Epoxidized soybean oil modified phenolic resin and method for producing non-fire-retardant paper based copper clad laminate by using same

A technology of epoxidized soybean oil and phenolic resin, which is applied in the field of epoxidized soybean oil modified phenolic resin and copper clad laminate production, can solve the problems of long production cycle of tung oil, limited amount of resources, and inability to meet market demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

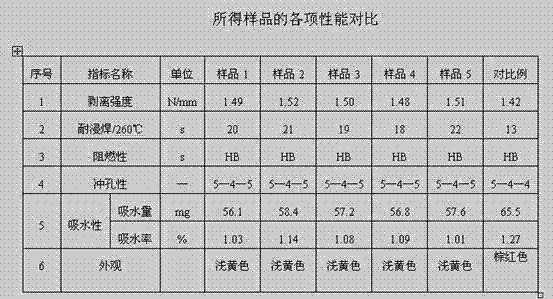

Examples

Embodiment

[0039] The epoxidized soybean oil modified phenolic resin in the resin composition of the present embodiment, the raw materials used are phenol, epoxidized soybean oil, amine catalyst, react in the range of 80-90 ℃ for 60-90 minutes, then add formaldehyde, containing Nitrogen phenolic resin, react in the range of 80-90°C for 70-90 minutes, and then dehydrate under reduced pressure; after dehydration, carry out thermal processing, test the gel time at 155-165°C, and control the gel time to 70-80 Seconds, methanol was added to obtain an epoxy soybean oil modified phenolic resin solution with a solid content of 48-53%.

[0040] Use 140 g / m2 high density (the industry usually uses 126 g / m2, 130 g / m2, 135 g / m2) bleached wood pulp paper to dip-coat epoxy soybean oil modified phenolic resin solution, and control the temperature at 160 degrees, The drying time is 1 minute, and the glue content is controlled to be 50±1% (the percentage of pure resin solids in the weight of the sizing s...

specific Embodiment 1

[0041] Into a 1000 ml three-neck flask, put in order: 200 grams of phenol, 50 grams of epoxidized soybean oil, 0.5 grams of amine catalysts, react in the range of 80-90 °C for 60-90 minutes, put in 200 grams of formaldehyde, and 20 grams of nitrogen-containing phenolic resin Carry out the reaction, react in the range of 80-90°C for 70-90 minutes, and then dehydrate under reduced pressure; after removing all the water, perform thermal processing, test the gelation time at 155-165°C, and control the gelation time to 70-80 seconds , adding methanol to obtain an epoxy soybean oil modified phenolic resin solution with a solid content of 48-53%, and then use it to impregnate 140g / m2 bleached wood pulp paper, and control the glue content to 50±1% (resin pure solid accounts for The percentage of the weight of the sizing sheet), fluidity 10±1% (the weight of the sizing material flowing out of the sizing material at a pressure of 70±5kg / cm2 and 160±2°C accounts for the percentage of the ...

specific Embodiment 2

[0042] Put 200 grams of phenol, 110 grams of epoxidized soybean oil, and 3 grams of amine catalyst into a 1000 ml three-necked flask, react at 80-90 °C for 60-90 minutes, add 300 grams of formaldehyde, and 40 grams of nitrogen-containing phenolic resin Carry out the reaction, operate according to the process of specific example 1, obtain sample 2. Test according to the same standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com