Patents

Literature

180results about How to "Improve flow stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

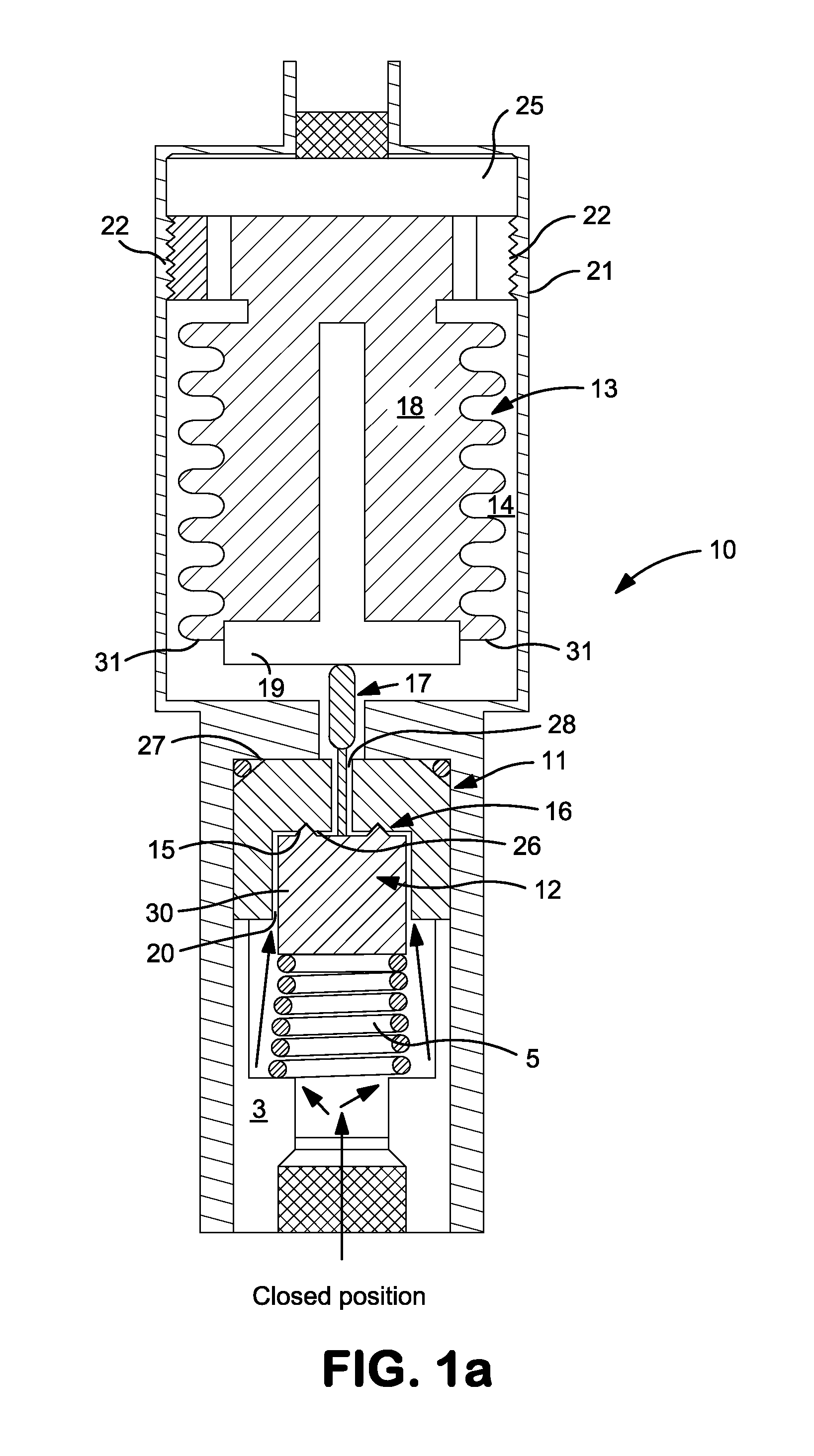

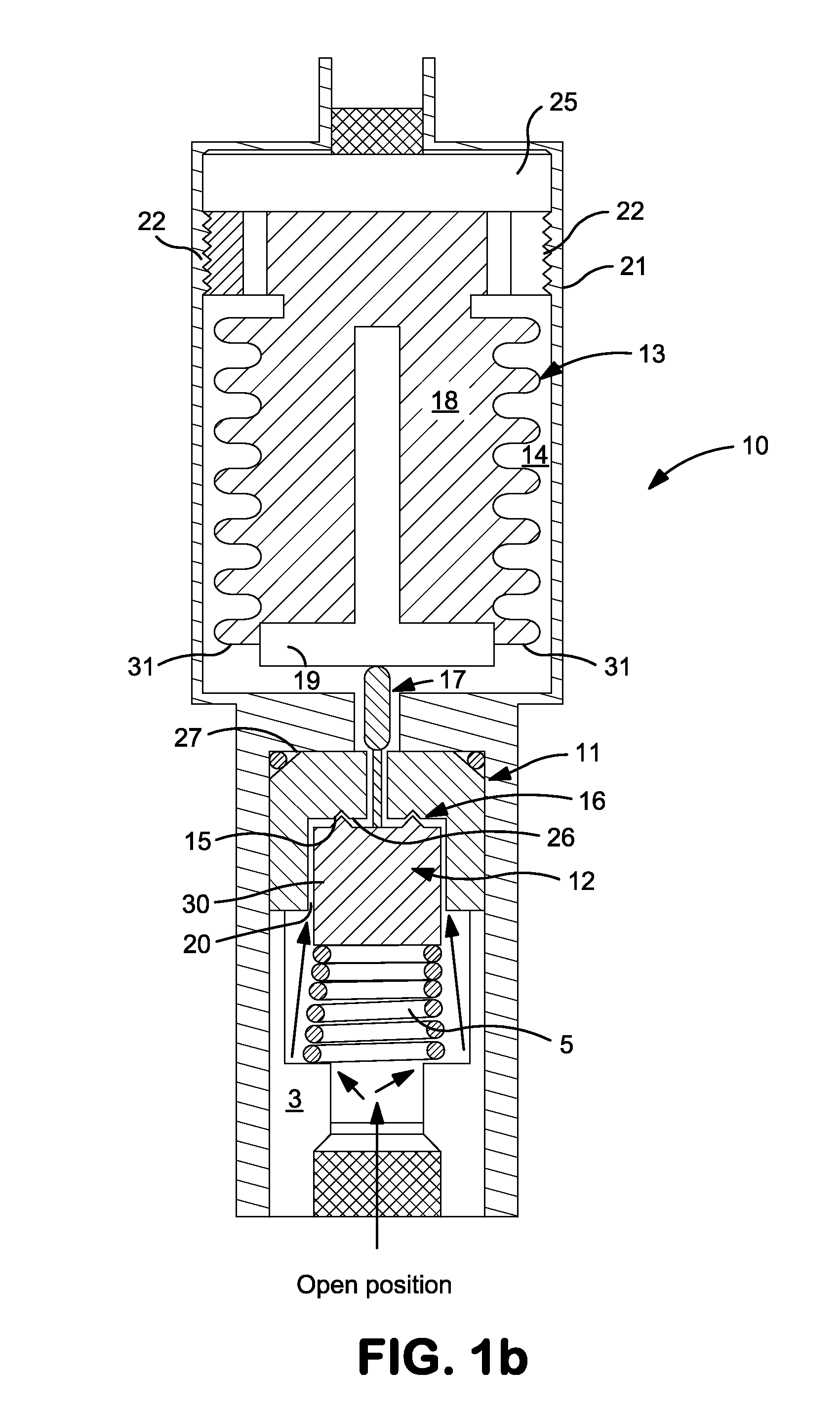

Flow control valve

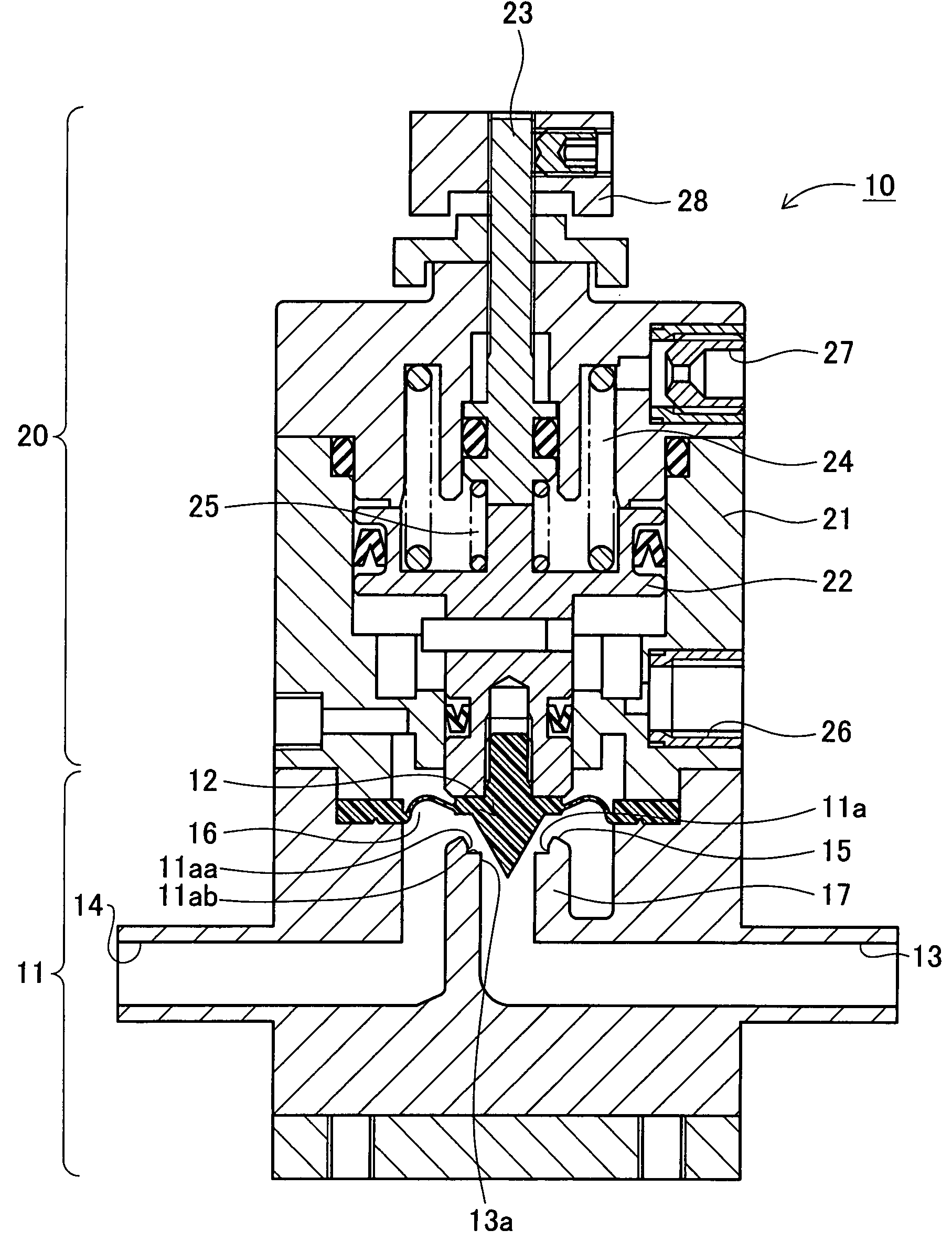

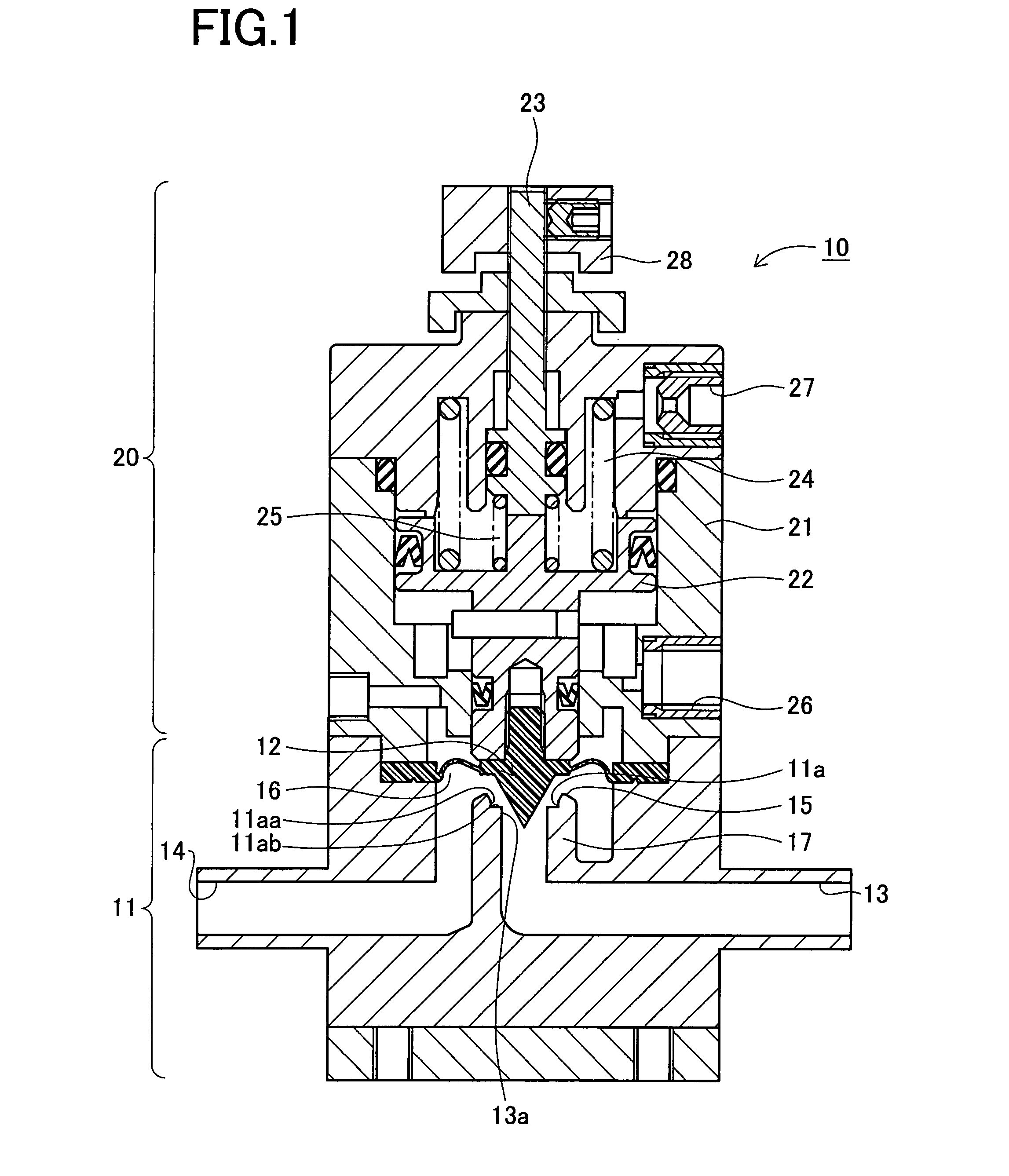

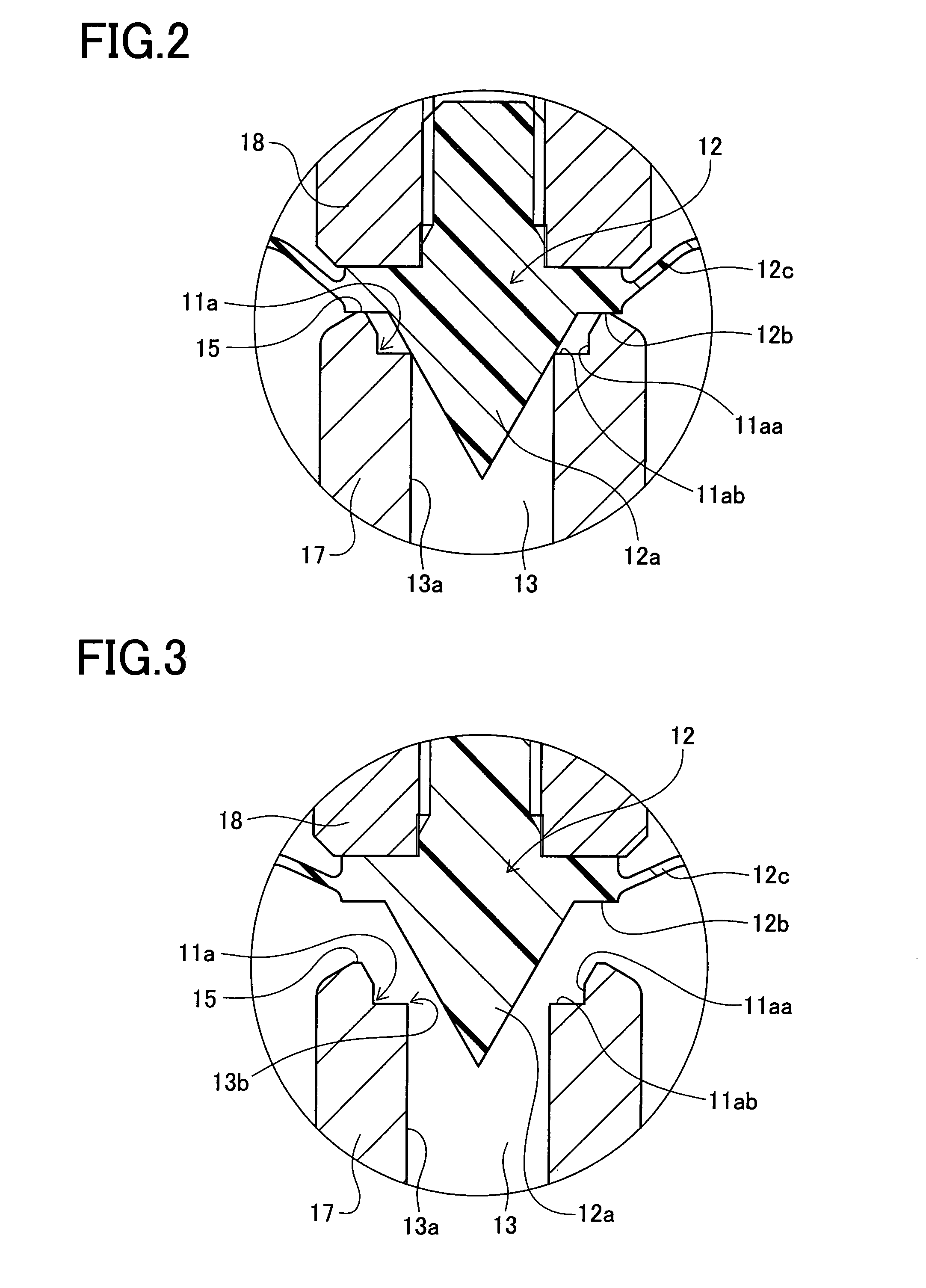

InactiveUS7537194B2Improve flow stabilityPrevent radial deformationDiaphragm valvesOperating means/releasing devices for valvesEngineeringControl valves

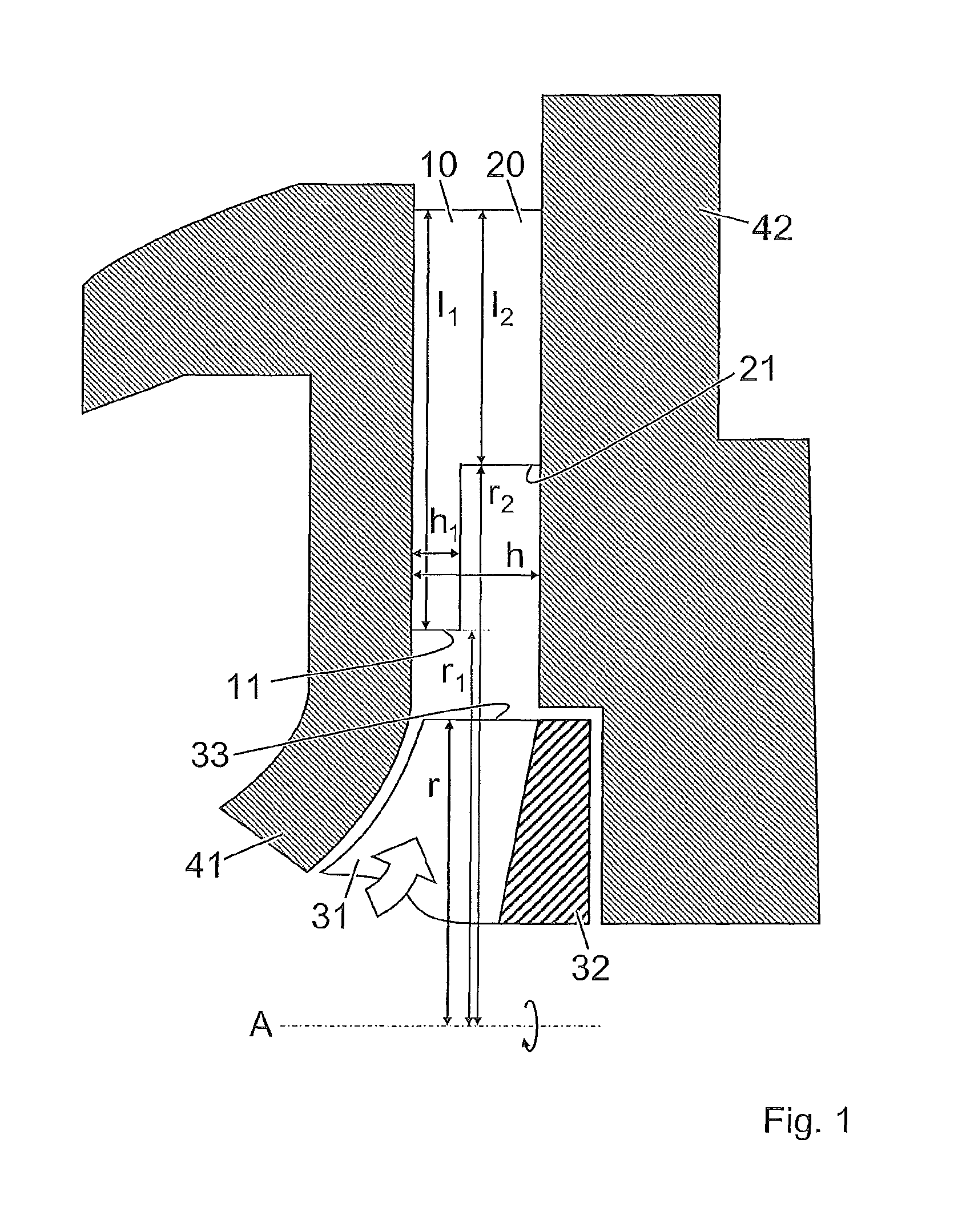

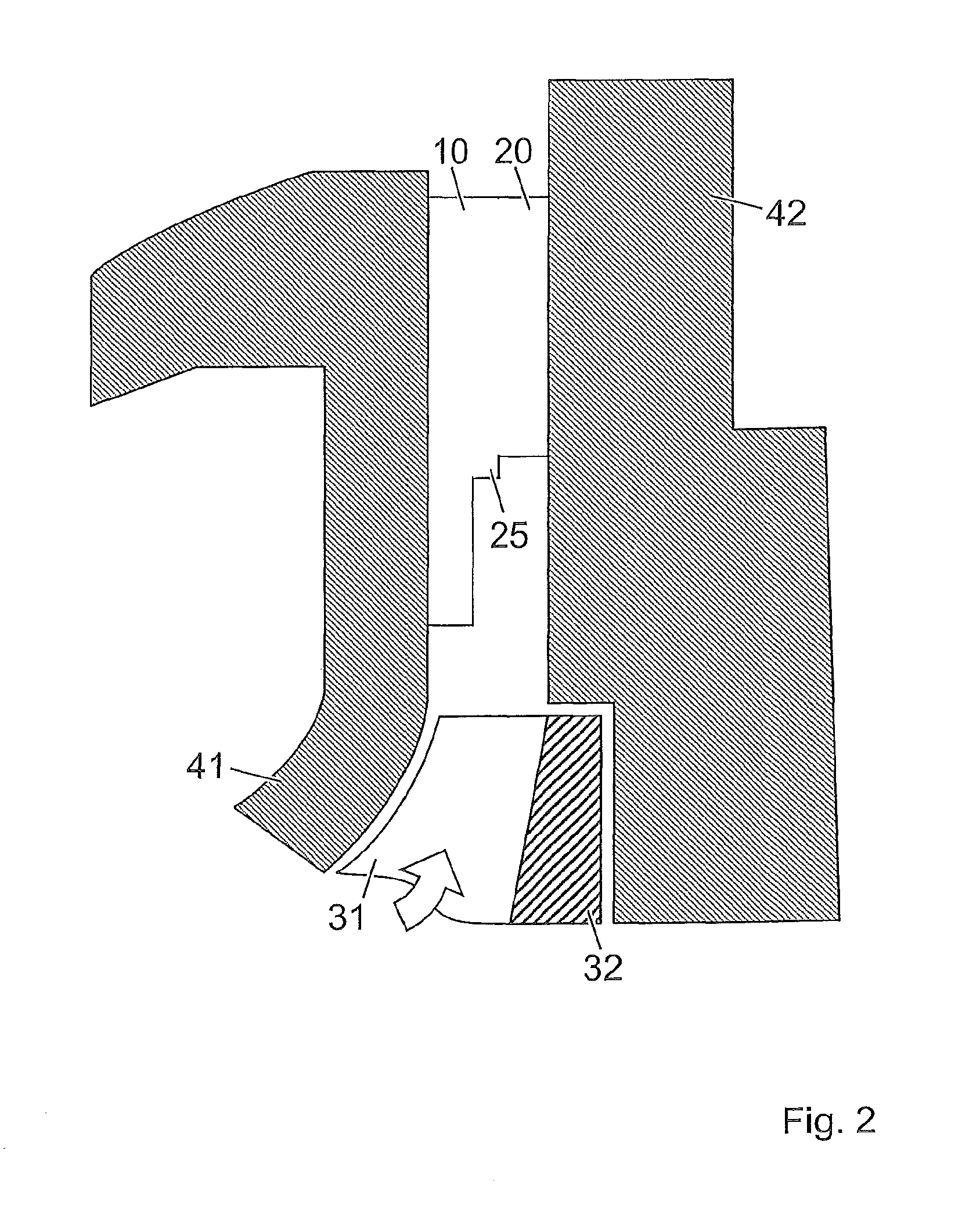

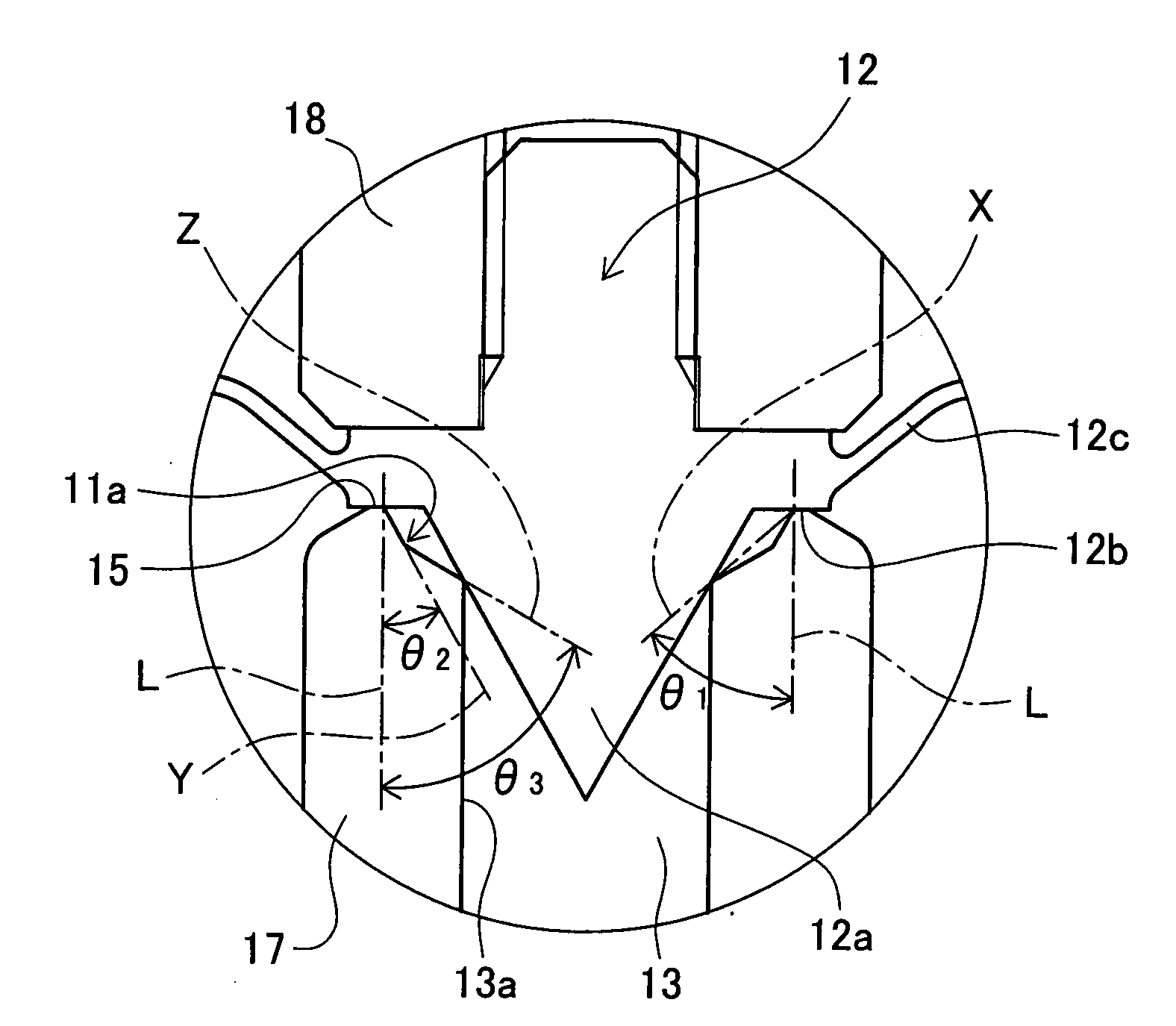

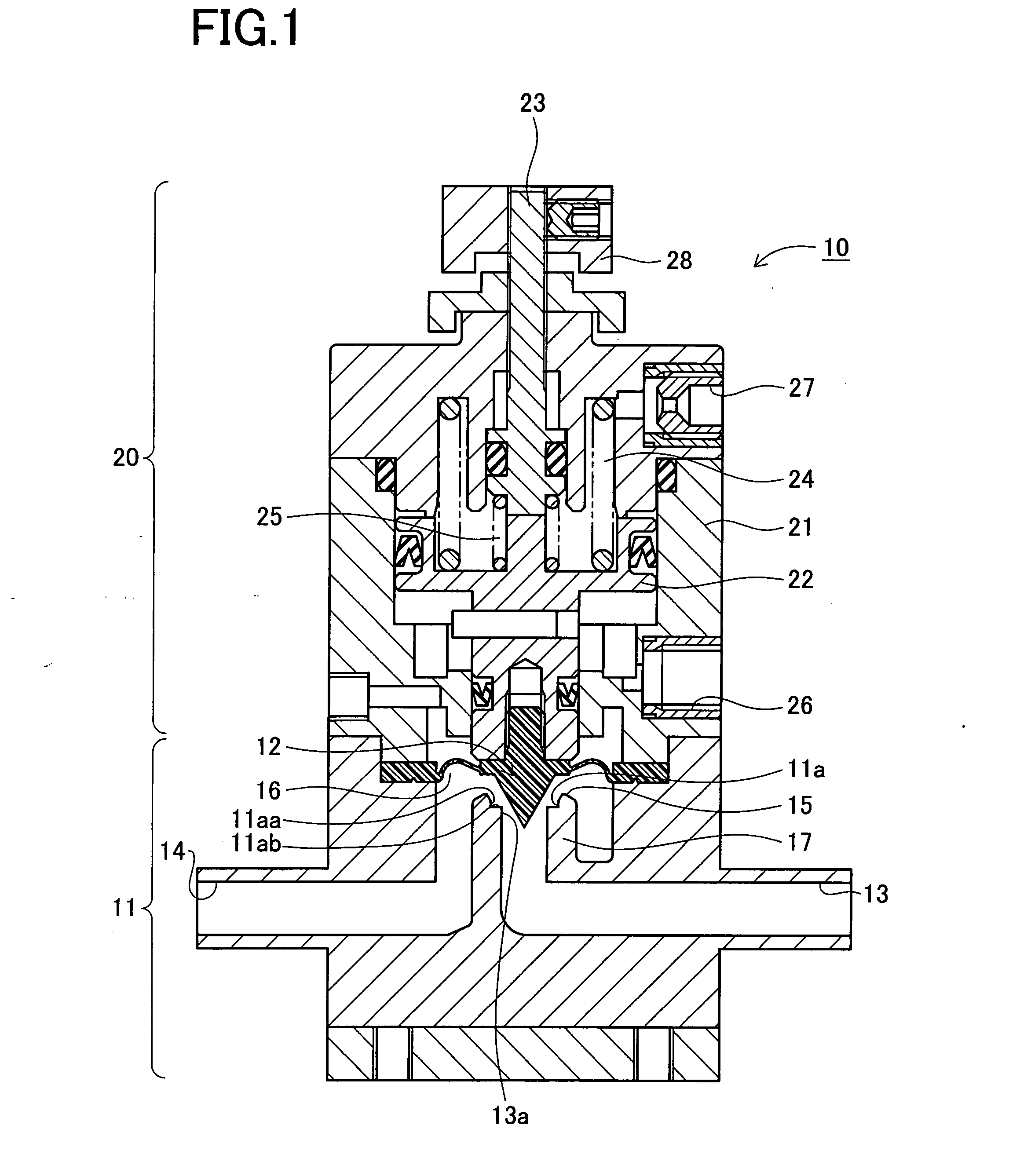

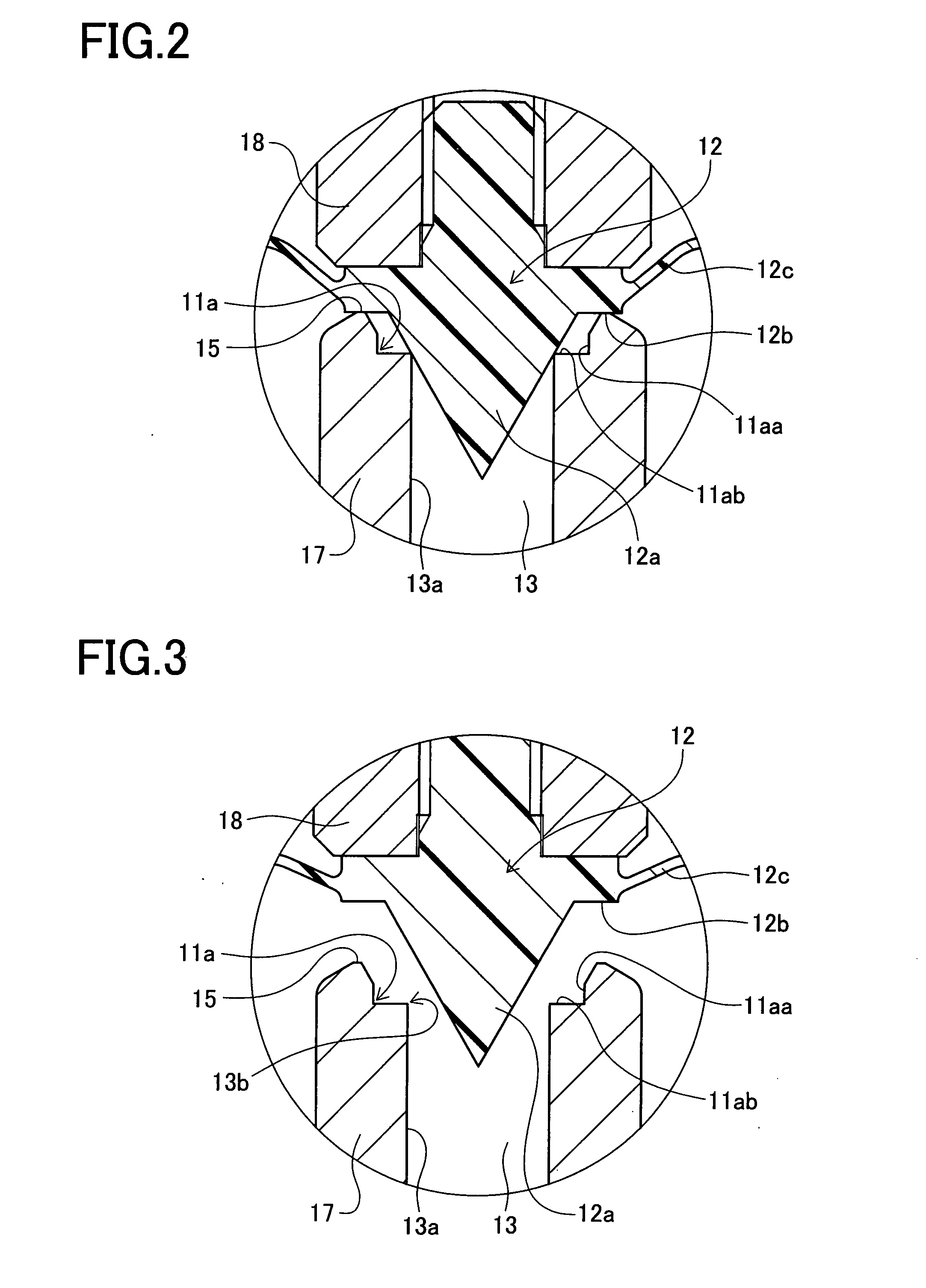

A compact flow control valve with high flow stability is arranged to comprises: a valve body made of resin including; a first passage formed in the valve body; a valve port communicating with the first passage; and a valve seat formed around the valve port; a valve element movable into contact with and away from the valve seat; a valve chamber formed around the valve seat; a second passage communicating with the valve chamber; and a flow adjustment rod for adjusting a flow rate of a fluid allowed to flow in the valve chamber, wherein the flow adjustment rod is adjustable in position to change an opening degree of the valve element relative to the valve seat for adjusting the flow rate, and the flow control valve further comprises an annular recess formed in an inner periphery of the valve seat formed surrounding the valve port and configured to prevent radial deformation of the valve port when the valve element is moved into contact with the valve seat.

