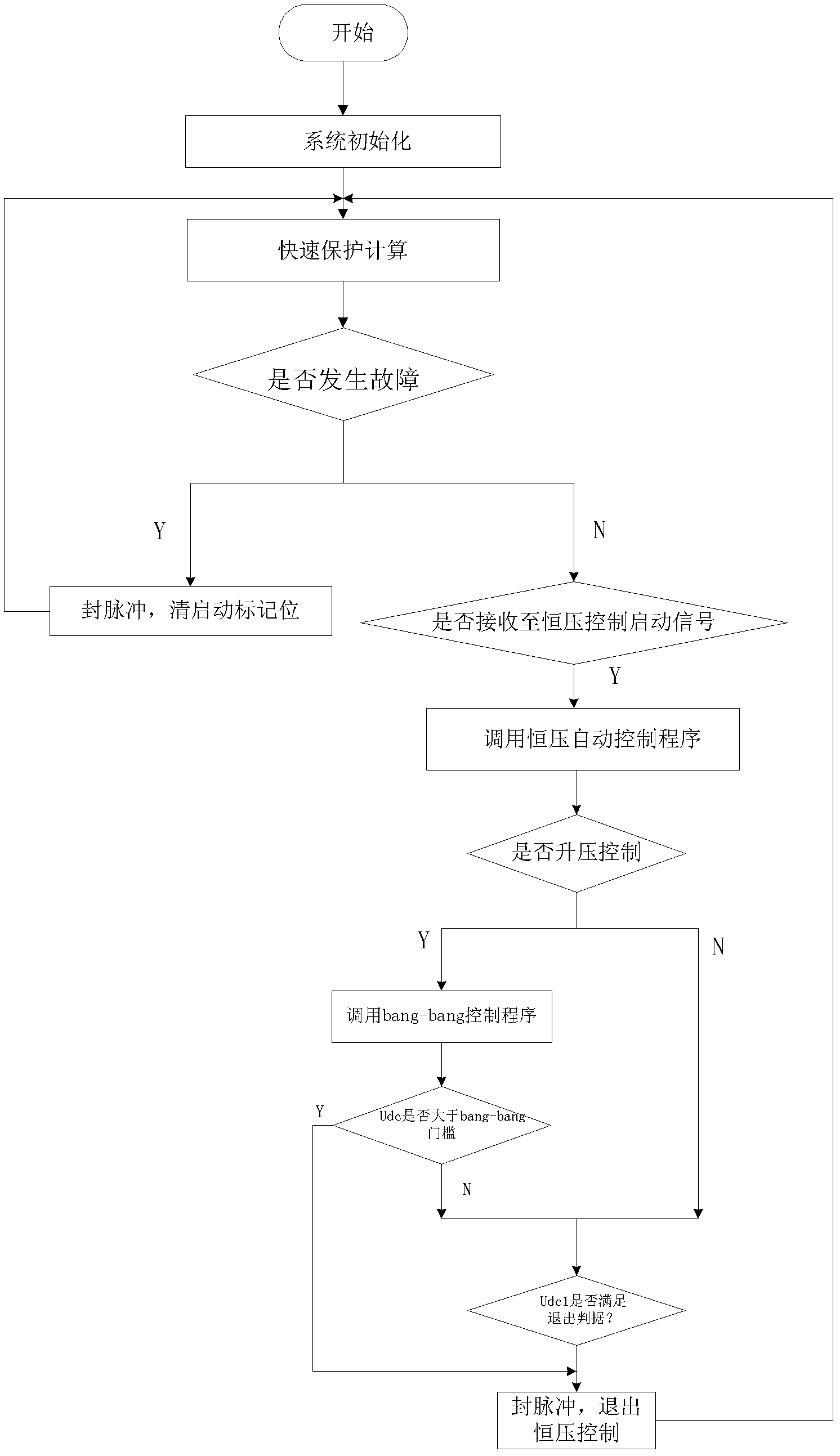

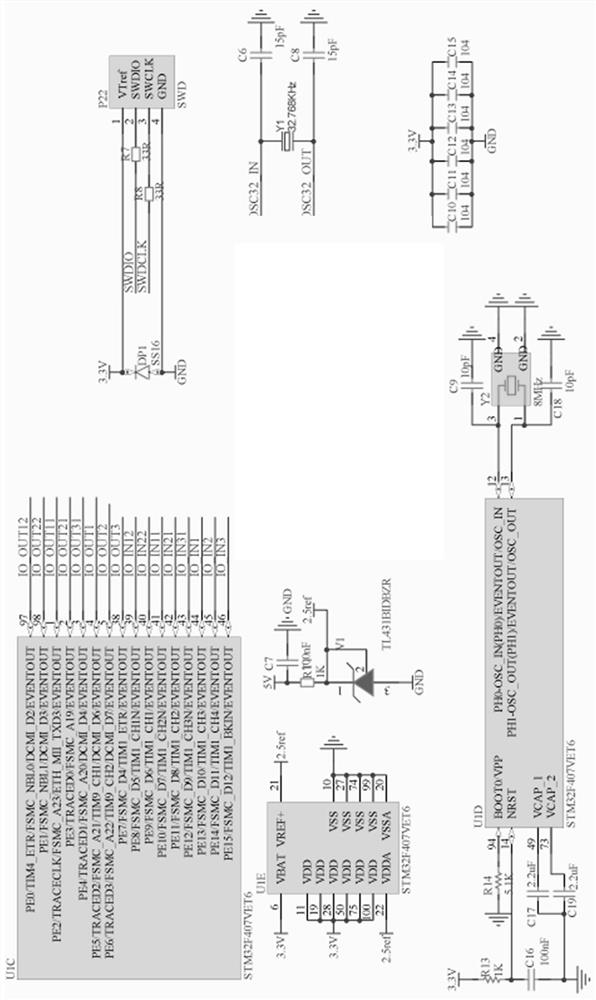

Abnormal voltage ride-through power supply of frequency converter

ActiveCN102545646BThe output voltage remains constantStable outputAc-ac conversionEmergency power supply arrangementsFrequency changerElectricity

