Patents

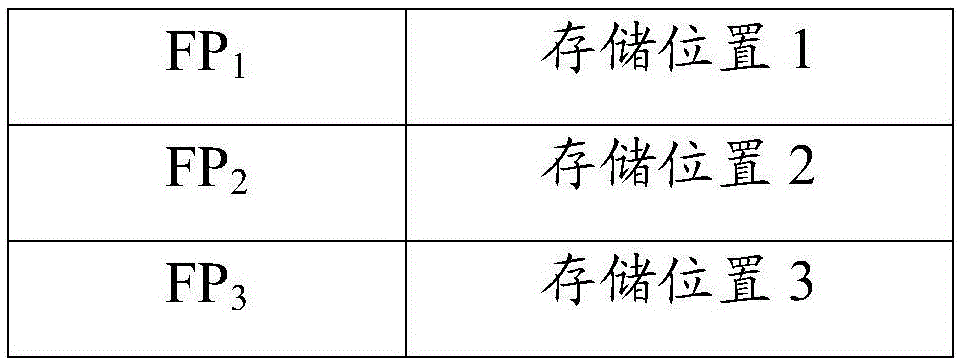

Literature

38results about How to "Reduce the amount of handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

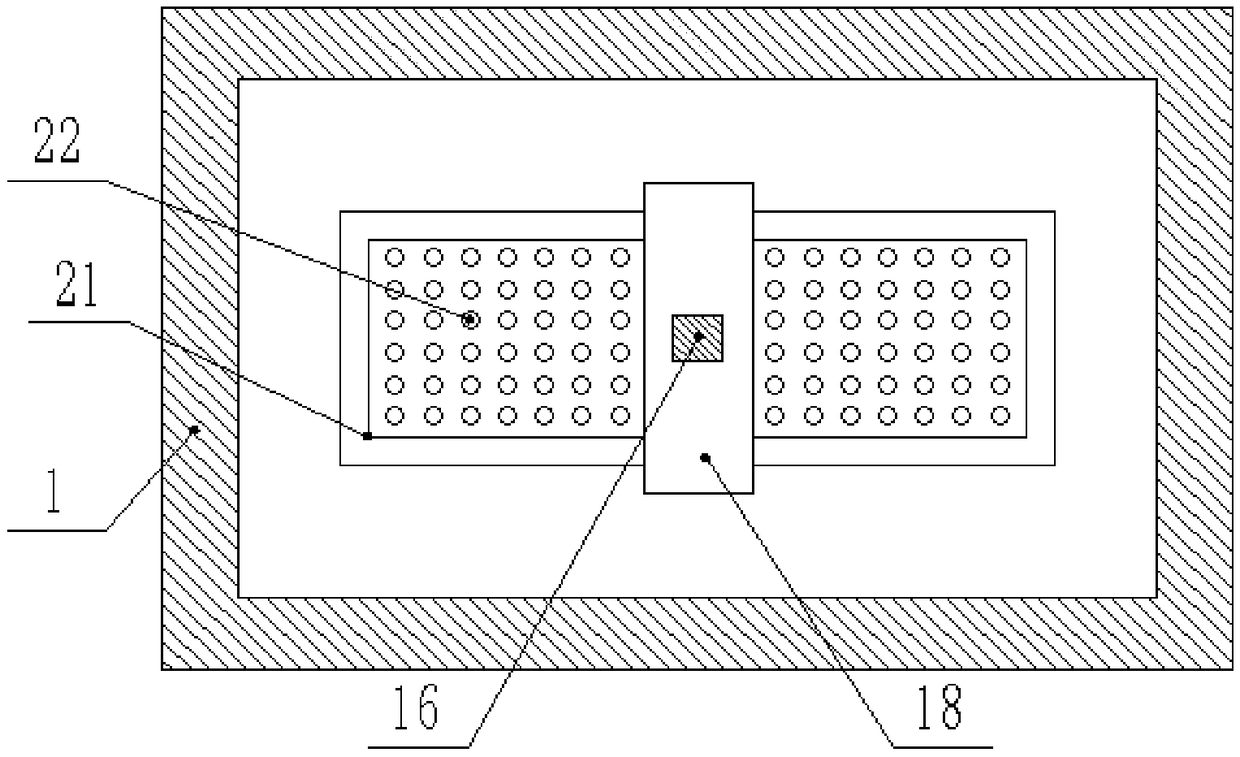

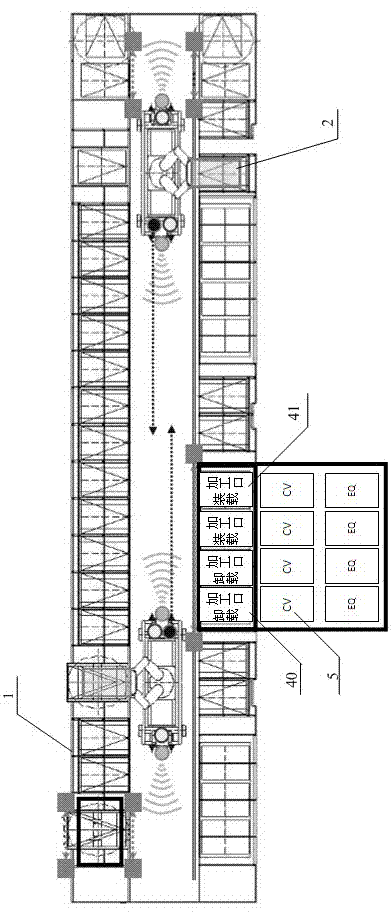

Tridimensional storage system

PendingCN108584271AReduce the amount of handlingHigh densityConveyorsStorage devicesEngineeringMechanical engineering

The invention provides a tridimensional storage system used for achieving precise operation and management of stored cargo outputting and inputting and increasing the storage utilization rate of warehouse space to achieve high-density storage and storing and sorting operation from cargoes to people. According to the technical scheme, the tridimensional storage system comprises at least one layer of tracks for hoisting running of a loading trolley, and a bearing platform is arranged under the tracks; the tracks comprise two single bearing pipes, and each single bearing pipe is shaped like a pipe and comprises a pipe cavity used for allowing rolling wheels to roll in the pipe cavity; each pipe cavity is provided with a strip-shaped axial opening used for allowing the rolling wheels to be inserted, and the two opposite single bearing pipes are arranged in parallel; the top of each bearing pipe serves as a cargo bearing portion; the loading trolley comprises a first walking mechanism and agripping mechanism, the first walking mechanism comprises first rolling wheels, and the first rolling wheels are arranged in the pipe cavities and roll in the pipe cavities; the gripping mechanism islocated under the tracks and comprises a gripper used for gripping the cargoes; and the loading trolley is suspended between the two bearing pipes and walks between the two bearing pipes in a suspended mode.