Owner:CKD

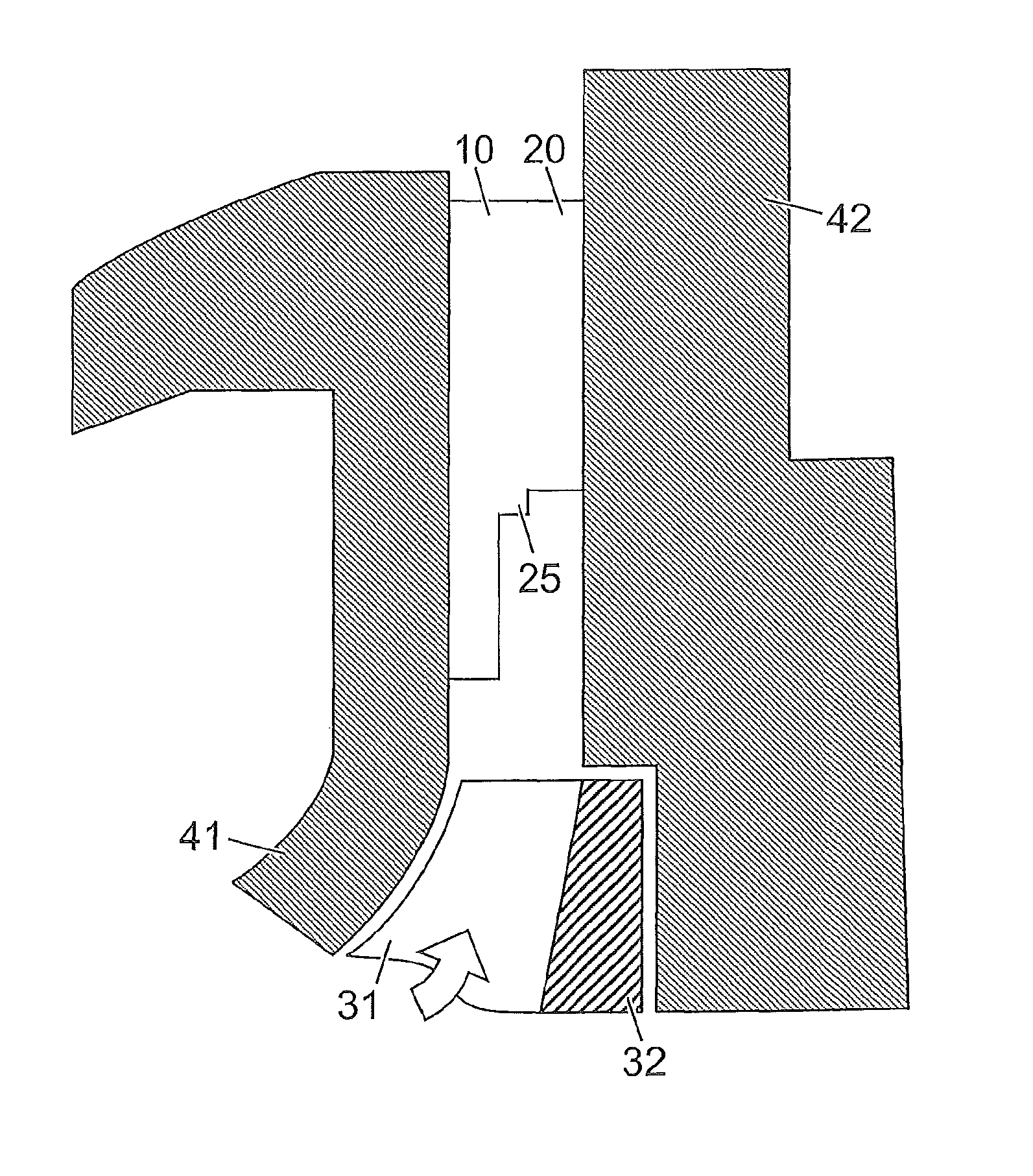

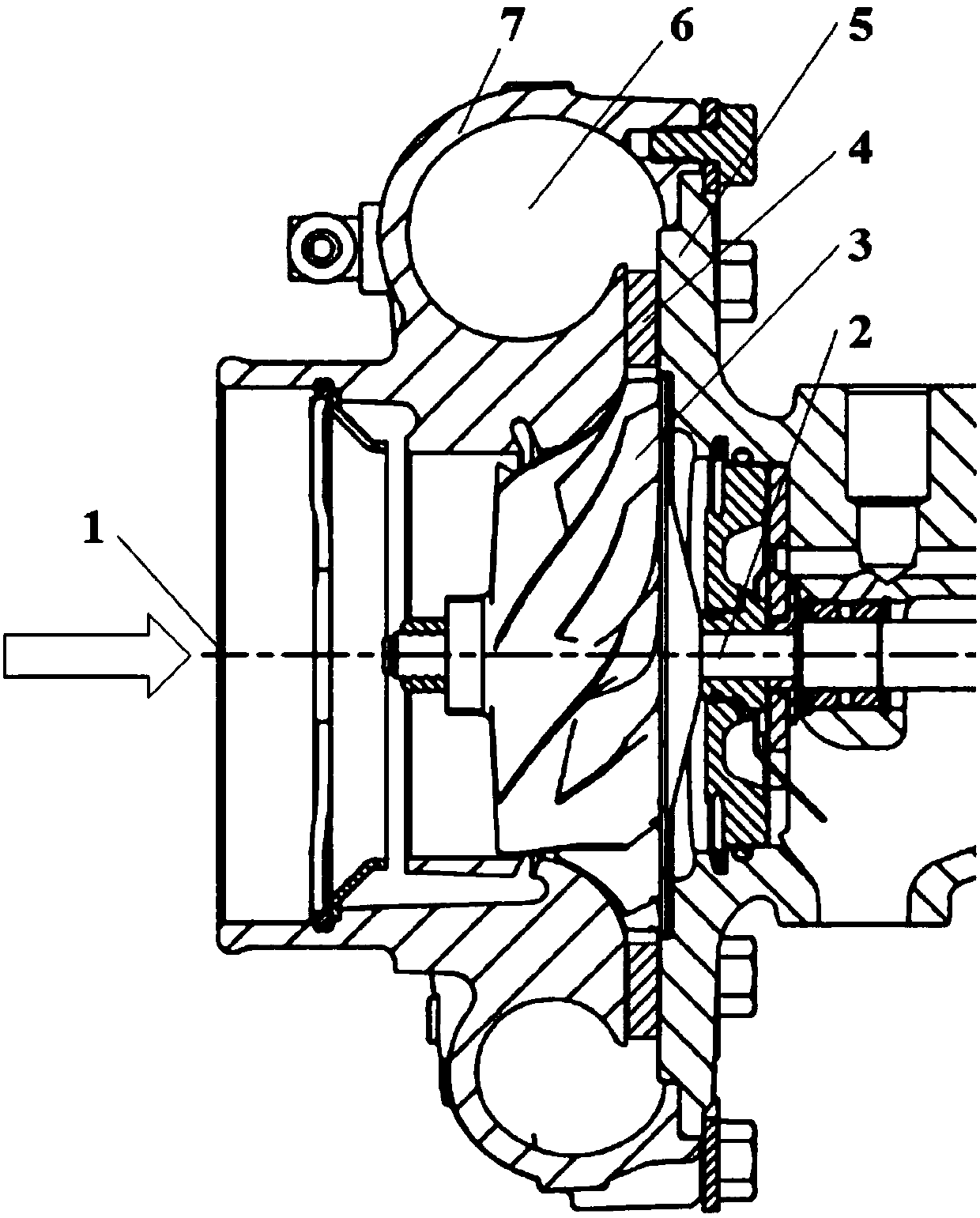

Diffusor

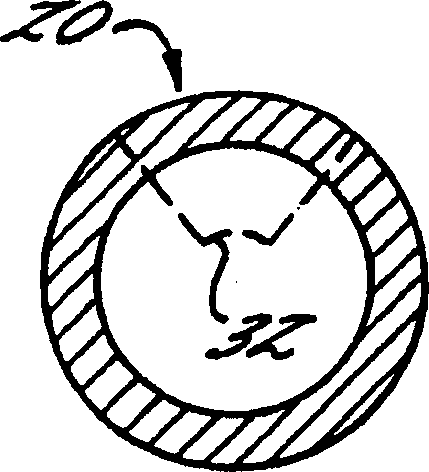

ActiveUS8162604B2Improve acoustic propertiesIncrease widthEngine manufacturePump componentsNoise fieldImpeller

The guide device for the diffusor at the compressor impeller outlet of a radial compressor has guide blades with stepped inlet edges. The step is implemented by setting back the hub-side inlet edge. This meridional stepping divides the guide blades into two component blades, of which the first component blade is made longer than the second component blade. The set-back of the inlet edge of the hub-side component blade and the associated superposition of the noise fields which are produced on the front and rear inlet edge of the diffusor leads to improvement of the acoustic properties of the compressor.

Owner:TURBO SYST SWITZERLAND LTD

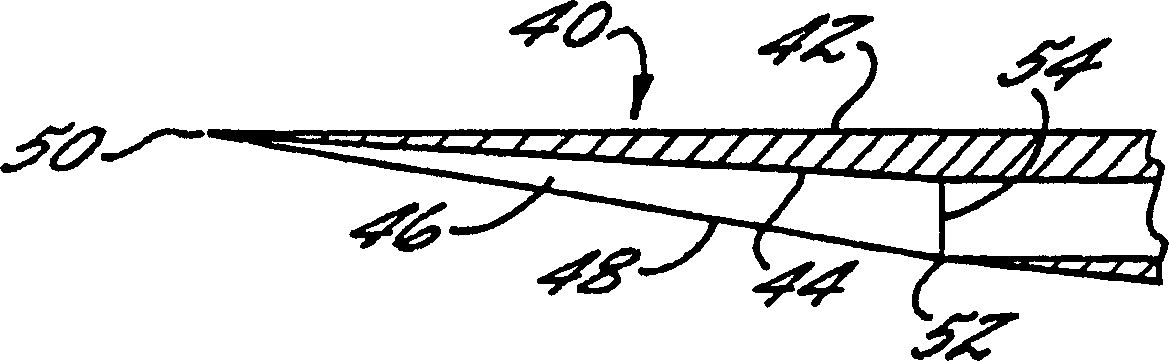

Supersonic external-compression diffuser and method for designing same

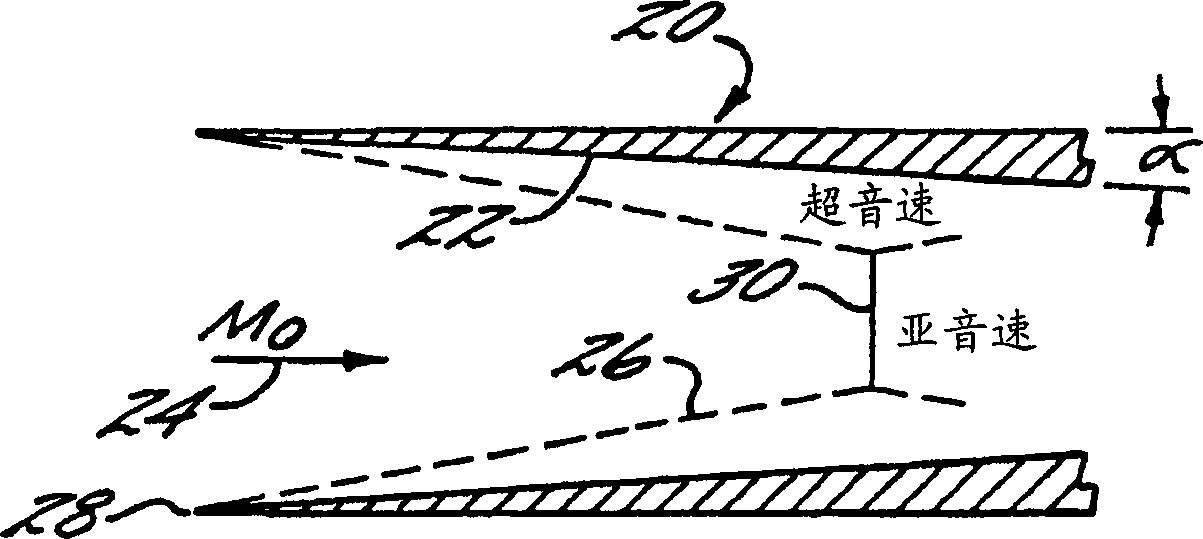

InactiveCN1384794AChange distanceKeep Smooth Flowing TransitionsPump componentsGas turbine plantsShock waveLeading edge

A supersonic externally pressurized inlet comprising a generally scoop-shaped supersonic pressurized portion for diffusing a supersonic free jet. The supersonic pressurization portion includes a main wall having a leading edge and a throat downstream of the leading edge; and sides joined to opposed side edges of the main wall to form a generally scoop-shaped member. The sides preferably protrude far enough into the supersonic flow to encompass the initial oblique shock attached to the leading edge of the main wall. The main wall has an inner surface generally formed as an inclined sector of the surface of revolution, the inner surface of the main wall cooperating with the inner surfaces of the sides to form a three-dimensional external pressurized surface. The supersonic external pressurization inlet also includes a subsonic diffuser section arranged to receive airflow from the supersonic pressurization section and diffuse the airflow to subsonic conditions. The variable geometry inlet includes an outer ramp hinged about its forward edge and forming part of the inner surface of the spoon diffuser, the pivotal movement of the outer ramp being used to vary the throat size of the inlet. The subsonic diffuser includes an inner ramp hinged around its trailing edge to maintain a smooth transition from the outer ramp.

Owner:THE BOEING CO

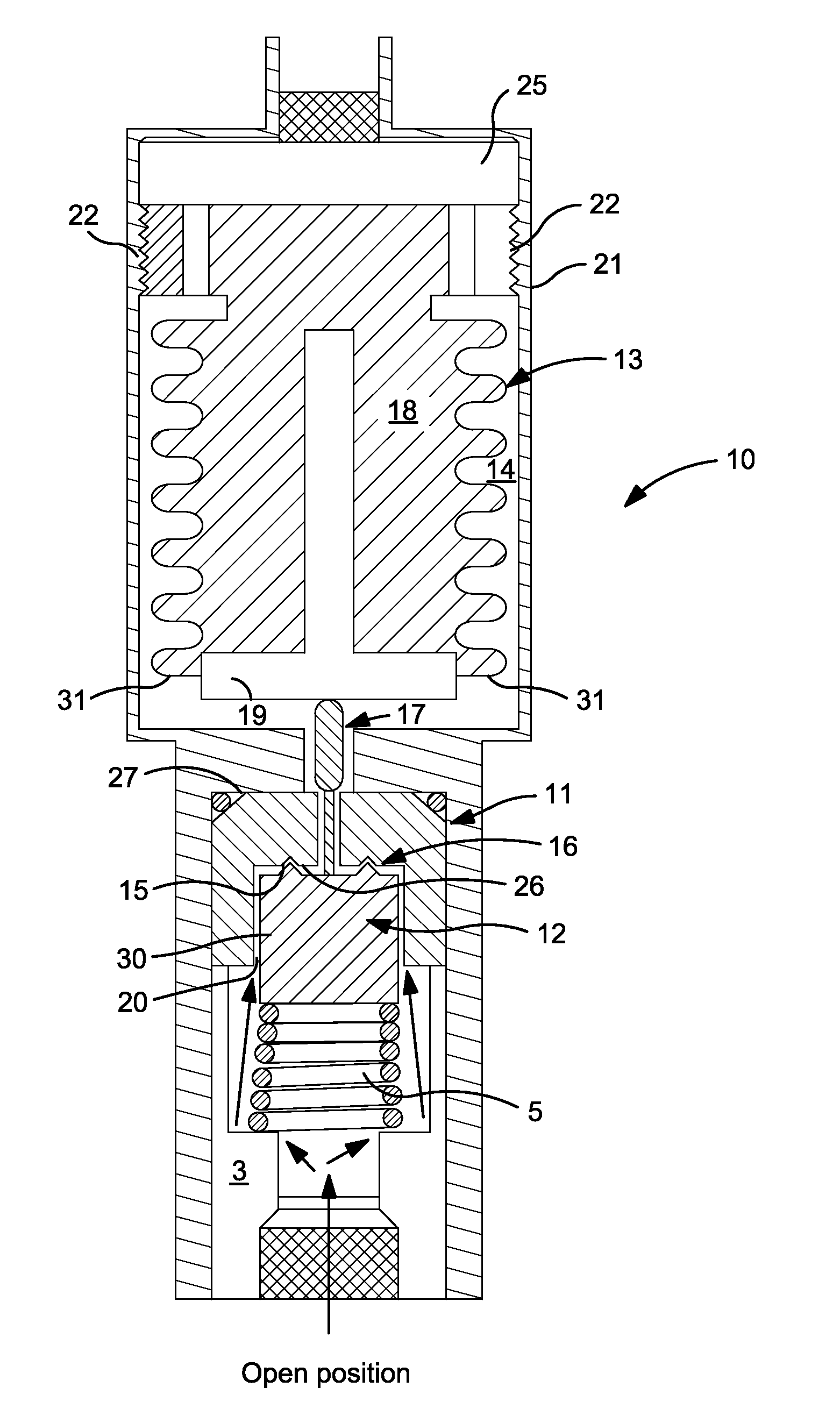

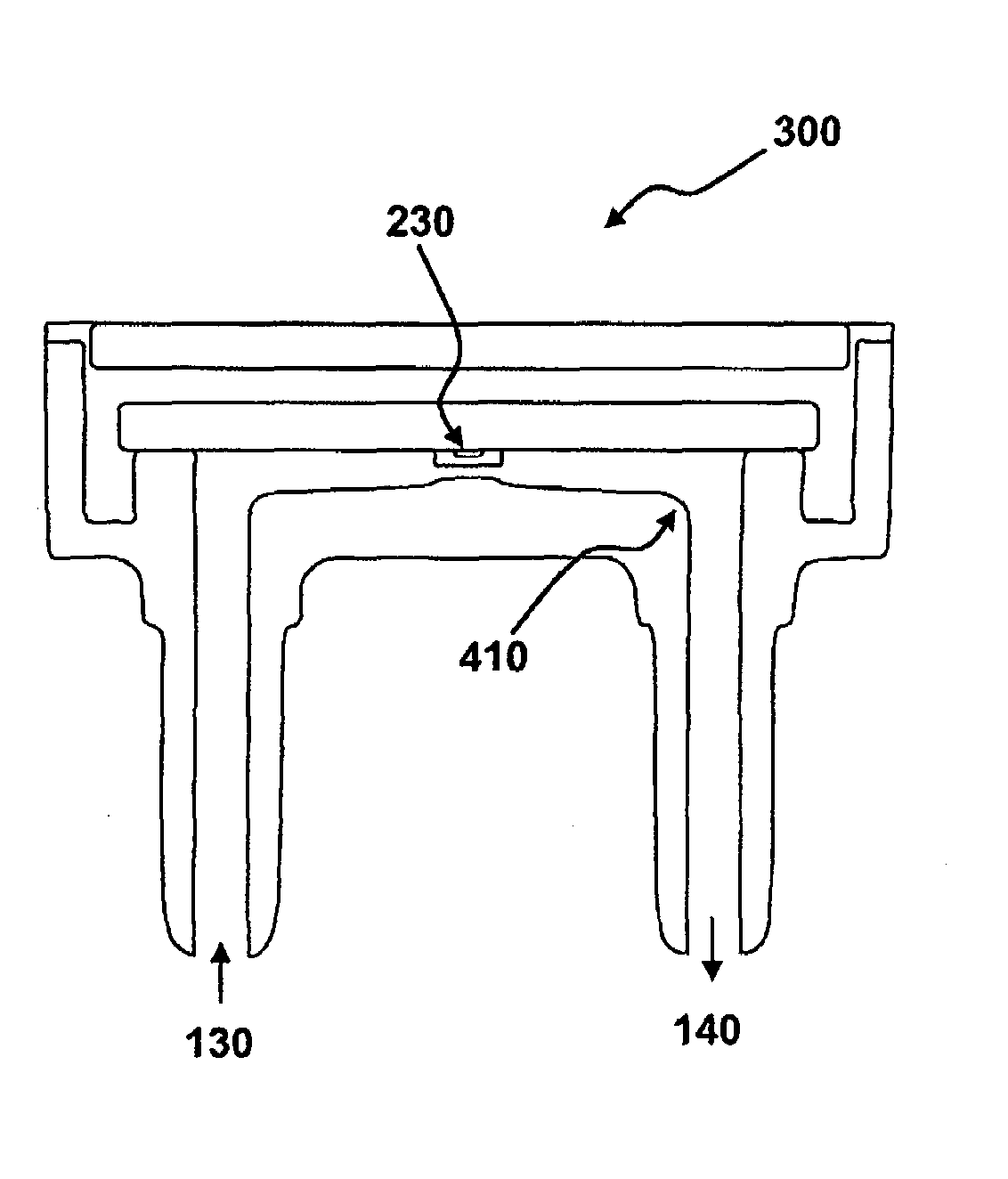

Modified vacuum actuated valve assembly and sealing mechanism for improved flow stability for fluids sub-atmospherically dispensed from storage and delivery systems

ActiveUS20160258537A1Improve stability of flowImprove flow stabilityVessel mounting detailsVessel geometry/arrangement/sizeEngineeringBellows

A modified vacuum actuated valve assembly and sealing mechanism is provided for improved sub-atmospheric flow stability characterized by the absence of delivery pressure spikes and flow excursions. The valve assembly includes a non-stationary thermoplastic seat and a stabber. The stabber is characterized by a top portion having a circular periphery designed to mechanically engage and disengage with an inner sealing surface of the thermoplastic seat. The sealing surface is coined to eliminate surface irregularities contained therein, thereby producing a relatively smooth coined mating inner sealing surface for the circular top portion of the stabber. The valve assembly also includes a modified bellows capable of fine tuning the delivery pressure of the valve assembly.

Owner:PRAXAIR TECH INC

Flow control valve

InactiveUS20080001110A1Improve flow stabilityDownsizingDiaphragm valvesOperating means/releasing devices for valvesEngineeringControl valves

A compact flow control valve with high flow stability is arranged to comprises: a valve body made of resin including; a first passage formed in the valve body; a valve port communicating with the first passage; and a valve seat formed around the valve port; a valve element movable into contact with and away from the valve seat; a valve chamber formed around the valve seat; a second passage communicating with the valve chamber; and a flow adjustment rod for adjusting a flow rate of a fluid allowed to flow in the valve chamber, wherein the flow adjustment rod is adjustable in position to change an opening degree of the valve element relative to the valve seat for adjusting the flow rate, and the flow control valve further comprises an annular recess formed in an inner periphery of the valve seat formed surrounding the valve port and configured to prevent radial deformation of the valve port when the valve element is moved into contact with the valve seat.

Owner:CKD

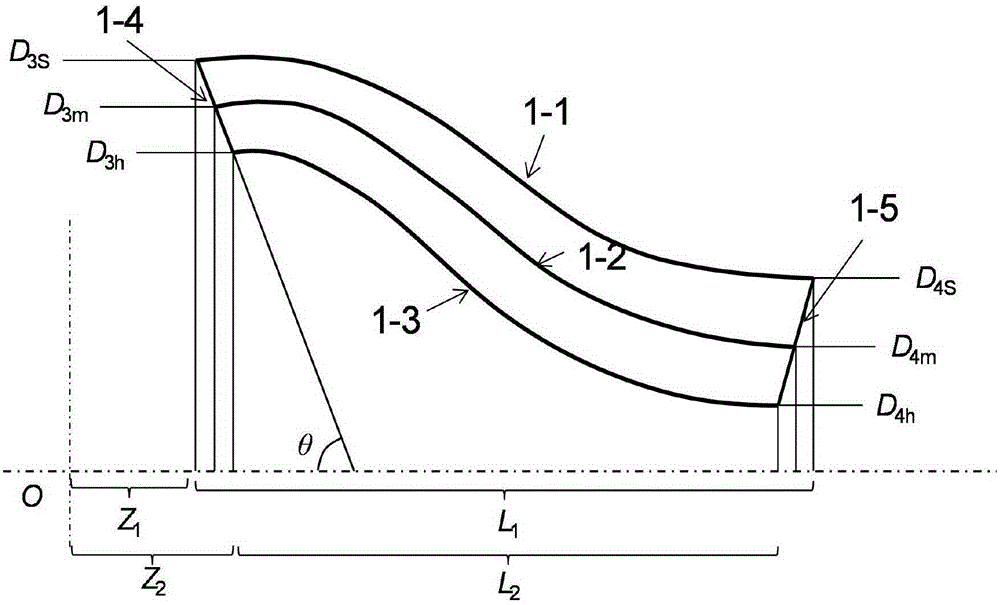

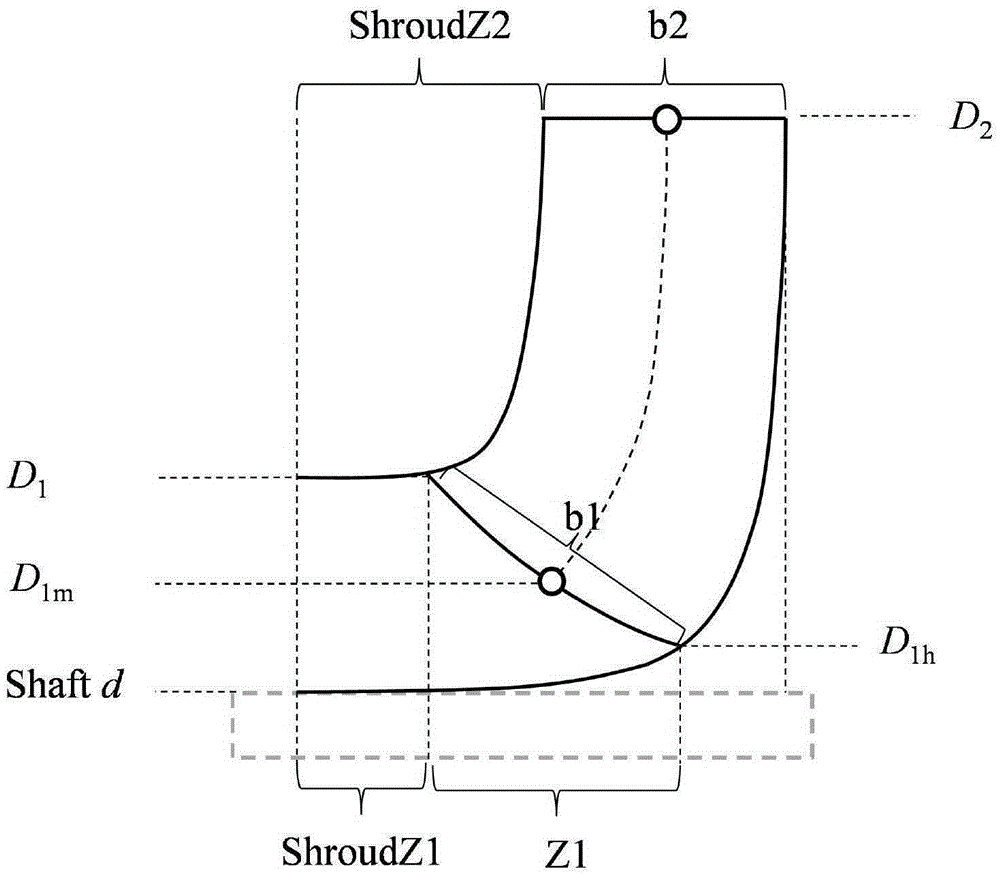

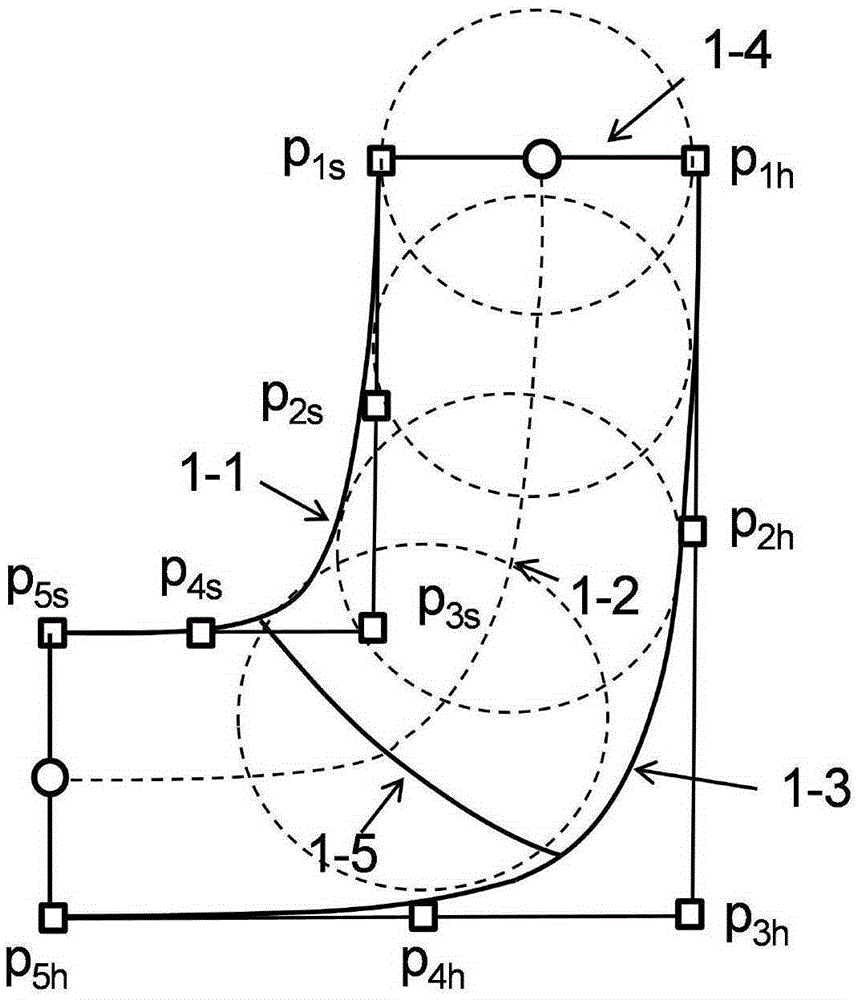

Designing method for hydraulic power of space guide-blade centrifugal pump

ActiveCN105201916AImprove centrifugal pump efficiencyImprove flow stabilityEngine manufacturePump componentsRotation velocityHydraulic structure

