Patents

Literature

446results about How to "Improve punching effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

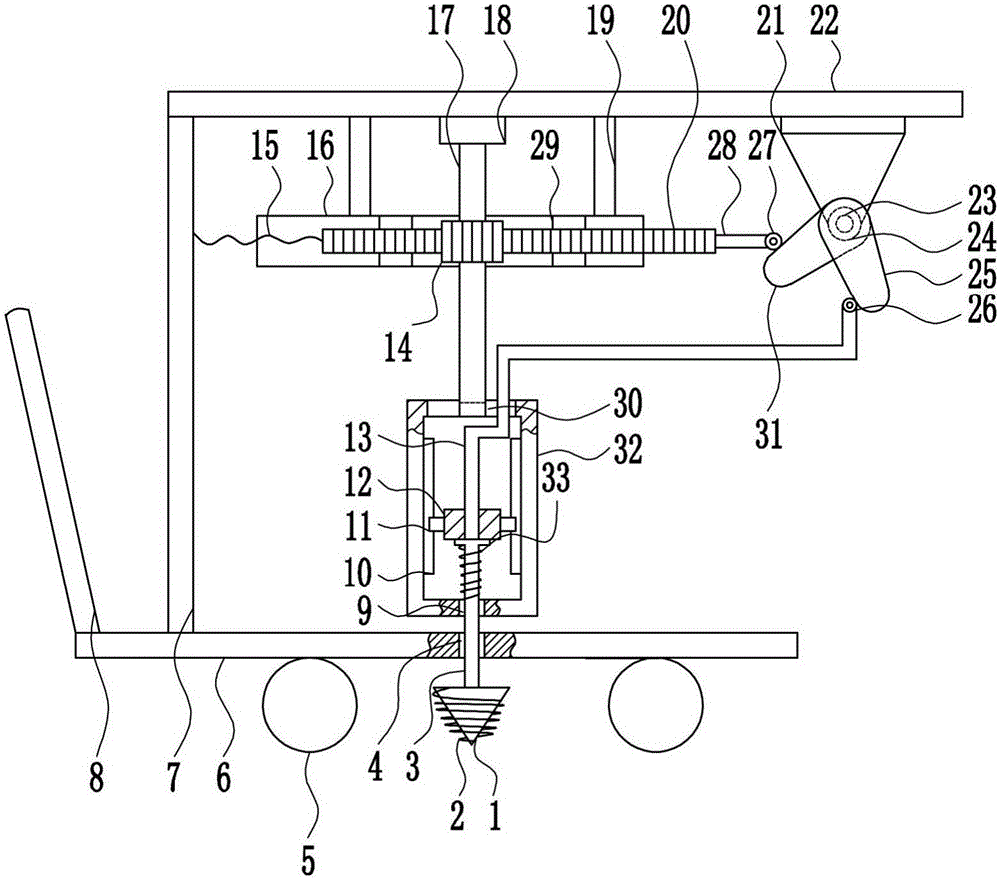

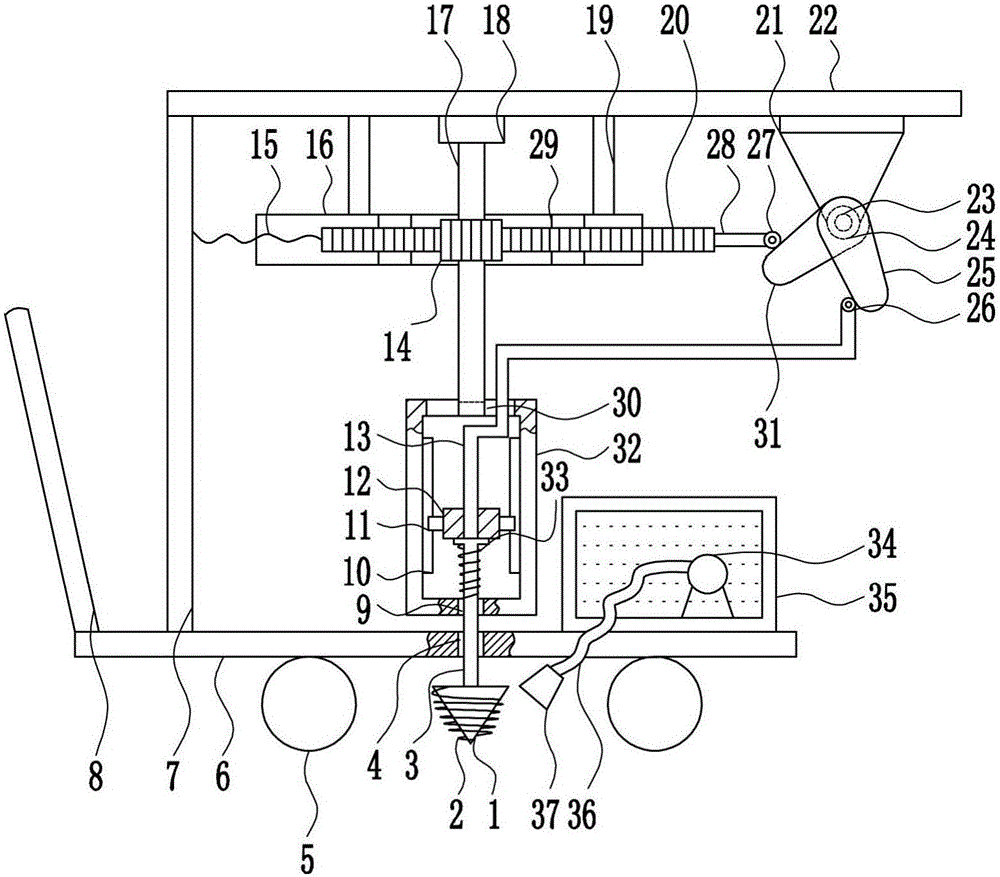

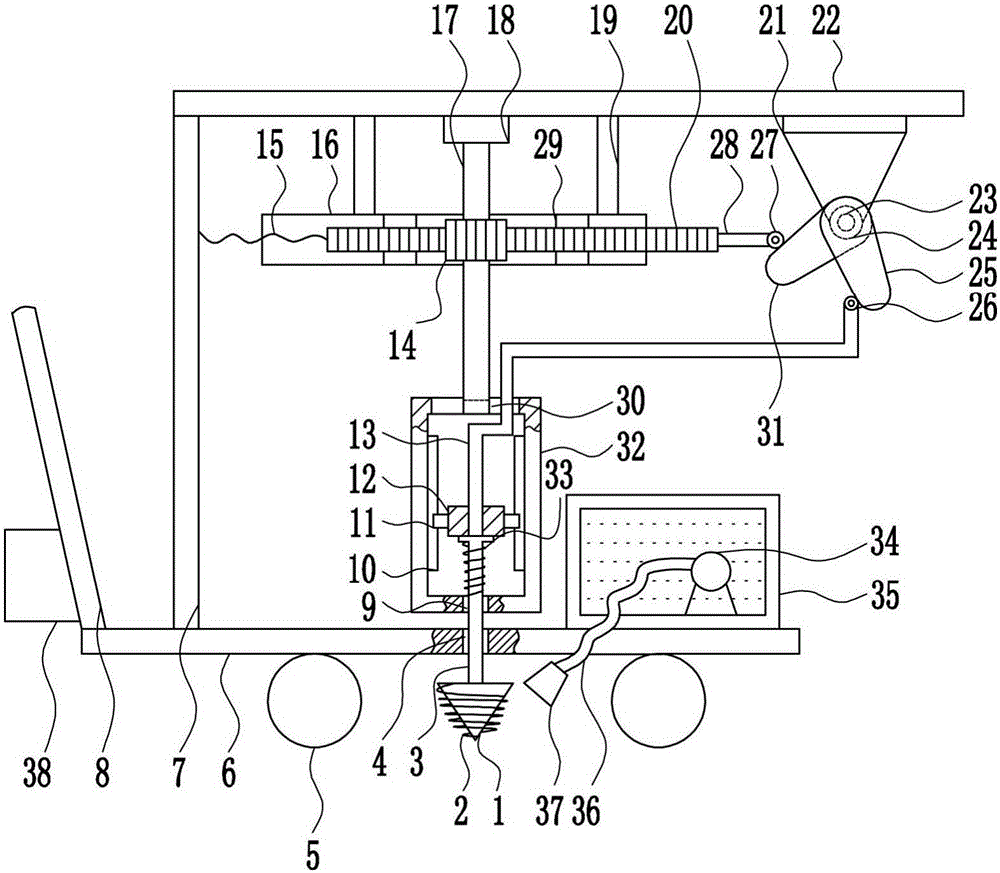

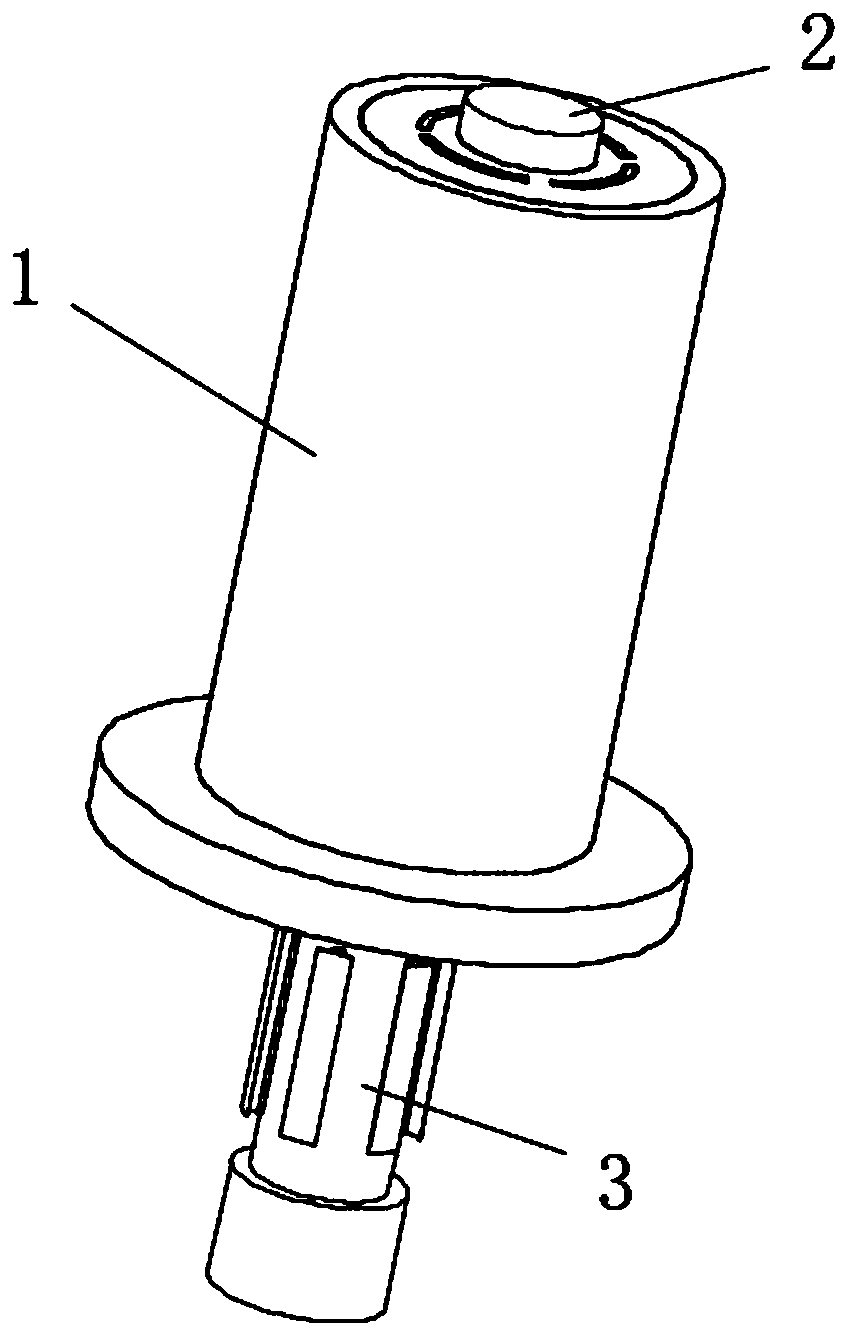

Soil drilling device for mounting string bamboo fence

InactiveCN106382094ANot easy to raiseEasy to punchConstructionsRotary drillingUltimate tensile strengthDrill bit

The invention relates to a soil drilling device and especially relates to the soil drilling device for mounting a string bamboo fence. The technical problem to be solved by the invention is to provide the soil drilling device for mounting the string bamboo fence, with low labor intensity, consistent drilling depth and novel structure. In order to solve the technical problem, the soil drilling device for mounting the string bamboo fence, provided by the invention, comprises a drilling bit, a screw rod, a first lifting rod, wheels, a base plate, a left frame, a pushing handle, a first slide rail, a first slide block, a first bearing base and a second lifting rod, wherein the wheels are symmetrically arranged at the bottom of the base plate; the pushing handle is welded at the left end at the top of the base plate; the left frame is welded on the left side at the top of the base plate; a first guide hole is formed in the right side of the base plate. The soil drilling device for mounting the string bamboo fence can achieve the effects of low labor intensity, consistent drilling depth and novel structure; the device plays an important role in achieving an excellent drilling effect and promoting the working efficiency; the safety is high.

Owner:防城港市宝兴工艺品有限公司

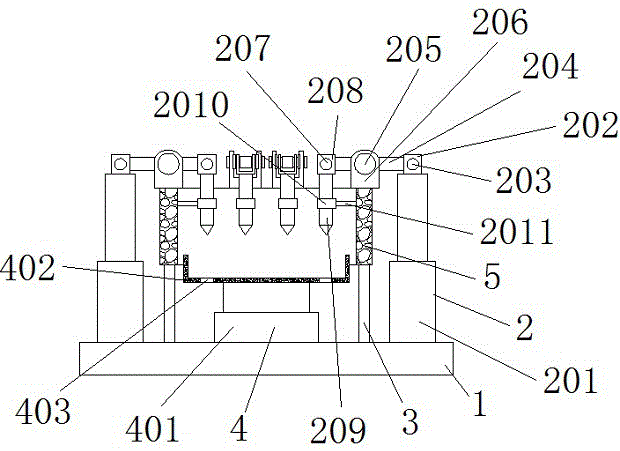

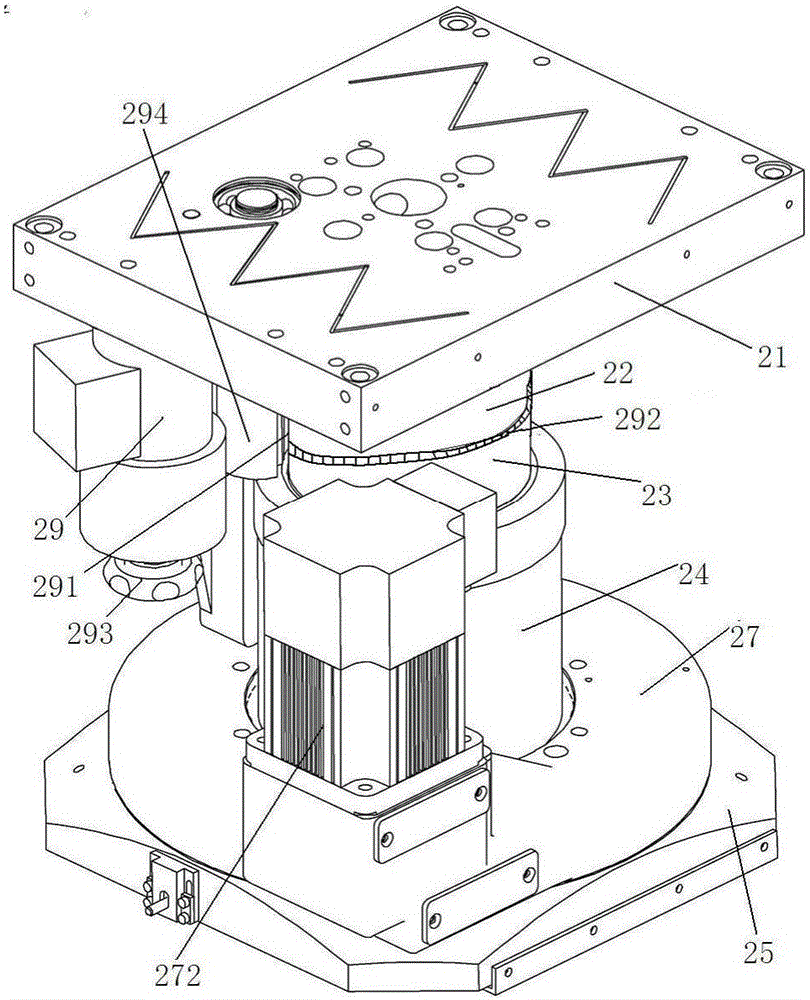

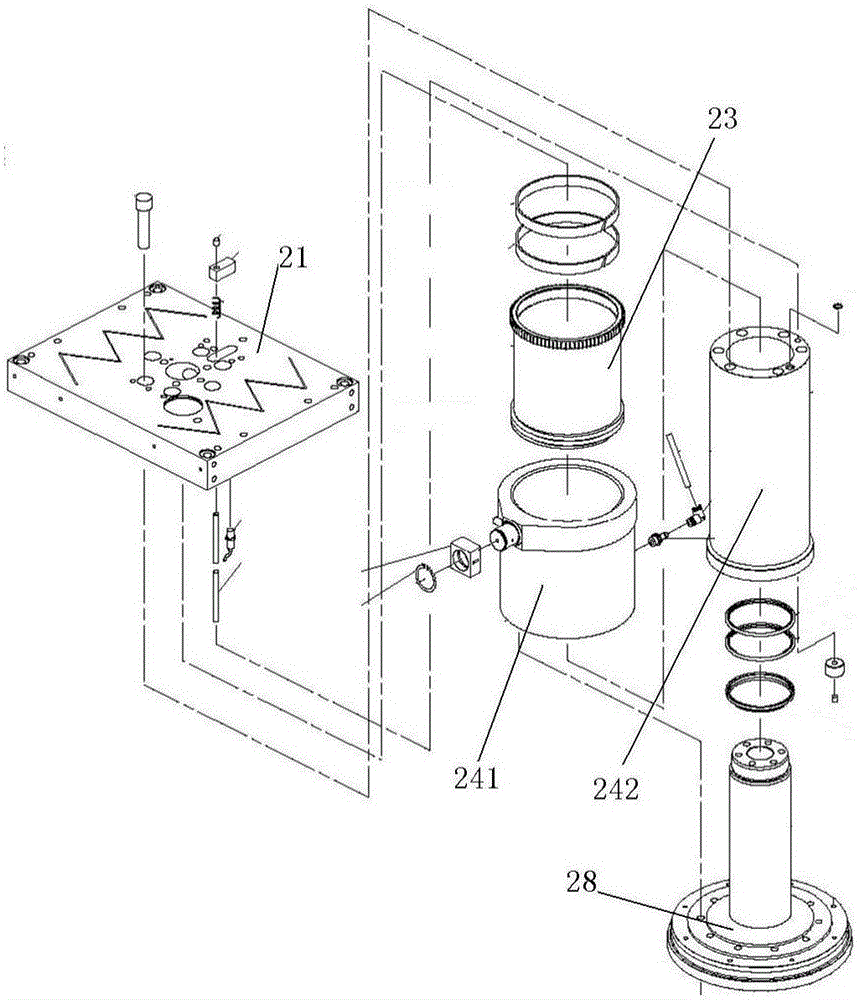

Automatic punching device for processing parts

InactiveCN109570548AHigh degree of automationImprove drilling accuracyFeeding apparatusPositioning apparatusAutomationThreaded rod

The invention discloses an automatic punching device for processing parts. The automatic punching device comprises a bottom plate, a bracket, a placing table, a bidirectional threaded rod and a transmission cavity; the right end of a working table is provided with a transmission cavity, a bevel gear D is arranged on the inner side of the transmission cavity, a rotating shaft of the bevel gear D penetrates through the transmission cavity to reach the upper end of the working table and to be fixedly connected with the lower end of the placing table, and the upper end of the placing table is provided with a fixing mechanism. The automatic punching device is novel in design, when a push plate moves downwards, a rack plate is driven by a connecting rod to move downwards, when the rack plate moves downwards, an annular gear on a third rotating rod drives ratchet teeth to rotate, the ratchet teeth cannot drive a second rotating rod to rotate under the effect of pawls, after punching is completed, a positive and negative rotation motor rotates reversely, at the time, the push plate moves upwards, rotation of the second rotating rod is achieved, the placing table is driven to be rotated under the effects of a bevel gear C and the bevel gear D, rotation of part plates is achieved, automatic transposition and punching are achieved, and the automation degree is high.

Owner:泰州市津专知识产权服务有限公司

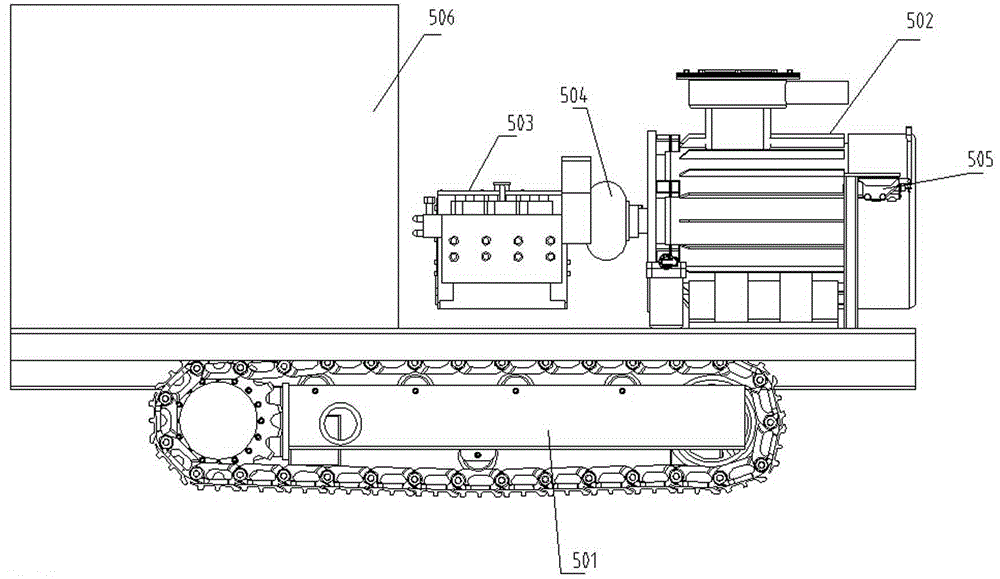

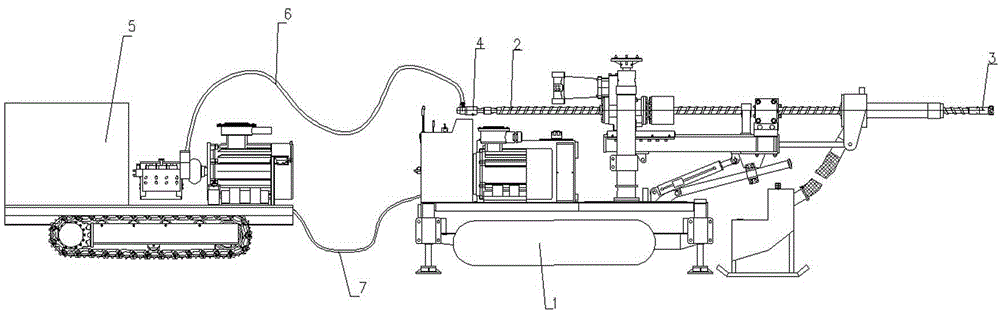

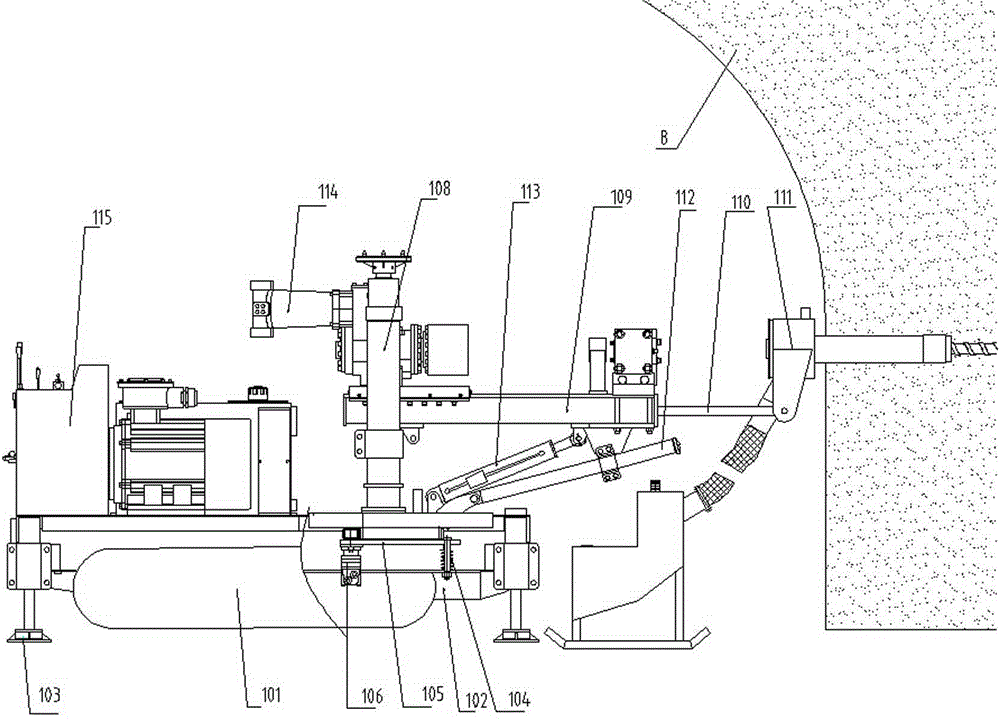

Coal mine downhole crawler type drilling and punching integrated equipment

ActiveCN104895484ASafe and efficient productionImprove extraction efficiencyConstructionsBorehole drivesPunchingDual purpose