Owner:SHENZHEN WHALEHOUSE TECH CO LTD

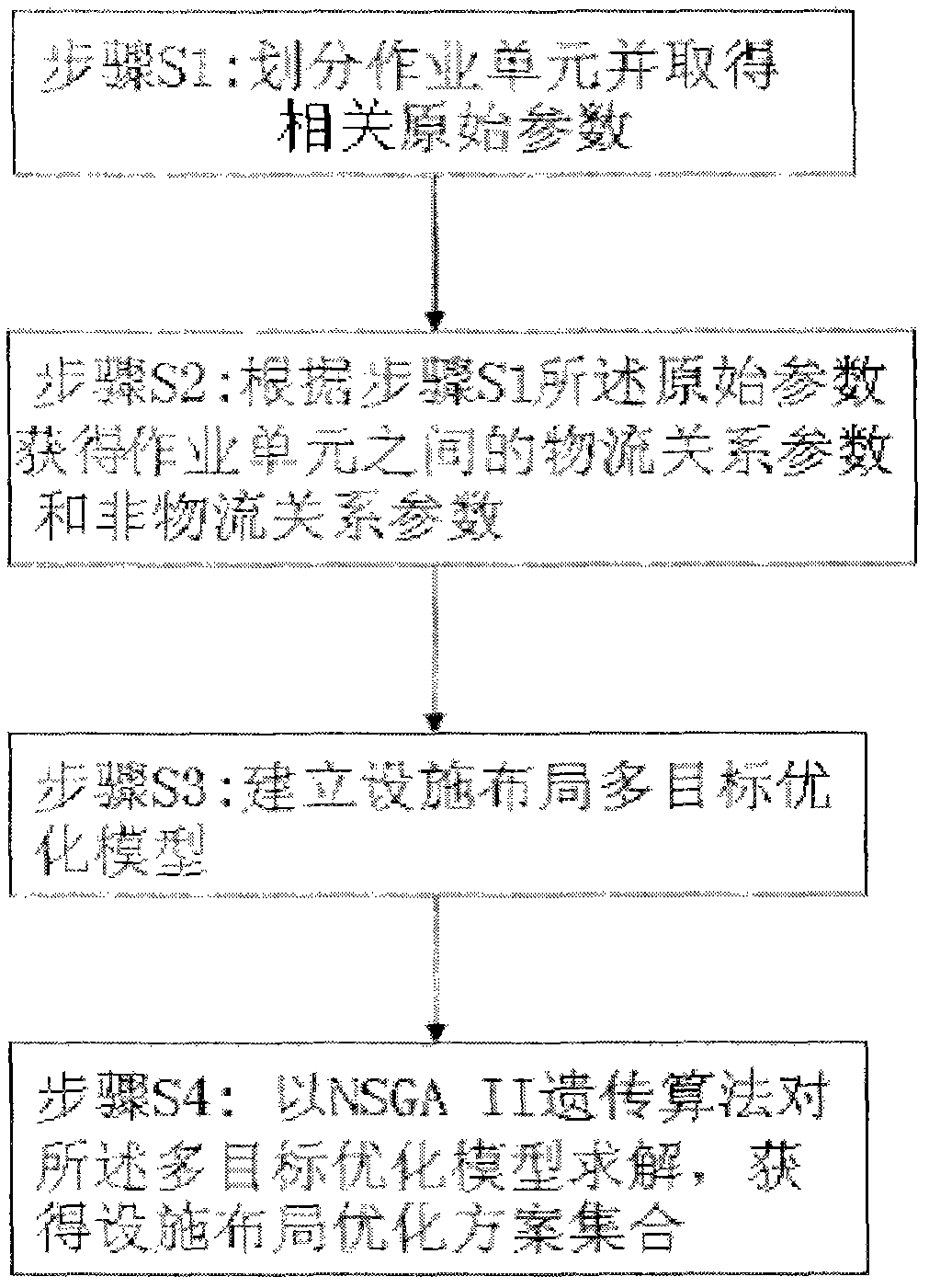

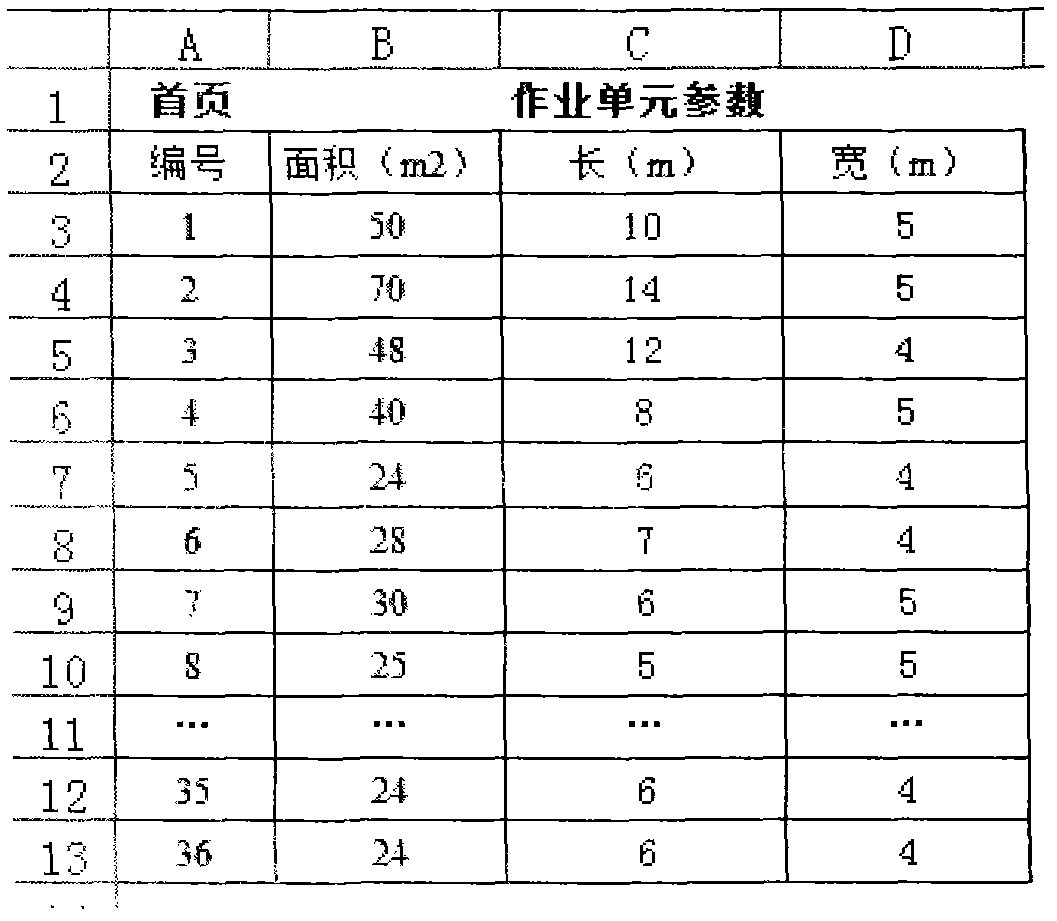

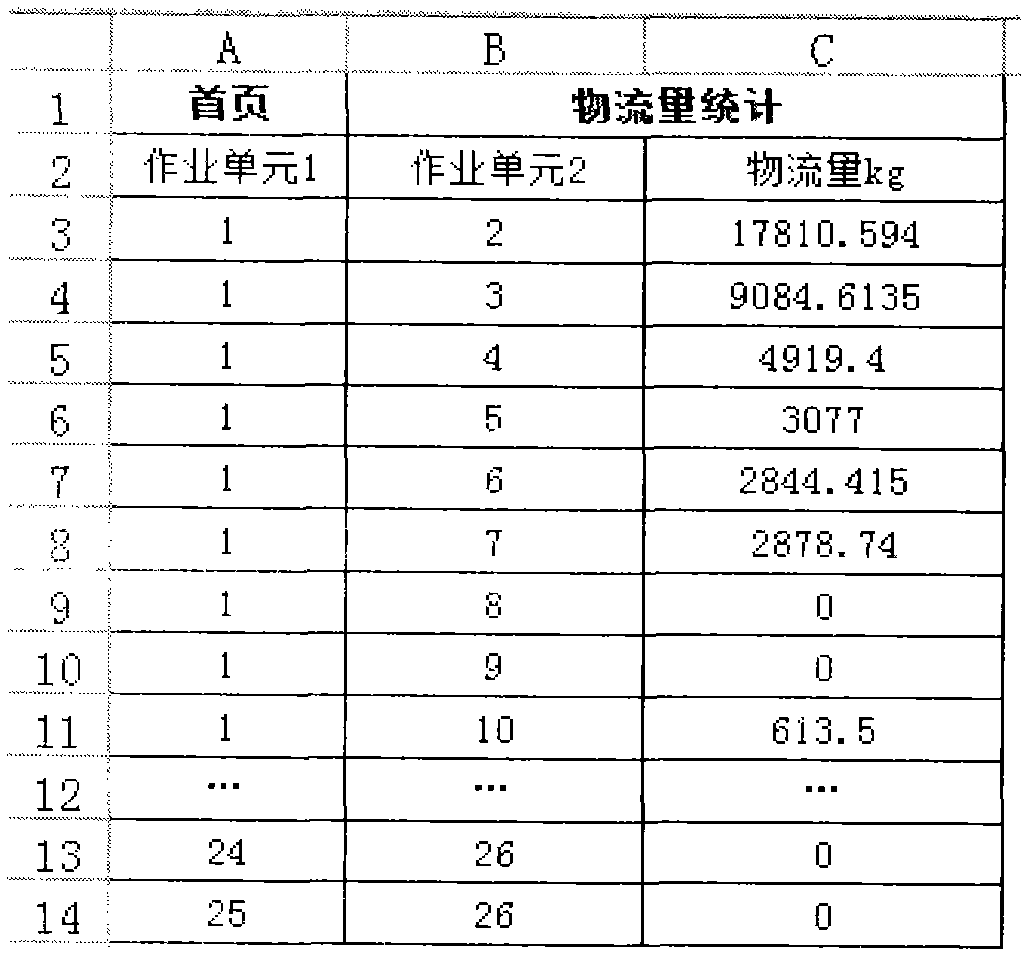

Multipurpose optimization method for distribution of facilities in plant

InactiveCN102214333AReduce Handling CrossoversIncrease intimacyInstrumentsComputer sciencePareto solution

The invention provides a multipurpose optimization method for distribution of facilities in a plant, which comprises the steps of: 1. dividing distribution areas of facilities in the plant into operation units and obtaining related original parameters; 2. obtaining logistic relation parameters and non-logistic relation parameters of the operation units according to the original parameters obtained from the step 1; 3. building a multipurpose facility distribution optimization model; and 4. solving the multipurpose optimization model by using an NSGA (non-dominated sorting genetic algorithm) II, thus obtaining a Pareto solution set as a facility distribution optimization scheme set. With the method, the technical problem that multipurpose optimization distribution is carried out on the facilities in a building of the plant is solved, and the use of the method has the advantages of high distribution efficiency, high operation vision degree, good optimization effect, low use cost and strong university.

