Patents

Literature

90results about How to "Good heat transfer effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

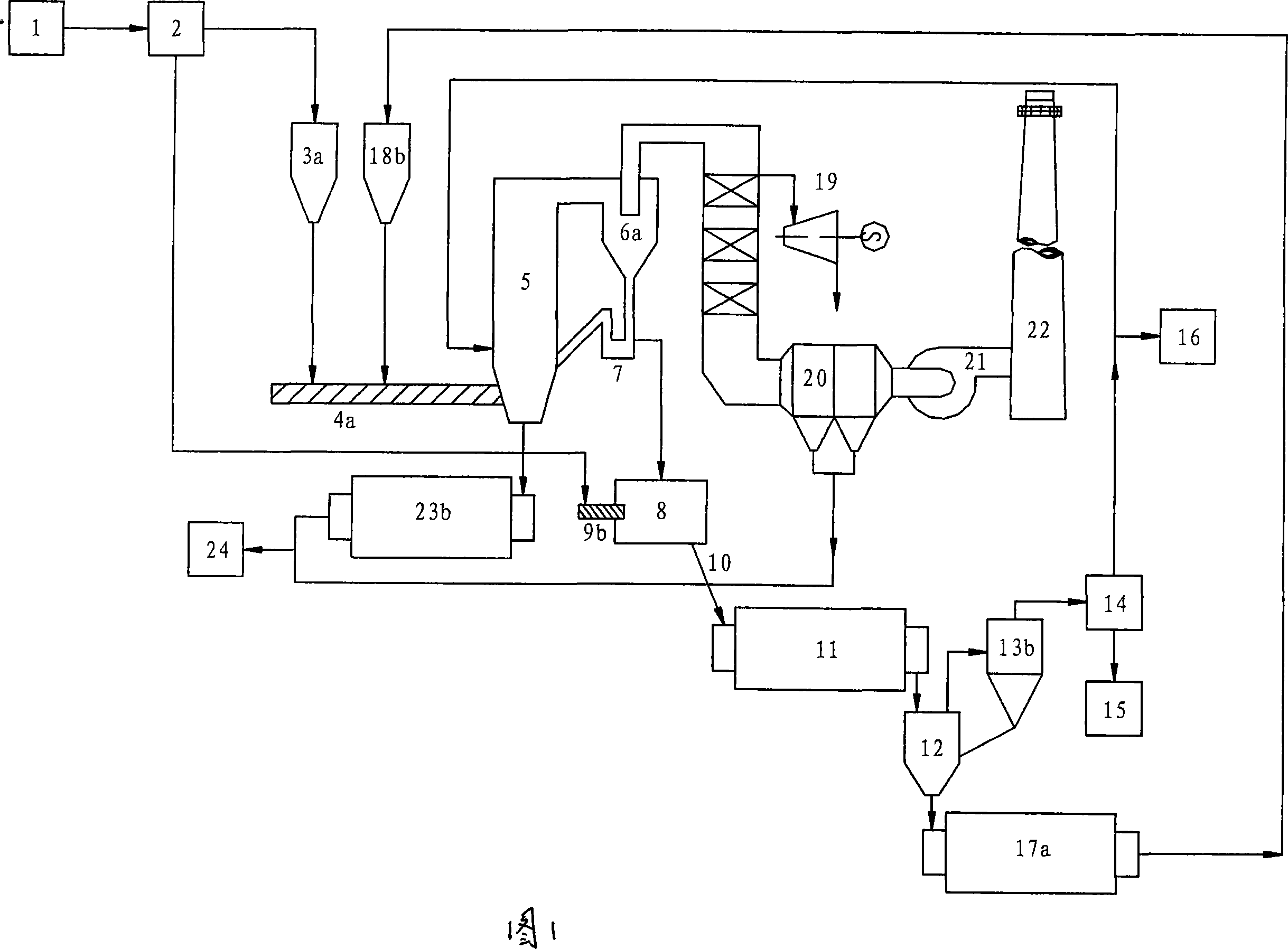

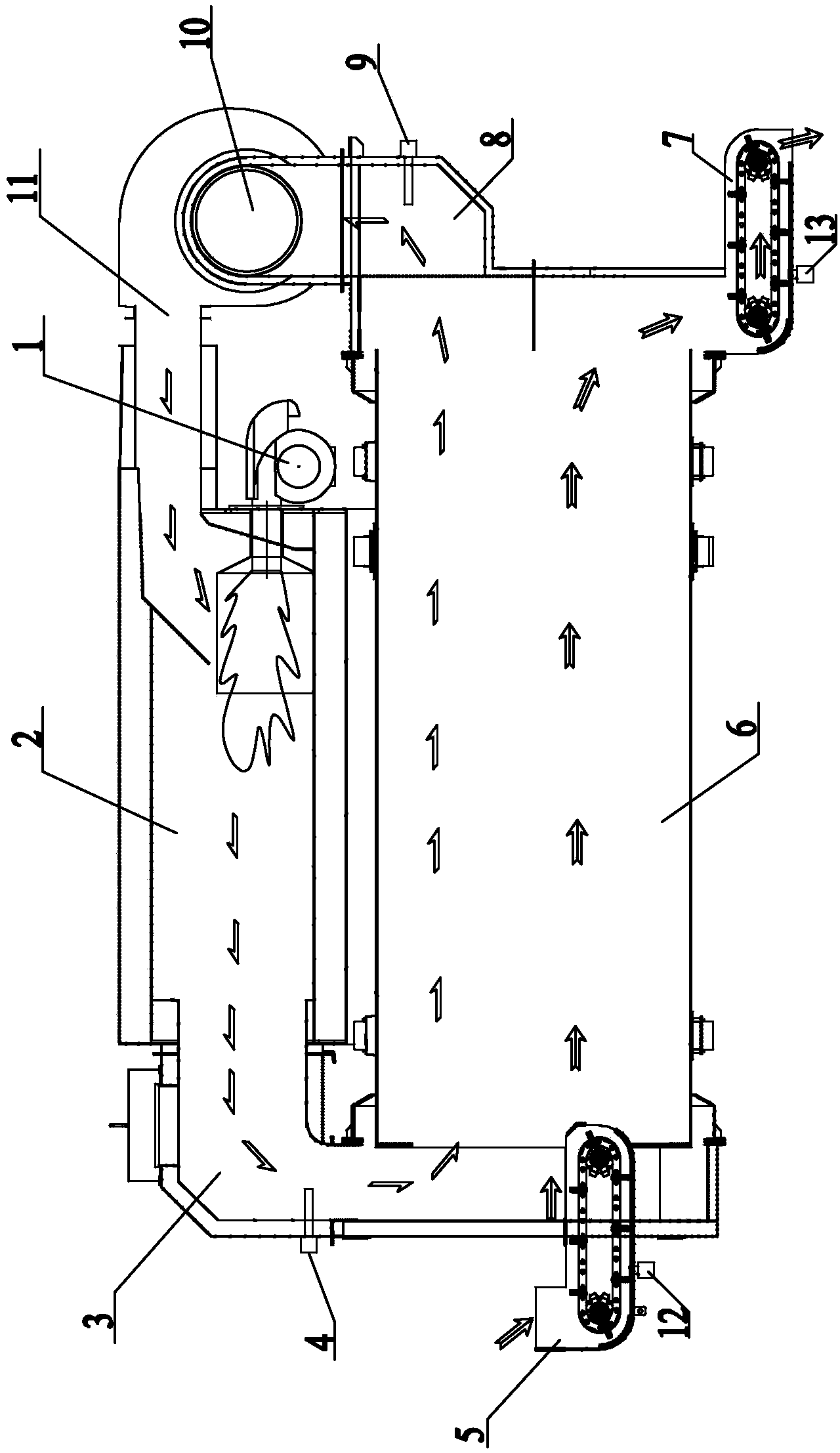

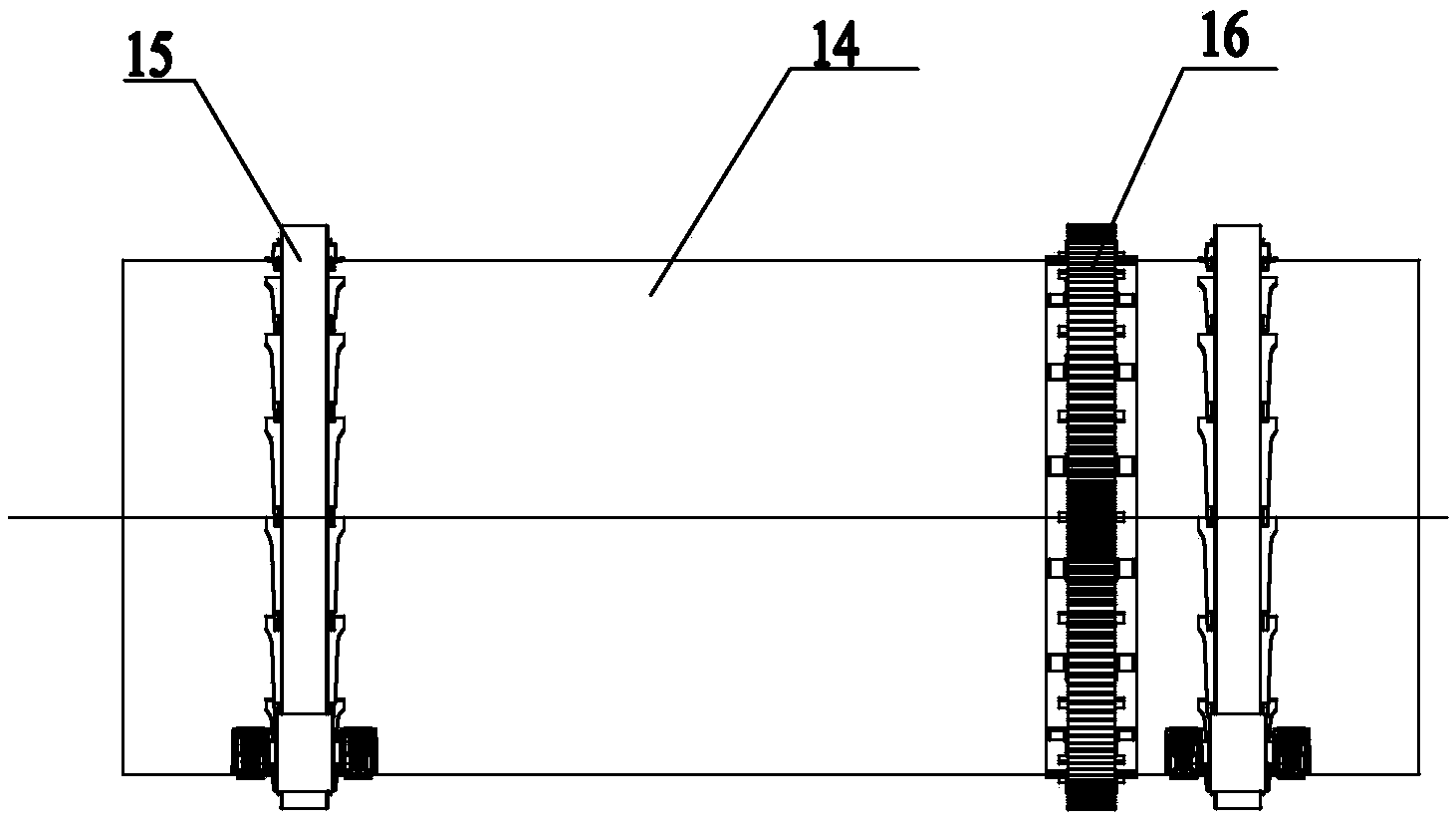

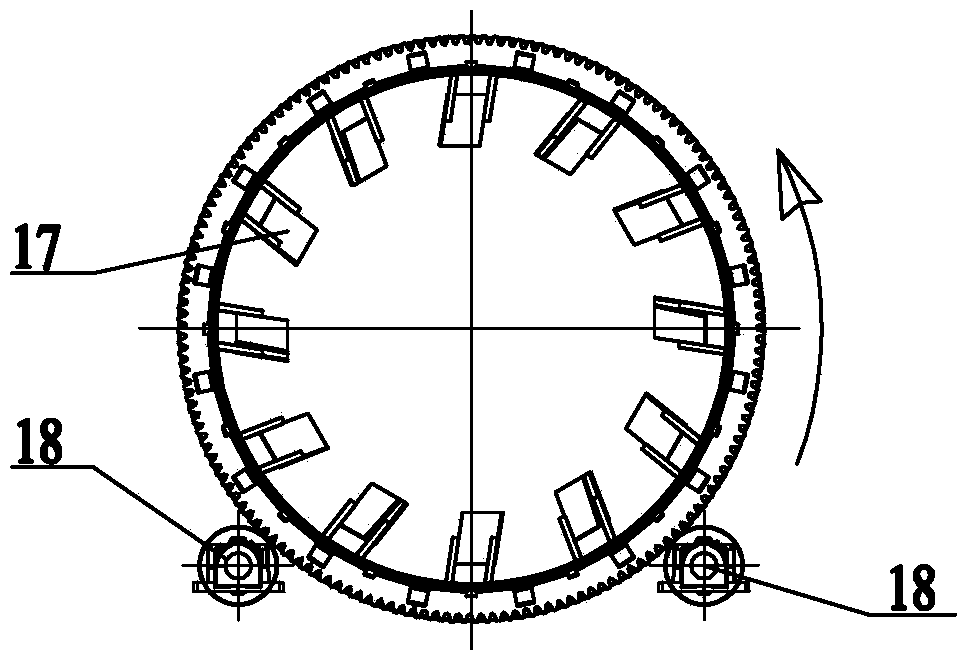

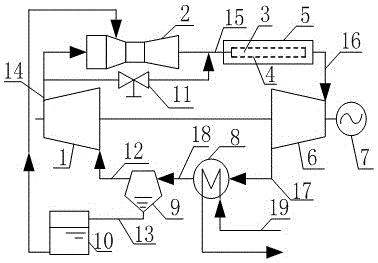

Integral process for oil shale retorting oil refining and coal-char combustion power generation

InactiveCN101117584AGood heat transfer effectImprove heat utilizationInternal combustion piston enginesPowdered engine fuelsHeat carrierCirculating fluidized bed boiler

