Numerically-controlled cutting machine capable of realizing rotating punching and punching method thereof

A cutting machine and blanking technology, applied in conveyors, metal processing, coiling strips, etc., can solve the problems of low precision control of punching height, inability to automatically adjust control, inconvenient punching adjustment, etc., to achieve punching The cutting effect is good, the interval is reasonable, and the replacement is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] In this embodiment, the structure of the invention is described in detail with reference to the drawings.

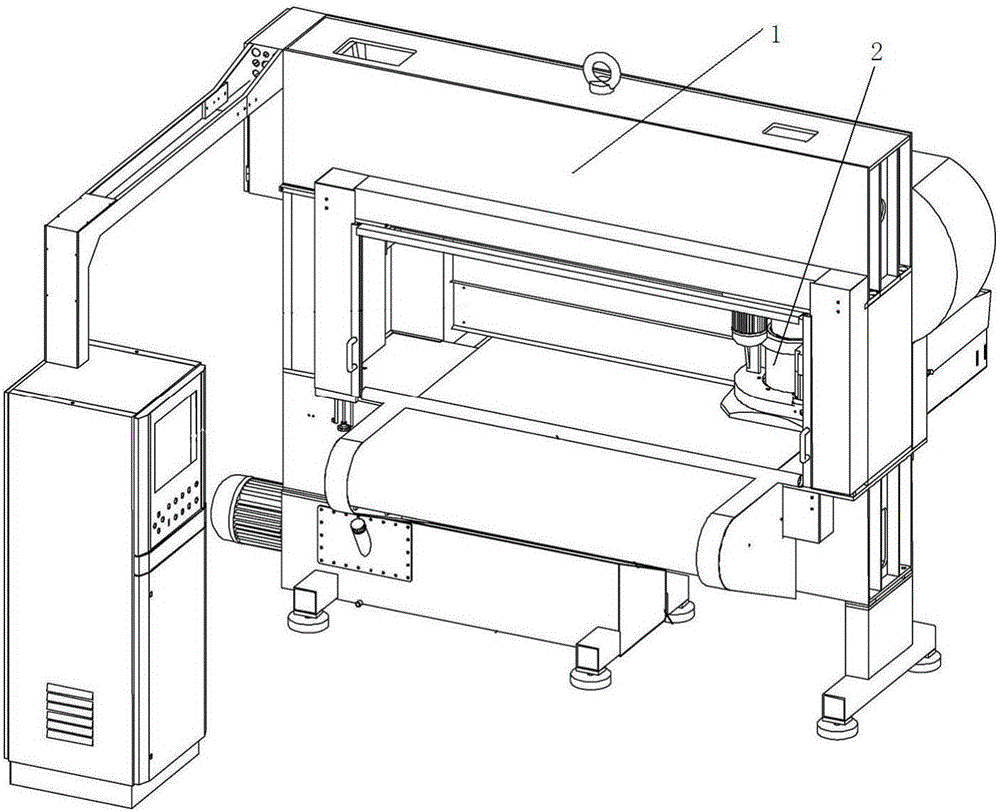

[0069] As shown in the figure, the rotary punching CNC cutting machine includes a gantry body 1 and a controller of the CNC cutting machine. The body is equipped with a rotary punching device, an automatic belt deviation correction device, a feeding device, a hydraulic device, and a synchronous reduction device;