Owner:HENAN POLYTECHNIC UNIV

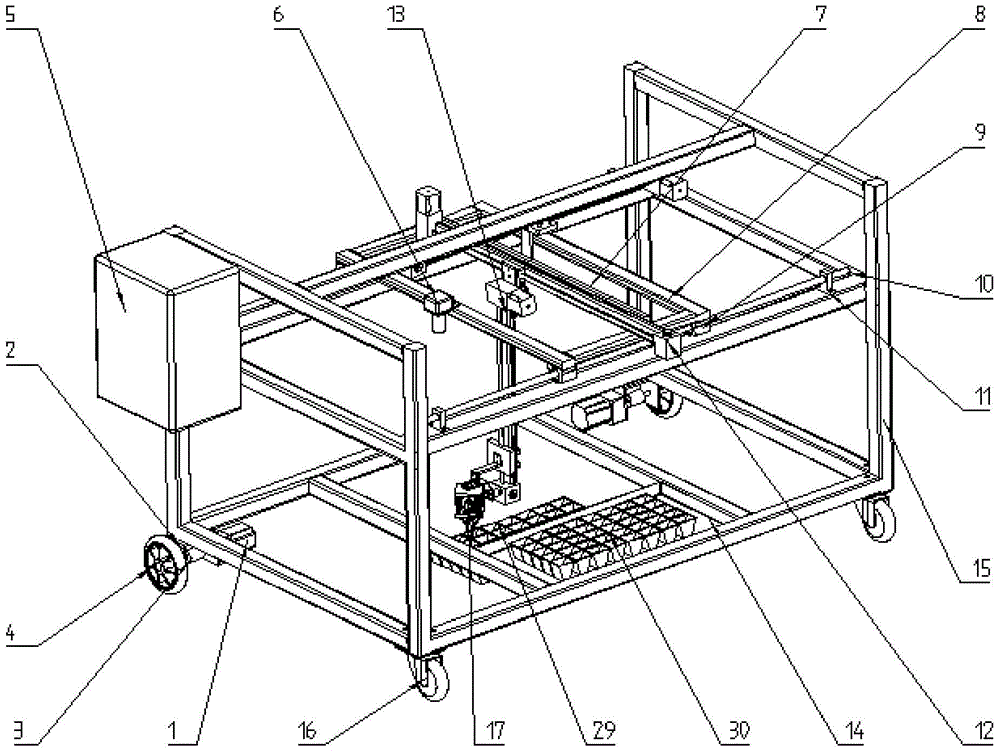

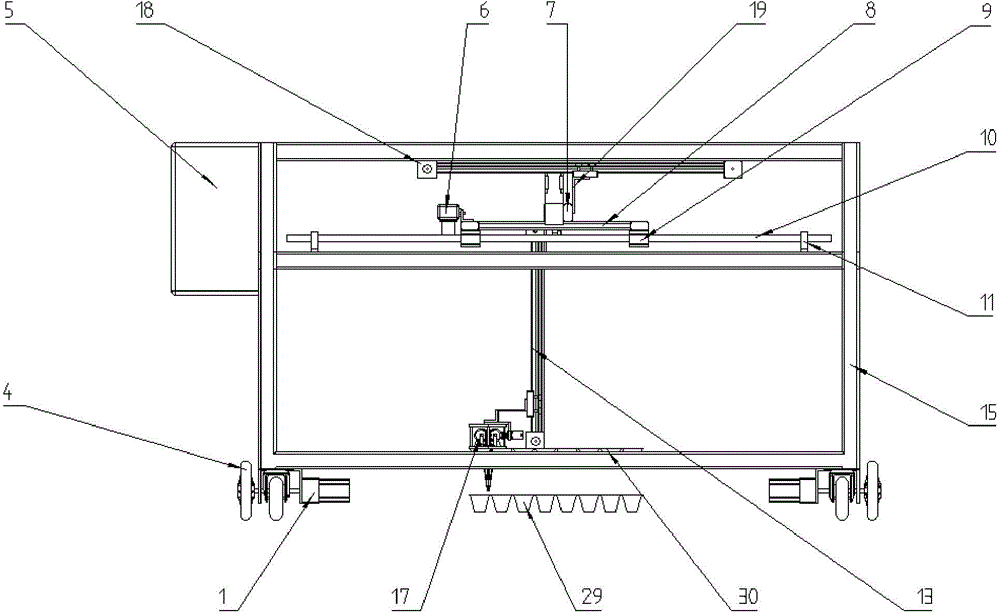

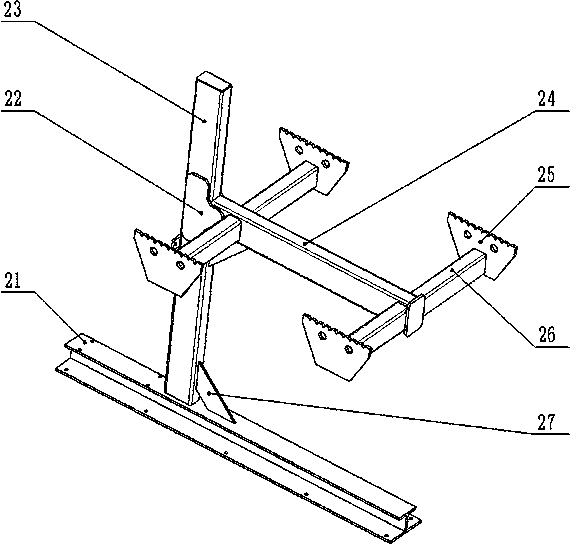

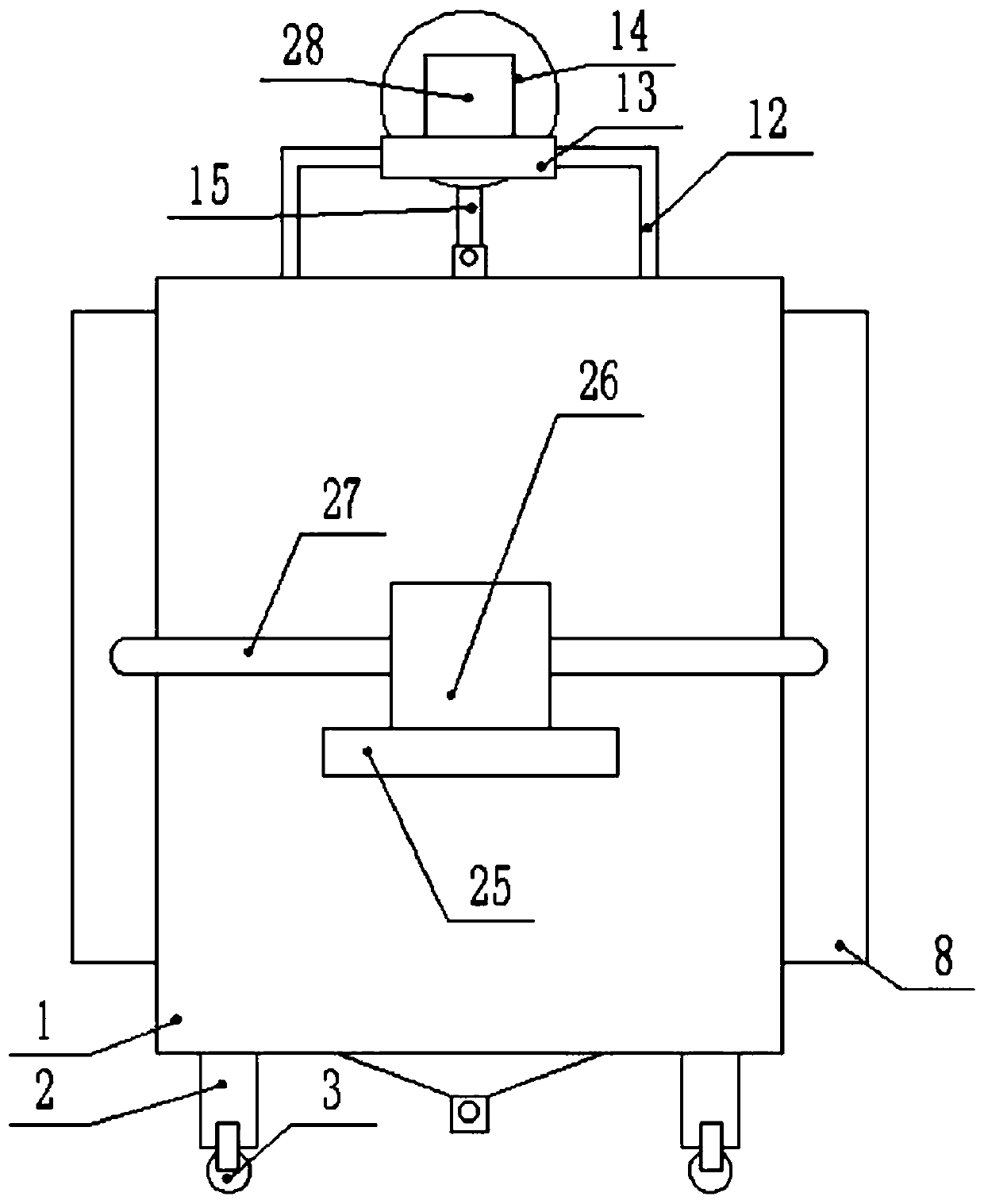

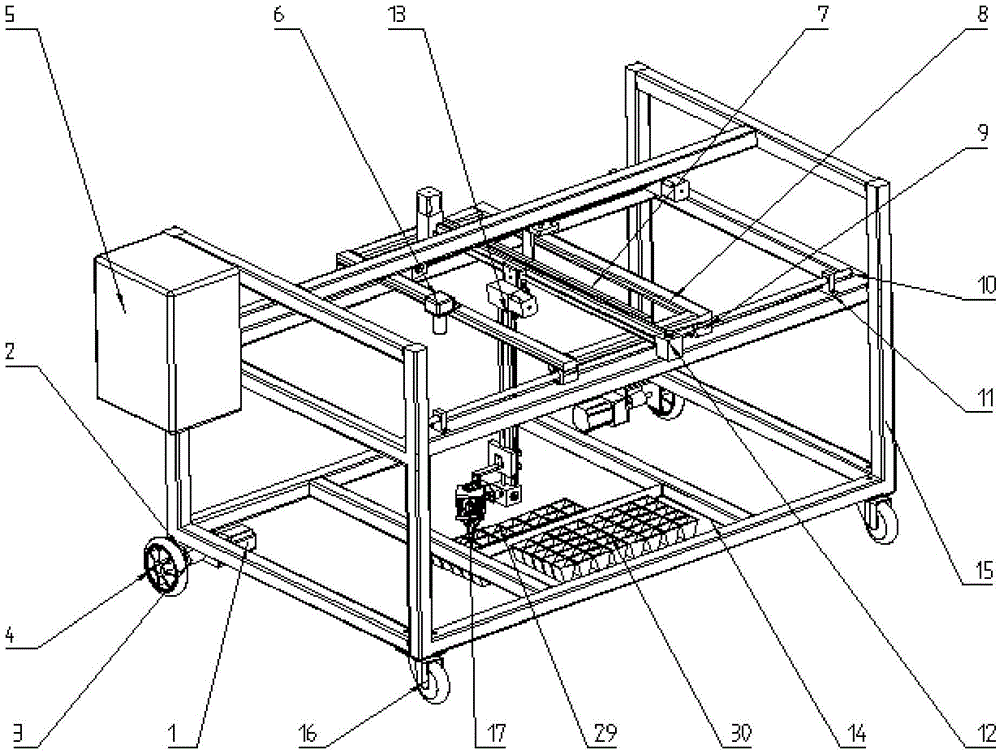

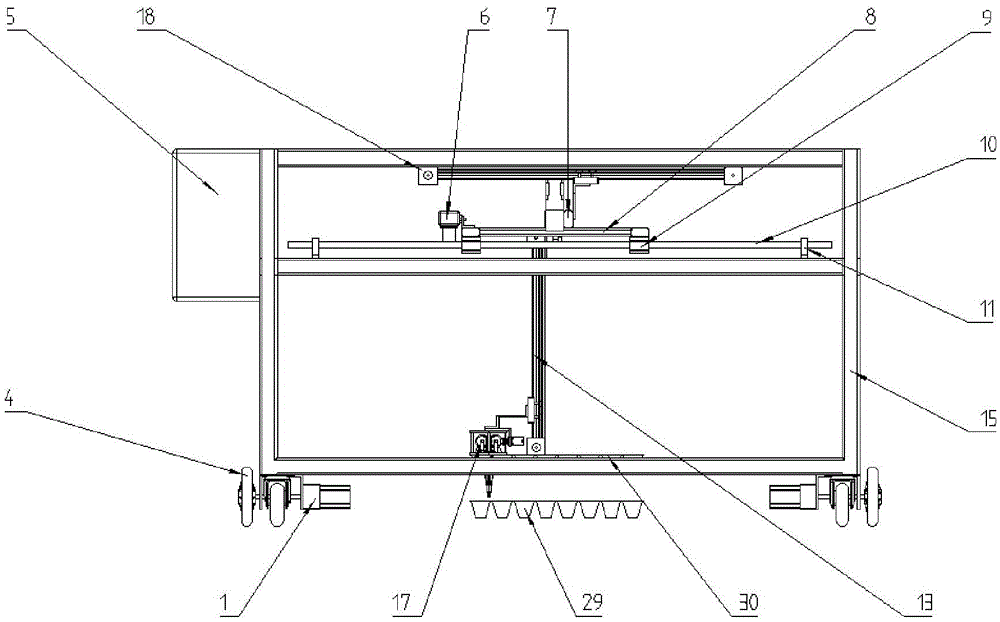

Mechanical operation device for automatically filling gaps with seedlings

ActiveCN104604403AAvoid the inconvenience of supplementing seedlingsSimple structureTransplantingCarrying capacityEngineering

The invention discloses a mechanical operation device for automatically filling gaps with seedlings. The device comprises a rack, a walking module, a mechanical arm module, a transplanting mechanical paw, a control box, an industrial camera and a computer, wherein the device is arranged on a track of an operation seedbed; the walking module is arranged at the bottom of the rack, and is used for driving the device to move on the track; the industrial camera is capable of automatically shooting a seeding tray; the computer is used for processing a shot picture, and obtaining seedling-missing positions on an operation seeding tray; the transplanting mechanical paw is arranged on the mechanical arm module; the mechanical arm module is used for driving the transplanting mechanical paw to reach the position needing work according to an instruction; and the mechanical arm module is matched with the transplanting mechanical paw, and is used for transplanting healthy seedlings into the seedling-missing positions on the operation seeding tray from a standby seeding tray, to finish the operation for automatically filling gaps with seedlings. According to the device disclosed by the invention, the inconvenience that the operation seeding tray needs to be moved to seedling filling equipment by manpower to fill gaps with seedlings in rows in traditional seedling filling equipment is avoided; the carrying capacity is reduced; and double hands of workers are liberated.