Coal mine downhole crawler type drilling and punching integrated equipment comprises a crawler type hydraulic drilling machine, a high-pressure-resistant sealing drill stem, a drilling and punching dual-purpose drill bit, a high-pressure rotation connector and a high-pressure water pump station, wherein the body of the high-pressure-resistant sealing drill stem penetrates and is fixed in the power head inner hole of the crawler type hydraulic drilling machine, a power head provides rotation speed and torque to the body of the high-pressure-resistant sealing drill stem, one end of the high-pressure-resistant sealing drill stem is connected with the high-pressure water pump station through the high-pressure rotation connector, the high-pressure water pump station provides high-pressure water needed by punching, the other end of the high-pressure-resistant sealing drill stem is connected with the drilling and punching dual-purpose drill bit, and hydraulic operations can be performed after drilling without replacing the drill bit. The coal mine downhole crawler type drilling and punching integrated equipment has the advantages that streamlined operations of coal mine downhole gas pressure relief, drilling and punching can be completed by the equipment, safe and efficient production of outburst mines is guaranteed, coal seam coal and gas outburst danger is eliminated, a regional pre-drainage gas drilling construction period is shortened, coal seam drilling and punching and gas extraction efficiency are increased, and gas disaster prevention and control cost is reduced.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD +1

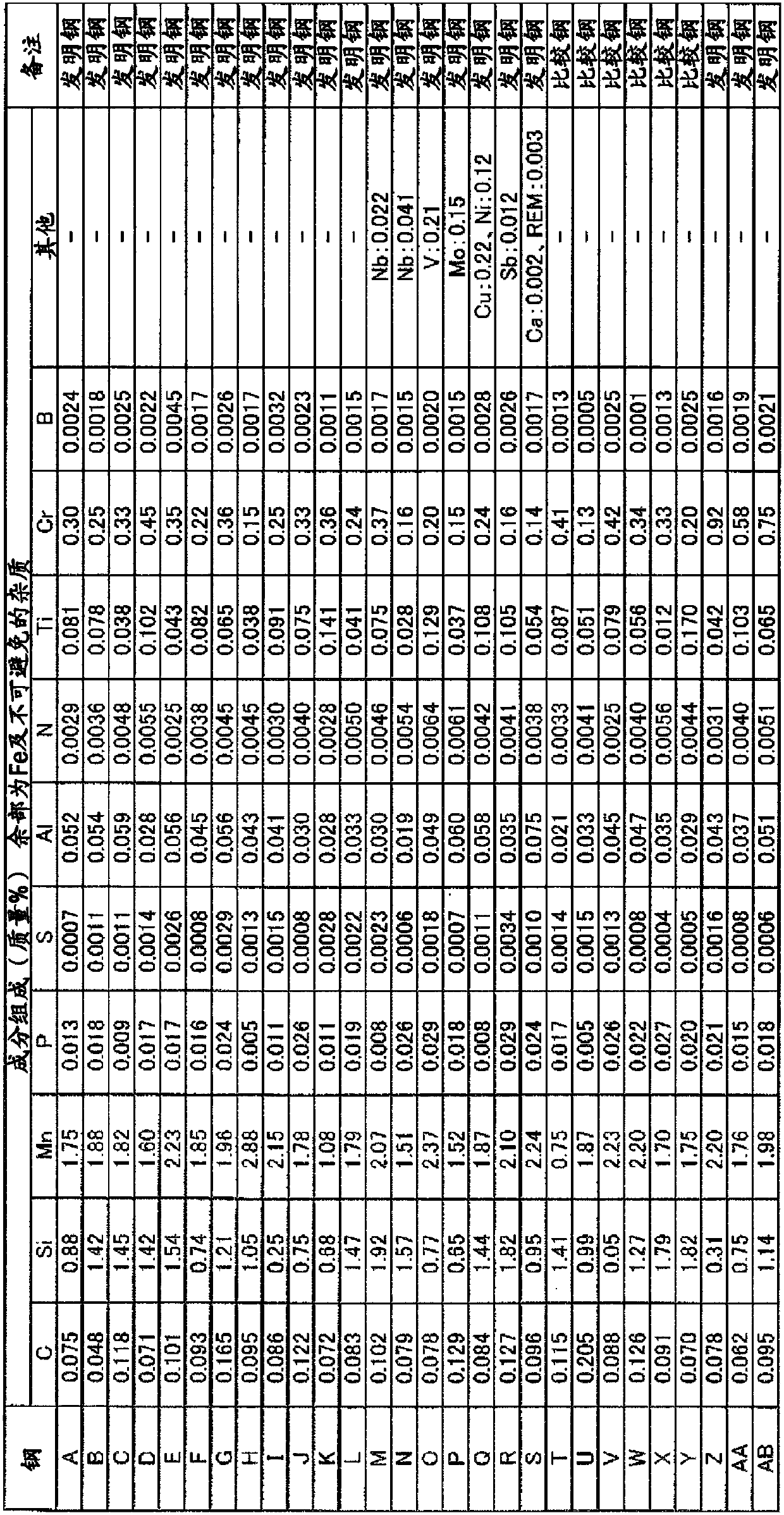

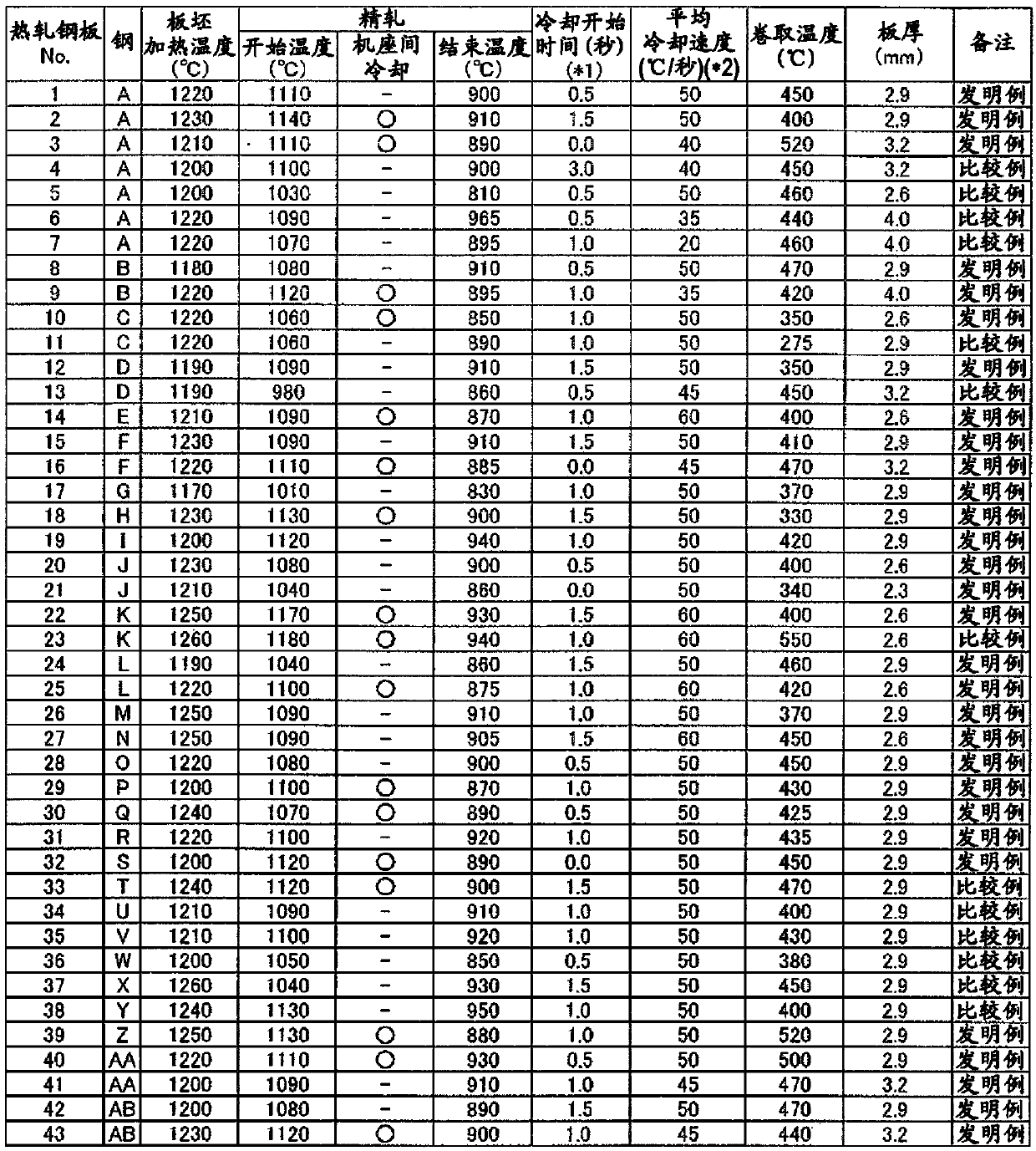

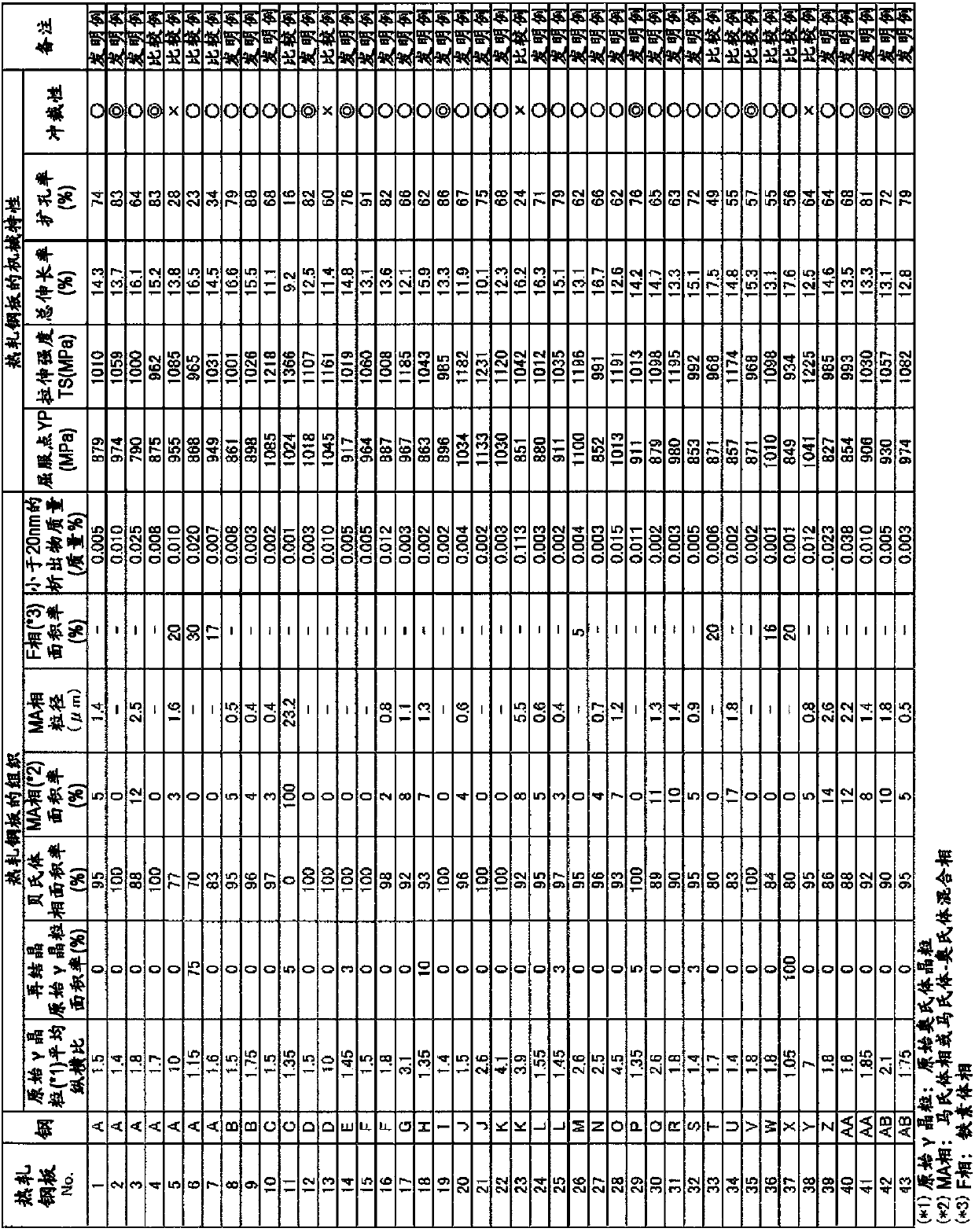

High strength hot rolled steel sheet and manufacturing method for same

InactiveCN107849663AImprove punching effectExcellent hole expandabilityFurnace typesHeat treatment furnacesAustenite grainSheet steel

Provided is a high strength hot rolled steel sheet having superior punchability and hole expandability and a tensile strength TS of at least 980 MPa and a manufacturing method for same. The high strength hot rolled steel sheet has a structure with specified amounts of C, Si, Mn, P, S, Al, N, Ti, Cr and B as a component composition and that comprises a main phase that is a bainite phase with an area ratio of at least 85%, a second phase that is a martensite phase or a martensite-austenite mixed phase with an area ratio of at most 15% and a ferrite phase that is the remainder, wherein the average grain size in the second phase is at most 3.0 [mu]m and furthermore, the average aspect ratio of the prior austenite grains is 1.3-5.0 and the area ratio of recrystallized prior austenite grains tounrecrystallized prior austenite grains is at most 15%, and wherein deposits under 20 nm in diameter are at most 0.10 mass%.

Owner:JFE STEEL CORP

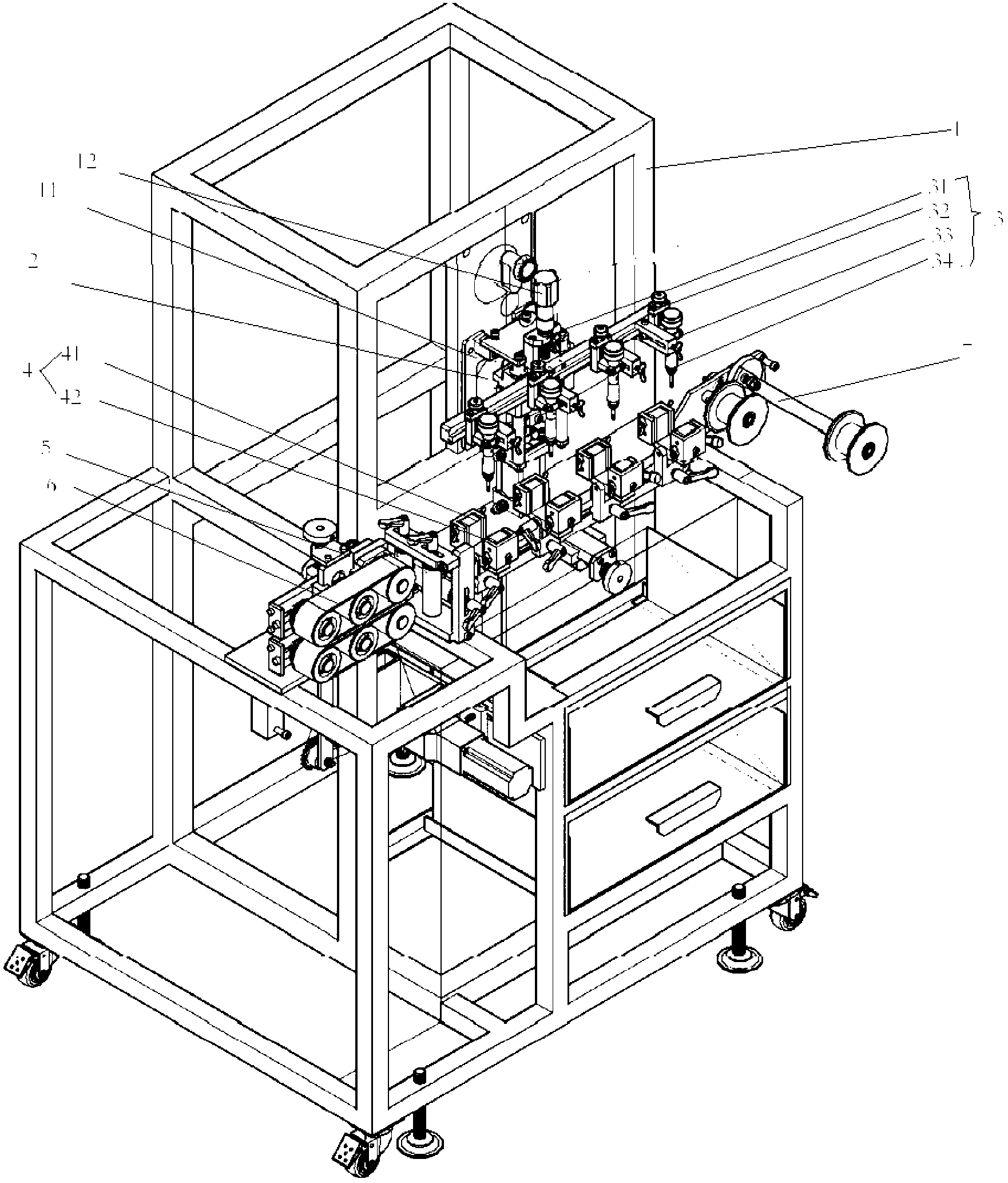

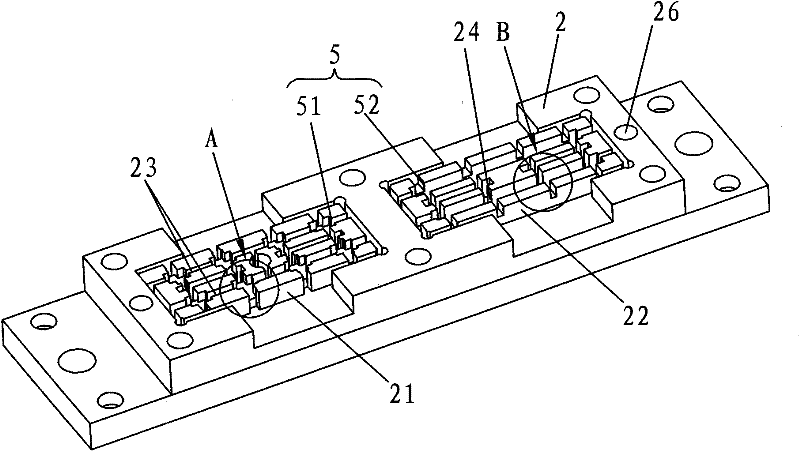

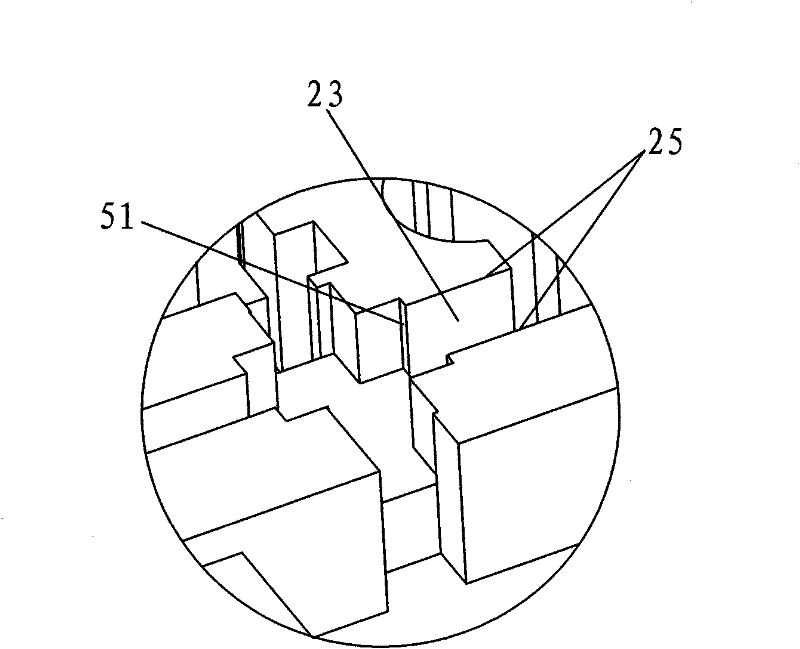

Online punching device for automobile sealing strip

ActiveCN103302700AEasy to fixThe punching position is accurateMetal working apparatusPunchingEngineering

The invention discloses an online punching device for an automobile sealing strip. The online punching device comprises a power unit, a fixing unit, a punching unit and a support, wherein the punching unit is driven by the power unit to move up and down and punches the automobile sealing strip fixed on the fixing unit; the support fixes the power unit, the fixing unit and the punching unit. According to the online punching device for the automobile sealing strip, and the automobile sealing strip can be well fixed through the fixing unit and can be prevented from sliding in the punching process, so that the punching position where the punching device punches the automobile sealing strip can be guaranteed to be accurate, and the punching effect is good.

