Impeller structure of artificial heart pump

A technology of artificial heart and pump impeller, applied in blood pumps, blood pumps, hypodermic injection devices, etc., can solve the problems of low efficiency, large speed and volume of single-stage centrifugal pumps, and achieve low hemolysis and thrombosis probability and high volume. Efficiency and the effect of a small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

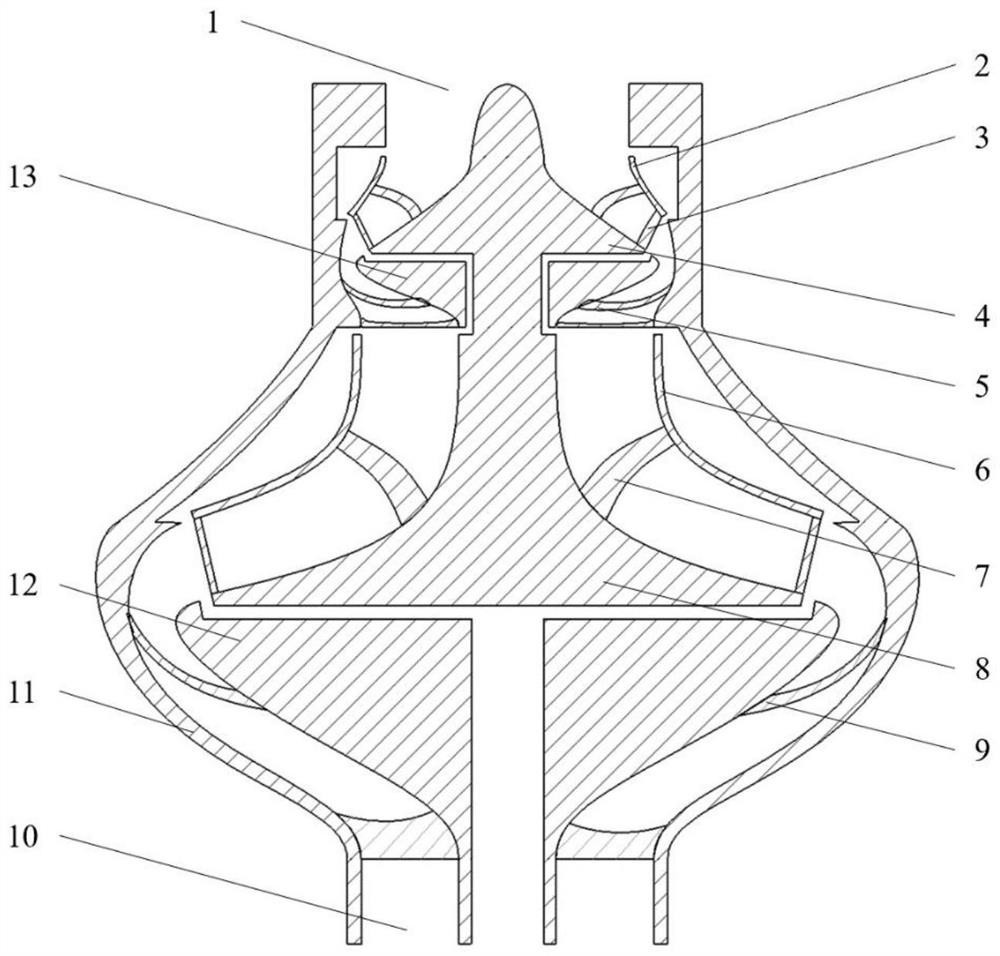

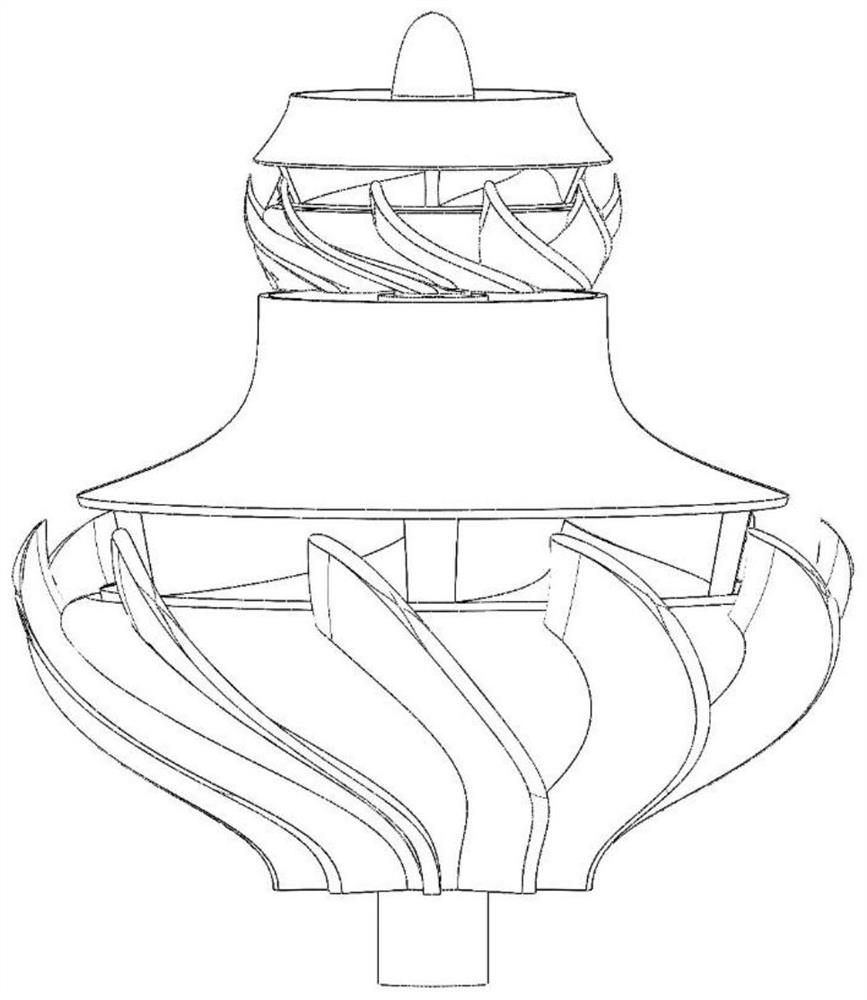

[0034] This embodiment provides an artificial heart pump impeller structure, such as Figure 1-3 As shown, the impeller structure includes the first-stage centrifugal pump upper cover 2, the first-stage centrifugal pump blades 3, the first-stage centrifugal pump guide cone 4, the second-stage centrifugal pump upper cover 6, the second-stage centrifugal pump Pump vane 7, second-stage centrifugal pump guide cone 8 and casing. Wherein, the bottom surface portion of the first-stage centrifugal pump guide cone 4 and the second-stage centrifugal pump guide cone 8 also serve as the lower cover plate of each stage of impeller. In addition to the outer casing 11, the casing also includes the first-stage guide vanes 5, the second-stage guide vanes A 9, the guide cones 12 of the second-stage guide vanes A, and the guide vanes of the first-stage guide vanes fixed thereon. Cone 13. The housing is divided into left and right parts, and the combination of the left housing and the right hou...

Embodiment 2

