Drum screen mesh unblocking device and drum screen mesh unblocking method

A drum sieve and drum technology, applied in chemical instruments and methods, sieves, solid separation, etc., can solve problems such as inability to effectively identify drum sieve holes, unsuitability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

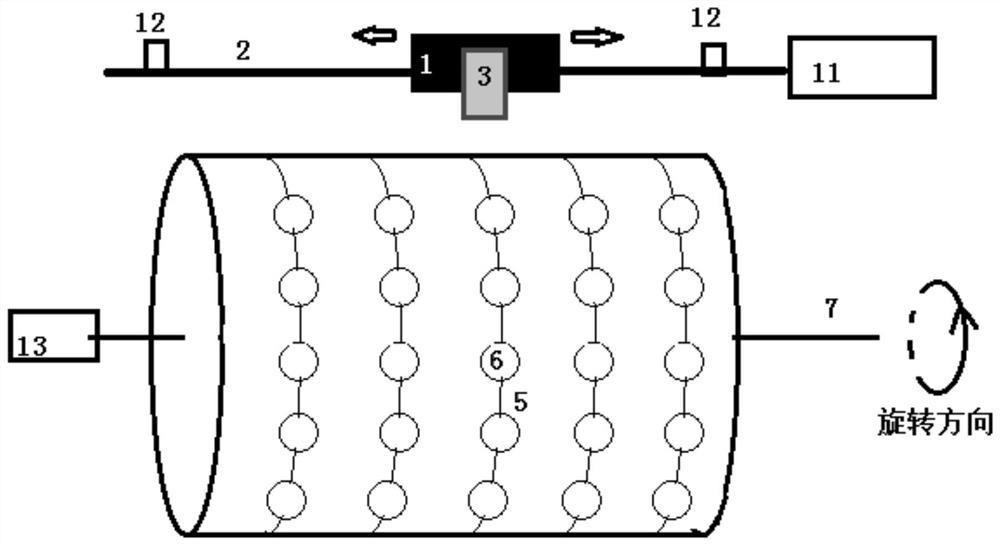

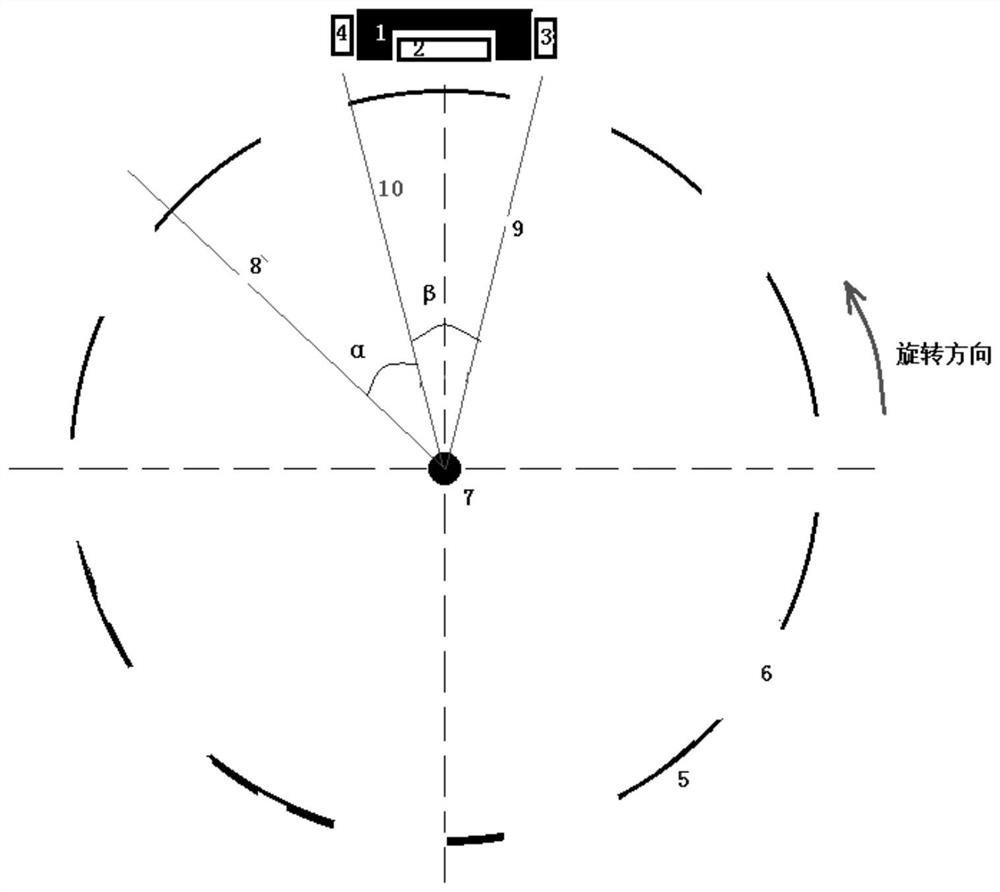

[0026] Such as Figure 1-2 As shown, the trommel screen hole unclogging device includes a stepping system, a laser distance measuring system, an angle encoding system, a unclogging system and a control system;

[0027] The stepping system includes a slide rail 2, a slider 1, a stepping motor 11 and a limit sensor 12. The slide rail is parallel to the rotation axis of the trommel screen, and the stepping motor drives the slider to reciprocate on the slide rail , the two ends of the slide rail are provided with limit sensors, the laser ranging system 3 and the gas nozzle 4 of the blockage removal system are fixed on both sides of the slider, facing the drum surface of the trommel 5, and moving with the slider;

[0028] The laser ranging system includes a laser emitting and receiving probe, a data analysis unit and a data transmission unit. The laser emitting and receiving probe emits and receives laser signals, and records the time difference between the emitted and received las...

Embodiment 2

[0034] A method for unclogging a trommel sieve hole, the steps comprising:

[0035] (1) The slider dragged by the stepping motor carries the laser ranging system and the gas nozzle, moves on the outside of the drum in a direction parallel to the rotation axis of the drum, and moves to a certain section position (m) of the drum screen to stop, the slider The beam emitted by the connected laser probe irradiates the surface of the roller at this position, that is, the surface of the roller at this position is measured; the roller rotates once, and the laser scans the surface of the roller at this section position for one circle;

[0036](2) After the slider stops, the laser ranging system connected to the slider measures the distance to the surface of the drum, and the angle encoder reads the angle at the same time. At this moment, the position of the light spot cast by the laser emitting and receiving probe on the drum wall is determined The position data (m) of the section wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com