Owner:SHANGHAI HONGYANG SEALING PROD

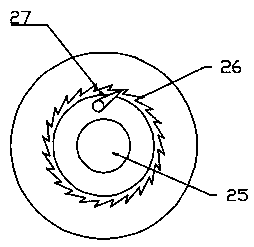

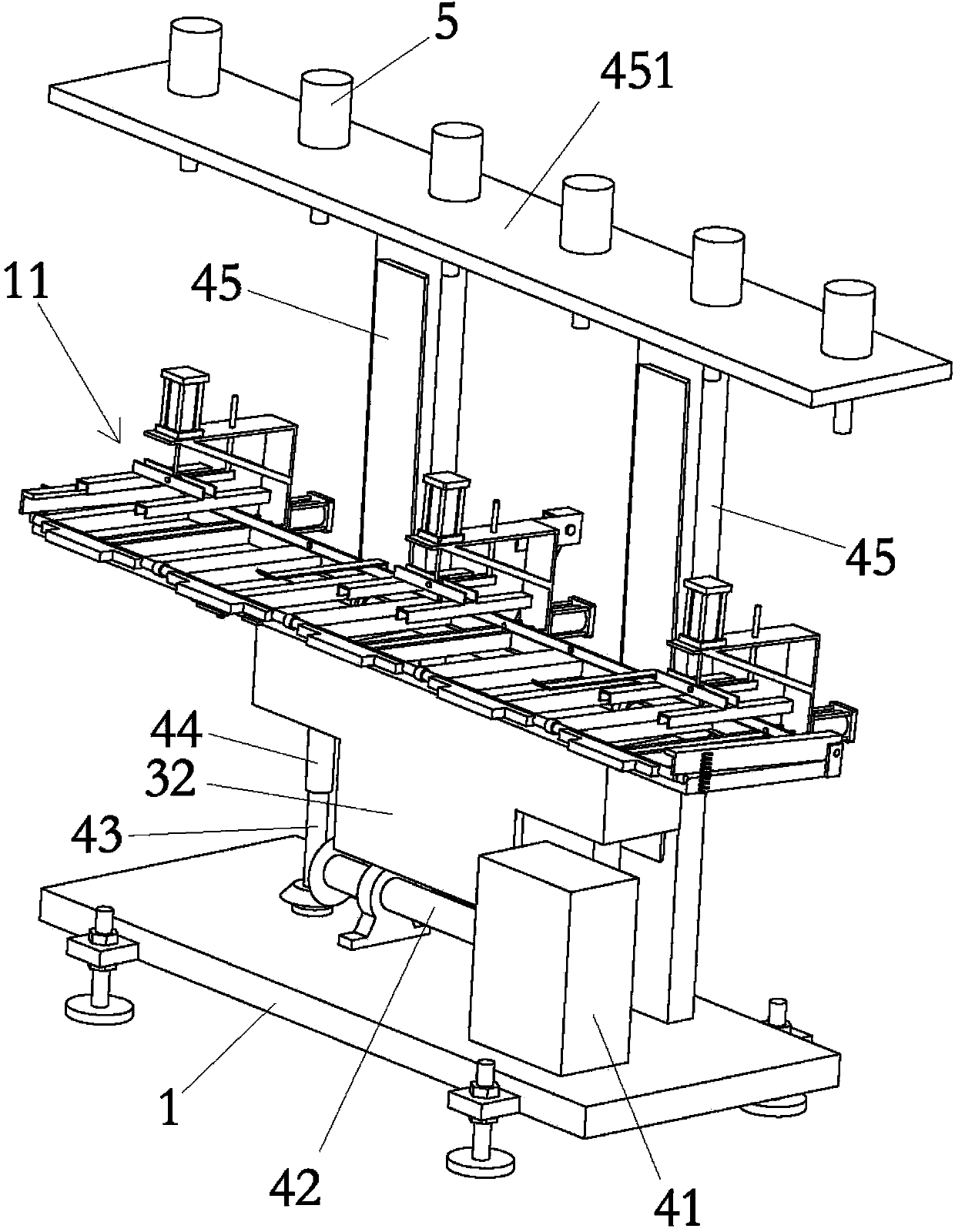

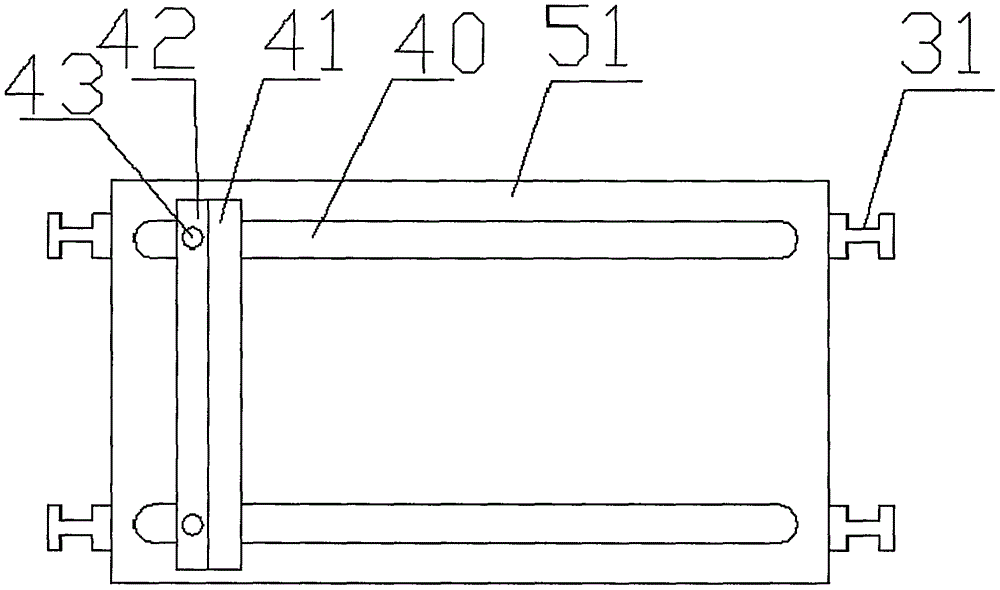

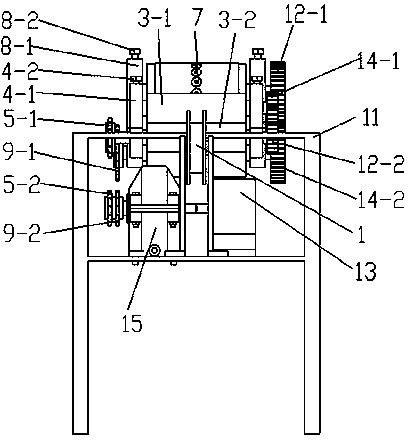

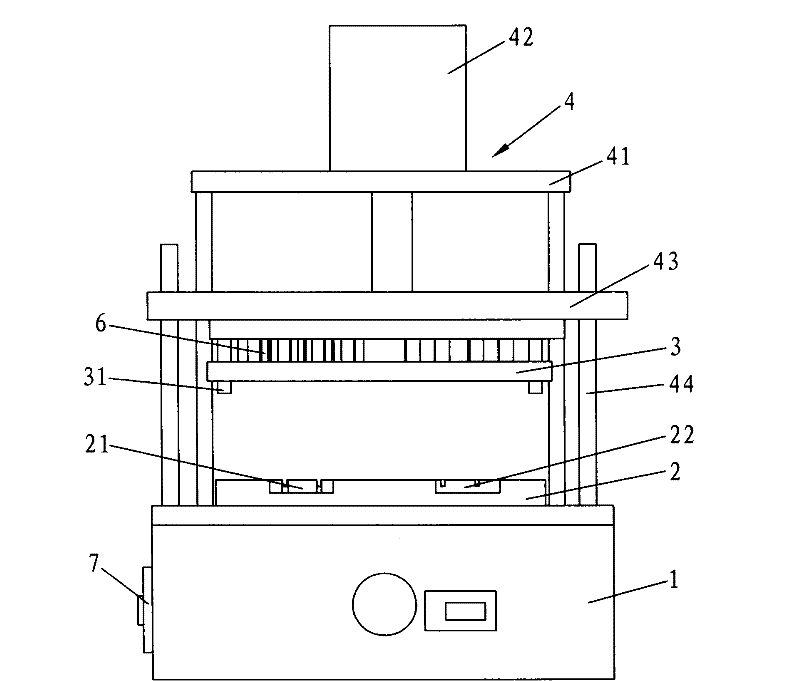

Bamboo perforating machine

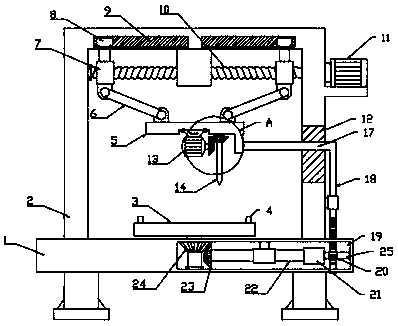

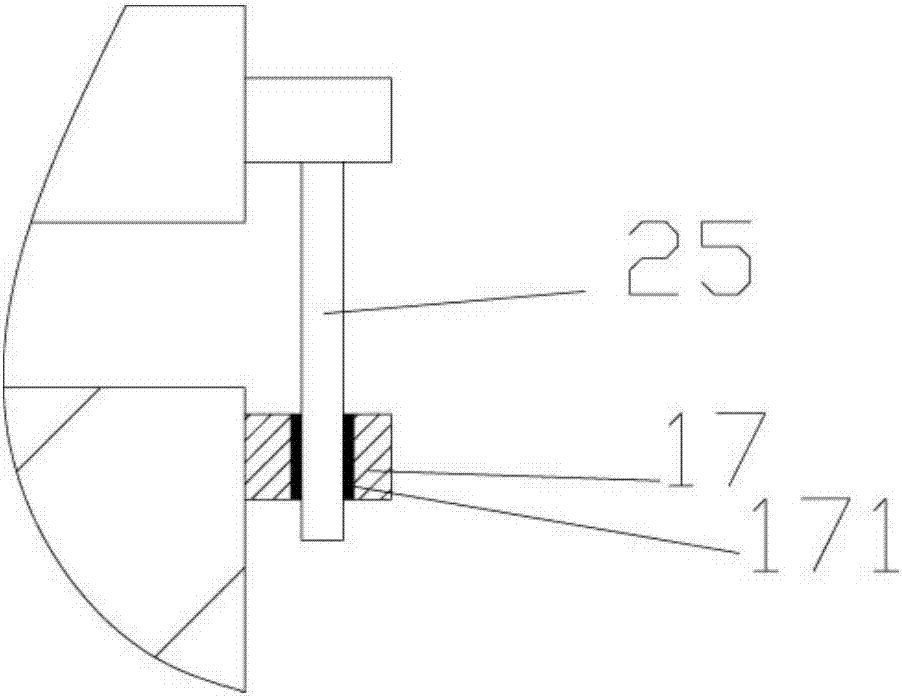

InactiveCN104175368AConducive to precise drillingSimple structureStationary drilling machinesRelative displacementEngineering

The invention relates to bamboo processing machinery and in particular relates to a bamboo perforating machine. According to the technical scheme, the bamboo perforating machine comprises a perforating component and a material clamping component which can generate relative displacement, wherein the material clamping component comprises a mounting rack, a horizontal clamping mechanism and a longitudinal clamping mechanism; the mounting rack is provided with a feeding side and a material pressing side, and the horizontal clamping mechanism and the longitudinal clamping mechanism are arranged on the mounting rack; the horizontal clamping mechanism comprises a rotating piece, a side pressing piece and a horizontal driving device; the rotating piece is rotatably connected to the feeding side; the side pressing piece is positioned on the material pressing side and can generate the relative displacement with the rotating piece in a turnup state so as to clamp or loosen materials in the horizontal direction; the horizontal driving device is used for driving the side pressing piece to be displaced; the longitudinal clamping mechanism comprises a longitudinal pressing piece and a longitudinal driving device; the longitudinal pressing piece can generate the longitudinal displacement so as to be matched with the mounting rack to clamp or loosen the materials in the longitudinal direction; the longitudinal driving device is used for driving the longitudinal pressing piece to be displaced. The bamboo perforating machine has a good positioning function on the materials and can realize a good automatic perforating effect.

Owner:周文

Efficient wood board perforating device

The invention discloses an efficient wood board perforating device. The efficient wood board perforating device comprises a bottom plate, a bracket, a storage table, a bidirectional threaded rod and atransmission cavity; the right end of a workbench is provided with the transmission cavity, the inner side of the transmission cavity is provided with a bevel gear D, and a rotary shaft of the bevelgear D penetrates through the transmission cavity to the upper end of the workbench and is fixedly connected with the lower end of the storage table; the right end of the bevel gear D is engaged witha bevel gear C, and the bevel gear C is fixedly connected with the outer side of a ratchet mechanism through a second rotary rod; the ratchet mechanism is composed of ratchets and a pawl; a drill bitis rotationally connected to the lower end of a push plate and fixedly provided with a bevel gear A; and the right end of the bevel gear A is engaged with a bevel gear B, and the bevel gear B is fixedly connected with a first rotary rod. According to the efficient wood board perforating device, the design is novel, continuous perforating can be achieved, the perforating efficiency is improved, theautomation degree is high, the labor intensity of operators is relieved, meanwhile, the precision of the interval of perforated holes is improved, and the perforating effect is good.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

Aluminum alloy substrate for high-cap bottle cap and production method thereof

The invention discloses an aluminum alloy substrate for a high-cap bottle cap. The aluminum alloy substrate comprises, by weight, 0.4 percent to 0.8 percent of Si, 0.6 percent to 0.9 percent of Fe, 0.02 percent to 0.04 percent of Cu, no larger than 0.1 percent of Mn, no larger than 0.05 percent of Mg, no larger than 0.1 percent of Zn, no larger than 0.05 percent of Cr, 0.01 percent to 0.03 percent of Ti, no larger than 0.15 percent of impurities and the balance Al. The invention further discloses a production method of the aluminum alloy substrate for the high-cap bottle cap. The production procedure comprises batching, casting, homogenization treatment, hot continuous rolling, cold rolling, heat treatment, cold rolling, stretching bending and straightening and cropping. In the procedure of homogenization treatment, the temperature of homogenization treatment is 550 DEG C to 600 DEGC, and heat preservation time is 6 h to 10 h; in the procedure of cold rolling, cold rolling is carried out on blanks obtained through the hot continuous rolling procedure till the blanks are 0.4 mm to 0.5 mm, then heat treatment is carried out, the temperature of heat treatment ranges from 300 DEG C to 330 DEG C, heat preservation time ranges from 5 h to 9 h, and discharging cooling is carried out. Finally, cold rolling is carried out the blanks till the designed thickness is achieved.