The invention discloses a designing method for hydraulic power of a space guide-blade centrifugal pump. An impeller hydraulic structure comprises a front cover plate, blades and a rear cover plate. The method comprises the following steps: (1) according to a given impeller geometric parameter as well as the flow rate, lift and rotation velocity value, solving a calculation method of the space guide-blade shaft surface hydraulic design parameters and a control algorithm of a guide-blade shaft surface shape and blade mold-line bezier curve on the basis of a binary flow theory; carrying out the hydraulic optimization design for space guide blades according to the method; (2) controlling streamlines on the upper cover plate shaft surface and streamlines on the shaft surface of the lower cover plate of the space blades by adopting a ternary Bezier curve equation, and adjusting the shaft surface streamlines on the basis of the variation rule of a guide-blade shaft surface flowing area; (3) controlling the vane mold-line arrangement angle distribution principle of the space blades by adopting a quartic Bezier curve equation; (4) adopting the data obtained in the steps (1) to (3) as dimensional parameters of the centrifugal pump space blades, and manufacturing the centrifugal pump space blades meeting the design requirement. The designed space blade can reduce the hydraulic loss in the vanes, improve the flowing situation inside the blade and improve the operation stability and hydraulic efficiency of the centrifugal pump.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

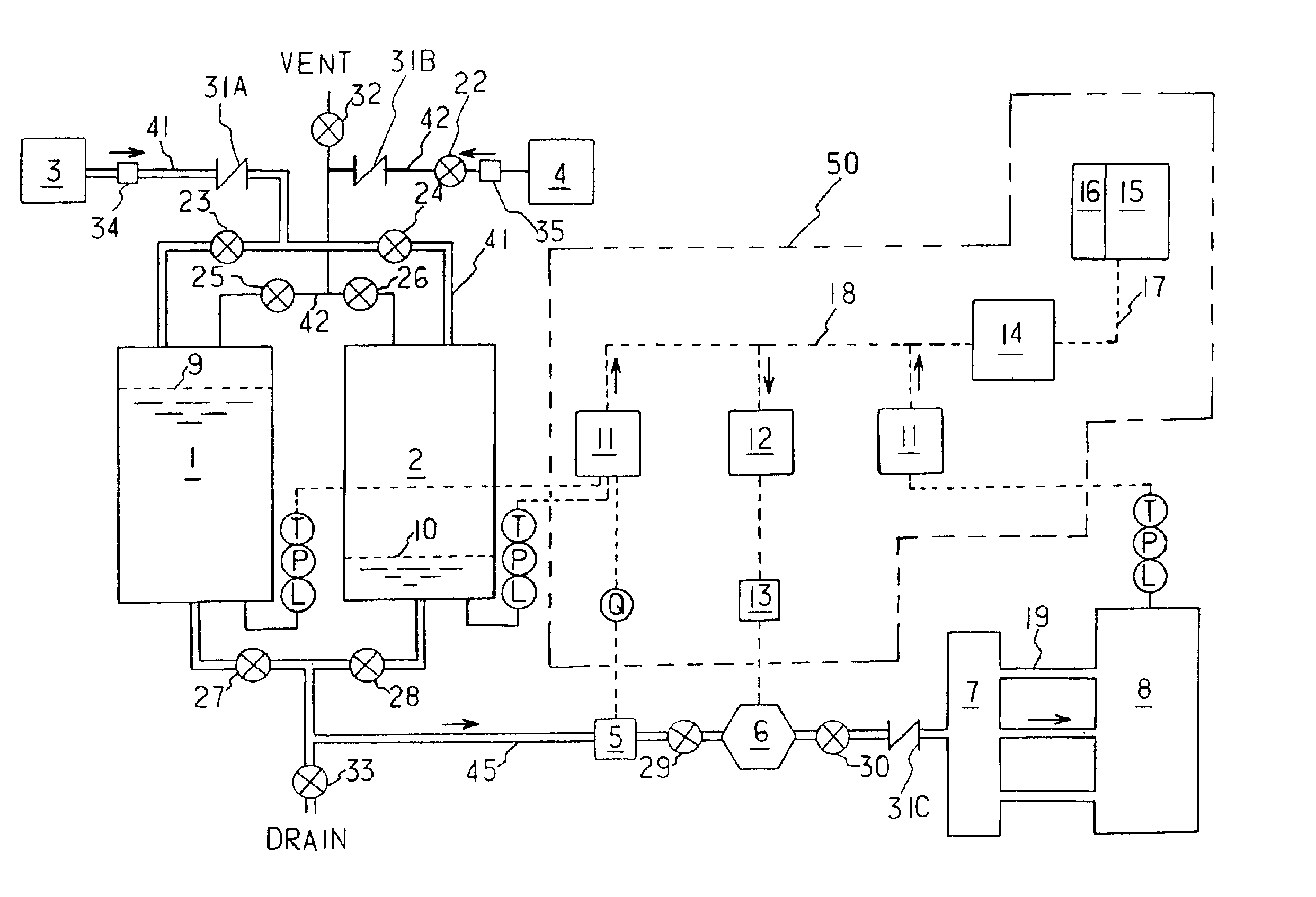

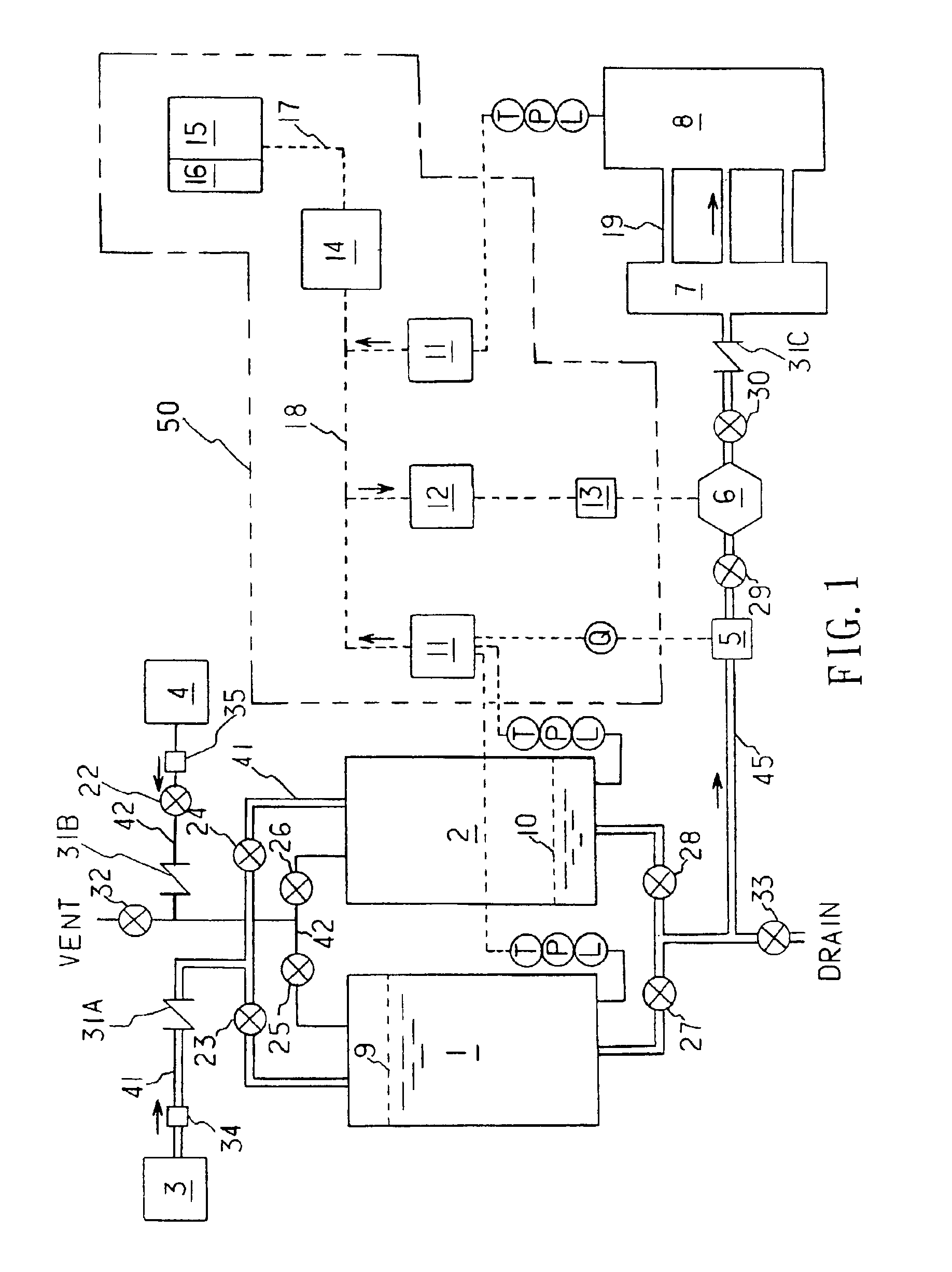

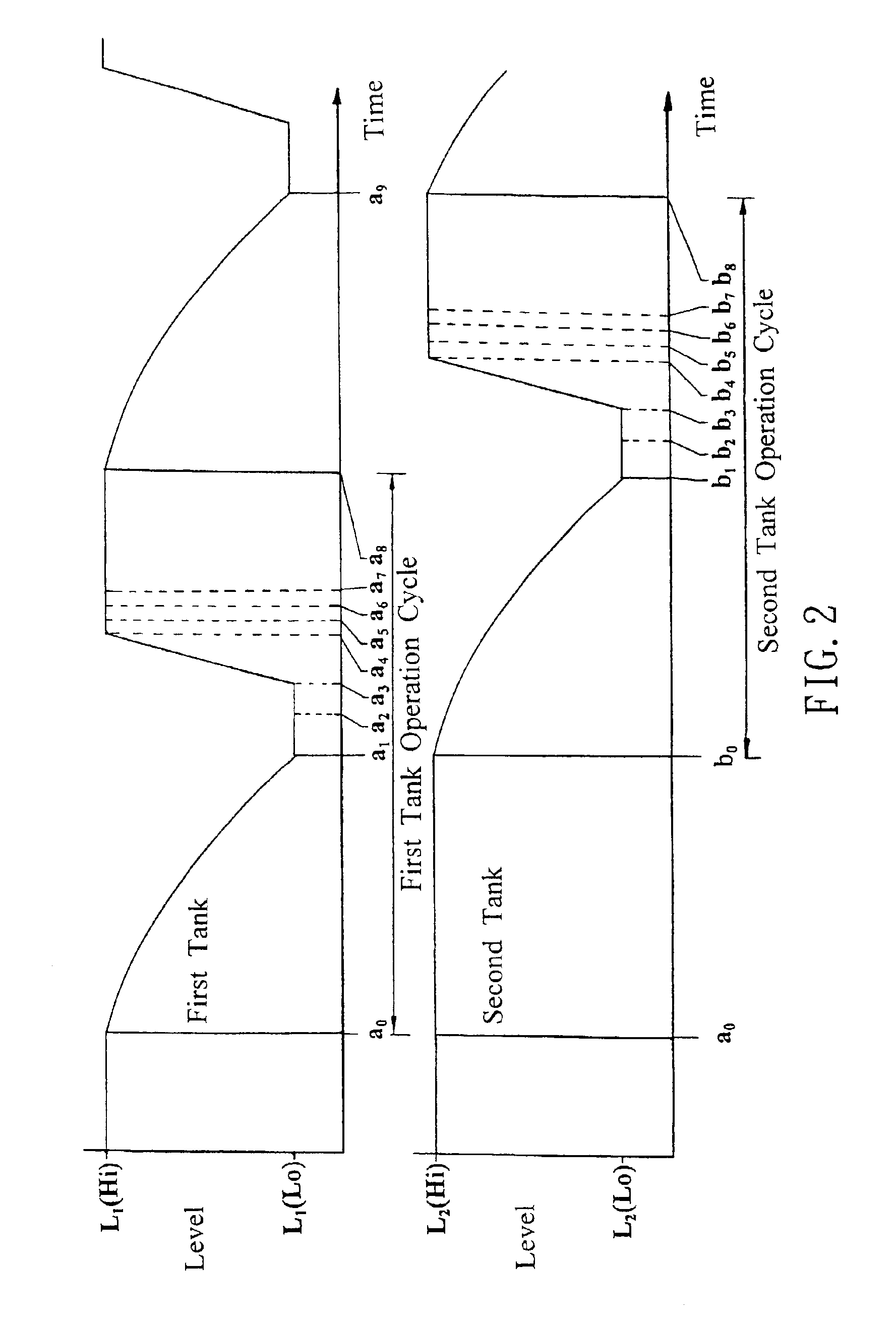

Multifunction passive and continuous fluid feeding system

InactiveUS7100631B2Realize functionEasy to controlOperating means/releasing devices for valvesControlling ratio of multiple fluid flowsEngineeringHigh pressure

The present invention is to provide a kind of multifunction passive and continuous fluid feeding system for external systems, the fluid-feed system including a storing and transmitting component, a measuring and regulating component, and a control unit characterized by: pressurizing from above fluid level surface of the feed fluid tank by high-pressure gas supply source to fulfill the passive fluid feeding function, performing the feed fluid measuring and regulating through the flow meter and flow control valve installed on the transmission pipe lines connecting to the external systems, fulfilling function of continuous fluid feeding by switching between two fluid-feed tanks, and combining the feed fluid requirements of the external systems through the control unit to achieve the multifunction fluid-feed art of automatic operation, continuous fluid feeding, and flow rate controlling. The present invention does not utilize high-head and high-pressure pumps as the driving components, thus it is not only cost-saving but makes easier in coping with various fluid-feed requirements by the external systems, hence, possessing potentials of extending applicability into various industrial fields.

Owner:INST NUCLEAR ENERGY RES ROCAEC

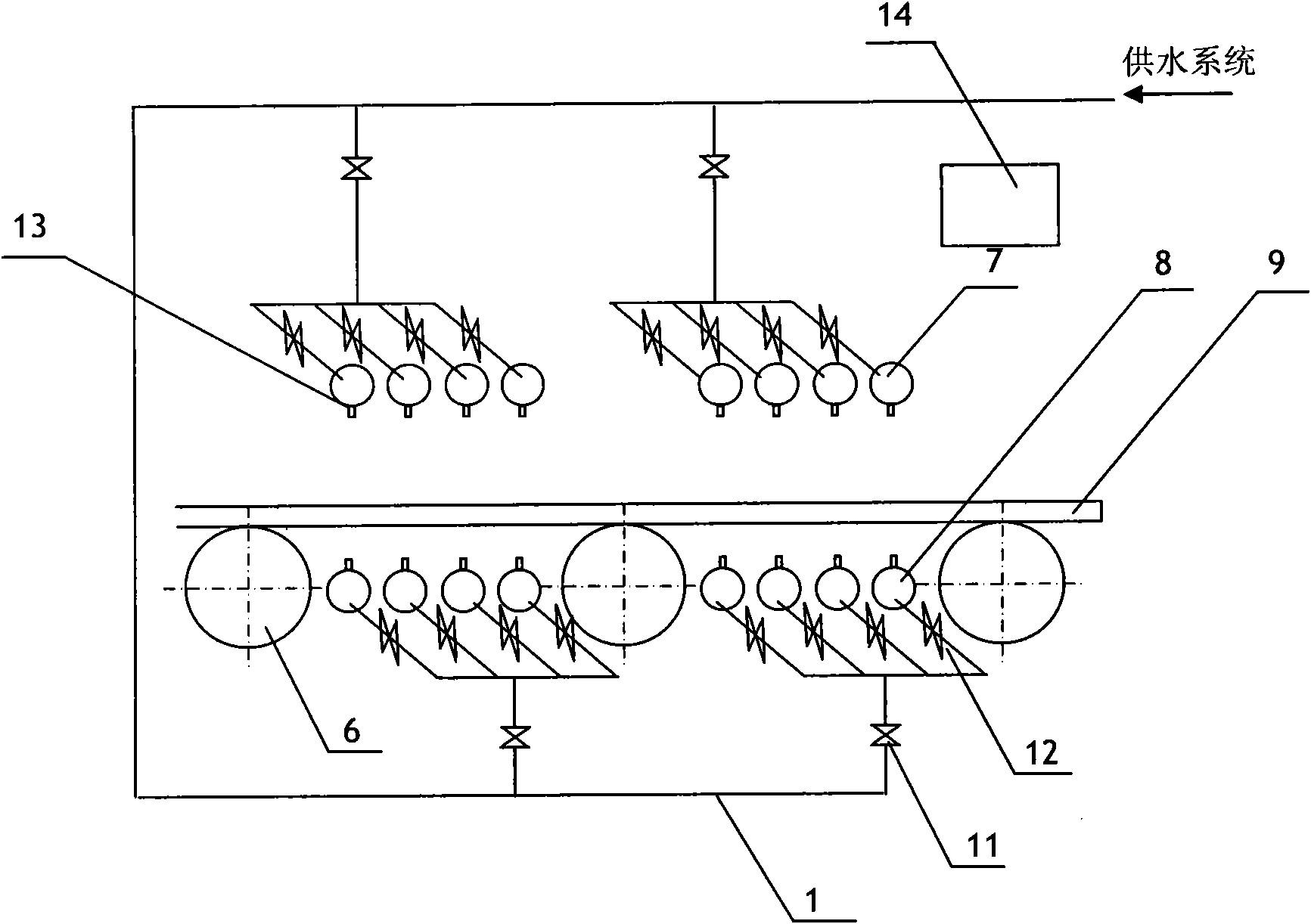

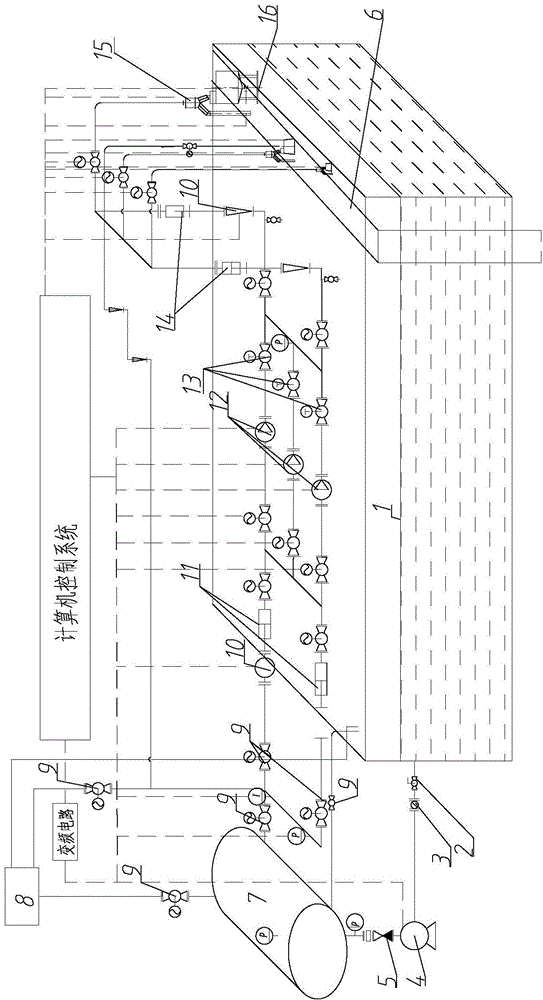

Device and method for cooling intermediate rolled blank of hot rolled strip

ActiveCN101972782ALess prone to overcoolingCool evenlyTemperature control deviceWork treatment devicesPipe waterWater quality

The invention provides a device and method for cooling an intermediate rolled blank of a hot rolled strip. The device comprises an upper collecting pipe arranged above roller beds and a lower collecting pipe arranged between the roller beds, wherein the upper collecting pipe and the lower collecting pipe are both provided with nozzles and opening and closing control valves and are connected with a workshop circulating water system through collecting pipe water supply pipelines; and the collecting pipe water supply pipelines are provided with flow control valves. The opening and closing control valves and the flow control valves are controlled by a programmable controller. A plurality of groups of cooling collecting pipes which can be independently controlled to open and close and has smaller flow are arranged between every two roller beds, the intermediate blank is cooled by adopting water jet, and the cooling speed is correspondingly dynamically controlled according to the transmission speed of the intermediate blank. The invention has the advantages of relatively simple structure of the device, low requirement for water quality, good flow stability and high production efficiency, and is convenient to maintain and free of limit of speed raising of a roughing mill and deceleration of throwing steel; rolling mill cooling water is adopted and a single water supply and drainage system is not needed; and grains of the intermediate blank are remarkably refined, and the mechanical property of a steel plate is improved.

