Biomass continuous pyrolysis control system and biomass continuous pyrolysis control method

A technology of control system and control method, applied in general control system, control/regulation system, program control, etc., can solve problems such as hidden safety hazards and different product quality, and achieve safety, continuous feeding and carbon discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

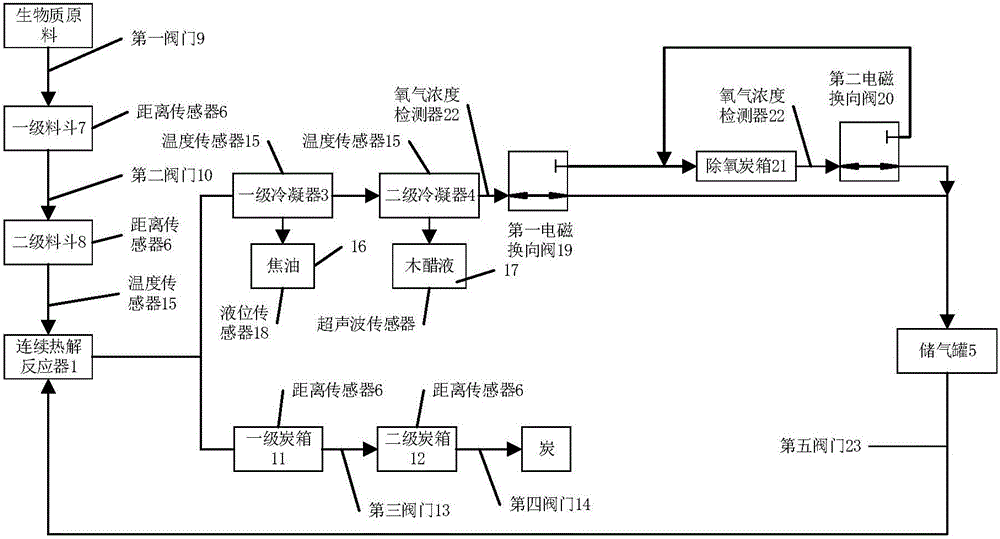

Embodiment 1

[0075] A biomass continuous pyrolysis control system and method of the present invention, through real-time monitoring of the amount of biomass raw material in the first-level hopper, the amount of biomass raw material in the second-level hopper, the amount of carbon in the first-level carbon box, the amount of carbon in the second-level carbon box, and wood vinegar Liquid level, tar level, water temperature of water cooling circulation outlet, air temperature of air cooling outlet, combustion furnace temperature, oxygen content of back-burning gas pipeline and other working parameters, and automatically control the feeding system, feeding system, condensation and so on according to the corresponding control strategy system, charcoal output system, tar and wood vinegar collection system, heating system, oxygen removal system, to ensure that the working parameters of the pyrolysis system are maintained within the normal working range. The control system and method can realize the...

Embodiment 2

[0095] The present invention also provides a method for controlling continuous pyrolysis of biomass, which is realized by using the system described in Example 1.

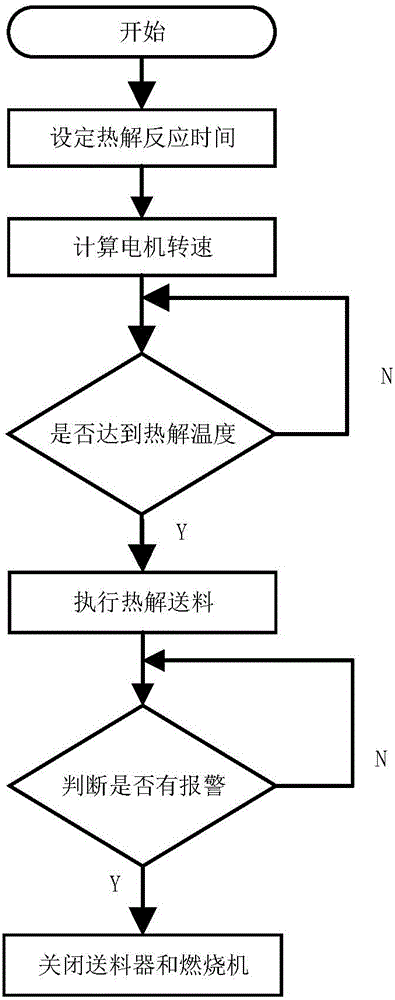

[0096] The method in this specific embodiment specifically includes a feed control step, a feed control step, a discharge control step, a condensation control step, a liquid discharge control step, an oxygen removal control step, and a pyrolysis control step.

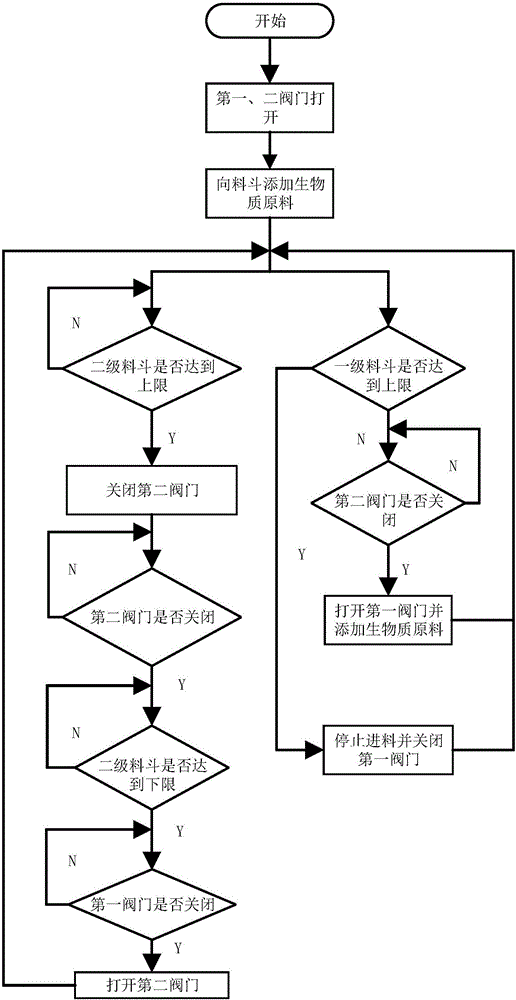

[0097] Such as figure 2 As shown, the feed control steps are specifically:

[0098] S1. During the initial feeding, open the first valve and the second valve, feed materials to the primary hopper and the secondary hopper, and execute steps S2 and S3 at the same time;

[0099] S2. The controller detects whether the raw material in the secondary hopper reaches the set upper threshold through the distance sensor in the secondary hopper, and if so, controls the second valve to close, and executes step S4;

[0100] S3. The controller detects whether the raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com