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

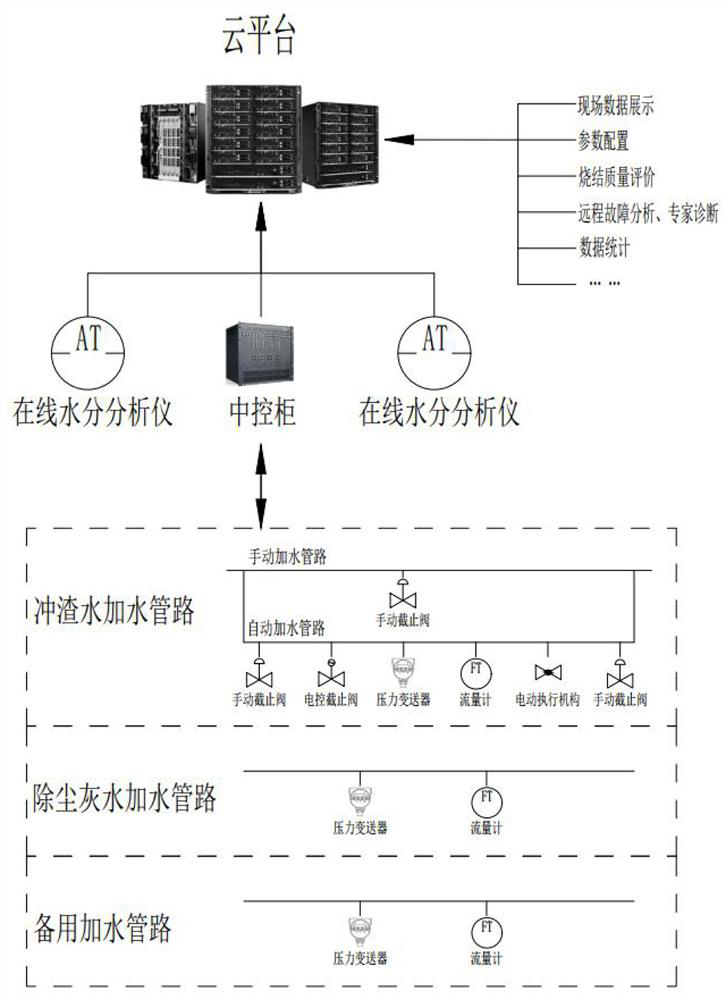

Automatic water adding device and its control system based on microwave on-line moisture detector

ActiveCN111929332BGuaranteed uptimeGuaranteed non-stopMoisture content investigation using microwavesSimultaneous control of multiple variablesControl systemProcess engineering

The invention discloses an automatic water adding device based on a microwave online moisture detector. The device is characterized in that the device comprises a central control cabinet, an online moisture detector, a water adding pipeline and a cloud platform, wherein the central control cabinet is connected with the online moisture detector and the water adding pipeline, the central control cabinet transmits data to the cloud platform through a network, and the data of the cloud platform can be externally displayed through a computer webpage terminal and a mobile phone APP terminal, and thewater adding pipeline comprises a main water adding pipeline, an auxiliary water adding pipeline and a standby water adding pipeline. The device has the advantages of stable equipment operation, long-time fault-free operation, high response speed, small control lag, accurate moisture control, accurate, safe and reliable moisture measurement, on-site learning ability, automatic optimization control and reservation of a manual water adding pipeline.