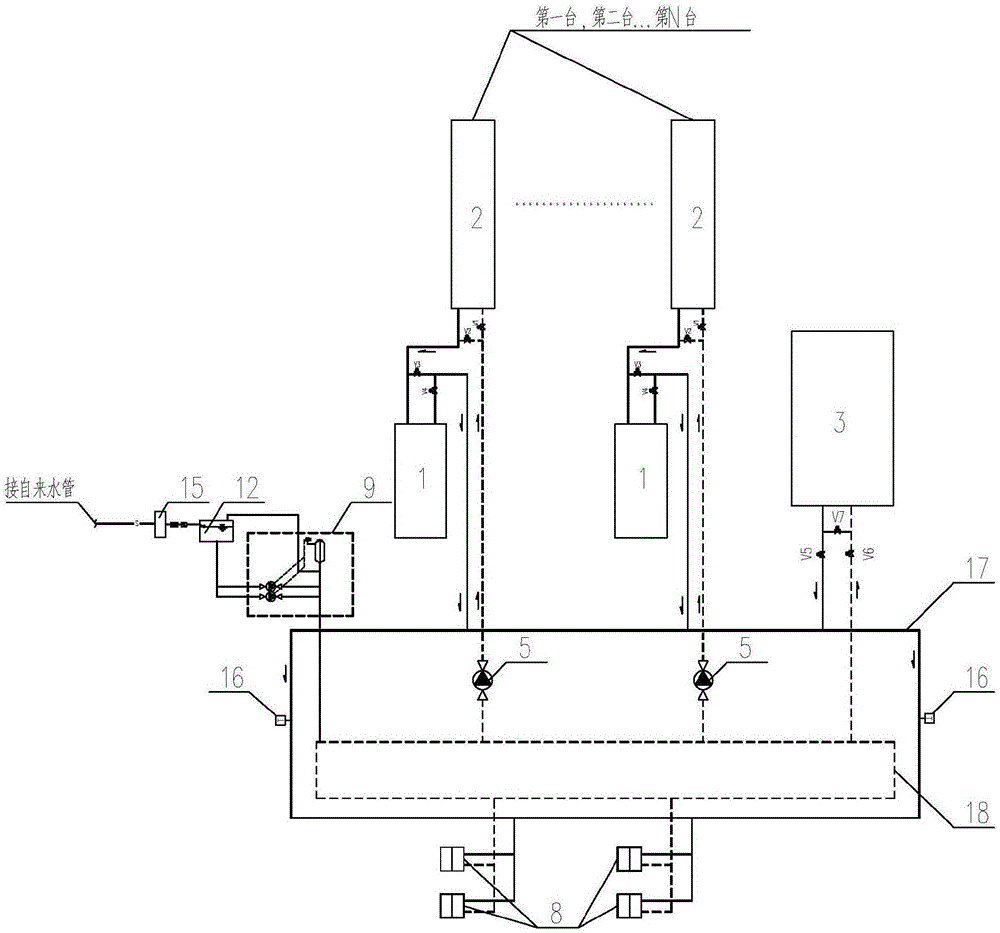

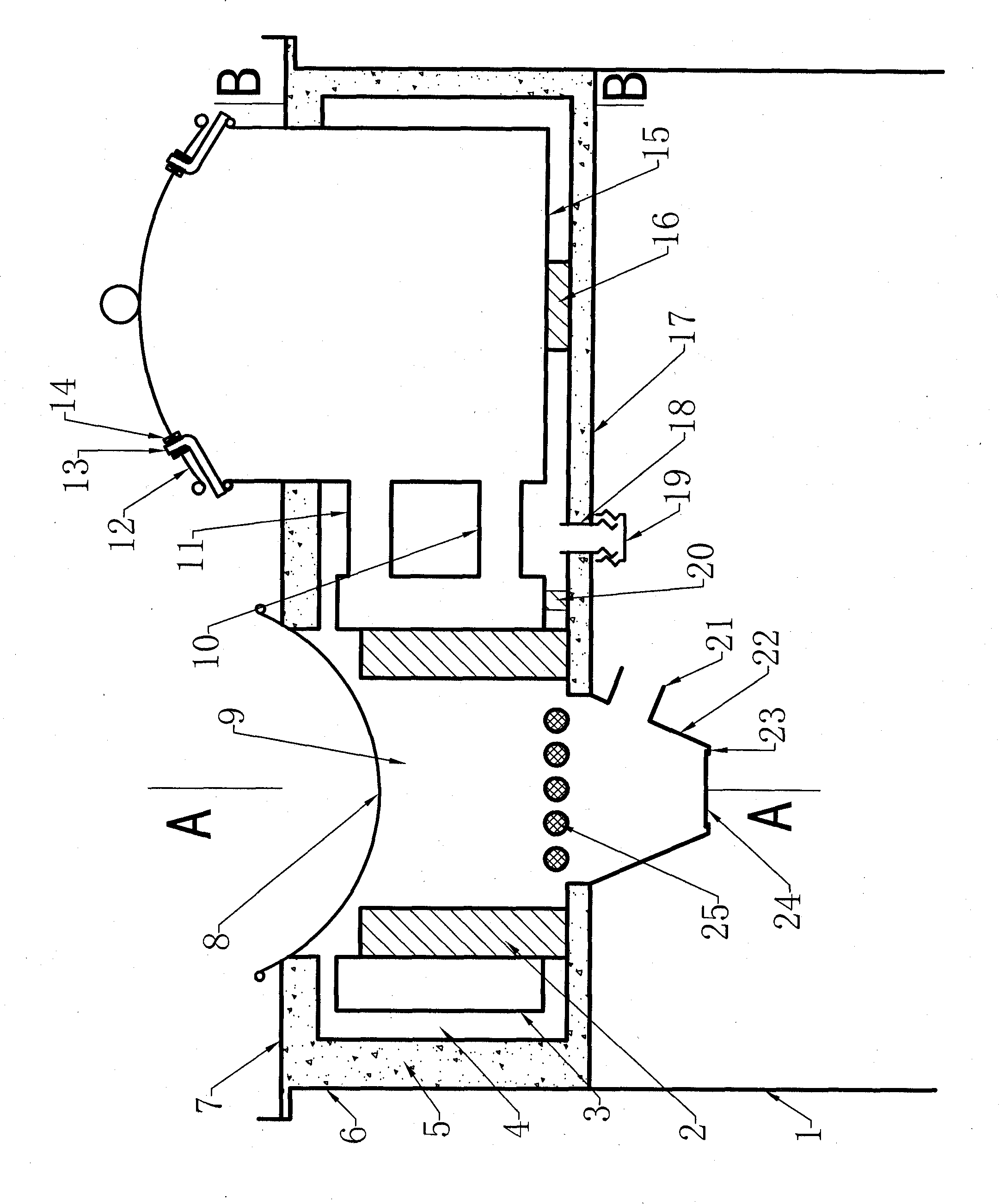

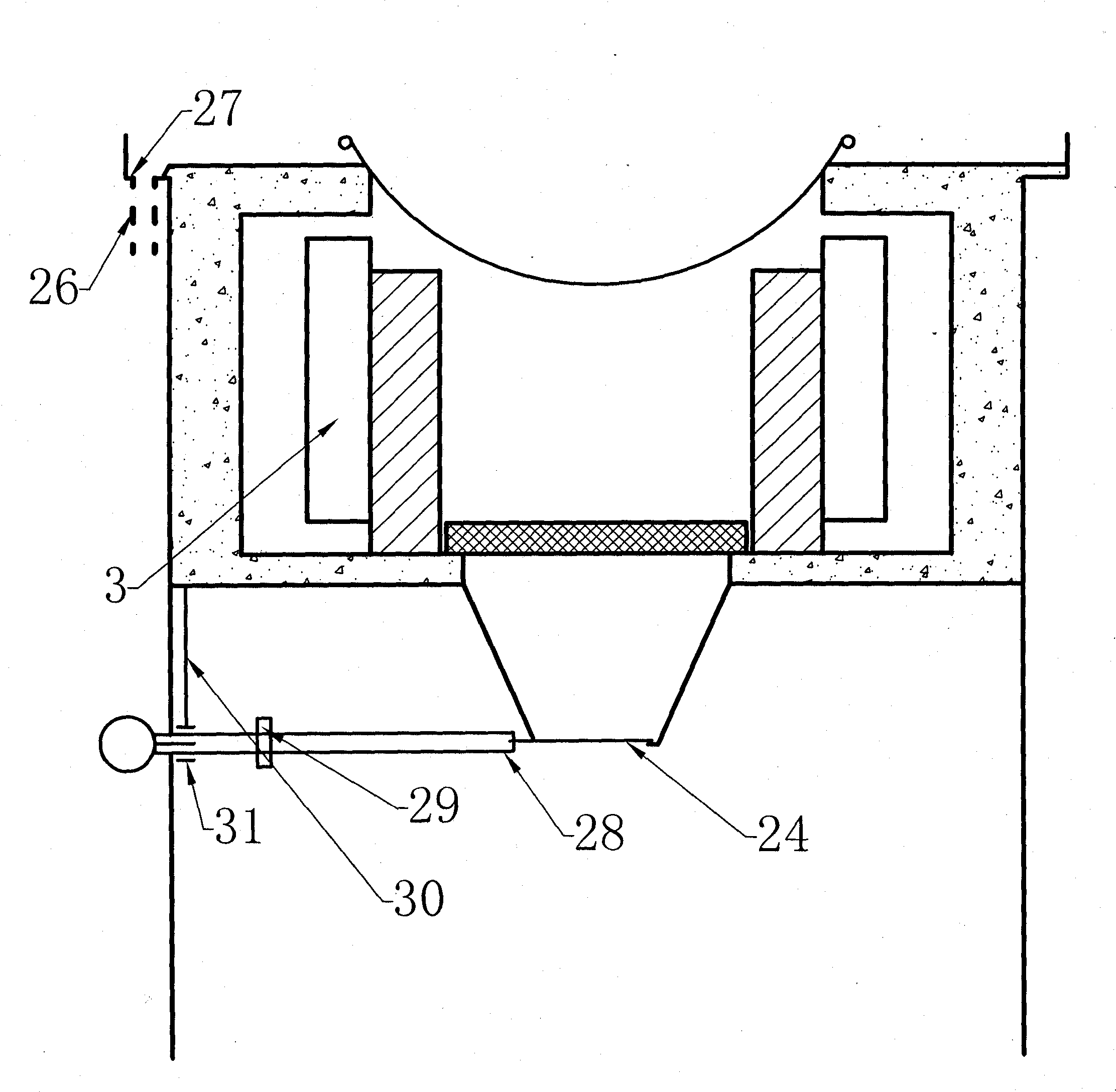

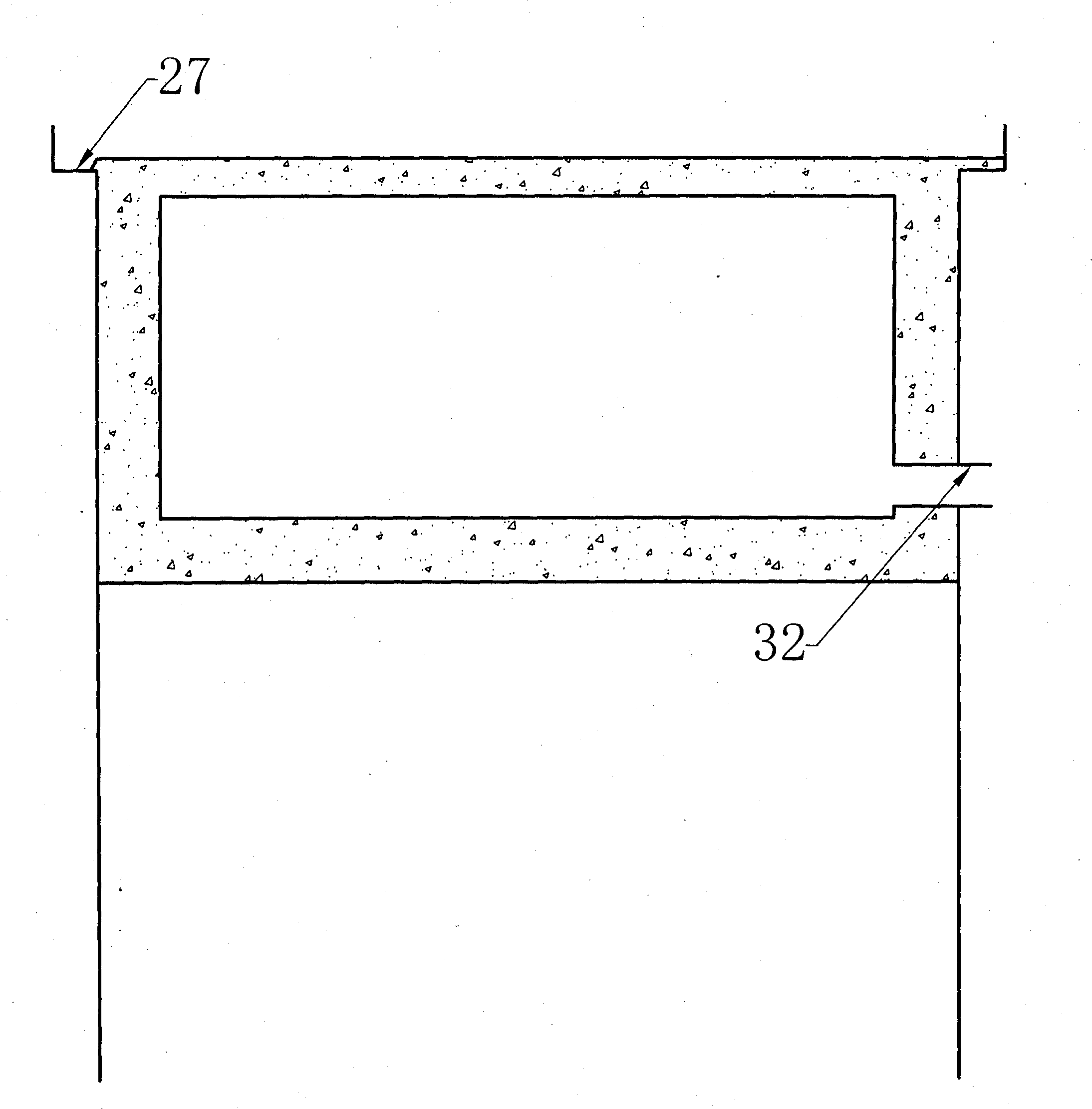

The present invention discloses an oil shale carbonization oil refining, carbocoal burning electricity generating integrated technology. The present invention is characterized in that green ore oil shale is crushed into 0 to 15mm grains by a crusher, through that circulating fluid bed boiler circulating ash is used as a solid heat carrier, the mixture of the oil shale and the circulating ash is fed into a roller retort to form oil shale oil refining, carbocoal and the oil shale are mixed, fluidized and burned to generate electricity as a whole, separated non-condensation carbonization coal gas is fed into the circulating fluid bed boiler and the both are burned with the carbocoal and the oil shale together or is fed into a gas engine for direct-fired power generation; the carbon content of the clinker after burned on the circulating fluid bed is less than 2 percent, thus no further roasting is necessary, and the present invention can be directly used as building raw material; the thermal value of produced carbonization coal gas which can be directly used as fuel to feed into the boiler for burning is high, the quantity of heat released through burning can be transferred to the water through the heated surface of the boiler, the water is heated into a overheat steam to be used as out-supplied working substance and / or to be fed into a steam turbine for power and electricity generating. The present invention has the advantages that the comprehensive utilization degree is high, the cost is low, the technology is scientific and reasonable, etc.

Owner:NORTHEAST DIANLI UNIVERSITY +1

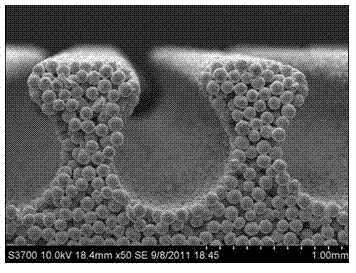

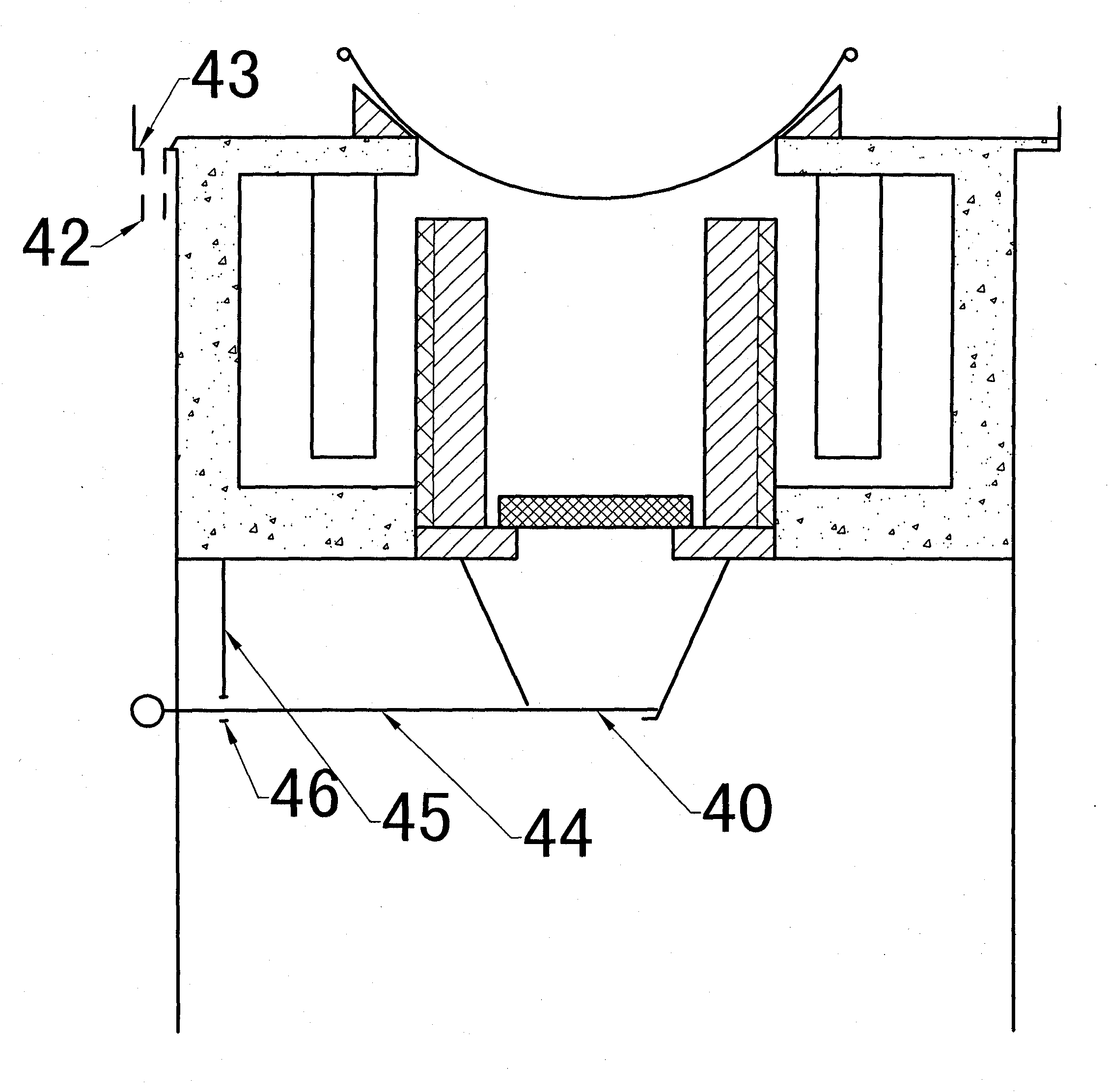

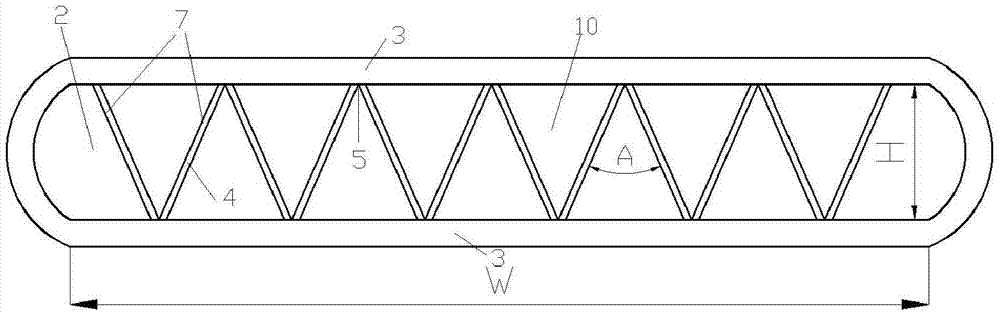

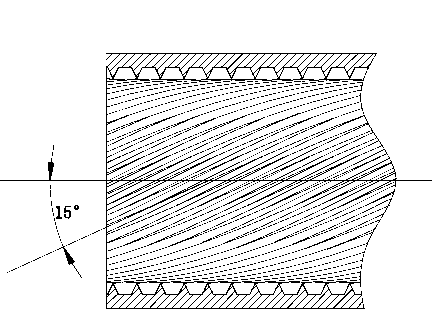

Inner groove porous strengthened boiling micro-channel structure, manufacture method and application

InactiveCN102878845AHigh transmission frequencyHigh porosityIndirect heat exchangersHeat flowEnhanced heat transfer

The invention discloses an inner groove porous strengthened boiling micro-channel structure, which includes a metal sintered felt formed by sintering metal powder and provided with uniformly-distributed particles, wherein a plurality of inner grooves are uniformly distributed in the metal sintered felt. The porous surface of the inner groove porous strengthened boiling micro-channel structure has excellent capillary characteristics, can keep the wall surface to be sufficiently damp, avoids the local scabbing and polymer deposit caused by hot spot and local drying, improves the heat transfer coefficient and critical heat flux density by adopting the porous structure for strengthened boiling heat transfer, and has excellent strengthened heat transfer effect.

Owner:SOUTH CHINA UNIV OF TECH

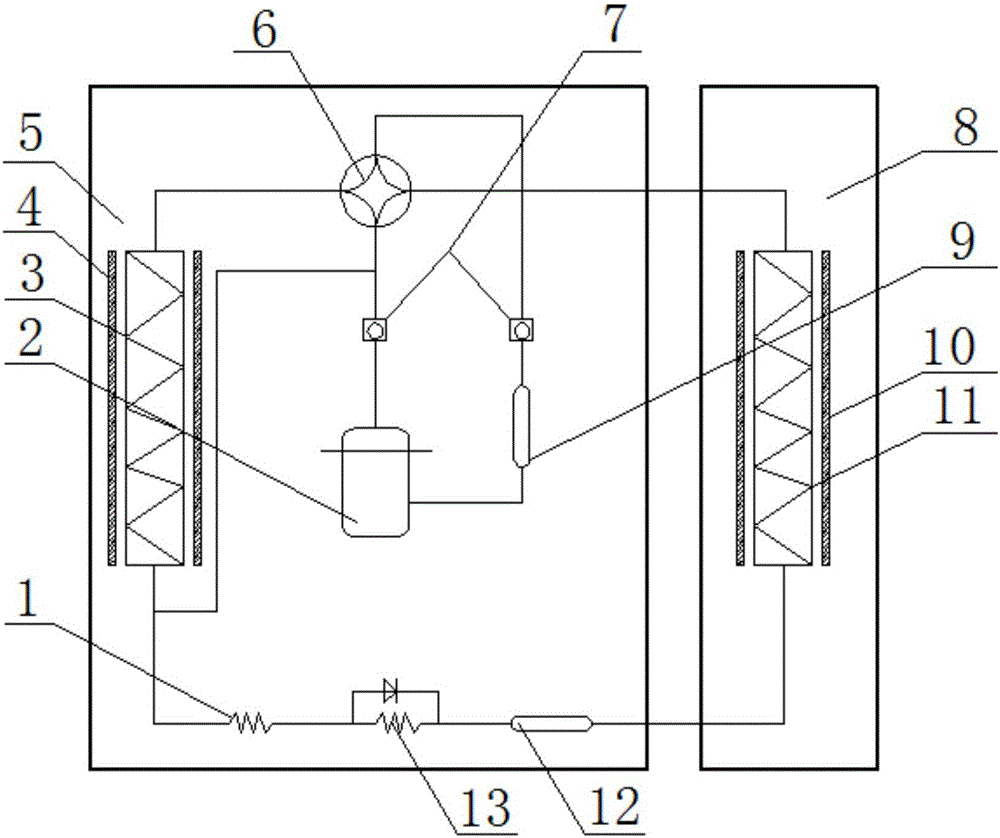

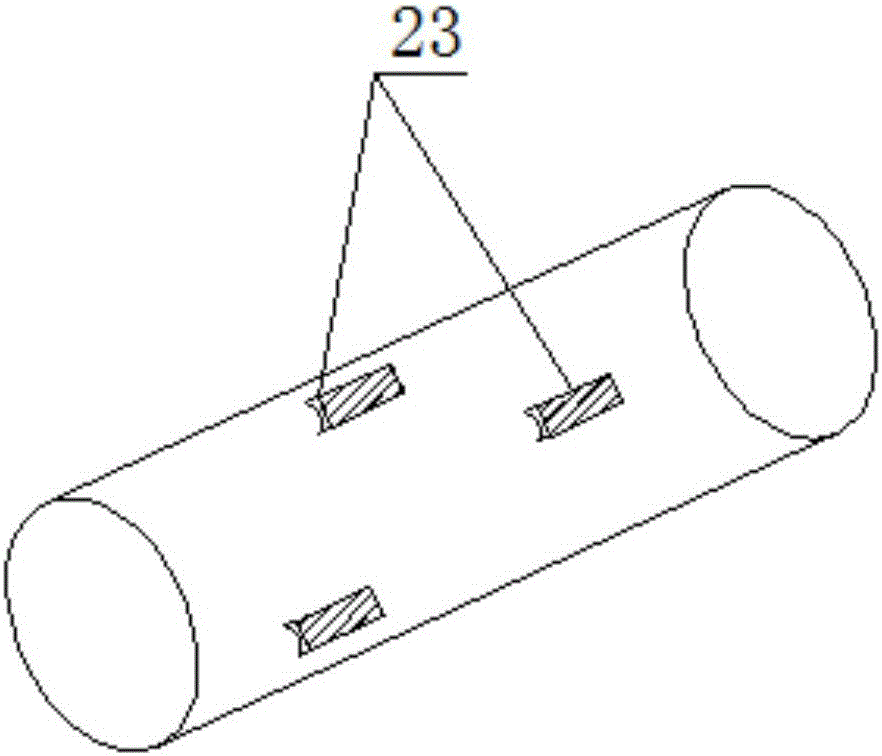

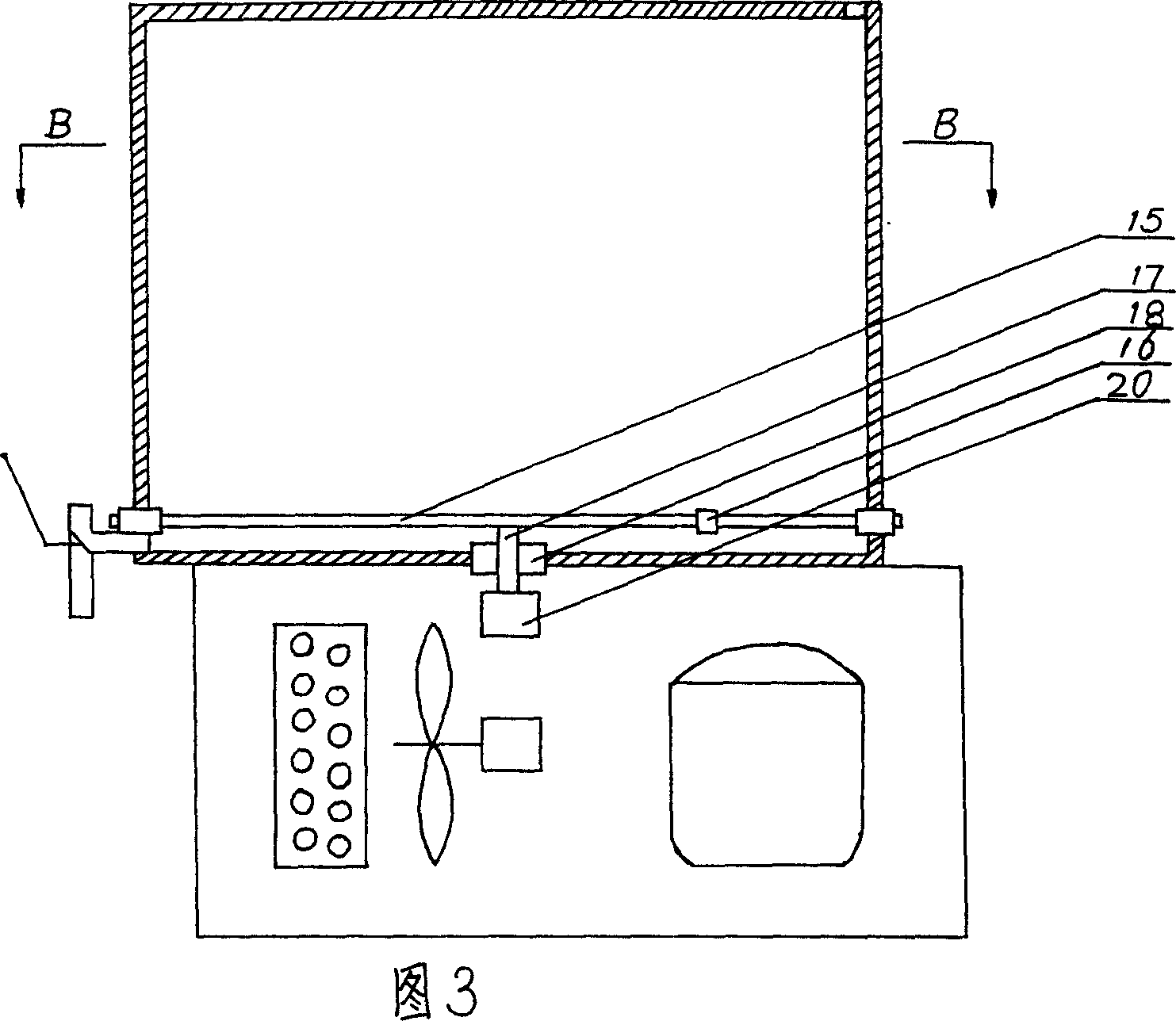

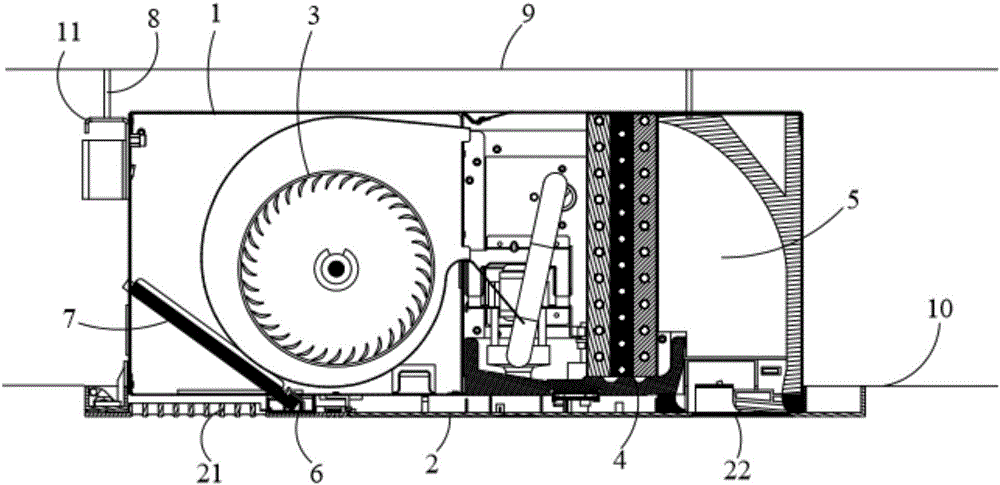

Internal descaling and external defrosting novel air conditioner applying ultrasonic oscillators

InactiveCN105890050AStable operating environmentExtended service lifeMechanical apparatusNoise suppressionVapor–liquid separatorShell and tube heat exchanger

The invention provides an internal descaling and external defrosting novel air conditioner applying ultrasonic oscillators. The internal descaling and external defrosting novel air conditioner comprises an outdoor unit and an indoor unit. The outdoor unit and the indoor unit are connected through a pipeline. The indoor unit comprises the indoor ultrasonic oscillators and an indoor heat exchanger, wherein the indoor ultrasonic oscillators are located around the indoor heat exchanger. The indoor heat exchanger is a shell and tube heat exchanger and comprises fins, U-shaped pipes, an air inlet pipe, process reinforcement tubes, a liquid outlet pipe and bridging elbows. Each U-shaped pipe comprises two free ends extending in the same direction in parallel, and a bent part located between the two free ends, wherein the free ends are inserted in the corresponding fins. Ports of the free ends of every two adjacent U-shaped pipes are connected through the corresponding bridging elbow. The outdoor unit comprises a capillary tube, a compressor, an outdoor heat exchanger, the outdoor ultrasonic oscillators, a four-way valve, air-liquid separators, a filter and a check valve, wherein the outdoor ultrasonic oscillators are located around the outdoor heat exchanger. By means of the internal descaling and external defrosting novel air conditioner, ultrasonic non-stop on-line internal descaling and external defrosting can be achieved, the stable running environment of the air conditioner is ensured, and the service life is prolonged.