Owner:CHINALCO SWA COLD ROLLING

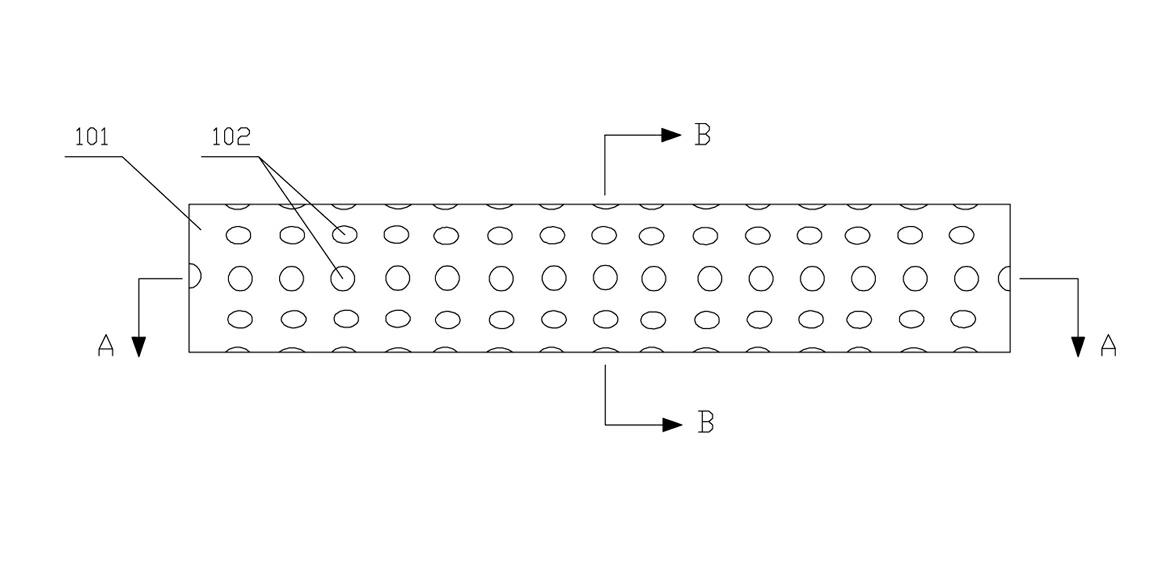

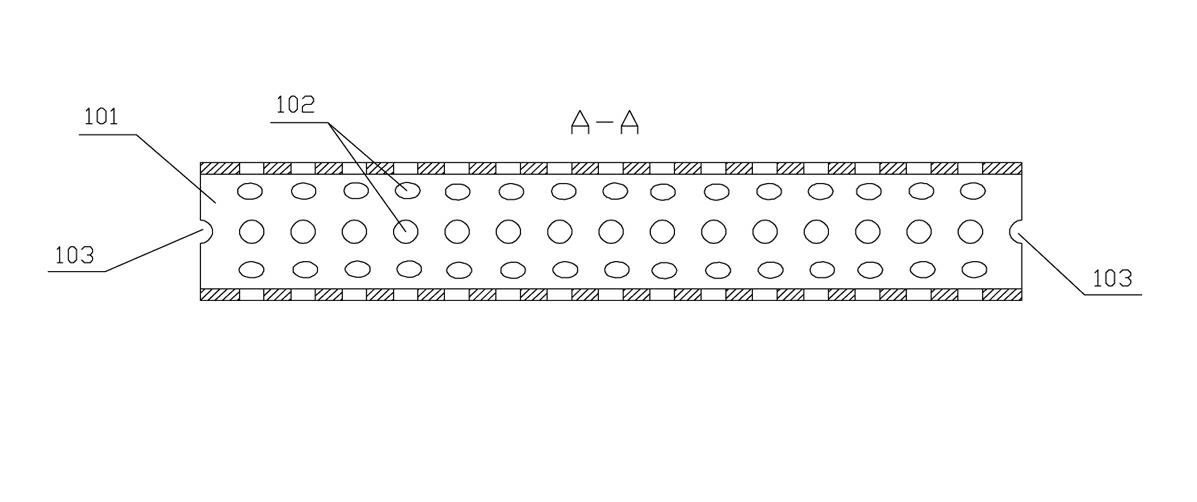

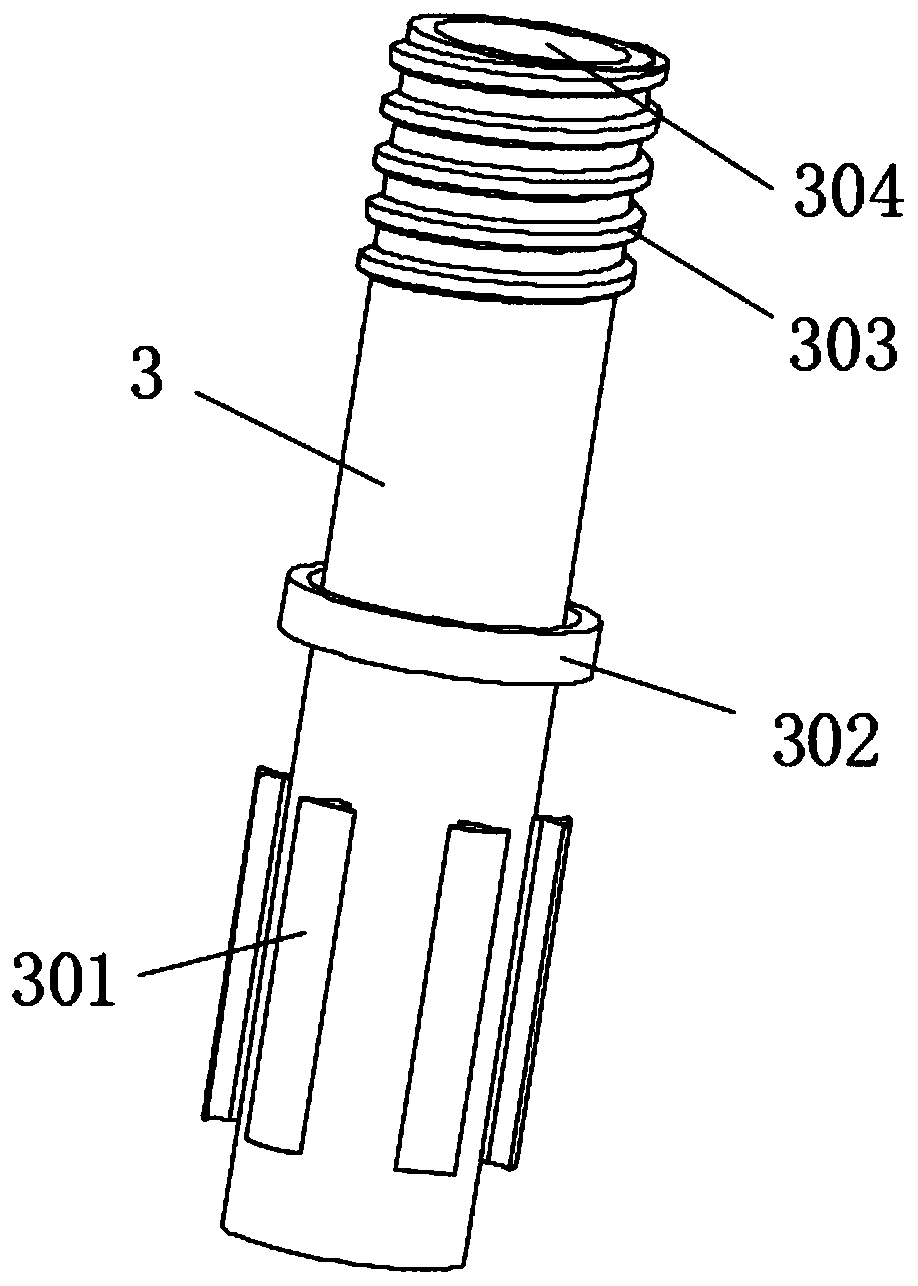

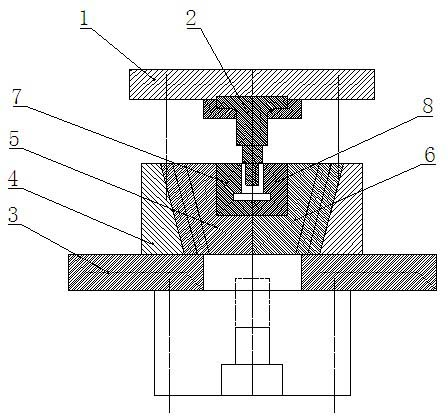

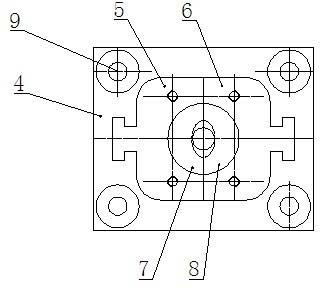

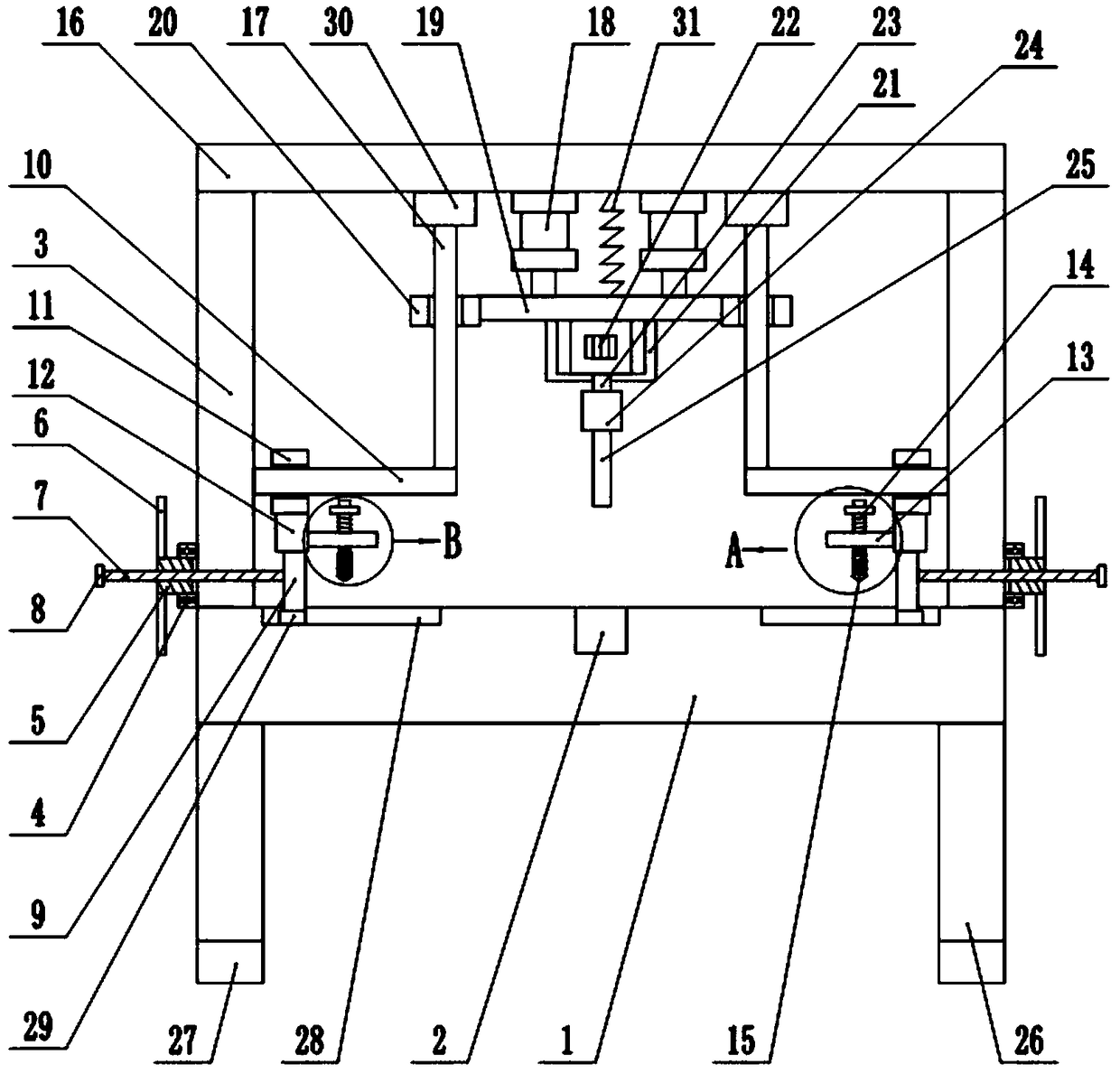

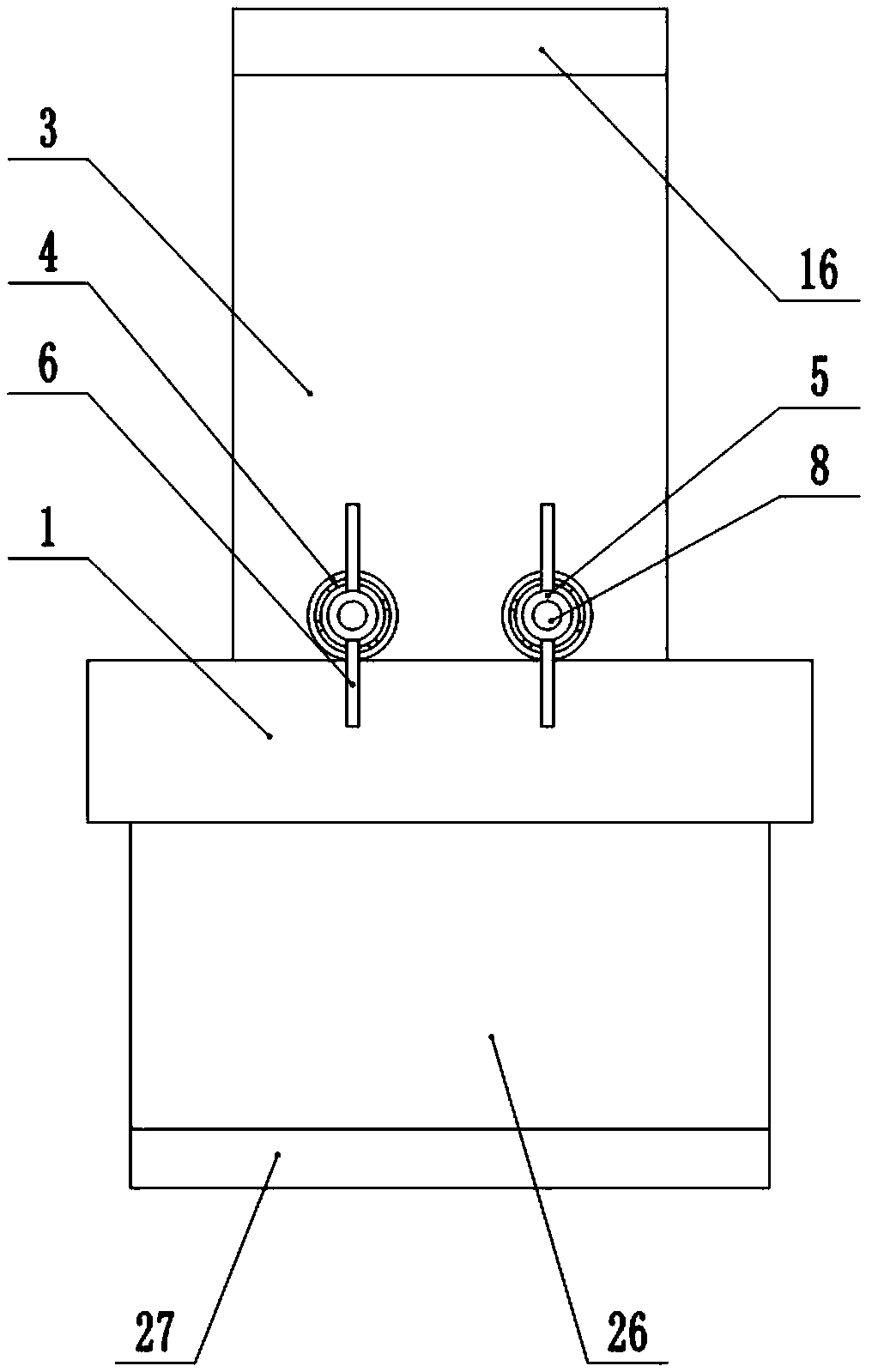

Punching die for drainage holes of stainless steel tubes

InactiveCN102615173AImprove work efficiencyImprove production accuracyShaping toolsPerforating toolsPunchingEngineering

The invention relates to a punching die for drainage holes of stainless steel tubes, which is characterized by comprising an upper die and a lower die. The upper die comprises a die handle (201), an upper die plate (202), a cushion plate (203), a fixed plate (207) and a plurality of abreast punching heads (205). The lower die comprises a product location device (301), a left location plate (320), a right location plate (303), a lower fixing plate (317) and a bottom plate (316), wherein the lower fixing plate (317) is arranged at the upper end face of the bottom plate (316), the left location plate (320) is positioned on the left side of the lower fixing plate (317), the right location plate (303) is installed on the right side of the lower fixing plate (317), the product location device (301) is arranged on the left side of the left location plate (320), and stainless steel tube insertion holes are arranged on the right location plate (303). The punching die for drainage holes of stainless steel tubes is small in manual operation and high in production efficiency.

Owner:宁海县雁苍山电力建设有限公司 +4

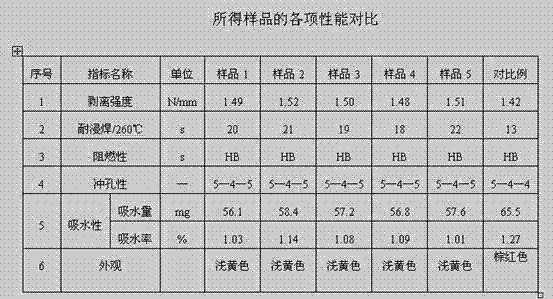

Cashew phenol modified phenolic resin and method for manufacturing paper-based laminated board

ActiveCN101096405ALow water absorptionImprove punching effectReinforcing agents additionMetal layered productsCopper foilSolvent

The invention relates to a cashew phenol modified formaldehyde-phenol resin and a method for manufacturing paper basal layer clamping plate with the resin in the roofing copper production method technique field. The material of the cashew phenol modified linear formaldehyde-phenol resin is cashew phenol, phenol, formaldehyde, basic catalyst and the solvent. The method comprises the following steps: (1)proceeding with the reaction of cashew phenol, phenol, formaldehyde for 1-2 hours at 80-90Deg. C in the basic catalyst function; controlling the gel time at 100-160 s / 160+-5Deg. C; reducing the pressure and dewatering; acquiring the cashew phenol modified formaldehyde-phenol resin; (2)getting 50-52% solid content cashew phenol modified formaldehyde-phenol resin by diluting with the solvent; (3)dipping the wood-pulp paper with the diluted modified formaldehyde-phenol resin; forming the semi-solid sheet by gluing and drying; formulating a gluing copper foil and a plurality of semi-solid sheets together; heating; increasing the pressure; manufacturing the paper basal roofing copper. The paper basal roofing copper is provided with low water absorption ratio, the low punching property and the good drilling hole processability; and the high-density wiring board is provided with the high soldering resistance, which is fit for leadless reflow soldering.

Owner:SHANDONG JINBAO ELECTRONICS

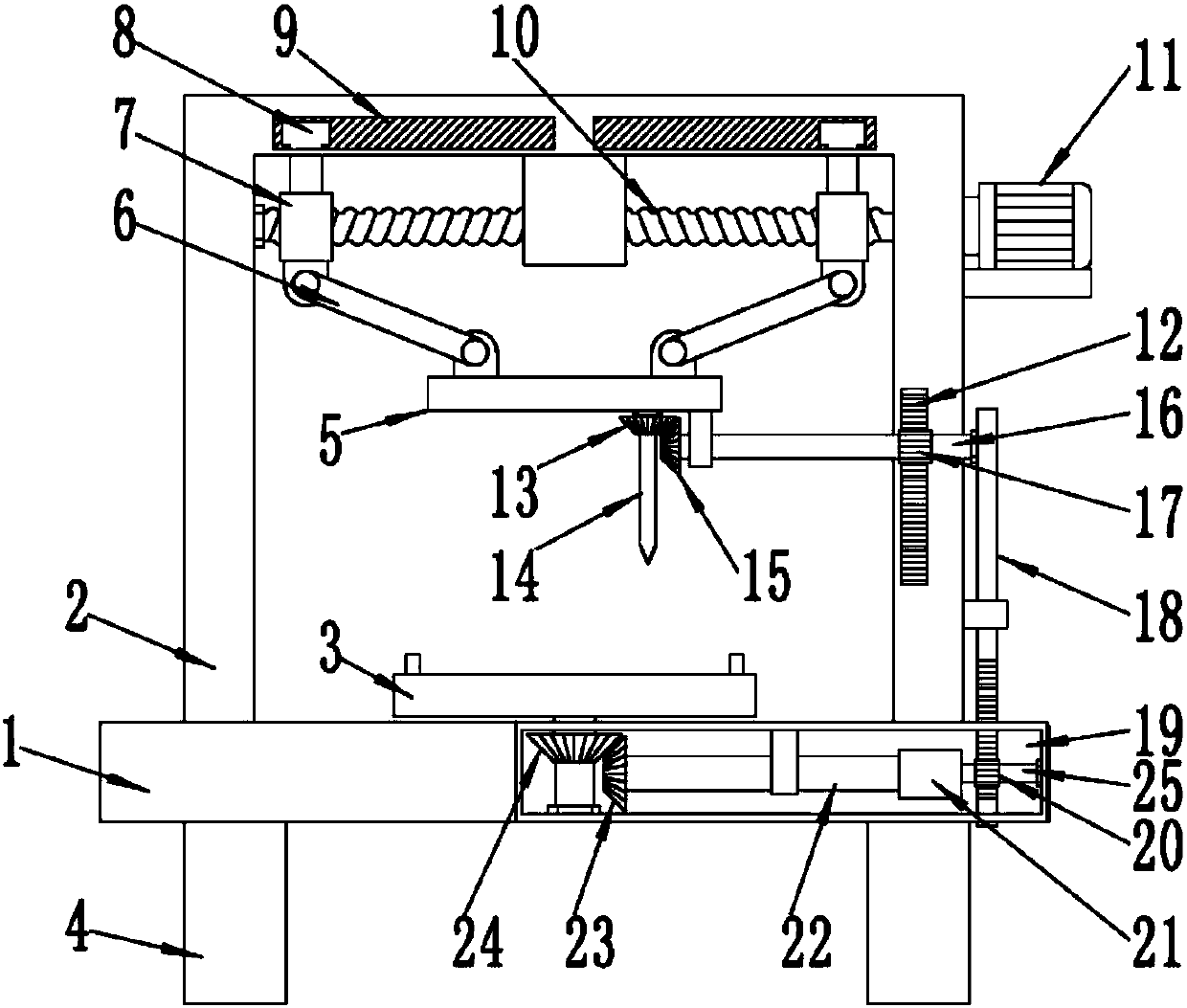

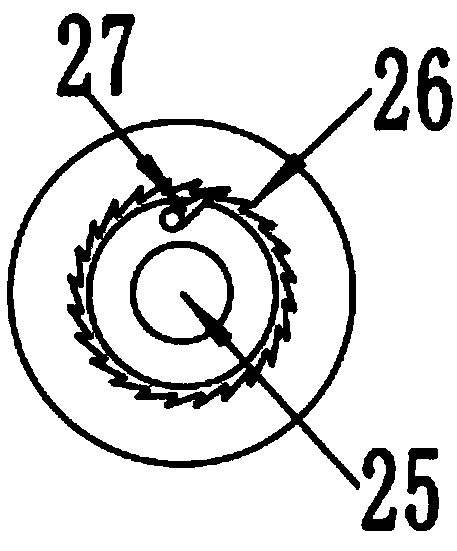

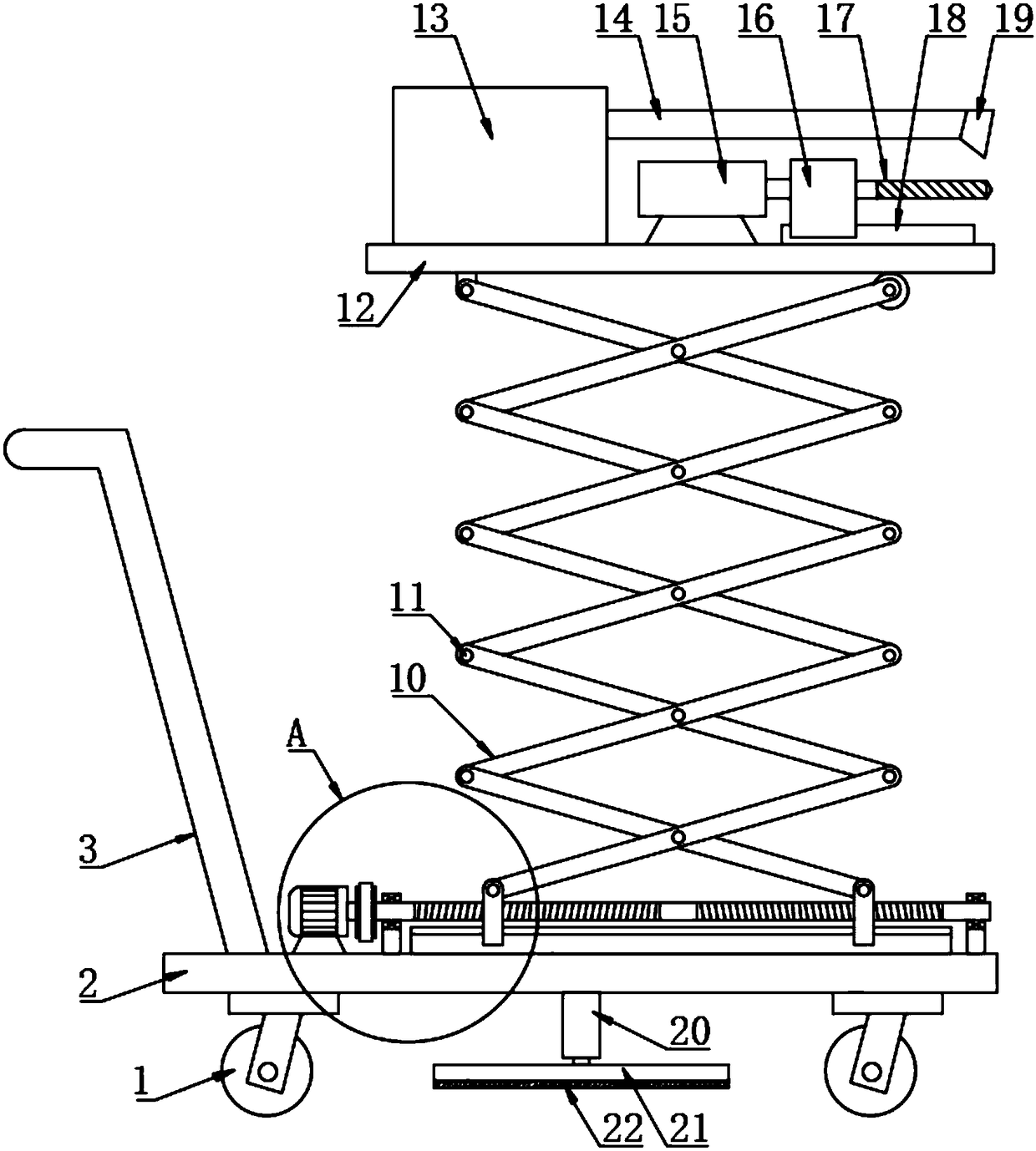

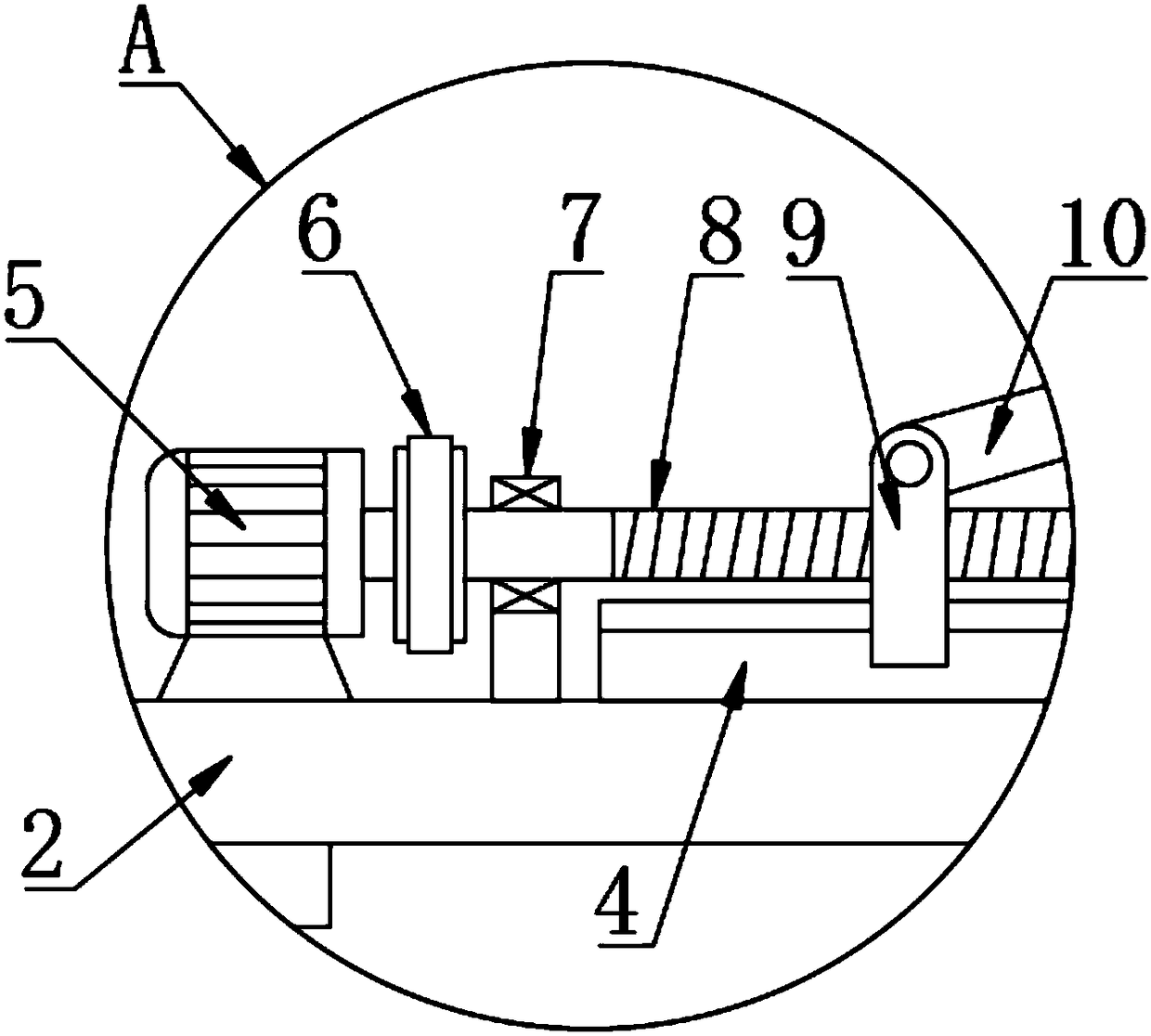

Stable scissor lifting wall surface punching device

InactiveCN108127798AAvoid the hassle of climbingAvoid dangerWorking accessoriesStone-like material working toolsPunchingEngineering

The invention discloses a stable scissor lifting wall surface punching device. The device comprises a base, the top of the base is provided with two front and rear slide rails, each of the slide railsis slidably connected with two left and right movable seats, supporting rods are hinged above the movable seats, the left and right supporting rods are cross-arranged, and the middles of the left andright supporting rods are hinged;a plurality of pairs of supporting rods are provided, the bottom ends of the upper supporting rodsare hinged to the top ends of the lower supporting rodsthrough connecting rods,the front supporting rods and the rear supporting rodsare connected through the connecting rod, andtop platesare arranged above the supporting rods; the top of the base is also fixedly provided with a gear motor, and a motor shaft at the right end of the gear motor is connected with the left end of a front side screw rod; the top of the top plate is fixedly provided with an electric push rod,the right end of the electric push rod is fixedly connected with an electric drill, and a drill bit is connected to the right side of the drill. According to the device, punching heights are adjusted by a scissor lifting mechanism,the punching heights can be achieved by controlling the forward and reverse rotation of the gear motor, the control is simple, andtrouble and danger caused by climbing of a person with the electric drill in hands are avoided.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

