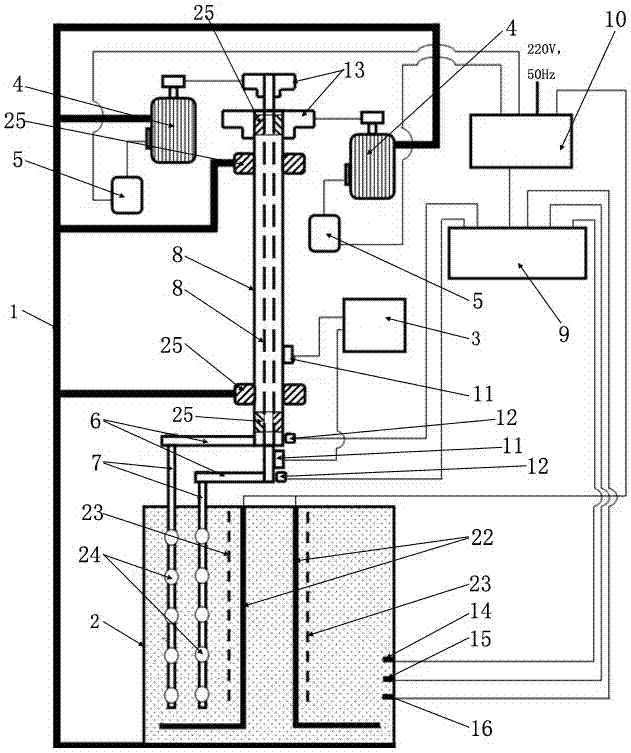

Dual-arm backward erosion corrosion testing device

A reverse erosion and corrosion test technology, applied in the field of erosion and corrosion, can solve the problems that the influence of fluid flow state distribution cannot be evaluated, and the erosion and corrosion parameters cannot be obtained, so as to improve the actual effect, improve the stability of flow state, and easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

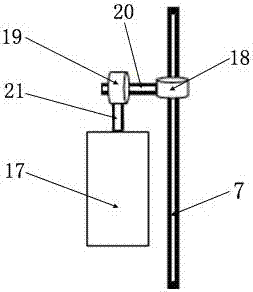

Method used

Image

Examples

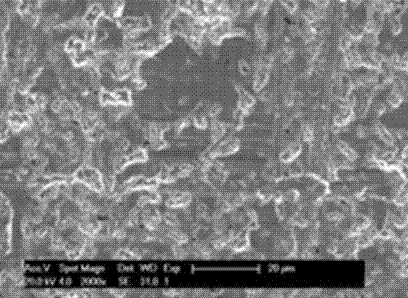

Embodiment 1

[0042] Using the B10 copper alloy plate as the sample, the medium contained in the test tank 2 is the real sea water in Xiamen sea area, where the real sea water is the sea water in the actual sea area taken at a distance of more than 50m from the shore in the test sea area at high tide level ; The test temperature is 45°C; the rotation speed of the two rotating shafts is 500rpm, and the rotation is opposite; the impact angle of the sample is 30°.

[0043] The experimental process is as follows:

[0044] (1) Install the samples on the two sample racks 7 respectively, adjust the angle between the sample and the vertical direction to be 30°, and fix the two sample racks 7 on the two turntables 6 in turn;

[0045] (2) Put the seawater from the real sea in Xiamen sea area into the experimental tank 2;

[0046] (3) Start the control cabinet 10 and the computer 9, complete the system self-inspection, and confirm that the signal processor and feedback adjustment software are effecti...

Embodiment 2

[0053] Using the B10 copper alloy plate as the sample, the medium contained in the test tank 2 is the real sea water in Xiamen sea area, where the real sea water is the sea water in the actual sea area taken at a distance of more than 50m from the shore in the test sea area at high tide level ;Test temperature is 45℃;

[0054] The rotating shaft located inside the hollow rotating shaft and the accessory parts arranged on the rotating shaft are discarded, that is, the single-axis rotation scour test is realized by using the rotating shaft of the present invention. The rotating speed of the rotating shaft is 500rpm; the impact angle of the sample is 0°.

[0055] The experimental process is as follows:

[0056] (1) Install the sample on the sample rack 7, adjust the sample vertically downward, and fix the sample rack 7 on the turntable 6;

[0057] (2) Put the seawater from the real sea in Xiamen sea area into the experimental tank 2;

[0058] (3) Start the control cabinet 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com