Owner:ZHEJIANG UNIV

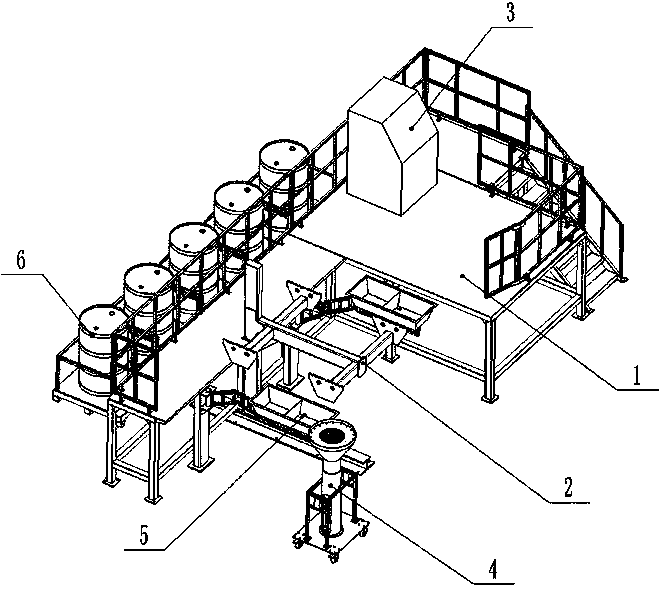

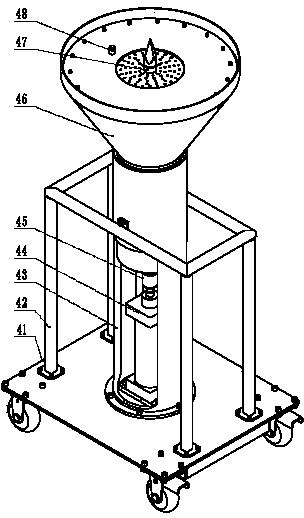

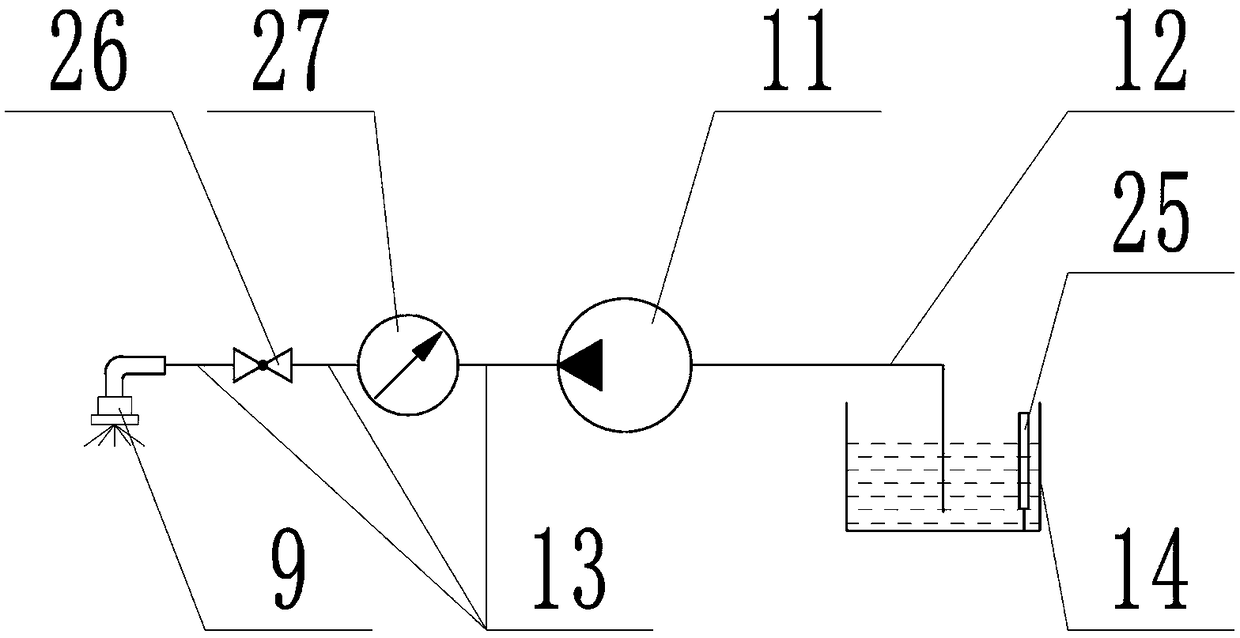

Scraped car refrigerant and oil liquid recovery device

InactiveCN104043634AEasy to recycleReduce usageWaste processingSolid waste disposalWaste oilRefrigerant

The invention relates to a scraped car refrigerant and oil liquid recovery device including an operating platform, a scraped car fixing frame, a refrigerant recovery machine, an oil liquid recovery trolley, oil liquid recovery devices and oil storage tanks; the front part of the operating platform is provided with the scraped car fixing frame for fixing and supporting a scraped car; the movable oil liquid recovery trolley and the oil liquid recovery devices are arranged below the scraped car fixing frame, the movable refrigerant recovery machine for extracting a refrigerant is arranged on the operating platform, and furthermore, the oil storage tanks for storing recycled waste oil are arranged above the rear part of the operating platform. The scraped car refrigerant and oil liquid recovery device can intensively operate, and has the advantages of good safety, high work efficiency, energy saving and environmental protection.