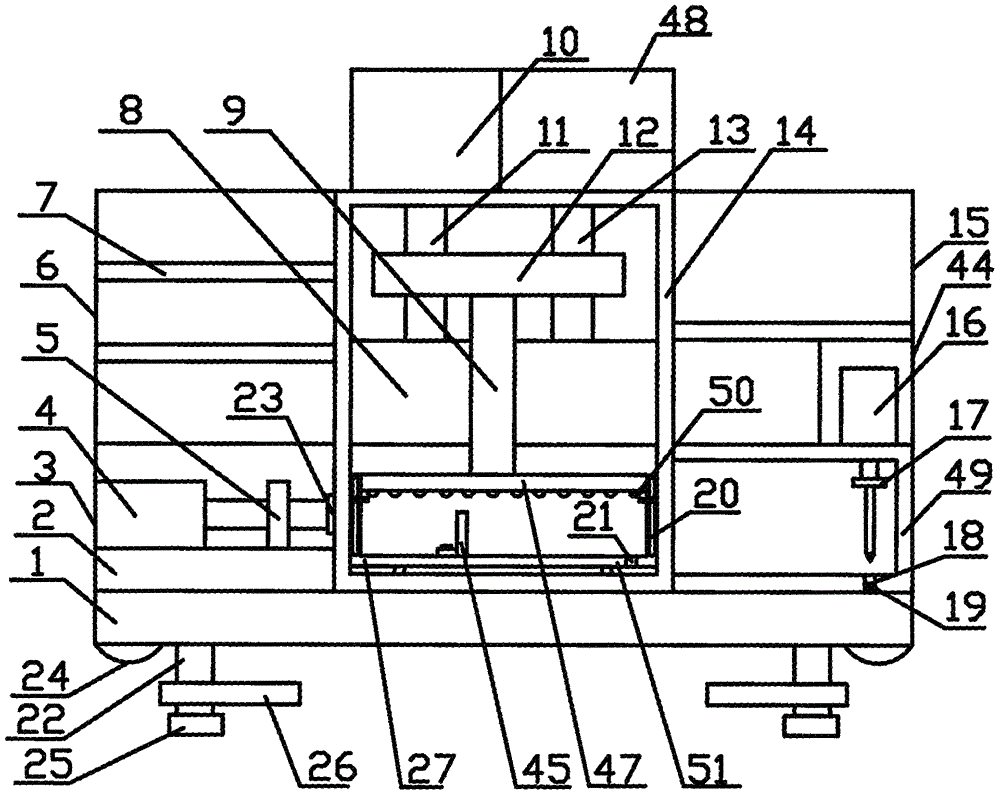

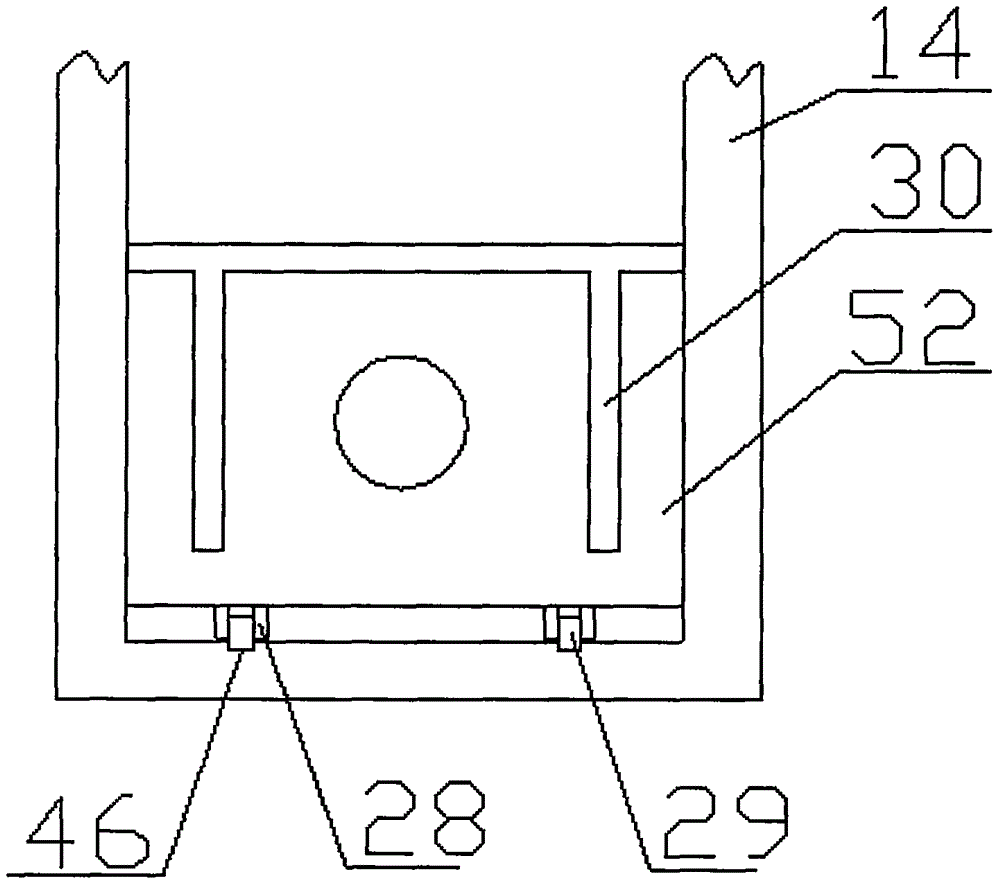

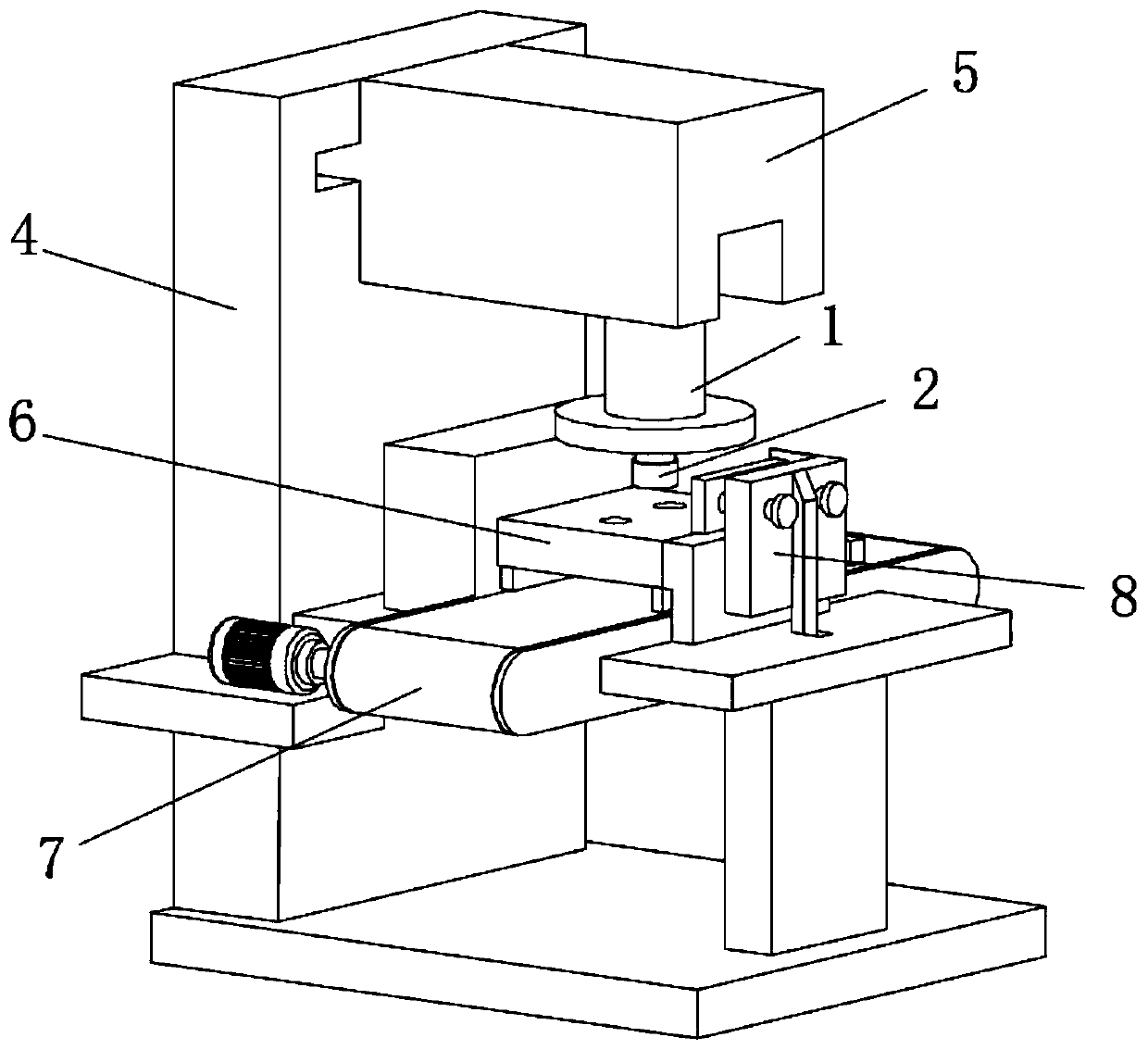

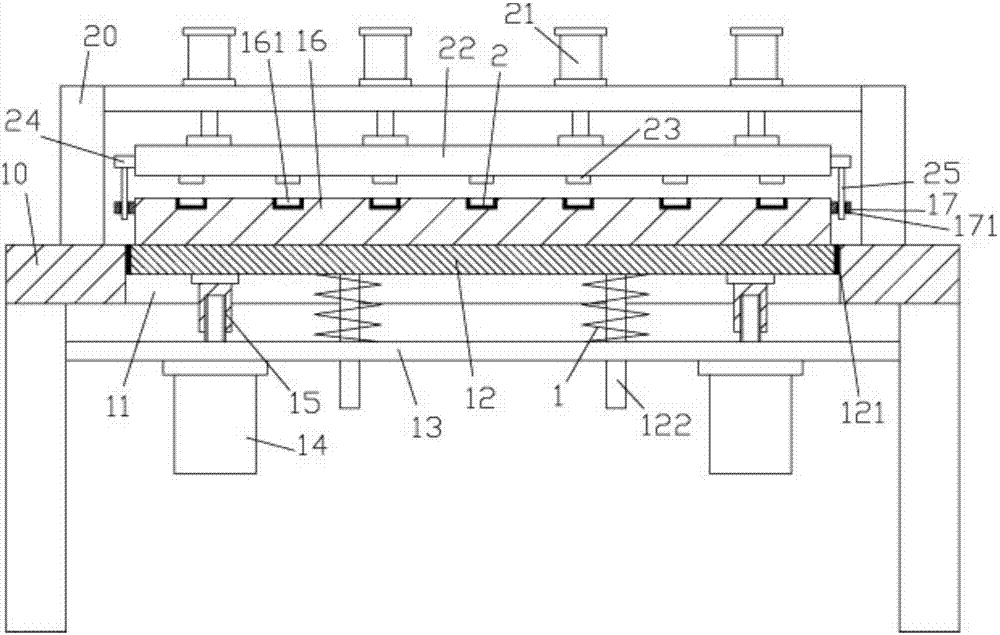

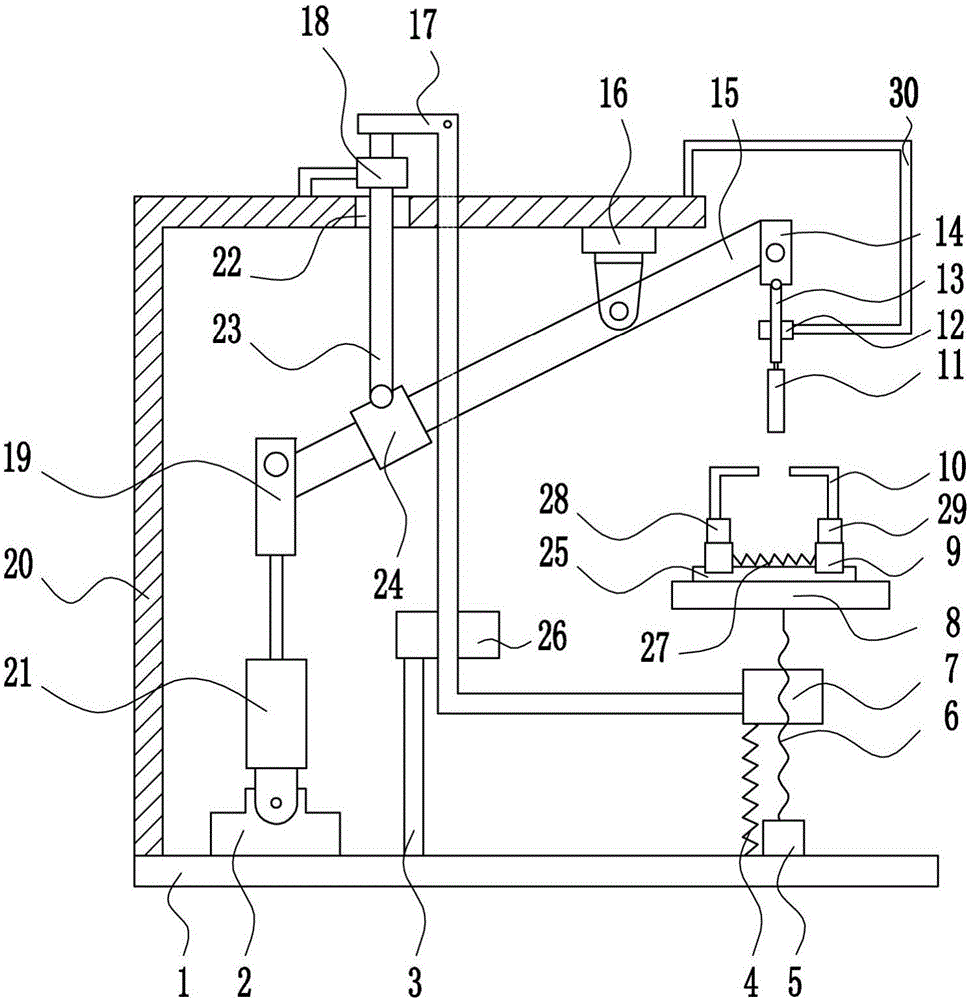

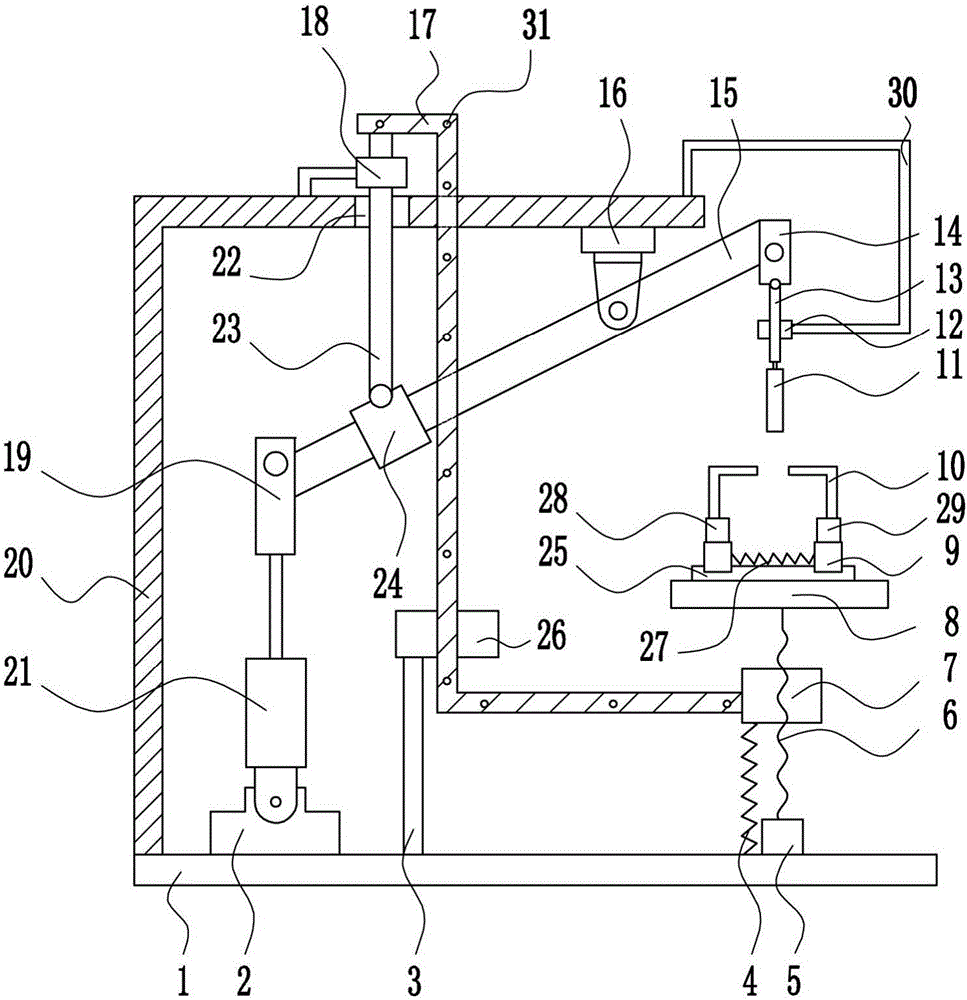

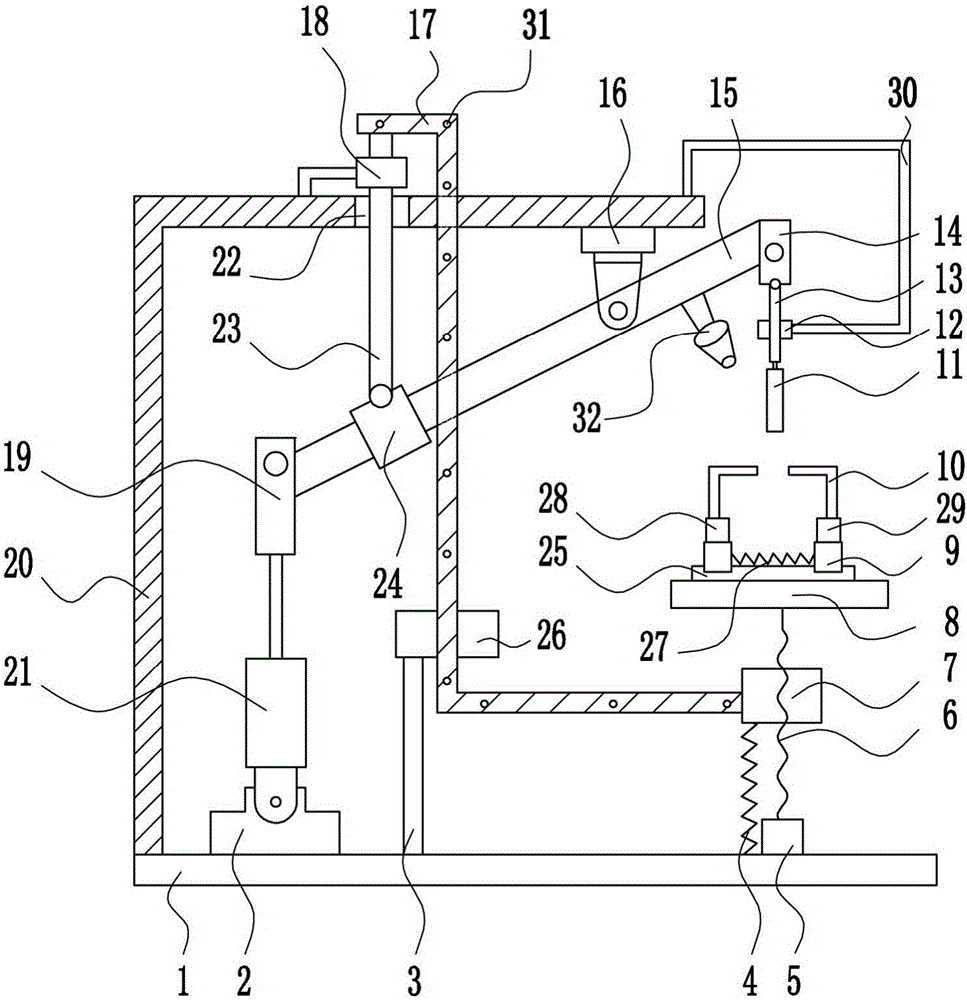

Accounting bill automatic flattening and perforating device

ActiveCN106626866ASimple structureReasonable designSheet bindingBookbinding pressesEngineeringMechanical engineering

The invention belongs to an accounting bill automatic flattening and perforating device. The device comprises a support base; a fixing device is arranged at the bottom of the support base; a pressing box is arranged at the top of the support base; an electric cylinder 1 storage box and a perforating box are respectively arranged on two sides of the pressing box; a bill pressing box is arranged at the bottom in the pressing box; a bill pressing plate is arranged at the top of the bill pressing box; an extension guide rod is arranged at the top of the bill pressing plate, and penetrates through a support guide cross beam to connect with the bottom of a guide disc; a screw rod rotating shaft and a limiting guide rod are respectively arranged on two sides of the top of the support guide cross beam; the limiting guide rod penetrates through the guide disc to connect with the top in the pressing box; the screw rod rotating shaft penetrates through the guide disc to connected with a forward / reverse rotating motor arranged at the top of the pressing box; and a controller is arranged on one side of the forward / reverse rotating motor. The accounting bill automatic flattening and perforating device has the advantages of simple structure, reasonable design, solution of the difficulties of accounting bill flattening and perforation, adoption of a full-automatic operation mode in the whole operation process, operation through the controller, fastness, convenience, time and labor saving and good flattening and perforating effect.

Owner:HENAN MECHANICAL & ELECTRICAL ENG COLLEGE

Epoxidized soybean oil modified phenolic resin and method for producing non-fire-retardant paper based copper clad laminate by using same

The invention relates to epoxidized soybean oil modified phenolic resin and a method for producing the non-fire-retardant paper based laminate by using the resin, and belongs to the technical field of a production method of a copper clad laminate. The epoxidized soybean oil modified phenolic resin is characterized by comprising the following raw materials in parts by weight: 100-200 parts of phenol, 50-110 parts of epoxidized soybean oil, 0.5-3 parts of amine catalyst, 200-300 parts of formaldehyde, 20-40 parts of nitrogen-containing phenolic resin and 100-400 parts of solvent. The method forproducing the non-fire-retardant paper based copper clad laminate by using the epoxidized soybean oil modified phenolic resin is characterized by comprising the following steps: (1) preparing a resincomposition; (2) preparing a sizing material slice; and (3) preparing the non-fire-retardant paper based copper clad laminate.

Owner:SHANDONG JINBAO ELECTRONICS

Glue solution for copper-clad plate, composite based CEM-1 copper-clad plate, and preparation methods of glue solution and composite based CEM-1 copper-clad plate

ActiveCN106398110AImprove performanceWide range of usesSynthetic resin layered productsPaper/cardboard layered productsEpoxyOrganic solvent

The invention provides a glue solution for a copper-clad plate, a composite based CEM-1 copper-clad plate, and preparation methods of the glue solution and the composite based CEM-1 copper-clad plate. The glue solution for the copper-clad plate comprises the raw materials in parts by weight: 1200-2000 parts of epoxy soybean oil modified phenolic resin, 1200-2000 parts of epoxy resin, 150-250 parts of phenolic resin, 300-700 parts of a flame retardant, 250-350 parts of a curing agent, 1-5 parts of a curing accelerant, 50-150 parts of an inorganic filler and 100-300 parts of an organic solvent. On one hand, the epoxy soybean oil modified phenolic resin provided by the invention has the advantages of simple preparation process, good product performance and wide application; on the other hand, the glue solution for the copper-clad plate has the advantages of simple preparation process, good product performance, wide application and good permeability to wood pulp paper; what is noteworthy is that the composite based CEM-1 copper-clad plate provided by the invention has the advantages of simple preparation process, relatively good punching property, relatively good soldering resistance and good processing performance.

Owner:抚州市龙兴电子材料有限公司

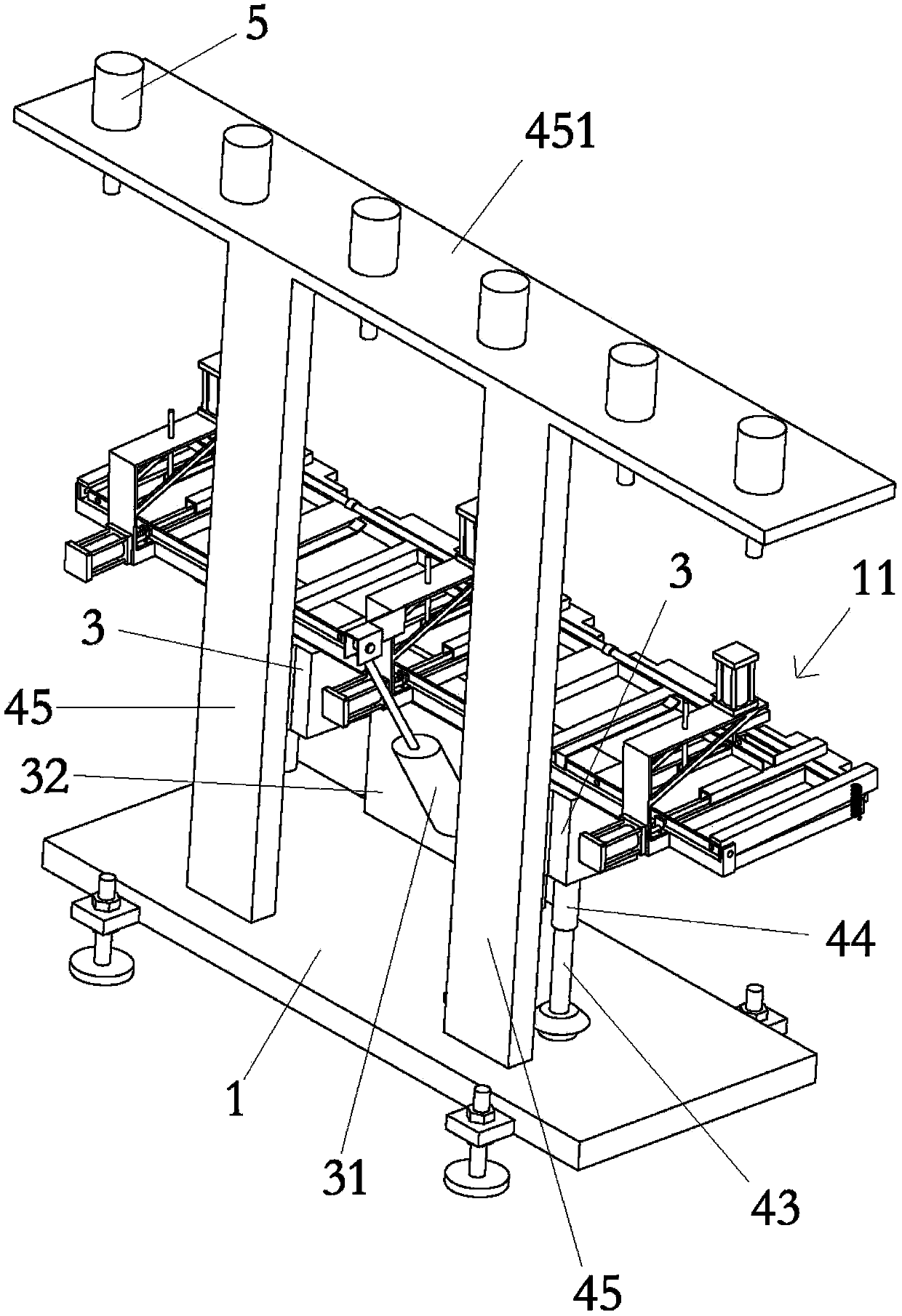

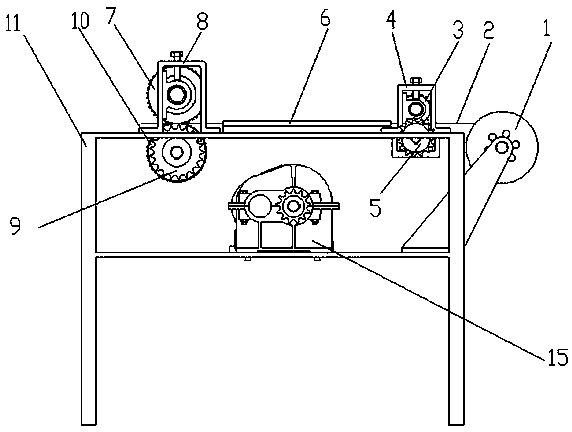

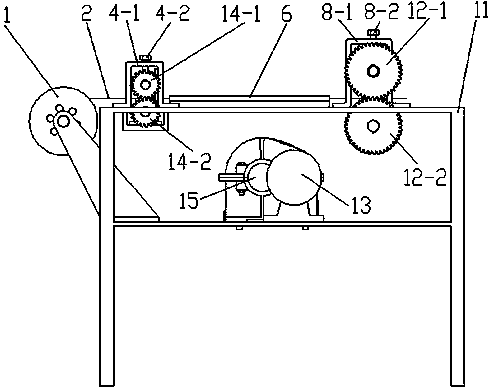

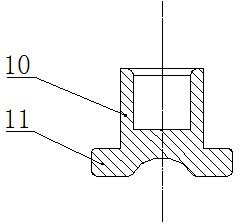

Thin-plate blanking device

ActiveCN103350431ASmall blanking gapDisadvantages of avoiding glitchesMetal working apparatusReduction driveReducer

The invention discloses a thin-plate blanking device which comprises a material roller (1), a feeding roller cylinder (3), a first roller cylinder adjusting device (4), a first chain transmission device (5), a strip material guiding device (6), a convex-concave mold roller (7), a second roller cylinder adjusting device (8), a second chain transmission device (9), a concave mold roller (10), a rack (11), a first gear transmission device, a motor (13), a second gear transmission device and a reducer (15). By the adoption of the roller pressing mode, the thin-plate blanking device can blank materials with the thickness smaller than 0.3 mm, blanking gaps of the materials can be adjusted, processing efficiency is high, and usage is convenient.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Intelligent punching device for case

ActiveCN111151643ASmall amount of deformationGuaranteed accuracyPerforating toolsMetal-working feeding devicesPunchingStructural engineering

The invention relates to the technical field of machining and discloses an intelligent punching device for a case. The intelligent punching device for the case comprises a body, wherein a control regulation device is arranged on the top of the body, a material clearing strip is arranged in the middle of the body, a die is arranged above the material clearing strip, a clamping and positioning device is arranged on the front surface of the die, the bottom of the control regulation device is connected to a punching outer sleeve and a punch structure, a punching sleeve structure is connected outside the punch structure in a sleeving manner, and a scraper, a reverse punch and a spiral convex ring are successively arranged from bottom to top of the outer surface of the punching sleeve structure.The intelligent punching device for the case can correct a collapsed hole edge during punching by arranging the punching outer sleeve pressing the surface of a panel of the case and the reverse punchcapable of punching reversely during punching, and can remove burrs attached to the inner wall of the a punched hole by arranging the punching sleeve structure provided with the reverse punch, the scraper and the spiral convex ring, so that the punching precision is improved.