Owner:UNIV OF SCI & TECH BEIJING

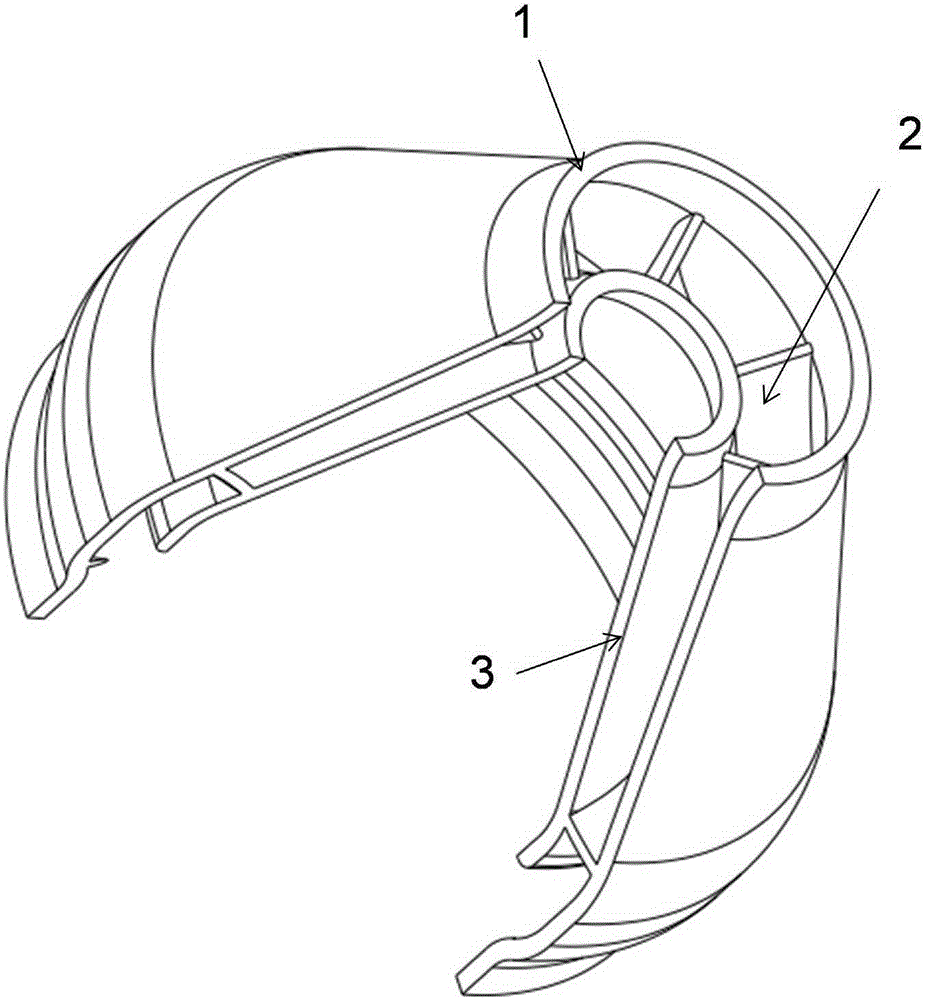

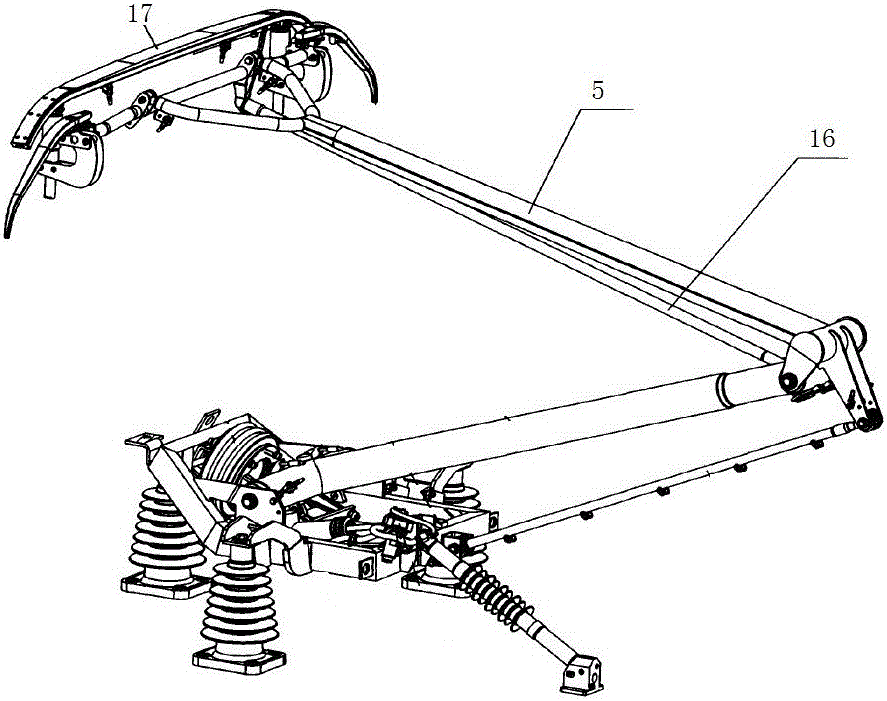

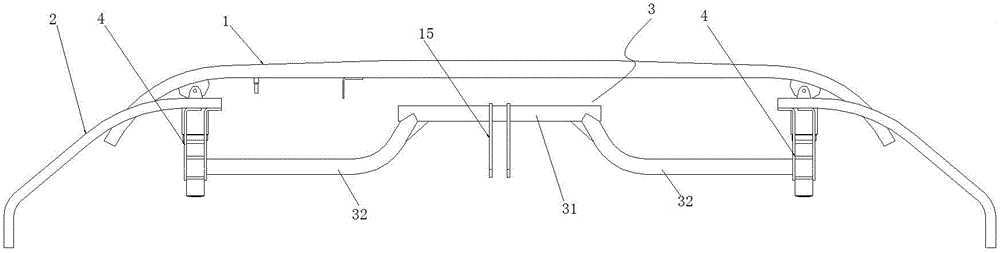

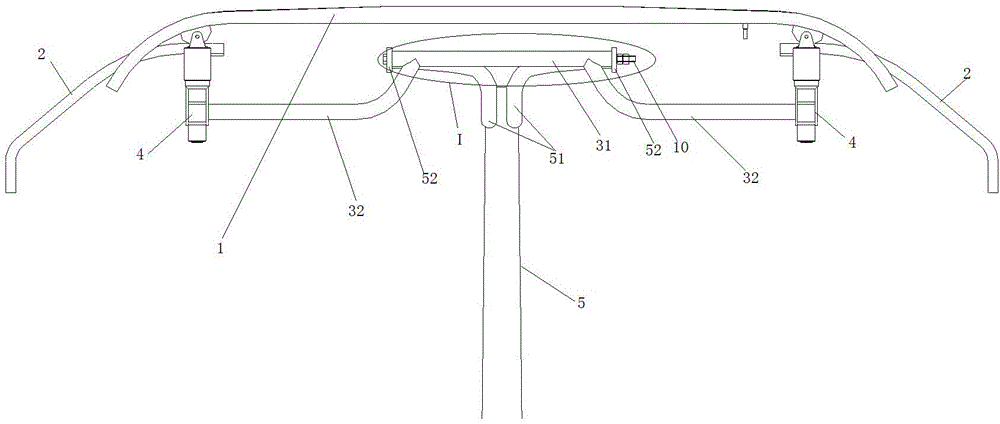

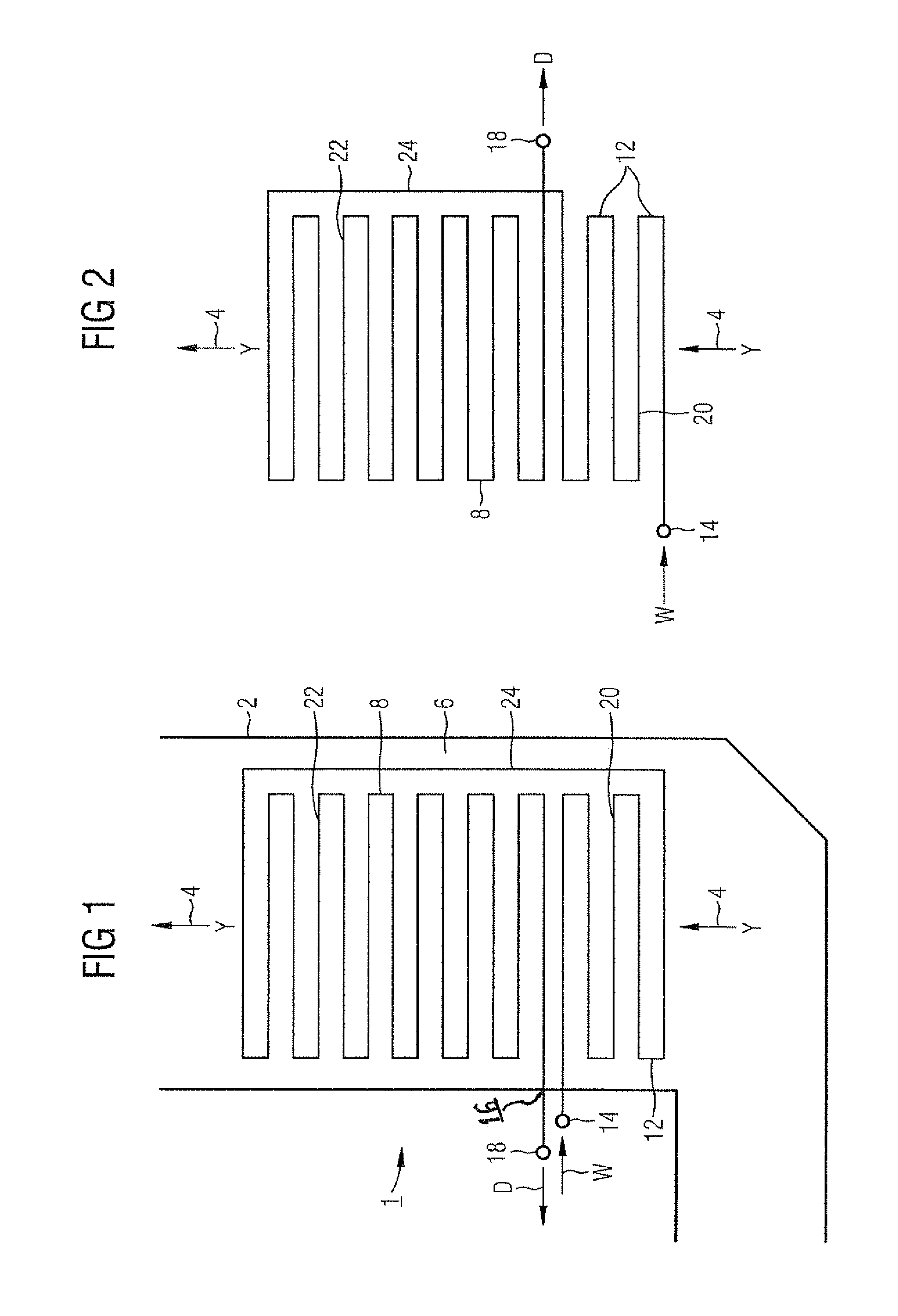

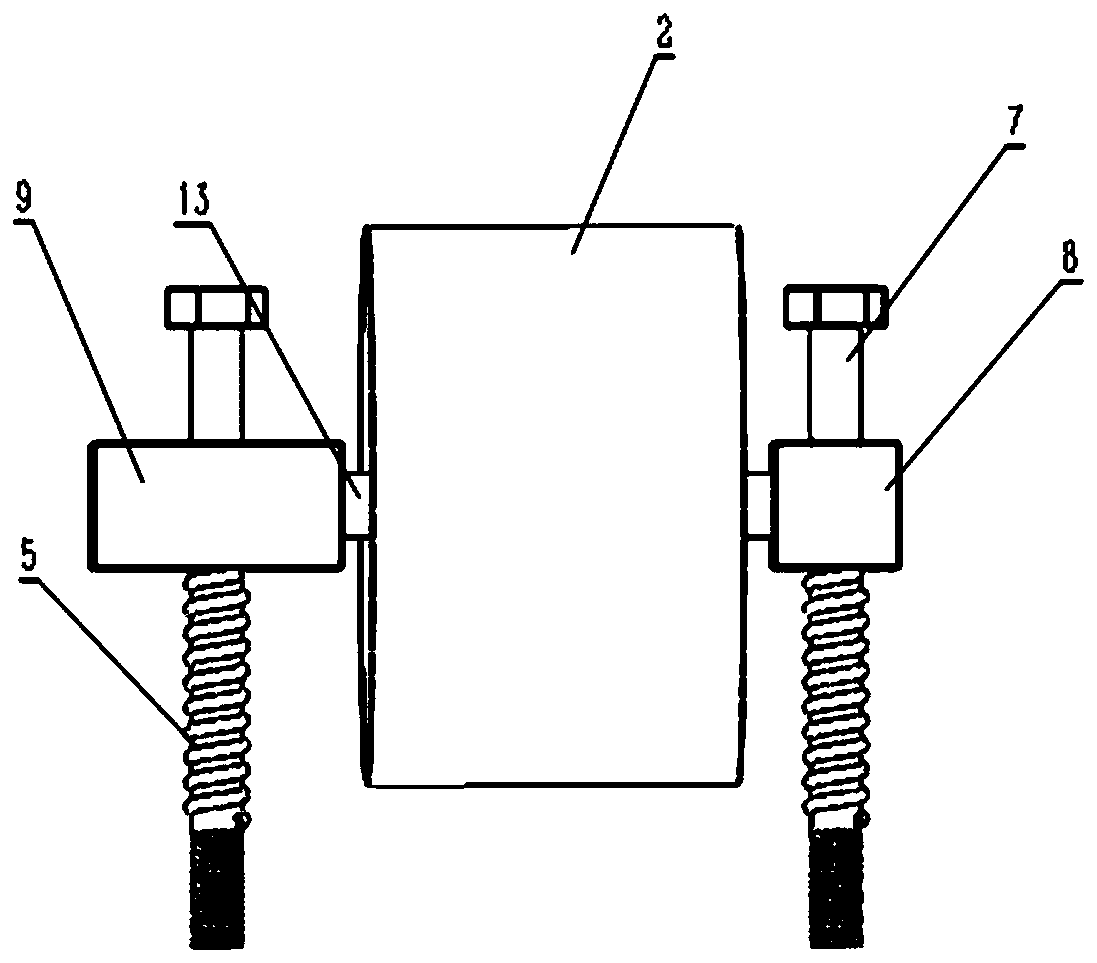

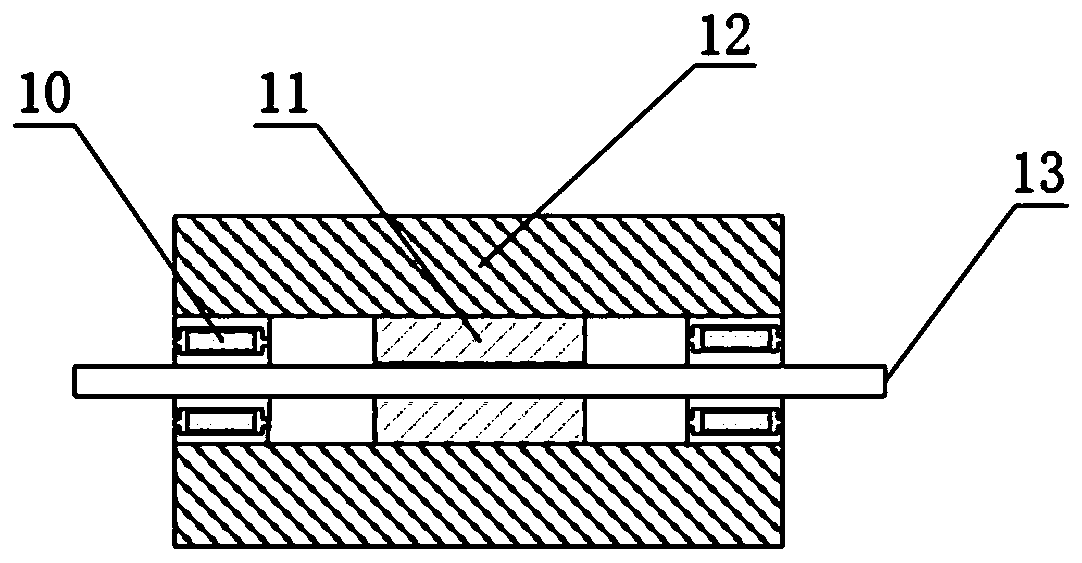

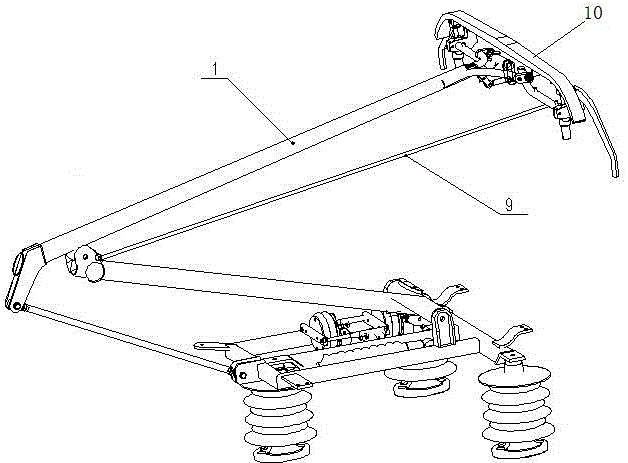

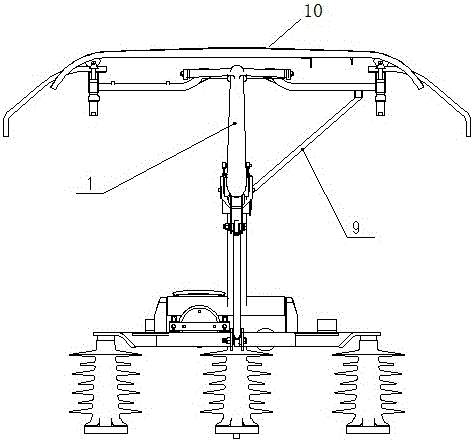

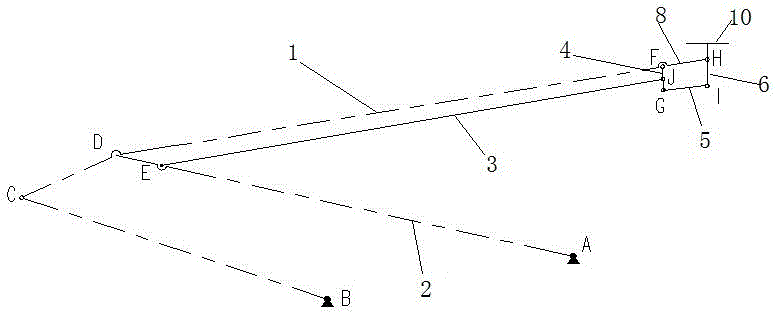

Pantograph

The invention discloses a pantograph which comprises an underframe, a lower arm rod, an upper arm rod, a pull rod, a lifting pantograph driving device and a pantograph head. The pantograph head comprises a pantograph corner, a pantograph head rotating shaft, an elastic buffer device and a sliding plate. A connecting part extends and is arranged at the upper end of the upper arm rod and hinged to the pantograph head rotating shaft, and the length between the joint of the pantograph head rotating shaft and the connecting part is smaller than the length between the joint of the pantograph head rotating shaft and the elastic buffer device and the sliding plate is smaller than the length between the joint of the pantograph head rotating shaft and the elastic buffer device and the sliding plate. The pantograph further comprises a balance rod system, the balance rod system comprises a first rod hinged to the upper end of the lower arm rod, a second rod hinged to the upper end of the upper arm rod, a fourth rod hinged to the pantograph head rotating shaft and a third rod, wherein one end of the third rod is hinged to the free end of the second rod, and the other end of the third rod is hinged to the free end of the fourth rod. The other end of the first rod is hinged to the middle of the second rod. The pantograph can reduce stress of the balance rod system and air lift force of the sliding plate, improve fatigue life of a structure member and have the advantages of being high in current collection stability and small in wind resistance.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

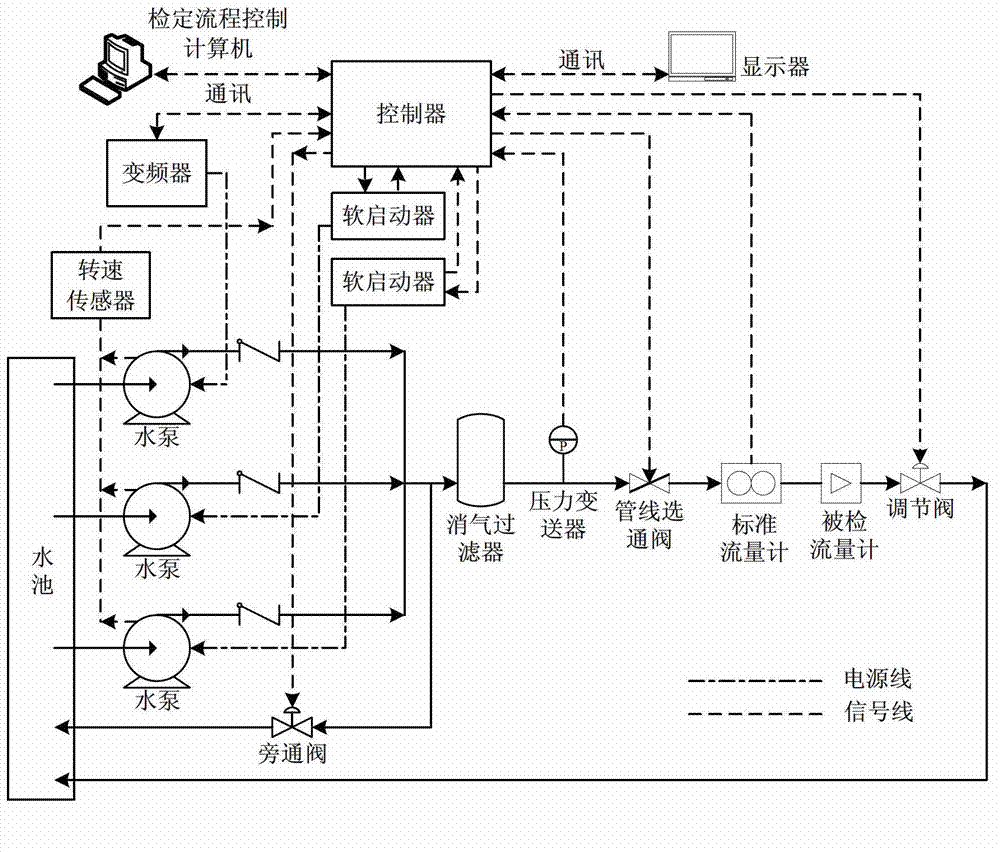

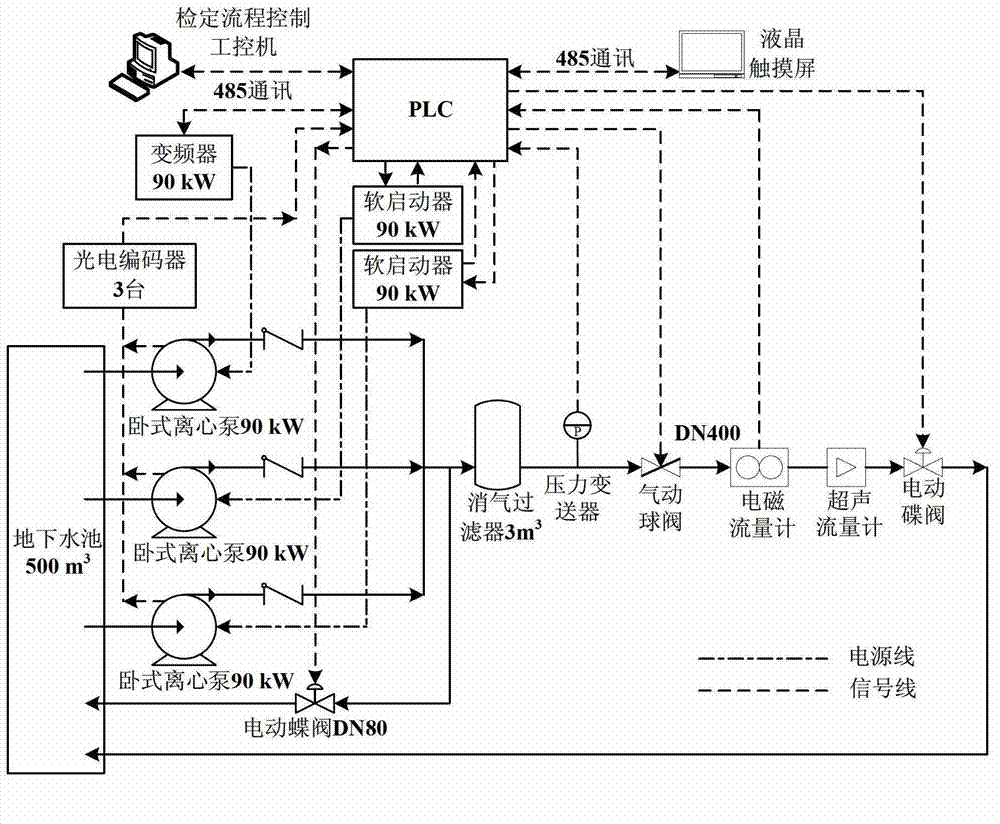

Water supplying system for flow device

InactiveCN103088872AImprove flow stabilityIncrease independenceService pipe systemsWater mainsLine tubingEngineering

The invention belongs to the field of flow detection and relates to a water supplying system for a flow device. The water supplying system comprises a water pump assembly, a water pump rotating speed measurement device, a pressure transmitter, a standard flow meter, a regulating valve, a bypass valve, a soft starter, a frequency converter and a controller. Detecting signals of the water pump rotating speed measurement device, the pressure transmitter and the standard flow meter are sent to the controller. The water pump assembly comprises at least two water pumps, one pump is controlled by the controller through the frequency converter, other water pumps are controlled by the controller through the soft starter, the water pumps are in parallel connection, the bypass valve is arranged on a bypass pipeline in parallel connection with the water pumps, and water supplied by the water pumps and the bypass valve flows into a detecting pipeline. The pressure transmitter, the regulating valve and the standard flow meter are arranged on the detecting pipeline. The water supplying system for the flow device has the advantages of being low in cost, small in occupied space and capable of meeting the precision requirement of a flow standard device.

Owner:TIANJIN UNIV

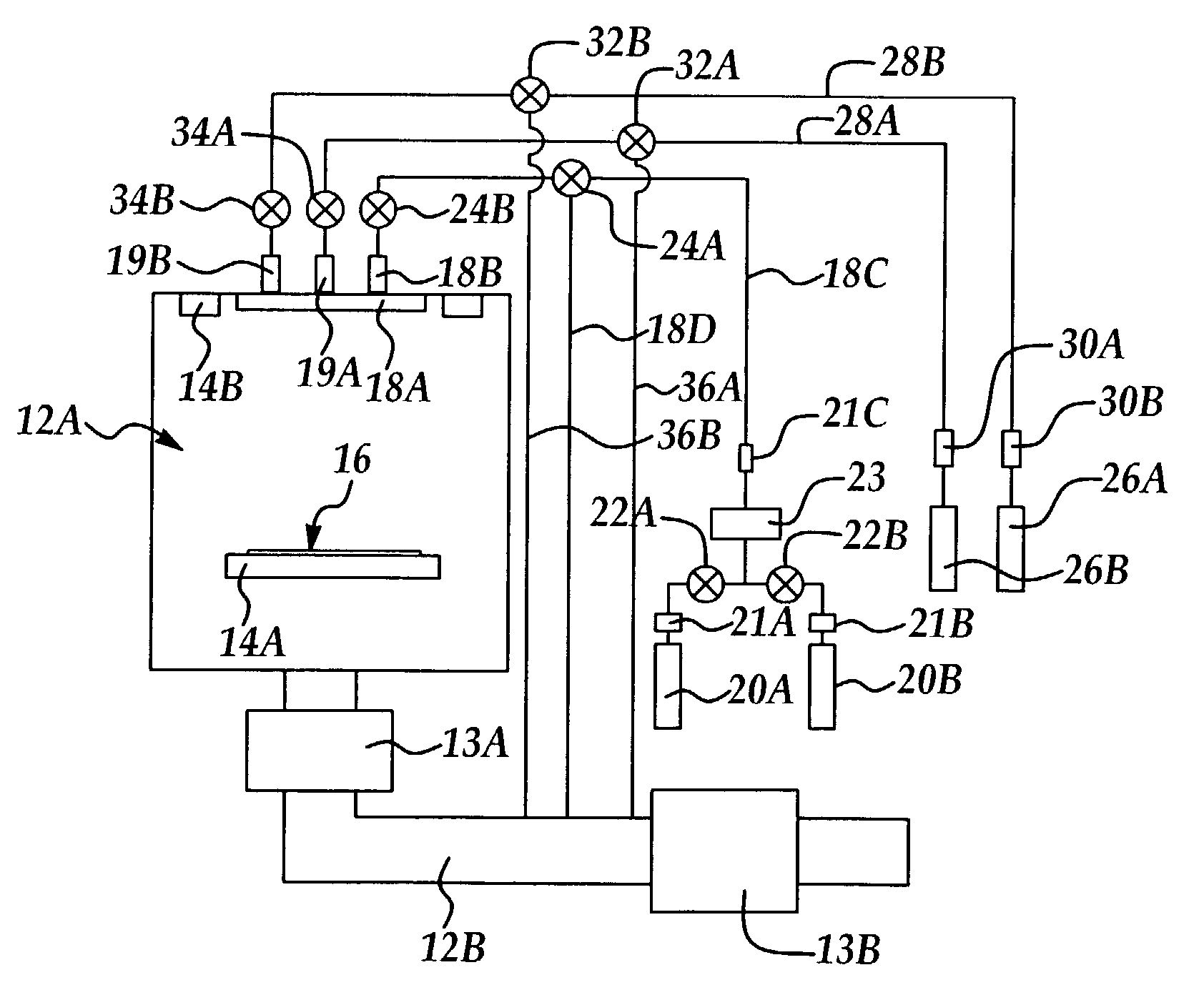

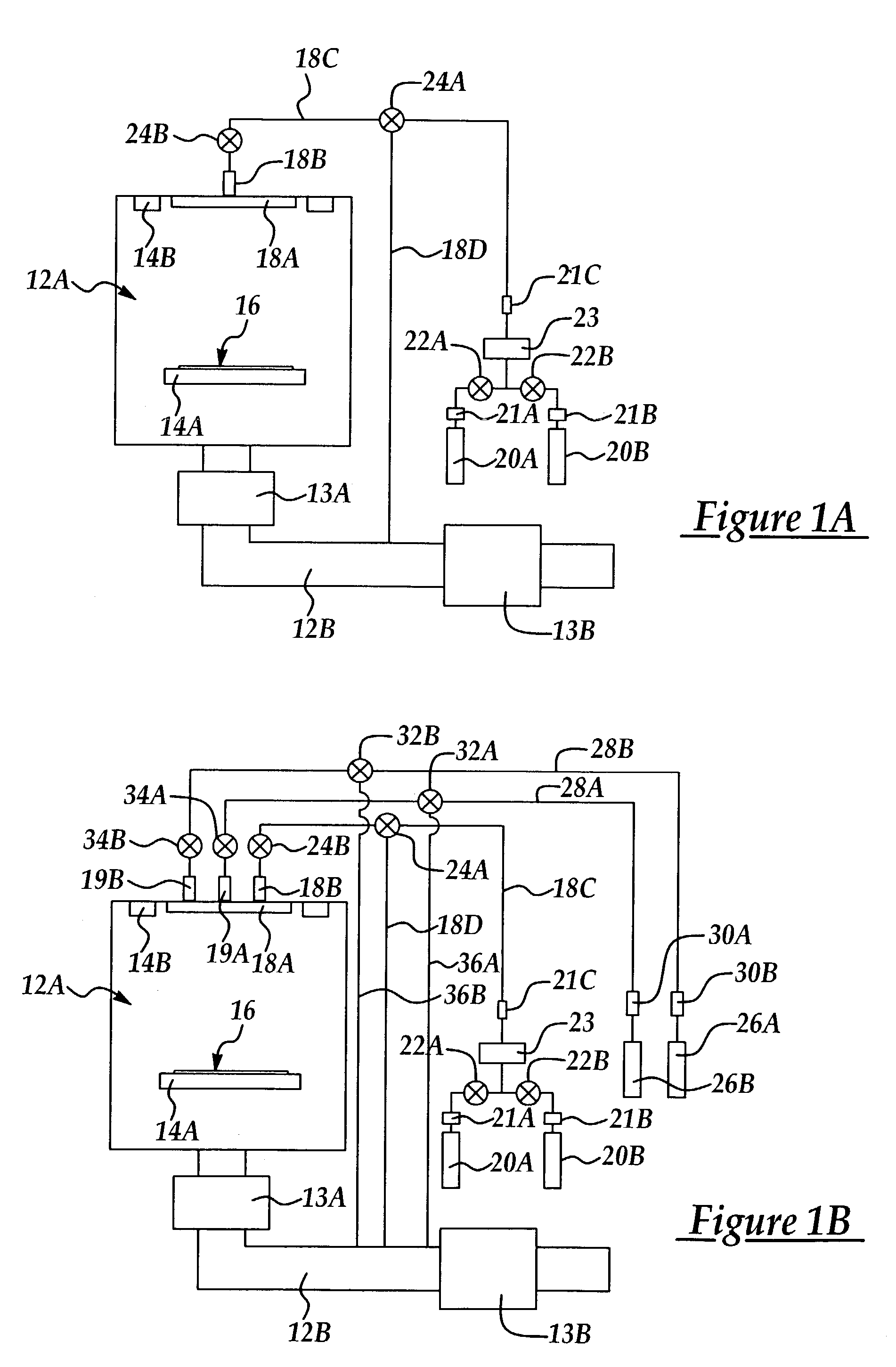

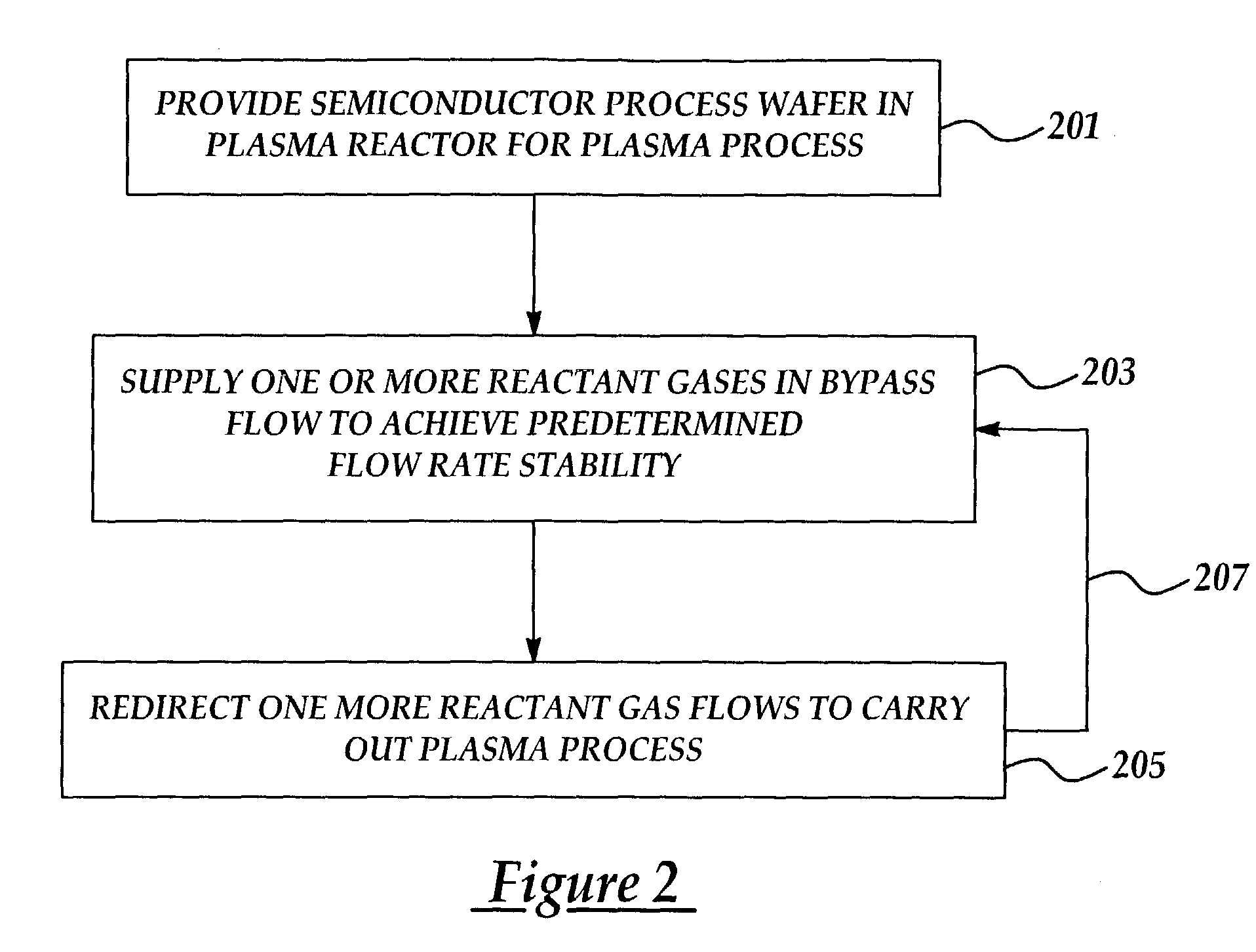

Bypass gas feed system and method to improve reactant gas flow and film deposition

InactiveUS7296532B2Improved gas flow stabilityEnhanced vapor depositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasSemiconductor

A method and reactant gas bypass system for carrying out a plasma enhanced chemical vapor deposition (PECVD) process with improved gas flow stability to avoid unionized reactant precursors and thickness non-uniformities the method including providing a semiconductor process wafer having a process surface within a plasma reactor chamber for carrying out at least one plasma process; supplying at least one reactant gas flow at a selected flow rate to bypass the plasma reactor chamber for a period of time to achieve a pre-determined flow rate stability; and, redirecting the at least one reactant gas flow into the plasma reactor chamber to carry out the at least one plasma process.

Owner:TAIWAN SEMICON MFG CO LTD

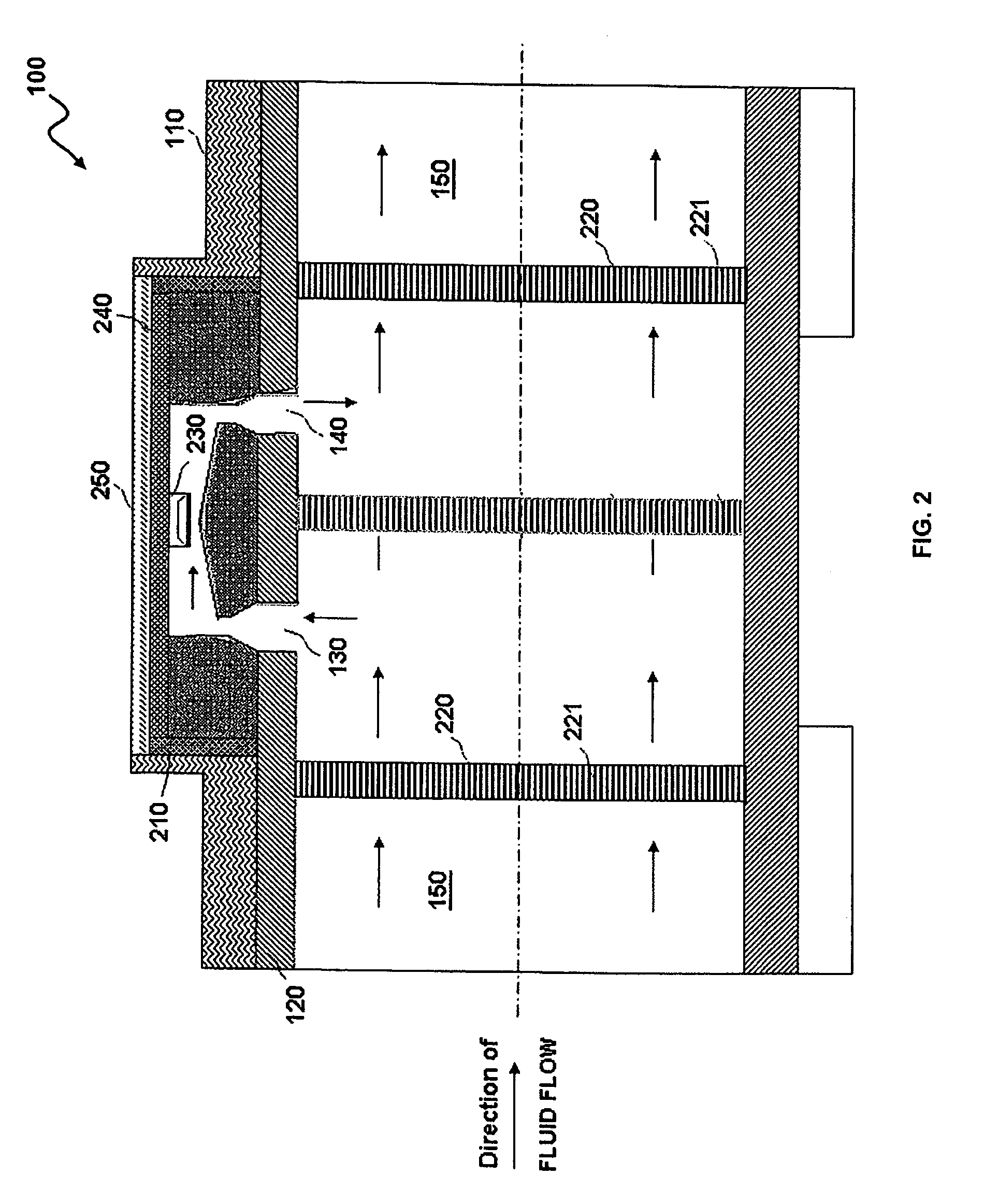

Flow sensing device including a tapered flow channel

ActiveUS8104340B2Reduce and prevent flowImprove Sensing PerformanceVolume/mass flow by thermal effectsVolume flow proportion measurementMain channelEngineering

A fluid flow sensing device can include a tapered fluid flow channel formed into a main channel defining a fluid flow tube as an alternate fluid flow path. A tapered fluid flow channel can bypass some fluid flow from the main fluid flow channel into the alternate fluid flow path and a flow sensor disposed within the alternate fluid flow path. The tapered flow channel is tapered in a direction of fluid flow toward the flow sensor to thereby reduce flow eddies and enable optimal sensing performance by fluid flow sensor. An upstream fluid flow channel and a downstream fluid flow channel can be molded into the main fluid flow channel, especially bypassed in the fluid flow path of the main fluid flow channel. A fluid flow sensor can be placed between the upstream fluid flow channel and the downstream fluid flow channel for measuring fluid flow rate the channel.