Owner:CHANGZHI CITY HUAJIE GUANG TECH CO LTD

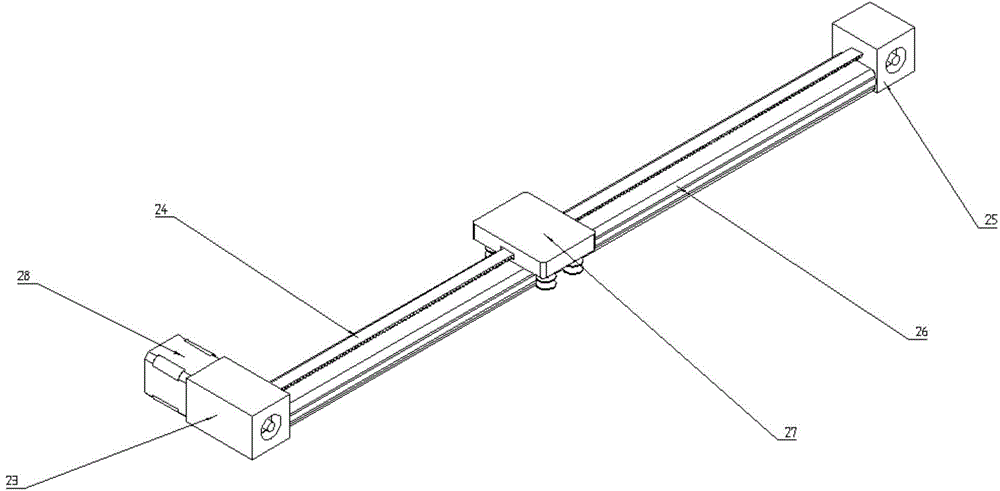

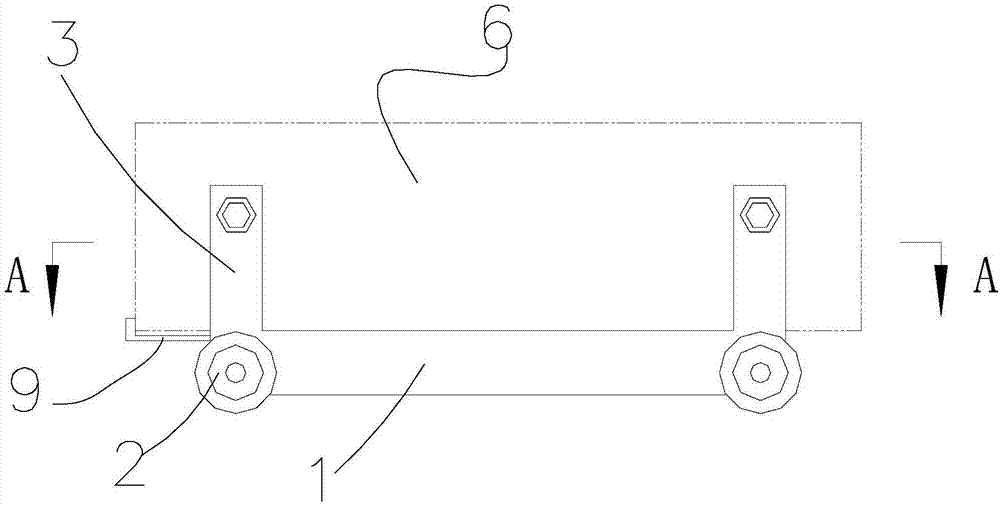

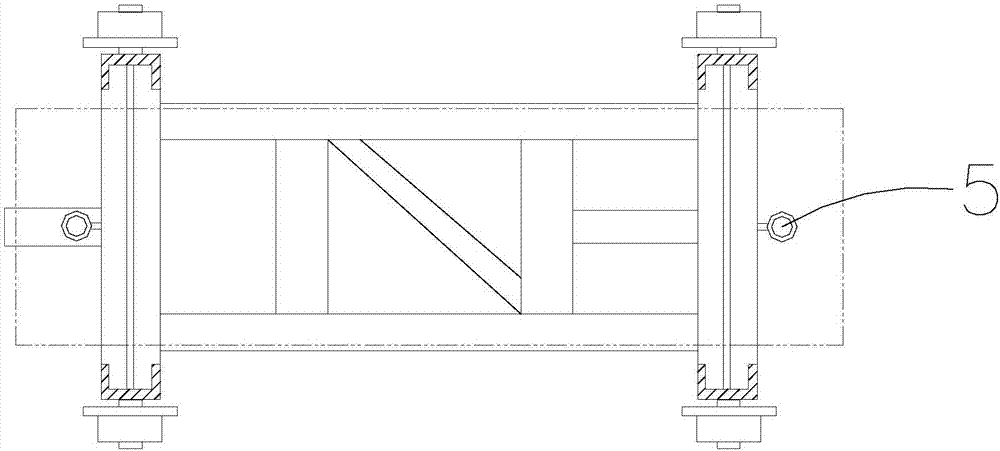

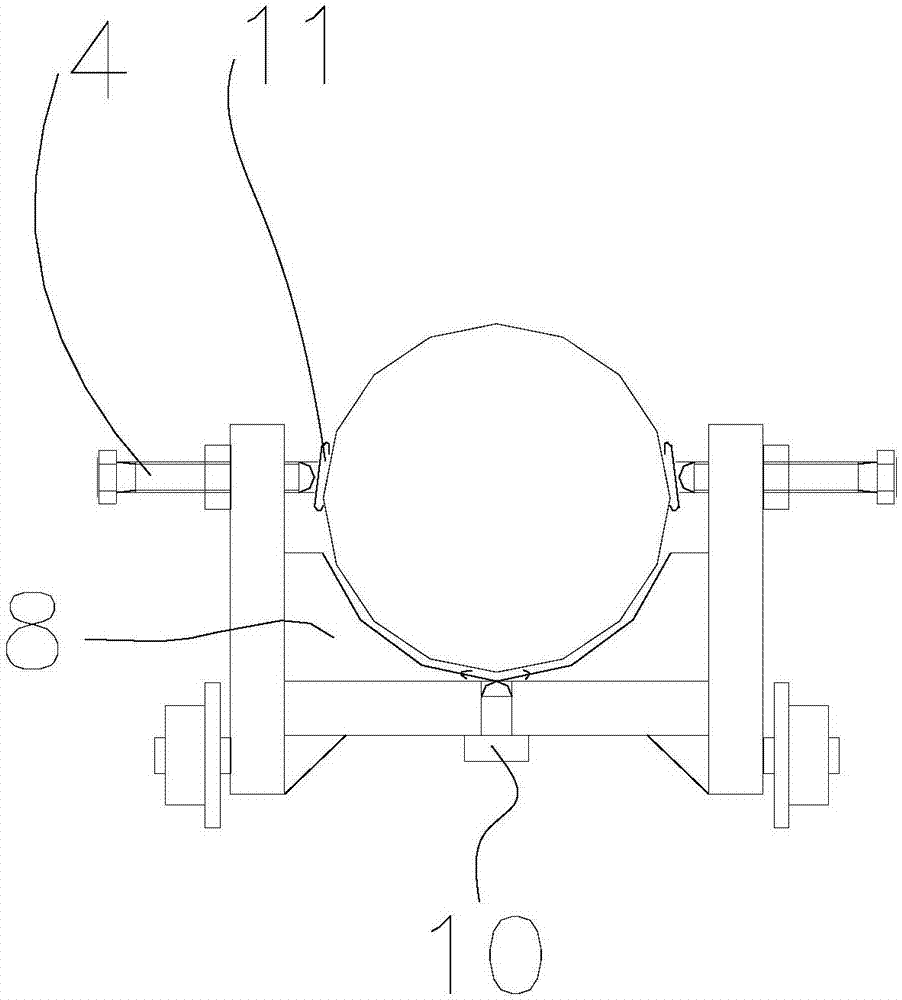

Rail cart and use method of rail cart in construction of large-diameter steel penstock

The invention provides a rail cart and a use method of the rail cart in the construction of a large-diameter steel penstock. The rail cart comprises a cart body consisting of a framework and at least four wheels which are symmetrically arranged on two sides of the cart body, wherein flanges which can be clamped on the inner side of rails are arranged on the wheels; a supporting plate for putting the large-diameter steel penstock is arranged at each of two ends of the cart body. Before the rail cart is used, firstly, temporary rails are arranged on two sides of a pipeline buttress along the design trend of the steel penstock; secondly, the rail cart is arranged on the rails and is connected with a winch, the steel penstock is arranged on the rail cart, and the winch is started for drawing the rail cart along the rails to move to be in place; the steel penstock is arranged from a high position to a low position; after mounting is finished, the winch is started for reeling off a steel wire rope, and the rail cart returns to a pipeline hoisting point along the rails under the action of gravity. According to a mounting method for the pipeline by using the rail cart under the condition that a hoisting machine cannot completely cover the pipeline, the operation amount of workers can be greatly reduced, and construction period is shortened.

Owner:POWERCHINA MUNICIPAL CONSTR GRP CO LTD

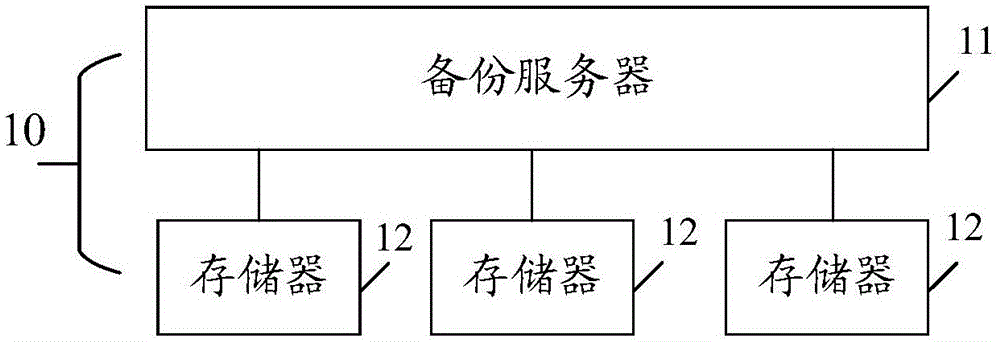

Data processing method, backup server and storage system

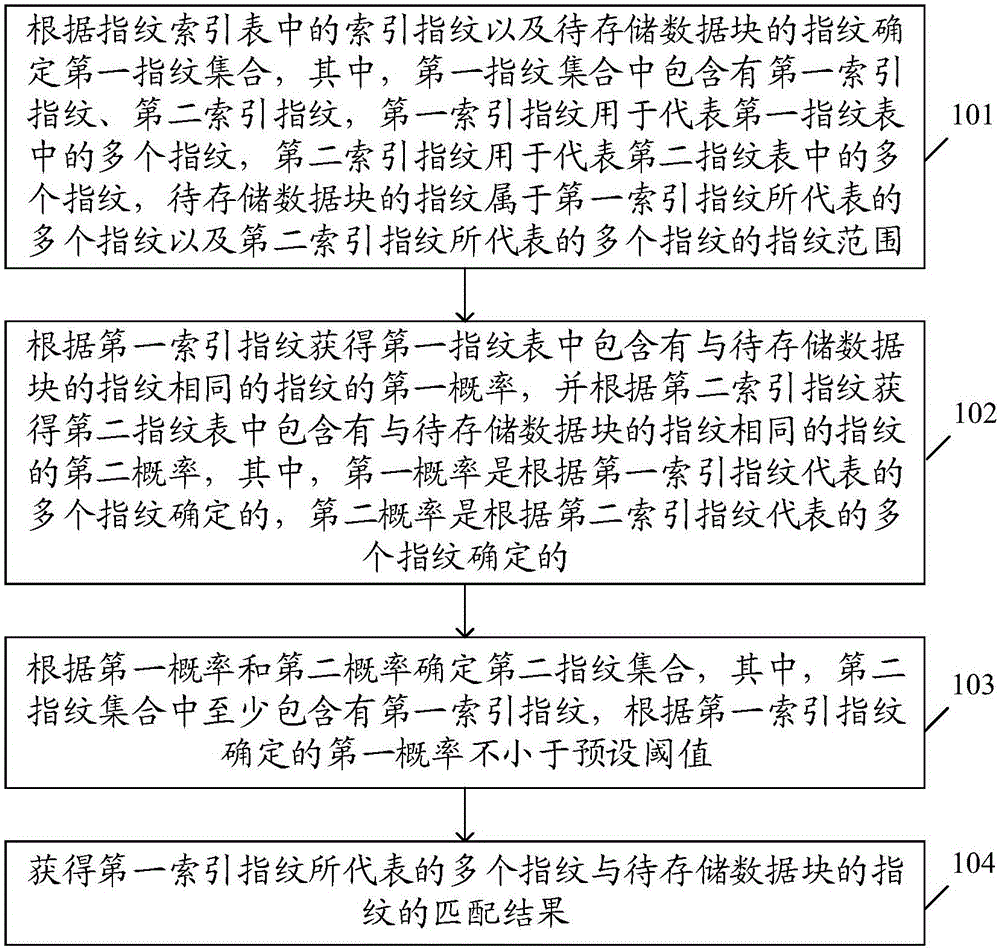

ActiveCN106407226AReduce the amount of handlingImprove processing efficiencySpecial data processing applicationsRedundant hardware error correctionFingerprintStorage efficiency

The invention discloses a data processing method, a backup server and a storage system, and aims to solve the problems of low data storage efficiency caused by fingerprint comparison consuming mass I / O resources; the data processing method comprises the following steps: determining a first fingerprint set according to index fingerprints in a fingerprint index table and a fingerprint of a to-be-stored data block; obtaining a first probability that the first fingerprint table contains the fingerprint identical to the fingerprint of the to-be-stored data block according to the first index fingerprint, and obtaining a second probability that the second fingerprint table contains the fingerprint identical to the fingerprint of the to-be-stored data block according to the second index fingerprint; determining a second fingerprint set according to the first and second probabilities; obtaining a matching result between the plurality of fingerprints represented by the first index fingerprint and the fingerprint of the to-be-stored data block.

