Method for calculating transfer trolley scheduling task in real time

A real-time calculation and task technology, applied in the production line of the foundry industry, foundry informatization, and foundry automation, and can solve problems such as equipment downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

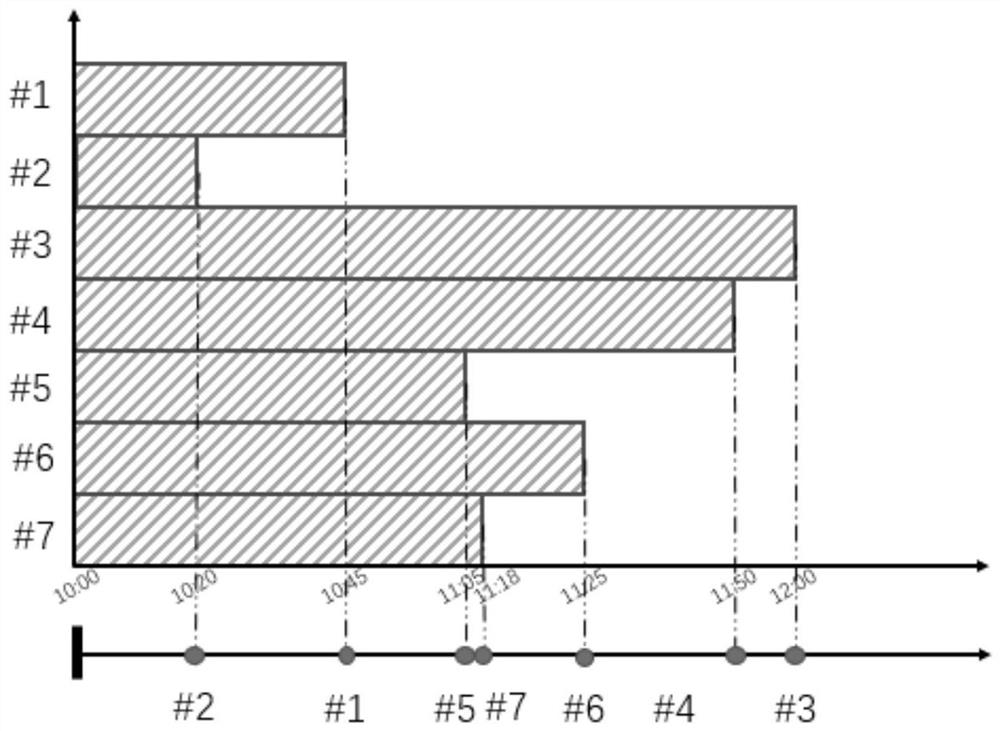

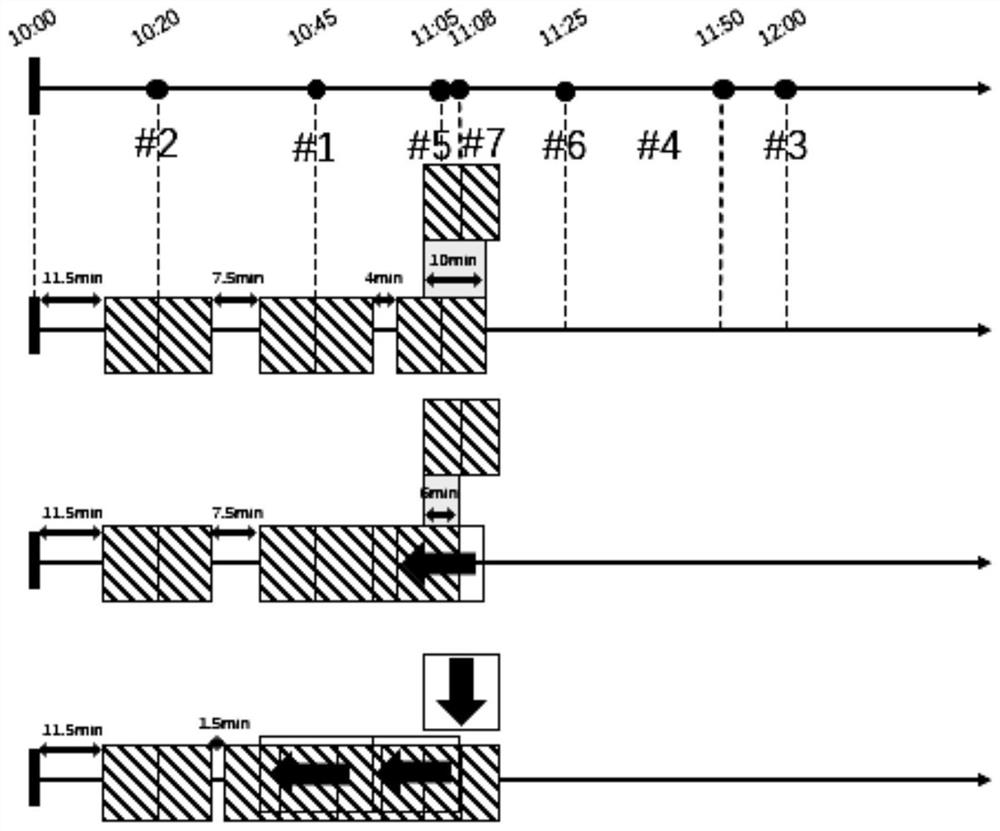

[0089] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

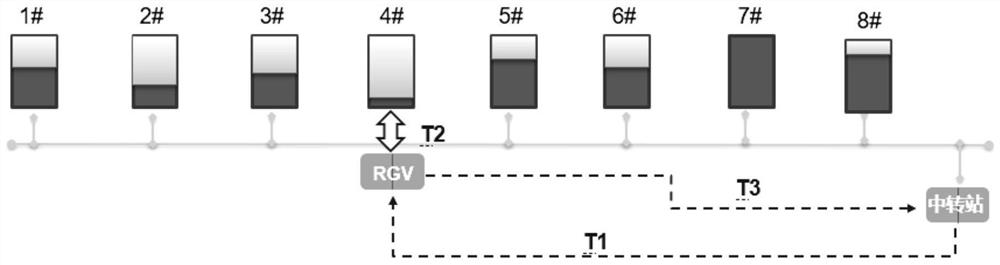

[0090] In view of the low production efficiency caused by manual operation of RGV trolleys, the dispatching system for RGV trolleys suitable for the foundry industry can control each trolley to complete a series of instructions in real time according to the current production status, improve the operating efficiency of the trolleys, and shorten the material consumption. The replacement time reduces the idle time of the equipment, and at the same time greatly reduces the cost of personnel, avoiding the risk caused by human error. The production line of this embodiment must contain more than two casting equipment, and it is equipped with a transfer table for placing aluminum crucibles and an RGV trolley for replacing aluminum crucibles.

[0091] The on-site interface provides production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com