A dynamic self-calibration control method for reheating flue gas temperature of waste heat boiler

A technology of dynamic self-calibration, waste heat boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

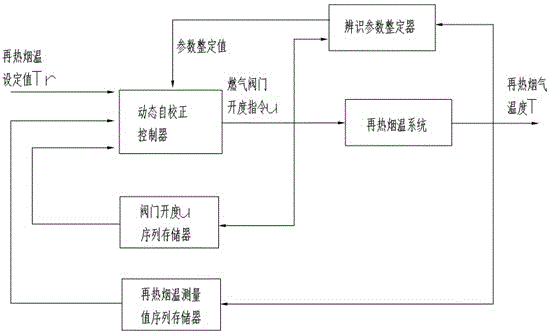

[0041] like figure 1 As shown, the present invention aims at the slow process of the traditional control method of the waste heat boiler reheat flue temperature control system, which is easy to cause overshoot and low degree of automation. Dynamic self-calibration control is adopted to make the waste heat boiler reheat flue temperature system respond quickly, Dynamic tracking performance is stable. The specific implementation method is as follows:

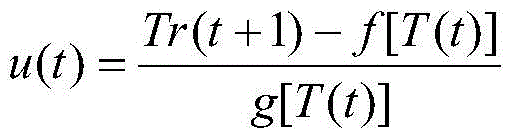

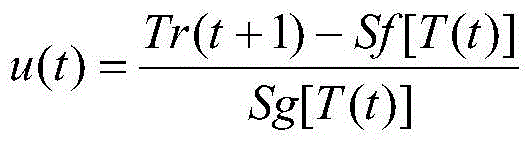

[0042] Step 1: The controlled object model of dynamic self-tuning control obtained through the step response test of the set value of rehe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com