Owner:HUAWEI TECH CO LTD +1

Half shaft machining process

InactiveCN106392469AImprove processing qualityReduce the amount of handlingMedium frequencyMachining process

The invention discloses an automobile half shaft machining process. The automobile half shaft machining process comprises 1, laying off raw materials entering the factory; 2, forging the half shaft; 3, carrying out thermal refining to the half shaft; 4, carrying out a rough shot blasting step; 5, carrying out a rough correction step; 6, carrying out rough turning to the long shaft of the half shaft and drilling a center hole; 7, calculating the total length of the half shaft and drilling a center hole; 8, grinding the center hole; 9, carrying out finish turning to the rod portion of the half shaft and cutting a thread; 10, carrying out gear rolling to the half shaft; 11, carrying out medium-frequency hardening heat treatment to the surface; 12, carrying out a tempering step; 13, carrying out a fine correction step; 14, carrying out supersonic flaw detection; 15, carrying a fine shot blasting step; 16, grinding the center hole; 17, carrying out finish turning to a disc structure of the half shaft; 18, drilling a hole; 19, cutting a thread; 20, grinding the shaft neck; 21, carrying out magnetic powder flaw detection; and 22, carrying out total detection. By employing the improved half shaft machining process, the carrying amount for machining is reduced, the machining quality of the half shaft is improved at the same time, the fact that the machined half shaft is without inner flaws is guaranteed, the half shaft machining process is simple to operate, and the coaxial consistency is high.

Owner:CHONGQING JINGJIANG AUTO SEMI AXLE CO LTD

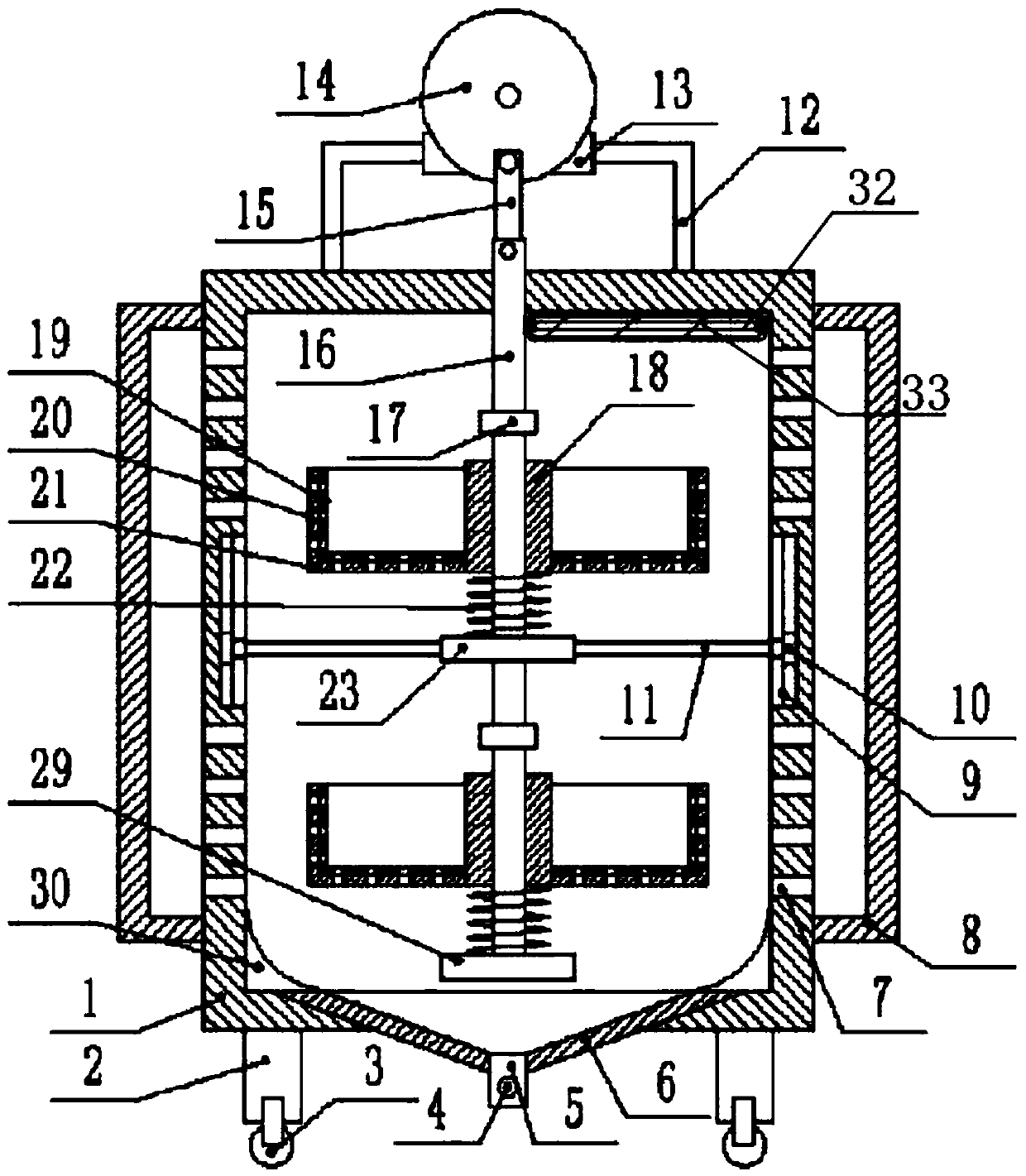

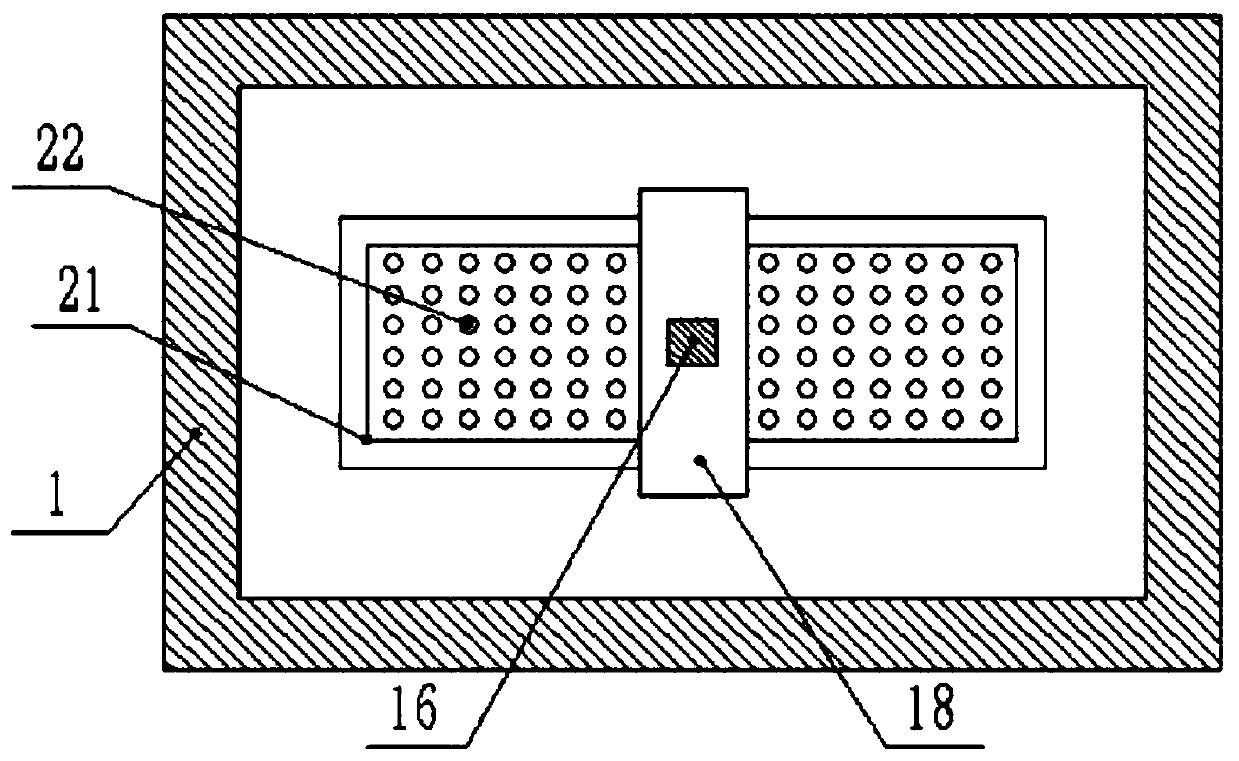

Hardware accessory drying device

InactiveCN109307408AAvoid wear and tearEfficient dryingDrying gas arrangementsDrying machines with non-progressive movementsEngineering

The invention discloses a hardware accessory drying device. The hardware accessory drying device comprises a box. The four corners of the bottom end of the box are fixedly connected with landing legs.Wheels are fixedly arranged at the bottom ends of the landing legs. Covers are arranged on the two side walls of the box, and a box door is arranged on one side of the box. The hardware accessory drying device is simple in structure; a rubber layer is arranged on the inner wall of a square groove, and abrasion caused by collisions between hardware accessories and the square groove can be effectively avoided. The device can dry more hardware accessories or multiple kinds of hardware accessories at the same time, and through batched drying, the work efficiency is effectively improved. Under running of a motor, the hardware accessories in the square groove slightly bump on a sliding rod under the action of springs, and the hardware accessories are effectively protected through slight bumping. Meanwhile, hot air can comprehensively and effectively dry the hardware accessories; and through the arrangement of the wheels, the carrying amount of the hardware accessories can be effectively reduced, the hardware accessories are conveniently dried, and the work efficiency is effectively improved.

