Spliced aluminum alloy fin calandria evaporator

A technology of aluminum alloy and finned tubes, which is applied in the field of heat exchangers and heat transfer, can solve the problems of many system failures, difficult quality assurance, and high cost of copper tubes, so as to avoid large temperature rise, uniform temperature, and heat transfer. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

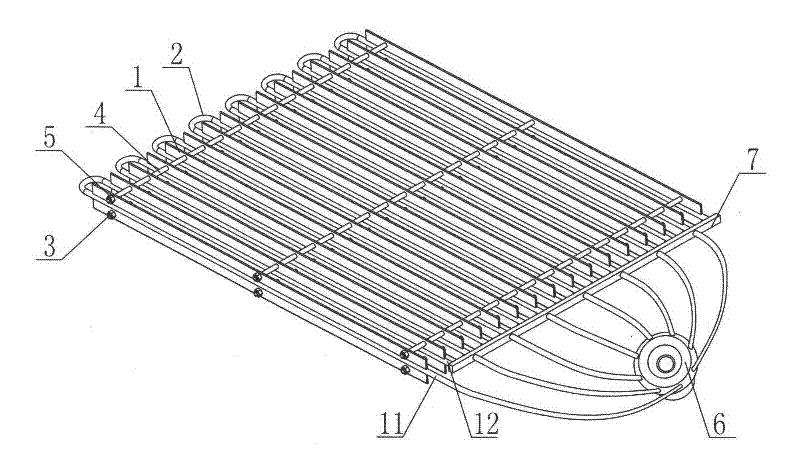

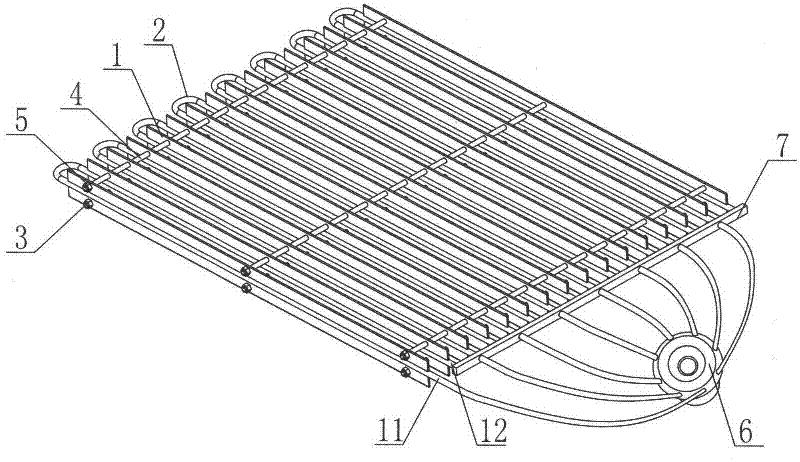

[0012] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

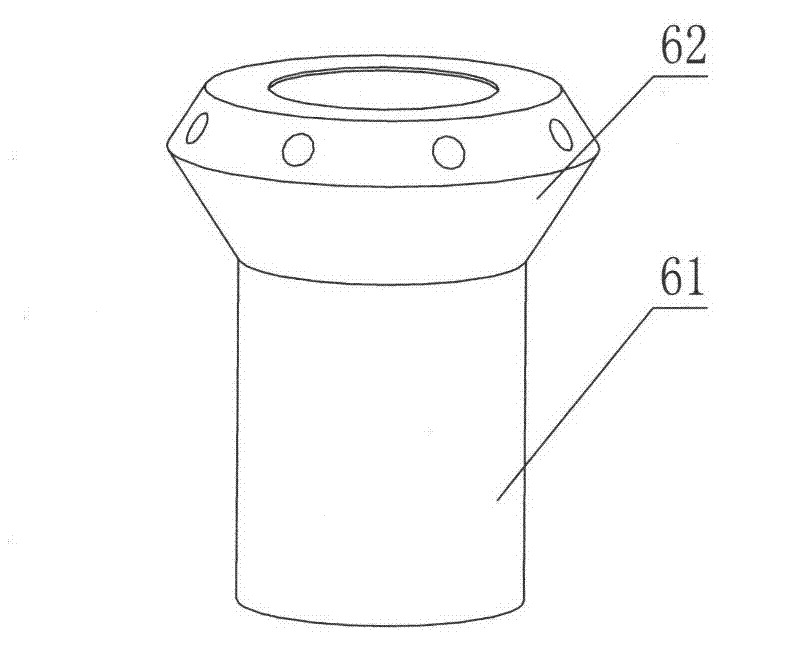

[0013] figure 1 figure 2 It is a structural schematic diagram of the best embodiment of the parallel connected aluminum alloy finned tube evaporator of the present invention, including a plurality of aluminum alloy finned tubes 1, bent tubes 2, lead screws 3, spacer tubes 4 and tight tubes arranged side by side. The fixed nut 5, the aluminum alloy finned tube 1 is provided with a mounting hole, the lead screw 3 is penetrated in the mounting hole of the aluminum alloy finned tube 1, and the lead screw 3 between adjacent aluminum alloy finned tubes 1 is passed through There are spacer tubes 4 for maintaining the spacing, the two ends of the lead screw 3 are f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com