Owner:HONEYWELL INT INC

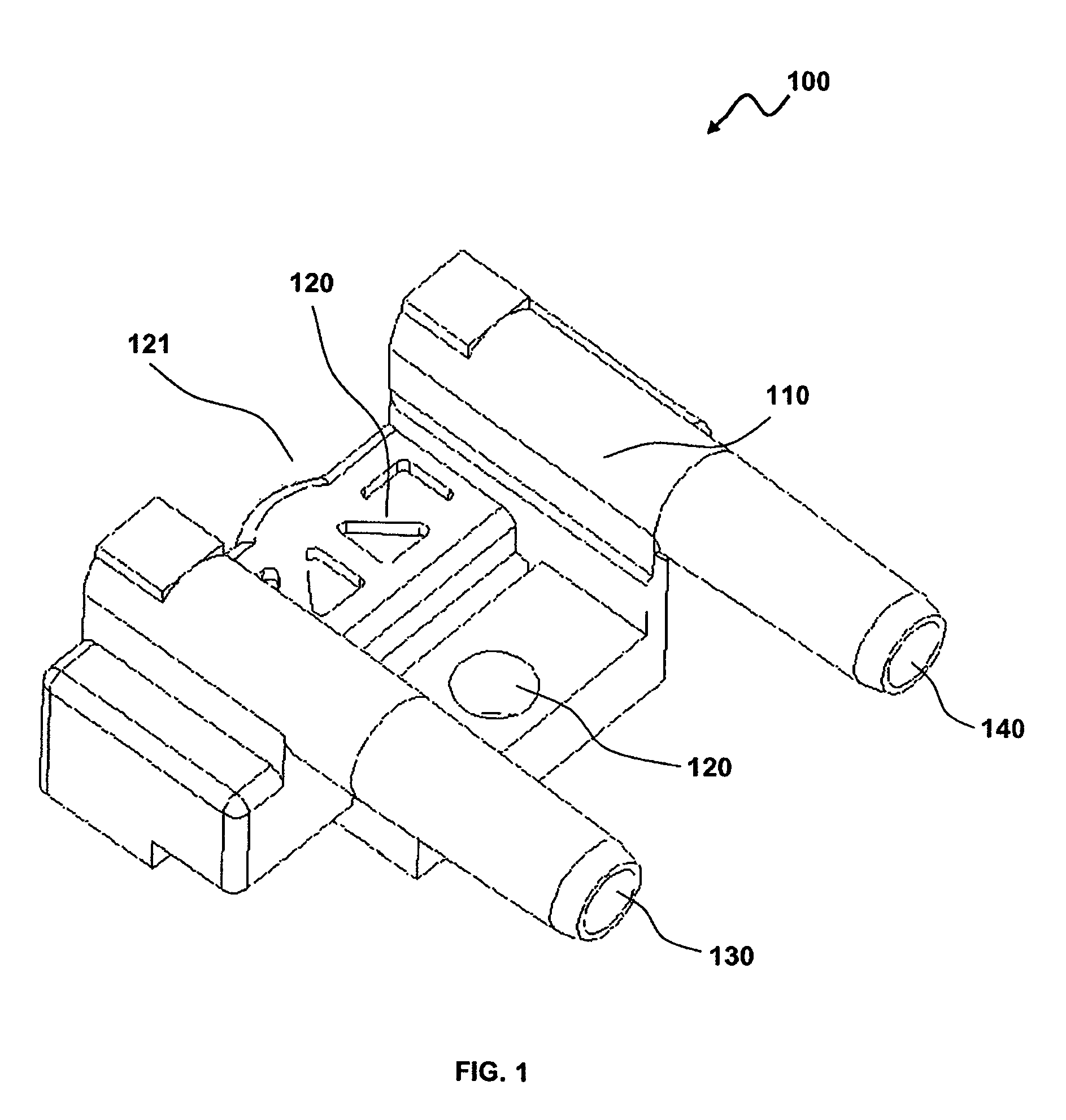

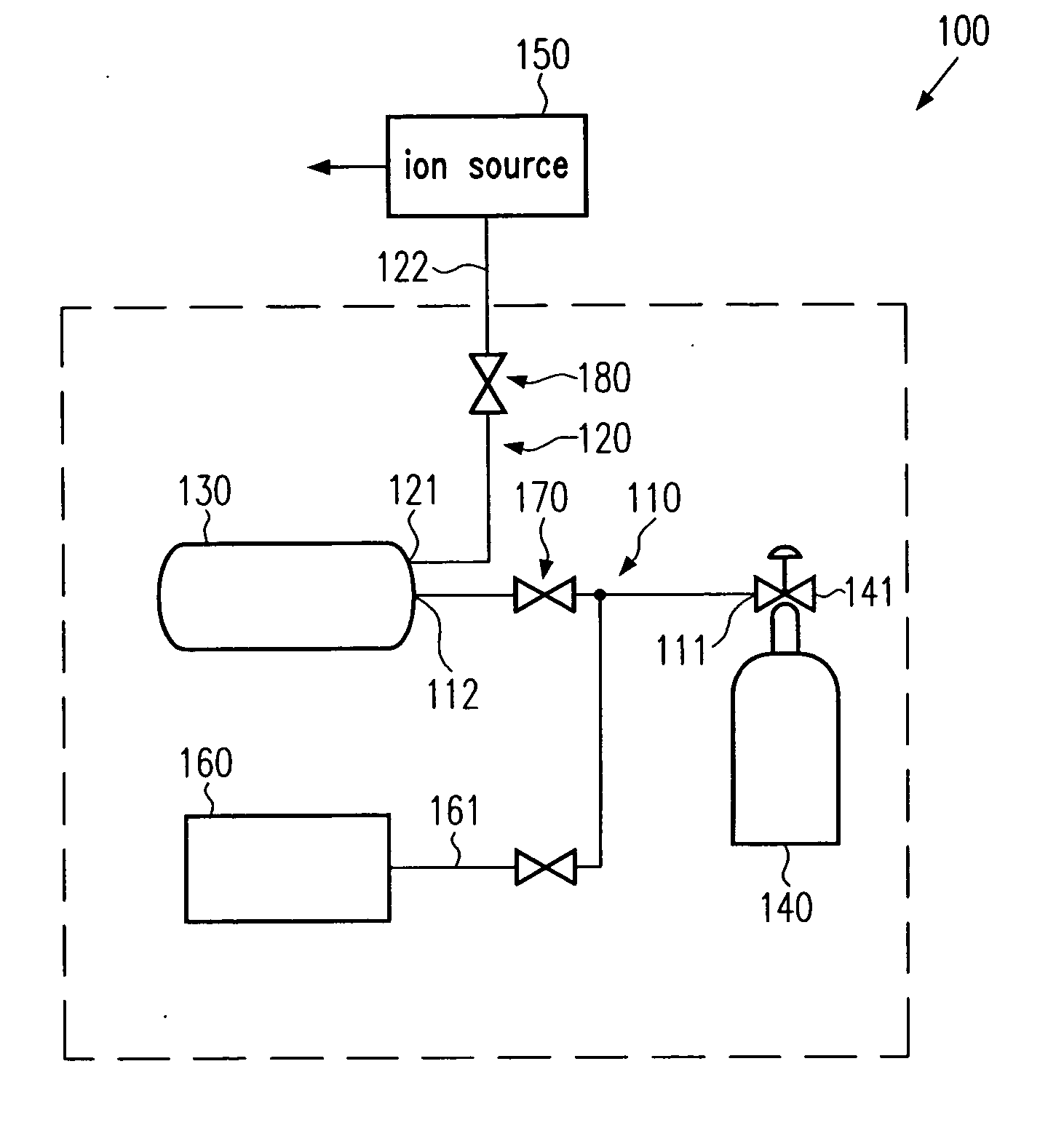

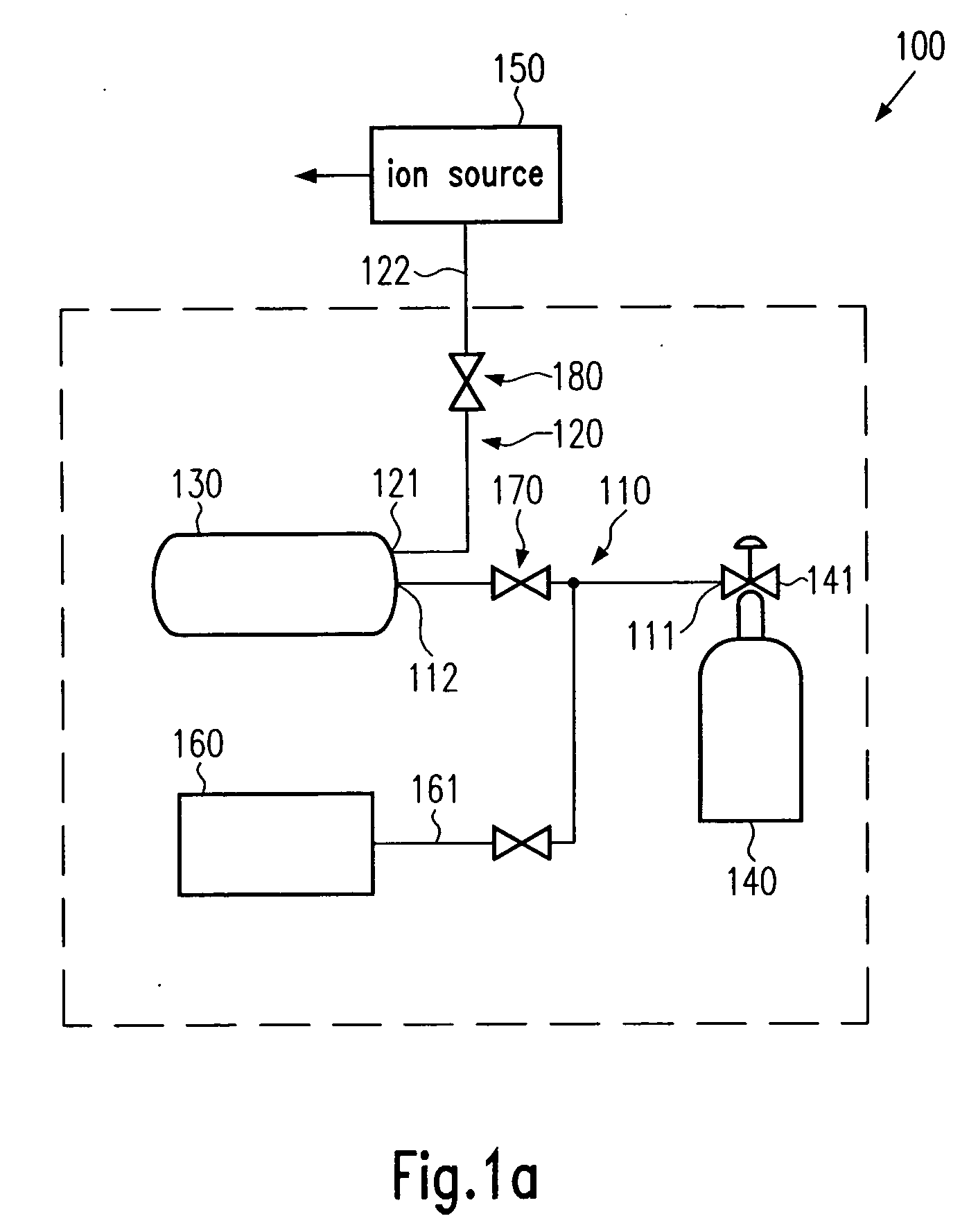

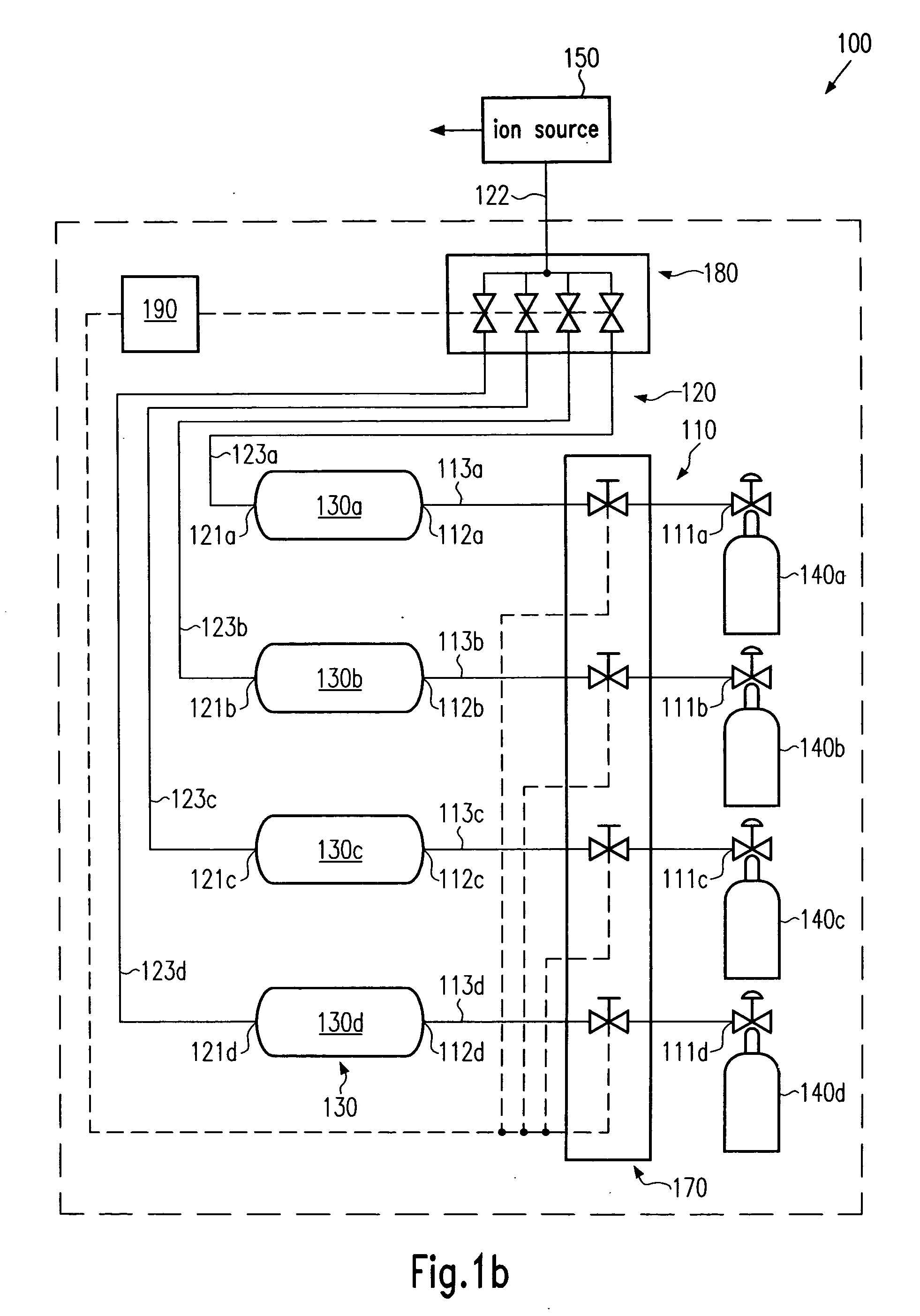

System and method for supplying precursor gases to an implantation tool

InactiveUS20060093754A1Reduce the amount of solutionIncreased environmental riskElectric discharge tubesVacuum evaporation coatingGas cylinderEngineering

An improved supply system for an ion source of an ion implantation tool and a method of operating the same is provided. By using a buffer volume between an SDS gas bottle and the ion source, stability of the gas flow to the ion source is significantly enhanced, while at the same time nearly all of the gas contents in the gas bottle may be available during operation of the ion implantation tool.

Owner:GLOBALFOUNDRIES INC

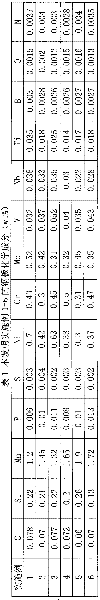

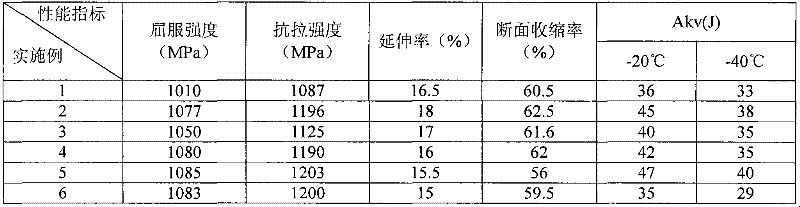

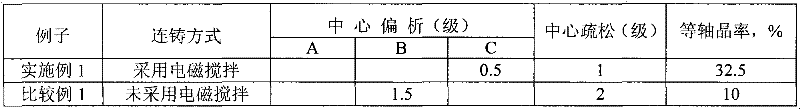

High-strength steel plate with yield strength 1,000 MPa and production method thereof

InactiveCN102409261AIncreased cooling capacitySimple structureTemperature control deviceFurnace typesSteel platesElectromagnetic stirring

The invention discloses a high-strength steel plate with the yield strength 1,000 MPa and a production method thereof. The steel plate comprises the following chemical components in percentage by weight: 0.05-0.08 percent of C, 0.1-0.3 percent of Si, 1-2 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.007 percent of S, 0.3-0.7 percent of Ni, 0.3-0.5 percent of Cr, 0.3-0.6 percent of Mo, 0.02-0.04 percent of Nb, 0.03-0.055 percent of V, 0.01-0.035 percent of Ti, 0.002-0.0035 percent of B and the balance of Fe and inevitable impurities, wherein the gas content [O] is controlled to be less than or equal to 0.002 percent and [N] is controlled to be less than or equal to 0.004 percent, Ti / N is more than or equal to 3.2, and the carbon equivalent index Ceq is less than or equal to 0.56 percent. The production method comprises the following steps of: performing continuous casting with an electromagnetic stirring technology, wherein the thickness of a continuously cast bloom after casting is not less than four times that of a finished steel plate; and heating a steel blank at the temperature 1,100-1,200 DEG C, rolling in a recrystallization region and a non-recrystallization region at two stages, performing relaxation temperature waiting for 5-20 seconds, quickly cooling to 300-450 DEG C at the speed 10-30 DEG C per second, draining water, stacking, slowly cooling, tempering the steel plate at the tempering temperature 400-600 DEG C, and preserving heat for 2-3 minutes per millimeter. The steel plate has high comprehensive performance, large specification coverage and greatly-lowered production cost and raw material cost in comparison to the conventional product of the same level, and can be widely applied to the fields of mines, engineering machinery and the like.

Owner:ANGANG STEEL CO LTD

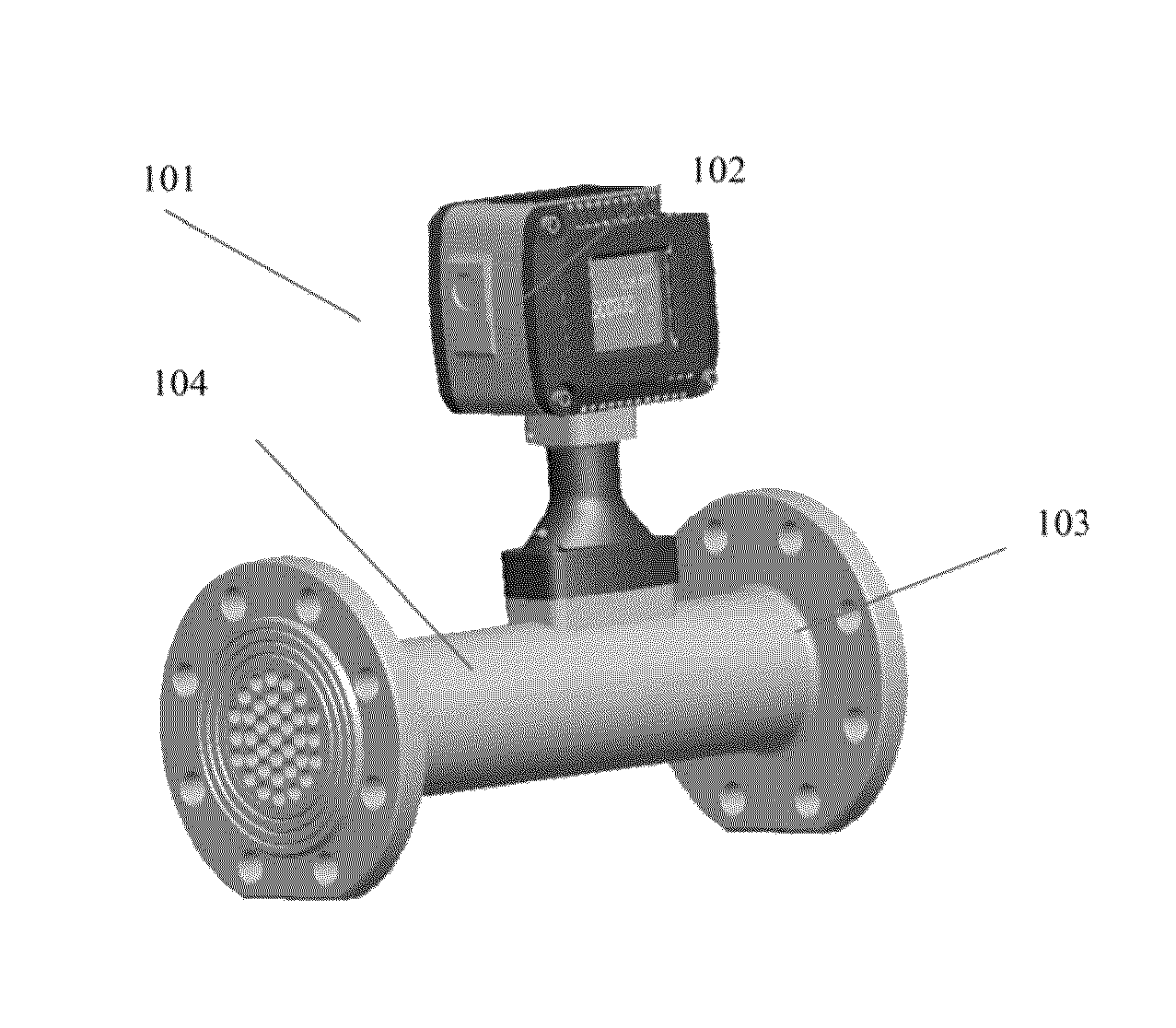

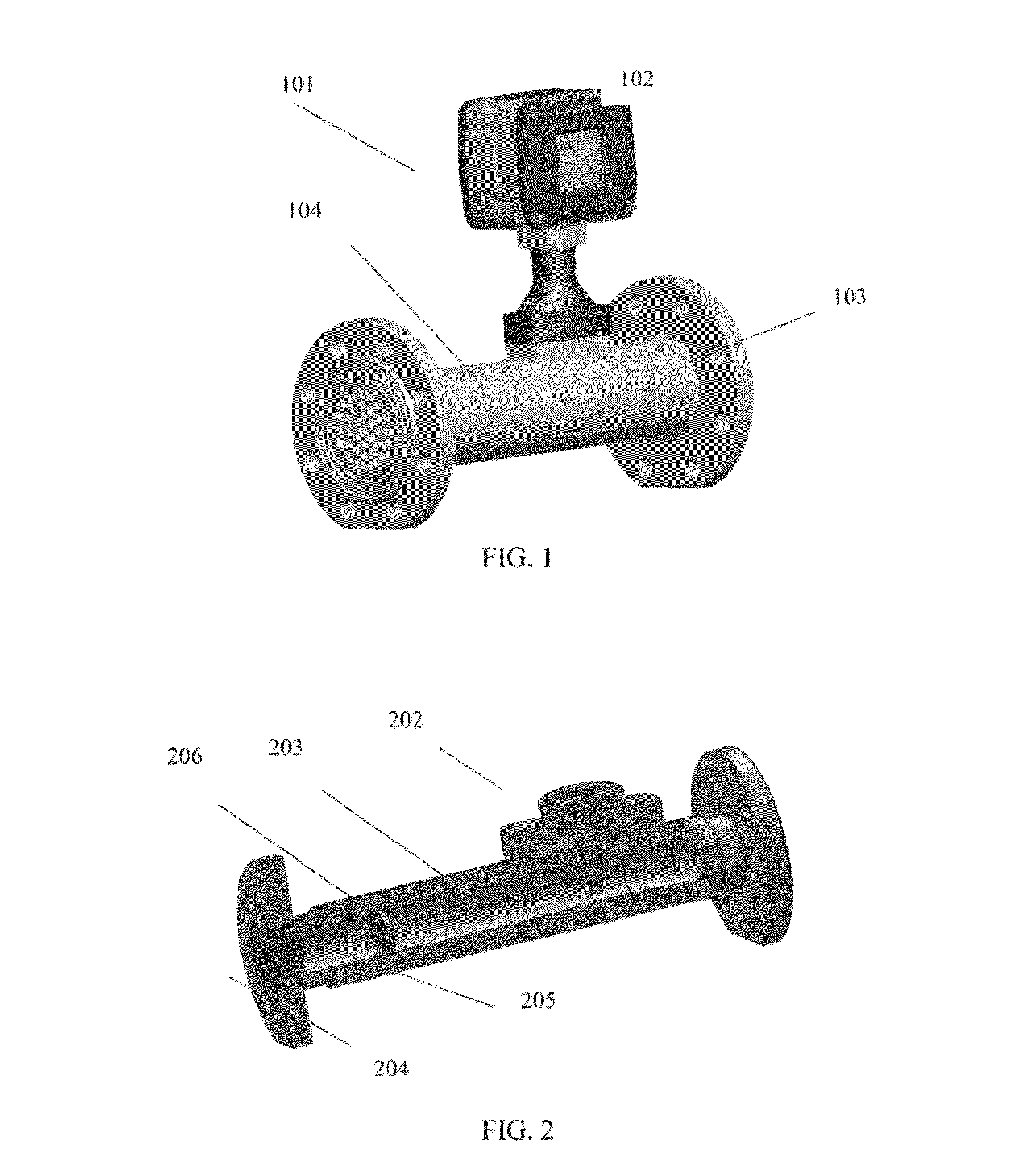

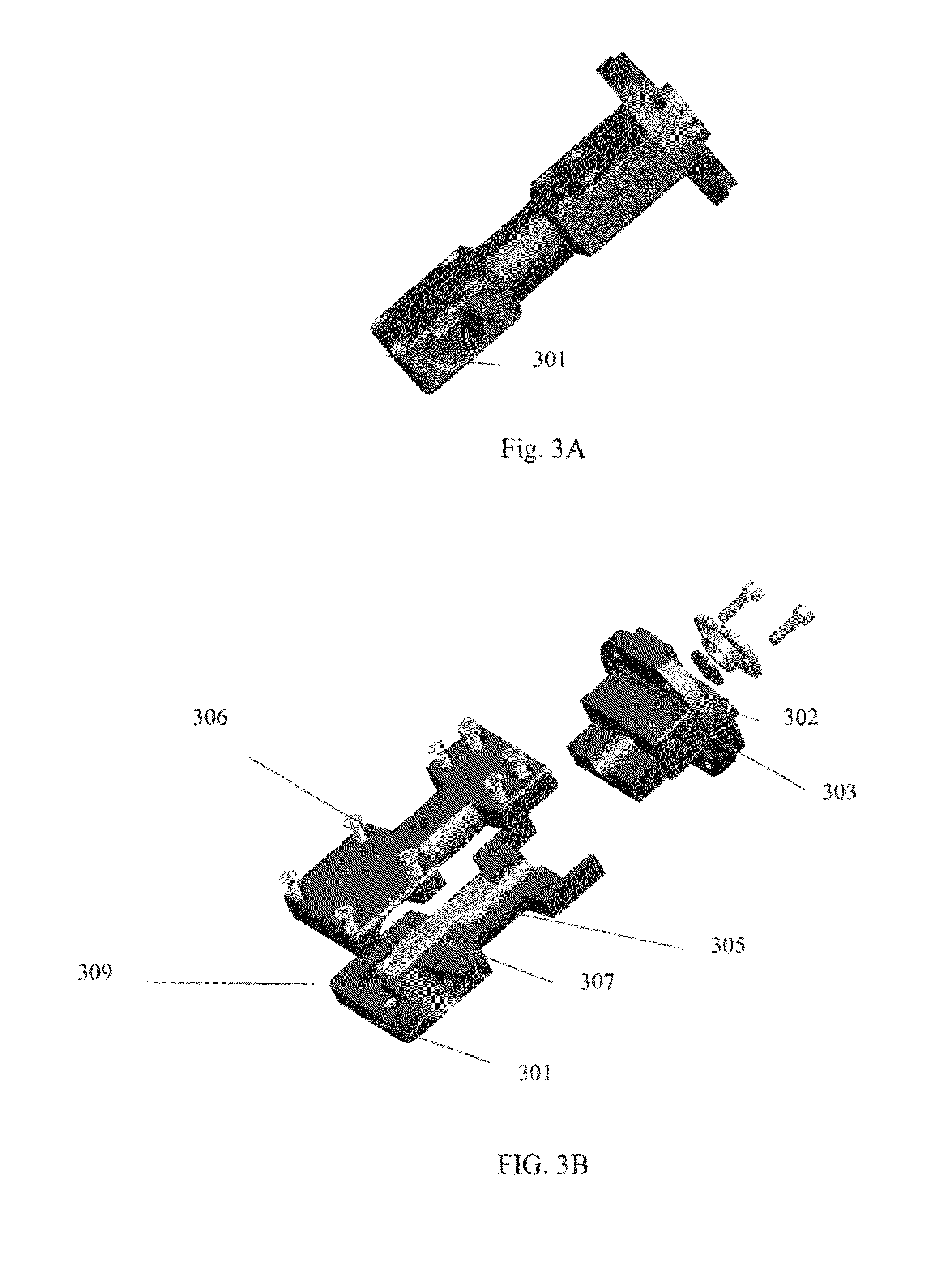

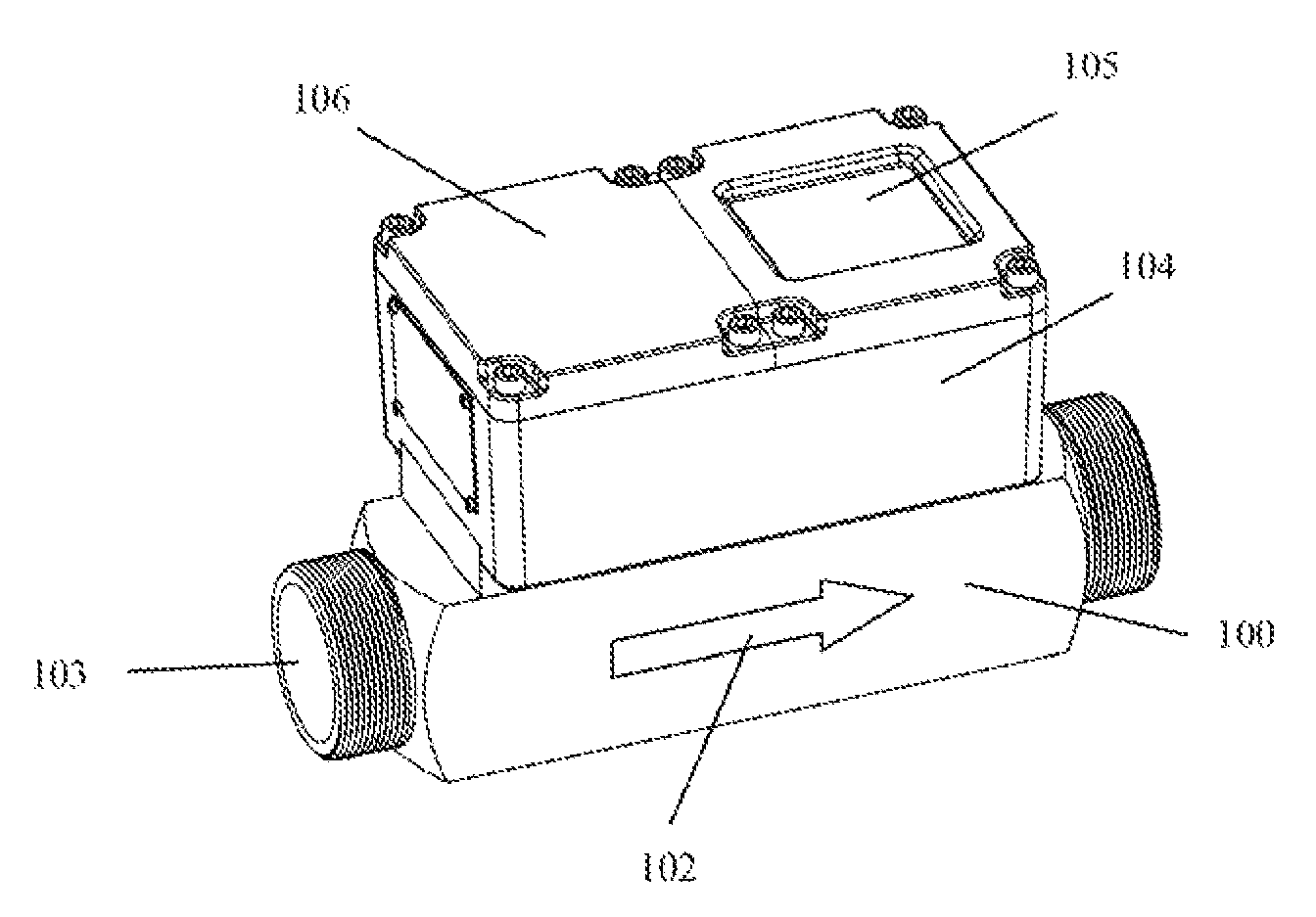

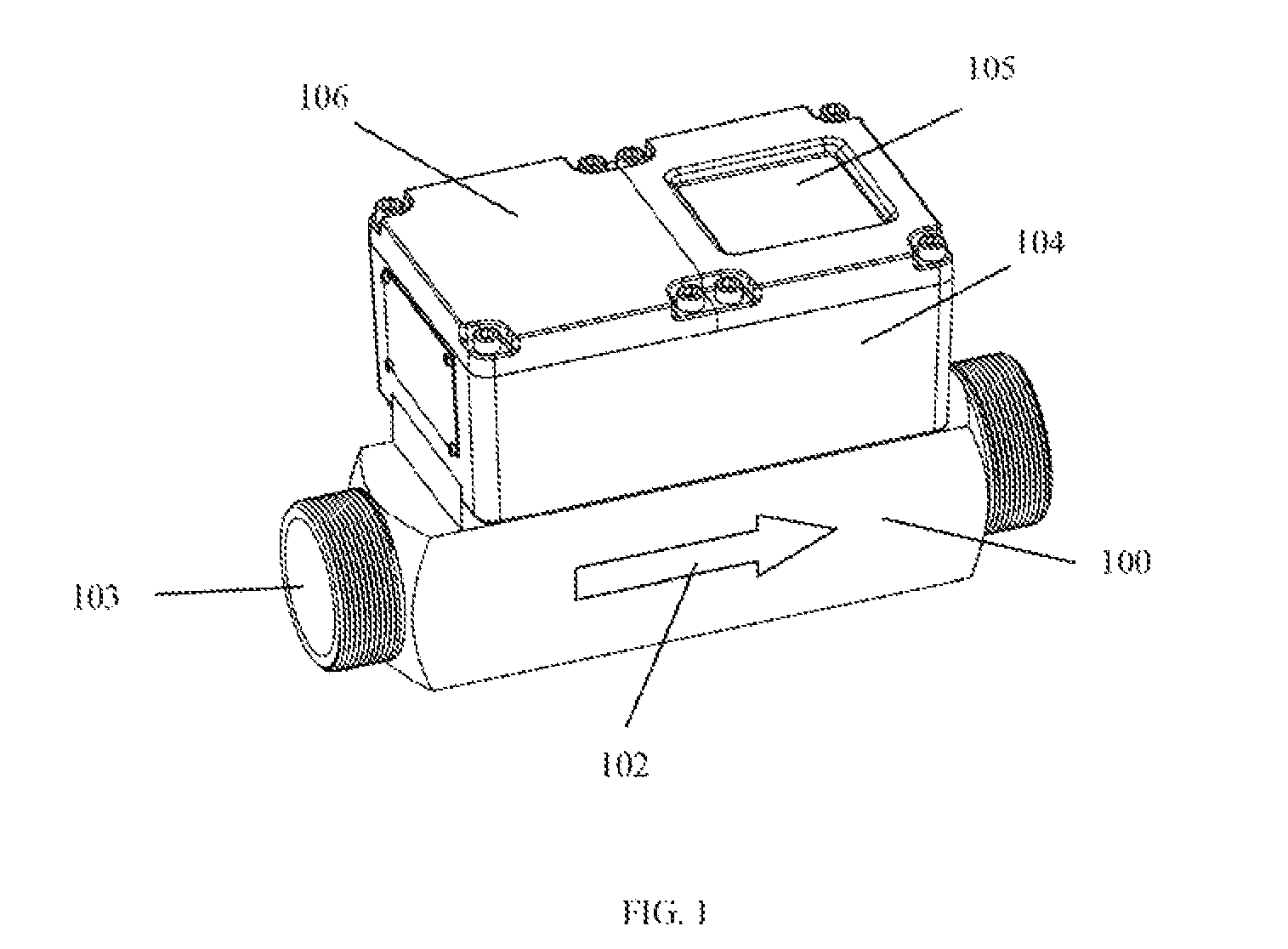

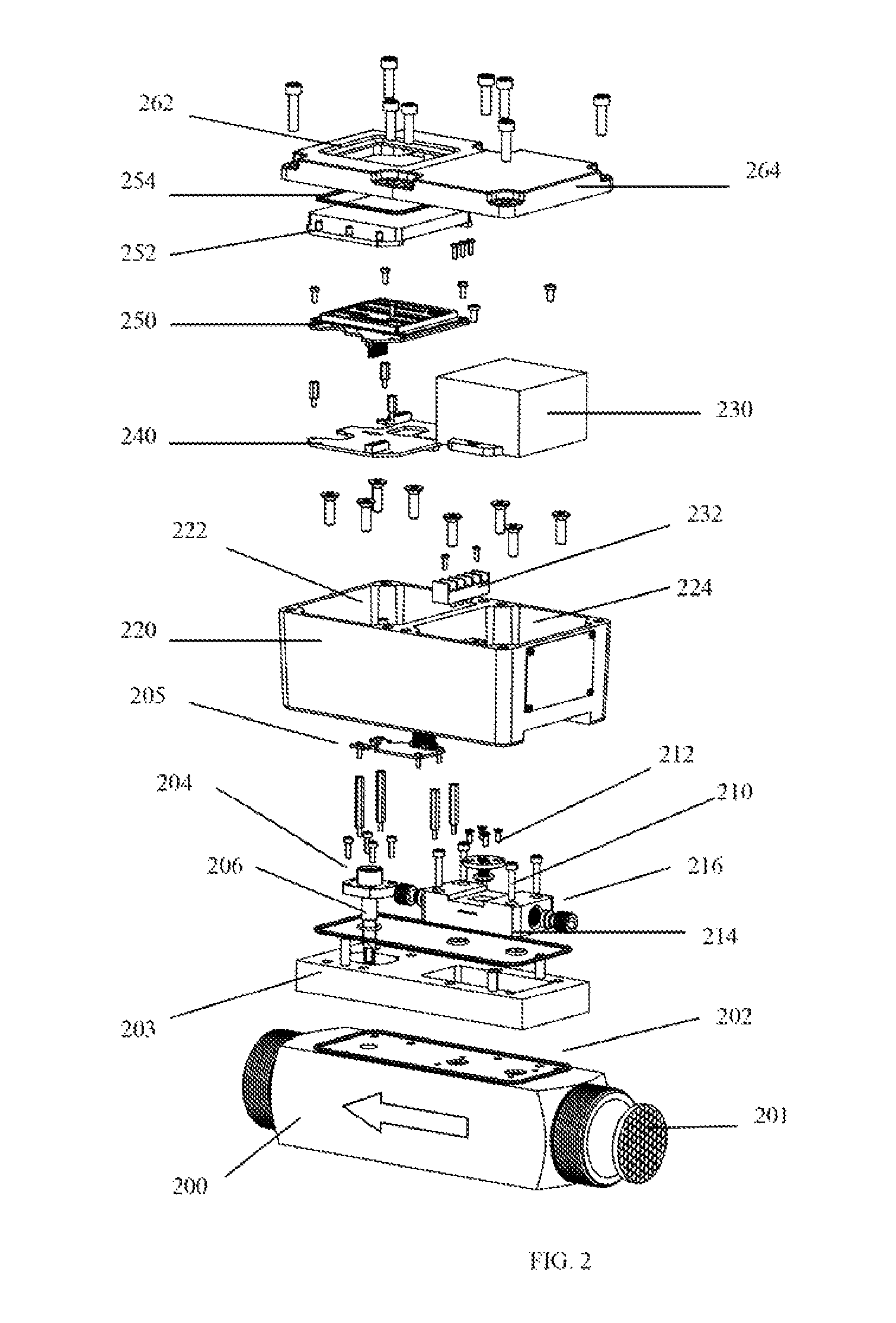

Utility mass flow gas meter

ActiveUS20170241822A1Improve flow stabilitySpeed up the flowTariff metering apparatusVolume meteringChemical safetyMetrology

An electronic utility gas meter using MEMS thermal mass flow sensor to measure gas custody transfer data in city gas metering application is disclosed in the present invention. The meter is designed to have its mechanical connectors identical to those of the current diaphragm gas meters while the insertion metrology unit guided channel is placed coaxially in the main flow channel inside the meter body with gas flow conditioning apparatus. The mechanical installation of the electronic utility gas meter then can be fully compatible with the current mechanical utility gas meters, which allows a seamless replacement. The electronic utility gas meter provides gas metrology that significantly improves the accuracy of the city gas metering, and provides additional benefits for data safety, enhanced gas chemical safety, billing alternatives and full data management either locally or remotely.