Owner:NANJING NORMAL UNIVERSITY

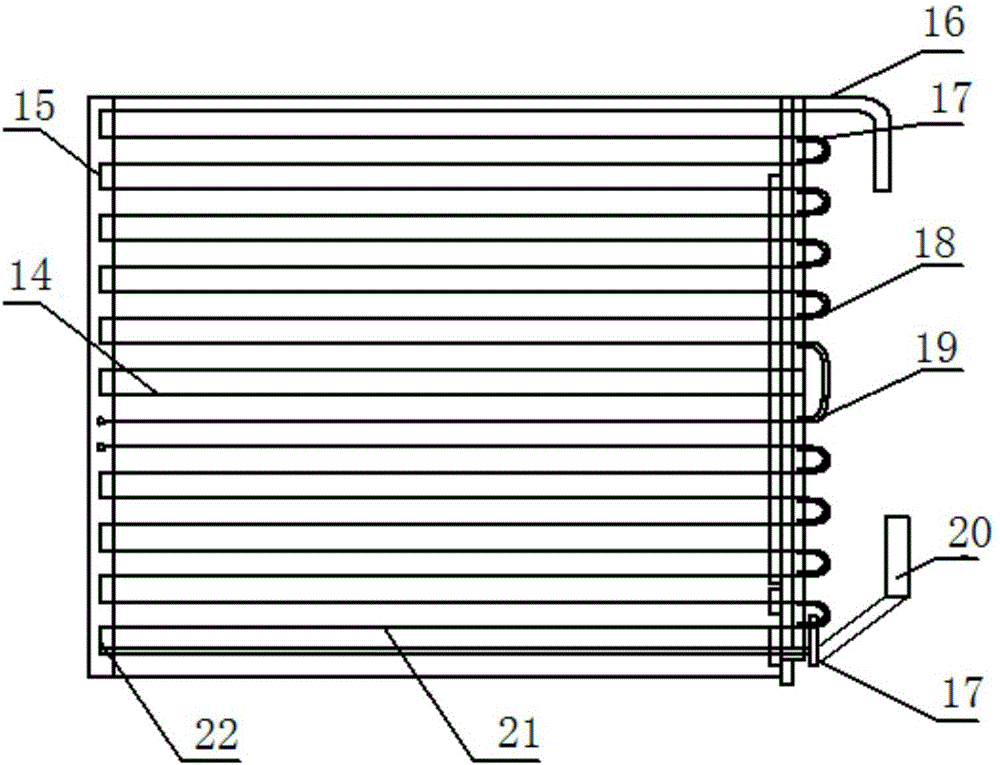

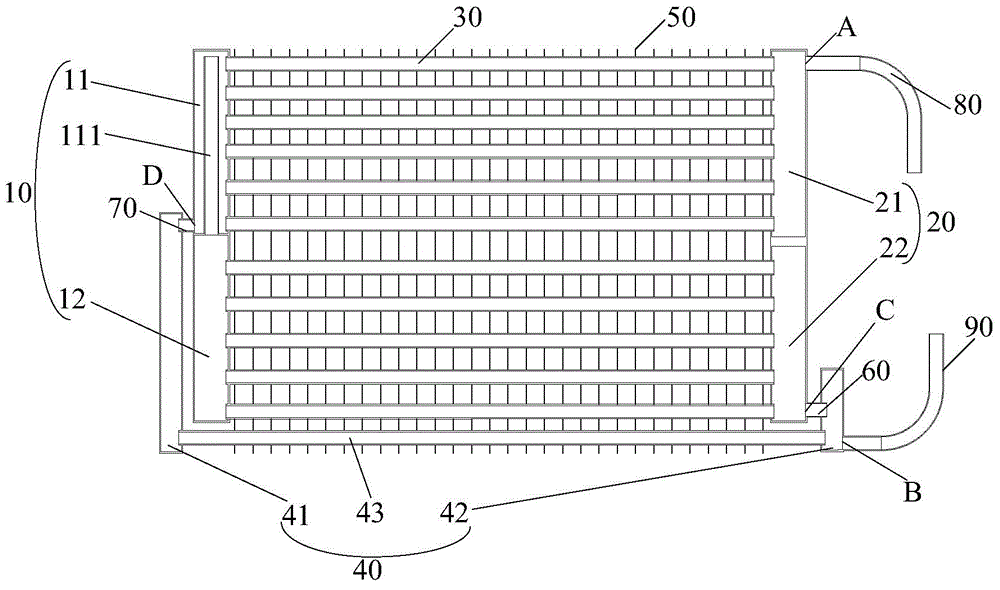

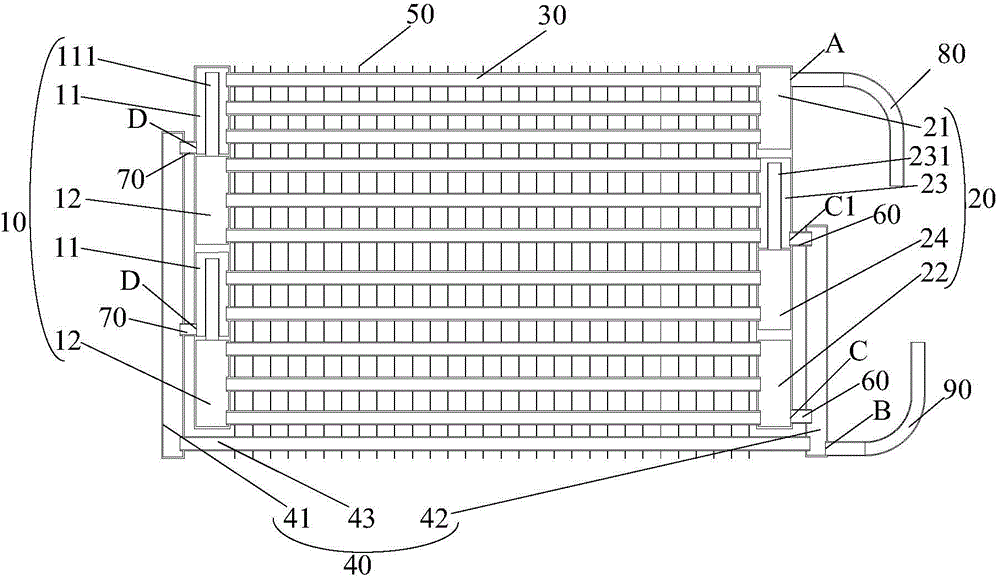

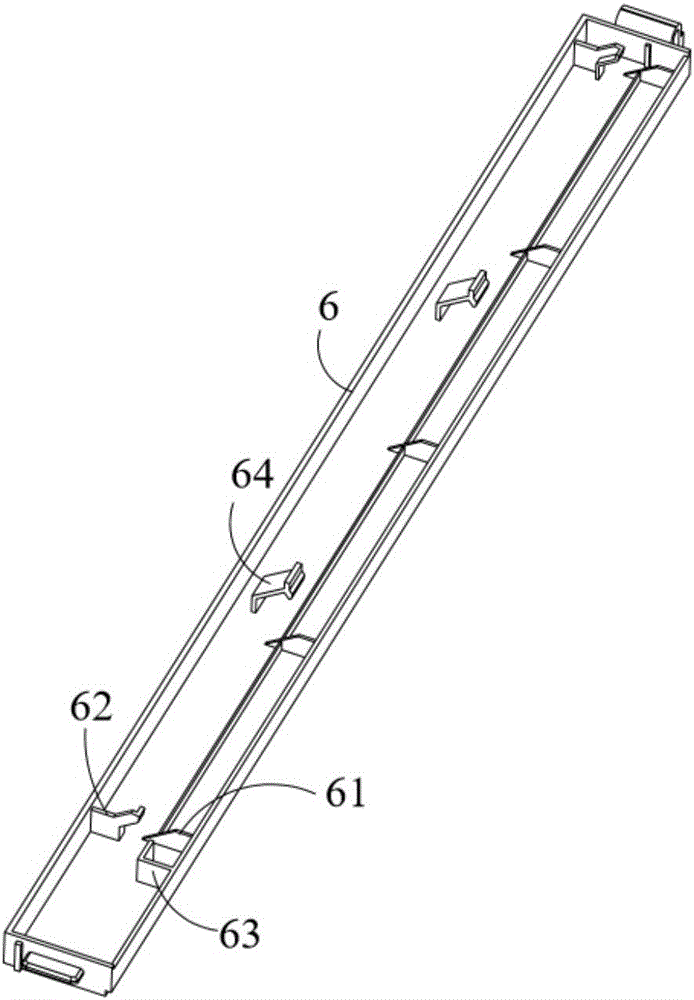

Condenser and air conditioner comprising same

ActiveCN103604255AIncrease the effective heat transfer areaGood heat transfer effectEvaporators/condensersRefrigerantEngineering

The invention discloses a condenser and an air conditioner comprising the same. The condenser comprises a left end flow collecting pipe, a right end flow collecting pipe, a liquid collecting pipeline communicated with the left end flow collecting pipe and the right end flow collecting pipe and a plurality of heat exchanging pipes connected between the left end flow collecting pipe and the right end flow collecting pipe in parallel. Two ends of the heat exchanging pipes are communicated with the left end flow collecting pipe and the right end flow collecting pipe, a refrigerant inlet is formed in the left end flow collecting pipe or the right end flow collecting pipe, and a refrigerant outlet is formed in the liquid collecting pipeline. The left end flow collecting pipe and the right end flow collecting pipe are used for separating liquid refrigerant formed after heat exchanging through the heat exchanging pipes from gaseous state refrigerant and guiding the separated liquid refrigerant to flow into the liquid collecting pipeline. By separating the liquid refrigerant formed through condensing, a large amount of space of the heat exchanging pipes can not be occupied by more and more liquid refrigerant, effective heat exchanging area of the heat exchanging pipes can be kept maximum all the time, a heat exchanging effect is good, and heat exchanging efficiency of the condenser is greatly improved.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