Owner:开平市红火卫浴有限公司

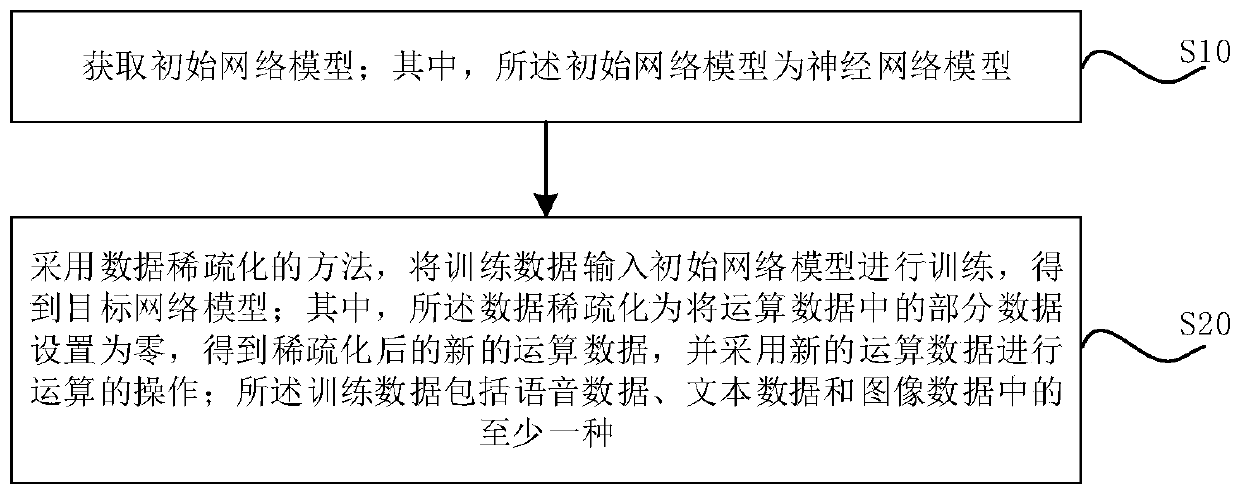

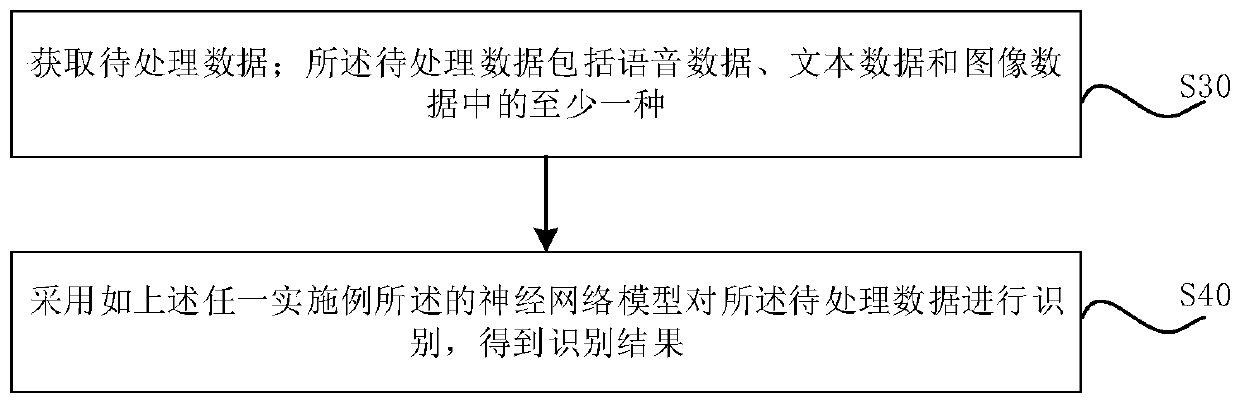

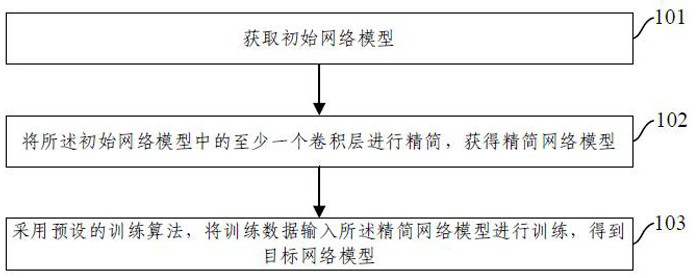

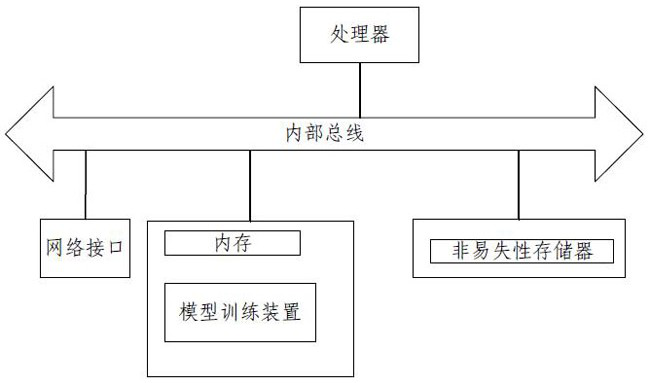

Neural network model training method, data processing method and related products

PendingCN111126600ASave storage spaceReduce power consumptionNeural learning methodsEngineeringNetwork model

The invention relates to a neural network model training method, a data processing method and related products. The method comprises the steps of obtaining an initial network model, wherein the initial network model is a neural network model; inputting training data into the initial network model for training to obtain a target network model, wherein the training data comprises at least one of voice data, text data and image data. By adopting the method, the processing efficiency of voice data, text data and image data can be improved, and the power consumption of the processor is reduced.

Owner:SHANGHAI CAMBRICON INFORMATION TECH CO LTD

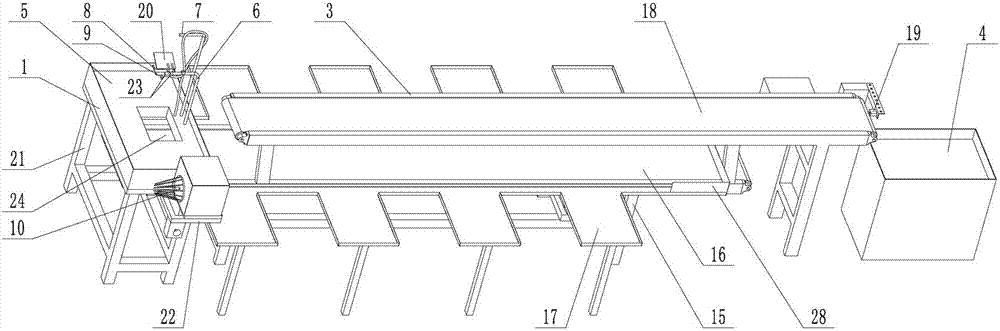

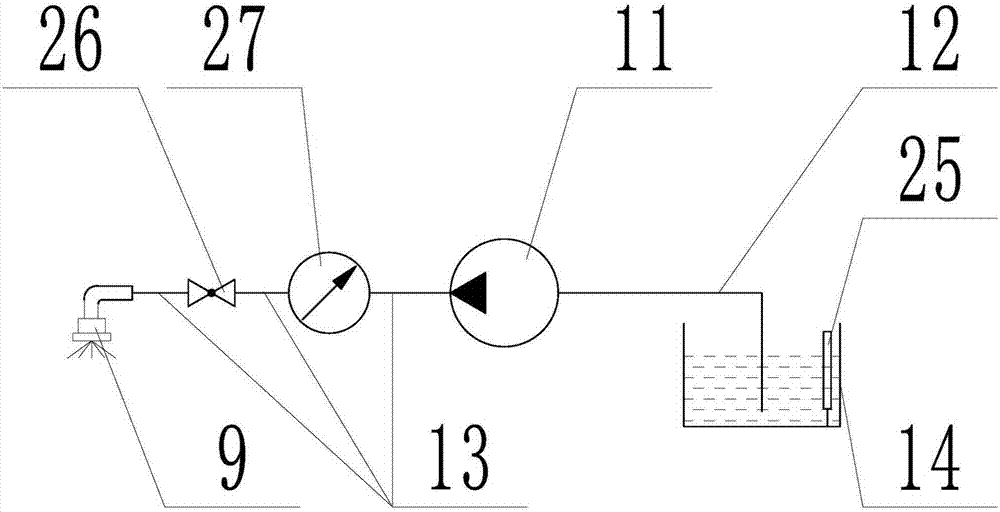

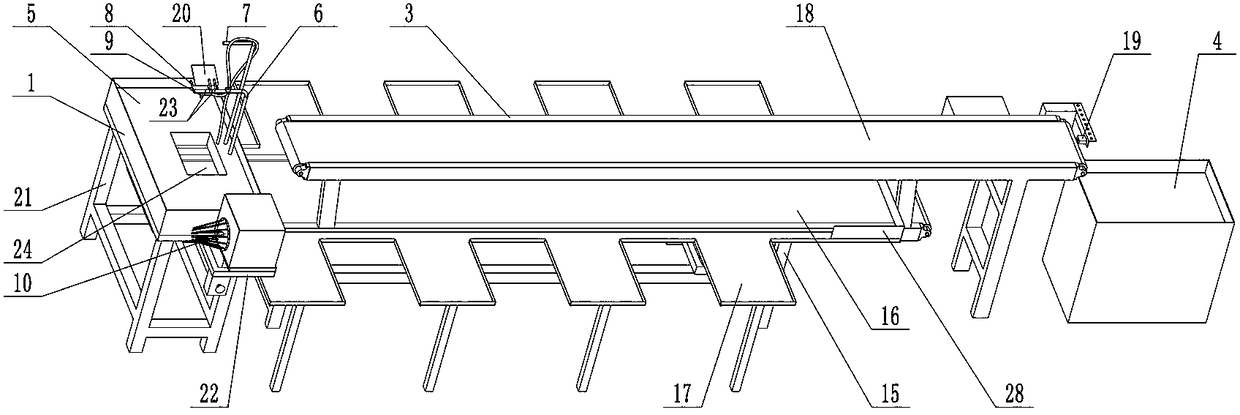

Production line for sausage packaging

ActiveCN107054784AReduce physical laborReduce the amount of handlingConveyorsControl devices for conveyorsProduction lineSpray nozzle

The invention relates to a production line for sausage packaging. The problems that the space using rate is low, the labor amount of workers is large, and stations are not synchronous are solved. According to the technical scheme, the production line comprises a section shearing machine provided with an oil spraying machine, a double-layer conveying belt is arranged behind the section shearing machine, and a vacuum package machine is arranged behind the double-layer conveying belt; the section shearing machine comprises a first working table provided with a first hanging bracket and a second hanging bracket, the first hanging bracket is provided with a cutting plate, a spraying nozzle is arranged below the cutting plate, and a reel is arranged on one side of the first working table; the oil spraying machine comprises an oil pump provided with a first pipe and a second pipe, an oil cylinder is arranged at the other end of the first pipe, and the second pipe is connected with the spraying nozzle; and the double-layer conveying belt comprises a second support provided with a lower-layer conveying belt, a plurality of second working tables are arranged on the two sides of the lower-layer conveying belt, and an upper-layer conveying belt is arranged above the lower-layer conveying belt. The production line is reliable in performance, ingenious in conception and convenient to maintain, the space using rate of a packaging workshop is improved, the labor amount of workers in the workshop is reduced, and the overall production efficiency is obviously improved.

