Radiating nozzle of 3D printer

A 3D printer and nozzle technology, applied in 3D object support structures, coating devices, additive manufacturing, etc., can solve problems such as uneven air velocity, printer nozzle vibration, printer nozzle clogging, etc., to ensure adhesion firmness, improve Heat dissipation efficiency, the effect of prolonging the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

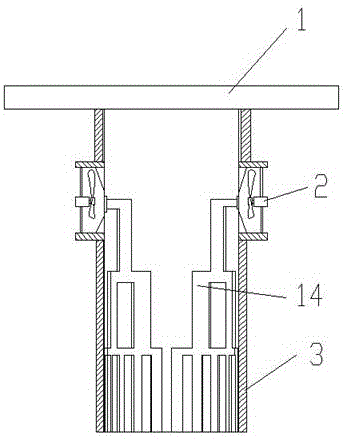

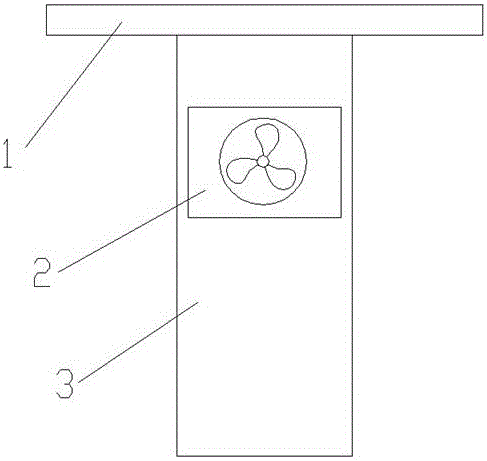

[0028] Such as Figure 1-5 As shown, a heat dissipation nozzle of a 3D printer of the present invention includes a spray head 1, an air blower 2 and a sleeve 3, the spray head 1 has a material spray channel 11, and the outside of the material spray channel 11 side wall is provided with a heat dissipation groove 14, The heat dissipation groove 14 diverges towards the outlet of the spraying channel 11; the air blower 2 is used to supply air to the heat dissipation groove 14, and the sleeve 3 is set on the spray head 1 and cooperates with the heat dissipation groove 14 to form a heat dissipation channel. The air outlet direction of the air outlet of the heat dissipation channel is the same as the spraying direction of the spray head 1 . The inner sidewall of the sleeve 3 covers and seals the notch of the cooling groove 14 . The cooling groove 14 has a branch structure, and there is a rectangular protrusion at the branch, and a local vortex can be formed when the air flows throug...

Embodiment 2

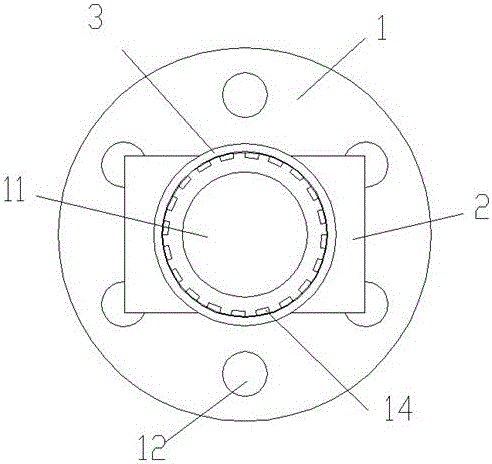

[0030] A heat dissipation nozzle of a 3D printer of the present invention comprises a spray head 1, an air blower 2 and a casing 3, the spray head 1 has a material spray channel 11, and the outer side of the material spray channel 11 side wall is provided with a heat dissipation groove 14, and the heat dissipation groove 14 diverges toward the outlet of the spraying channel 11; the air blower 2 is used to supply air to the heat sink 14, and the sleeve 3 is set on the spray head 1 and cooperates with the heat sink 14 to form a heat dissipation channel. The nozzle 1 includes a tubular portion and a connecting portion, the connecting portion is disc-shaped and located at one end of the tubular portion, the cooling groove 14 is located on the outer wall of the tubular portion, and the cooling groove 14 diverges away from the connecting portion. 3. Cooperate with the outside of the tubular part.

[0031] The outer wall of the tubular part has an air-gathering cavity 13, and the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com