Coal mine downhole crawler type drilling and punching integrated equipment

A crawler and punching technology, which is applied in the direction of percussion drilling, rotary drilling, drilling equipment and methods, etc., can solve the problems of large consumption of manpower and material resources, complicated and redundant construction procedures, and large and complex equipment. Achieve the effects of eliminating danger, good high-pressure sealing effect, and small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

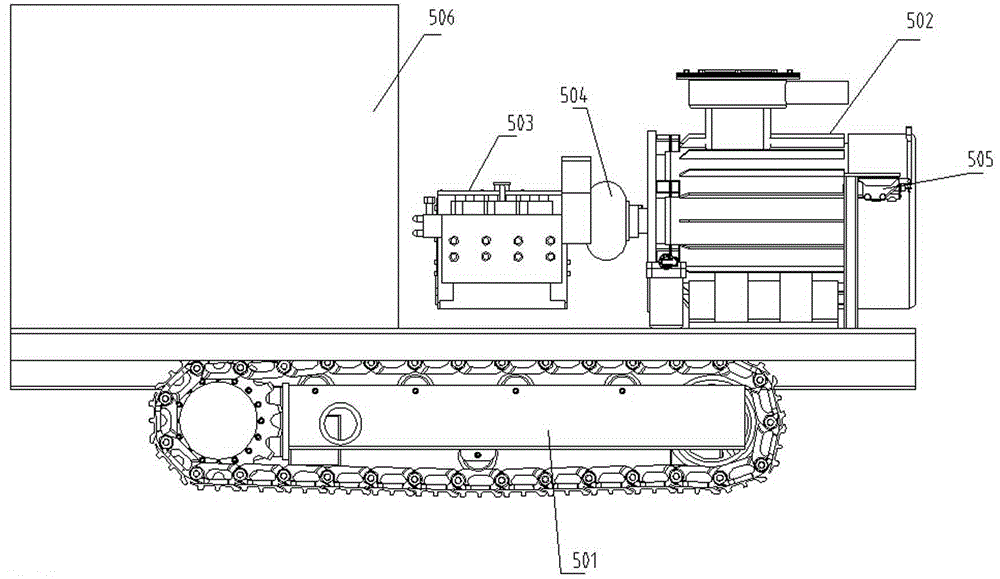

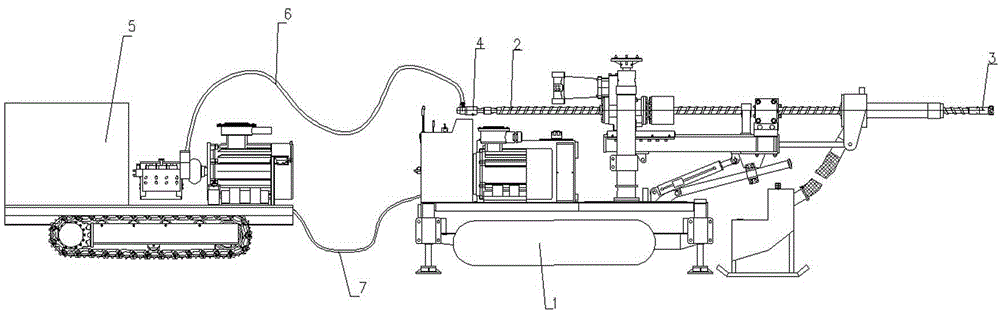

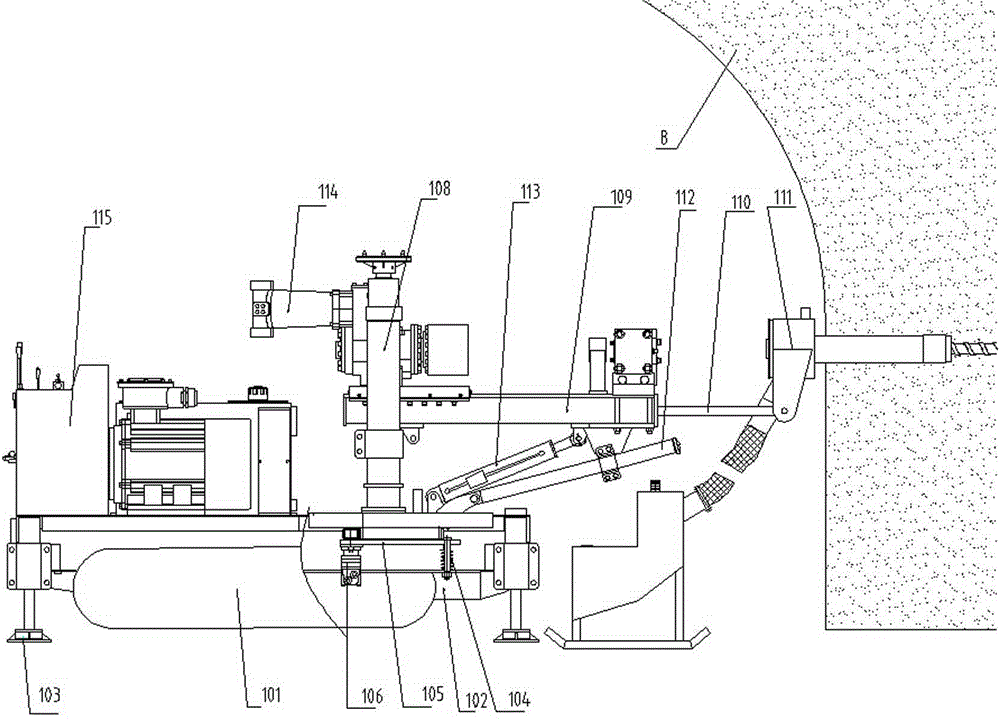

[0033] Such as figure 1 As shown, a crawler-type drilling and punching integrated equipment for underground coal mines includes a crawler-type hydraulic drilling rig 1, a high-pressure-resistant sealed drill pipe 2, a dual-purpose drill bit 3 for drilling and punching, a high-pressure rotary joint 4, and a high-pressure water pump station 5, The rod body 201 of the high-pressure sealing drill pipe 2 passes through and is fixed in the inner hole of the power head 114 of the crawler hydraulic drilling rig 1, and the power head 114 provides the high-pressure sealing drill pipe 2 with rotational speed and torque, and the high-pressure sealing One end of the drill pipe 2 is connected to the dual-purpose drill bit 3 for drilling and punching, and the other end is connected to the high-pressure water pump station 5 through the high-pressure rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com