Device and method for cooling intermediate rolled blank of hot rolled strip

A hot-rolled strip and cooling device technology, applied in the field of cooling devices for hot-rolled strip rolling intermediate billets, can solve the problems of large overall investment, complex equipment, high requirements for gas path cleanliness and pressure control range, and achieve Reduce investment, simplify equipment manufacturing process, and improve control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

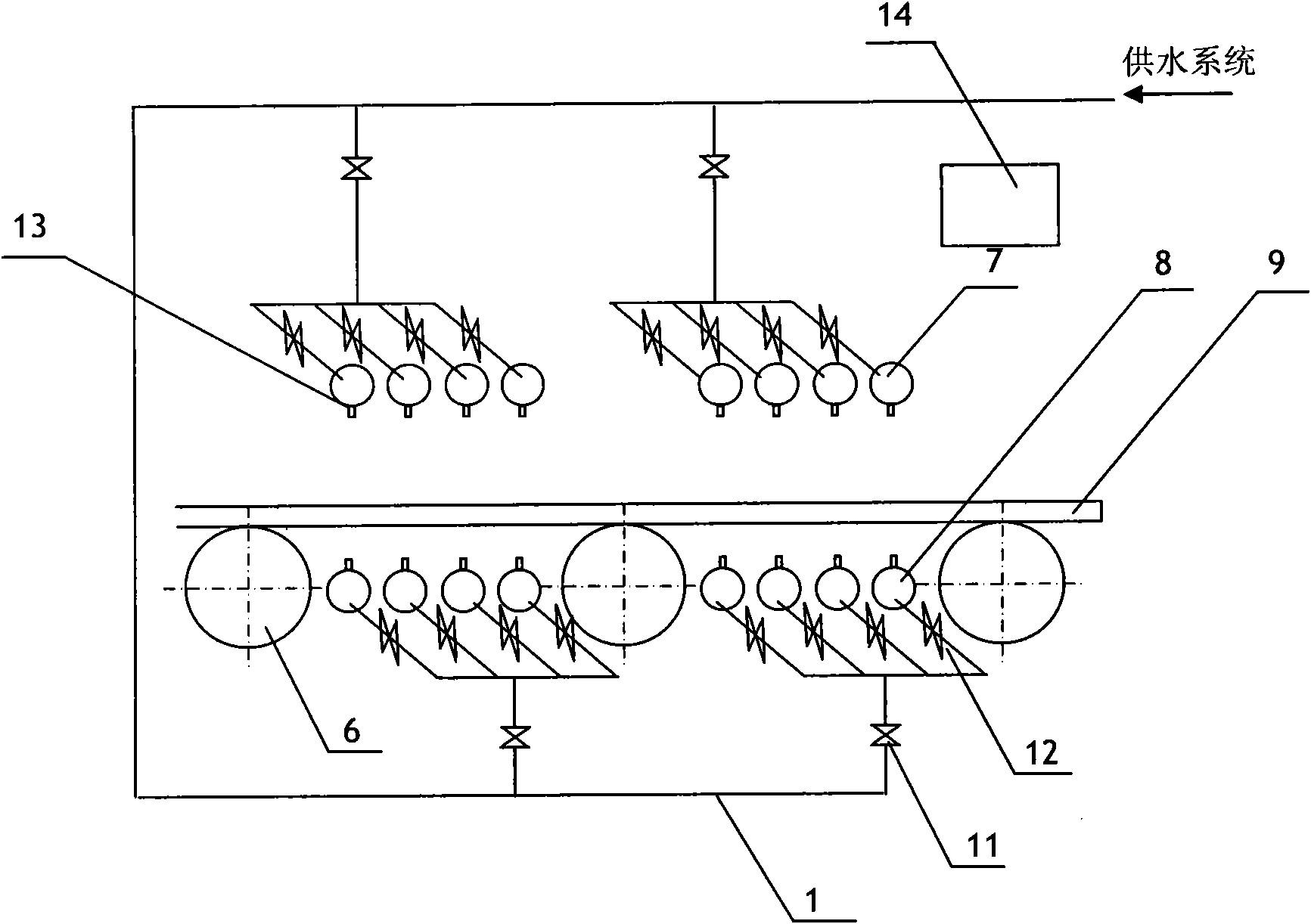

[0043] The production of 18.5mm thick × 80 pipeline steel by controlled rolling process is as follows: image 3The arrangement shown implements controlled cooling of the intermediate billet. 48 groups of cooling devices are installed on the conveying roller table at the exit of the roughing mill to form a cooling area. The cooling water pressure is 1.0MPa. First, the raw billet is rolled by the roughing mill into an intermediate billet with a thickness of 55mm. The temperature of the intermediate billet is 1030-1050°C. While rolling, it is sent into the cooling area; the computer calculates the amount of cooling water according to the thickness, width, steel type and temperature of the intermediate billet, and the target cooling temperature of the intermediate billet, and controls the opening and closing of the control valve through the programmable controller. The number of opening and closing and the flow rate of the flow control valve, the upper and lower headers implement ...

