Method and system for improving in-phase depth of generator

A generator and phase advance technology, applied in electrical components, circuit devices, AC network circuits, etc., can solve the problem of low phase advance depth of power plant generators, and achieve the effect of improving phase advance depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

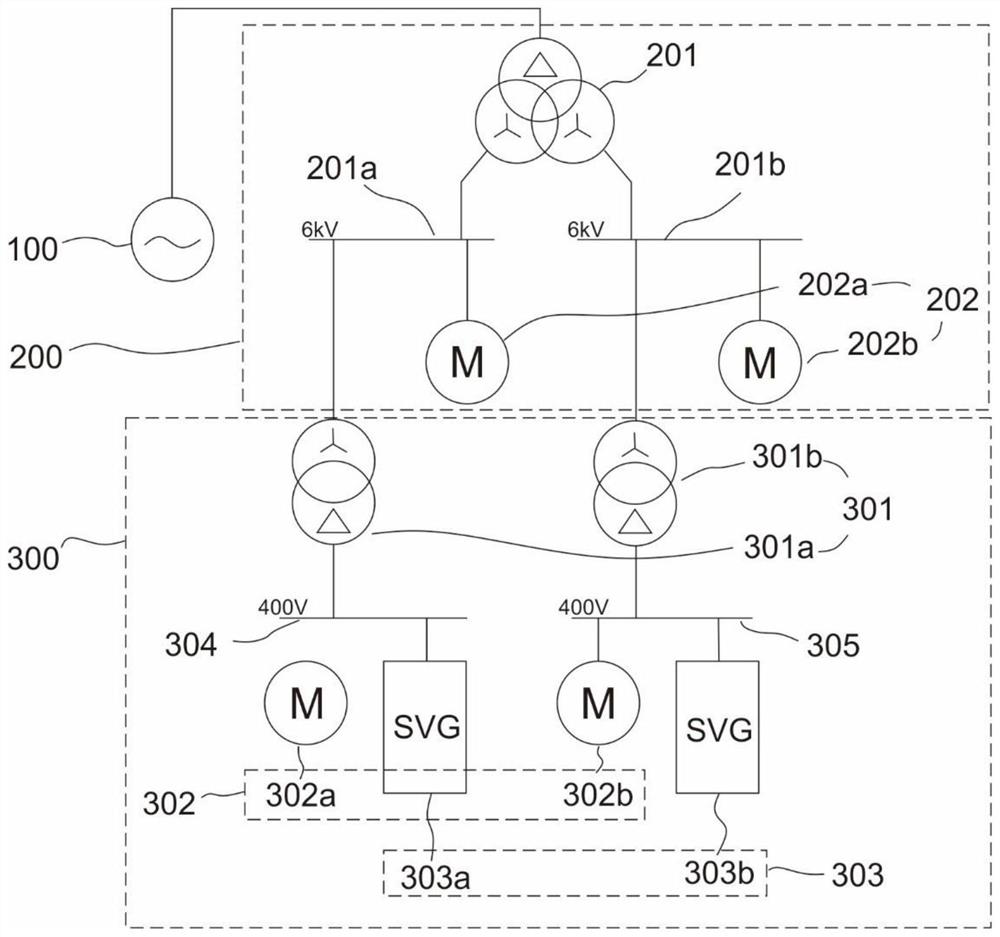

[0030] refer to figure 1 , which is the first embodiment of the present invention, provides a method and system for increasing the phase advance depth of a generator. The system includes a generator 100, a high-voltage plant assembly 200 and a low-voltage plant assembly 300, wherein the generator 100; The high-voltage plant assembly 200 is connected to the generator 100, including a three-phase split transformer 201, and a plant high-voltage auxiliary machine 202 connected to the three-phase split transformer 201; and, the low-voltage plant assembly 300 is connected to the high-voltage The plant components 200 are connected, including a double-winding step-down transformer 301 connected to the high-voltage plant component 200 , a plant low-voltage auxiliary machine 302 and a reactive power compensation device 303 connected to the double-winding step-down transformer 301 .

[0031] Among them, the generator 100 provides energy supply for the system, the high-voltage plant compo...

Embodiment 2

[0033] refer to Figure 1~2 , is the second embodiment of the present invention, which is different from the first embodiment in that: the output port of the generator 100 is connected to the three-phase split transformer 201 . The two output ports of the three-phase split transformer 201 are connected to the high-voltage bus A section 201a and the high-voltage bus B section 201b respectively, except for the connection with the generator 100. The high-voltage busbar A section 201a and the high-voltage busbar B section 201b are 6kV industrial busbars, and the industrial high-voltage auxiliary equipment 202 includes a first industrial high-voltage auxiliary equipment 202a and a second industrial high-voltage auxiliary equipment 202b. The plant high-voltage auxiliary machine 202a and the second plant high-voltage auxiliary machine 202b are 6kV plant high-voltage auxiliary machines.

[0034]The first factory high-voltage auxiliary machine 202a is connected to the three-phase spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com