Owner:WEIFANG LICHUANG ELECTRONICS TECH

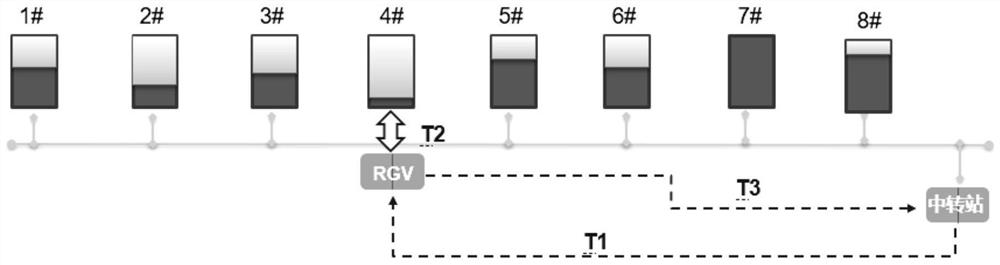

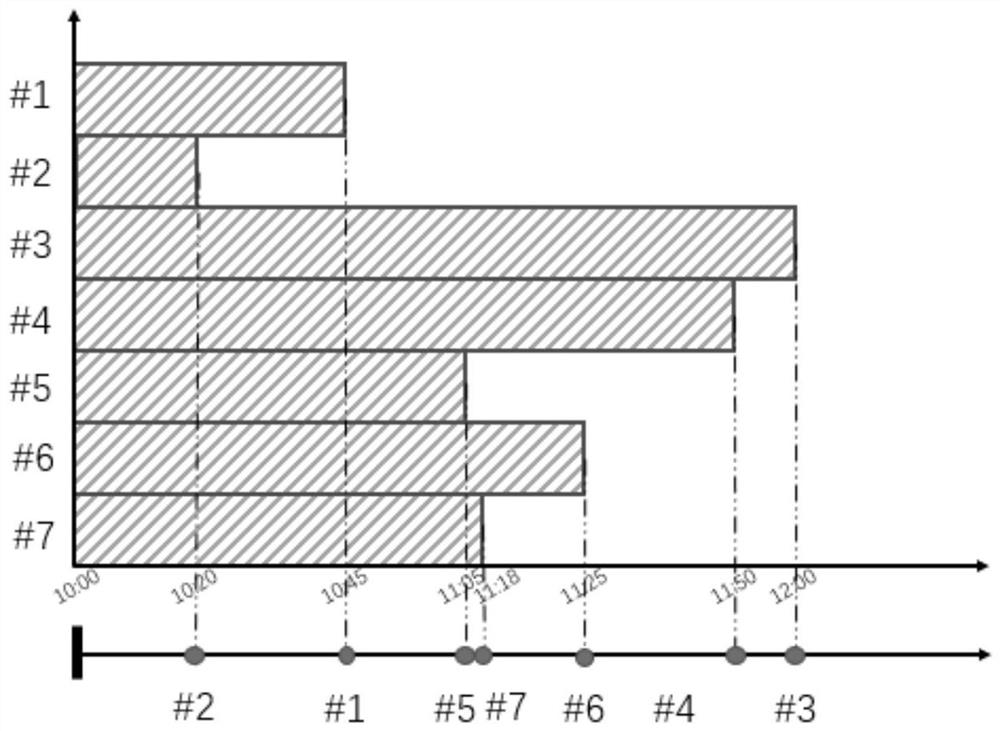

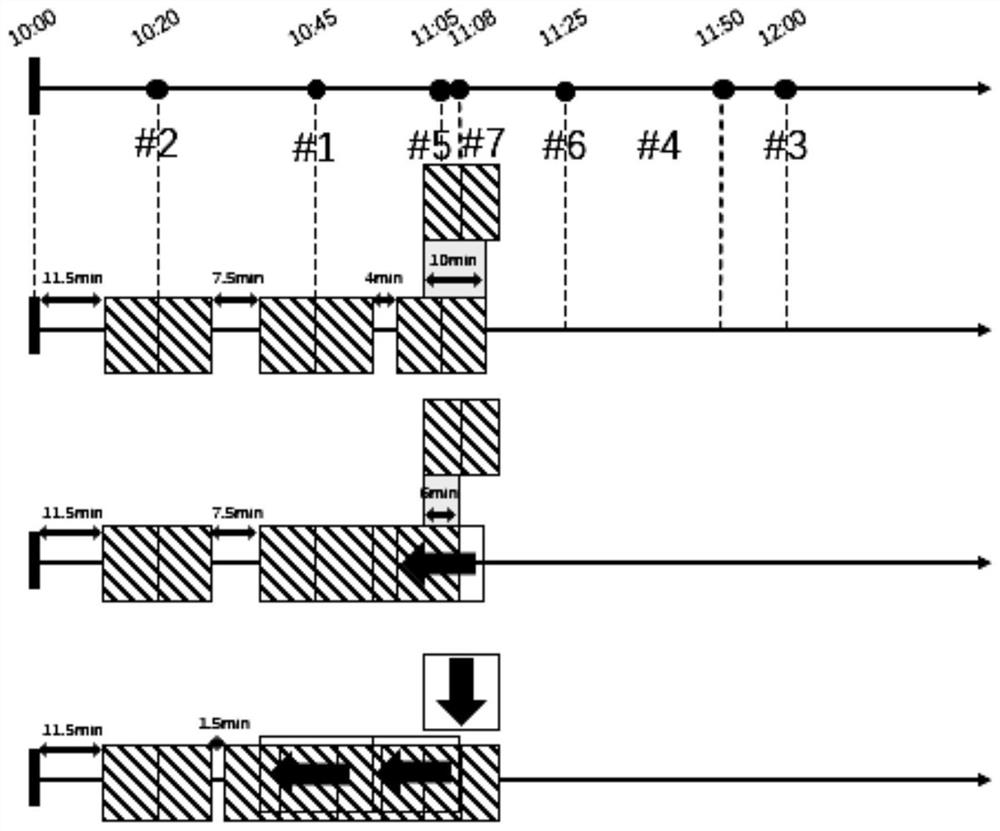

Method for calculating transfer trolley scheduling task in real time

PendingCN112053062AImprove fault toleranceGuaranteed non-stopOffice automationResourcesProduction lineStart time

The invention discloses a method for calculating a transfer trolley scheduling task in real time. The method comprises the following steps of 1, acquiring field information of a casting machine production line, and recording the field information; 2, screening out a pot changing demand queue, and calculating remaining time of molten aluminum of each casting machine production line in the queue; and 3, creating a pot changing task, calculating planned starting time of the pot changing task and the available time of subsequent tasks according to the current time and the molten aluminum remainingtime, wherein the planned starting time of the subsequent tasks is not shorter than the available time of the subsequent tasks. According to the method, the reasonable planned starting time of the pot changing task can be accurately calculated according to the casting machine information, when multiple casting devices need molten aluminum at the same time, the previous pot changing task starts tochange pots in advance, and subsequent devices are ensured not to stop.

Owner:江苏天和信息技术有限公司

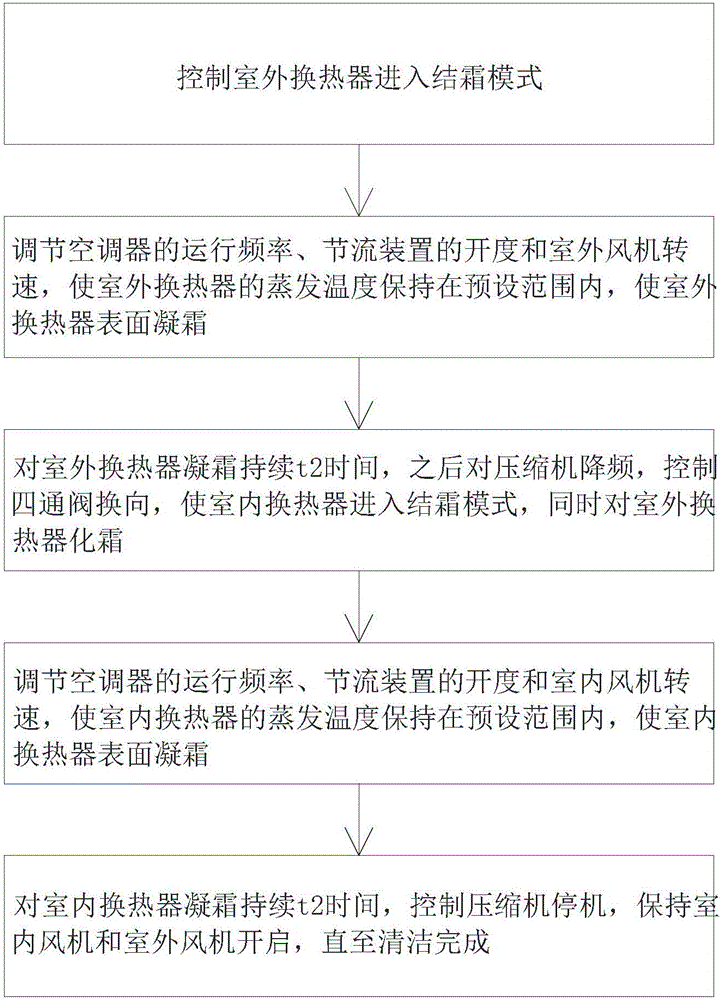

A protection control method and device for an air conditioner

ActiveCN107747790BShort maintenance periodAvoid actionMechanical apparatusSpace heating and ventilation safety systemsStopped workConstant frequency

A method and device for protection control of an air conditioner, which belongs to the technical field of air conditioners. The method comprises the following steps: acquiring the operation voltage of the air conditioner and the ambient temperature (S1); and when the operation voltage and the ambient temperature are outside of a preset range, reducing the revolution speed of an indoor fan (S2 and S3). The described technical solution solves the problem of when a constant frequency air conditioner is in a high temperature-low voltage environment, a compressor is liable to stop working due to the action of the overload protector of the compressor.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