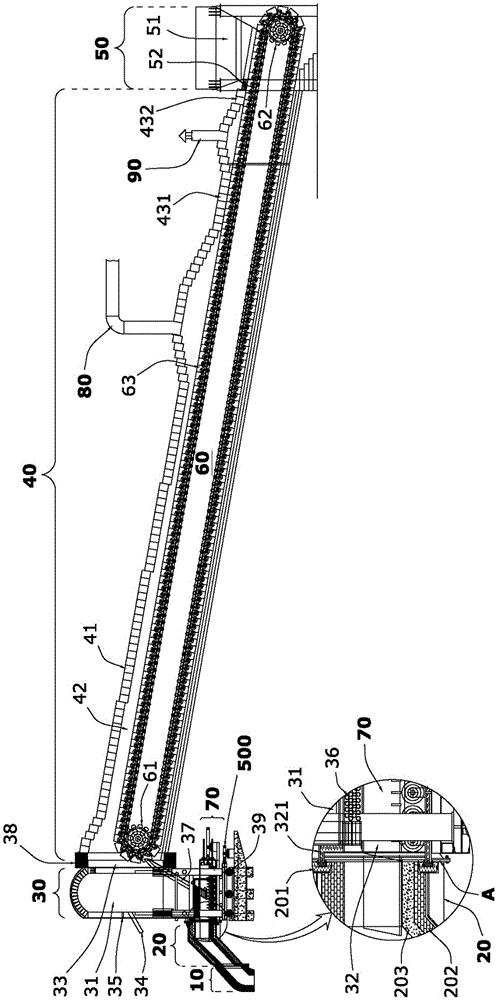

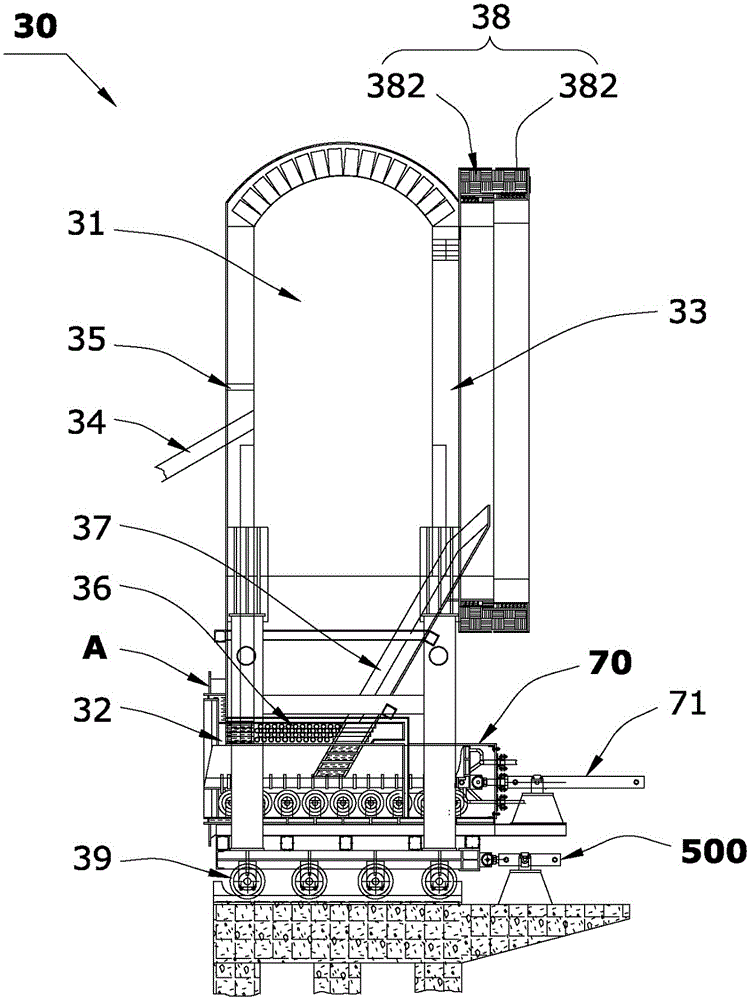

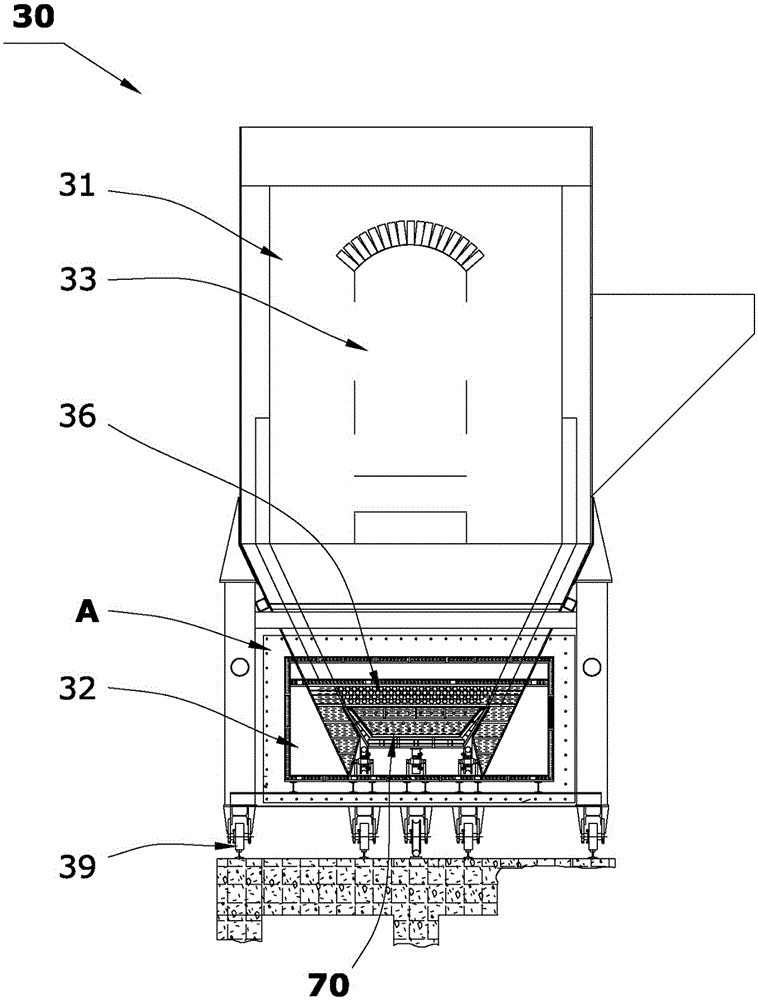

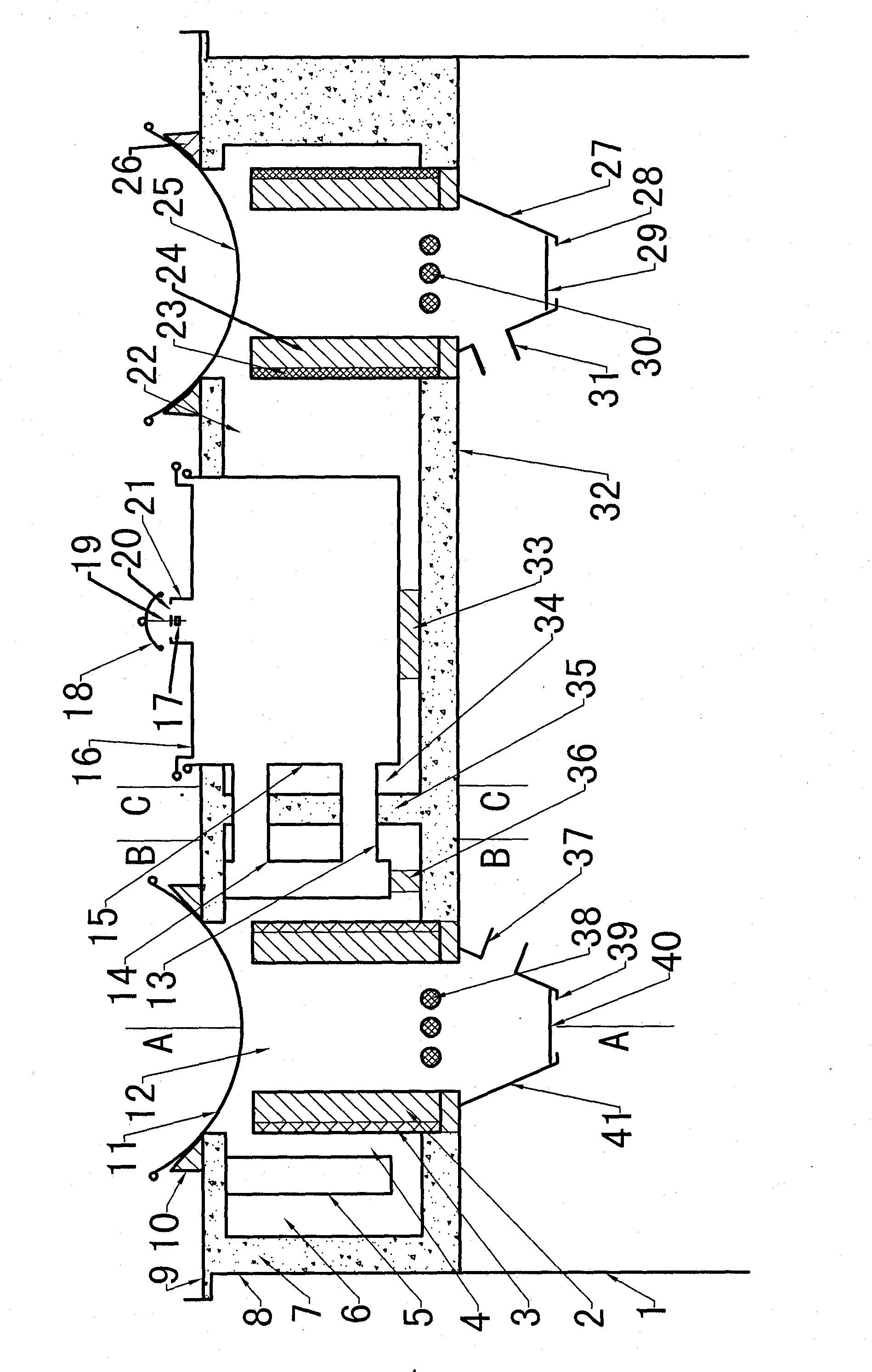

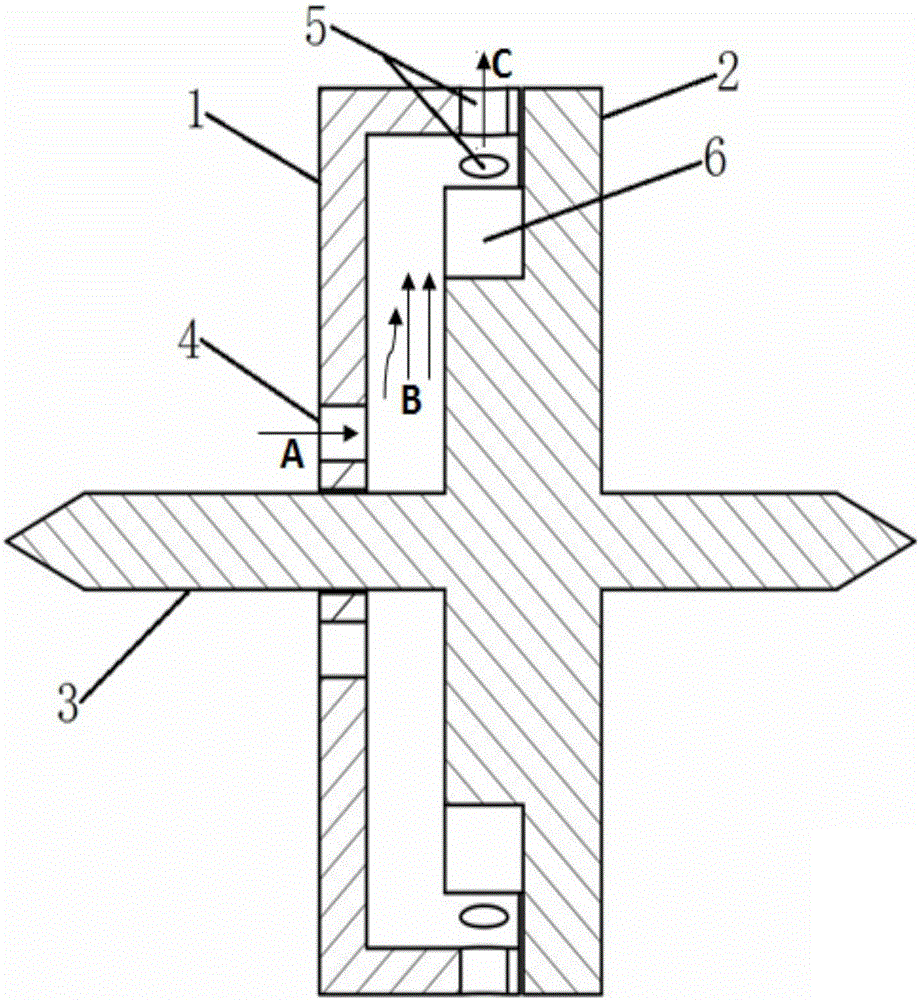

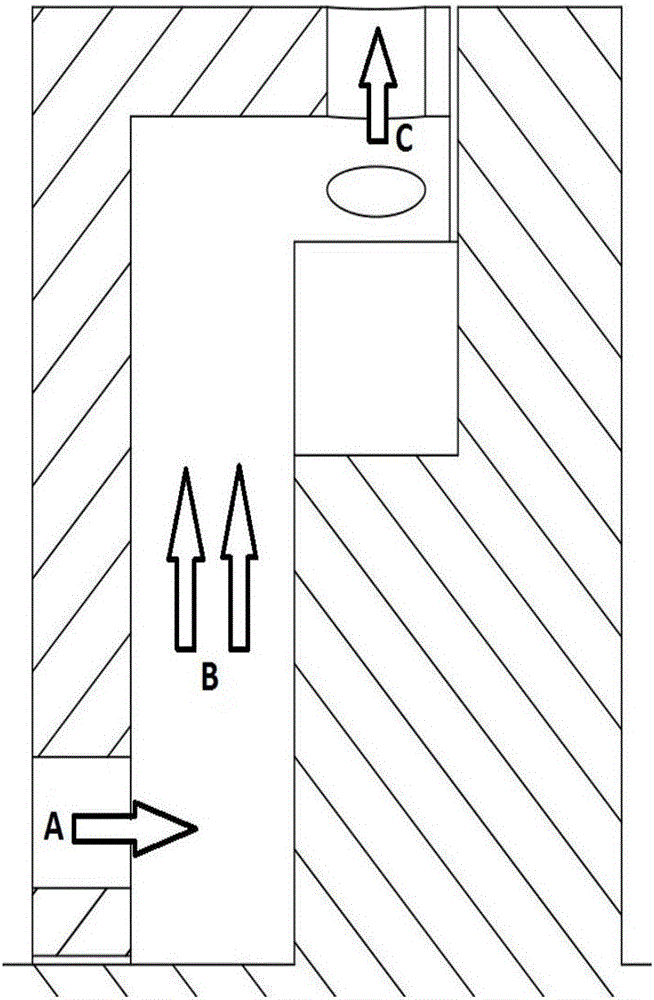

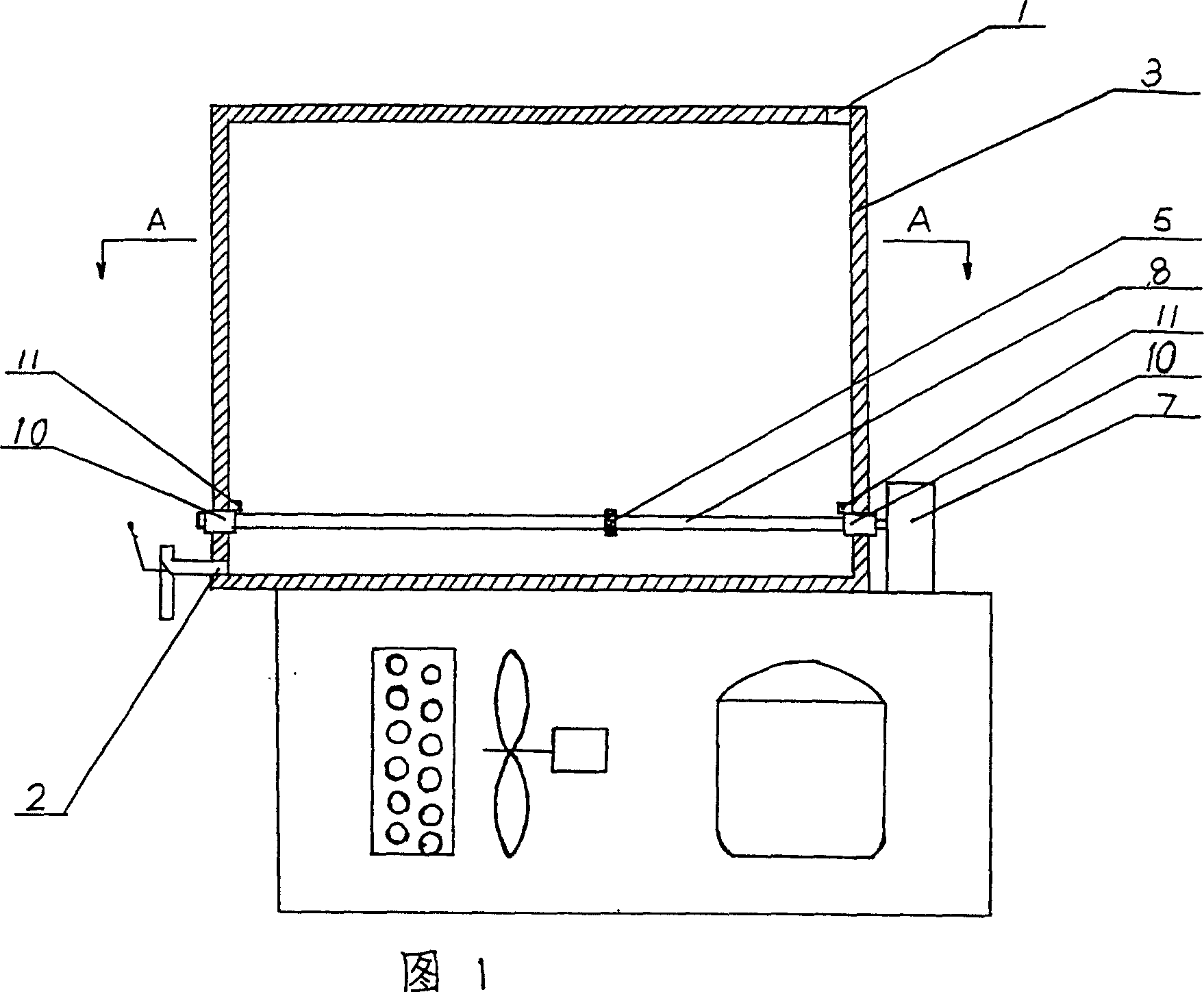

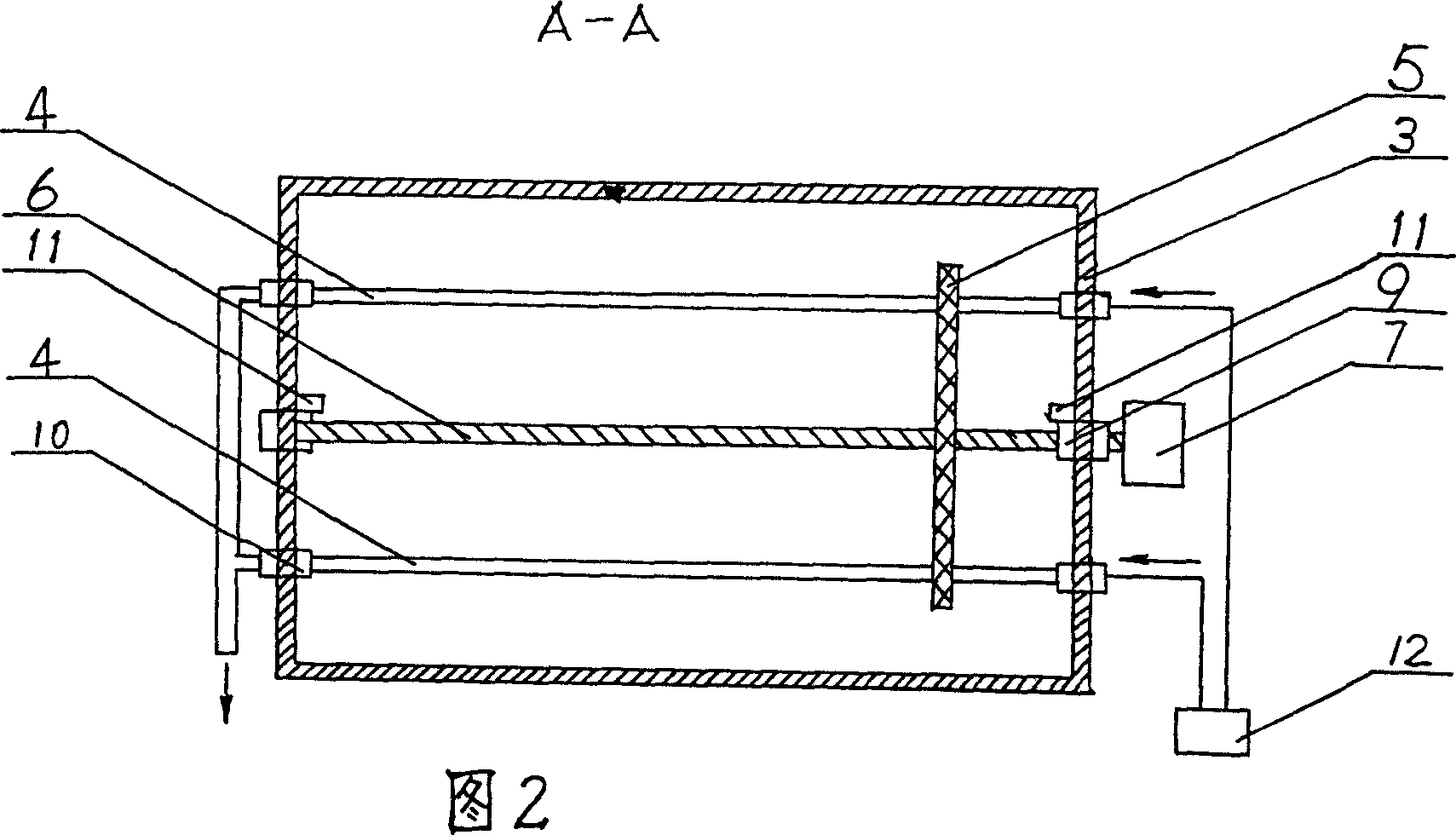

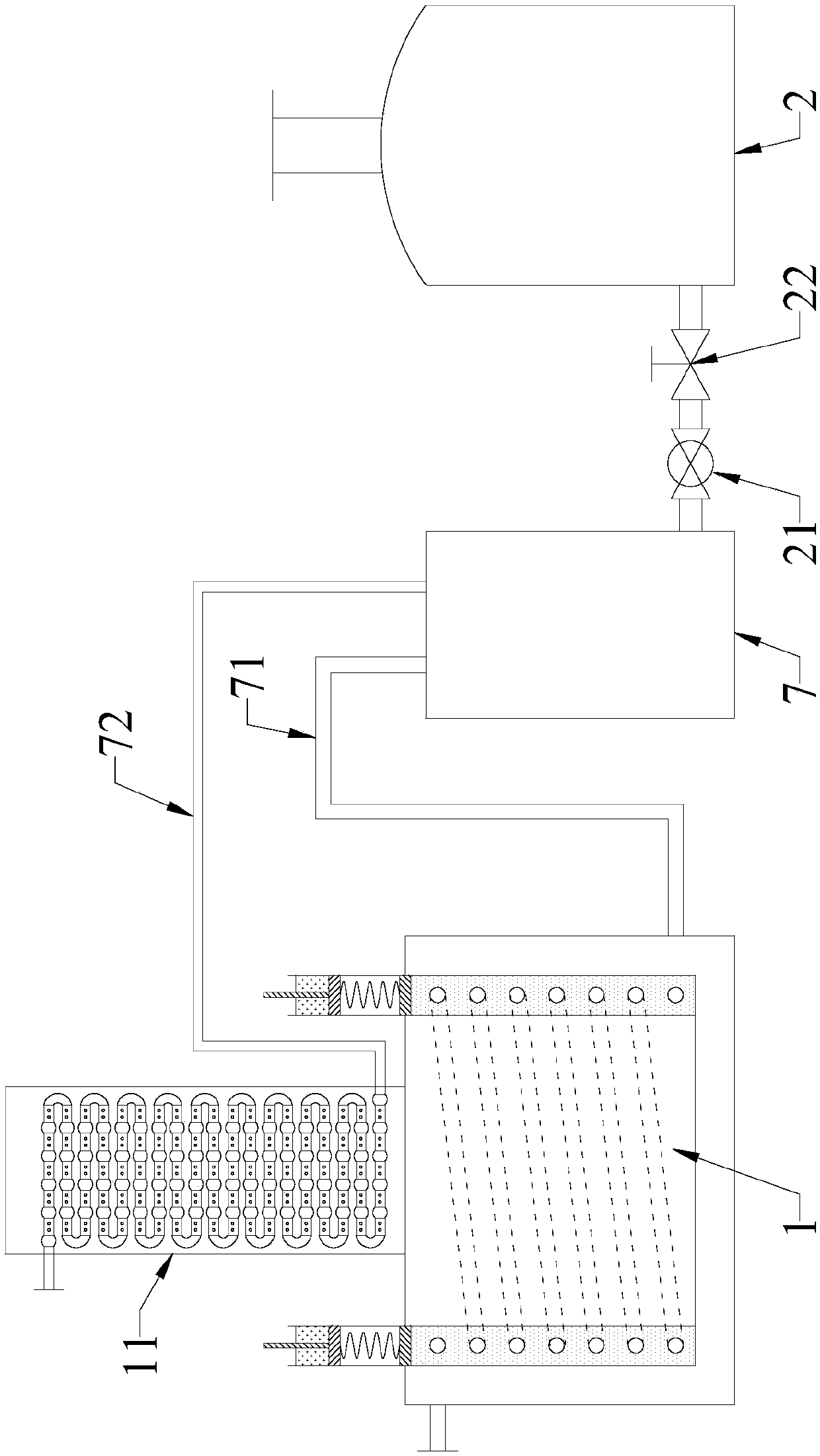

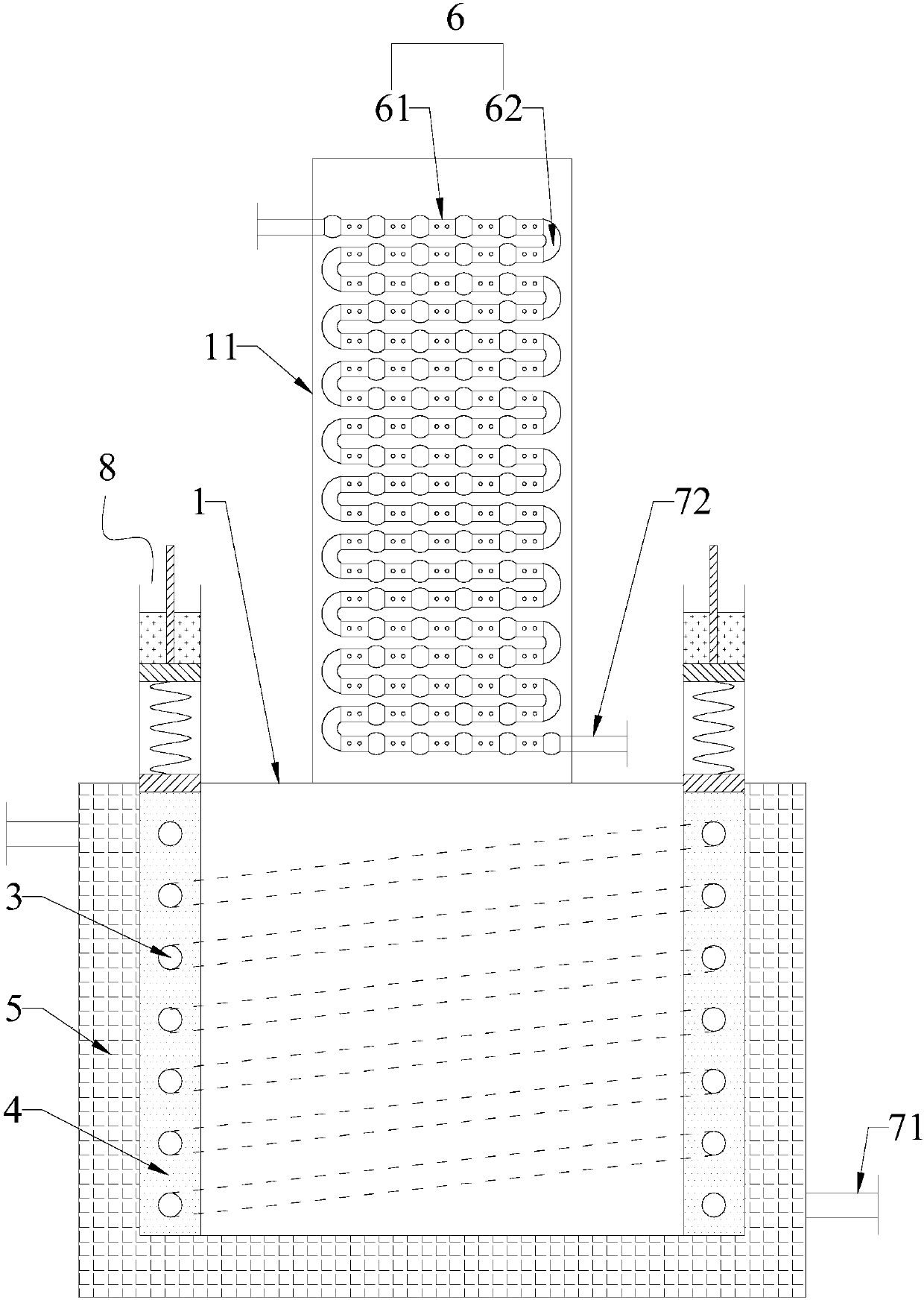

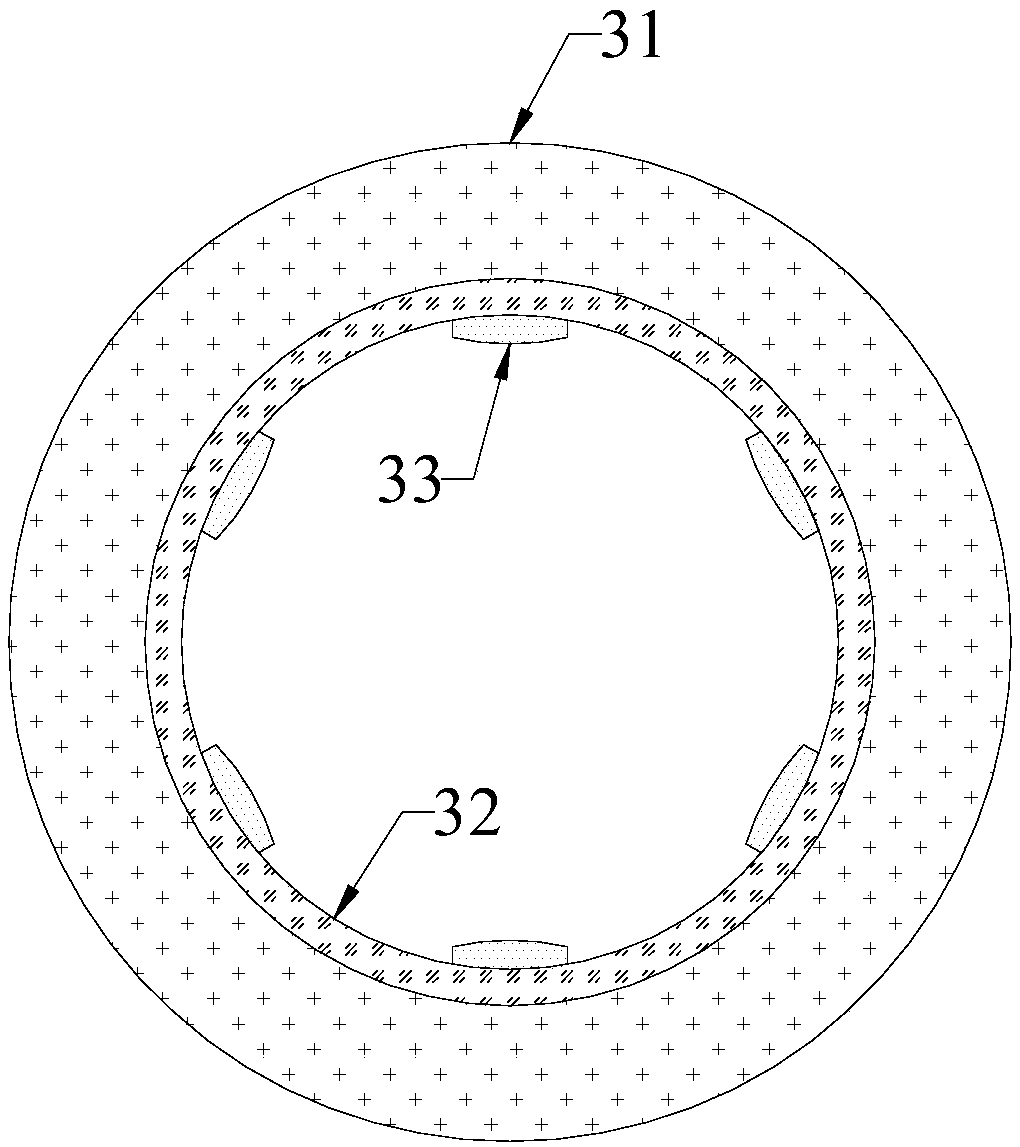

Scrap steel preheating and continuous feeding system constructed based on waste heat recovering channel of electric-arc furnace and application method of system

ActiveCN105132619AIncrease contact areaGood heat transfer effectConveyorsProcess efficiency improvementSlagScrap

The invention discloses a scrap steel preheating and continuous feeding system constructed based on a waste heat recovering channel of an electric-arc furnace and an application method of the system. The waste heat recovering channel of the electric-arc furnace is formed by connecting a flow guide tube, a transition tube, a heat exchange and material storing box and a preheating channel, wherein hot gas sequentially flows through the flow guide tube, the transition tube, the heat exchange and material storing tube and the preheating channel; a scrap steel storing box, a heat-resistant chain scraper conveyor and a hydraulically-controlled feeding trolley are mounted on a foundation of the waste heat recovering channel of the electric-arc furnace to form the scrap steel preheating and continuous feeding system; the scrap steel is conveyed from low to high through the chain scraper conveyor in the preheating channel and continuously fed into the heat exchange and material storing box to be stacked, and then the feeding trolley at the inner bottom part of the heat exchange and material storing box can continuously intermittently move to push the scrap steel by layers from the bottom into the electric-arc furnace to smelt; the scrap steel fed into the furnace is at the temperature exceeding 900 DEG C, and more than 120kW.H / T of electricity can be saved; the gas can be discharged from the preheating channel while being cooled to be 100-150 DEG C and then dedusted for later use, and thus the energy can be saved, and the consumption can be decreased; in addition, the continuous feeding system does not affect the automatic slag flowing and tapping works of the electric-arc furnace.

Owner:NANJING YOU RONG ENERGY SAVING TECH CO LTD

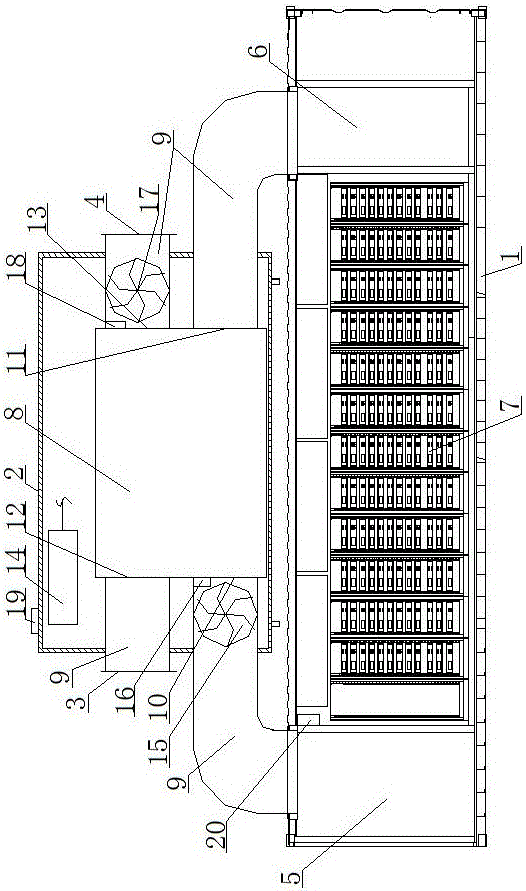

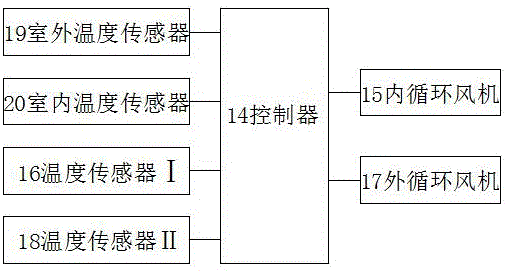

Frequency-conversional multi-connected air-conditioning system and control method thereof

ActiveCN108195099AGood heat transfer effectReduce protection downtimeCompressorMechanical apparatusRefrigerantChiller

The invention discloses a frequency-conversional multi-connected air-conditioning system and a control method thereof, and relates to the technical field of multi-connected air-conditioning systems. The frequency-conversional multi-connected air-conditioning system and the control method thereof aim to solve the problem that in the prior art, a compressor is protected and stopped due to the fact that the amount of a refrigerant in a cooler is too small. The frequency-conversional multi-connected air-conditioning system comprises an outdoor unit, a plurality of indoor units and a heat exchangemain loop; the outdoor unit comprises a first throttling device and a heat exchange branch, wherein the first throttling device and the heat exchange branch are arranged on the heat exchange main loop; the heat exchange branch comprises a cooling heat exchanger and a second throttling device; the cooling heat exchanger is used for cooling a driving circuit board of a compressor; a temperature sensor arranged on the driving circuit board of the compressor is further arranged and is used for detecting the temperature of the driving circuit board; a controller used for acquiring the temperature of the driving circuit board from the temperature sensor is further arranged; and under the condition that the temperature meets the first condition, the opening degree of the first throttling device is decreased, and / or the opening degree of the second throttling device is increased. The frequency-conversional multi-connected air-conditioning system is used for providing cooling or heating for a plurality of rooms with variable refrigerant flow.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