Owner:M TECH INSTR HLDG

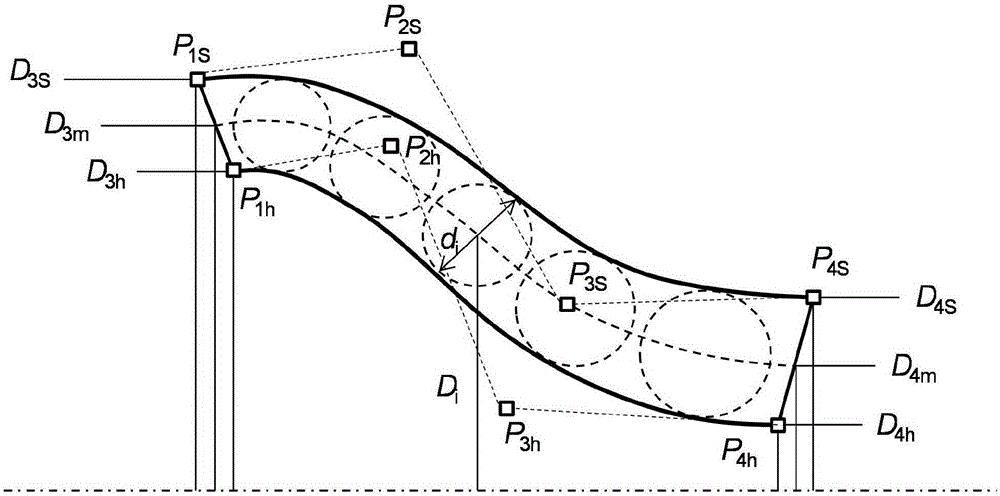

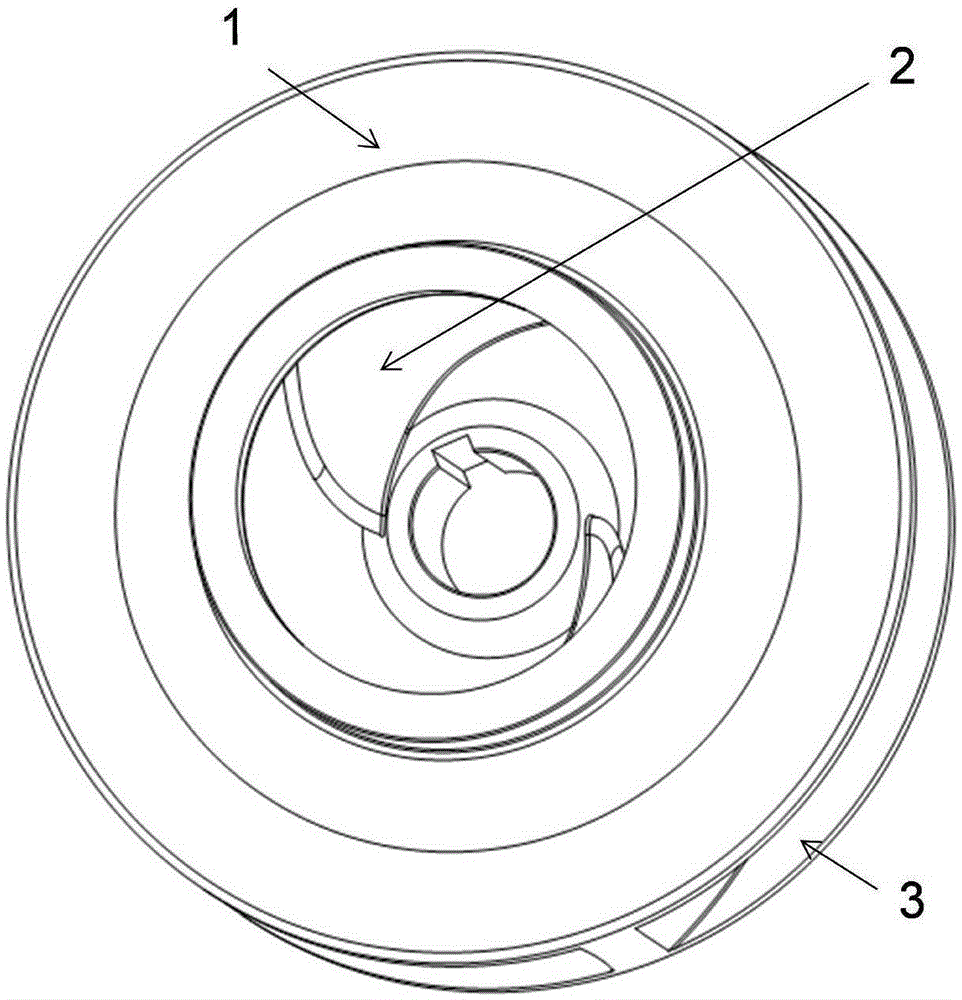

Hydraulic design method for double-blade non-block centrifugal impeller

InactiveCN105240310AImprove hydraulic efficiencyImprove flow stabilityPump componentsPumpsImpellerGenetic algorithm

The invention discloses a hydraulic design method for a double-blade non-block centrifugal impeller. The double-blade non-block centrifugal impeller structurally comprises a front cover plate, blades and a rear cover plate. The hydraulic design method comprises the steps that (1) the main hydraulic geometrical parameters of the double-blade non-block centrifugal impeller are worked out based on a velocity coefficient method; (2) the shapes of the axial surfaces of the blades are controlled based on a quadratic Bezier curve control algorithm; (3) the molded line installation angles of the blades are controlled based on a quartic Bezier curve control algorithm; (4) optimization design is conducted on the double-blade non-block centrifugal impeller based on a non-dominated sorting genetic algorithm (NSGA) II; and (5) the double-blade non-block centrifugal impeller according with the given flow, the given lift, the given pump efficiency and the given rotating speed value is manufactured by using the data obtained in the step (1) to step (4) as the dimension parameters of the double-blade non-block centrifugal impeller. By the adoption of the double-blade non-block centrifugal impeller designed through the method, the flow capacity and the anti-twining capacity of the impeller can be improved, the internal flowing condition of the impeller is improved, and the operating stability and the hydraulic efficiency of the impeller are improved.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

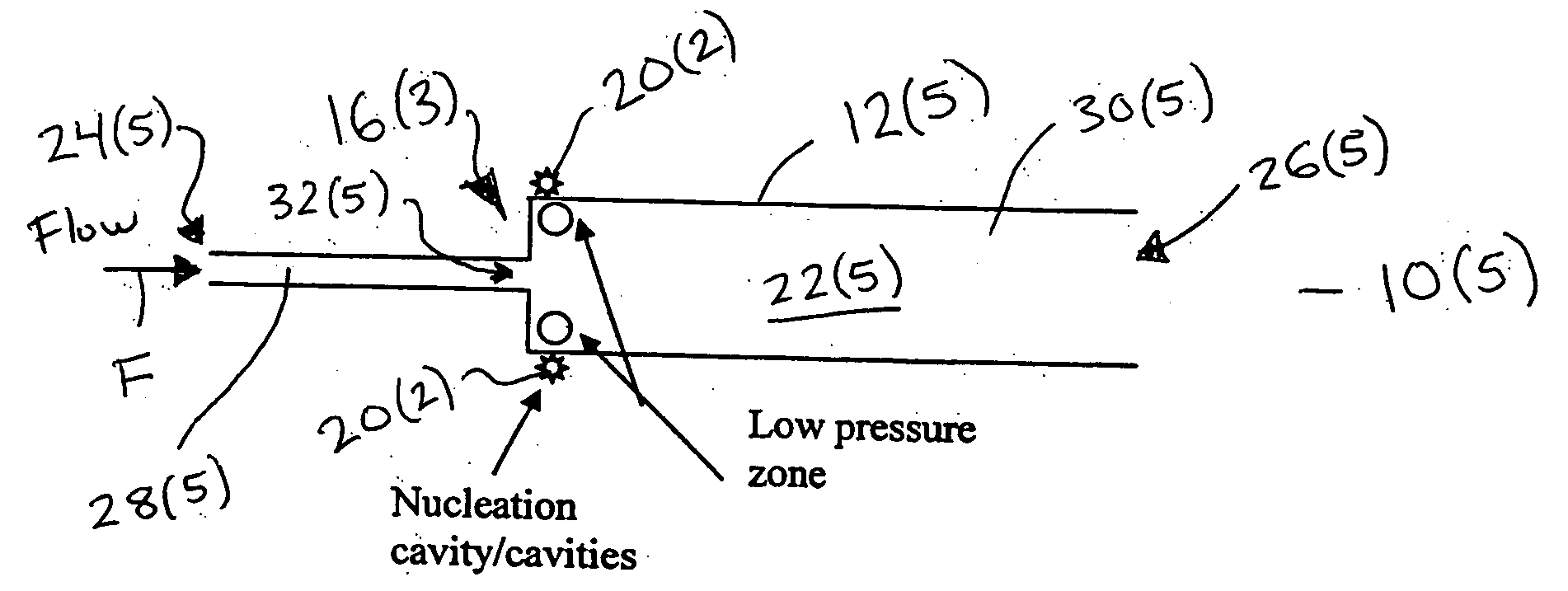

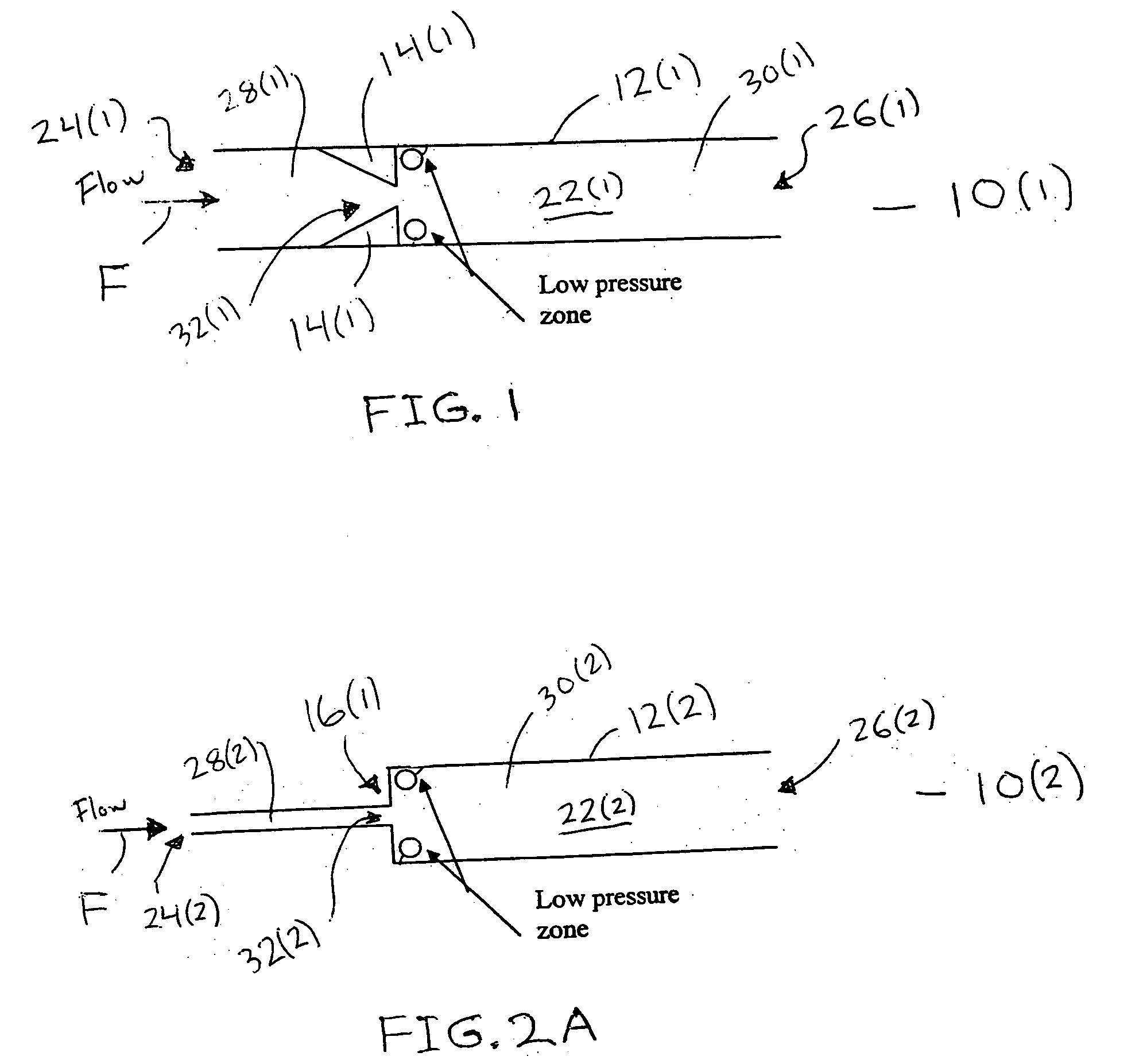

Methods for stabilizing flow in channels and systems thereof

ActiveUS20050061481A1Efficient removalOvercomes severe oscillatory natureCorrosion preventionVibration cleaningEngineering

A method and system for stabilizing flow includes introducing a flow into a channel with a minimum cross-sectional dimension of less than three millimeters and triggering a release of one or more bubbles in the flow at one or more locations in the channel. The one or more locations are spaced in from an inlet and an outlet to the channel.

Owner:ROCHESTER INSTITUTE OF TECHNOLOGY

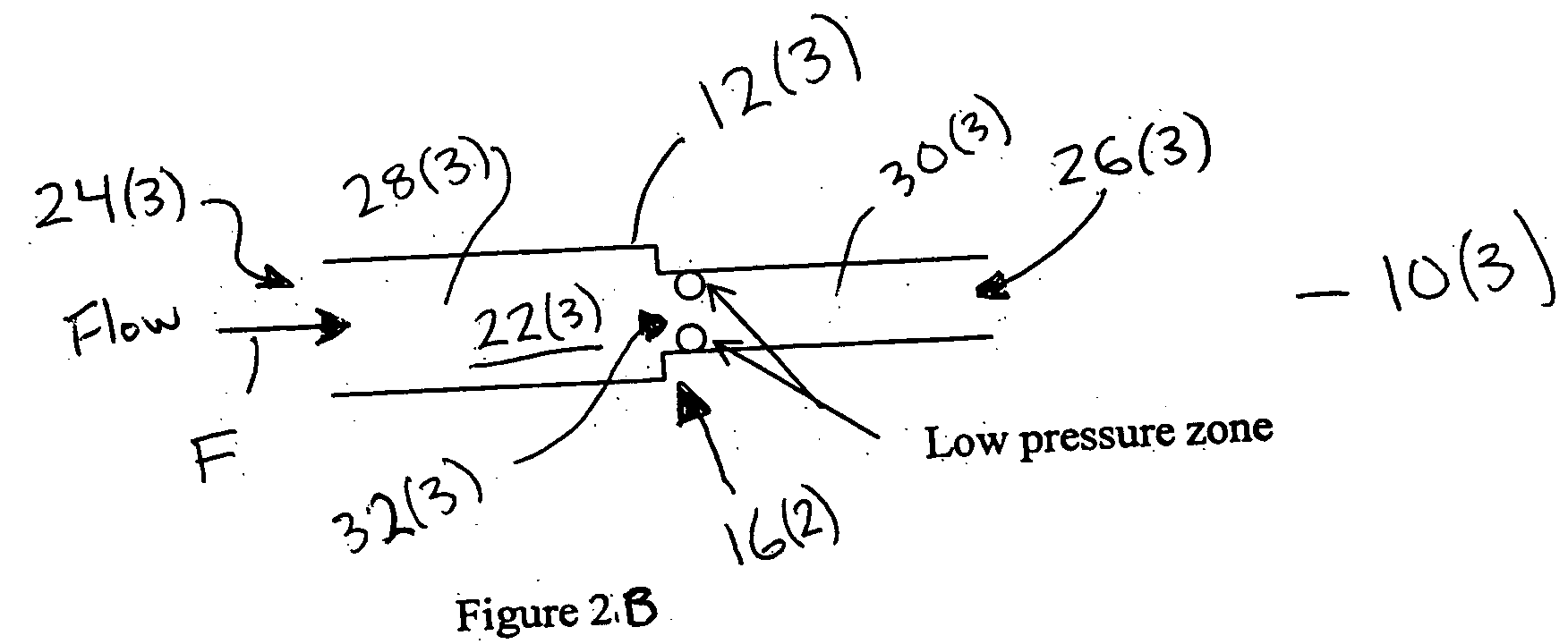

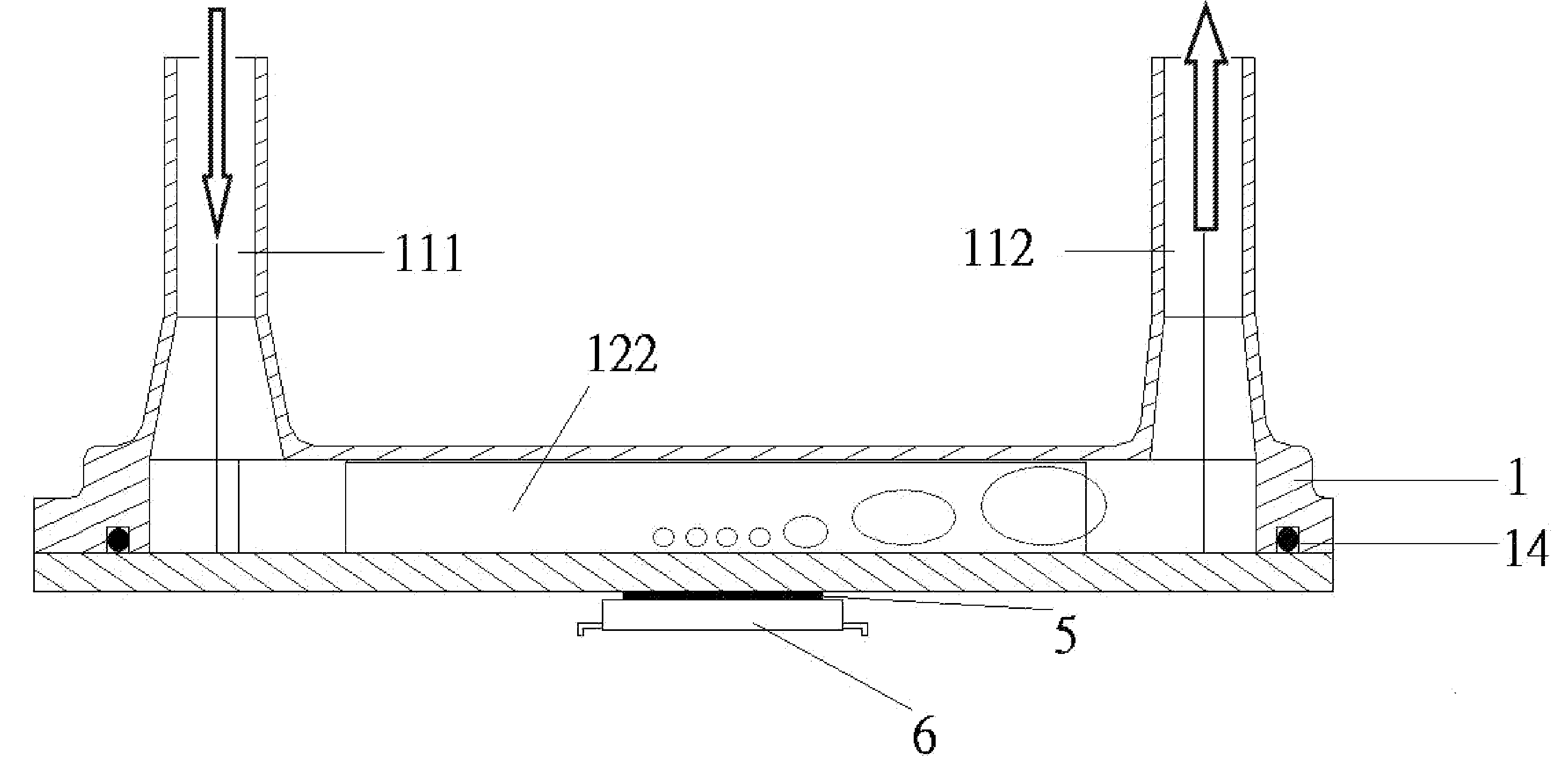

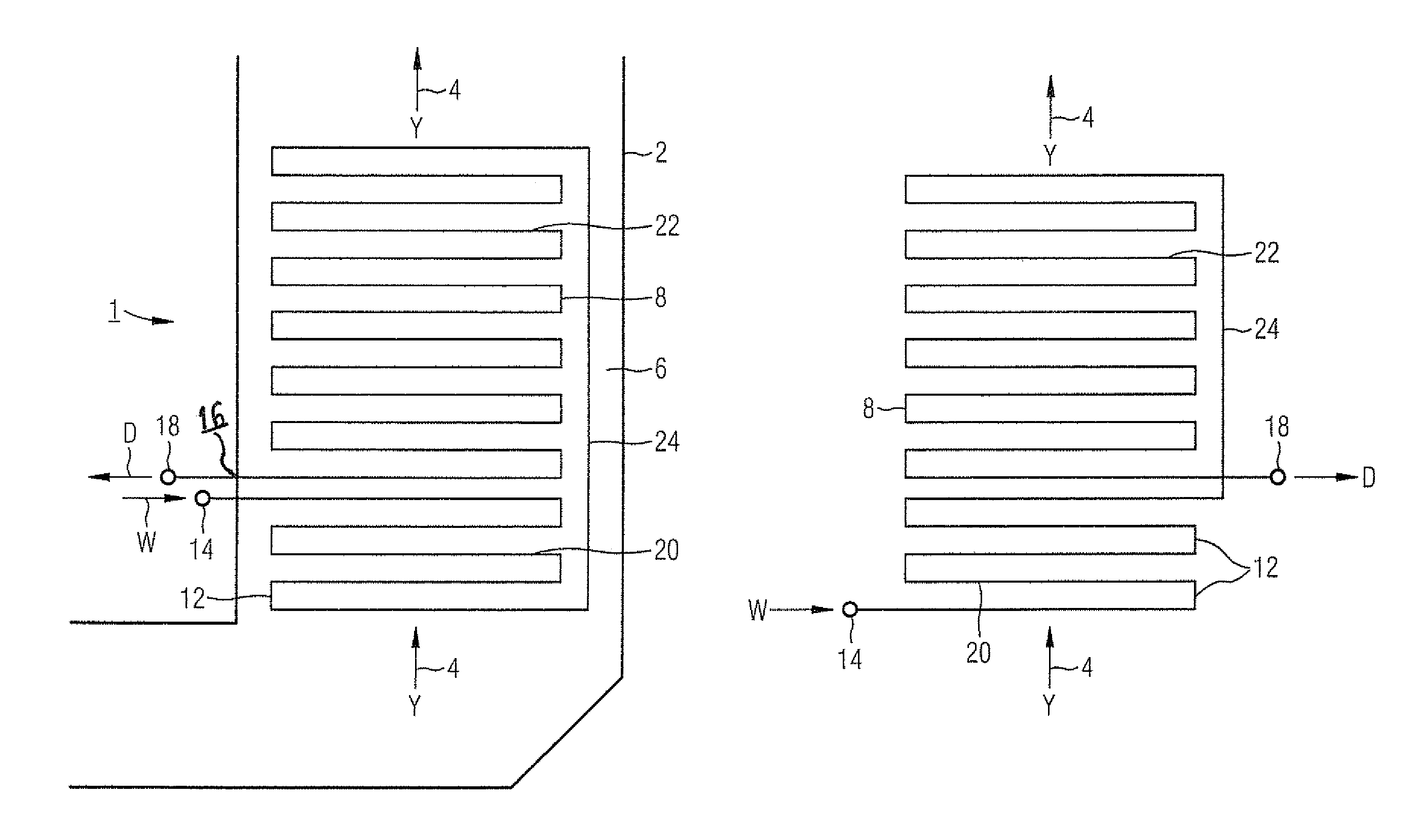

Micro passage cold plate device for a liquid cooling radiator

InactiveUS20100296249A1Reduce thermal resistanceImprove cooling effectDigital data processing detailsSemiconductor/solid-state device detailsEngineeringCold plate

A micro passage cold plate device for a liquid cooling radiator includes a upper cover and a lower plate. The upper cover has a working medium inlet at a side thereof and a working medium outlet at another side thereof. The inlet and outlet are trumpet-shaped such that the working medium expansively enters the cold plate gradually and leaves the cold plate with a reduced way gradually. Hence, the cold plate provides an even distribution of temperature, a lower thermal resistance and a better heat dissipation performance such that the stability of the two-state flow of the working medium is enhanced for heat dissipation device in the field of electronic field.

