Aluminum profile production line waste heat comprehensive utilization system

A production line and aluminum profile technology, applied in the field of aluminum profile processing, can solve problems such as waste of heat energy, achieve high economic value, less heat loss, and shorten heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

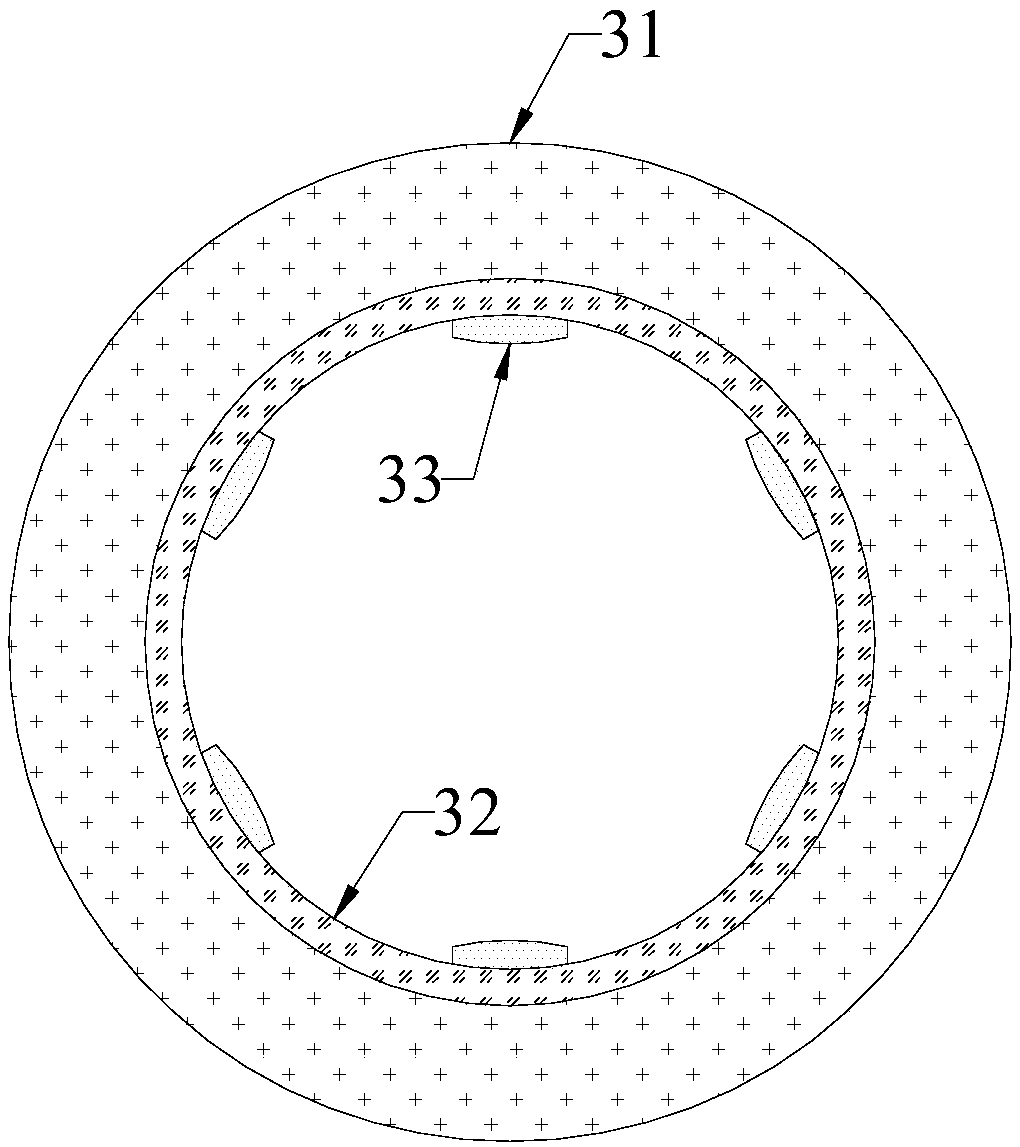

[0039] 1) The round copper tube body 31 is made of red copper. After the inner wall of the round copper tube body 31 is cleaned and polished, a silver mirror layer 32 is formed on the inner wall of the round copper tube body 31 by chemical silver plating or electroplating;

[0040] 2) Mix graphene and water at a mass ratio of 1:100, and then use ultrasonic vibration to disperse for 5 hours to make a graphene solution; mix the reducing agent hydrazine hydrate and water at a mass ratio of 1:66 to prepare Obtain reducing agent solution; Silver ammonia solution, reducing agent solution, graphene solution are mixed according to the ratio of 1:10:53 according to mass ratio and carry out reduction silver reaction, obtain silver-graphene composite solution; Silver-graphene composite solution is static Set aside for 6 hours to produce a precipitate, filter the precipitate and then dry it at 60°C, add water to the dried material to make a mixed solution with a pH of 8, let the mixed solu...

Embodiment 2

[0043] 1) The round copper tube body 31 is made of red copper. After the inner wall of the round copper tube body 31 is cleaned and polished, a silver mirror layer 32 is formed on the inner wall of the round copper tube body 31 by chemical silver plating or electroplating;

[0044] 2) Mix graphene and water at a mass ratio of 1:120, and then use ultrasonic vibration to disperse for 5.5 hours to make a graphene solution; mix the reducing agent hydrazine hydrate and water at a mass ratio of 1:69, Prepare reducing agent solution; Silver ammonia solution, reducing agent solution, graphene solution are mixed according to the ratio of 1:10:53 according to mass ratio and carry out reduction silver reaction, obtain silver-graphene composite solution; Silver-graphene composite solution Stand still for 6.5 hours to produce a precipitate, filter the precipitate and then dry it at a temperature of 80°C, add water to the dried material to make a mixed solution with a pH of 8, and leave the ...

Embodiment 3

[0047] 1) The round copper tube body 31 is made of red copper. After the inner wall of the round copper tube body 31 is cleaned and polished, a silver mirror layer 32 is formed on the inner wall of the round copper tube body 31 by chemical silver plating or electroplating;

[0048] 2) Mix graphene and water at a mass ratio of 1:150, and then use ultrasonic vibration to disperse for 6 hours to make a graphene solution; mix the reducing agent hydrazine hydrate and water at a mass ratio of 1:80 to prepare Obtain reducing agent solution; Silver ammonia solution, reducing agent solution, graphene solution are mixed according to the ratio of 1:10:53 according to mass ratio and carry out reduction silver reaction, obtain silver-graphene composite solution; Silver-graphene composite solution is static Set aside for 7 hours to produce a precipitate, filter the precipitate and then dry it at a temperature of 90°C, add water to the dried material to make a mixed solution with a pH of 8, let...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com