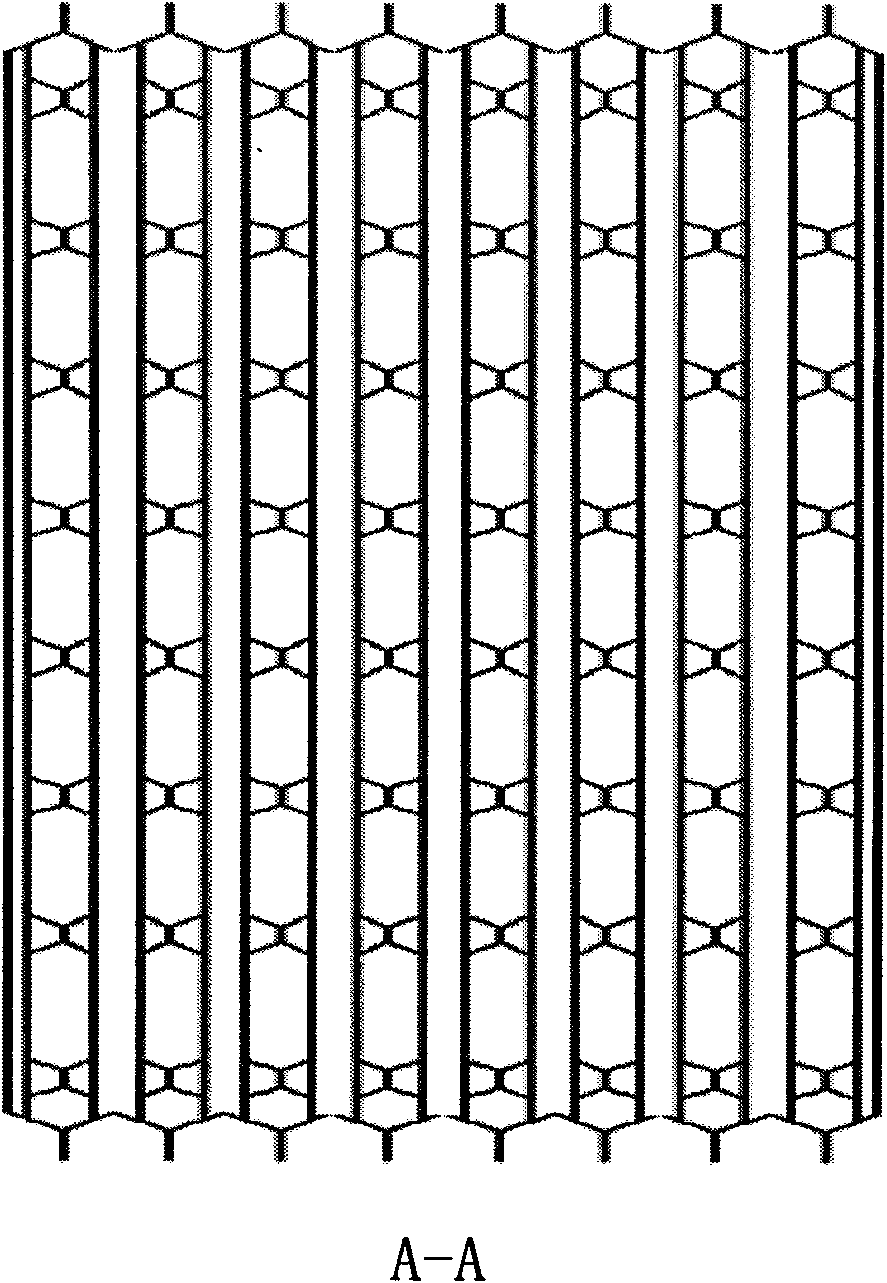

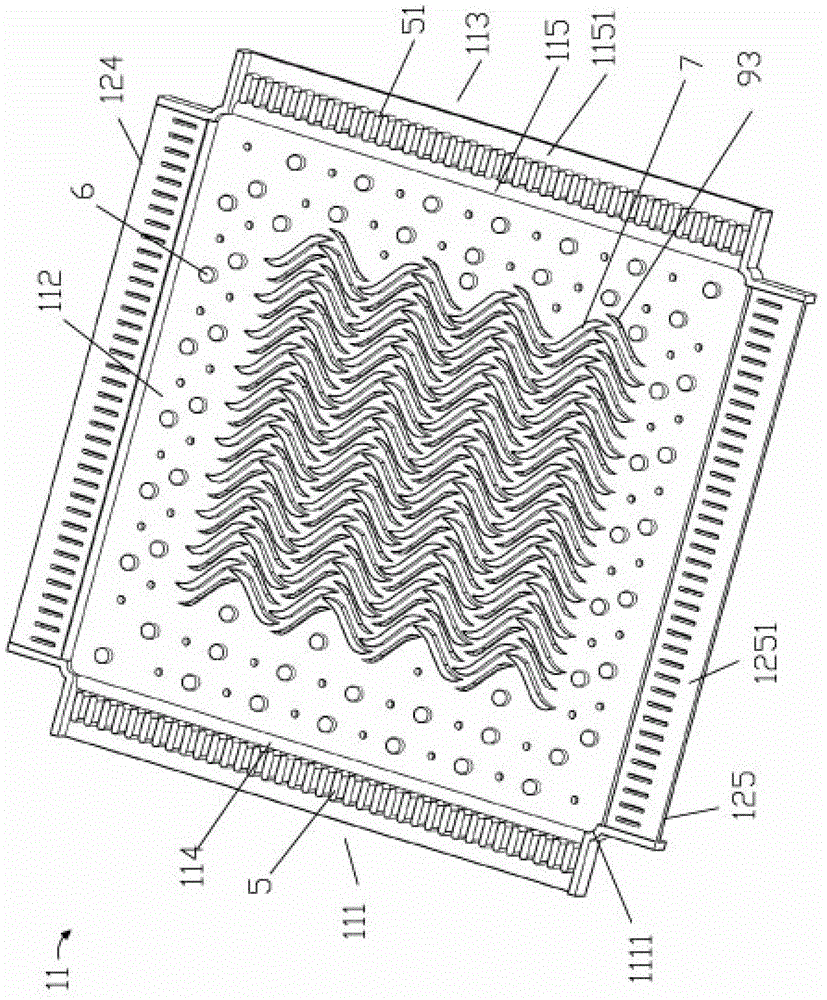

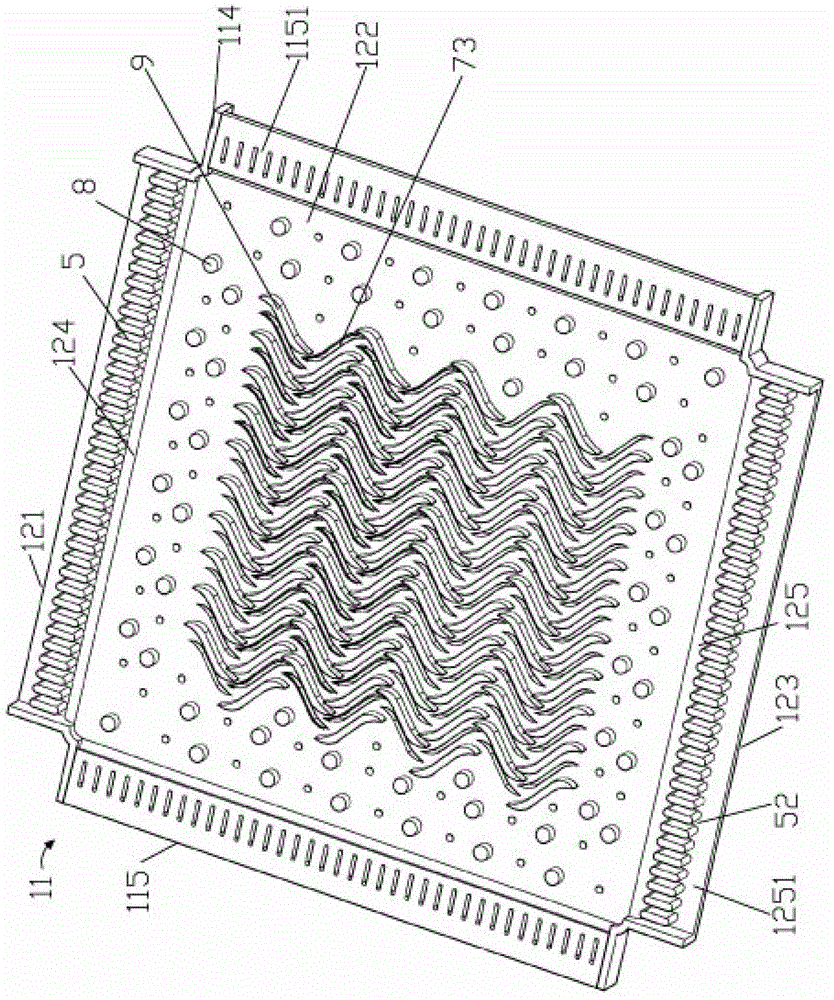

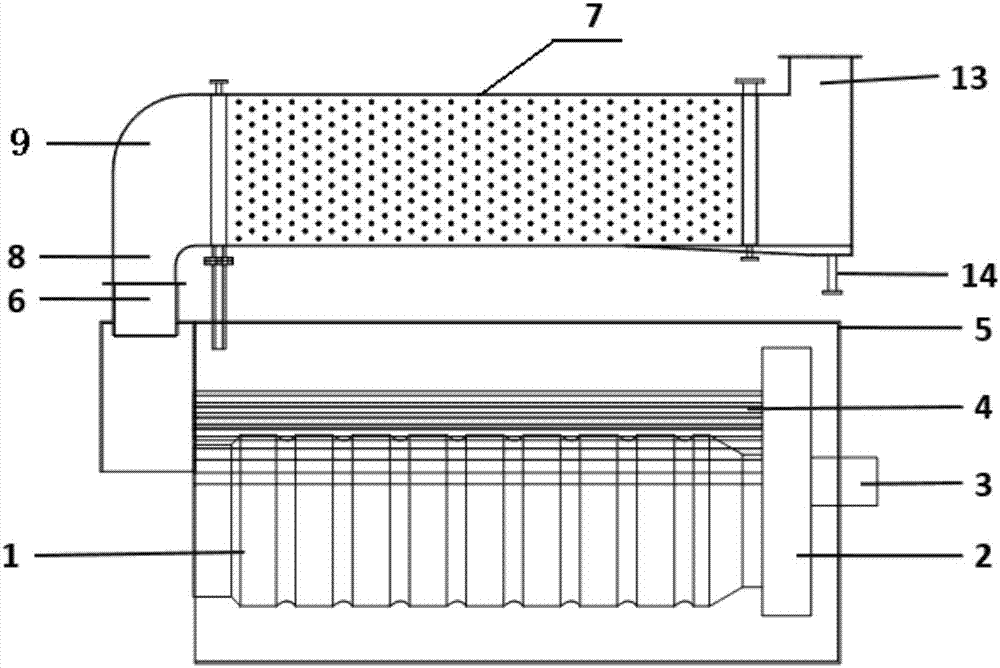

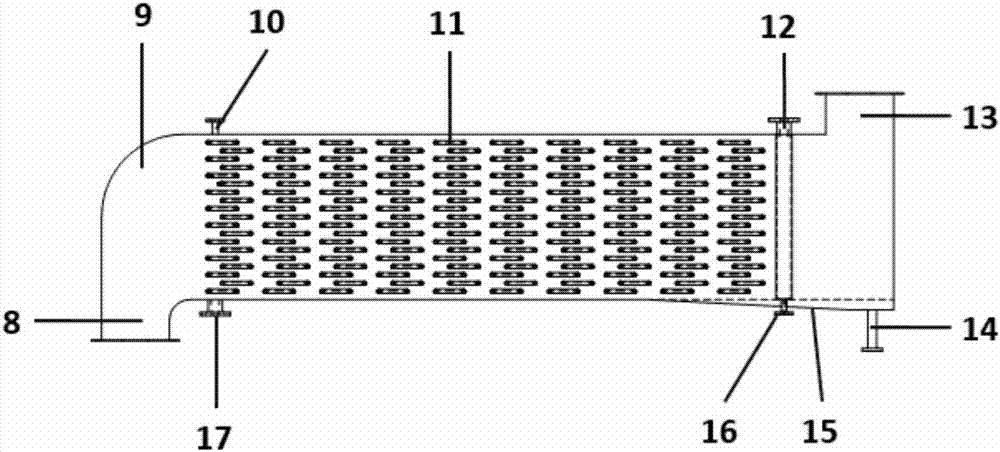

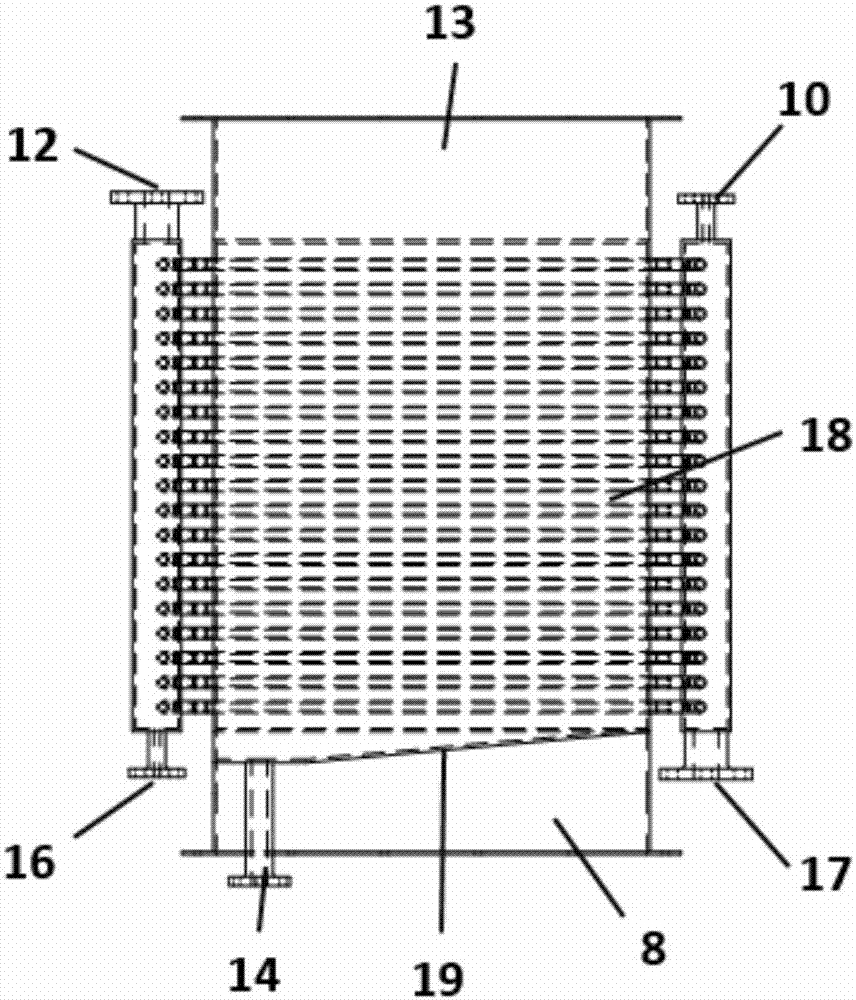

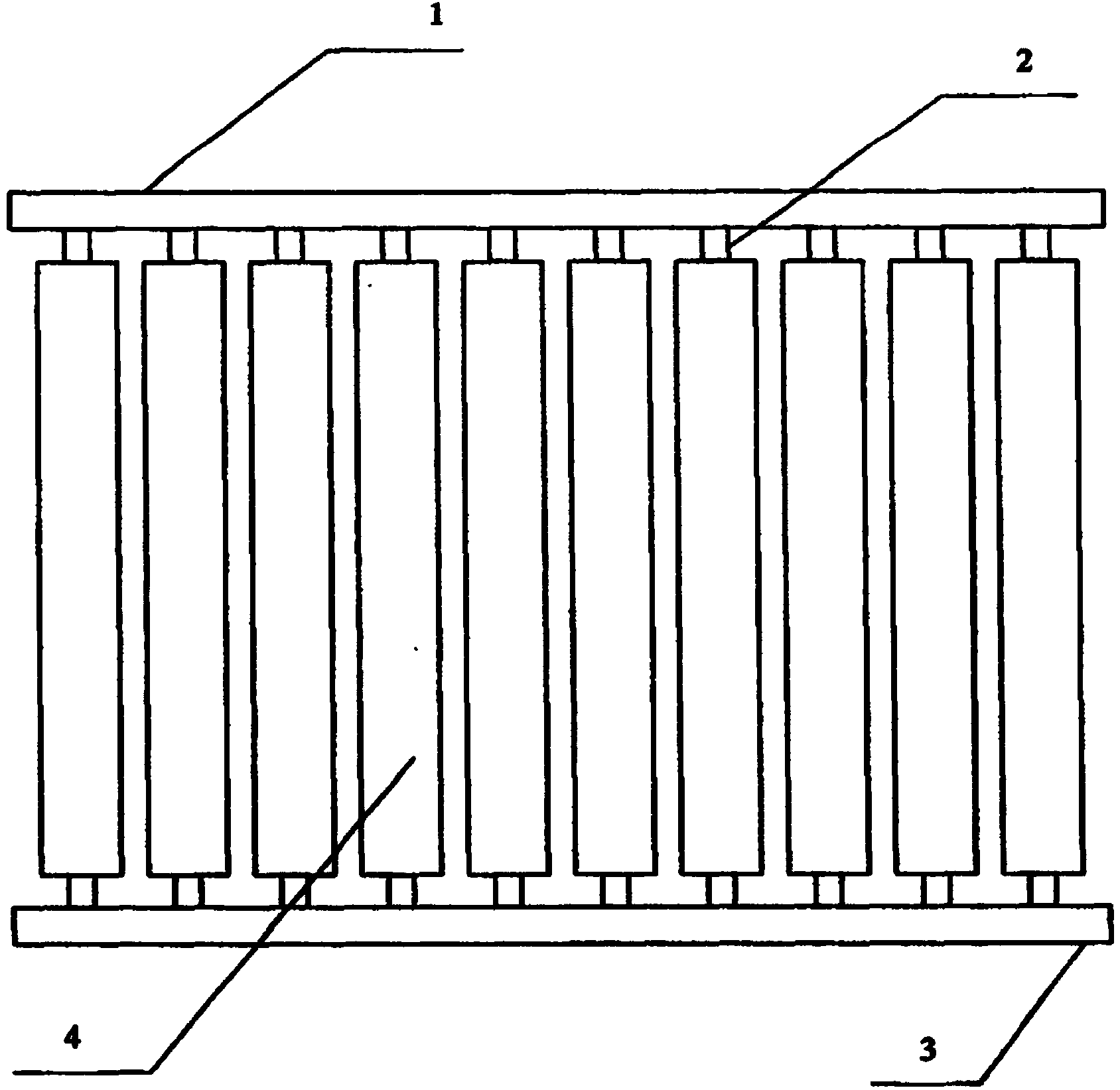

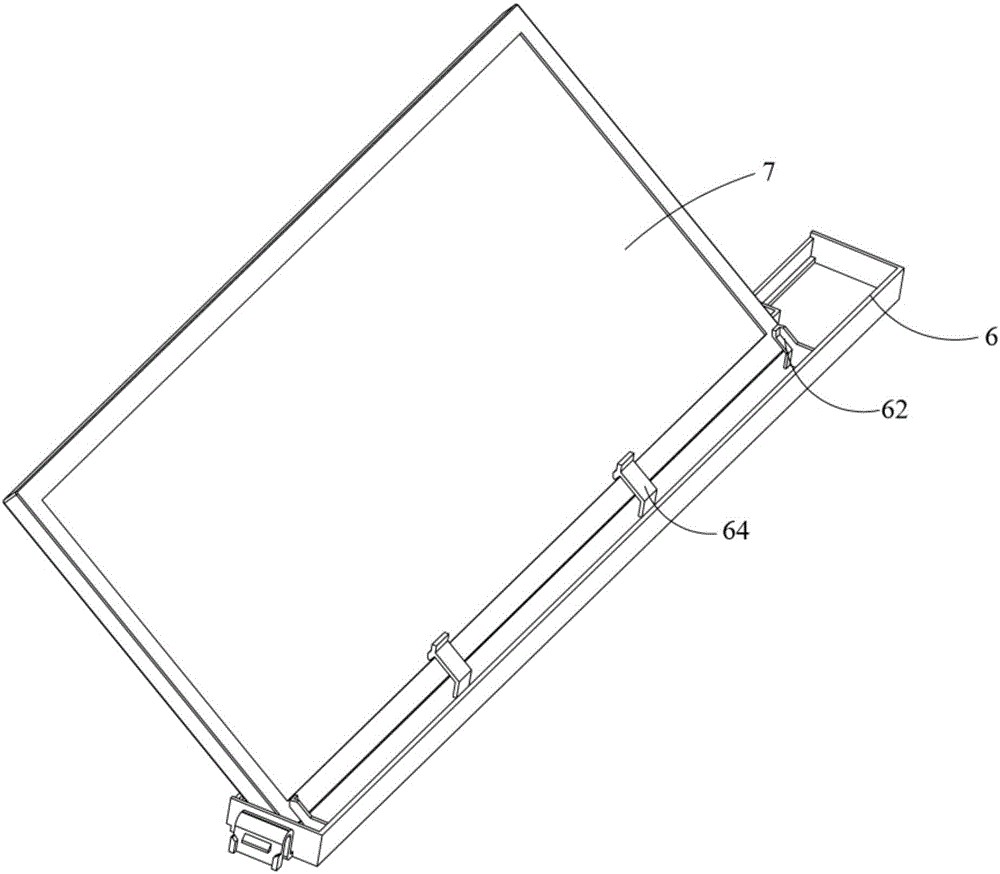

Lamella heat exchanger and manufacturing method thereof and lamella evaporative condensing equipment

InactiveCN101782345AGood heat transfer effectImprove heat transfer efficiencyLaminated elementsEngineeringFlange

The invention discloses a lamella heat exchanger comprising a lower pipe plate and heat exchange plate bundles which are vertically welded on the lower pipe plate. The heat exchange pipe bundle arranged on the outmost side is provided with a runner inlet and a runner outlet; each heat exchange pipe bundle comprises at least two mutually-overlapped and welded heat exchange plate sheets; transversely and longitudinally-arranged grooves and / or flanges are evenly distributed on the surfaces of the heat exchange plate sheets; and zigzag structures are arranged at the top ends of the heat exchange plate sheets. The invention simultaneously provides lamella evaporative condensing equipment applying the lamella heat exchanger, comprising an upper box body and a lower box body which are mutually connected as well as a water pump and a circulating water pipeline; an air inlet is formed above the upper box body; a spray device is arranged below the air inlet; and the lamella heat exchanger is positioned below the spray device and fixed to the upper box body through bolts. The invention simultaneously discloses a manufacturing method of the lamella heat exchanger. The lamella heat exchanger and the manufacturing method thereof and the lamella evaporative condensing equipment have high heat exchange efficiency, convenient cleaning, simple processing and low cost.