Owner:BEIJING AVC TECH RES CENT

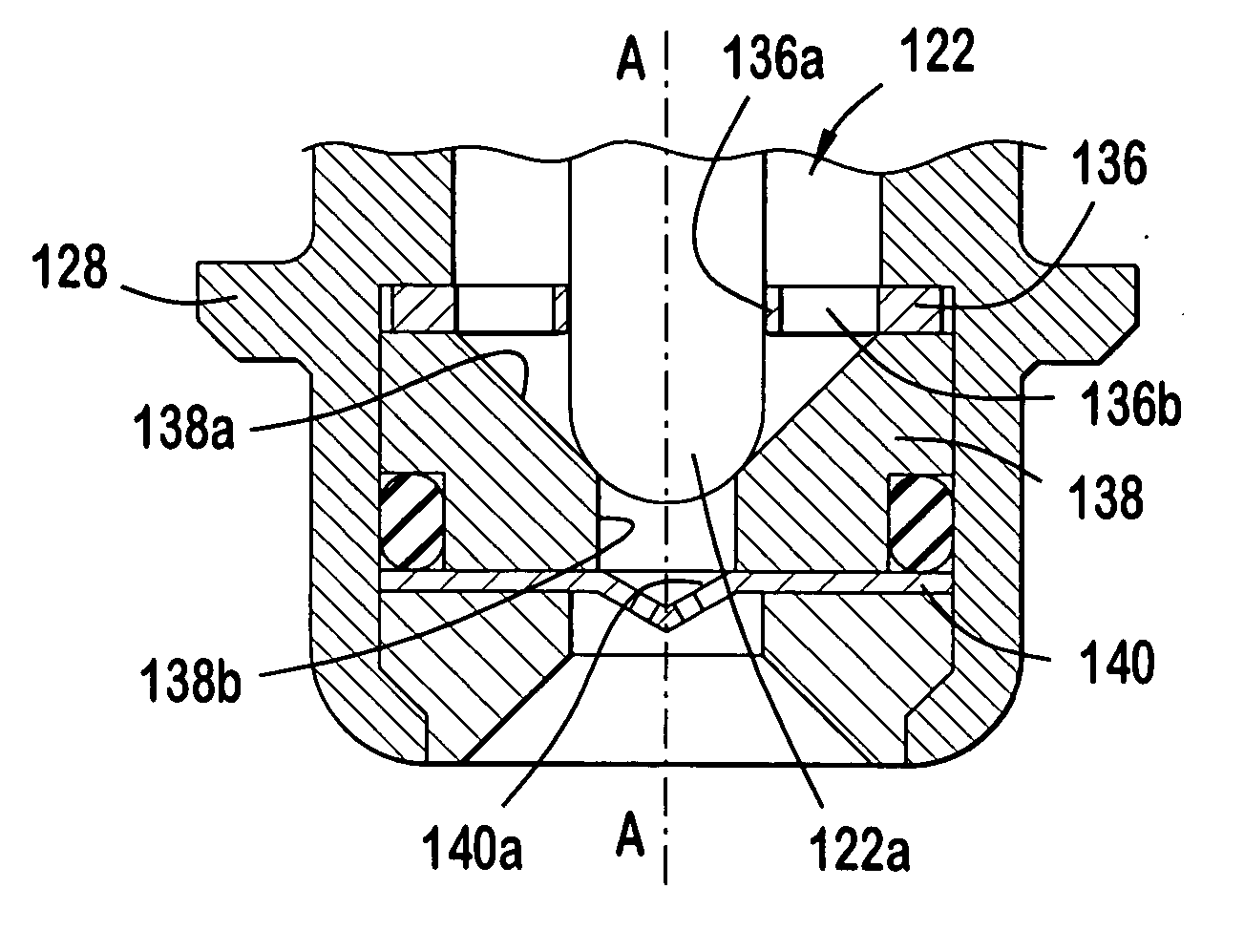

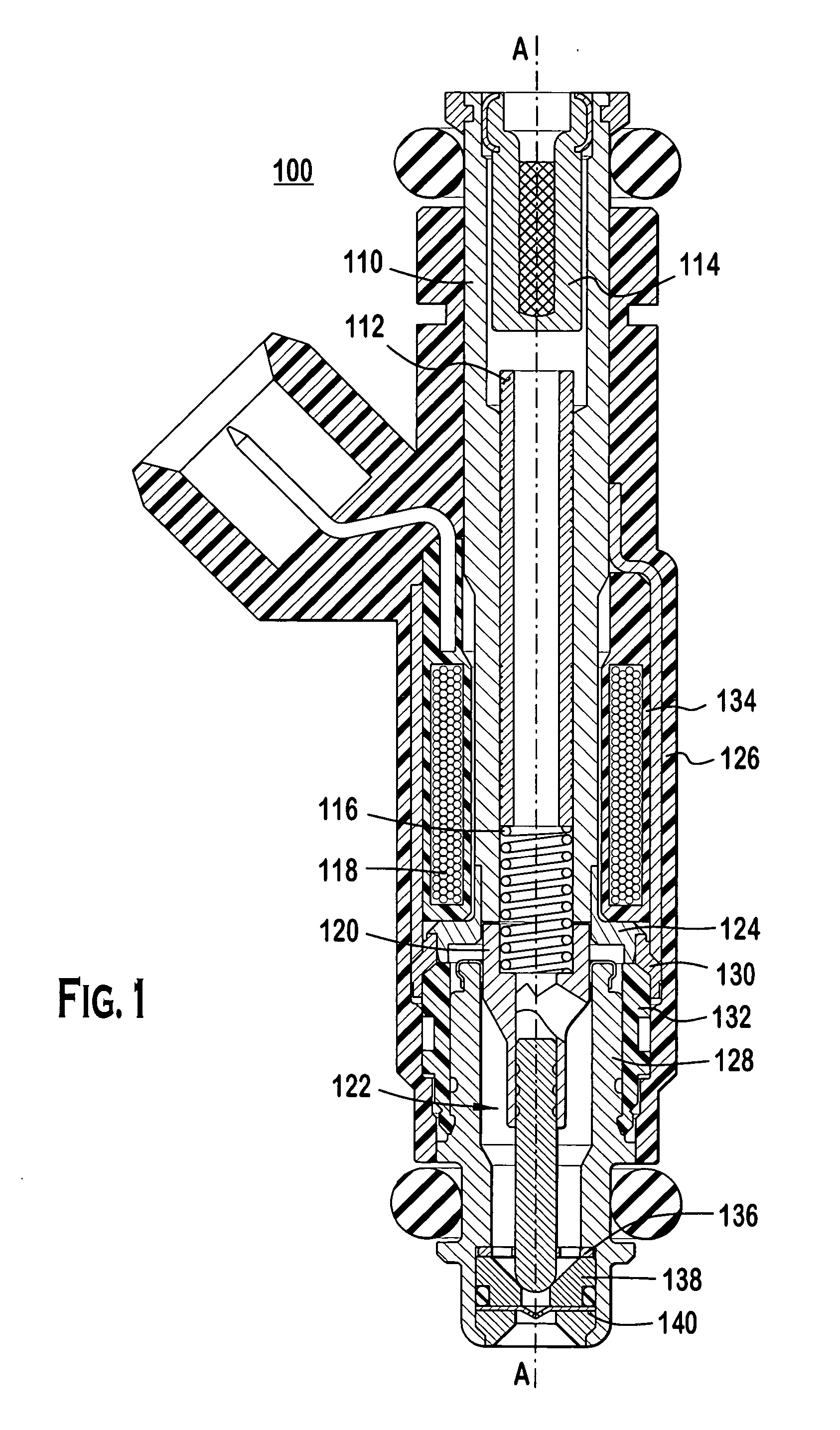

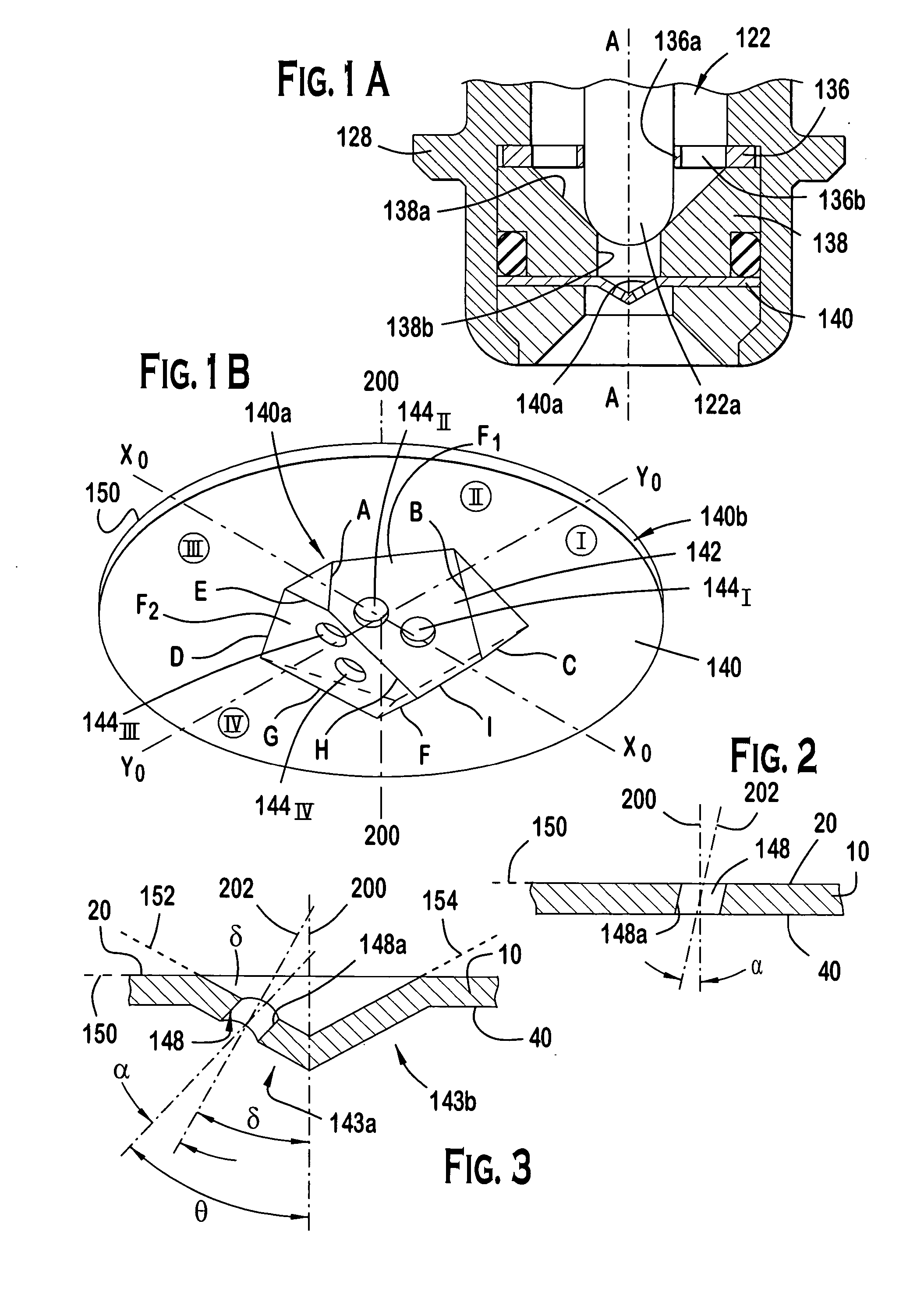

Fuel injector including a compound angle orifice disc for adjusting spray targeting

ActiveUS20050242214A1Improve abilitiesImprove flow stabilityFuel-injection pumpsSpray nozzlesEngineeringFirst relationship

A fuel injector includes an orifice disc. The orifice disc includes a peripheral portion, a central portion, and an orifice. The peripheral portion is with respect to a longitudinal axis and extends parallel to a base plane. The peripheral portion bounds the central portion. The central portion includes a facet that extends parallel to a plane that is oblique with respect to the base plane. The orifice penetrates the facet and extends along an orifice axis that is oblique with respect to the plane. As such, the orientation of the orifice with respect to the longitudinal axis is defined by a combination of (1) a first relationship of the plane with respect to the base plane, and (2) a second relationship of the orifice axis with respect to the plane. A method of forming a multi-facetted dimple for the orifice disc is also described.

Owner:VITESCO TECH USA LLC

MEMS utility meters with integrated mass flow sensors

ActiveUS9109935B2Stable conditionRapid responseVolume/mass flow by thermal effectsVolume meteringUtility industryEngineering

Owner:M TECH INSTR HLDG

Continuous steam generator and method for operating said continuous steam generator

InactiveUS7383791B2High degreeImprove flow stabilityWater circulationBoiler controlVolumetric Mass DensityProduct gas

The invention relates to a continuous steam generator wherein an evaporator throughflow heating surface is disposed in a gas duct which can be cross flown in an approximately vertical manner in a heating gas device, said evaporator throughflow heating surface comprising a plurality of parallel connected steam generating pipes enabling a flow medium to flow through, also enabling particularly high operating stability and security during the supply of the flow medium having a comparatively high mass flow density. The inventive evaporator throughflow heating surface comprises a heating surface segment which can be cross-flown by the flow medium in an opposite direction to the gas duct, the flow medium side exit is positioned in such a manner that it can be seen in the heating direction of the gas such that the saturated steam generator which is adjusted during operation according to pressure in the evaporator throughflow heating surface deviates by less than a maximum predetermined amount from the heating gas temperature prevailing during operation at the position of the exit of the heating surface segment.

Owner:SIEMENS AG

Lubricating oil additive, preparation method thereof and lubricating oil containing same

InactiveCN102199469AGood viscosity increasing effectHigh viscosity indexLubricant compositionViscosity indexCarbon atom

The invention relates to a lubricating oil additive, a preparation method thereof and lubricating oil containing the same. The lubricating oil additive has an acrylic acid series segmented copolymer structure and also has a general formula comprising at least one of (A-B)a, (A-B)b-A or (B-A)c-B, wherein A stands for a copolymer block consisting of (methyl) acrylic acid alkyl ester with alkyl with 1-3 carbon atoms; and B stands for a copolymer block consisting of (methyl) acrylic acid alkyl ester with alkyl with 4-30 carbon atoms, and the mass ratio of A to B is 1 / 99-40 / 60. Compared with the traditional acrylic acid series lubricating oil additive, the lubricating oil additive provided by the invention has good tackifying effect and can ensure that the viscosity index of the lubricating oil can be greatly improved with less addition amount, the low-temperature characteristics, the flowing characteristics and the shearing stability can be improved, the service life of the lubricating oil can be prolonged, energy resources can be saved, and the load on global environment is reduced.

Owner:巴鲁德(天津)润滑科技有限公司

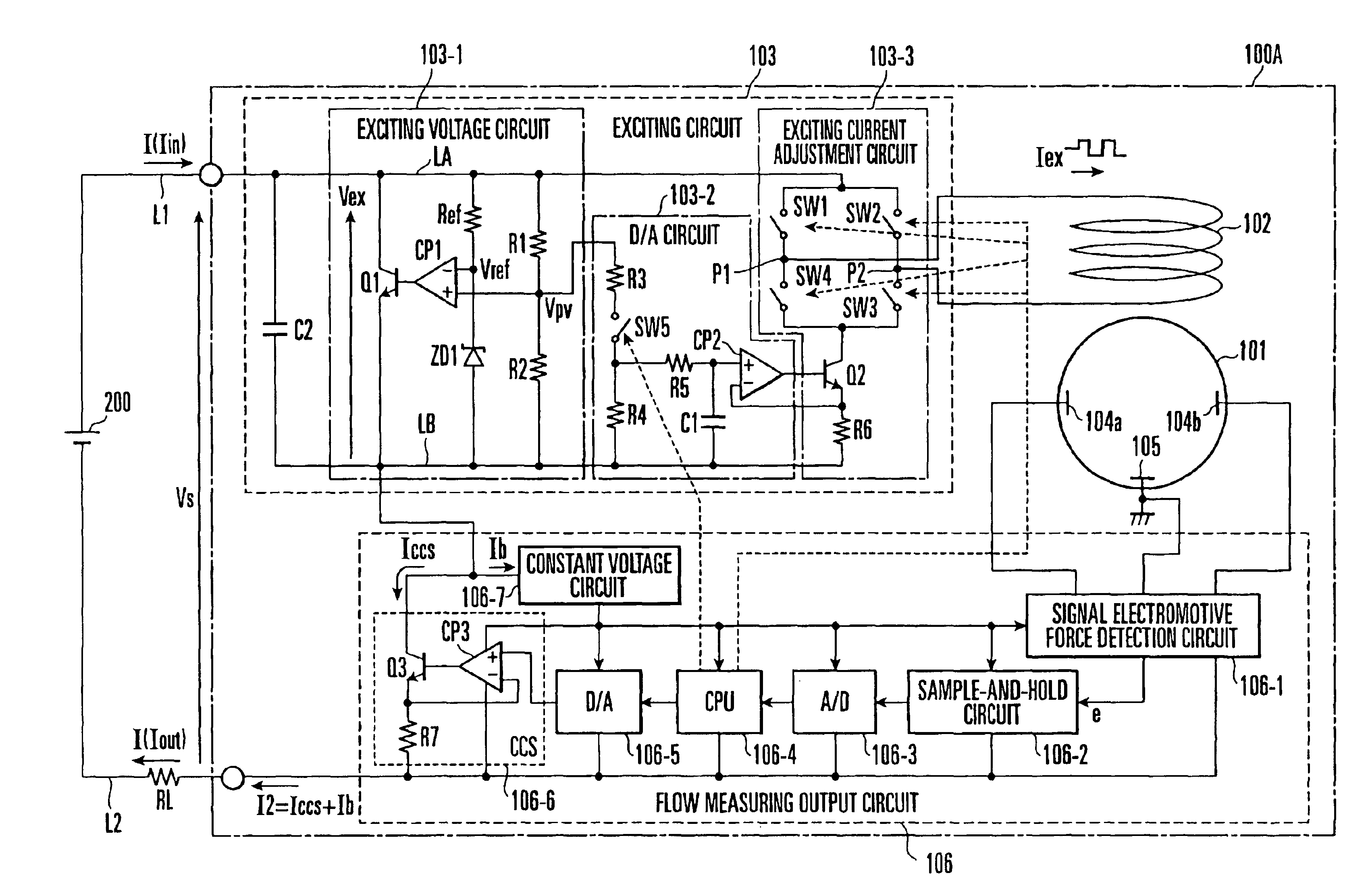

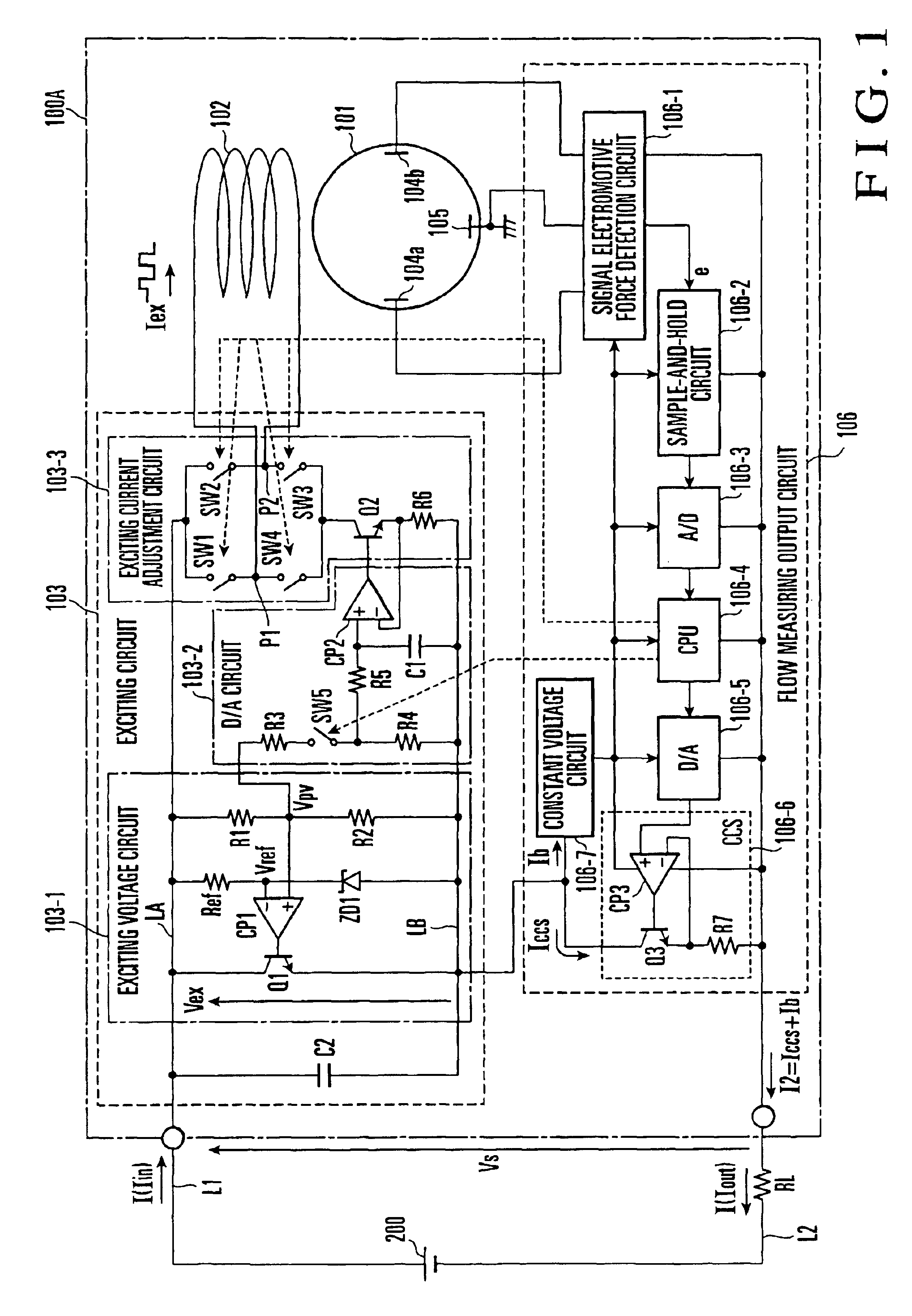

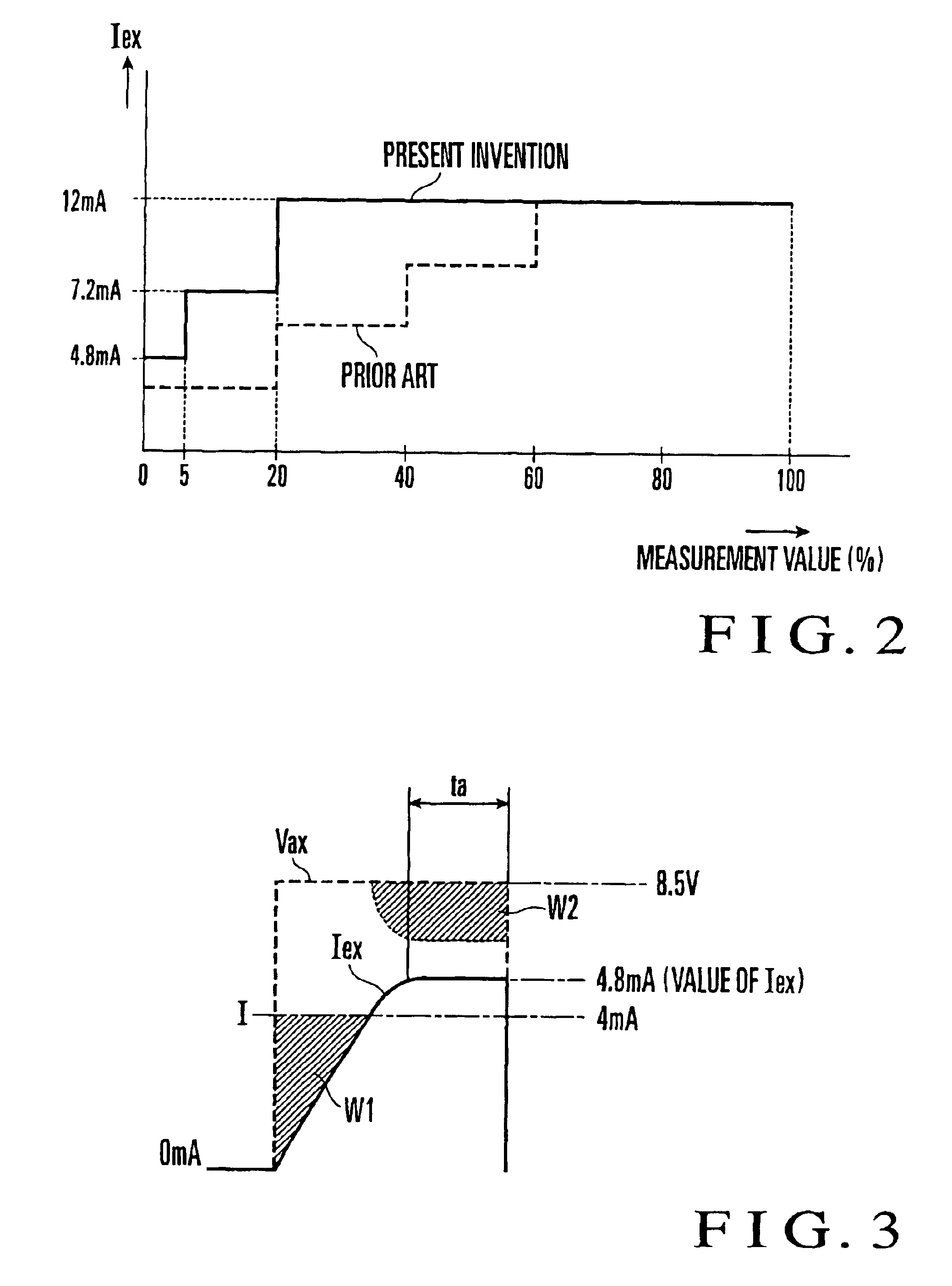

Two-wire electromagnetic flowmeter

InactiveUS6853928B1Improve flow stabilityImprove stabilityFlow propertiesFluid pressure measurement by mechanical elementsExcitation currentMeasuring output

In a two-wire electromagnetic flowmeter, an exciting coil generates a magnetic field in a direction perpendicular to the flowing direction of a fluid that flows through a measurement tube. A flow measuring output circuit adjusts an output current that flows to a pair of power supply lines to which an external power is supplied, in accordance with a flow measurement value obtained on the basis of a signal electromotive force which is generated in a direction perpendicular to the flowing direction of the fluid that flows through the measurement tube and the direction of the magnetic field generated from the exciting coil. An exciting circuit is connected in series with the flow measuring output circuit between the pair of power supply lines and supplies part of the output current to the exciting coil as an exciting current. In the exciting circuit, an exciting voltage circuit generates an exciting voltage between first and second lines. An exciting current adjustment circuit adjusts the value of the exciting current in accordance with the magnitude of the output current adjusted by the flow measuring output circuit. A capacitor is connected in parallel with the exciting voltage circuit between the first and second lines.

Owner:YAMATAKE HONEYWELL CO LTD

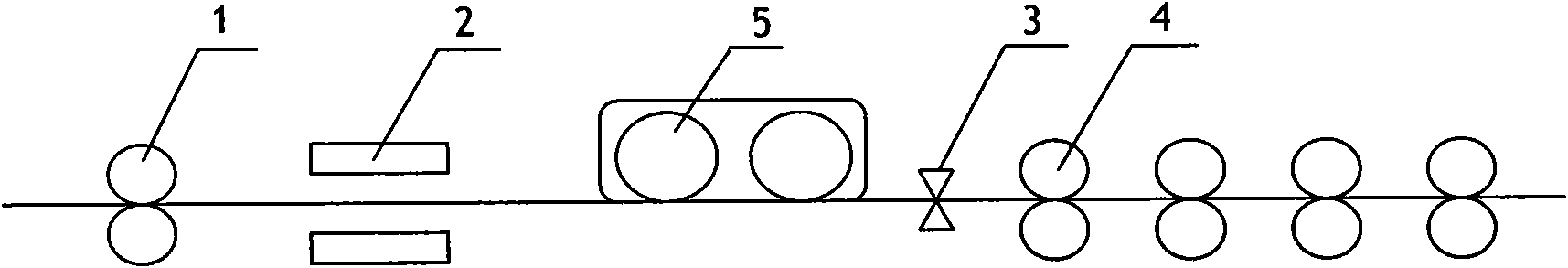

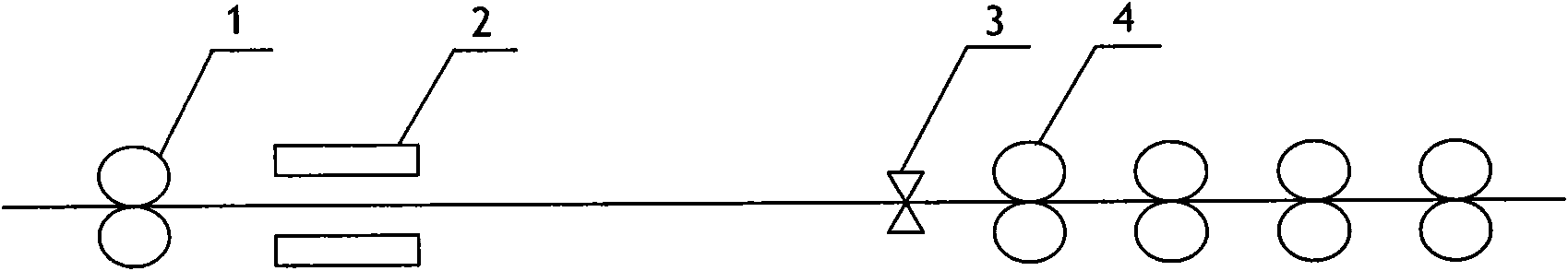

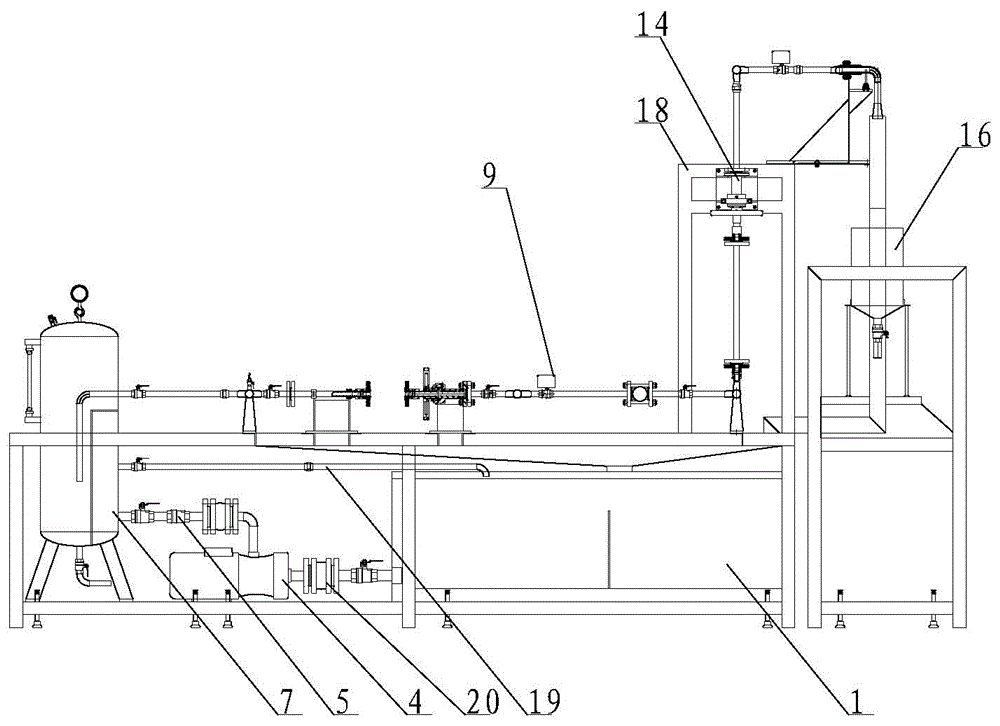

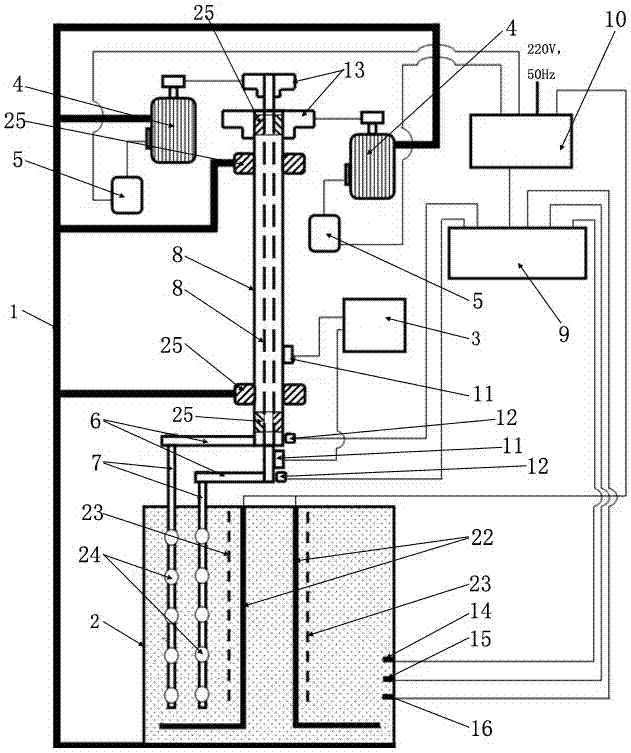

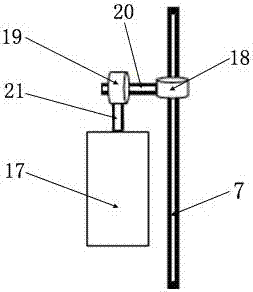

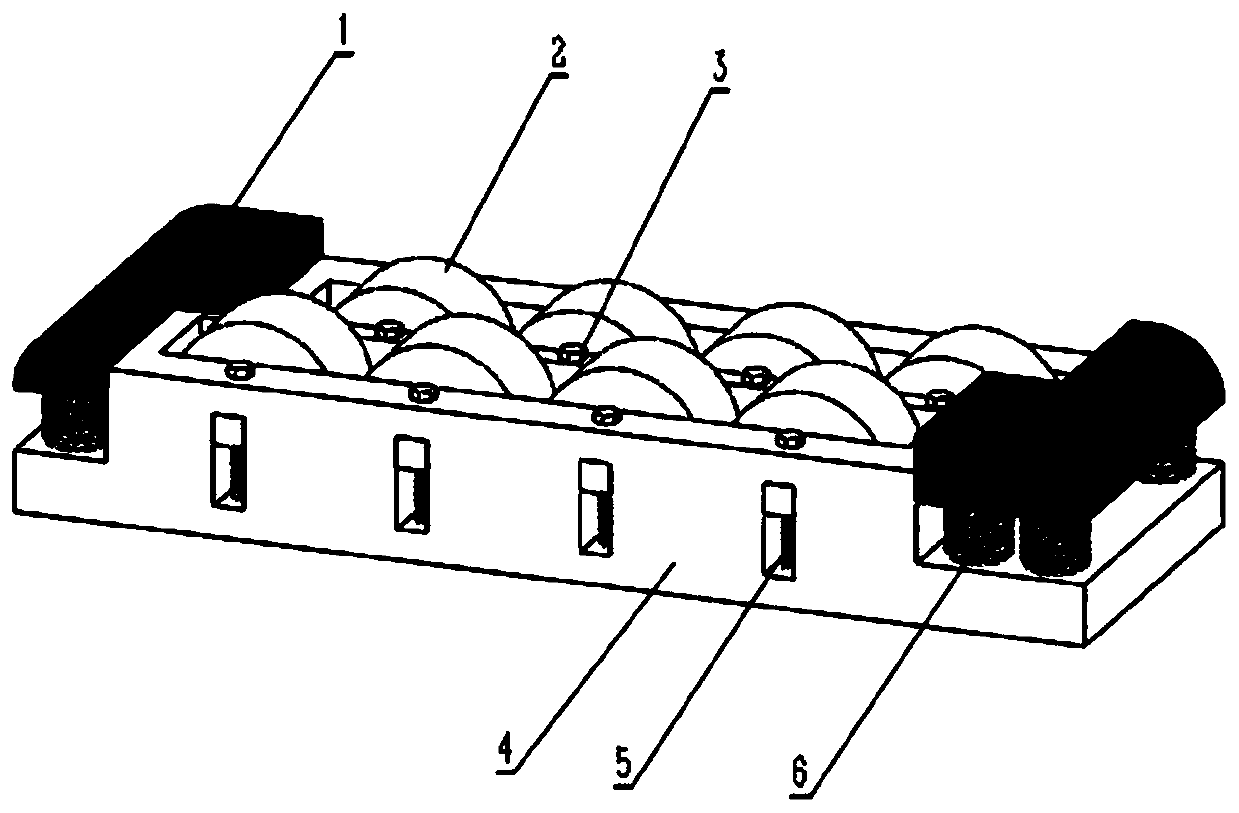

Mass method/standard meter method micro-flow water flow standard device

ActiveCN104482994AAvoid unstable water flow and swimming problemsImprove stabilityTesting/calibration apparatusSurge tankWater storage tank

The invention relates to a mass method / standard meter method micro-flow water flow standard device. The device comprises a water storage tank which is connected with the lower end of a surge tank through a water pump, a high-level water tank is connected with the surge tank, the surge tank and the high-level water tank are connected with a front detected-meter header of a horizontal detected-flow-meter placement pipeline through electric switching valves respectively, the front detected-meter header is connected with two horizontal expansion joints in parallel, detected flow meters with different calibers are installed through the horizontal expansion joints, the two horizontal expansion joints gather on a front standard meter header, three standard meters with different calibers are installed at the outlet of the front standard meter header and connected to a rear standard meter header, two vertical detected-flow-meter placement pipelines are connected through the rear standard meter header, detected flow meters can be installed on the vertical detected-flow-meter placement pipelines through vertical expansion joints, three redirectors with different calibers are arranged at the tail ends of the two vertical detected-flow-meter placement pipelines in a connected mode, and one water outlet of each redirector corresponds to a weighing container.