Owner:HANGZHOU FENGHENG ELECTROMECHANICAL

One-time forming mold for steel cap of pin type insulator

InactiveCN102284619AAchieve demouldingGood punching effectShaping toolsEjection devicesEngineeringPin insulator

The invention relates to a one-time forming mold for a pin-type insulator steel cap, which includes an upper template and a lower template. The left mold and the right mold, the outside of the left mold and the right mold are provided with a T-shaped slider structure, the mold base is provided with a T-shaped guide groove that can fit the T-shaped slider, and the T-shaped guide groove is formed from the bottom of the mold base The outside extends obliquely upwards; the inner surfaces of the left mold and the right mold are respectively connected with a left mold core and a right mold core by bolts, and the combination of the left mold core and the right mold core forms a cavity of a pin-type insulator steel cap. Through the cooperation of the punch and the left and right mold cores, the pin-type insulator steel cap is punched and formed at one time, and the punching effect is good and the yield is high. When demoulding, the left and right molds are lifted by the demoulding cylinder below, so that the left and right molds are opened to both sides under the action of the T-shaped slider and the T-shaped guide groove, and the demoulding of the steel cap is realized.

Owner:RUGAO DASHENG LINE EQUIP

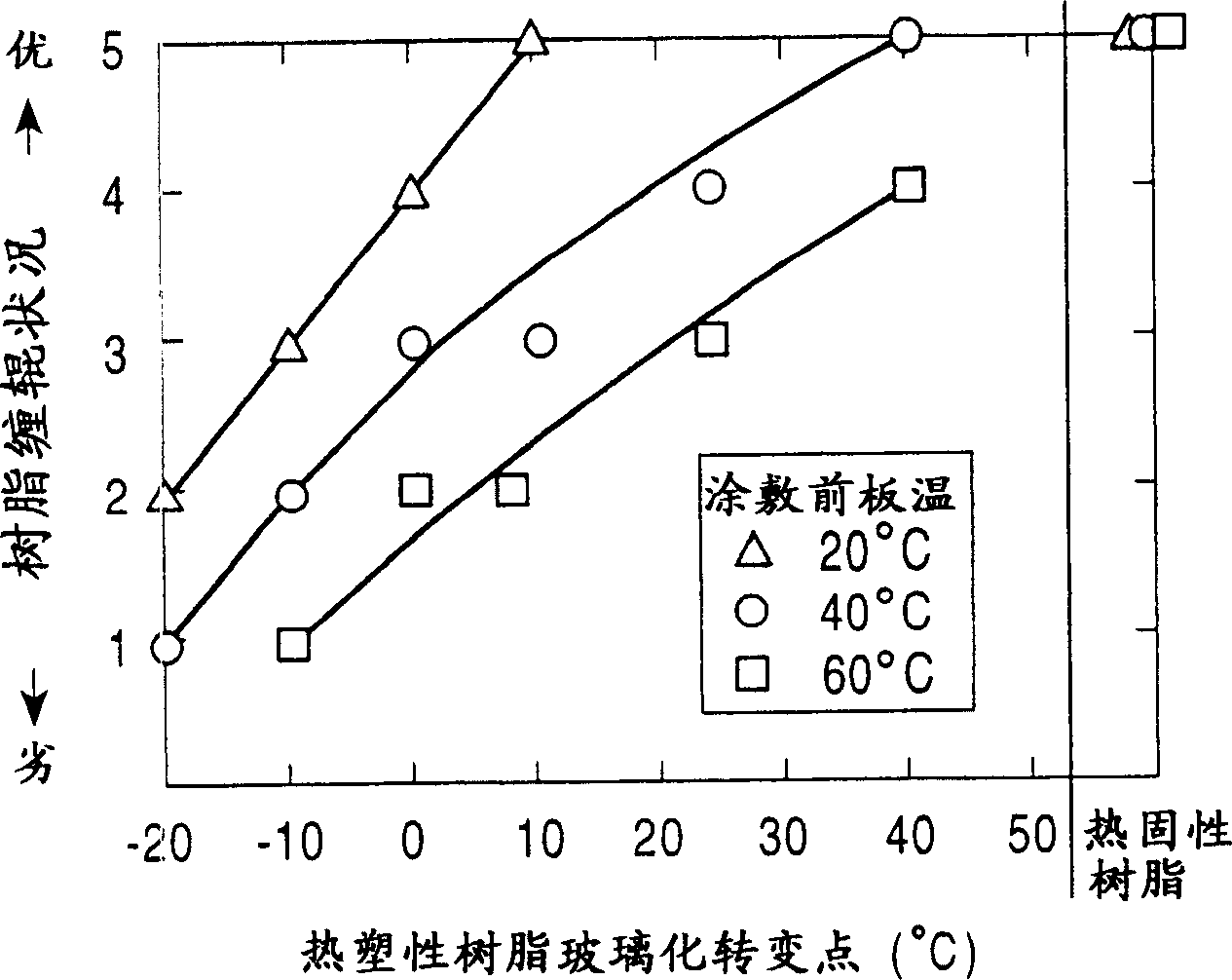

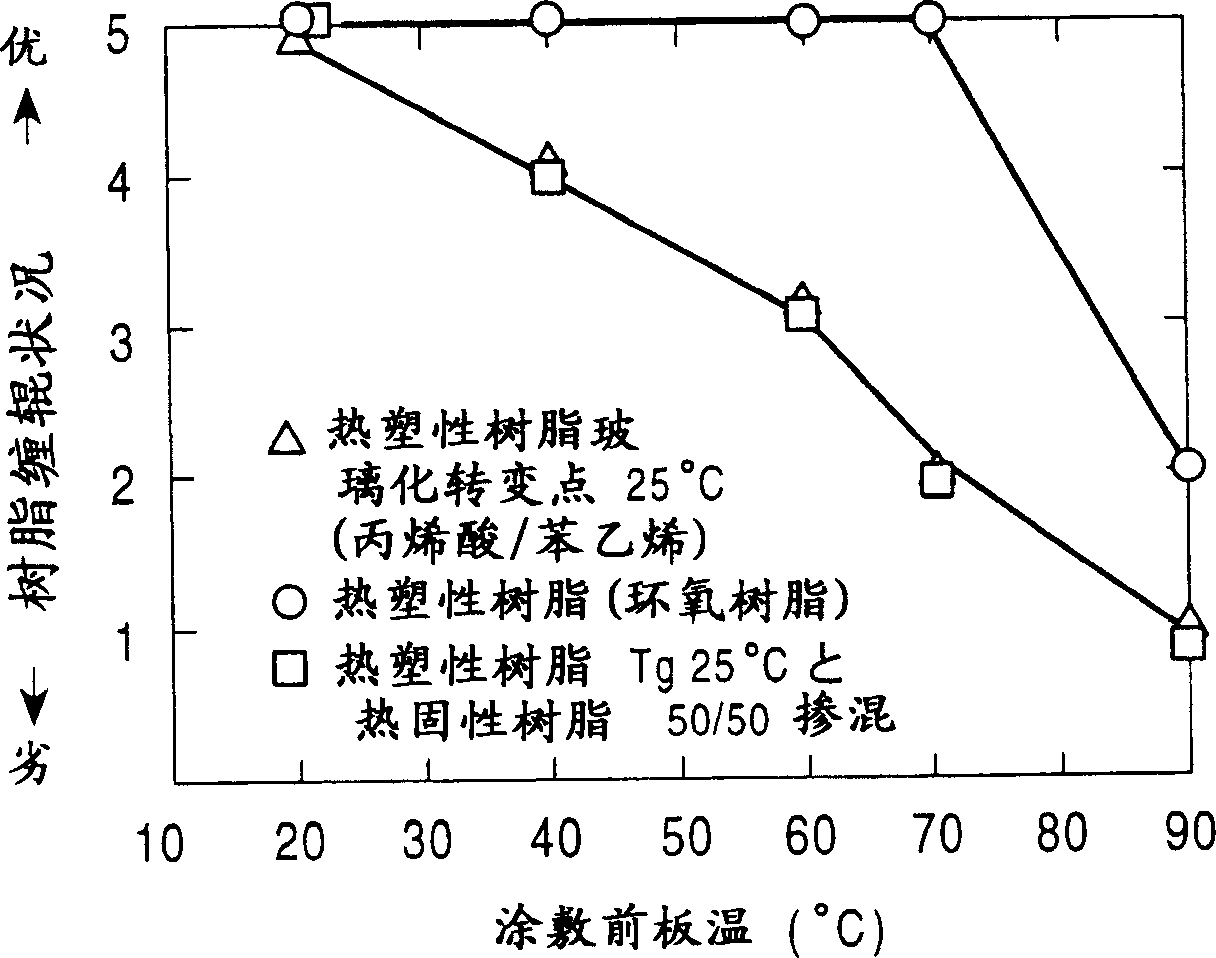

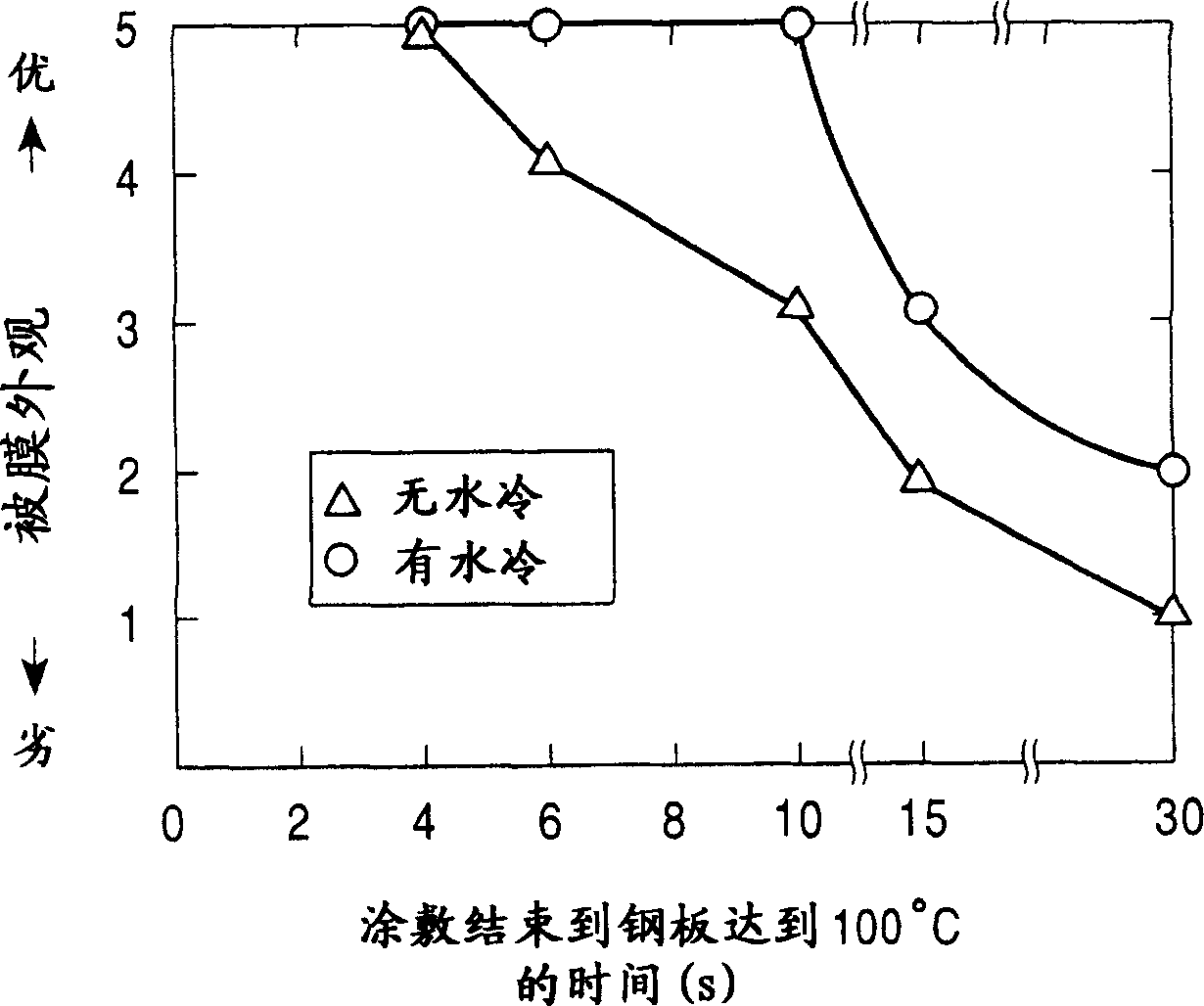

Method for producing coated steel sheet

InactiveCN1642662AGood lookingAvoid entanglementPretreated surfacesInorganic material magnetismWater basedSheet steel

In a process for manufacturing a coated steel sheet such as a coated electromagnetic steel sheet using a water-based coating liquid containing an organic resin, to perform steps subsequent to an annealing step continuously at high speed without causing appearance defects such as coating unevenness; to provide an electromagnetic steel sheet having an insulating film thereon, in which properties of the film are satisfactory, superior weldability and punchability can be obtained without deteriorating the space factor, and the satisfactory film properties can be maintained even if the electromagnetic steel sheet having the insulating film thereon is temper-rolled. A coating liquid is applied onto an untreated steel sheet as settle means of the invention. The applied liquid is heated on the side close to the steel sheet in such a manner that the time elapsed until the steel sheet temperature is increased to 100 DEG C. after the application is completed is 10 seconds or less, thereby drying the coating liquid. The steel sheet temperature is further increased to a predetermined temperature, thereby forming a coating film. When insulating films for electromagnetic steel sheets are formed, the coating liquid preferably further contains a water based inorganic component.

Owner:JFE STEEL CORP

Cashew phenol modified linetype phenolic resin and method for manufacturing composite laminated board

InactiveCN101096404AImprove heat resistanceImprove punching effectLamination ancillary operationsLaminationEpoxyCopper foil

The invention relates to a cashew phenol modified linear formaldehyde-phenol resin and a method for manufacturing composite basal layer clamping plate in the roofing copper production method technique field. The material of the cashew phenol modified linear formaldehyde-phenol resin is cashew phenol, phenol, formaldehyde, acid catalyst and the solvent. The method comprises the following steps: 1, manufacturing the cashew phenol modified linear formaldehyde-phenol resin; 2, preparing resin adhesive by mixing the modified linear formaldehyde-phenol resin, epoxide resin, fire retardant and brightener; 3, dipping the wood-pulp paper with the resin adhesive; drying the paper base-material sheet; getting the paper base semi-solid sheet; formulating glass cloth base-material sheet, copper foil and the paper base semi-solid sheet together; heating; increasing the pressure; manufacturing the composite basal layer clamping plate. The cashew phenol modified linear formaldehyde-phenol resin is provided with the good fire-resisting property, the good punching property and the high planeness; and the wiring board is provided with the high fire-resisting property, which is fit for leadless reflow soldering.