example 2

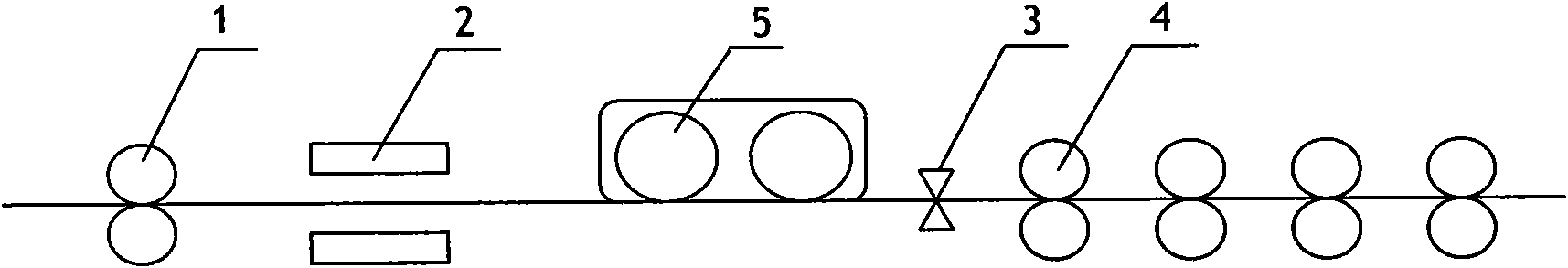

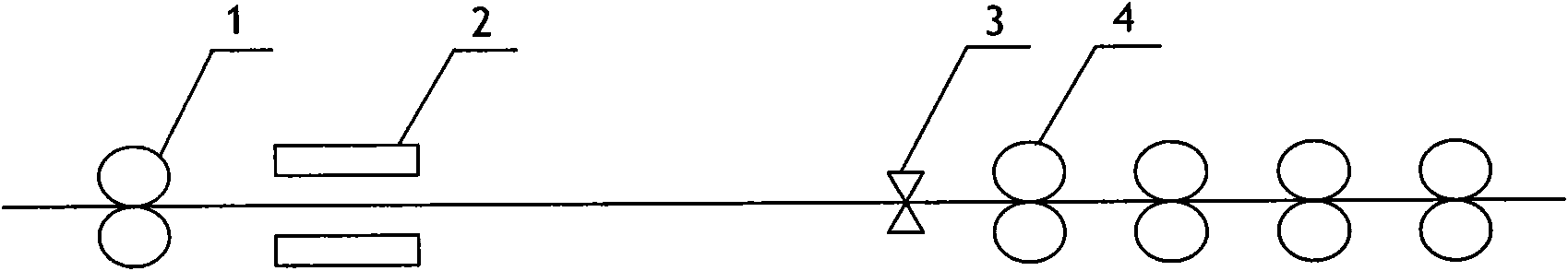

[0045] Ferritic rolling process produces 2.0mm thick IF steel, such as figure 2 The arrangement shown implements controlled cooling of the intermediate billet. 32 groups of cooling devices are installed on the conveying roller table at the exit of the roughing mill to form a cooling area, the cooling water pressure is 0.40MPa, the raw billet is first rolled by the roughing mill into an intermediate billet with a thickness of 22mm, and the temperature of the intermediate billet is 1020-1050°C. While rolling, it is sent into the cooling area; the computer calculates the amount of cooling water according to the thickness, width, steel type and temperature of the intermediate billet, and the target cooling temperature of the intermediate billet, and the opening and closing control valve is operated by the programmable controller. The closing quantity and the flow rate of the flow control valve, the upper and lower headers implement impact jets to control the cooling rate of the i...

example 3

[0047] The production of 3.0mm welded bottle steel HP295 adopts such as figure 2 The arrangement shown implements controlled cooling of the intermediate billet. 36 groups of cooling devices are installed on the conveying roller table at the exit of the roughing mill to form a cooling area. The cooling water pressure is 0.60MPa. First, the roughing mill rolls the raw billet into an intermediate billet with a thickness of 32mm. The temperature of the intermediate billet is 1010-1040°C. While rolling, it is sent into the cooling area; the computer calculates the amount of cooling water according to the thickness, width, steel type and temperature of the intermediate billet, and the target cooling temperature of the intermediate billet, and the opening and closing control valve is operated by the programmable controller. The closing quantity and the flow rate of the flow control valve, the upper and lower headers implement impact jets to control the cooling of the intermediate bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com