Owner:丹东科泰仪器仪表有限公司

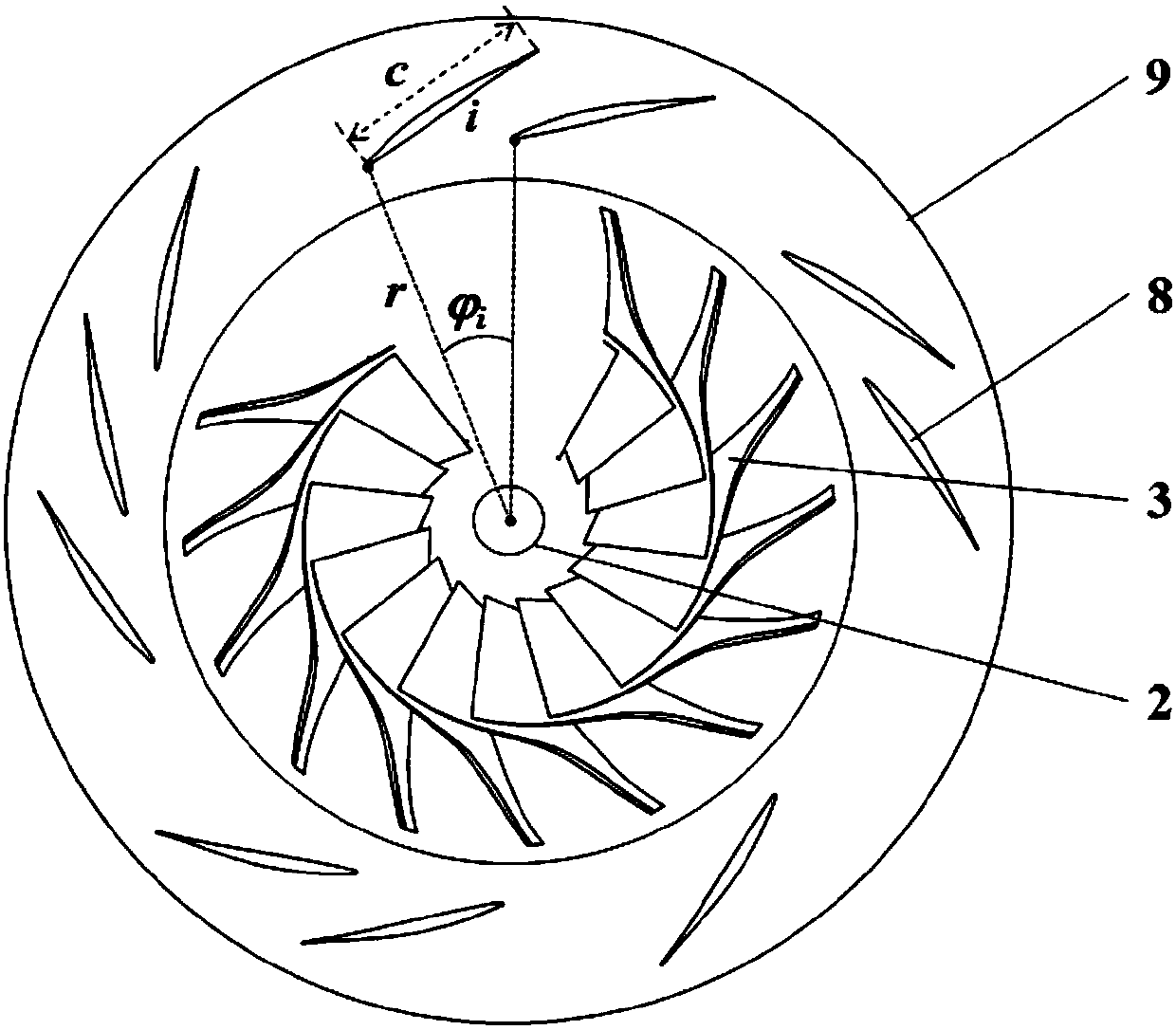

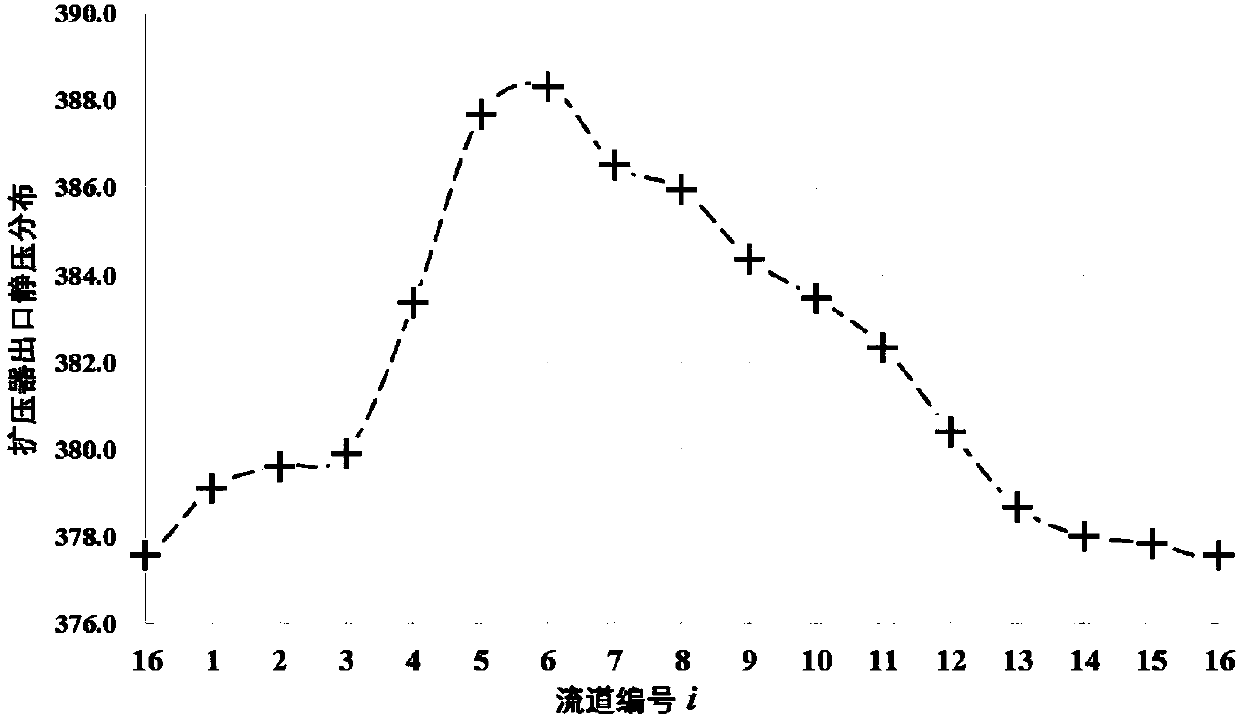

Centrifugal compressor using asymmetrical bladed diffuser with variable blade consistencies in circumferential direction

ActiveCN107061368AImprove flow field structureImprove performancePump componentsPumpsEngineeringFront edge

The invention relates to a centrifugal compressor using an asymmetrical bladed diffuser with variable blade consistencies in the circumferential direction, and belongs to the technical field of turbomachinery. The centrifugal compressor comprises a volute, a centrifugal impeller and the bladed diffuser. The inlet front edge positions and the bladed mounting angles are evenly distributed in the circumferential direction, the blade consistencies are asymmetrically distributed in the circumferential direction, and the consistencies are unequal in different circumferential positions. The blade consistencies are changed by changing the central angles (namely the front edge interval between every two adjacent blades) corresponding to flow channels. The compressor can effectively adapt to the downstream circumferential pressure distortion of the bladed diffuser, the nonuniformity of a flow field in the bladed diffuser is reduced, the flowing stability of the centrifugal compressor is effectively improved, and the stable working range of the centrifugal compressor is enlarged.

Owner:TSINGHUA UNIV +1

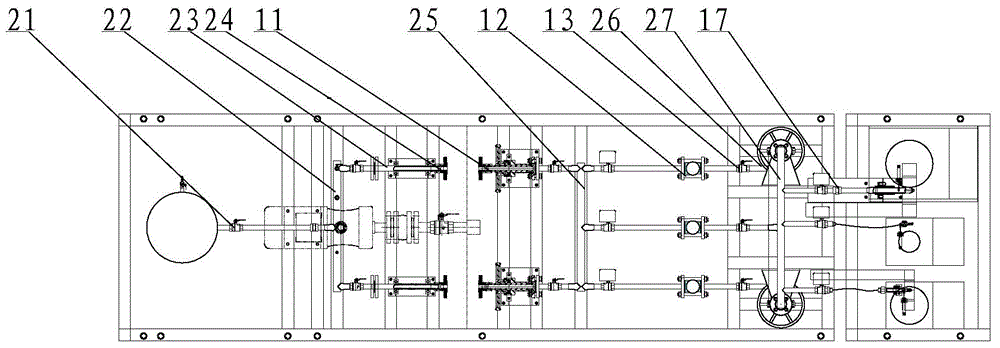

Dual-arm backward erosion corrosion testing device

ActiveCN107219138AFeasibility of real-time electrochemical testingGood effectWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceFrequency changerElectricity

The invention discloses a dual-arm backward erosion corrosion testing device. The dual-arm backward erosion corrosion testing device comprises a bracket, a test groove, a computer feedback control system, an electrochemical workstation and two groups of transmission systems, wherein a heater is arranged in the test groove; each group of transmission systems comprises a frequency converter, a rotary table, a sample frame, a revolving shaft and a motor connected with the frequency converter; the motors are connected with upper ends of the revolving shafts; lower ends of the revolving shafts are vertically connected with the rotary tables; the sample frames are vertically connected with the revolving shafts; the computer feedback control system comprises a computer and a control cabinet; the heater and the two frequency converters are connected with the control cabinet; the control cabinet is used for controlling the two groups of transmission systems to drive the two revolving shafts to rotate reversely in order to drive the sample frames on the two rotary tables to rotate in the test groove; outer walls of the revolving shafts are provided with electrochemical assemblies which are connected with the electrochemical workstation, and rotation speed sensors which are connected with the computer. By adopting the dual-arm backward erosion corrosion testing device, dual-shaft reverse rotation is adopted, so that a more accurate relative motion speed can be obtained during rotation of a sample, the flow state stability of a medium can be improved, and an optimal erosion effect is achieved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

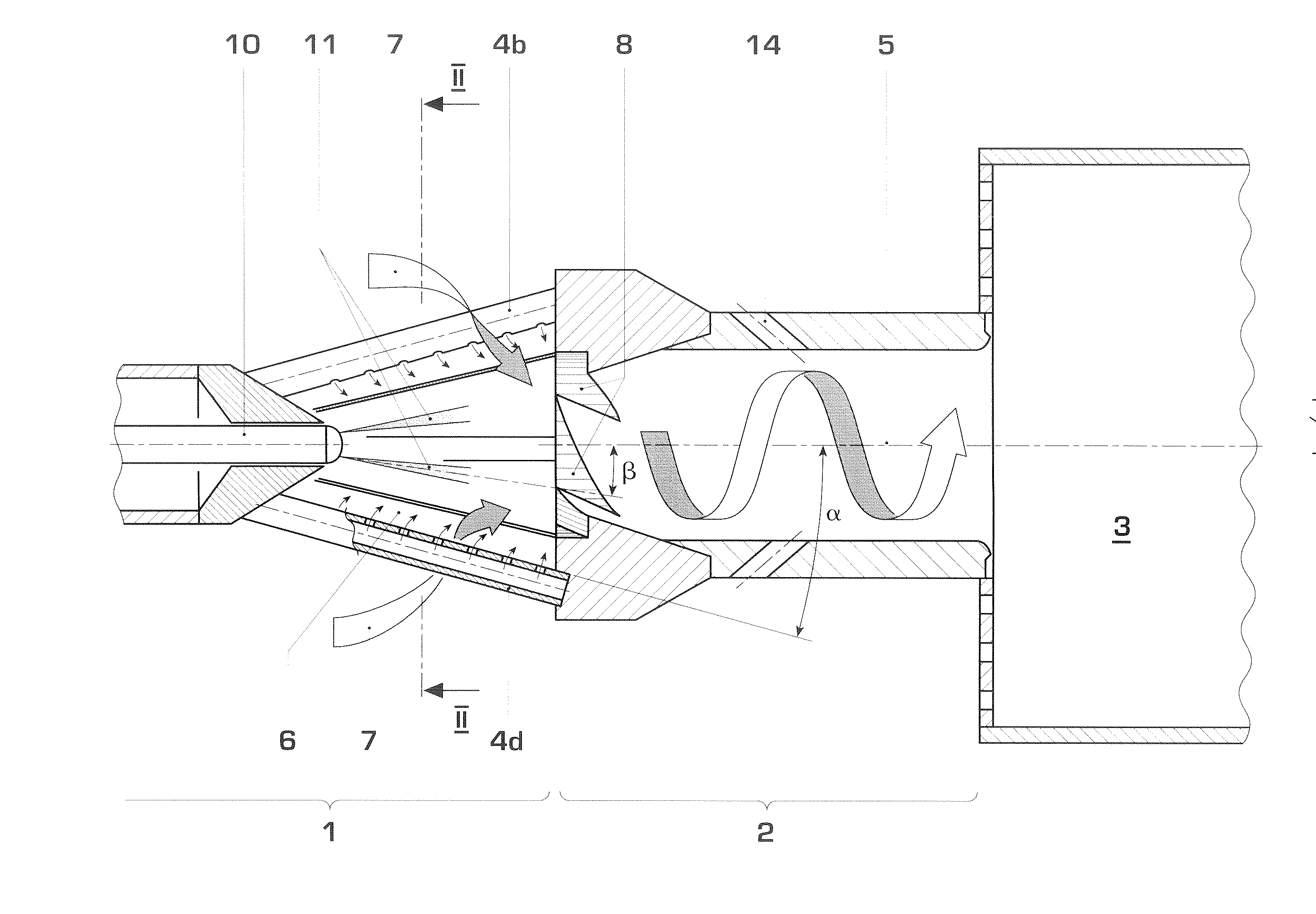

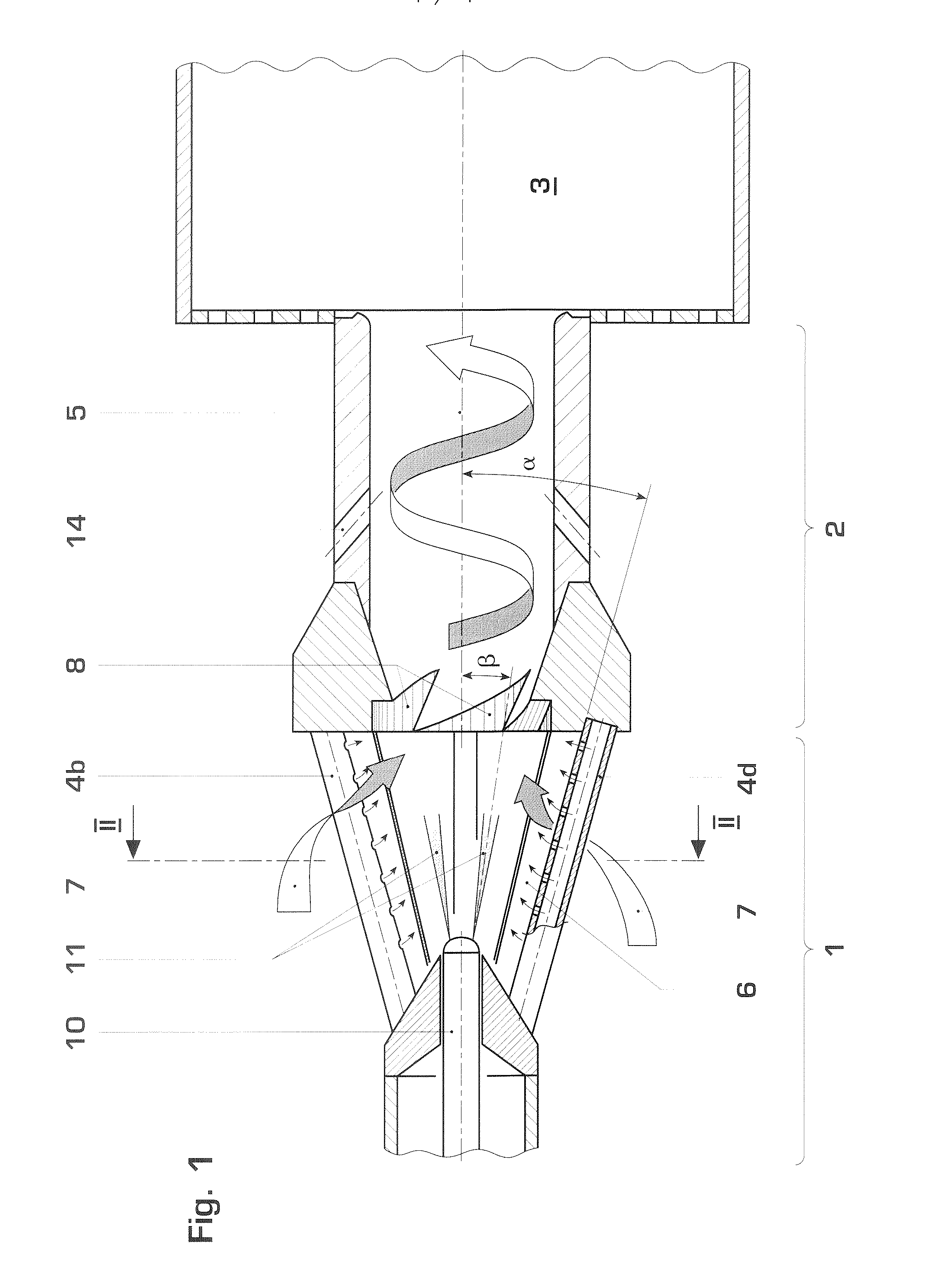

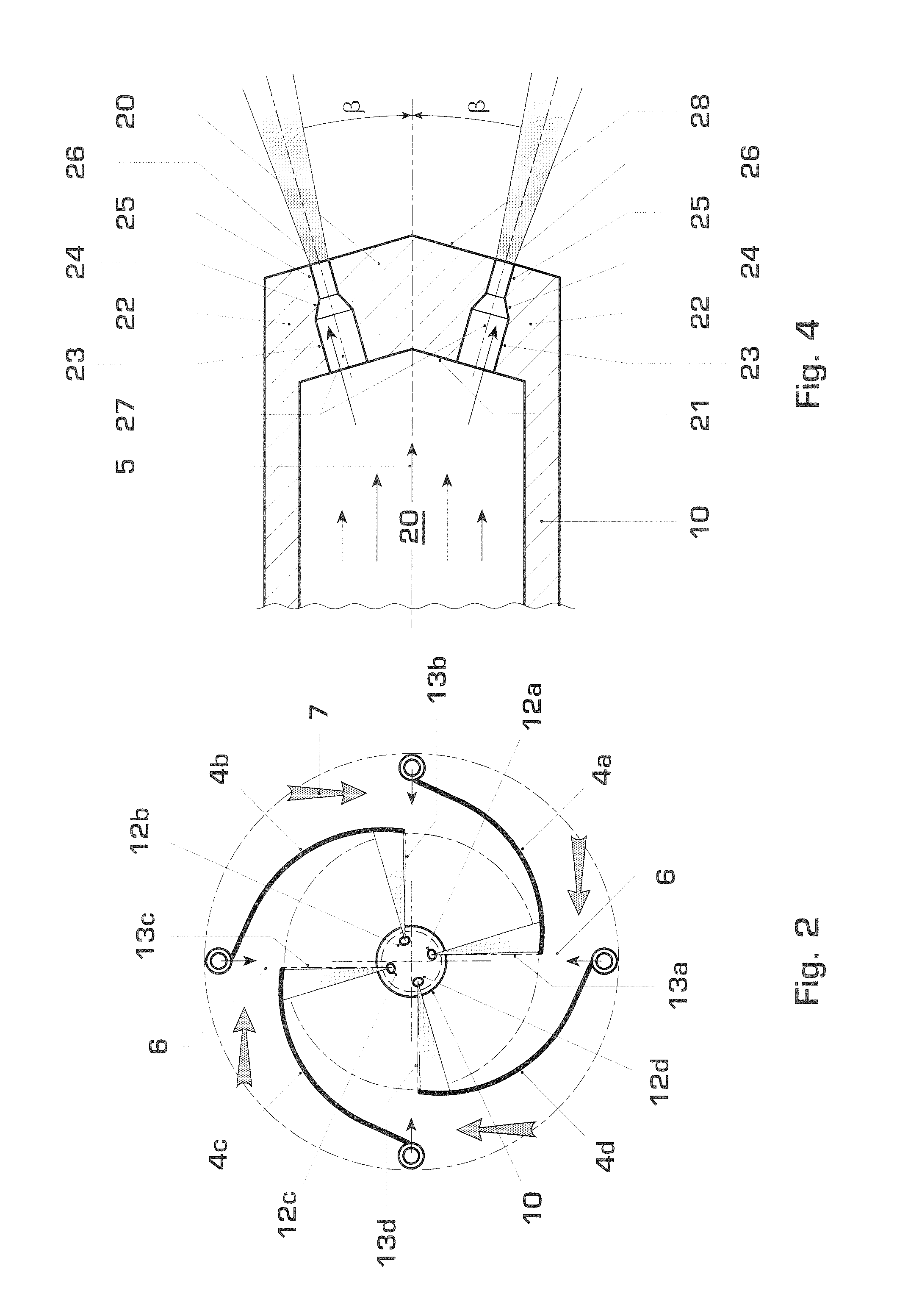

Burner for a Gas Turbine

InactiveUS20070207431A1Reduce turbulenceSmall angleContinuous combustion chamberGaseous fuel burnerCombustorSpray cone

A premix burner, for example for a gas turbine, having a conical swirl generator (1) and a cylindrical mixing section (2) which follows it in the direction of flow, includes a high-pressure atomizer nozzle (10) with one or more fuel feed passages. The high-pressure atomizer nozzle (10) includes at least two outlet passages, through which liquid fuel enters the swirl generator (1), these passages being arranged off-center with respect to the longitudinal axis of the nozzle and being configured in such a way that the spray cone (11) of the fuel is oriented at an angle (β) with respect to the longitudinal axis of the swirl generator (1) which is smaller than the cone half-angle (α) of the swirl generator (1). The outlet passages in particular have an internal geometry with a conically narrowed section.

Owner:ANSALDO ENERGIA SWITZERLAND AG

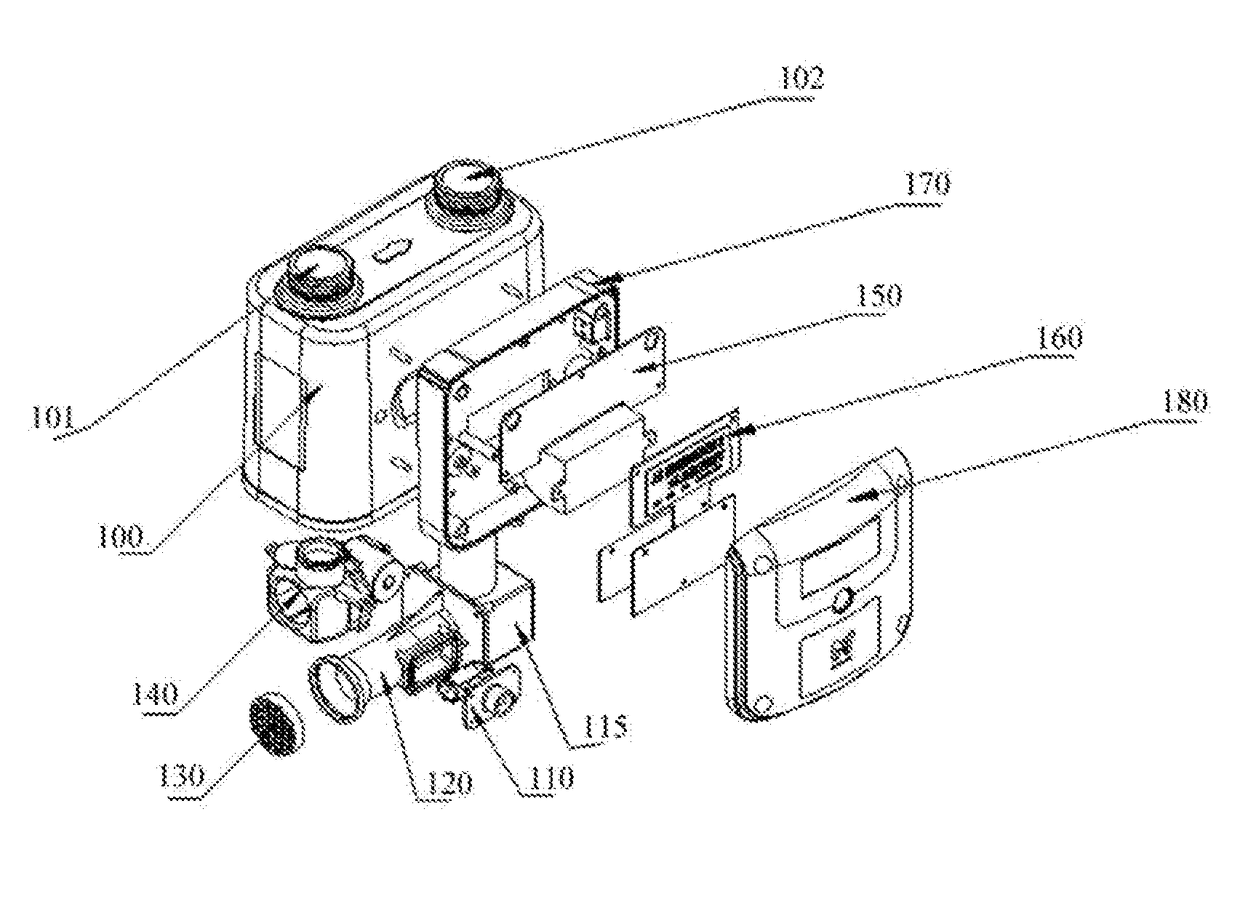

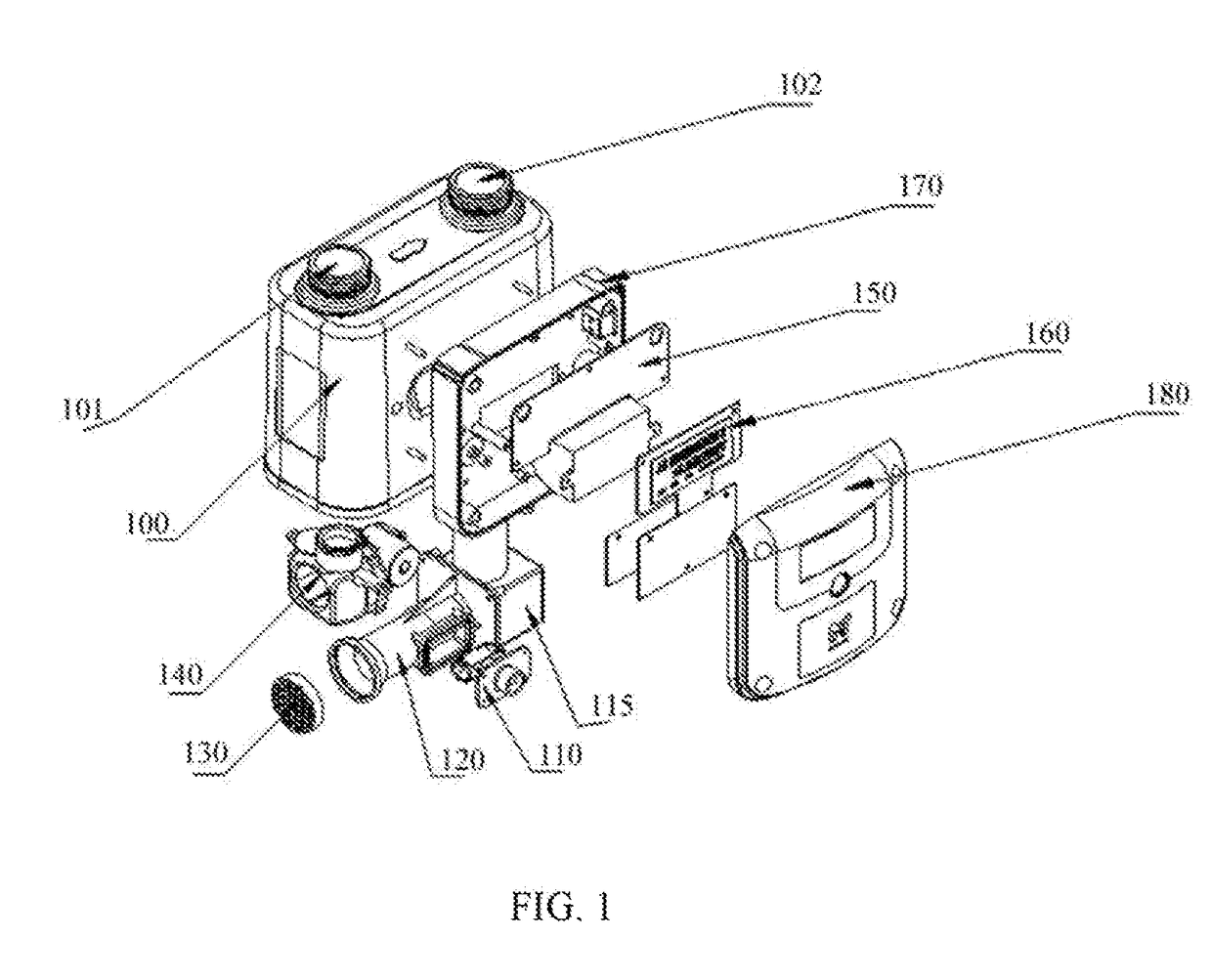

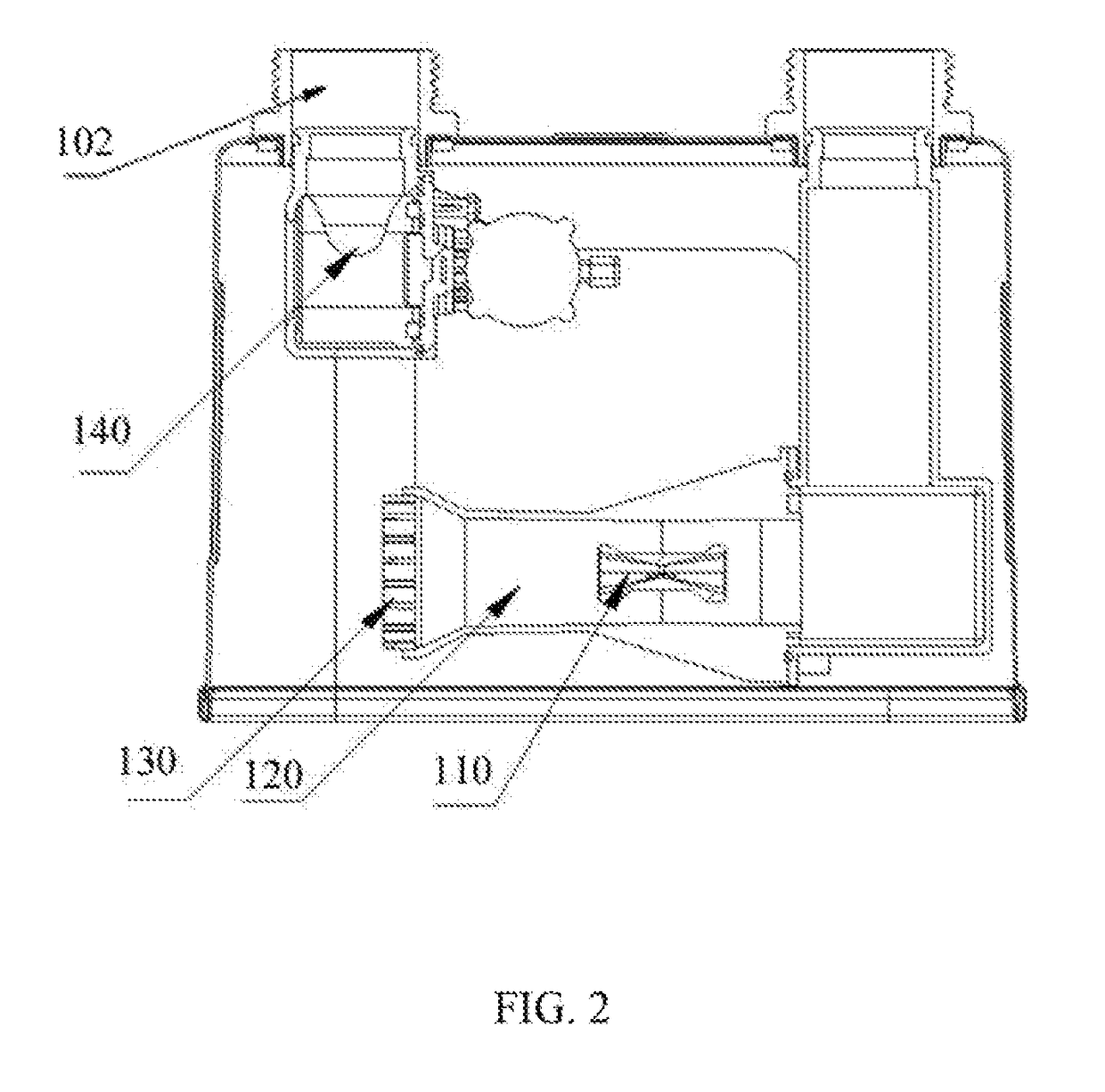

MEMS utility meters with exchangeable metrology unit

ActiveUS8994552B2Speed up the flowImprove performanceTransmission systemsVolume/mass flow by thermal effectsMetrologyElectrical battery

Owner:M TECH INSTR HLDG

Double-row multi-roller type modular current-receiving device for electric locomotive

PendingCN110370936AReduce wearReduced service lifeRotary current collectorPower current collectorsModularitySlide plate

Disclosed is a double-row multi-roller type modular current-receiving device for an electric locomotive. According to the double-row multi-roller type modular current-receiving device for the electriclocomotive, two rows of metal rollers are annularly arranged on an insulating base; each rolling wheel is arranged in the manner that two insulating stand columns are fixed to the insulating base, compression springs sleeve the two insulating stand columns correspondingly, insulating blocks sleeve the insulating stand columns and are located above the compression springs, metal shells of the rollers are installed on metal shafts through two insulating bearings, the metal shafts are fixed to the two insulating blocks, the outer surface of an annular current receiving electric brush makes contact with the roller metal shells to receive current, the inner surface of the annular current receiving electric brush is fixed to the metal shafts, all the metal shafts are connected through cables and are then used for supplying power to vehicle-mounted power consuming equipment, and two pure carbon sliding plates are fixed to the insulating base through more than four springs. The friction forceand the friction noise of the current-receiving device and a rigid contact rail can be effectively reduced, and the double-row multi-roller type modular current-receiving device can adapt to the changes of locomotive traction power requirements and has good buffering performance, heat dissipation performance and rail attaching performance.

Owner:SOUTHWEST JIAOTONG UNIV

Pantograph head balance device

ActiveCN106183830AImprove flow stabilityReduce the windward areaPower current collectorsEngineeringPantograph

The invention discloses a pantograph head balance device. The pantograph head balance device comprises a balance rod system located under an upper arm rod, and the balance rod system comprises a first rod hinged to the upper end of a lower arm rod, a second rod hinged to the upper end of the upper arm rod, a fourth rod hinged to a pantograph head rotating shaft and a third rod of which one end is hinged to the free end of the second rod and the other end is hinged to the free end of the fourth rod; the other end of the first rod is hinged to the middle of the second rod, the upper end of the upper arm rod extends to form a connection part, and the connection part is hinged to the pantograph head rotating shaft. According to the pantograph head balance device, a multi-connecting rod balance device with multi-sectional design is adopted to replace a traditional structure of one straight balance rod, the rotation angle of the pantograph head can remain unchanged in the rising and falling process of a pantograph, and the current collection stability is improved. Due to the fact that the balance device is arranged under the upper arm rod in a hidden mode, the windward area of the pantograph is decreased, wind resistance in high speed operation is reduced, and the aerodynamic performance of the pantograph is improved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com