Owner:SOUTH CHINA UNIV OF TECH

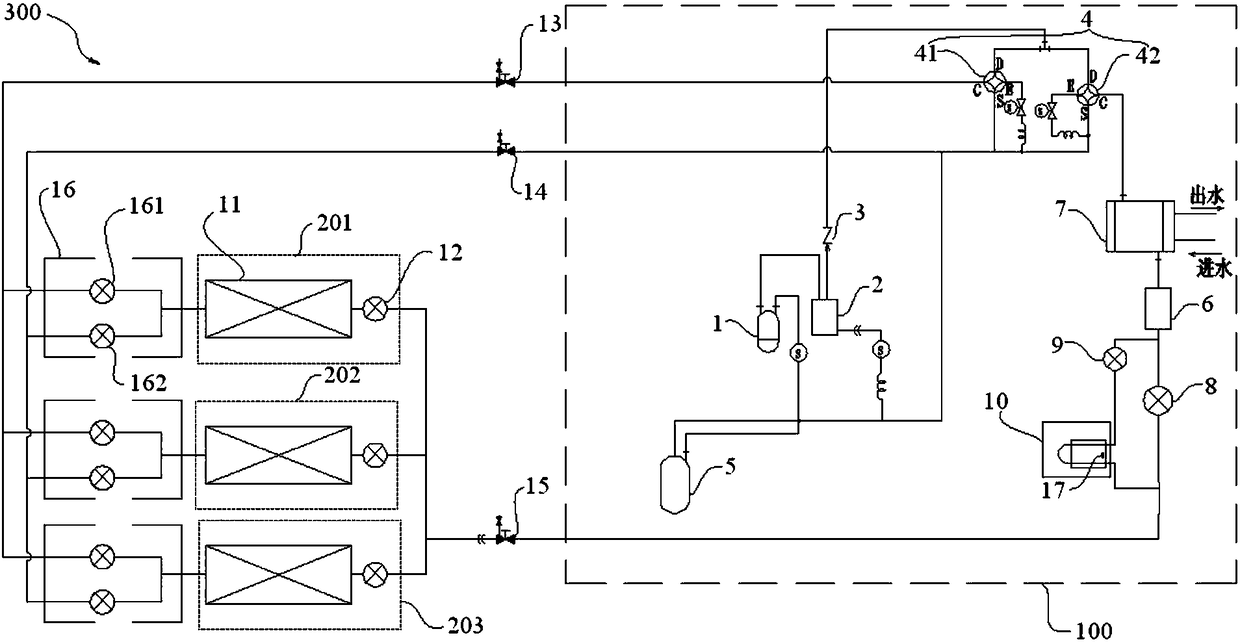

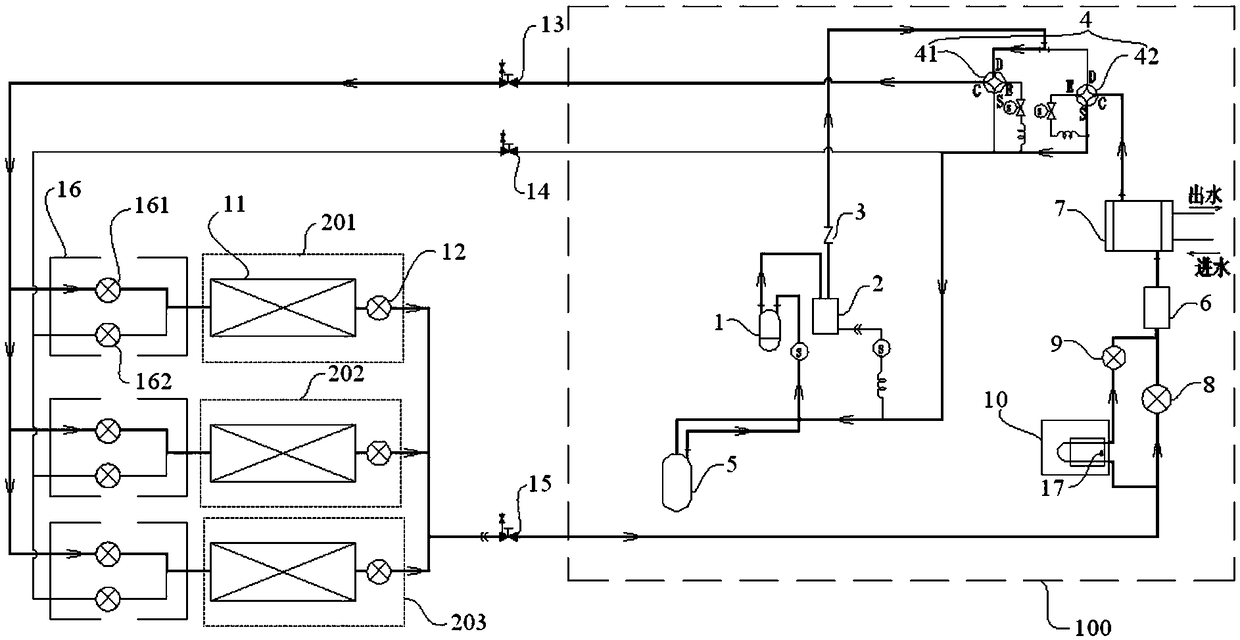

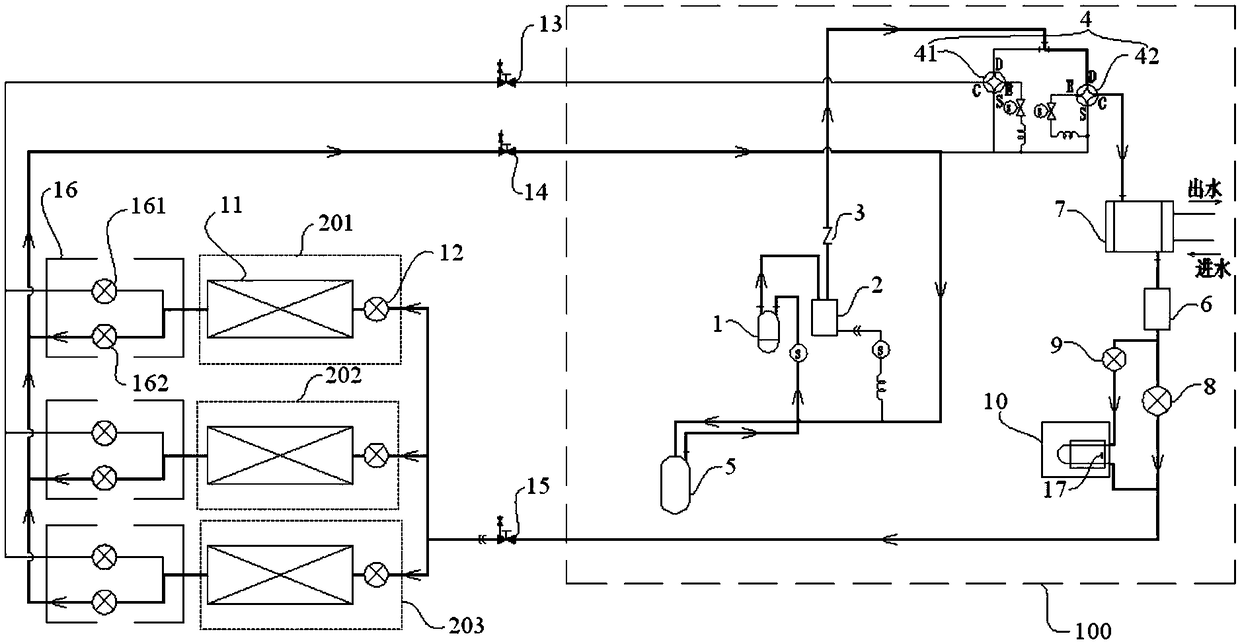

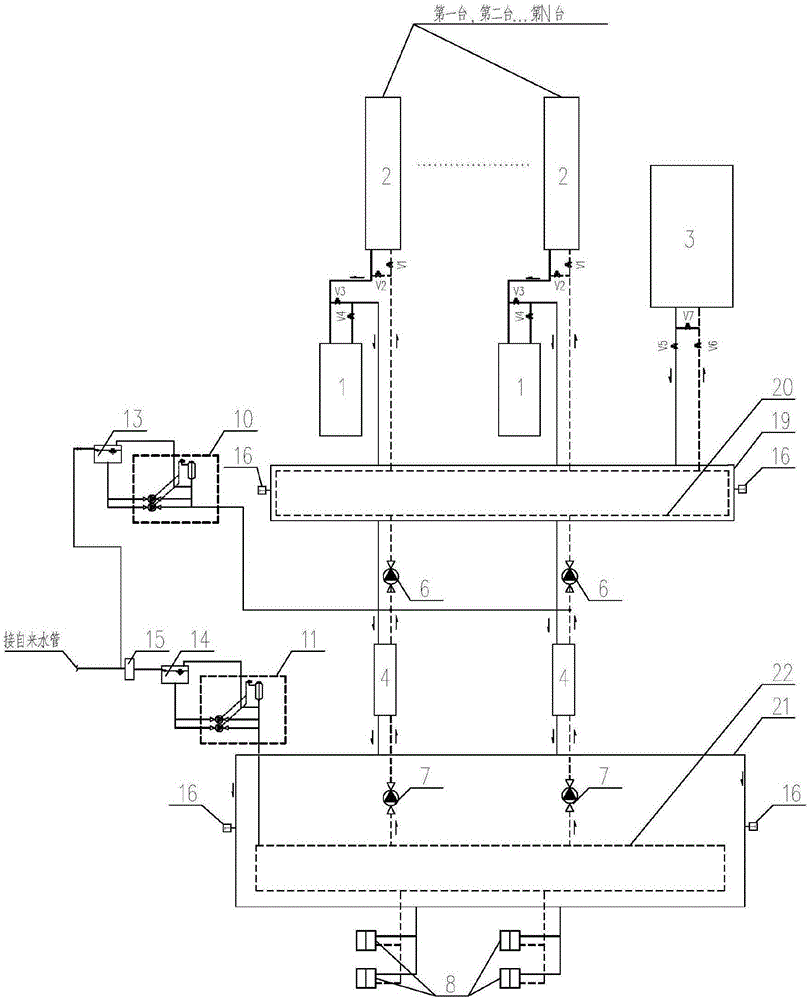

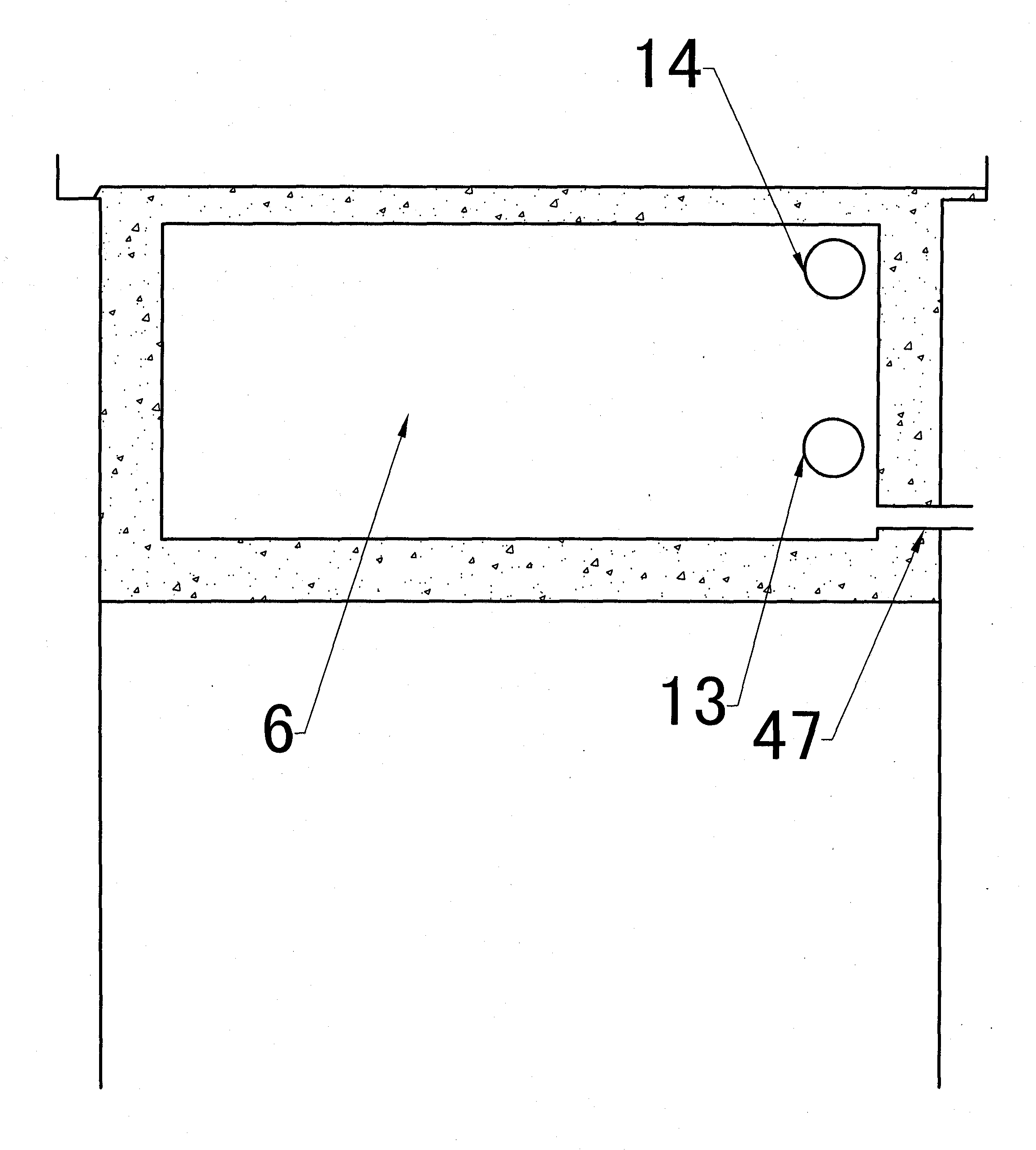

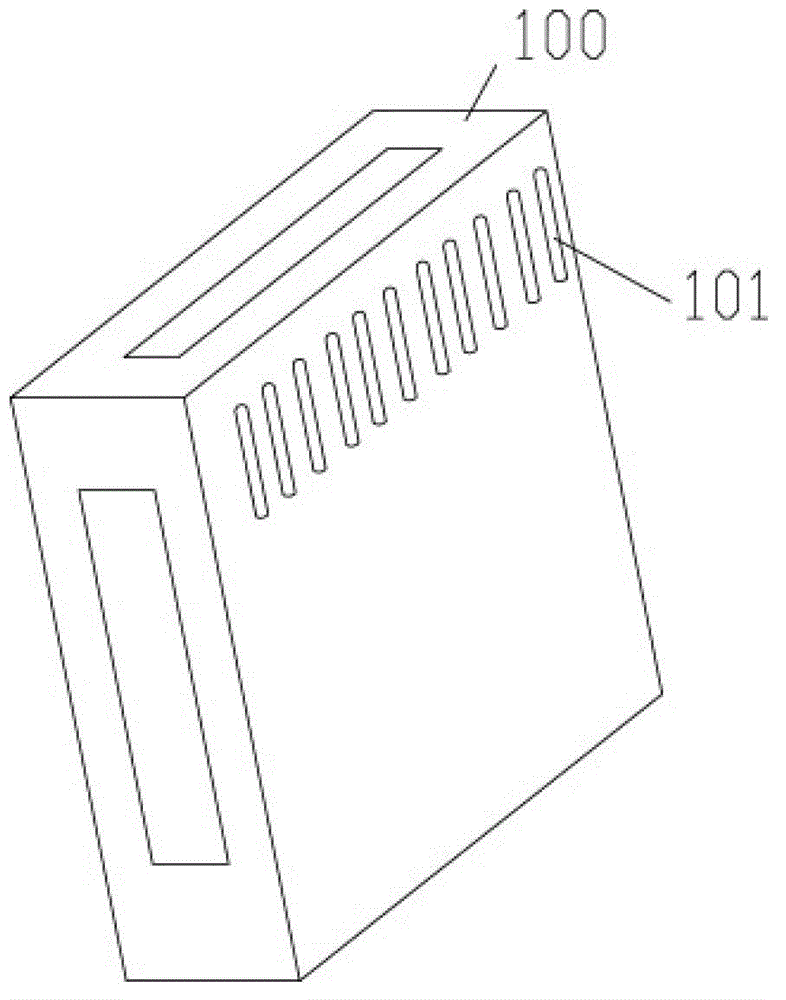

Cooling system combining natural cooling units and air-cooled water chilling units

ActiveCN105135577AWide temperature rangeGood heat transfer effectSpace heating and ventilation safety systemsLighting and heating apparatusPower usage effectivenessOutdoor temperature

The invention discloses a cooling system combining natural cooling units and air-cooled water chilling units and applied to a data center computer room. According to the system, the natural cooling units and the air-cooled water chilling units are arranged independently and connected in series in the whole air-conditioning water system, and different operation modes are adopted to supply cold water meeting design parameter requirements to a tail-end air conditioning device at different outdoor temperatures. The system is mainly characterized in that when the outdoor temperature is lower in winter and transition seasons, the natural cooling units with low energy consumption, instead of the air-cooled water chilling units with high energy consumption, use outdoor natural cold sources to refrigerate the system, an energy-saving effect is realized, and the PUE (power usage effectiveness) value of a data center is reduced. Besides, the system adopts a closed circulating system, is not affected by the drift rate, consumes very little water, is suitable for a water-deficient area and has the water saving function, so that the system is convenient and reliable to operate, adopts intelligent control and is energy-saving and environment-friendly.

Owner:DALIAN GREEN INTEGRATED TECH CO LTD

Charking hot water energy conservation stove

InactiveCN102878581AImprove heat transfer efficiencySave raw materialsLighting and heating apparatusStove/ranges for heating waterInsulation layerEngineering

The invention relates to a charking hot water energy conservation stove, mainly composed of a shell, a heat insulation layer, a fireproof layer, a water case, a heat exchanger and a circulating pipe, wherein the heat exchanger separated from the heat insulation layer by a gap, the water case and a connecting pipe are mounted in the cavity of the heat insulation layer; according to the benefit of the invention, high-temperature waste flame and high-temperature waste smoke are contacted with the heat exchanger, the water case and the connecting pipe between the heat exchanger and the water case at first time in a first space; heat exchange efficiency can be increased greatly; a plenty of hot water and boiled water can be generated by dint of the afterheat; a plenty of steam also can be generated and is used for steaming buns, boiling rice and steaming food; afterheat hot water, the boiled water and steam do not have pressure; therefore, any safety accidents cannot be caused no matter any operations; the use operation of the invention is very simple; when functions are changed, any switches and valves are not operated; and the charking hot water energy conservation stove is characterized by convenient use.

Owner:侯国山

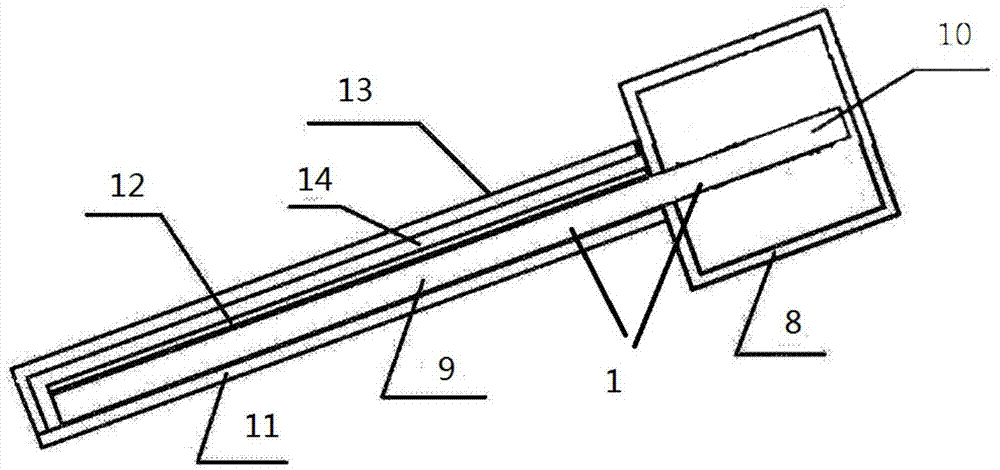

Continuous asphalt reclaimed material hot-air circulation heating device

InactiveCN103541303AGood heat transfer effectImprove efficiencyBridge structural detailsFlueEnvironmentally friendly

The invention relates to a heating device, particularly relates to a continuous asphalt reclaimed material hot-air circulation heating device and belongs to the technical field of road engineering machinery. According to the technical scheme, the device comprises a combustion chamber, a horizontal drying cylinder is arranged below the combustion chamber, the feeding end of the horizontal drying cylinder is connected with a high-temperature flue of the combustion chamber, the discharging end of the horizontal drying cylinder is connected with an air inlet of a circulating fan, and an air outlet of the circulating fan is connected with the combustion chamber through a low-temperature flue. A combustor is arranged on the combustion chamber and is disposed above the horizontal drying cylinder and adjacent to the circulating fan. A feeding mechanism is arranged at the feeding end of the horizontal drying cylinder, and a discharging mechanism is arranged at the discharging end of the horizontal drying cylinder. The device is compact in structure, high in heating efficiency, energy saving and environmentally friendly and safe and reliable; besides, asphalt is not prone to aging during heating.

Owner:WUXI XITONG ENG MACHINERY +2

Multifunctional charking energy conservation stove

InactiveCN102878582ASave raw materialsGood heat transfer effectSteam generation heating methodsStove/ranges for heating waterInsulation layerHearth

The invention relates to a multifunctional charking energy conservation stove, mainly composed of a shell, a heat insulation layer, a fireproof core, a water case, a heat exchanger and a circulating pipe, wherein the fireproof core separated from the heat insulation layer by a gap, the heat exchanger, a second fireproof core, the water case and a connecting pipe are mounted in the cavity of the heat insulation layer; according to the invention, when cooling and frying are processed normally by a boiler, a plenty of hot water and boiled water can be generated by dint of afterheat; a plenty of steam can be generated and is used for steaming buns, boiling rice and steaming food; the heat exchanger, the water case and the connecting pipe between the heat exchanger and the water case not only are functional structure components, but also are large-area heat exchangers; therefore, a plenty of raw material is saved; and very good heat exchange effect is acquired; and a novel structure designed by the invention cannot cause any safety accidents not matter any operations.

Owner:侯国山

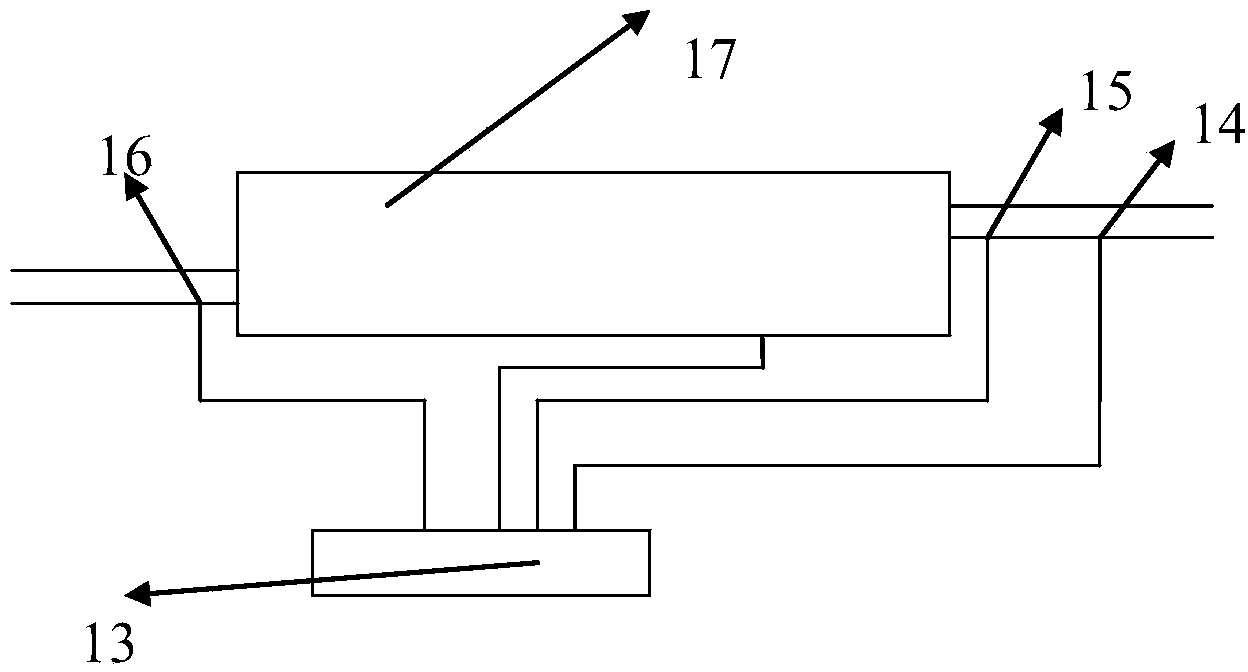

Container data center having cooling set-top heat transfer device and heat transfer method thereof

InactiveCN106793681AQuick transferGood heat transfer effectCooling/ventilation/heating modificationsCooling channelEngineering

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

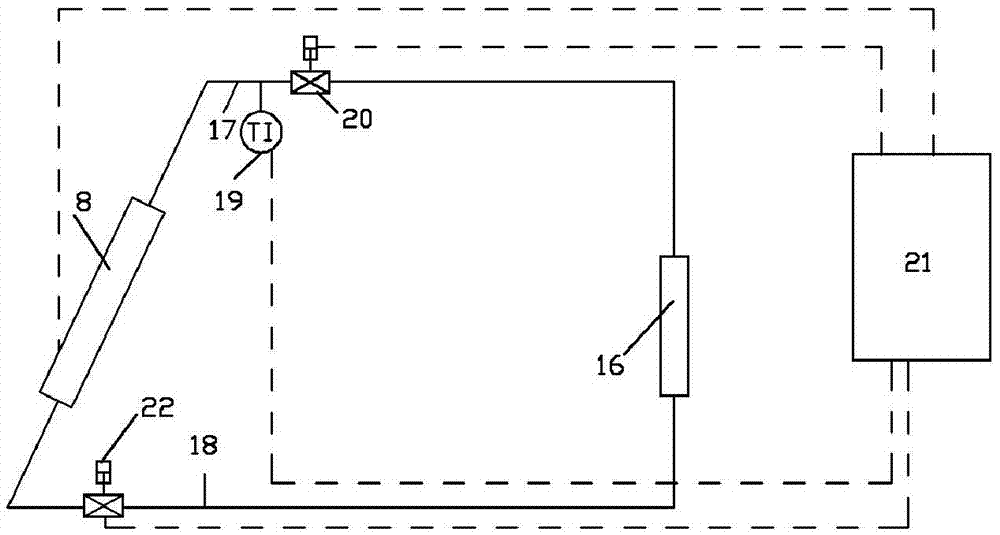

Method for intelligently controlling water temperature of solar energy system with multiple parameters

InactiveCN105444440AImprove intelligenceGood heat transfer effectSolar heating energySolar heat collector controllersAutomatic controlSolar water

The invention provides an intelligent control method for a solar energy system. A solar heat collector system comprises a heat collector, wherein the heat collector comprises a heat collecting pipe and a water tank; the heat collecting pipe comprises a heat absorbing end and a heat releasing end, and the heat releasing end is arranged in the water tank; a water level meter is arranged in the water tank, and an outlet pipe temperature sensor is arranged on an outlet pipeline of the water tank; an inlet pipe valve and an outlet pipe valve are respectively arranged on an inlet pipe and an outlet pipe of the water tank, and the water level meter, the temperature sensor, the inlet pipe valve and the outlet pipe valve are in data connection with a central controller; the central controller controls the size of the opening degree of the inlet pipe valve and the outlet pipe valve according to the temperature measured by the temperature sensor and the water level measured by the water level meter. The method automatically controls multiple parameters of the solar energy system, realizes intelligent control for the solar water temperature, and therefore improves the using intelligentization of the solar energy system.

Owner:SHANDONG UNIV OF TECH

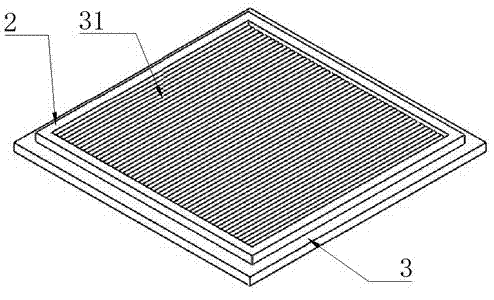

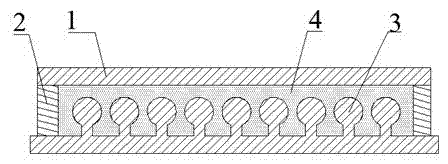

Novel heat exchanger provided with micro channel heat exchange plate

InactiveCN102914191AReduce thermal contact resistanceGood heat transfer effectLaminated elementsStationary plate conduit assembliesRefrigerantAtomic diffusion

The invention discloses a novel heat exchanger provided with a micro channel heat exchange plate, relating to the technical field of heat exchangers. The novel heat exchanger comprises a heat exchanger housing and a heat exchange device, wherein a heat exchange medium inlet, a heat exchange medium outlet, a refrigerant inlet and a refrigerant outlet are formed in the heat exchanger housing; the left side and the right side of the micro channel heat exchange plate of the heat exchange device are downwards bent to form a left end folded plate and a right end folded plate; the upper side and the lower side of the micro channel heat exchange plate are upwards bent to form an upper end folded plate and a lower end folded plate; baffles are welded and fixed at the four corners of the micro channel heat exchange plate; one side of each baffle is welded and fixed at the lateral side of the left end folded plate or the right end folded plate in the way of atomic diffusion; and the other side of the baffle is welded and fixed at the lateral side of the upper end folded plate or the lower end folded plate in the way of atomic diffusion. The novel heat exchanger provided with the micro channel heat exchange plate is very simple in structure, and convenient to manufacture; four access areas are as follows: a refrigerant inlet area, a refrigerant outlet area, a heat exchange medium inlet area and a heat exchange medium outlet area are arranged at the four directions of same micro channel heat exchange plate, so that the heat exchange effect is good and the connection is convenient.

Owner:董永梅

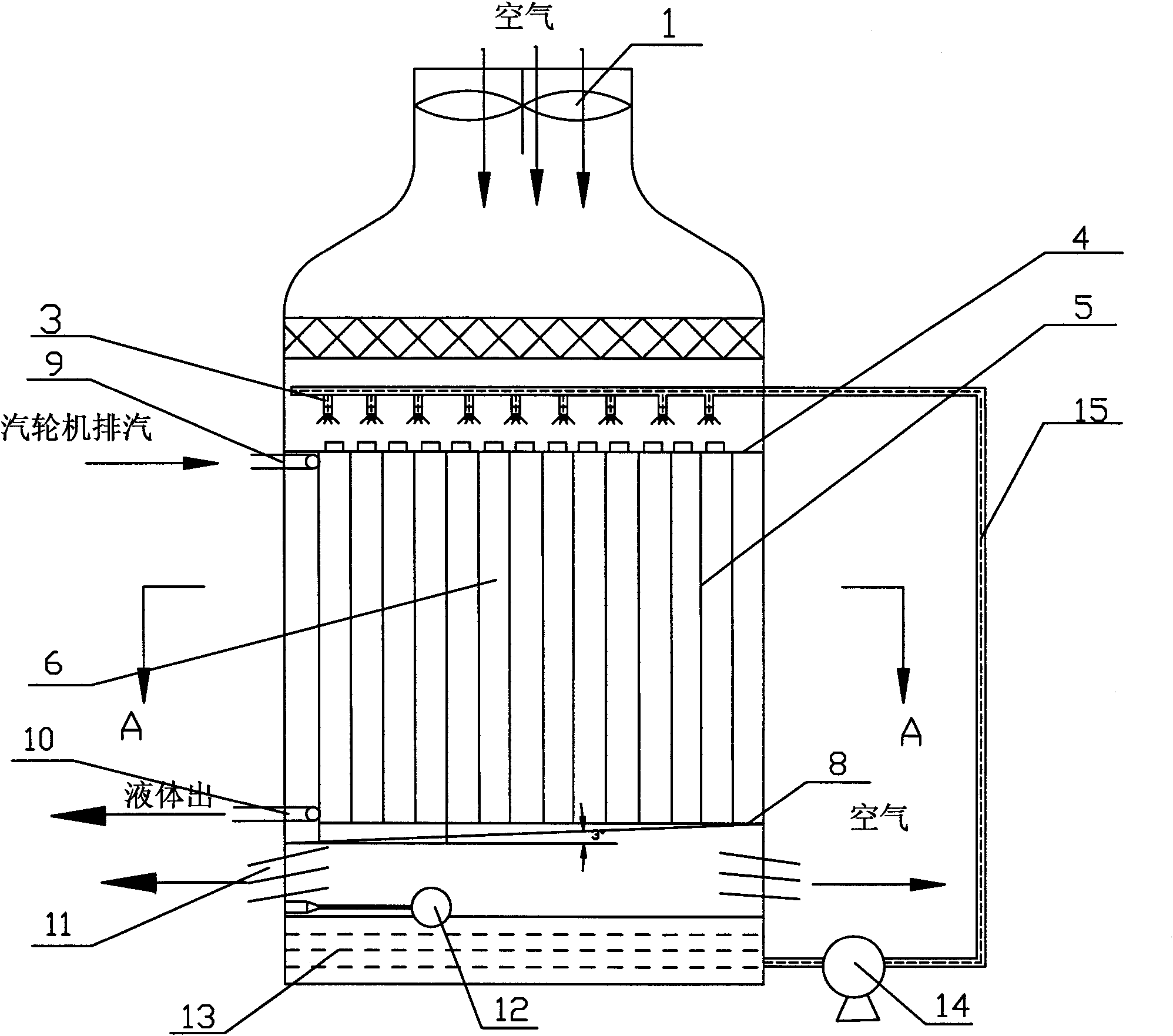

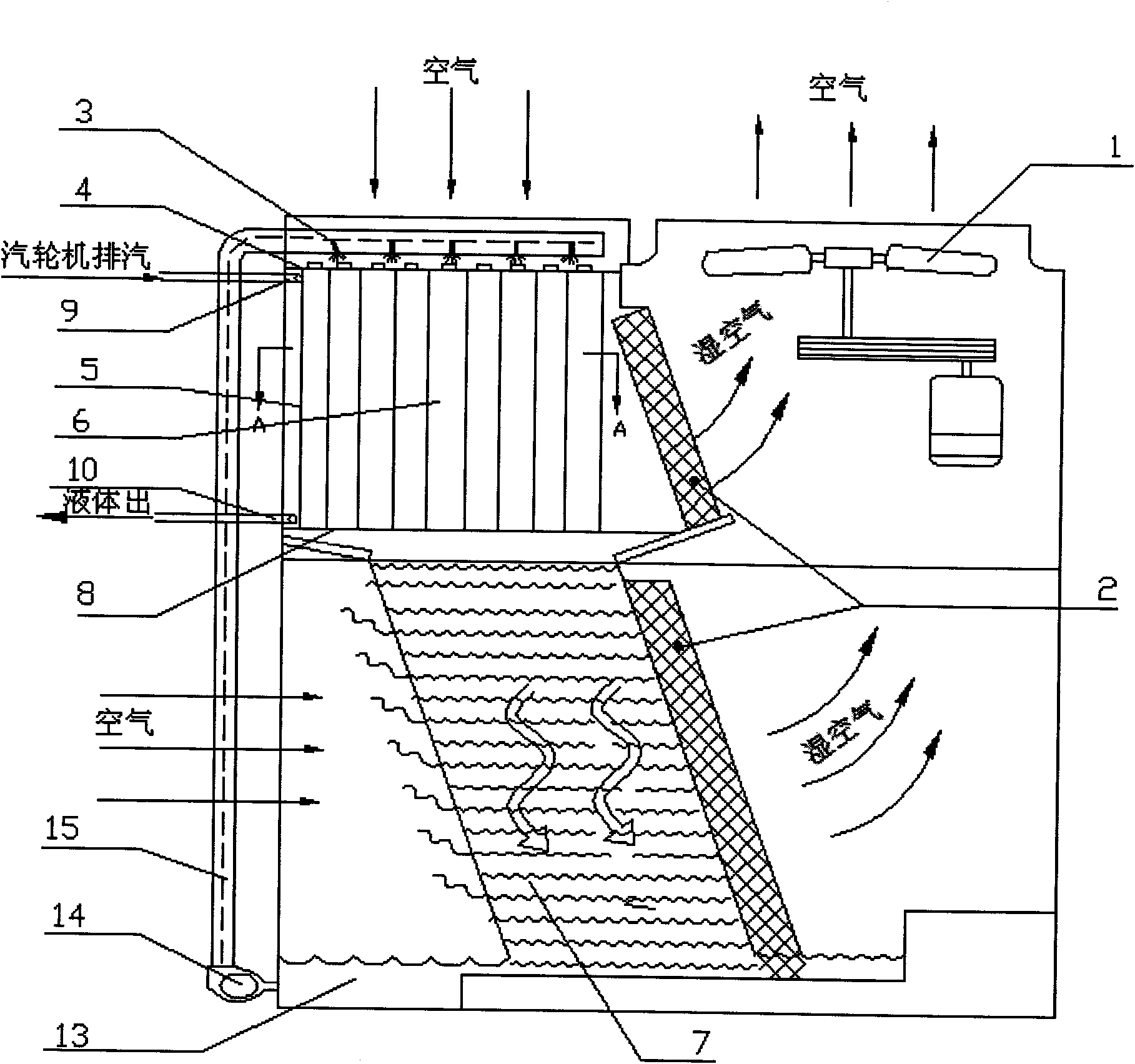

Process for heating and concentrating desalinated seawater by waste gas from boiler