Owner:SHANDONG JINBAO ELECTRONICS

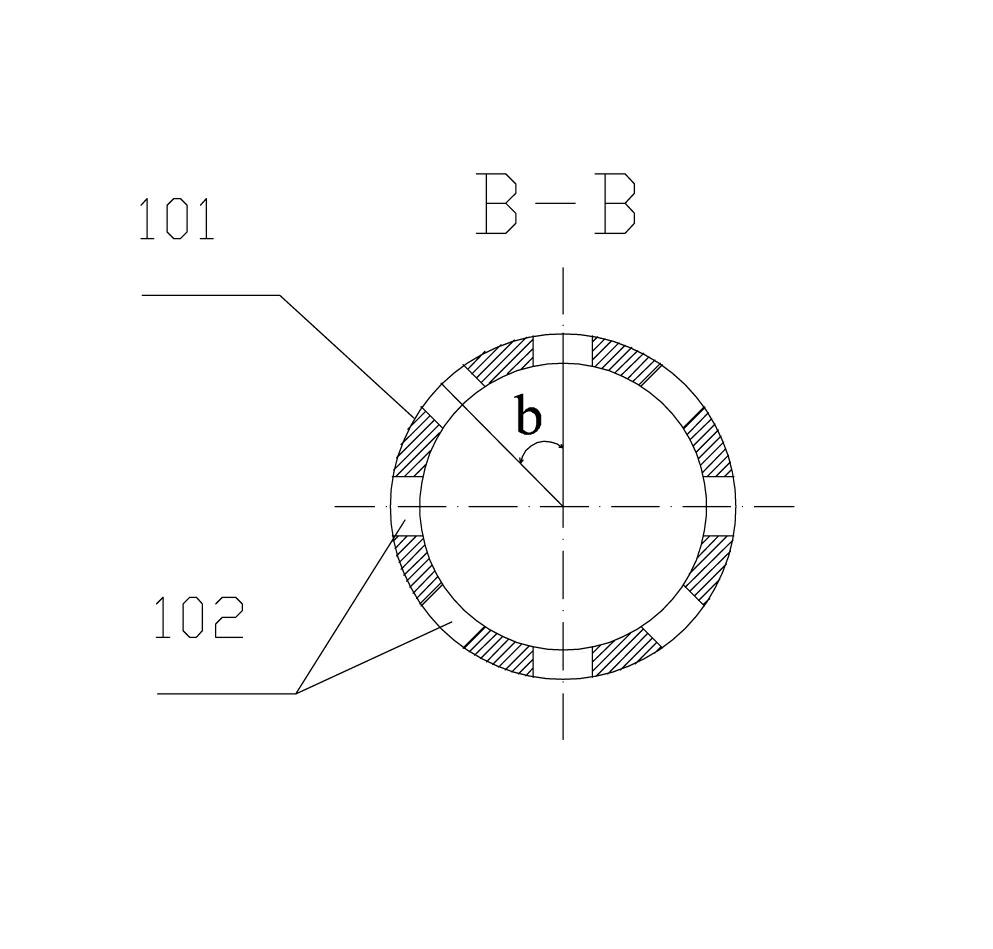

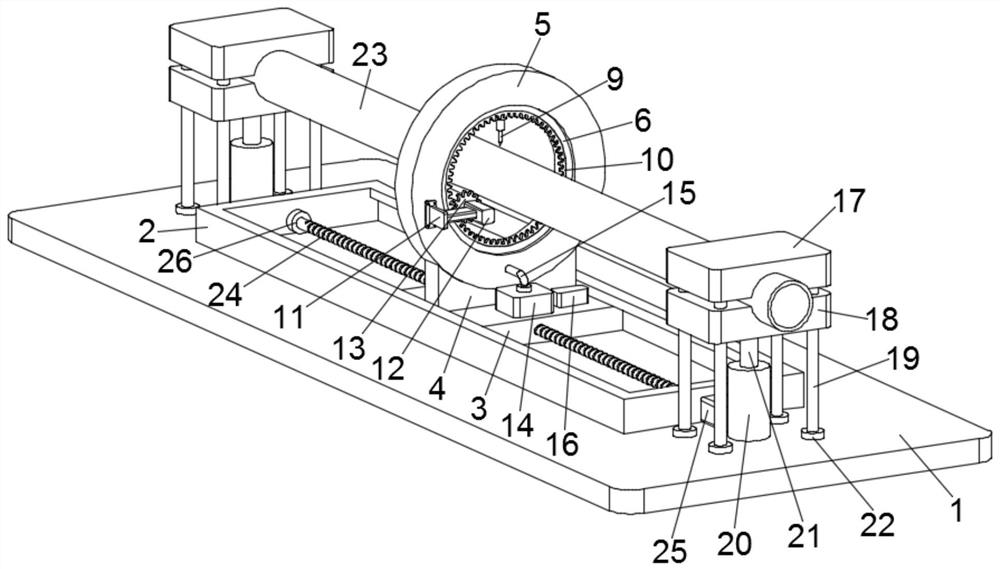

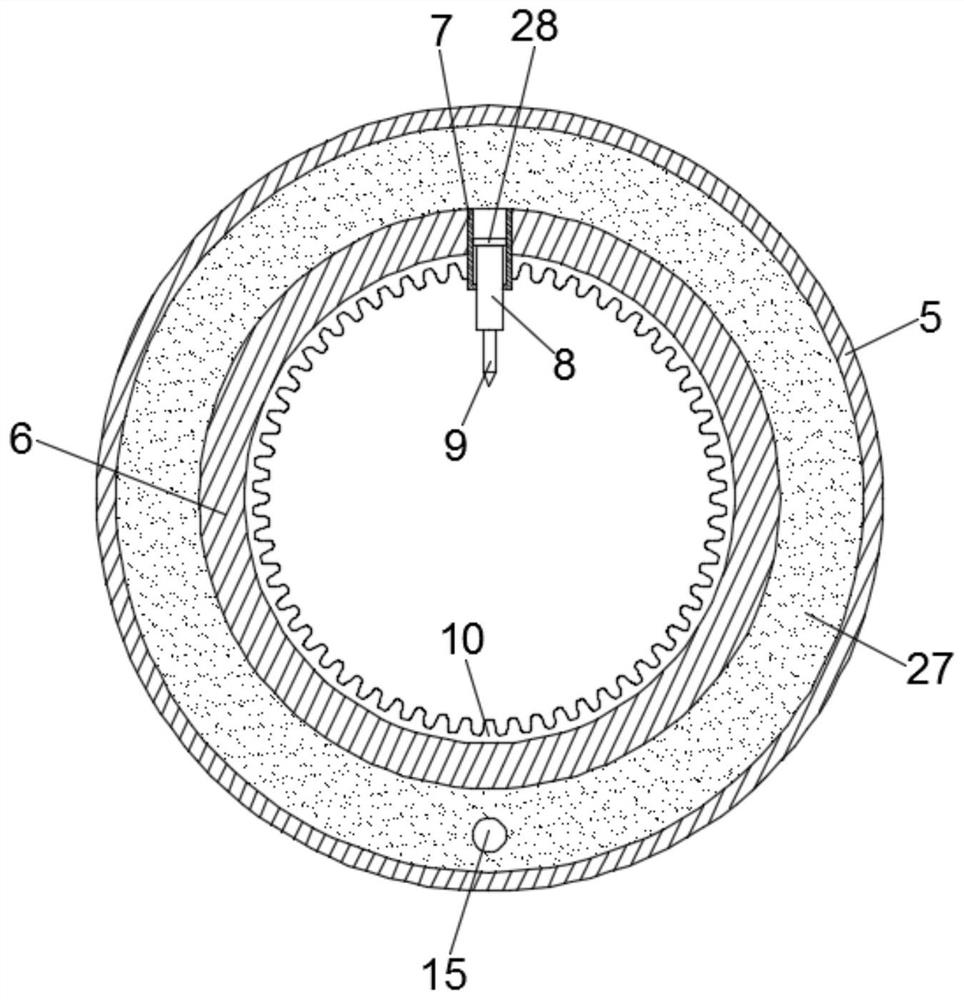

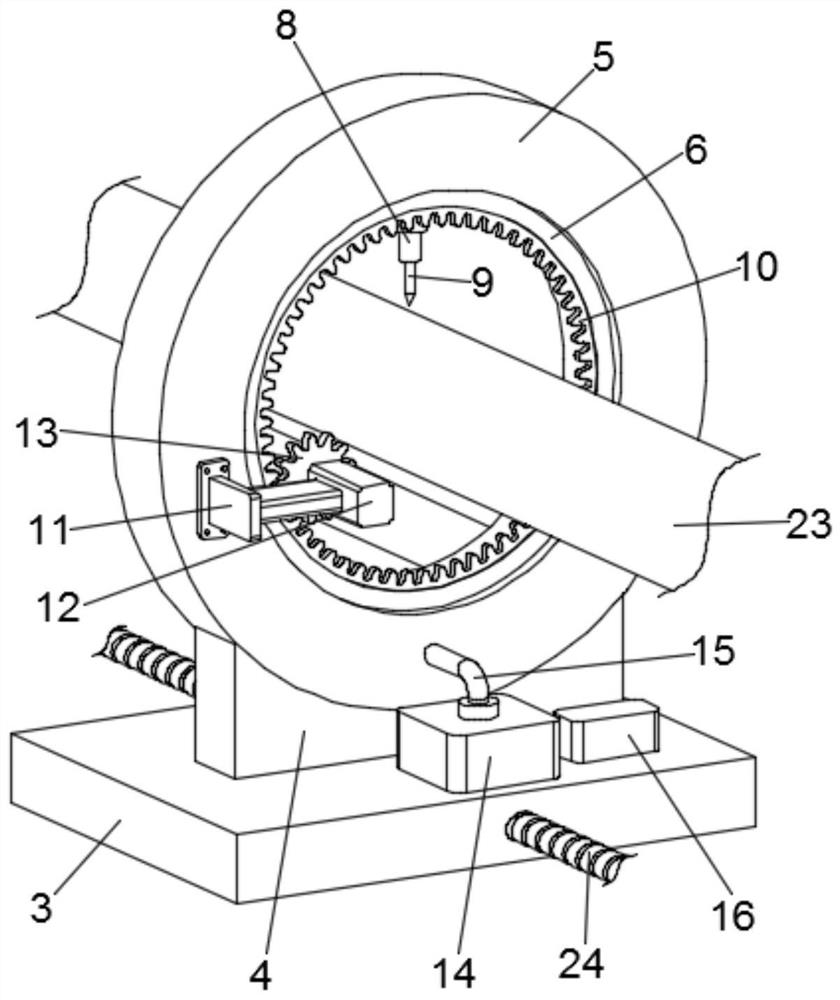

Steel pipe punching device for building construction

The invention discloses a steel pipe punching device for building construction. The steel pipe punching device comprises a base, a sliding rail is installed on the base, a ring sleeve is installed inthe sliding rail in a sliding mode, an annular cavity is formed in the ring sleeve, a rotating ring is rotationally clamped on the inner side of the ring sleeve, a sleeve is fixedly installed on the rotating ring, a telescopic ejector rod is movably sleeved with the sleeve, a punch is installed at the extending tail end of the telescopic ejector rod, and a hydraulic device communicating with the annular cavity is installed on a sliding block; a rotating motor is installed on the outer wall of the ring sleeve, a gear is rotationally installed at the output end of the rotating motor, a gear ringis arranged on the inner wall of the rotating ring, and a controller is installed on the sliding block; and a transverse moving mechanism is arranged on the sliding rail, and clamping assemblies arearranged at the two ends of the sliding rail. According to the steel pipe punching device for building construction, a steel pipe is clamped and fixed through the clamping assemblies, the ring sleeveis driven by the transverse moving mechanism to move transversely along the steel pipe, and meanwhile, the punch can rotate around the circumferential direction of the steel pipe to any angle, and therefore punching operation of the steel pipe at different positions and angles is achieved, adjustment is convenient and flexible, the punching precision is high, and the punching efficiency is improved.

Owner:潘帅

Material surface continuous punching device

InactiveCN105599052AContinuous and uniform punchingReduce manual interventionDrilling machinesMetal working apparatusPunchingEngineering

The invention discloses a material surface continuous punching device. The device comprises a base, supporting rods, a fixed shaft, a roller shaft, an arc-shaped rod, a pull rod, a spring, a roller, a grooved cam and a punching nail, wherein the multiple supporting rods are installed on the base, the supporting rods are connected through rotary shafts, and rolling cylinders are installed on the rotary shafts; a groove is formed in the base, the fixed shaft is installed on the groove, and a roll is installed on the fixed shaft and fixedly connected with the arc-shaped rod; the arc-shaped rod is hinged to the pull rod, the pull rod is sleeved with the spring, and the two ends of the spring are fixedly connected with the arc-shaped rod and the base; the bottom end of the pull rod is fixedly connected with a section of cross rod, and the roller is installed on the cross rod; the roller and the grooved cam form a cam mechanism, and the grooved cam is connected with a motor. The grooved cam mechanism is driven by the motor to move to be matched with a conveying device, the whole process is controlled by a program module, and quick and even punching is achieved. The punching effect is good, and the small equipment is simple in structure, convenient to operate and wider in application range.

Owner:陈泽林

Special sealing piece punching machine capable of selecting punching number

The invention discloses a special sealing piece punching machine capable of selecting the punching number. The special sealing piece punching machine comprises a bottom plate. Punching devices, first supporting rods and a limiting device are fixedly connected to the upper surface of the bottom plate. The first supporting rods are located between the punching devices and the limiting device. Each punching device comprises a first electric telescopic rod. The top end of each first electric telescopic rod is fixedly connected with a first connecting block. The front face of each first connecting block is movably connected with the front face of a lever through a first pin shaft. The front face of each lever is movably connected with the front face of a second connecting block through a second pin shaft. According to the special sealing piece punching machine capable of selecting the punching number, by means of the arrangement of the punching devices, the first electric telescopic rods are shortened, drill bits are elevated through the action of the levers, and therefore the usage number of the drill bits can be adjusted according to the number of holes needed by a sealing piece, accordingly, the punching number of the sealing piece can be controlled, and the functions of the sealing piece punching machine are diverse.

Owner:无锡市东特机械科技有限公司

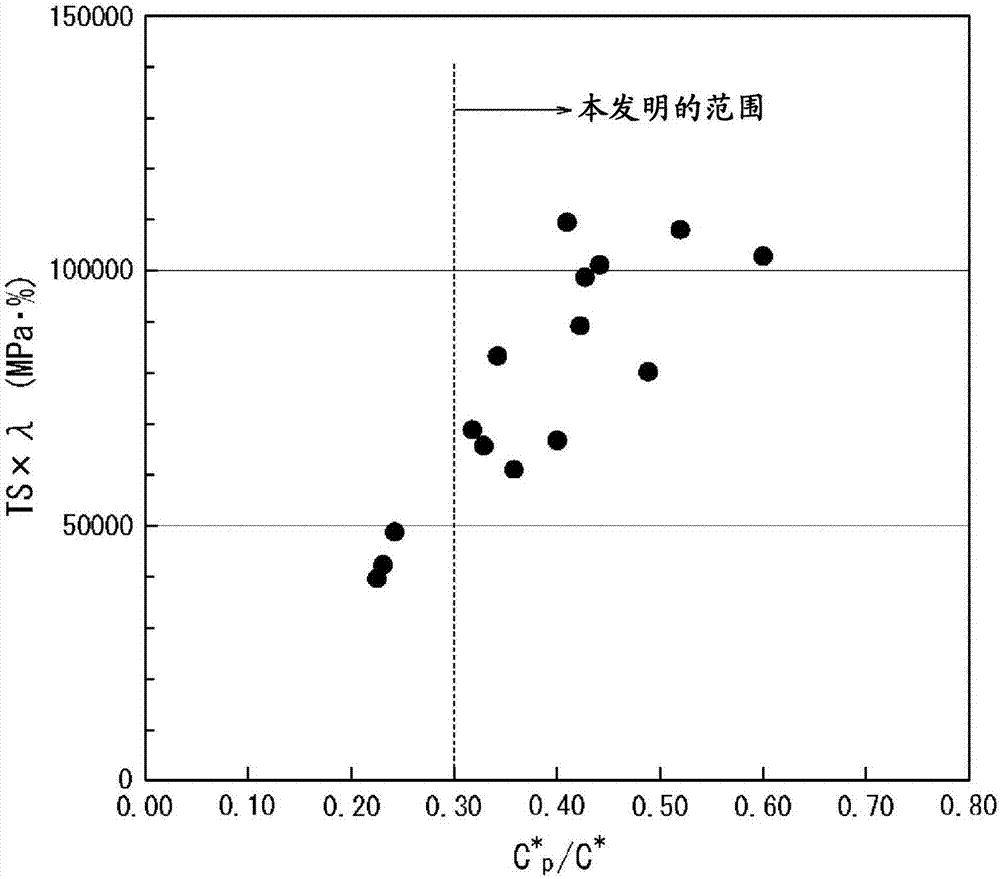

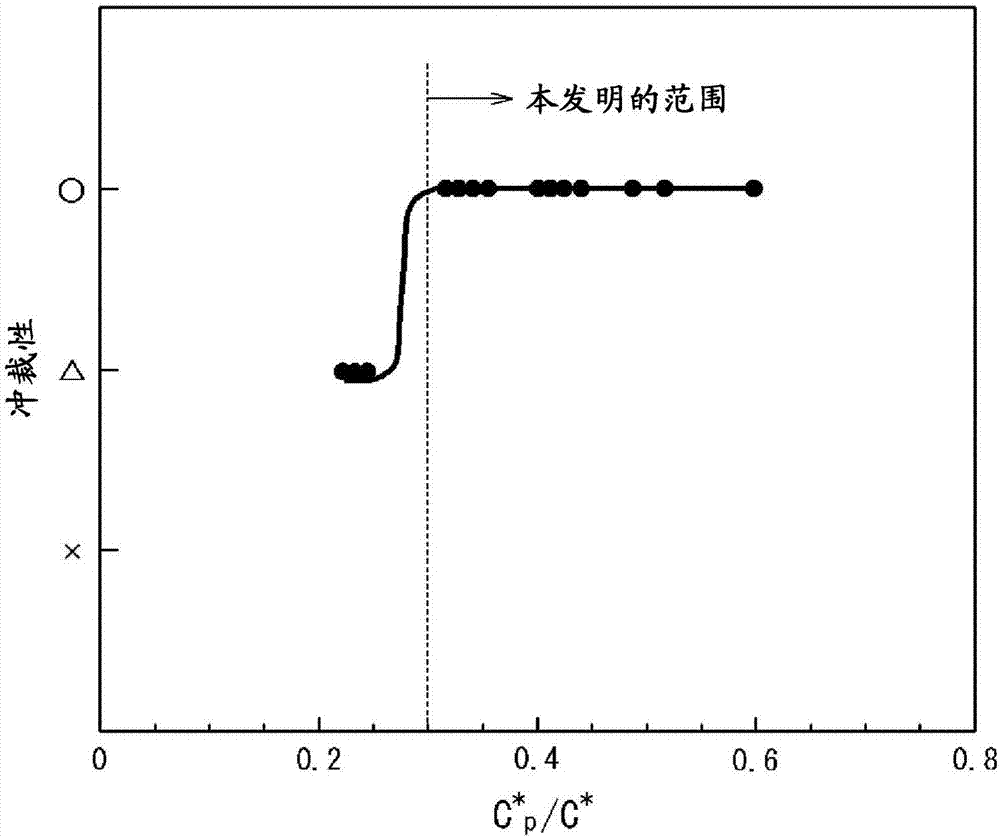

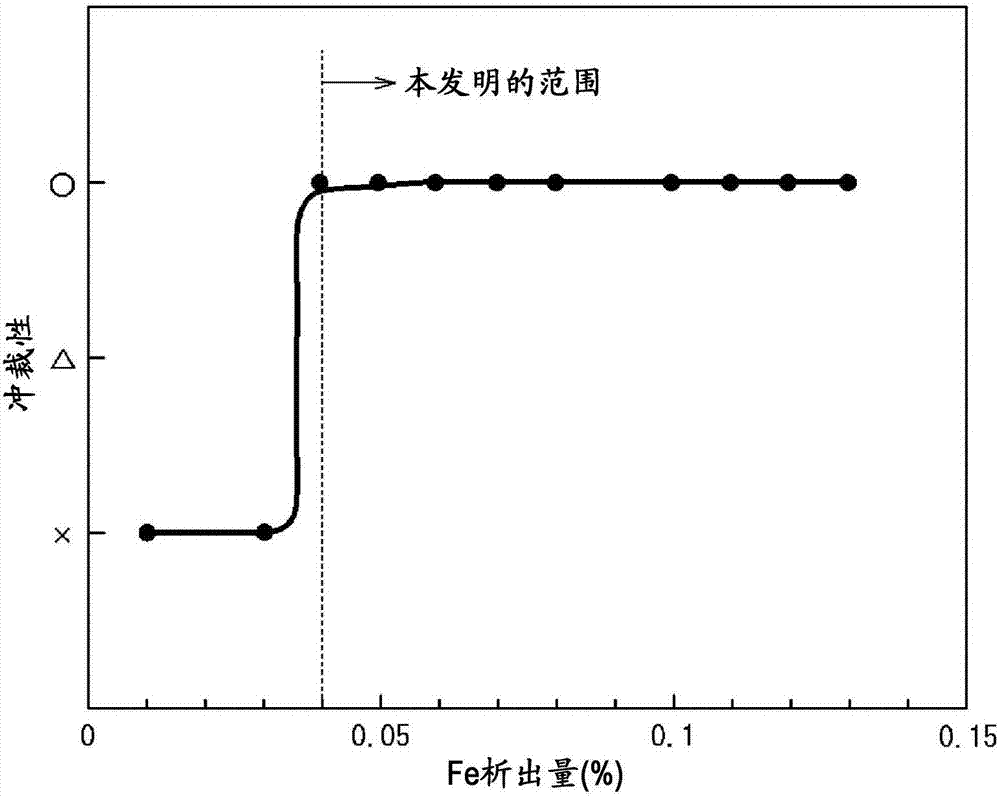

High strength steel sheet and manufacturing method therefor

ActiveCN107406937AHigh tensile strengthHigh strengthFurnace typesHeat treatment furnacesUltimate tensile strengthArea ratio

The purpose of the present invention is to provide: a high strength steel sheet that has high strength such that tensile strength is at least 780 MPa, and excellent blanking quality combined with stretch-flangeability; and a manufacturing method therefor. Provided is a high strength steel sheet wherein: the steel sheet contains, in mass%, C: 0.05-0.30%, Si: 0.6-2.0%, Mn 1.3-3.0%, P: not more than 0.10%, S: not more than 0.030%, Al: not more than 2.0%, N: not more than 0.010%, and one or more of Ti, Nb and V: 0.01-1.0% each, the balance being obtained from iron and unavoidable impurities; the steel sheet comprises at least 50% area ratio of ferrite structure; the amount of Fe deposited is at least 0.04 mass%; the steel sheet contains a deposit in which the particle diameter is less than 20 nm; and C* defined by expression (1) and C*p defined by expression (2) satisfy the conditions in expressions (3)-(5). C*=([Ti] / 48+[Nb] / 93+[V] / 51+[Mo] / 96+[Ta] / 181+[W] / 184) * 12... (1) C*p=([Ti]p / 48+[Nb]p / 93+[V]p / 51+[Mo]p / 96+[Ta]p / 181+[W]p / 184)*12... (2) C* >= 0.035... (3) -0.015 <=[C]-C* <= 0.03... (4) C*p / C* >=0.3... (5)

Owner:JFE STEEL CORP

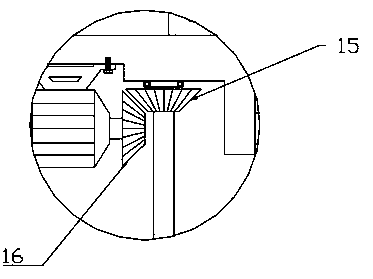

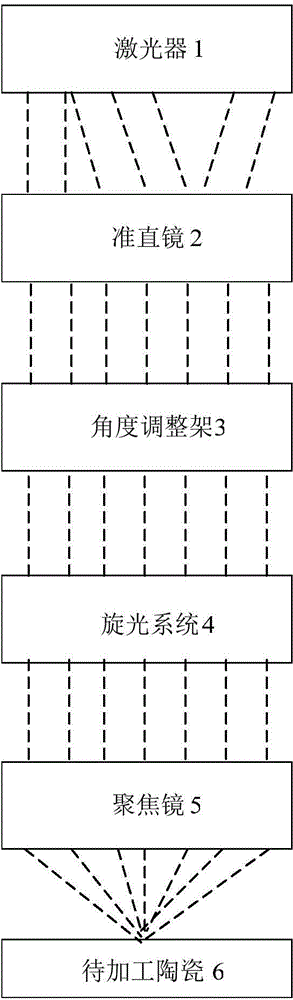

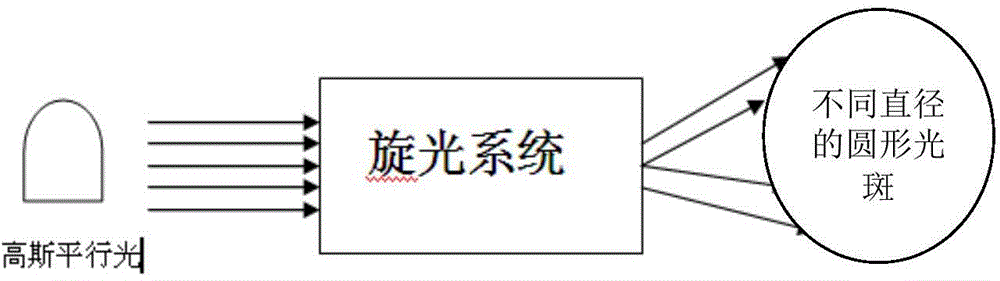

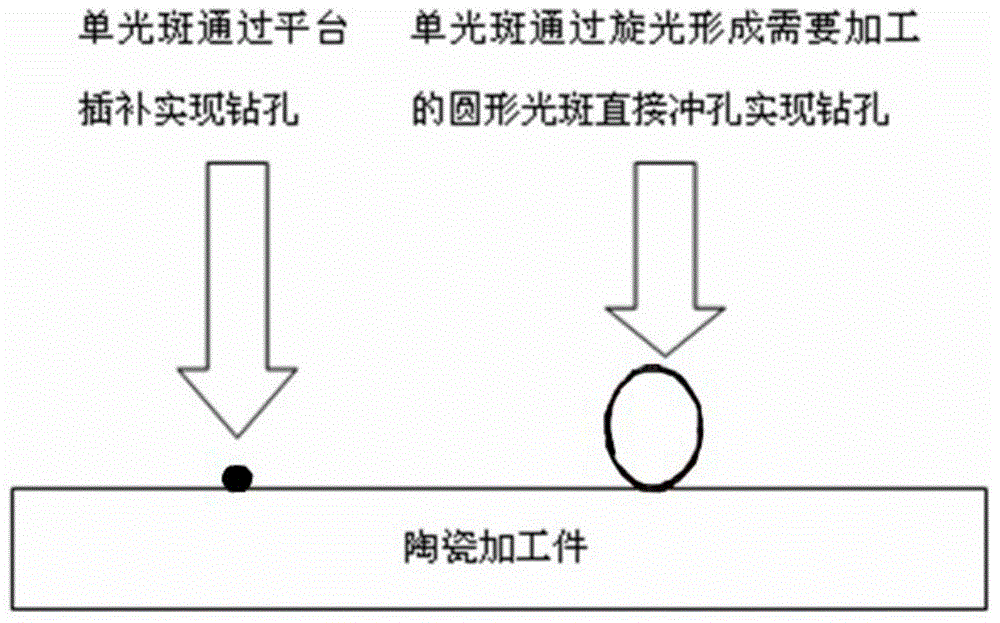

Device for processing aluminum oxide ceramic by fiber laser and method thereof

ActiveCN104384727APromote absorptionAchieve laser convergenceLaser beam welding apparatusLight spotFiber disk laser

The invention relates to a device for processing aluminum oxide ceramic by fiber laser and a method thereof. The device comprises a laser, a collimating mirror, an optical rotation system and a focusing mirror which are sequentially arranged along an optical path, wherein laser is emitted by the laser, runs through the collimating mirror and is converted to parallel light beams by divergent light; the collimated light beams are shaped by the optical rotation system; the optical rotation system is used for forming the parallel light beams as circular light rings with uniform energy distribution; the shaped light beams enter the focusing mirror to collect the laser; an auxiliary positioning image system is matched for controlling laser punching positions and is used for punching with high accuracy and monitoring the punching process in real time; the ceramic drilling, marking and cutting functions are implemented; different micorpores (D is smaller than or equal to 1mm) are punched in a single laser point; the device has the advantages of small light spots, high efficiency and low cost.