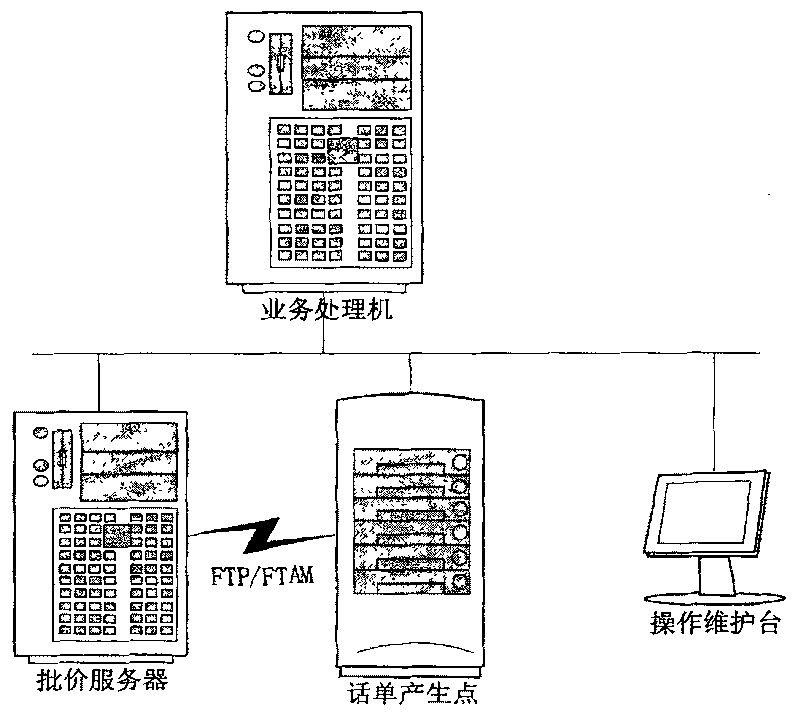

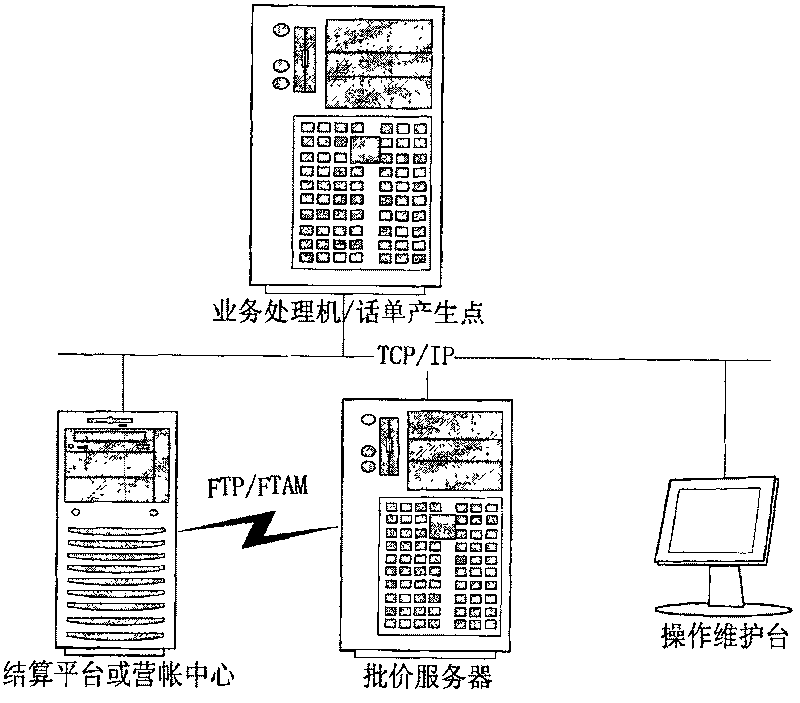

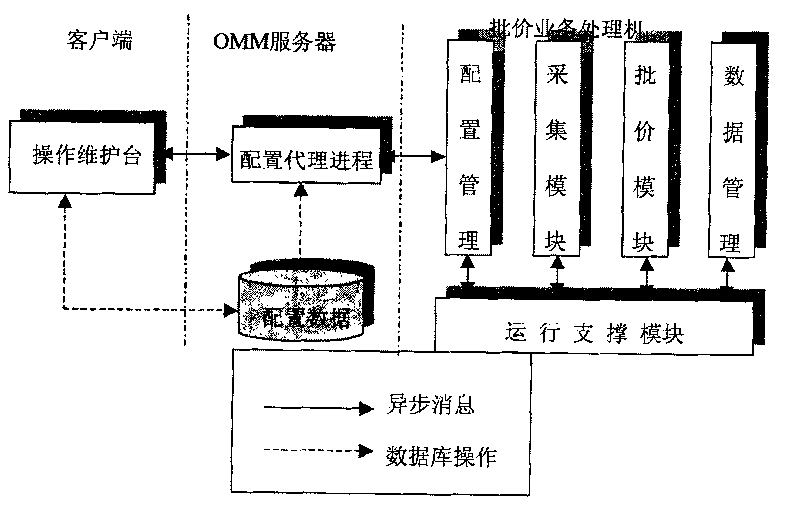

On-line price approving device and method of mobile communication network

InactiveCN1901587BImprove flexibilityFlexible modificationSupervisory/monitoring/testing arrangementsData synchronizationComputer science

This invention provides an on-line pricing device and a method for mobile communicatioin networks, in which, said device includes an operation maintenance stand and a pricing server including a collection module, a pricing module and a configuration management module, the collection module includes the collection part of original phone list and a real time collection part of real time receiving lists, the pricing moduoe includes a pre-process component of lists, a primary pricing process component and a secondary pricing process component and detailed written list interface process component,said configuration management module is connected with the operation maintenance stand to transmit the configurated information to the configuration management module then to be transferred to the pricing module.

Owner:ZTE CORP

A dynamic self-calibration control method for reheating flue gas temperature of waste heat boiler

ActiveCN103076742BQuick responseStable dynamic tracking performanceAdaptive controlHysteresisAutomatic control

The invention discloses a dynamic self-correction control method of reheating smoke temperature of a waste heat boiler. The method comprises the following steps of according to a dynamic self-correction control model of a controlled object obtained by a step response test of reheating smoke temperature settings, enabling an automatic control system of the reheating smoke temperature of the waste heat boiler to record a gas valve opening instruction sequence and a reheating smoke temperature measuring value sequence in a real-time way; and dynamically setting each parameter by a controller, so as to obtain the current gas valve opening increment instruction. The method has the advantages that the dynamic performance of the reheating smoke temperature control system of the waste heat boiler is improved, and the problems of large hysteresis and slow response speed of the reheating smoke temperature control system are effectively solved; the offset range between the reheating smoke temperature and the specified value is ensured, and the stability of the reheating smoke temperature control system is improved; and meanwhile, the stop of the waste heat boiler is avoided under the accident working conditions of great change of a waste heat source, no waste heat source, and the like.

Owner:南京博纳能源环保科技有限公司

Vacuum keeping system

ActiveCN105545783AGuaranteed to workGuaranteed non-stopPump componentsPump controlAutomatic controlPulp and paper industry

The invention discloses a vacuum keeping system, and relates to the field of vacuum equipment. The vacuum keeping system comprises a control box, a water ring vacuum pump unit, a motor unit, a pre-positioned gas-water separator, a post-positioned gas-water separator and a control device; the water ring vacuum pump unit comprises a main water ring vacuum pump and a standby water ring vacuum pump; the motor unit comprises a first motor and a second motor, one end of the first motor is connected with the main water ring vacuum pump, the other end of the first motor is connected with the control box, one end of the second motor is connected with the standby water ring vacuum pump, and the other end of the second motor is connected with the control box; the pre-positioned gas-water separator is connected with a vacuum main pipe through a water inlet pipeline, the water inlet pipeline is provided with a switch valve connected with the control box, and the pre-positioned gas-water separator is in one-way communication with the main water ring vacuum pump and the standby water ring vacuum pump; the post-positioned gas-water separator is communicated with the main water ring vacuum pump and the standby water ring vacuum pump; one end of the control device is connected with the pre-positioned gas-water separator, and the other end of the control device is connected with the control box to be used for controlling starting and stopping of the main water ring vacuum pump and the standby water ring vacuum pump. According to the vacuum keeping system, the vacuum degree of an axially split centrifugal pump water inlet pipeline system can be automatically controlled.