InactiveCN102452691ALess investment in equipmentGood heat transfer effectGeneral water supply conservationSeawater treatmentSeawaterProcess engineering

The invention provides a process for heating and concentrating desalinated seawater by a waste gas from a boiler. The process employs the waste gas from the boiler to be used as a heat source, wherein the waste gas directly exchanges heat with desalinated seawater discharged after seawater is desalted in a natural induced draft cooling tower so as to heat and evaporate the desalinated seawater to obtain desalinated seawater with a high temperature and a high concentration; the desalinated seawater at the normal temperature is sent into the tower through a potential difference or power; the waste gas from the boiler enters the tower through the power delivery. The advantage of the invention is that in comparison with the known methods, the heat exchange rate in the heat exchange and evaporation technological process of the invention is largely raised and close to 100%. The process has characteristics of low equipment investment, good heat exchange effect, energy saving and emission reduction, waste heat utilization and so on.

Owner:CHINA LIGHT IND INT ENG CO LTD +1

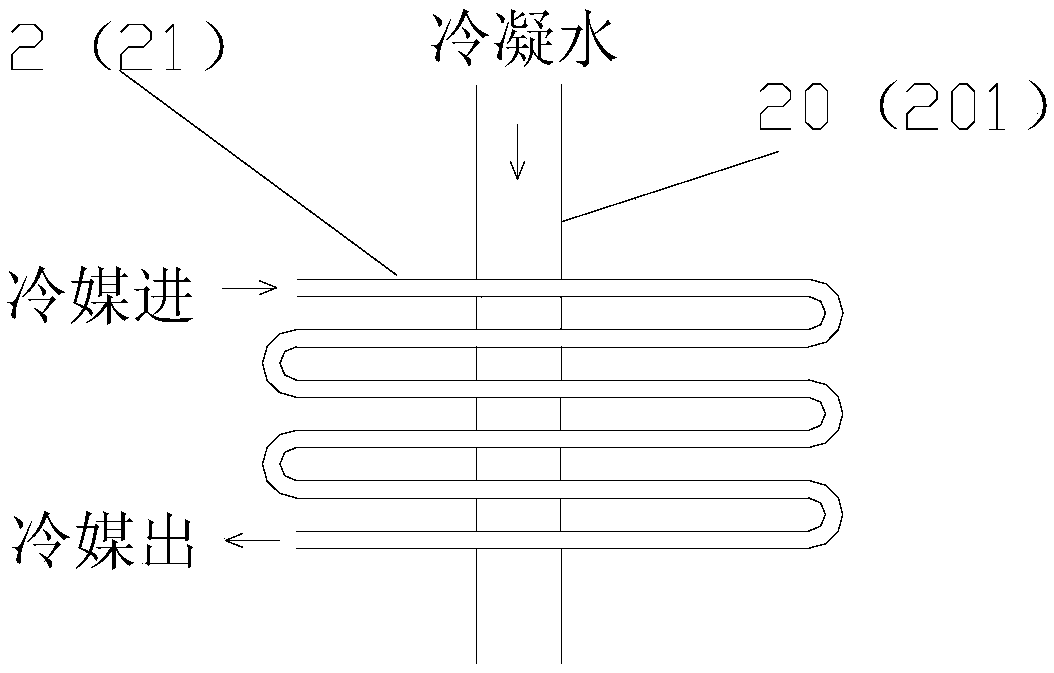

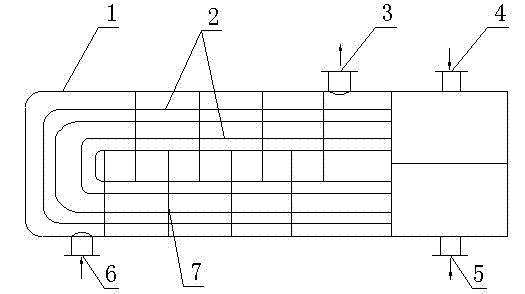

Modular compact gas boiler provided with three-dimensional finned tubes and condenser

InactiveCN106979619AIncrease the scope of applicationGood heat transfer effectChemical industryAir heatersChemical industryCondensed water

The invention discloses a modular compact gas boiler provided with three-dimensional finned tubes and a condenser. The gas boiler comprises a gas boiler body and the condenser and is characterized in that a condenser smoke flow equalization bent zone is arranged at the front end of the condenser; smoke outlets of second return stroke heat exchange tubes are connected with a condenser smoke inlet at the front end of the condenser smoke flow equalization bent zone; a condenser smoke outlet is arranged at the upper end of the tail of the condenser; a condensed water drain port is arranged at the lower end of the tail of the condenser; multiple three-dimensional heat exchange tubes arranged in parallel in the height direction are arranged in the middle of the condenser; each three-dimensional heat exchange tube is arranged in an S shape; the water inlet end of each three-dimensional heat exchange tube is connected with a condenser water inlet tube; the water outlet end of each three-dimensional heat exchange tube is connected with a condenser water outlet tube; one end of the condenser water inlet tube is connected with a water inlet pump through an adjusting valve; and one end of the condenser water outlet tube is connected with a water inlet of the boiler. The gas boiler can be widely applied in the fields of energy, chemical industries and the like.

Owner:CHONGQING UNIV +1

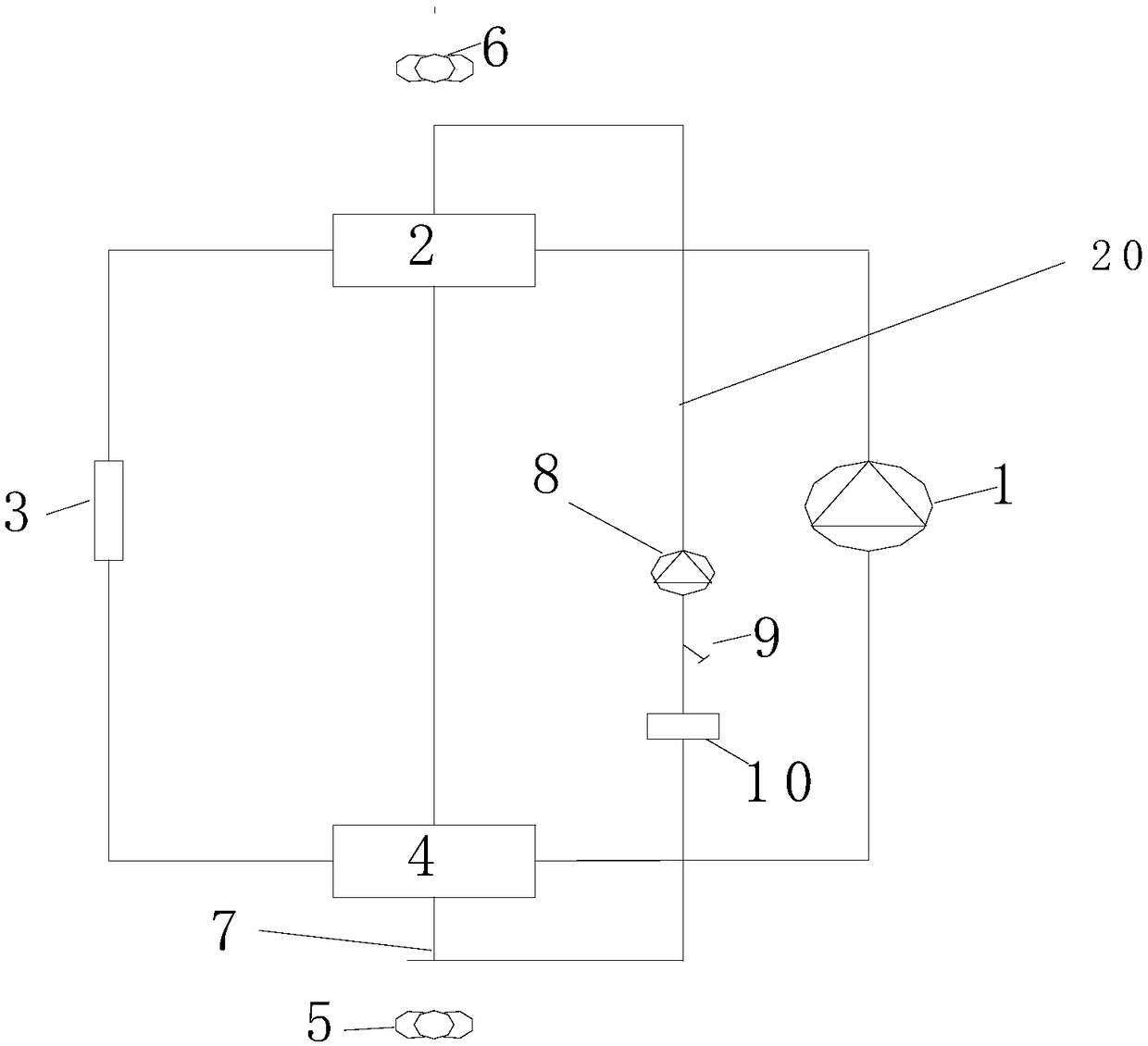

Air conditioner, and humidification control method of air conditioner

PendingCN108844145AGood heat transfer effectRealize compact utilizationMechanical apparatusCondensate preventionEvaporatorEngineering

The invention provides an air conditioner and a humidification control method of the air conditioner. The air conditioner comprises a compressor (1), a condenser (2), a throttling device (3), an evaporator (4), and a delivery pipeline (20) capable of delivering condensation water produced in the evaporator (4), wherein the delivery pipeline (20) can be connected with the condenser (2) so as to cool and exchange heat for a refrigerant in the condenser (2). According to the air conditioner and the humidification control method of the air conditioner provided by the invention, the condensation water of the air conditioner evaporator can be effectively recycled and is utilized for exchanging heat with the condenser, so that the refrigerant in the condenser is effectively cooled, meanwhile, heat of the refrigerant is effectively recycled, the refrigerant temperature of an outdoor heat exchanger is reduced, a better heat exchange effect is achieved, the compact utilization of energy is realized, and the problem of increasingly serious resource shortage is solved.

Owner:GREE ELECTRIC APPLIANCES INC

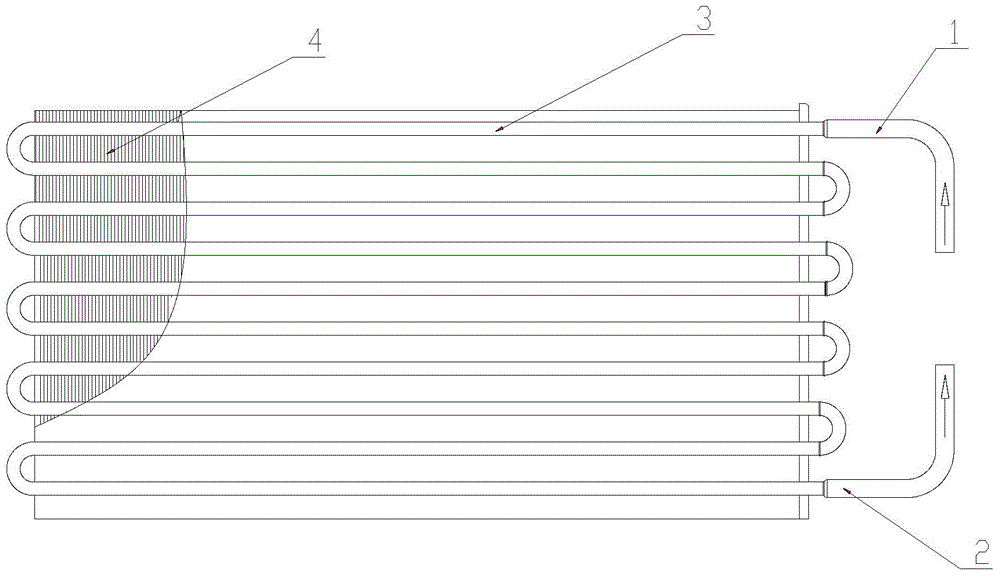

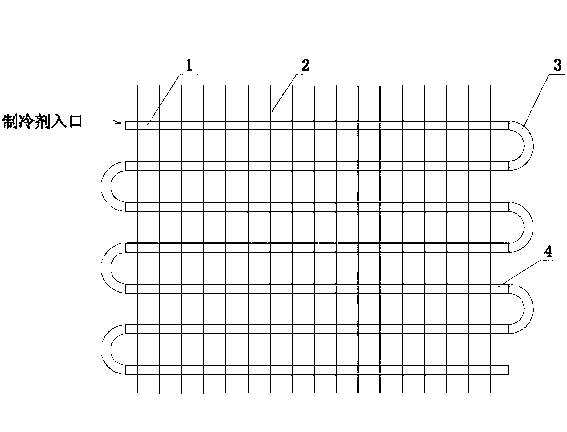

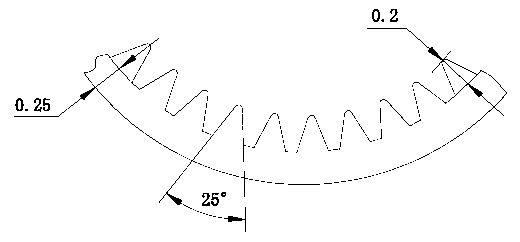

Condenser with variable-toothform internal-thread enhanced tube

ActiveCN103225934AGood heat transfer effectImprove performanceEvaporators/condensersPhysicsRefrigerant

The invention relates to a condenser with a variable-toothform internal-thread enhanced tube. The condenser with the variable-toothform internal-thread enhanced tube is characterized by comprising more than two first tube sections, more than two second tube sections, more than three connecting elbows and more than two fins, wherein more than three gear racks are uniformly arranged in the axial direction of the inner wall of each first tube section and are spirally distributed; the second tube sections and the first tube sections have the same length; more than three gear racks are uniformly arranged in the axial direction of the inner wall of each second tube section and are spirally distributed; the ratio range of the number of the gear racks of each first tube section to the number of the gear racks of each second tube section is 1-1.5; the ratio range of the spiral angle of each gear rack of each first tube section to the spiral angle of each gear rack of each second tube section is 0.5-1; according to the flowing direction of a refrigerating agent, the connecting elbows communicate every two adjacent tube sections; and each fin is arranged on all the first tube sections and the second tube sections in a sleeving manenr. The condenser with the variable-toothform internal-thread enhanced tube has the advantages as follows: in the whole heat exchanging process of the condenser, the refrigerating agent uses enhanced heat exchanging tubes with different toothforms in different stages, so that the integral heat exchanging effect of the condenser is optimal and thus the performance of a refrigerating system is improved.

Owner:SHUNDE POLYTECHNIC

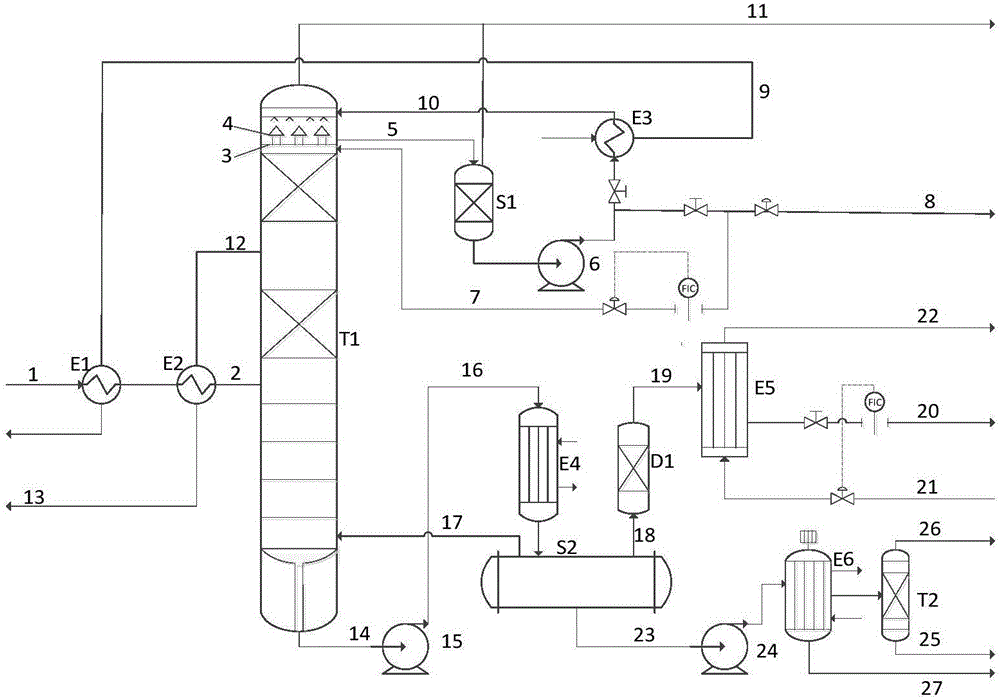

Low-cost separation method and device for fatty acid mixture

InactiveCN105733817AGood heat transfer effectAvoid condensationFatty acids production/refiningChemical industryVapor phaseRecovery boiler

The invention discloses a low-cost separation method and device for fatty acid mixture.A decompression rectifying tower is used for continuously separating and refining C12-C22 fatty acid components.A direct contact condensation mode is adopted in the tower top to efficiently cool rising material steam, the cooled rising material steam is processed by a heat recovery boiler into secondary steam to be used, a vapor-phase product on the tower bottom is processed by a demister and then condensed, and acceptable products are extracted.Residues on the tower bottom enter a wiped film evaporator and an erucic acid refining tower to be separated, and high-purity erucic acid is acquired.In the whole process, by means of thermal coupling gradient utilization, the heat consumption in the production process is minimized, and low cost, low emission and high yield are achieved.

Owner:张志炳

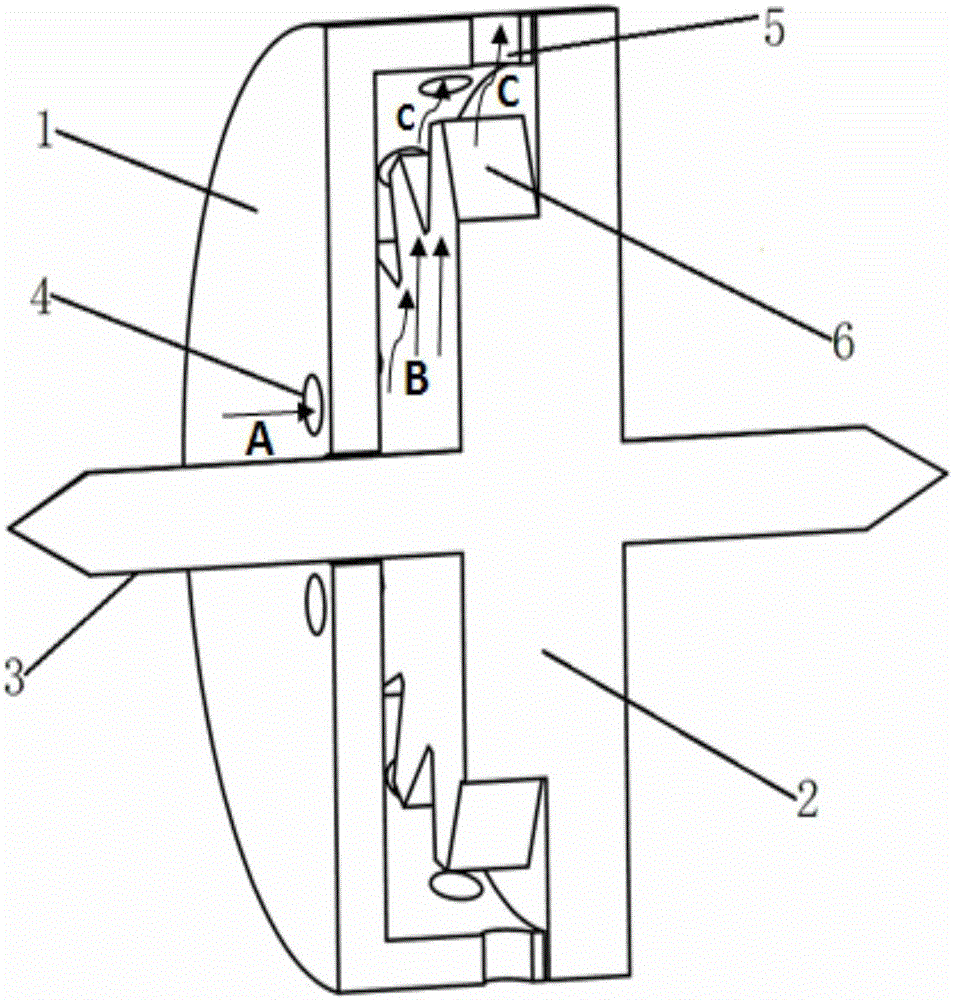

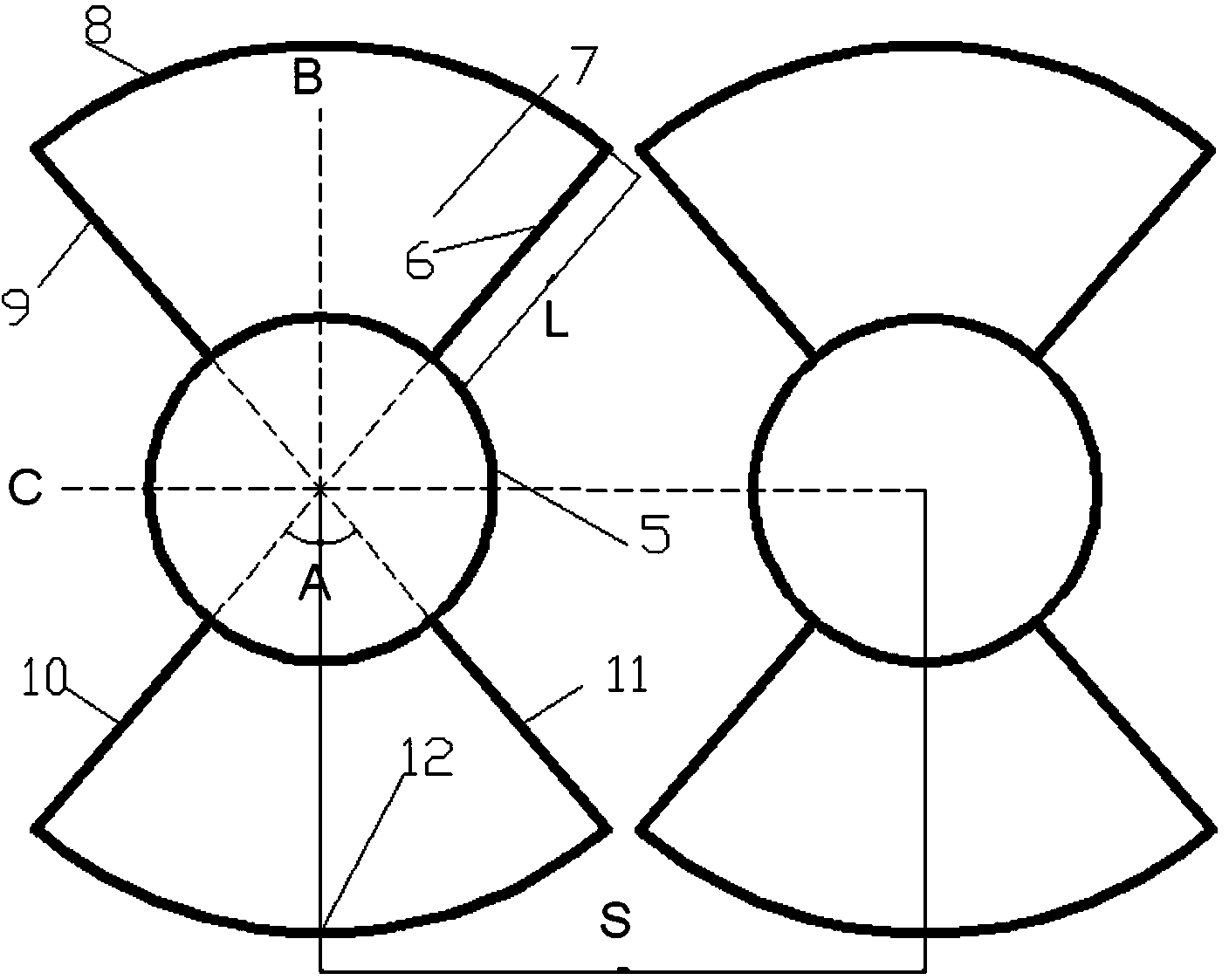

Rotor disc boss type periodic pressure wave generating device

InactiveCN105927288AGood adaptabilityGood heat transfer effectBlade accessoriesMachines/enginesStatorAirflow

