IoT (Internet of Things) based rotating disk type hinge punching device

A punching device and turntable technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine parts, etc., can solve the problems of increasing the waste of human resources and increasing the labor intensity of workers, and achieve the goal of drilling Excellent hole effect and waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

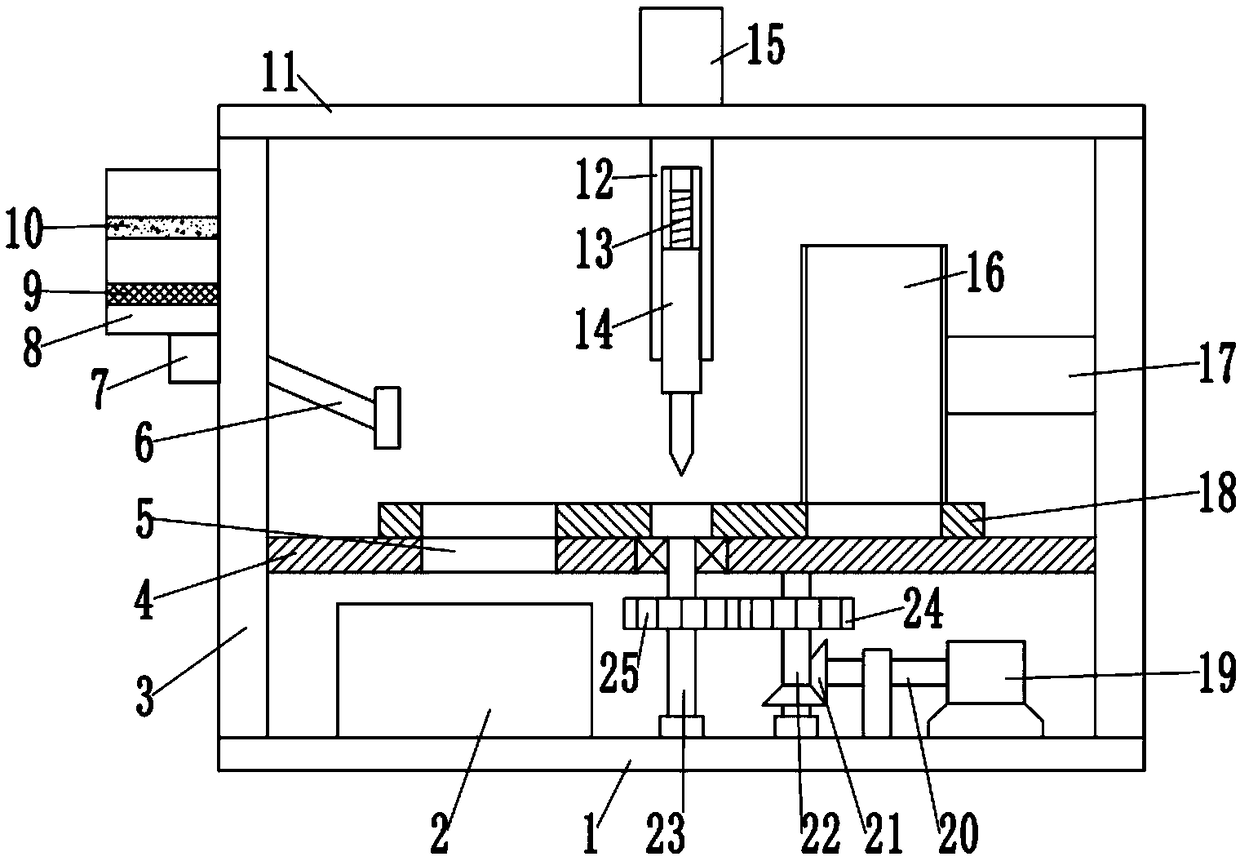

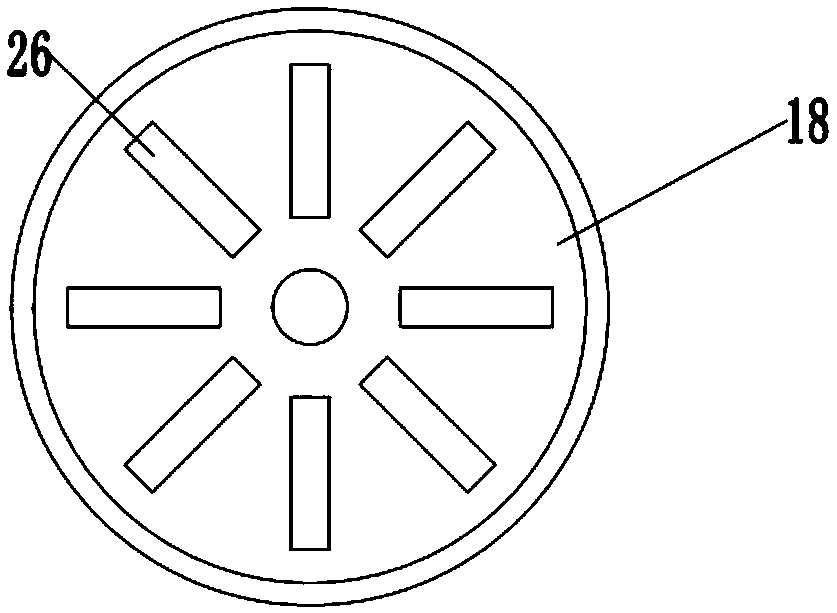

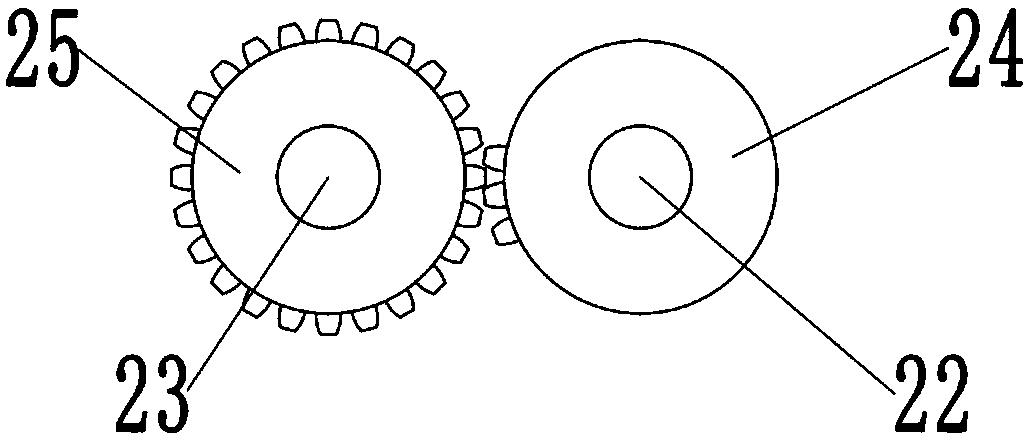

Embodiment 1

[0023] see Figure 1~3 , in an embodiment of the present invention, a turntable hinge punching device based on the Internet of Things includes a bottom plate 1 and a turntable 18; two side plates 3 are fixedly fixed on the left and right sides of the bottom plate 1, and the top of the side plate 3 The top plate 11 is fixedly installed, and the partition plate 4 is also fixedly installed between the two side plates 3; the turntable 18 is installed on the bottom plate 1 through the rotation of the third rotating shaft 23, and the lower side of the turntable 18 is close to the upper side of the partition plate 4 , and the dividing plate 18 is evenly provided with a number of placement grooves 26 for placing hinges to be punched, eight placement grooves 26 are arranged symmetrically, and the placement grooves 26 are through groove structures; the upper right side of the turntable 18 is provided with a Feeding pipe 16, feeding pipe 16 is fixedly installed on the side plate 3 by bra...

Embodiment 2

[0030] see Figure 1~3 , in an embodiment of the present invention, a turntable hinge punching device based on the Internet of Things includes a bottom plate 1 and a turntable 18; two side plates 3 are fixedly fixed on the left and right sides of the bottom plate 1, and the top of the side plate 3 The top plate 11 is fixedly installed, and the partition plate 4 is also fixedly installed between the two side plates 3; the turntable 18 is installed on the bottom plate 1 through the rotation of the third rotating shaft 23, and the lower side of the turntable 18 is close to the upper side of the partition plate 4 , and the dividing plate 18 is evenly provided with a number of placement grooves 26 for placing hinges to be punched, eight placement grooves 26 are arranged symmetrically, and the placement grooves 26 are through groove structures; the upper right side of the turntable 18 is provided with a Feeding pipe 16, feeding pipe 16 is fixedly installed on the side plate 3 by bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com