Owner:WUHAN EDW PUMP & VALVE

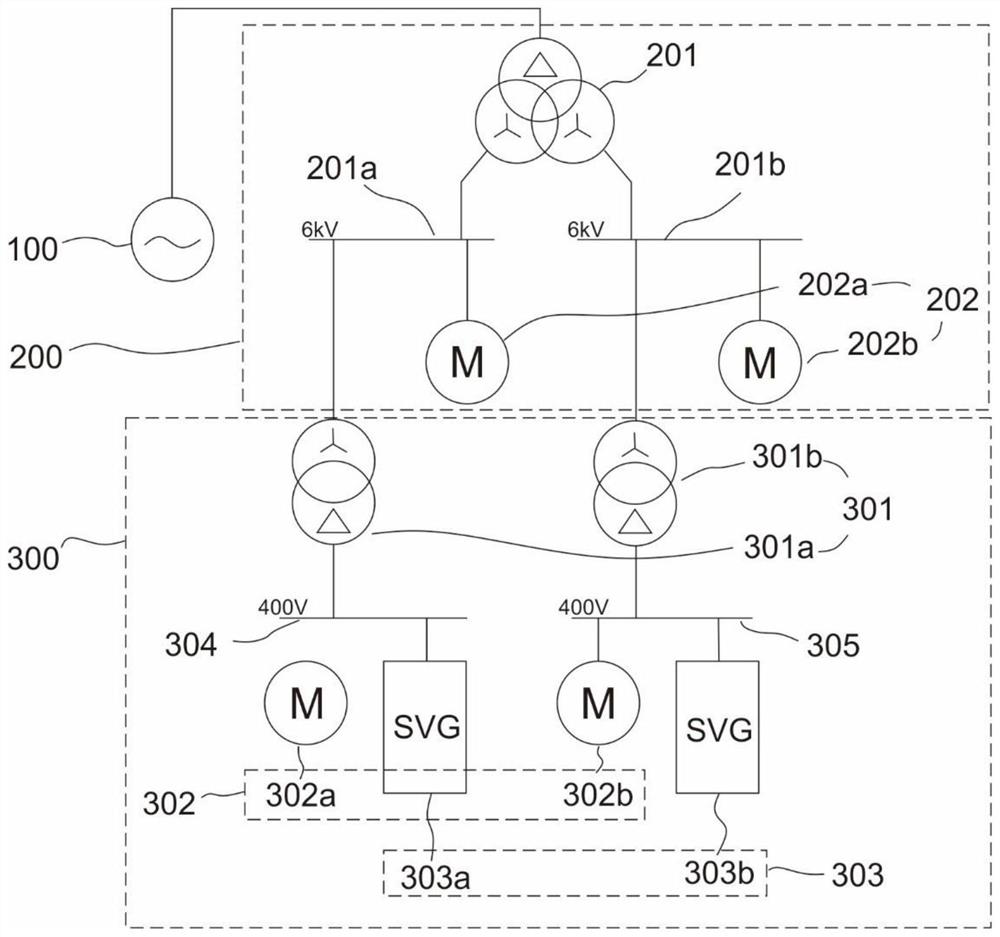

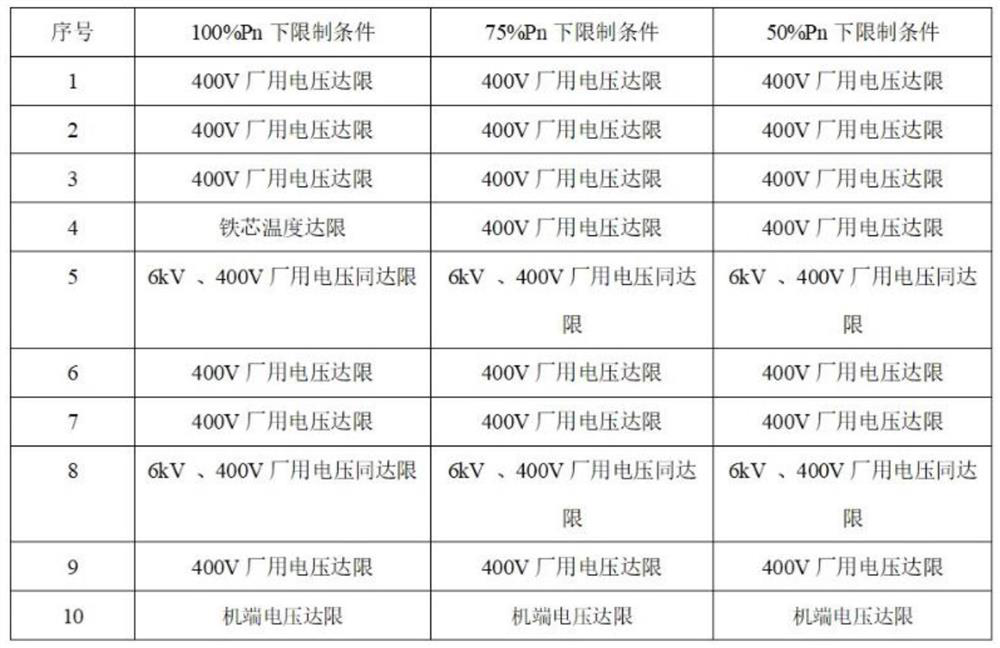

Method and system for improving in-phase depth of generator

InactiveCN113270870AIncreased phase depthGuaranteed non-stopReactive power adjustment/elimination/compensationReactive power compensationPower compensationTransformer

The invention discloses a method and system for improving the in-phase depth of a generator. The system comprises the generator, a high-voltage factory assembly, and a low-voltage factory assembly, wherein the high-voltage factory assembly is connected with the generator and comprises a three-phase split transformer and a factory high-voltage auxiliary machine connected with the three-phase split transformer; and the low-voltage factory assembly is connected with the high-voltage factory assembly and comprises a double-winding step-down transformer connected with the high-voltage factory assembly, and a factory low-voltage auxiliary machine and a reactive power compensation device which are connected with the double-winding step-down transformer. The invention provides the method and system for improving the in-phase depth of the generator, aiming at the problem that the voltage of a 400V factory auxiliary machine is too low, and the 400V factory auxiliary machine can not work normally during an in-phase test, so that the in-phase depth of the generator for a power plant is not high, a dynamic reactive power compensation device is added in a 400V low-voltage factory bus of the power plant, and the dynamic reactive power compensation device can automatically adjust the inductive reactive power output according to the voltage drop amplitude to improve the in-phase depth of the power plant.