The invention discloses a rotor disc boss type periodic pressure wave generating device which is composed of a stator disc and a rotor disc. The stator disc is of a concave disc structure. A plurality of air intake holes which are the same are distributed in the end wall of the stator disc at equal intervals in the circumferential direction of a center axis hole. A plurality of air exhaust holes which are the same are formed in the circumferential side wall of the stator disc. The stator disc is installed on a rotary shaft. The rotor disc and the rotary shaft are of an integrated structure. One end face of the rotor disc is a plane, and a plurality of bosses are evenly distributed on the protruding portion of the other end face of the rotor disc in the circumferential direction. The bosses on the rotor disc correspond to air outlet holes in the stator disc in position. A cooling airflow input and output channel is formed between the rotor disc and the stator disc. Stable-pressure airflow flowing in via the air inlet holes is converted into airflow with pressure showing pressure fluctuation features with time, a periodically regular change is shown, and the airflow with the periodic pressure fluctuation features has the high heat transfer rate and good airflow heat exchange effect. The pressure wave generating device adapts to the complex working environment of high-temperature components, and is good in practical effect and wide in application range.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Manufacturing method for high-quality electric cooker electric hot tray

InactiveCN107282387AGood qualityGood heat transfer effectPretreated surfacesChemical vapor deposition coatingVapor phaseCooker

The invention discloses a manufacturing method for a high-quality electric cooker electric hot tray. The manufacturing method comprises the following operation steps that firstly, the surface of a demolded electric hot tray is washed thoroughly through cleanout fluid, and then the electric hot tray is naturally air-dried; secondly, a layer of silicon film deposits on the surface of the electric hot tray through a vapor phase method; and thirdly, the surface of the electric hot tray is evenly coated with a high-temperature resistant coating, then, high-temperature baking and curing are carried out, and the high-quality electric cooker electric hot tray is manufactured. The electric hot tray treated through the method is excellent in quality and remarkable in heat conduction effect, the surface color of the electric hot tray is uniform, especially the problem that yellow smudginess is prone to appearing in the using process of the electric hot tray is solved, and the quality of the electric hot tray is greatly improved.

Owner:泾县信达工贸有限公司

U-shaped pipe type heat exchanger

InactiveCN102889804ASimple structureGood heat transfer effectStationary tubular conduit assembliesEngineeringBody shape

The invention provides a U-shaped pipe type heat exchanger. The heat exchanger comprises a shell, a U-shaped pipe and a plurality of separation plates, wherein the shell is in a hollow pot body shape; the U-shaped pipe is mounted in the shell; two end openings of the U-shaped pipe respectively correspond to an outlet and an inlet of cold fluid; the plurality of the separation plates form a hot fluid flow channel so as to realize crossed heat exchange of the temperature of cold and hot fluid; the separation plates are mounted on the top of the shell and at the bottom of the shell and are parallel and staggered; an inlet of hot fluid is located at the bottom of the shell; and an outlet of the hot fluid is located at the top of the shell. The U-shaped pipe type heat exchanger disclosed by the invention is simple in structure and good in heat exchange effect, and is convenient to operate.

Owner:TSUWA KOKI WUXI

Arc-shaped closed-structure heat exchanger for descaling with sound waves

InactiveCN103528395AGood heat transfer effectImproved high heat resistance and high thermal conductivityStationary conduit assembliesVibration cleaningEnergy converterEngineering

The invention provides an arc-shaped closed-structure heat exchanger for descaling with sound waves. The heat exchanger comprises an upper collecting pipe, a lower collecting pipe and an arc-shaped closed finned pipe connected with the upper collecting pipe and the lower collecting pipe, the heat exchanger comprises a descaling device, superaudio frequency pulse signals are sent by a main engine of an automatic scale prevention device and are converted by an energy converter to generate superaudio frequency pulse vibration, the superaudio frequency pulse vibration acts on water in the metal pipe of the energy converter, the superaudio frequency pulse vibration enables high-speed microflow and a cavitation effect to be generated between the metal pipe and the water, scales are prevented from being formed, heat exchanging resistance is reduced, heat exchange efficiency maximization is achieved to save energy, and the aim of environment protection and energy saving is achieved.

Owner:SHANDONG UNIV

Ice maker

InactiveCN101073371AImprove heat transfer coefficientGood heat transfer effectFrozen sweetsRefrigerantEvaporator

The invention is concerned with the soft ice machine, includes the beverage box, the feeding opening, the discharge opening, the refrigeration system, the refrigeration system consists of the metal tubes, the evaporator is layed at the bottom of the middle box of the beverage box or the location closing to the bottom of the box, the blowing ice parts touches with the metal tube or with a small gap, the blowing ice parts moves by the power steeing. It is: the refrigerant evaporates in the metal tube in order to freezing the beverage out of the metal tube, the evaporator is not only low cost but also high heat transfer coefficient, and moreover, it is simple structure and higher guidable plot ratio.

Owner:谢长耿 +1

Aluminum profile production line waste heat comprehensive utilization system

ActiveCN107894171AImprove heat transfer efficiencyGood heat transfer effectIncreasing energy efficiencyWater heatersAluminiumFlue gas

The invention relates to an aluminum profile production line waste heat comprehensive utilization system, and belongs to the technical field of aluminum profile processing. A second heat exchange pipeis utilized to carry out heat exchange on waste heat in high temperature flue gas discharged from an aluminum smelting furnace, a first heat exchange pipe is utilized to be matched with heat conduction powder to use residual waste heat of the aluminum smelting furnace after smelting of the aluminum smelting furnace, the heat exchange efficiency of the first heat exchange pipe and the second heatexchange pipe is high, the heat exchange effect is good, and heat loss is small; the waste heat is utilized to heat tap water in the first heat exchange pipe and the second heat exchange pipe into hotwater, the hot water is temporarily stored in a heat preservation water tank, when a boiler needs to use water, the hot water stored in the heat preservation water tank can be directly used, the heating time of the boiler is shortened, the waste heat of the aluminum smelting furnace is made full use of, the utilization rate of the waste heat is high, coal, other fuels and consumption of electricenergy are saved, the economic value is high, environmental pollution is reduced, greenhouse effects are reduced, and the aluminum profile production line waste heat comprehensive utilization system accords with policy requirements for energy conservation and environmental protection of our country, and has great promotional value.

Owner:奋安铝业股份有限公司

Closed gas-liquid two-phase impingement cooling system and method

ActiveCN106247658AGood heat transfer effectReduce energy consumptionCompression machinesRefrigeration componentsElectric generatorGas turbines

The invention discloses a closed gas-liquid two-phase impingement cooling system and method, and belongs to the field of cooling high heating flux density parts in aviation, aerospace, power machinery, electronics and the like. The closed gas-liquid two-phase impingement cooling system mainly comprises an air compressor, a gas-water ejector, an impact cavity, an expansion machine, an electric generator, a condenser and a gas-water separator. The closed gas-liquid two-phase impingement cooling system is characterized in that the ejector is adopted for atomizing water, atomized liquid drops are formed in airflow, the advantages that the liquid phase is large in amount of vaporization latent heat, capable of enhancing cooling and good in impingement cooling effect are combined together, and the high-temperature cooled surface can be effectively cooled; the expansion machine outputs power and meanwhile can output electric energy outwards under the condition that power consumption of the air compressor is provided; the gas-water separator is adopted so that air and water can be separated, the water flows into a water tank, and the air enters the compressor; and in this way, cycle operation continues, and a closed system is formed. The cooling system can be applied to the occasions like hypersonic speed aircraft leading edges and gas turbine blades with high heating flux density.

Owner:江苏江杭石化工程有限公司

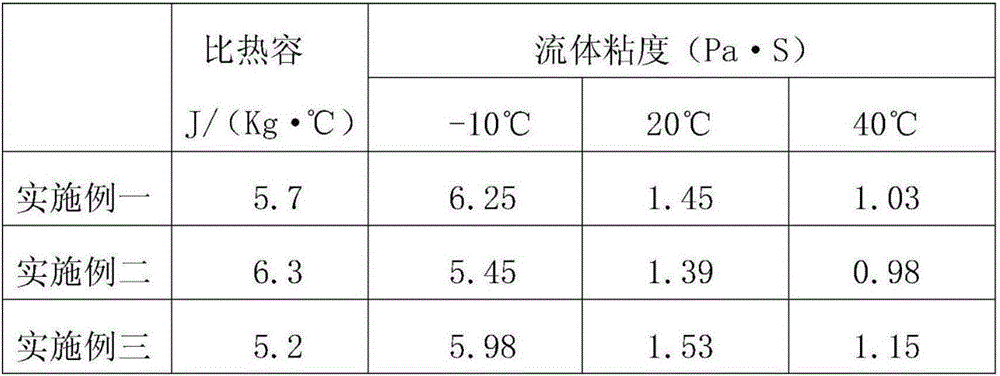

Heat dissipating working medium of heat radiator and preparation method thereof

InactiveCN106118612AHigh specific heat capacityGood heat transfer effectHeat-exchange elementsChemistryGlycerol

Owner:GUANYANG CHENGONG ORE DRESSING MACHINERY MFG

Kitchen air conditioner

ActiveCN106678994AGood heat transfer effectAvoid corrosionMechanical apparatusLighting and heating apparatusEvaporatorOblique angle

The invention discloses a kitchen air conditioner which comprises a panel and a mounting base which are connected with each other to form an inner cavity. The panel is provided with an air inlet and an air outlet. The inner cavity is provided with a blade, an evaporator, an oil fume filter device and an oil receiving disc. An air duct is formed between the evaporator and the air outlet. The oil fume filter device is arranged between the air inlet and the blade. The oil receiving disc is arranged on the panel. An oblique angle is formed between the oil fume filter device and the panel. The end of the oil fume filter device faces the oil receiving disc. The kitchen air conditioner is provided with the oil fume filter device, oil fume is prevented from blocking the evaporator, the heat exchange effect of the kitchen air conditioner is better, the oil fume is prevented from corroding elements in the air conditioner, and the service life of the air conditioner is prolonged.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

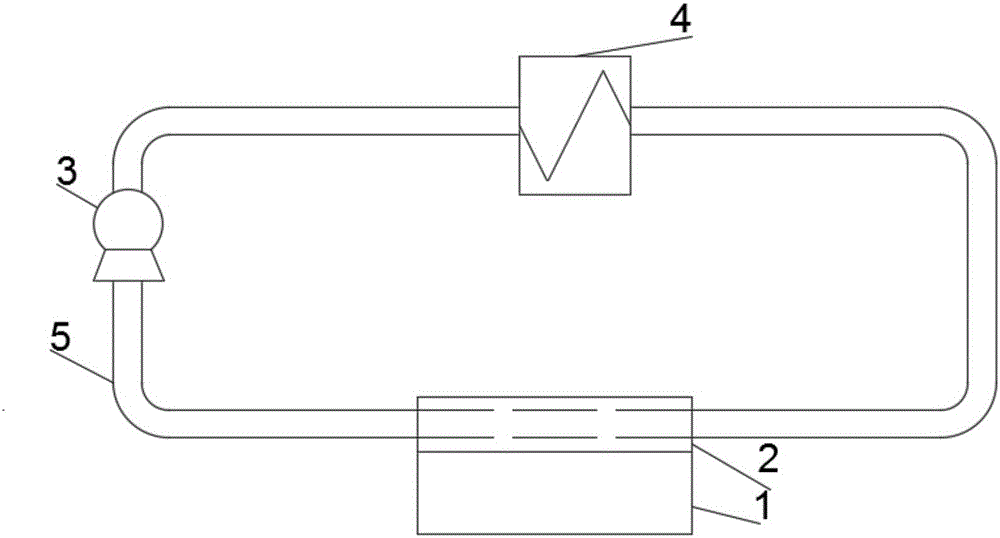

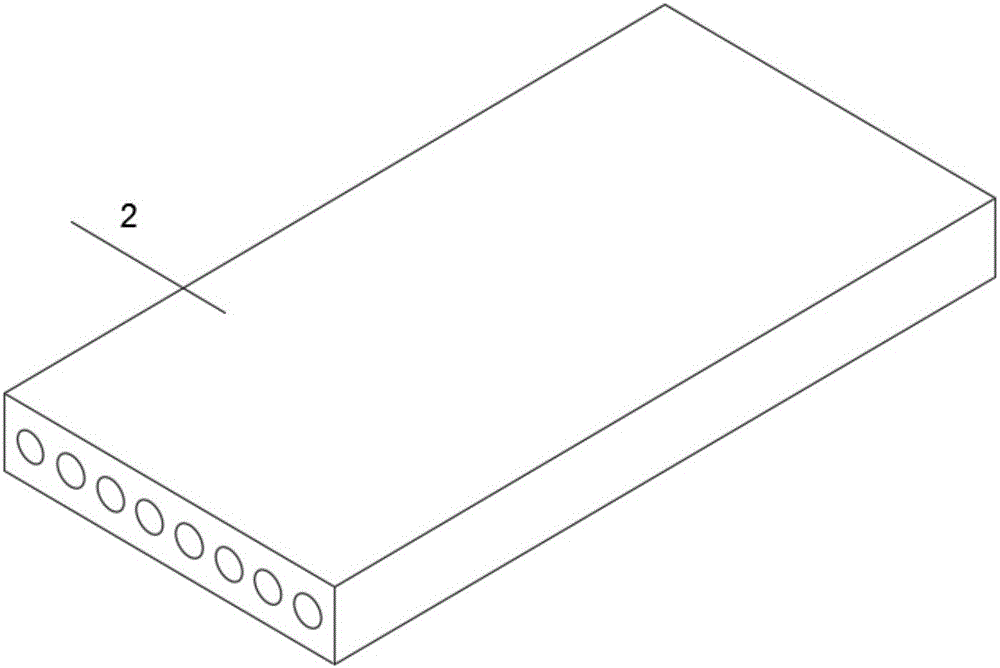

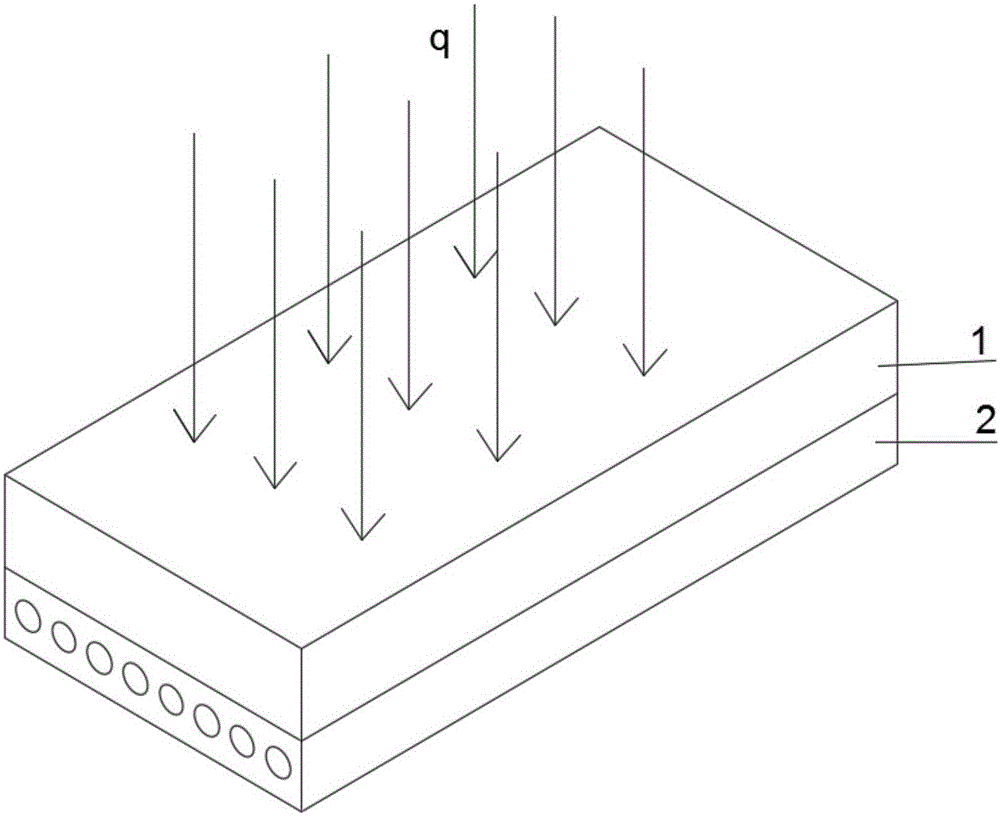

Microchannel heat exchange-based waste-heat direct power generation device

InactiveCN105897062AStrong heat transfer capacityGood heat transfer effectGenerators/motorsEngineeringCopper

The invention provides a microchannel heat exchange-based waste-heat direct power generation device, which comprises a thermoelectric material, a microchannel heat exchanger, a working medium pump, an ordinary heat exchanger and a pipeline, wherein a cold end of the thermoelectric material is in tight contact with the microchannel heat exchanger; the working medium in a microchannel is R30 or R21; the working medium and the cold end of the thermoelectric material are subjected to efficient boiling heat exchange; and the cold end is maintained in a stable low-temperature condition, so that the thermoelectric conversion efficiency is ensured. The boiling working medium brings heat to the ordinary heat exchanger through the working medium pump and then heat exchange is carried out on the working medium and the environment, so that the working medium is liquefied. The microchannel heat exchange device is a copper rectangular thin plate; a plurality of microchannels are arranged in the microchannel heat exchange device; round holes or square holes are selected as the microchannels according to the practical application; and an air-cooled heat exchanger, a water-cooled heat exchanger or a ground source heat exchanger is selected as the ordinary heat exchanger according to the actual condition. The temperature of the cold end of the thermoelectric material is controlled by combining the microchannel heat exchanger and the working medium in a boiling heat exchange manner and is kept at a stable low temperature; the power generation efficiency of the thermoelectric material is improved; and the service lifetime of the thermoelectric material is prolonged.

Owner:CHINA UNIV OF MINING & TECH

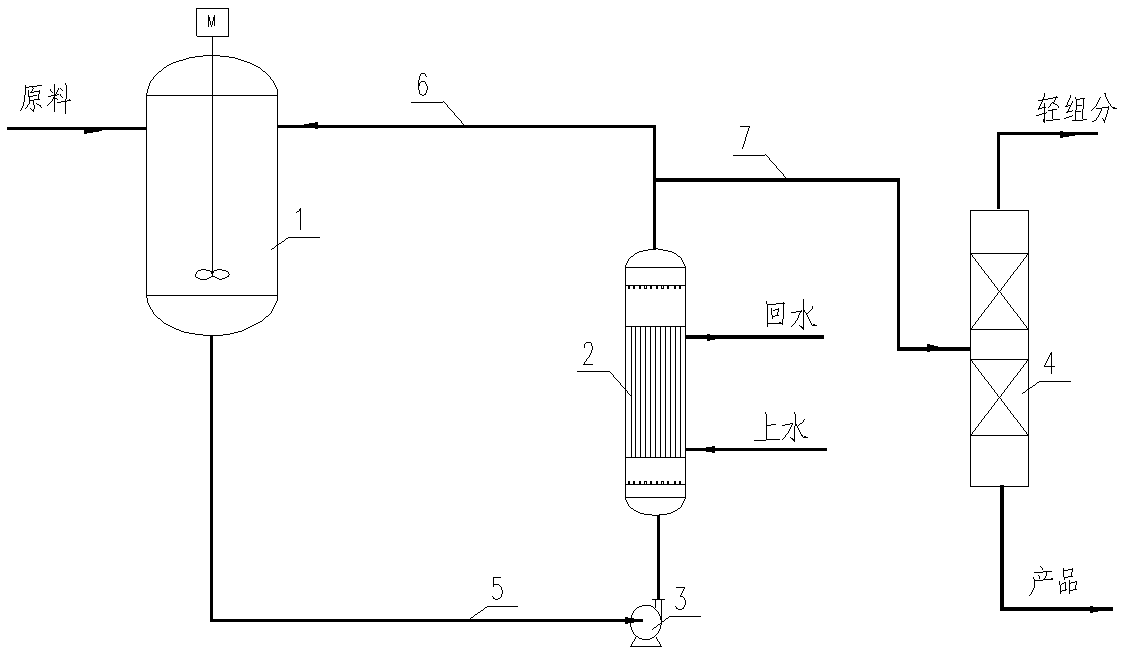

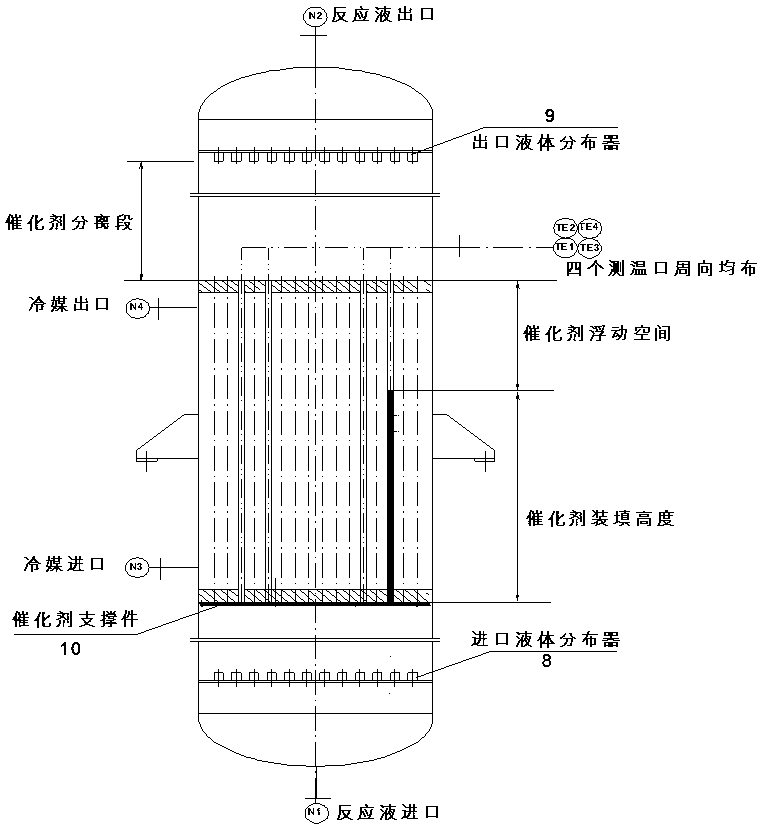

Reaction system of synthesizing polyoxymethylene dimethyl ether

ActiveCN108484371AGood heat transfer effectUniform temperature distributionOrganic chemistryOrganic compound preparationPolyoxymethylene dimethyl ethersProcess engineering

The invention discloses a reaction system of synthesizing polyoxymethylene dimethyl ether. The system comprises a raw material mixer and a reactor; the reactor is a tubular floating bed reactor, a discharging port of the raw material mixer is connected with the bottom of the reactor through a supply pipe, and a feeding pump is arranged in the supply pipe; a circulation return pipe and a separationpipe are connected to the branches of the top of the reactor, the raw material mixer is connected to the other end of the circulation return pipe, and the other end of the separation pipe is connected to a downstream separation system. According to the reaction system, it can be guaranteed that a raw material mixture is sufficiently and evenly mixed, the reaction duration time is prolonged, the mixture can be quickly matched with reaction heat, and the temperature of a catalyst bed layer is effectively controlled; the pressure drop of the tubular floating bed reactor is small, blocking is noteasily caused, the raw materials are in sufficient contact with a catalyst, the catalyst is effectively separated from a coarse reaction solution at the same time, the problem of catalyst separationand recycle is solved, and the tubular reactor is easy to amplify and suitable for the reaction system for large-scale industrial production.

Owner:EAST CHINA ENG SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com