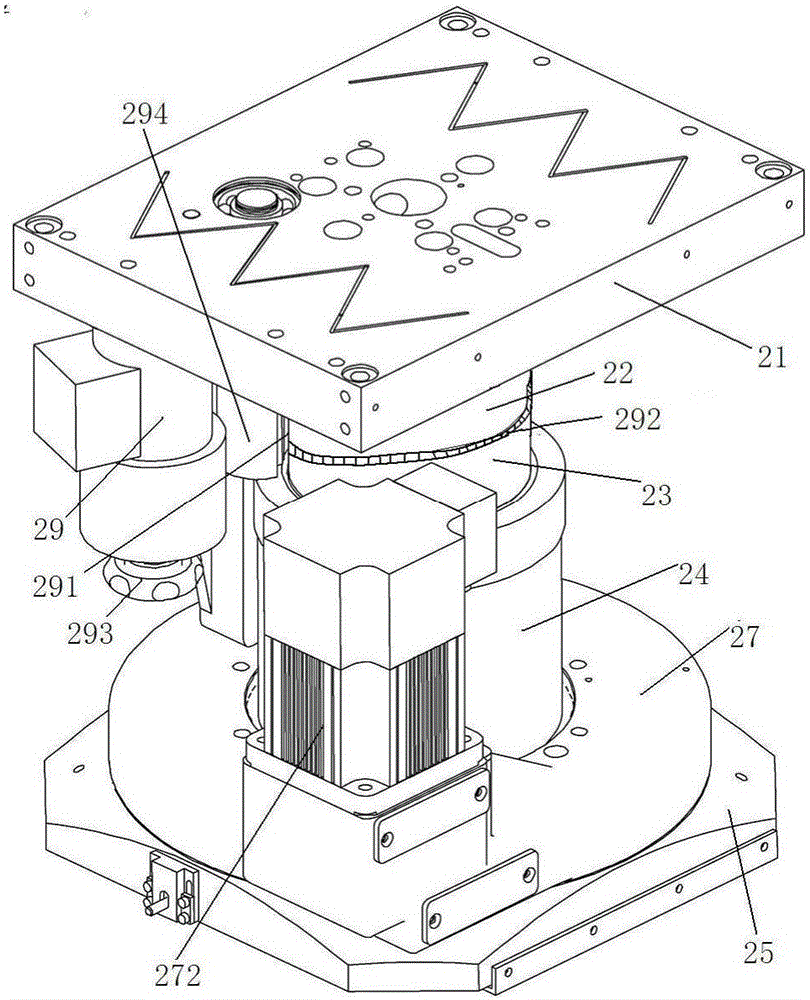

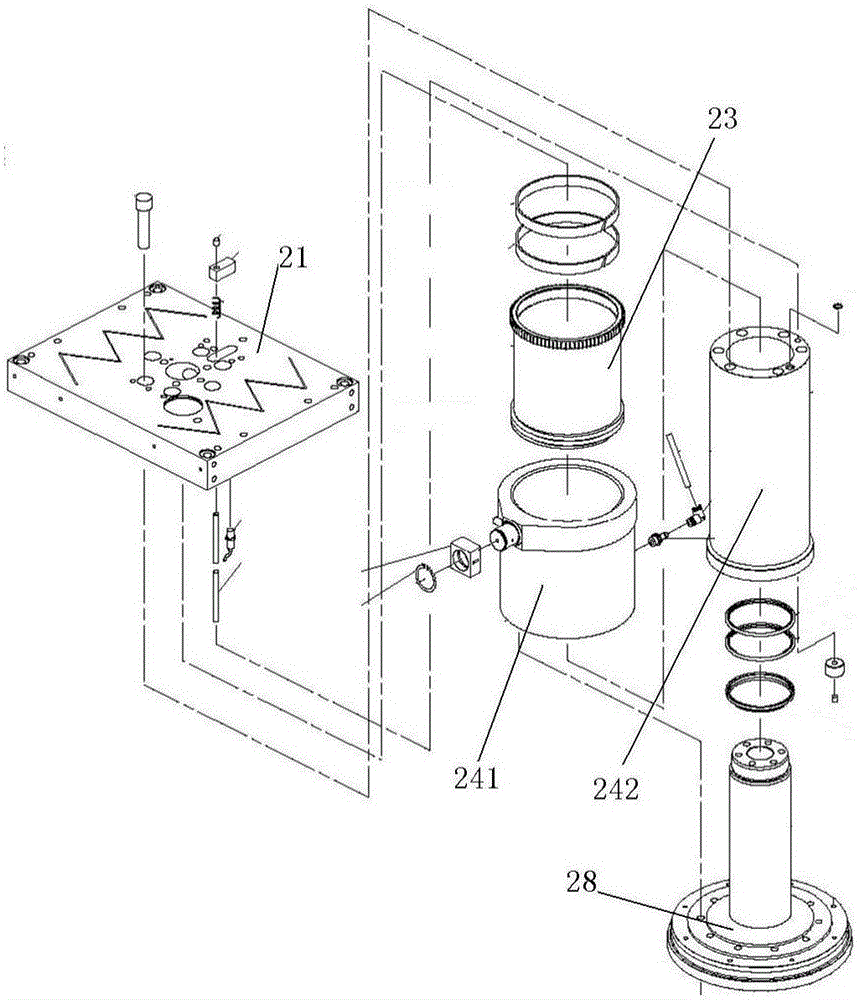

[0070] The body 1 is provided with a rotary punching device 2, which includes:

[0071] Horizontal mobile platform 21, which can move horizontally is located on the body 1;

[0072] The punching mechanism includes a cylinder 22 arranged on a horizontal moving table 21. The lower end of the cylinder 22 can be raised and lowered with a rotating cylinder liner 23. The outer wall of the lower end of the rotating cylinder liner 23 is connected to the inner wall of the oil cylinder 24 through threads and drives the oil cylinder 24. , the cylinder 22, the rota...

Embodiment 2

[0084] With reference to Embodiment 1, the feeding device includes a belt-drawing mechanism, a belt-pressing mechanism, and a feeding mechanism.

[0085] The drawstring mechanism includes an endless drawstring 33 that moves counterclockwise. The pull belt mechanism includes a first pull pulley 331 and a second pull pulley 332 horizontally arranged on the inside of the drawstring 33, and a third pull pulley 333 is also arranged below the first pull pulley 331 and the second pull pulley 332 .

[0086] A belt pressing mechanism, which includes a first pressing roller 35 that presses the blank 34 to be cut on the draw belt 33 and moves clockwise;

[0087] Feeding mechanism, it comprises movable feeding car 36, is provided with a plurality of front drums 38 and rear drums 39 for placing blank 34 on the feeding car 36, and the front end of feeding car 36 is also provided with to be used for blank 34 preliminary Gather up the compacted second compaction roller 310 or compaction whe...

Embodiment 3

[0095] In combination with Embodiment 1, the CNC cutting machine is provided with an automatic belt deviation correction device, which includes an offset detection mechanism 44, an offset correction mechanism 45, and a controller 47; the deviation correction detection mechanism 44 is arranged on both sides of the belt 43, including rolling elements 441, the rolling parts are bearings or rollers. Other circular moving objects can also be used, so that the contact between the offset detection mechanism 44 and the belt 43 is a sliding contact, which reduces friction and makes the belt move more smoothly without jamming. The top of the correction detection mechanism is also provided with a belt positioning groove plate 46, one side of which is provided with a through groove 461 for the belt to pass through, and the other side is provided with a mounting hole 462 for installing the rolling element and the turret, and the mounting hole 462 is connected with the through groove. 461 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com