Owner:SUZHOU DELPHI LASER +1

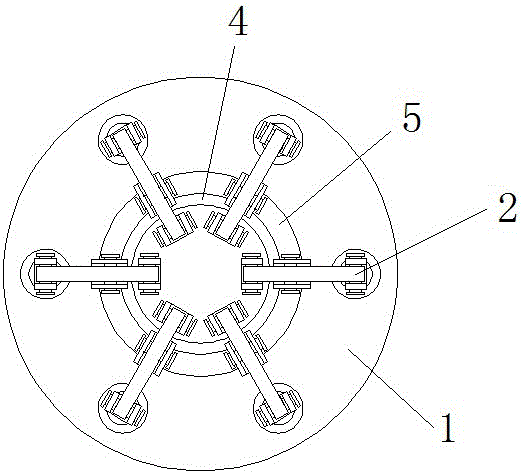

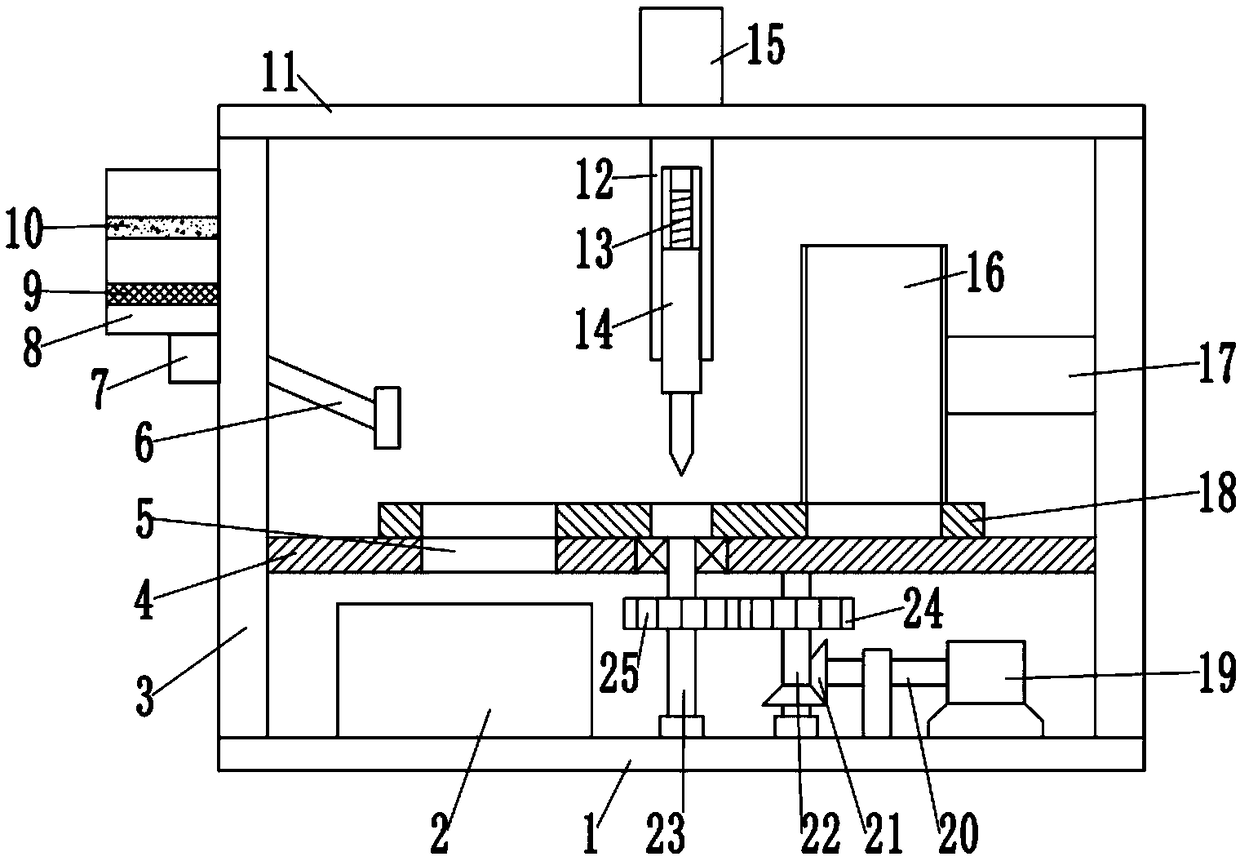

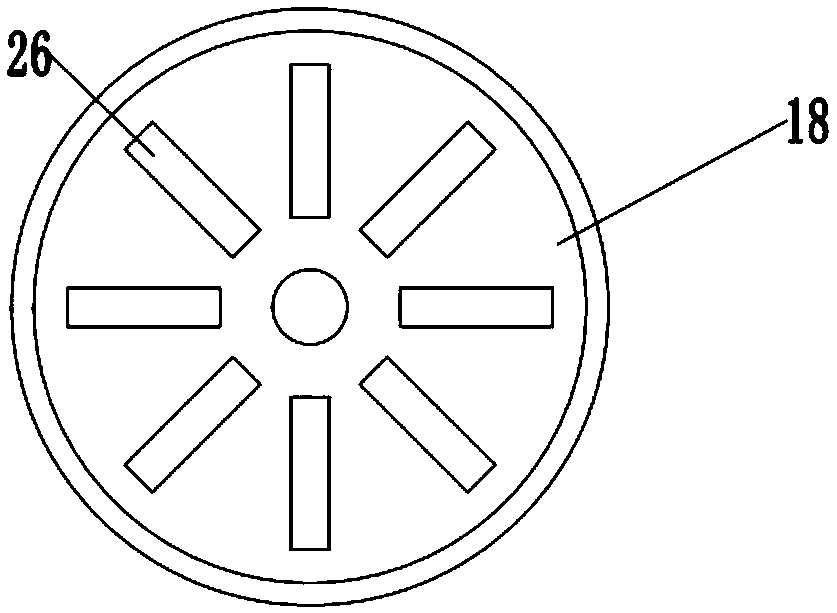

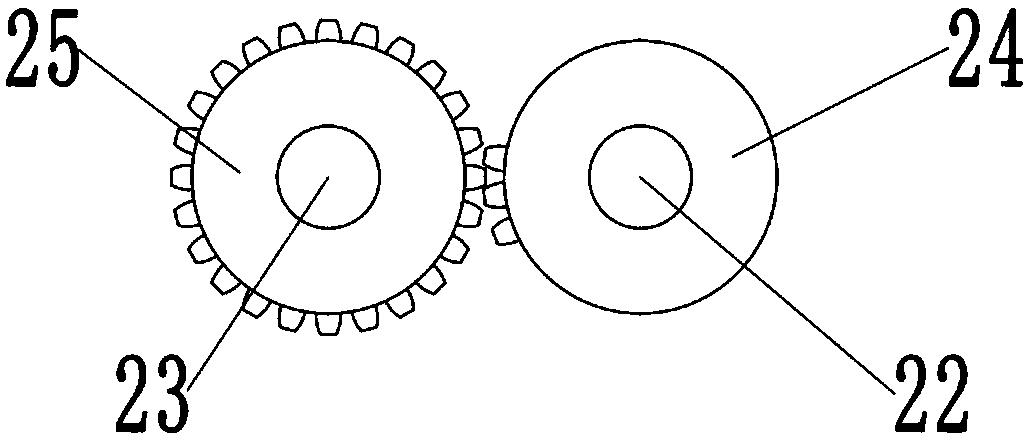

IoT (Internet of Things) based rotating disk type hinge punching device

InactiveCN109202127AReduce wasteGood punching effectLarge fixed membersBoring/drilling componentsPunchingEngineering

The invention discloses an IoT based rotating disk type hinge punching device. The device comprises a base plate and a rotating disk; two side plates are symmetrically fixedly mounted in the left andright sides of the base plate respectively, a top plate is fixedly mounted in the tops of the side plates, and a separator plate is fixedly mounted between the side plates; the rotating disk is rotationally mounted on the base plate via a third rotating shaft, the lower side of the rotating disk clings to the upper side of the separator plate, and standing grooves for placing a hinged to be punched are formed uniformly in the separator plate; the bottom of the top plate is rotationally and fixedly provided with a frame, the frame is internally rotationally provided with a screw, the lower endof the screw is in threaded connection with a thread sleeve, the lower end of the thread sleeve is fixedly provided with a drilling device for punching, and the drilling device positioned above the standing grooves in the back side the rotating disk, and the left side of the separator plate is provided with a discharging opening under the standing grooves. Punching is completed automatically, manual punching is not needed, waste of labor resources can be reduced, and the punching effect is good.

Owner:魏赛尔

Hardware punching mechanism

The invention discloses a hardware punching mechanism which comprises a rack; an upper supporting frame is fixed on the top surface of a top plate of the rack; a center through groove is arranged at the middle part of the top plate of the rack; a bottom supporting block is inserted into the center through groove in a sleeved manner; a lower horizontal plate is fixed on two supporting legs of the rack; a plurality of regulation motors are fixed on the bottom surface of the lower horizontal plate; an output shaft of each regulation motor penetrates through the lower horizontal plate and is in screw jointing to a regulation threaded sleeve; the top ends of the regulation threaded sleeves are fixed on the bottom surface of the bottom supporting block; a lower die block is fixed on the top surface of the bottom supporting block; a plurality of positioning stamping holes are formed in the top surface of the lower die block; a plurality of stamping oil cylinders are fixed on the top surface of the top plate of the upper supporting frame; a push rod of each stamping oil cylinder penetrates through the top plate of the upper supporting frame and is fixed on the top surface of an upper pressure block; and a plurality of punches, corresponding to the positioning stamping holes, are arranged on the bottom surface of the upper pressure block. The hardware punching mechanism can punch multiple holes at a time and is good in punching effect and high in punching efficiency.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

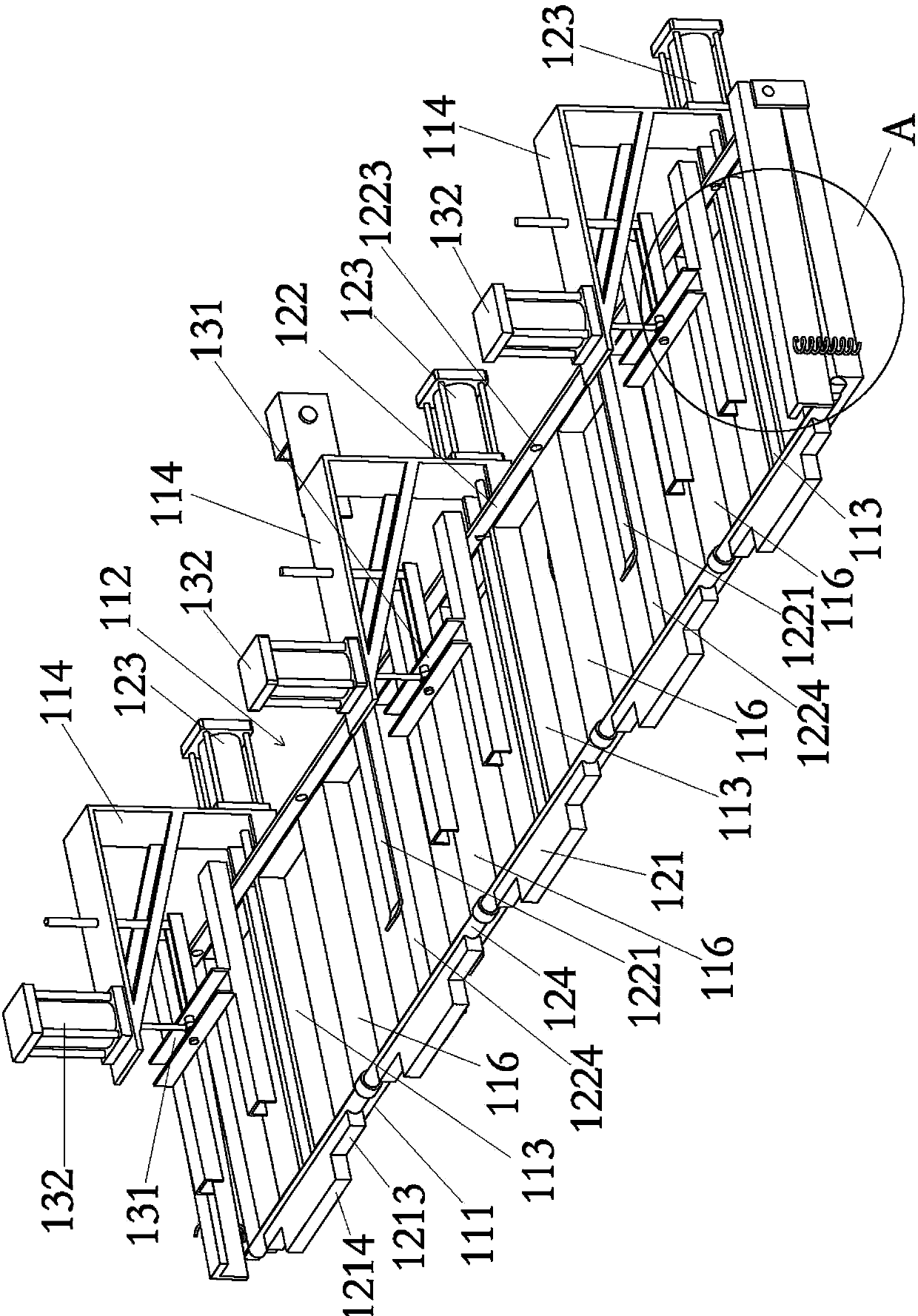

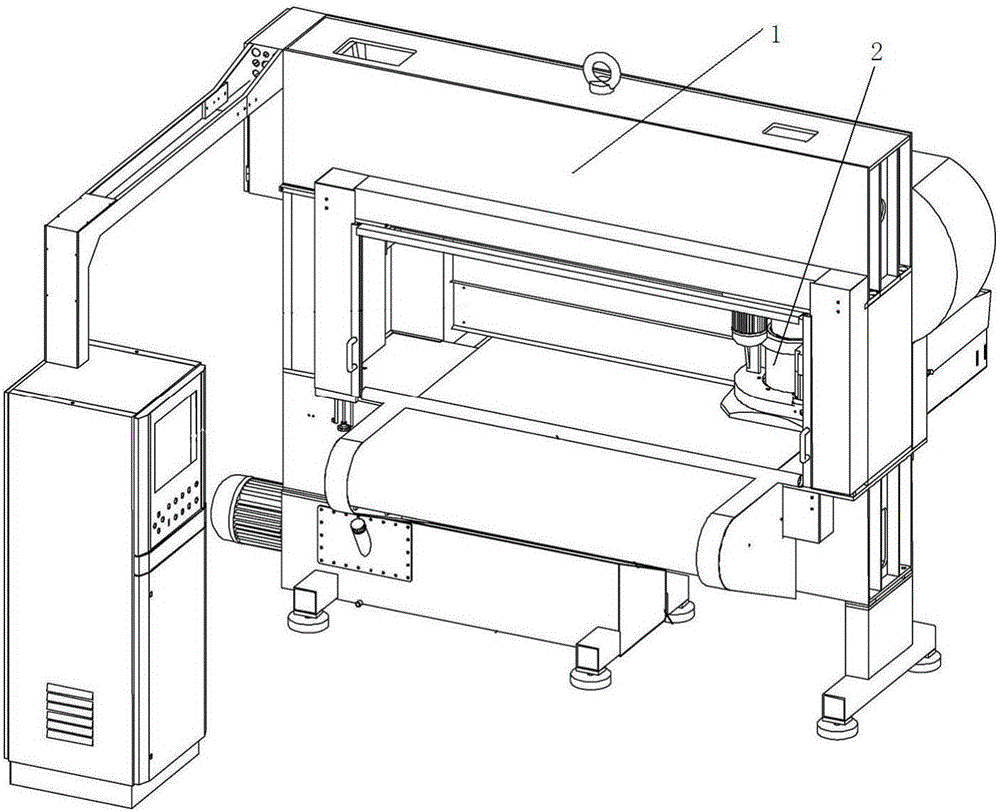

Numerically-controlled cutting machine capable of realizing rotating punching and punching method thereof

ActiveCN106142216AFast punching responseHigh punching pressureConveyorsMetal working apparatusPunchingEngineering

The invention discloses a numerically-controlled cutting machine capable of realizing rotating punching. The machine comprises a rotating punching device, an automatic belt deviation correcting device, a feeding device, a hydraulic device, a synchronous speed reduction device, a horizontal moving table, a punching mechanism, a rotating mechanism and a travel adjusting mechanism, wherein the punching mechanism comprises a cylinder barrel, a rotating cylinder sleeve, an oil cylinder and a piston assembly; the rotating mechanism comprises a suspending plate with a tool arranged at the bottom; a protecting cover is rotationally connected; and the travel adjusting mechanism comprises a double-end motor, a gear shaft and a fine-adjustment handle. According to the machine, a combined oil cylinder assembly and the combined piston assembly are arranged, the punching reaction speed is high, the punching pressure is high, and the punching effect is good; the travel adjusting mechanism is arranged, the punching travel can be adjusted rapidly by the aid of the double-end motor, the double-end motor can be rotated manually while change, and ultra-high-precision fine travel adjustment is realized; and the rotatable rotating mechanism is arranged, the tool is convenient to replace, and meanwhile, the utilization rate of materials can be greatly increased.

Owner:QUZHOU TAIWEI PRECISE MASCH CO LTD

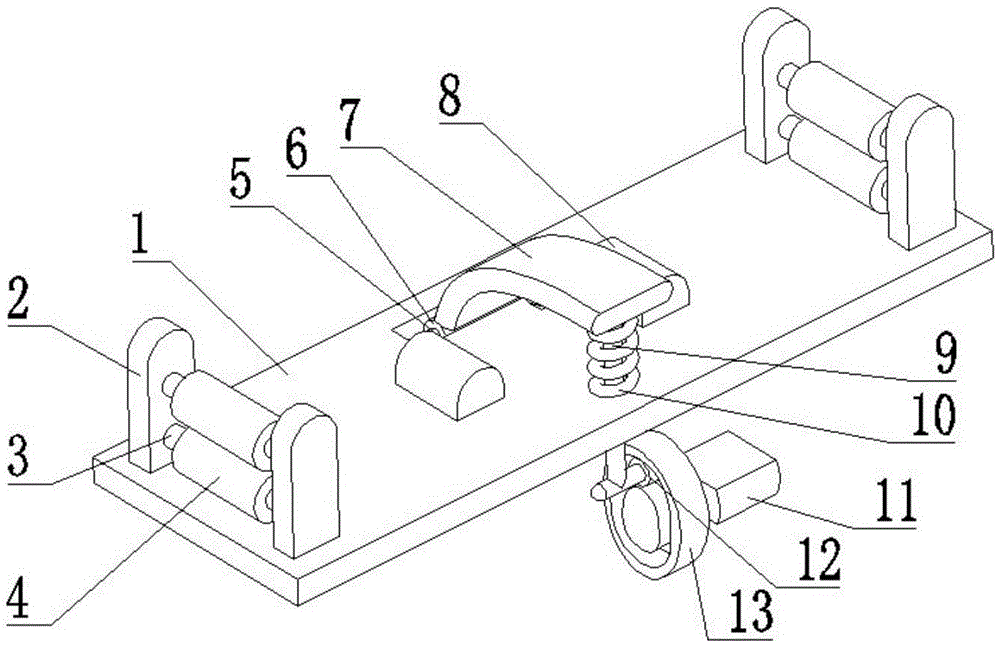

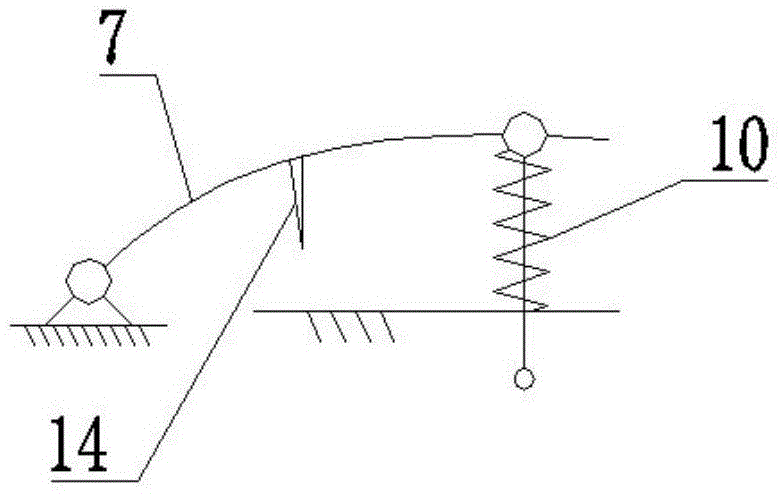

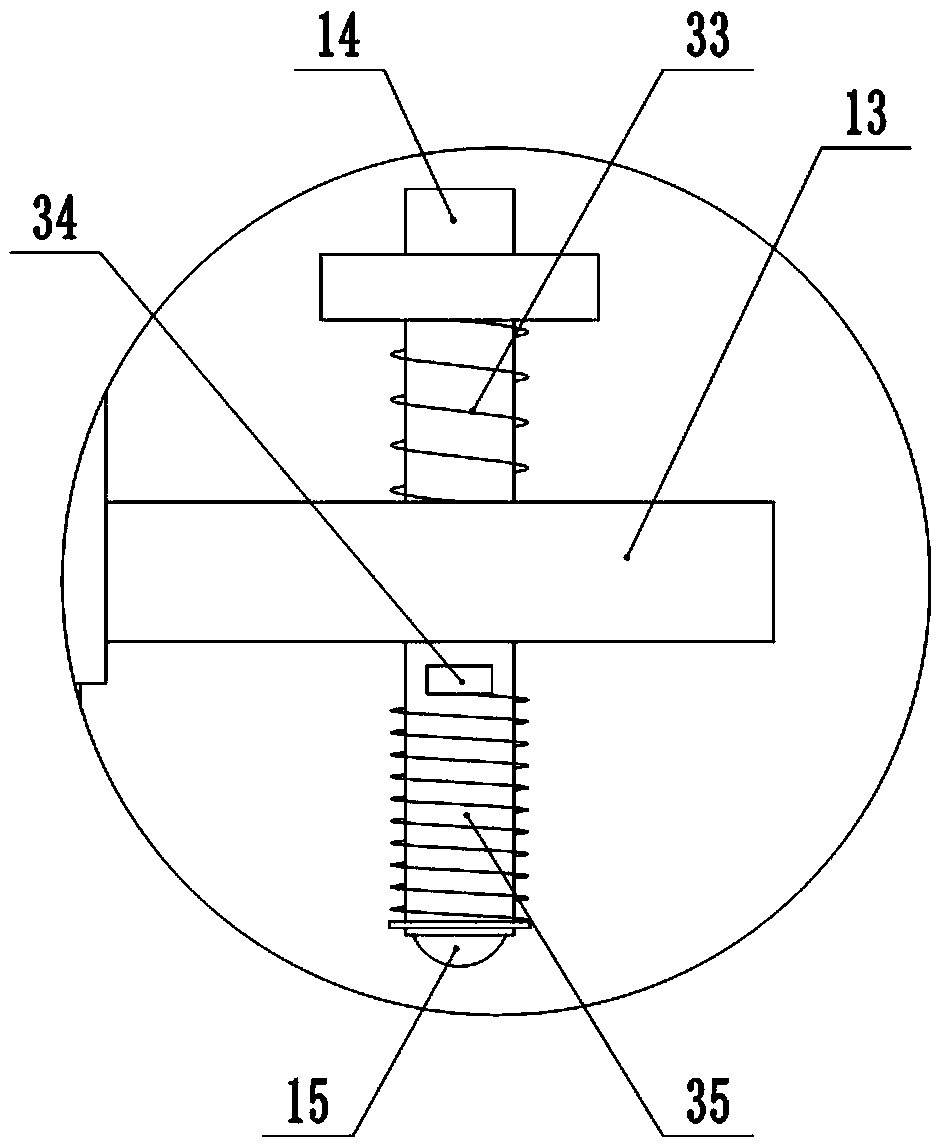

Fast key punching device for hardware manufacturing

ActiveCN106141244AReduce weightGood for up and down movementLarge fixed membersDriving apparatusPunchingEngineering

The invention relates to a punching device, in particular to a fast key punching device for hardware manufacturing. The technical aim of providing the precise punching fast key punching device for hardware manufacturing is achieved. In order to achieve the technical aim, the fast key punching device for hardware manufacturing comprises a bottom support, a first swing seat, a third connecting rod, a first spring, a bearing pedestal, a lead screw, a nut, a fixed plate, sliding blocks, first supporting rods, an electric drill, a first guide sleeve, a second supporting rod, a first connecting rod, a swing rod, a second swing seat, a supporting rod and the like. A left support, the first swing seat, the third connecting rod, the first spring and the bearing pedestal are sequentially arranged at the top of the bottom support from left to right. The fast key punching device achieves the effects of being precise and efficient in key punching for hardware manufacturing, punching is fast and convenient, the punching device is easy to operate and convenient to use, the conception of rotary punching is novel, and time and labor are saved.

Owner:宁津润科创投有限公司

Secondary punching equipment for hard and soft rubber inlets of plastic product

The invention relates to the technical field of machining equipment for rubber inlets of plastic products, in particular to secondary punching equipment for hard and soft rubber inlets of a plastic product. The equipment comprises a base, a lower die, an upper die and a driving device, wherein a hard rubber punching bottom die and a soft rubber punching bottom die are arranged on the lower die; more than one rubber inlet hole is formed in the hard rubber punching bottom die; more than one blanking hole is formed in the soft rubber punching bottom die; lower cutters are arranged at the periphery of the rubber inlet hole and the blanking hole; and the upper die is fixedly provided with upper cutters. By the equipment, the hard and soft rubber inlets of the product are punched for two times, so that the hard rubber inlet and the soft rubber inlet of the product which are opposite to each other can be extremely accurately positioned by a jig lower die, the phenomena of cut wounds and high residual rubber inlets can be prevented by a punched product, and the equipment has a good punching effect; when the soft rubber inlet is punched, the hard rubber inlet of the next plastic product can be punched in the hard rubber punching bottom die simultaneously; and a product in a mold can be machined well when the upper die punches downwards every time, so that the equipment has high production efficiency, saves labor and reduces production cost.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Drilling machine for steel structure machining

InactiveCN109277593AImprove accuracyGood punching effectWorkpiecesTurning toolsDrill holeSlide plate

The invention discloses a drilling machine for steel structure machining. The drilling machine for steel structure machining comprises an operation platform. A perforating groove is formed in the midpoint position of the top of the operation platform. The left side and the right side of the top of the operation platform are fixedly connected with supporting plates. The sides, far away from the perforating groove, of the supporting plates are fixedly connected with connection bearings. The inner walls of inner rings of the connection bearings are fixedly connected with thread bushings, and thesides, far away from the perforating groove, of the thread bushings penetrate through the corresponding connection bearings and extend to the exteriors of the connection bearings. According to the drilling machine for steel structure machining, by means of the cooperation of the supporting plates, the connection bearings, the thread bushings, rotary handles, threaded rods, pushing plates, first supporting slide plates, supporting sliding sleeves, fixed plates, sliding rods, rolling balls, second supporting slide plates, air cylinders, movable plates and connection sliding sleeves, the drillingmachine for steel structure machining is good in positioning and drilling effect and good in drilling stability, the drilling machine is conveniently adjusted to an accurate drilling position, the accuracy rate of drilling to a steel structure is increased, the defective percentage of a steel structure product is reduced, and the machining cost of the steel structure is indirectly saved.

Owner:李友新

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com