Owner:HUANENG HAINAN POWER INC

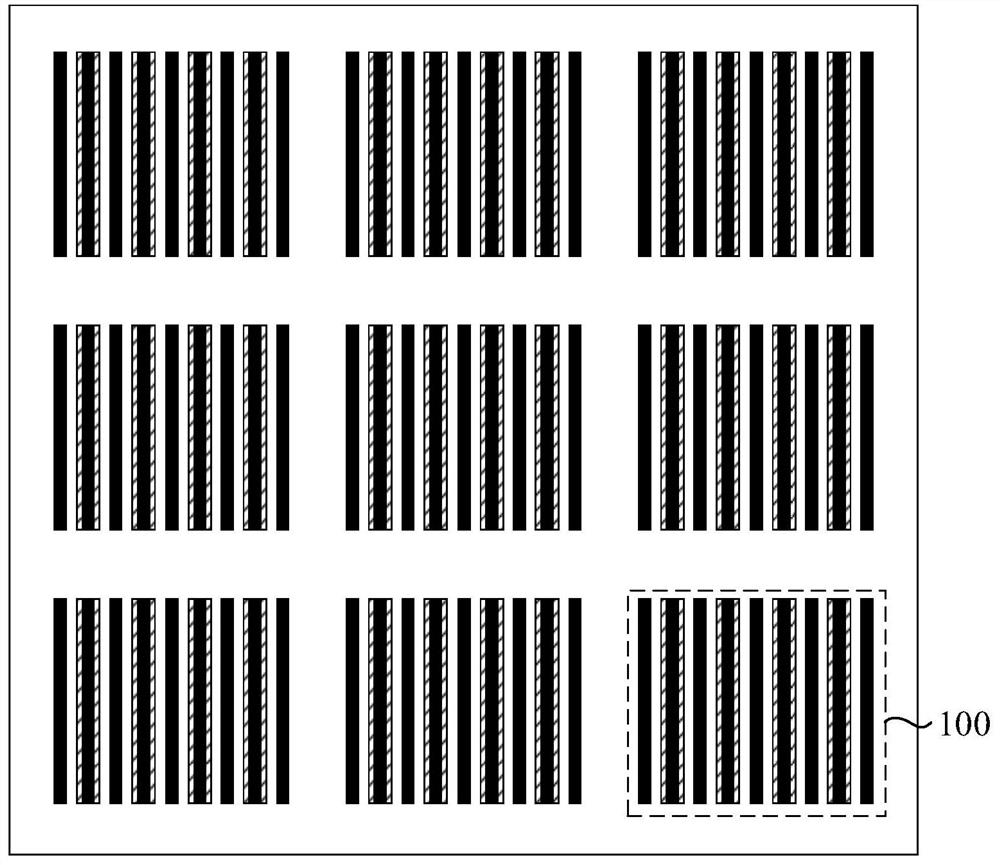

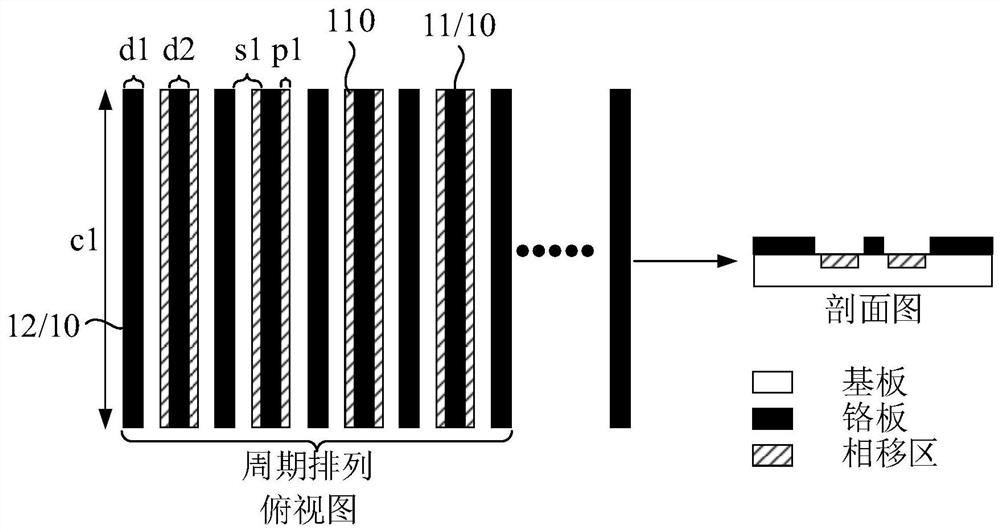

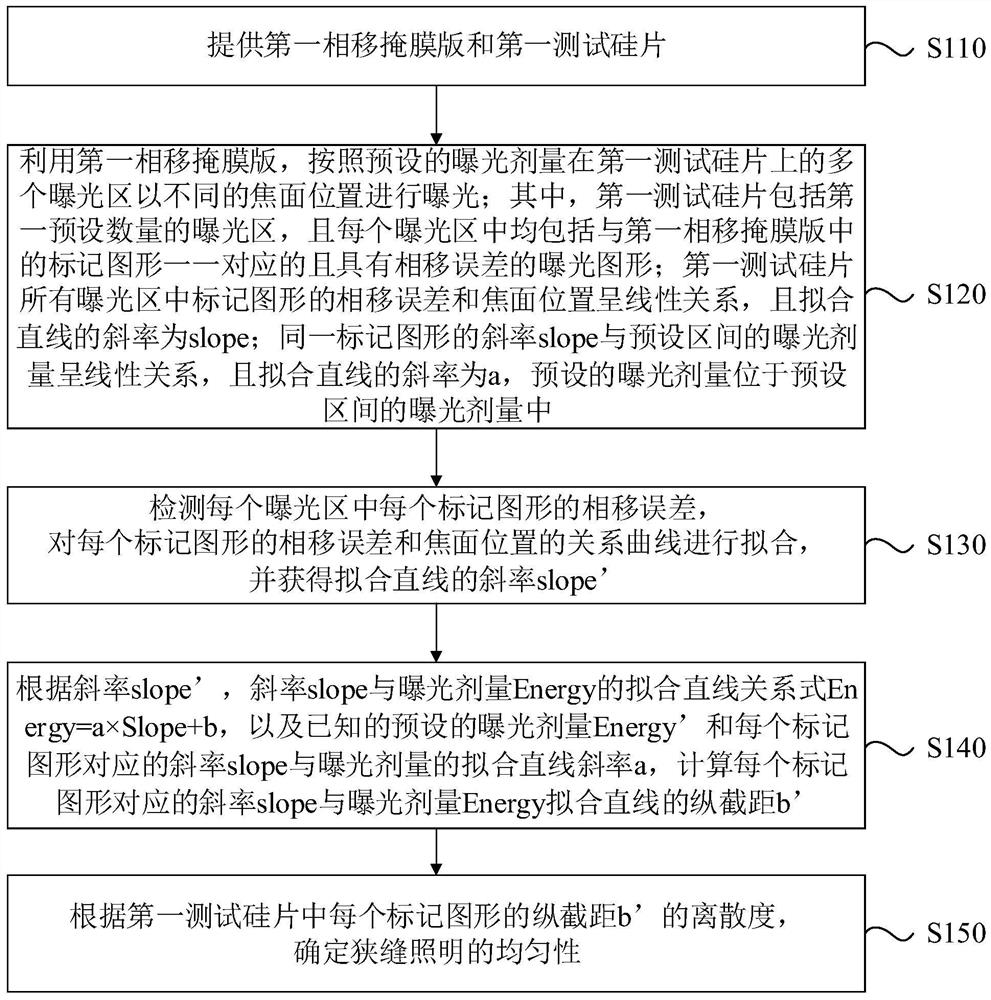

Phase shift mask and detection method for light transmission uniformity of slit of photoetching machine

PendingCN114690537APrevent yield lossSolve the problem that only offline measurement strategy can be adoptedPhotomechanical exposure apparatusMicrolithography exposure apparatusSilicon chipExposure

The embodiment of the invention discloses a phase shift mask and a detection method for light transmission uniformity of a slit of a photoetching machine. The detection method comprises the following steps: respectively exposing on a first test silicon wafer at different focal plane positions according to a preset exposure dose by using a first phase shift mask; detecting a phase shift error of each marked pattern at different focal plane positions, fitting a relation curve between the phase shift error and the focal plane position, and obtaining a slope '; calculating a longitudinal intercept b'of a slope corresponding to each marked pattern and an exposure dose fitting straight line; and finally, determining the uniformity of slit illumination according to the dispersion of the longitudinal intercept b'of each marked pattern. The embodiment of the invention can solve the problem that the existing illumination uniformity measurement can only adopt off-line measurement, not only can adapt to complex and changeable actual working conditions, but also can quickly judge whether the vertical illumination system needs to be recalibrated or not, simplify the measurement process, and ensure that a machine does not stop and continuous production is realized.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