[0039] This embodiment provides a second artificial heart pump impeller structure, such as Figure 4-5 As shown, compared with Embodiment 1, the outlet of the second-stage centrifugal pump vane 7 is not inclined, and does not have the second-stage guide vane A 9 and the guide cone 12 of the second-stage guide vane A, and the casing is made Adjustment. The shell of this embodiment 2 is still divided into two parts: left and right. After the two parts are combined, an inner chamber and an inlet 1 are formed. The outlet 10 is located on the right half of the shell. The half part is constructed in the form of a volute as the kinetic energy conversion device of the last stage impeller. The internal structure of this embodiment is as follows Figure 4 shown, the overall appearance is as Figure 5 shown.

[0040] In this embodiment, the blood flows in from the inlet 1 of the pump body, and the first half of the blood flowing through is the same as that in Embodiment 1, except tha...

Embodiment 3

[0042] like Figure 6-7 As shown, compared with Embodiment 2, this embodiment only adds the second-stage guide vane B14 to the outer ring of the second-stage centrifugal pump impeller, the second-stage guide vane B14 is fixed on the casing, and the appearance of the second-stage guide vane B14 like Figure 7 As shown, two types of guide vanes, open type and closed type, can be used, and the lower cover plate of the second-stage guide vane B14 in the figure is a part of the casing.

[0043] The blood flow in this embodiment is similar to that in Embodiment 2, except that the guide vane and the volute are used together as the kinetic energy conversion device of the second-stage impeller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com