Centrifugal compressor using asymmetrical bladed diffuser with variable blade consistencies in circumferential direction

A centrifugal compressor, blade consistency technology, applied in the direction of machines/engines, pumping devices for elastic fluids, mechanical equipment, etc., can solve the problem of reducing diffuser efficiency, local flow instability, and deterioration of flow instability and other problems, to achieve the effect of improving flow stability, reducing non-uniformity, and uniform flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

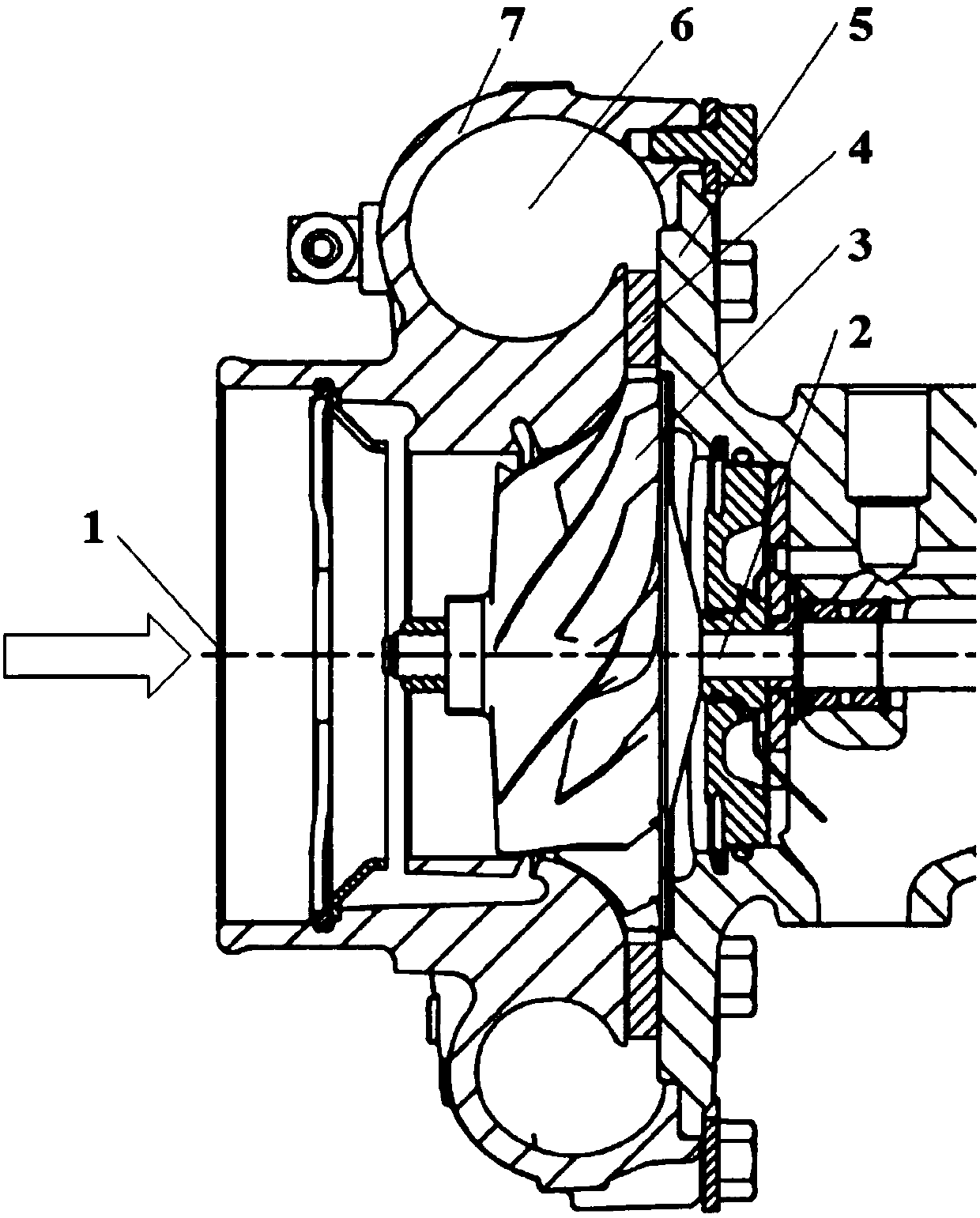

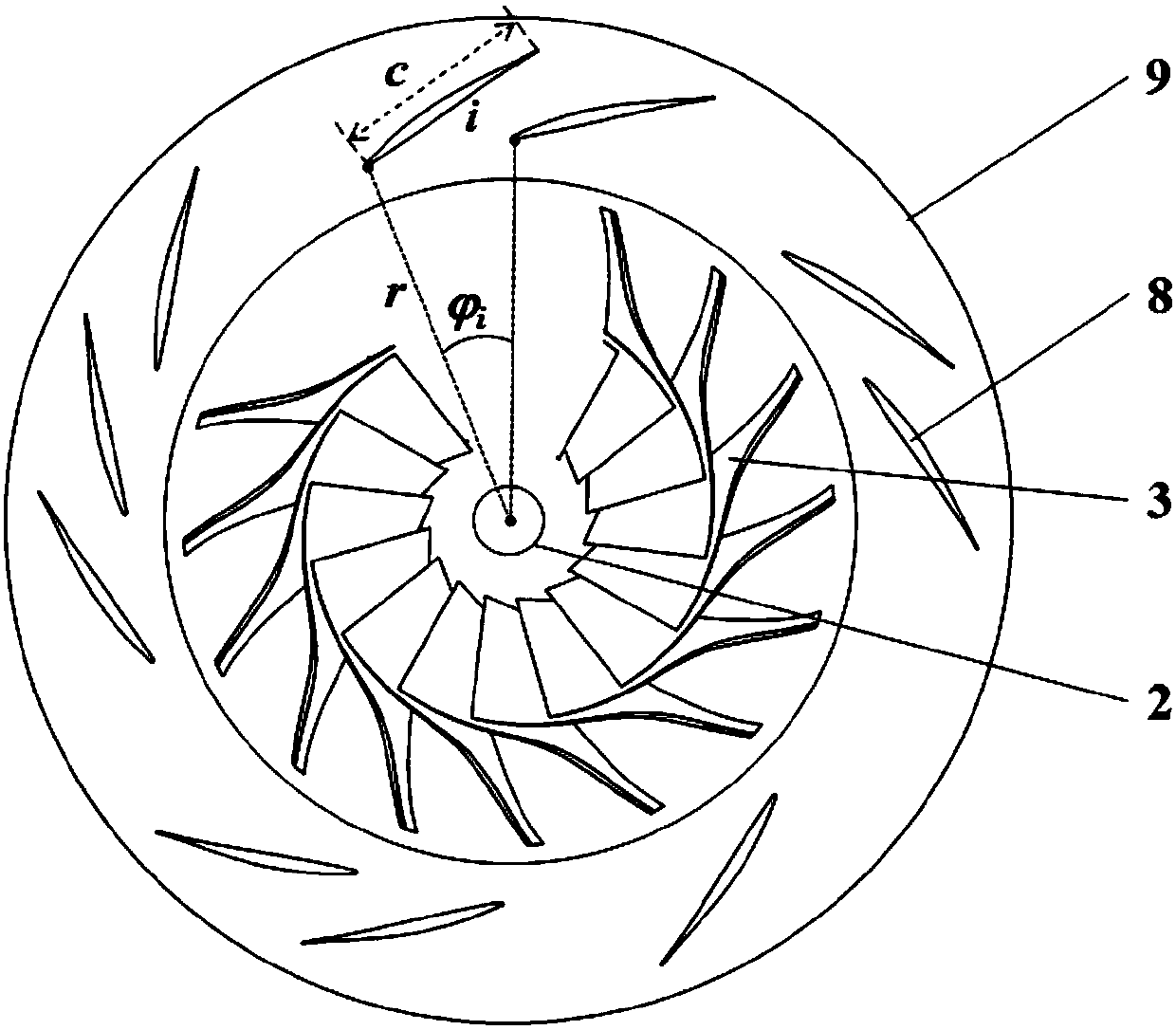

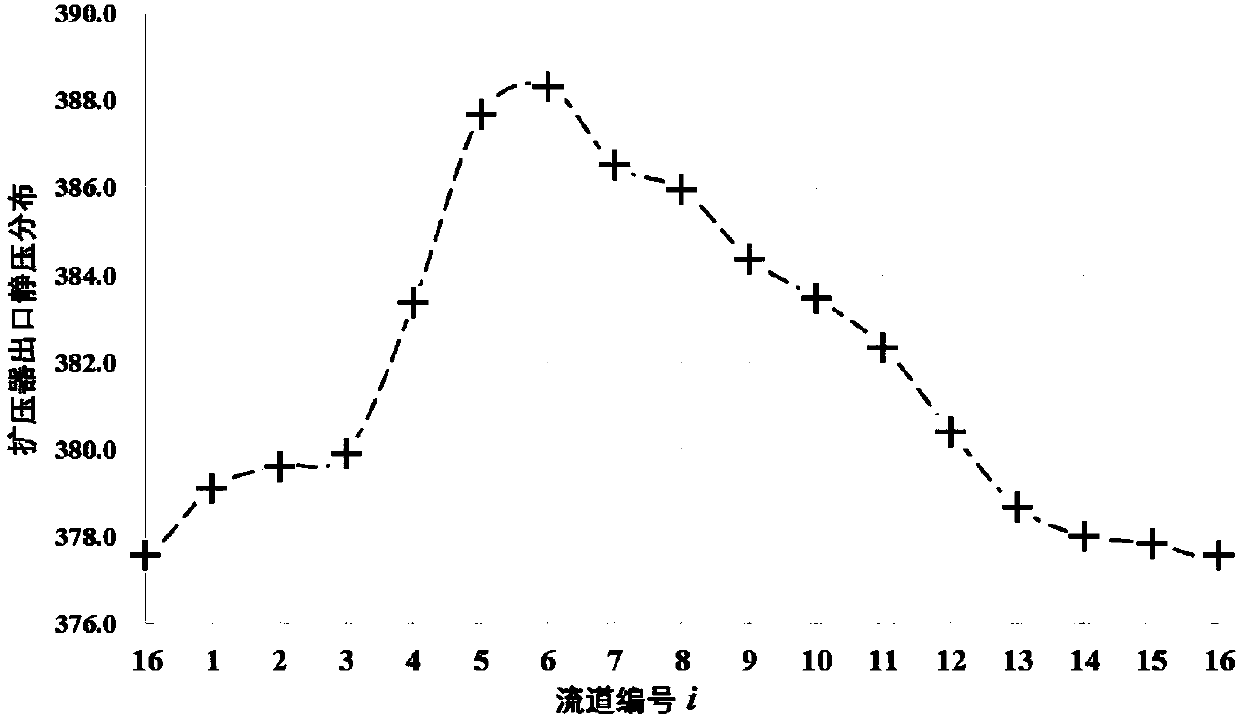

[0015] The present invention proposes a centrifugal compressor that adopts an asymmetric vaned diffuser with variable blade consistency in the circumferential direction, and its structure is as follows: figure 1 As shown, it includes a casing 7, a centrifugal impeller 3, a back plate 5 and a diffuser 4. The casing 7 is relatively fixed to the back plate 5 , and the outer end of the casing 7 forms a volute flow channel 6 . The centrifugal impeller 3 and the diffuser 4 are coaxially installed, the centrifugal impeller 3 is driven by the rotating shaft 2 of the centrifugal compressor, and the diffuser 4 is composed of a plurality of diffuser blades 8, such as figure 2 As shown in , a plurality of diffuser blades are fixed on the casing 7 or the back plate 5 along the circumference, flow passages are formed between two adjacent diffuser blades, and the thickness S of the diffuser blades installed along the circumference i for:

[0016]

[0017] Among them, i is the flow chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com