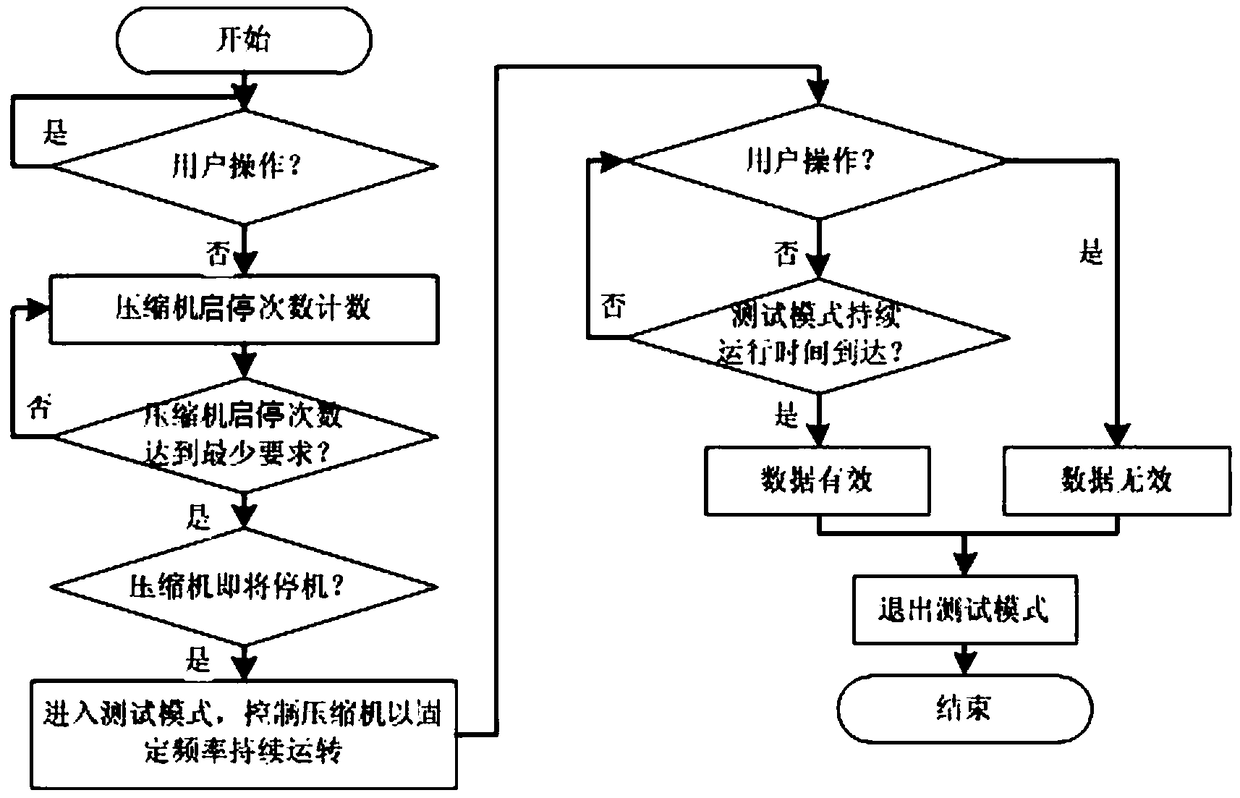

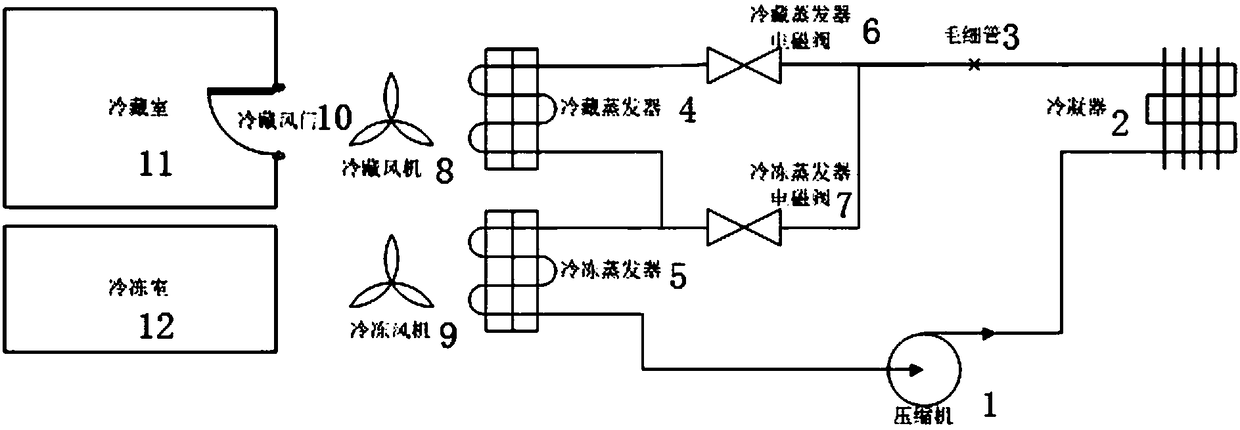

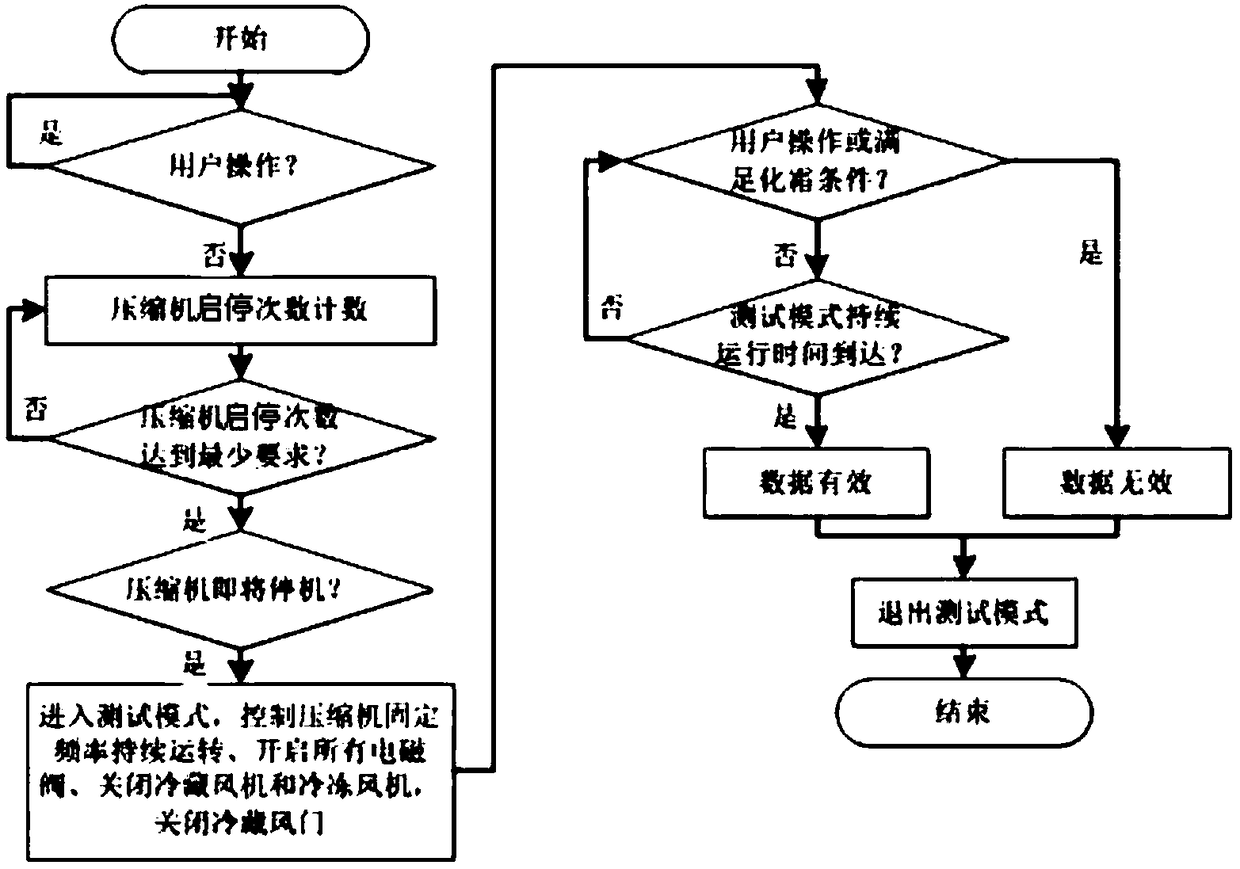

Refrigeration system performance test mode design method for failure prediction and health management

ActiveCN107941543BGuaranteed non-stopDoes not affect normal useStructural/machines measurementManufacturing intelligenceOperation mode

The invention discloses a refrigeration system performance test mode design method used for fault prediction and health management. The method comprises three aspects of test mode starting time, refrigeration system operation state control and an operation mode. According to a user operation change condition, a product operation state and a start and stop state of a compressor, after the startingtime of a refrigeration system performance test is determined, state control is performed on components in a refrigeration system. In a normal operation mode, a work mode of a section of test is embedded. By using the method of the invention, refrigeration system performance can be monitored, diagnosed and predicted in real-time and on-line modes; health management is performed in advance, and therefrigeration system is ensured not to stop; a carefree usage experience is created and an intelligent level of a product is increased; simultaneously, operation and maintenance cost is reduced.

Owner:CHINA AERO POLYTECH ESTAB +1

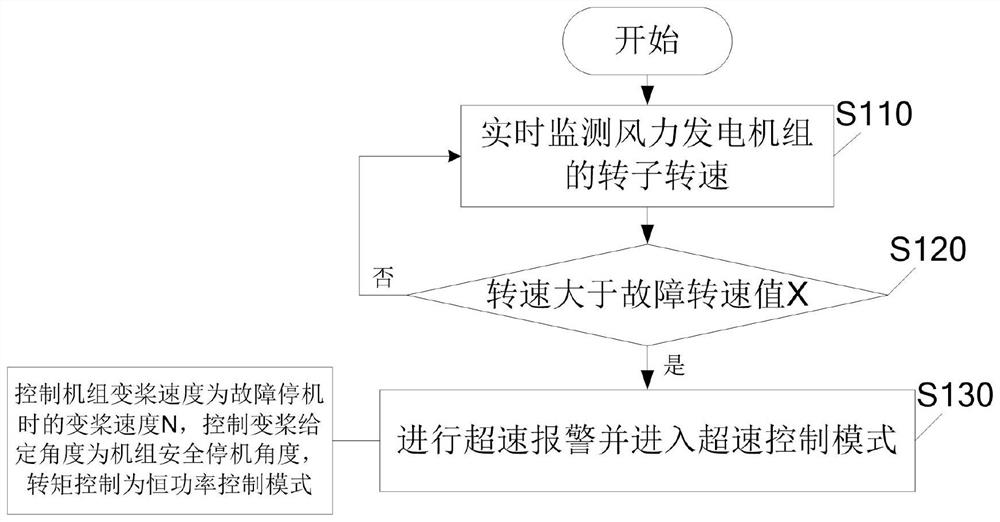

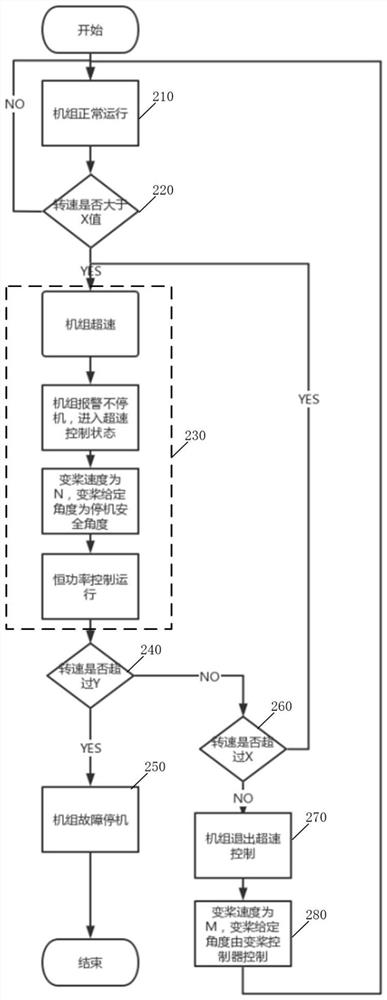

Control method and device for inhibiting overspeed of rotor of wind generating set

PendingCN114198252AReduce downtimeIncrease power generationWind motor controlMachines/enginesConstant powerEconomic benefits

The invention relates to the technical field of wind power generation, and discloses a control method and device for inhibiting overspeed of a rotor of a wind generating set, and the method comprises the steps: monitoring the rotating speed of the rotor of the wind generating set in real time, and giving an overspeed alarm and entering an overspeed control mode when the rotating speed of the rotor is greater than a fault rotating speed value; according to the overspeed control mode, the variable-pitch speed of the unit is controlled to be the variable-pitch speed during fault shutdown, the variable-pitch given angle is controlled to be the safe shutdown angle of the unit, and the torque is controlled to be in the constant-power control mode. When the rotating speed of a rotor is larger than a fault rotating speed value, unit shutdown operation is not carried out, overspeed alarm is carried out, an overspeed control mode is entered, in the overspeed control mode, rapid propeller retracting action is carried out by controlling the variable propeller speed, the variable propeller given angle and the torque of the unit, it is guaranteed that the load of the unit is within a safe range, and therefore the fault time is effectively shortened, and the working efficiency is improved. The economic benefits are guaranteed; moreover, the method does not relate to hardware transformation, only relates to software optimization, and is low in transformation cost.

Owner:CHONGQING HAIZHUANG WINDPOWER ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com