Ice maker

A technology of ice cream machine and powder machine, which is applied in the fields of frozen desserts, food science, and application, can solve the problems of small disposable volume ratio of freezing cylinder, low heat transfer coefficient of evaporator, and small disposable volume, etc. The effect of large volume ratio, good heat transfer effect and large heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

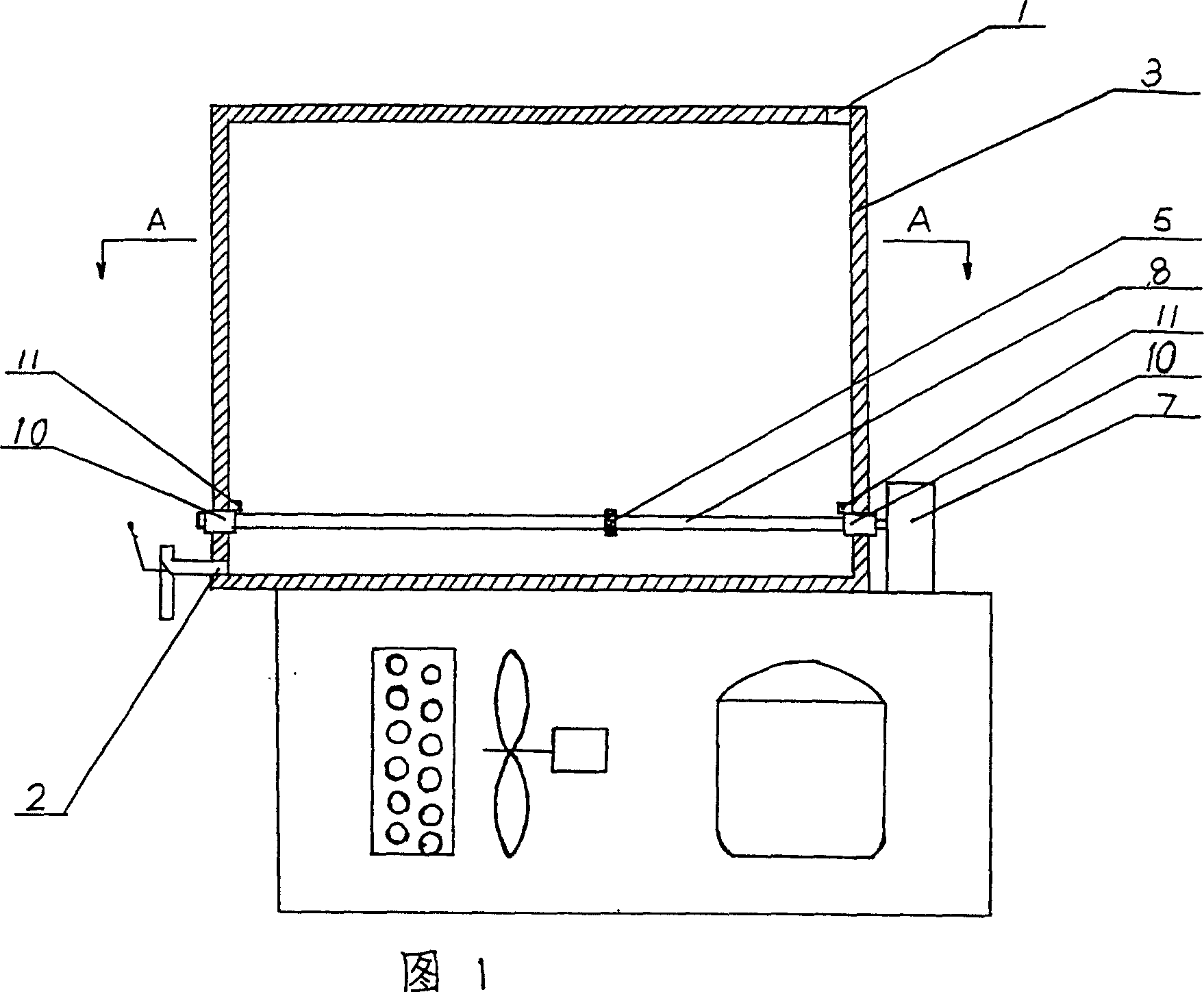

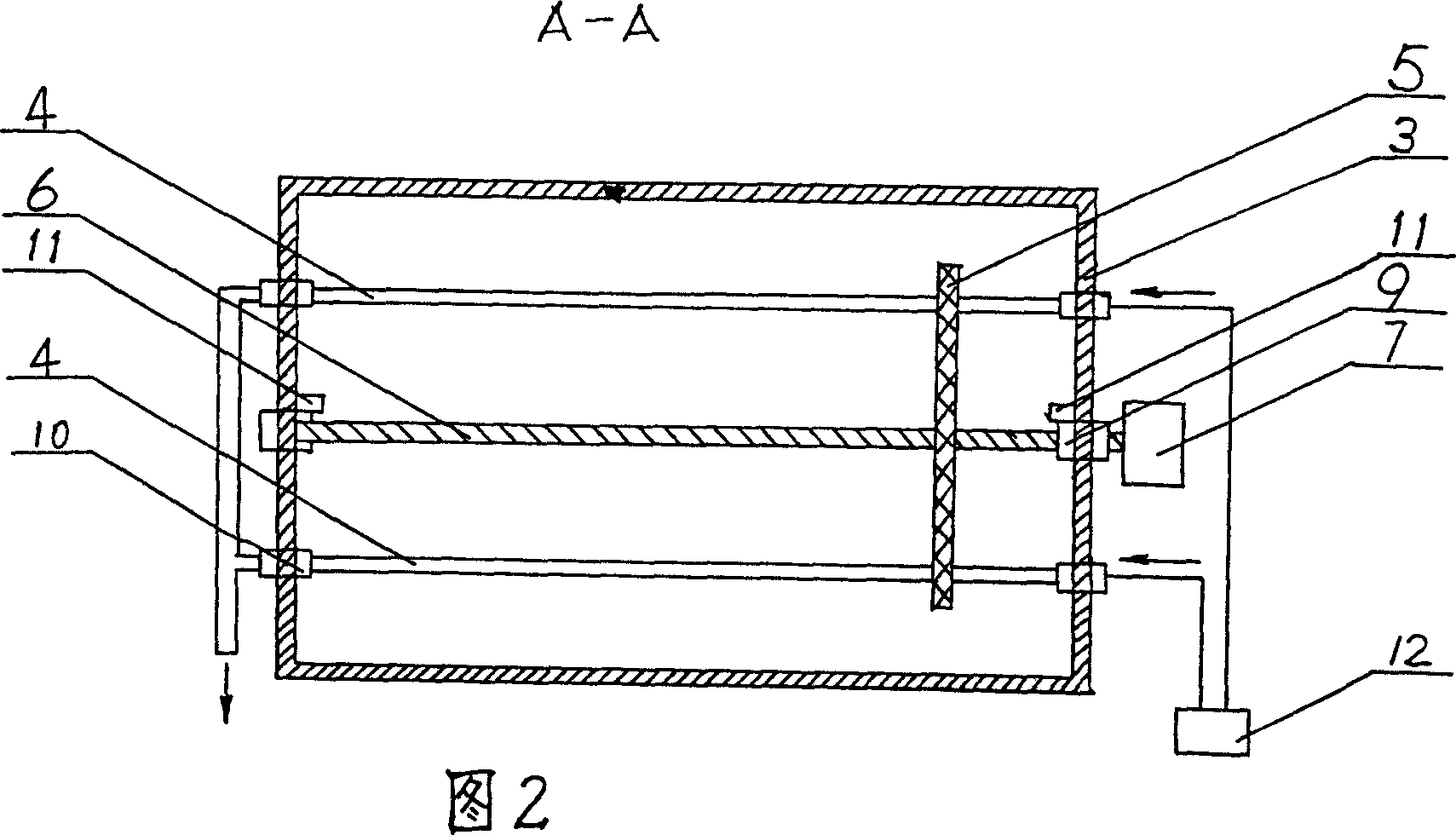

[0023] In order to better illustrate the preferred embodiment of the minced ice machine of the present invention, firstly refer to the cross-sectional side view of the first embodiment of the present invention shown in FIG. 1 . This picture shows the basic structure of the ice cream machine. The evaporator 8 is placed in the beverage box 3 near the bottom of the box. Referring to the front view of the ice scraper 5 shown in FIG. 5 : there is a threaded hole 14 and a plurality of through holes 13 on the ice scraper 5 . Referring to the cross-sectional view cut along the A-A line shown in Figure 2: the evaporator 8 is composed of a plurality of metal straight pipes 4, and the place where the metal straight pipes 4 pass through the wall of the beverage box is sealed with a sealing device 10, and the front of the entrance of the metal straight pipes 4 There is a refrigerant distributor 12, and an ice scraper 5 with a plurality of through holes 13 is sleeved on the evaporator 8 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com