Owner:漯河市谊加谊食品有限公司

Supporting method of carboniferous system geologic structure in-zone breaking country rock roadway

ActiveCN103122768AEffective control of deformationControl deformationMine roof capsAnchoring boltsTectonicsFactor of safety

The invention particularly discloses a supporting method of a carboniferous system geologic structure in-zone breaking country rock roadway. The problems of that support of the carboniferous system geologic structure in-zone breaking country rock roadway is incomplete is solved. According to the supporting method of the carboniferous system geologic structure in-zone breaking country rock roadway, temporary support to a roadway is carried out when a heading machine group is stepped forward and cut to a certain distance, and then permanent support composed of two steps is carried out. The permanent support comprises that a steel wire mesh is laid, girders are loaded up, roof bolts are installed, gang-part bolts are installed, and roof anchor ropes are installed. The supporting method of the carboniferous system geologic structure in-zone breaking country rock roadway is capable of lightening digging subsidiary transport work amount and improving a safety factor inside the roadway and has high economic effectiveness.

Owner:DATONG COAL MINE GRP

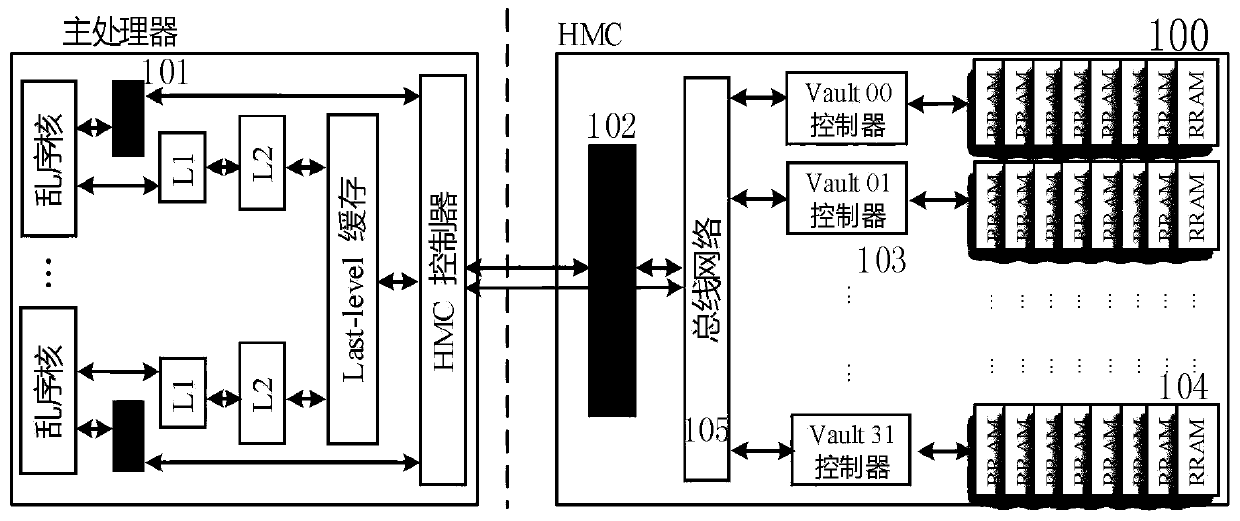

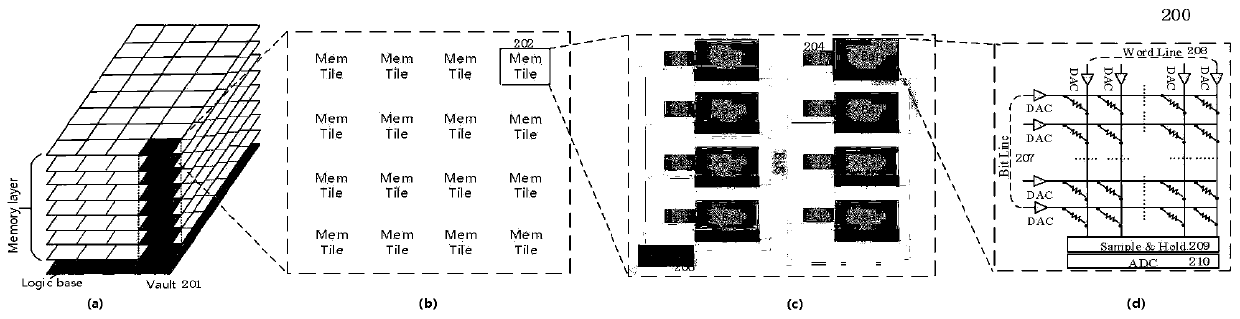

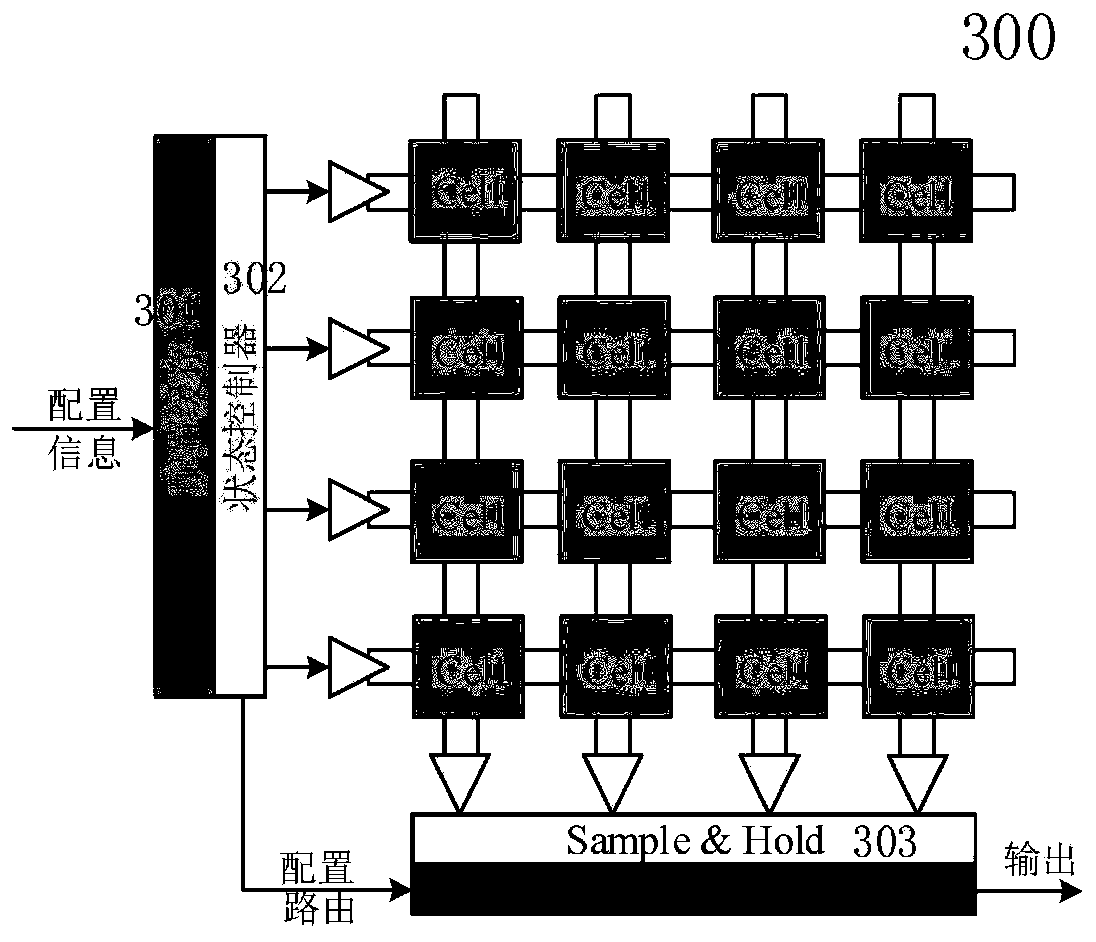

Universal blockchain application processing acceleration method and system based on resistive random access memory

ActiveCN110890120AReduce handlingReduce the amount of handlingDigital storageData streamParallel computing

The invention provides a universal blockchain application processing acceleration method and system based on a resistive random access memory. The method comprises the steps that whether a current program is a blockchain acceleration processing program or not is judged, if so, the current program is sent to an HMC memory end comprising a memory processor and a resistive random access memory, wherein the storage processor is integrated in a logic control layer at the end of the HMC memory; wherein the resistive random access memory is integrated on a three-dimensional storage layer at the end of the HMC memory; and the storage processor completes near storage calculation of the current program in a data flow running mode by controlling the three-dimensional storage layer to obtain an execution result of the current program, and returns the execution result to the main processor end, otherwise, the out-of-order core in the main processor end executes the current program in a control flowrunning mode according to the current program to obtain an execution result. According to the method, the execution speed is high, the energy efficiency ratio is remarkably improved, and higher execution efficiency and energy efficiency can be obtained in combination with data flow task allocation and execution modes.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

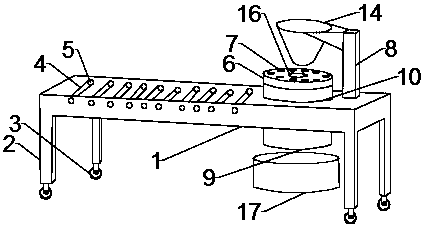

Automatic apple packaging machine

InactiveCN106742374AImprove efficiencyReduce workloadPackaging automatic controlPackaging fruits/vegetablesEngineeringWorkload

The invention discloses an automatic apple packaging machine which comprises an operating platform, wherein landing legs are connected with four corners of the operating platform; universal wheels are mounted below the landing legs; transmission idler wheels are mounted on the left side of the interior of the operating platform; middle shafts are mounted in the transmission idler wheels; a packaging cylinder is mounted on the right side of the interior of the operating platform; leakage holes are uniformly formed in the packaging cylinder; a transformation disc is mounted below the packaging cylinder; a packaging bag storage room is connected with a position below the transformation disc; a support rod is mounted on the right side of the packaging cylinder; and a feeding device is connected with the right side of the support rod. According to the automatic apple packaging machine, as the packaging cylinder is arranged, ten apples can be simultaneously packaged, the packaging efficiency is improved, and the workload of a packaging worker is reduced; as the transmission idler wheels are arranged, the packaged apples can be transmitted to a next working procedure, and the carrying quantity of the worker is reduced; as the transformation disc is arranged, a sealed product can be transmitted to transformation idler wheels; and the automatic apple packaging machine is simple and practical and excellent in application prospect.

Owner:CHENGDU JUZHI IND DESIGN

Telescopic arm structure, working arm and engineering machine

ActiveCN111704043AAdjustable working radiusExpand the scope of workForestryLoad-engaging elementsEngineeringMachine

The invention relates to the technical field of engineering machines, and particularly discloses a telescopic arm structure, a working arm and an engineering machine. The telescopic arm structure comprises a first section arm, a second section arm, a compensation mechanism and an oil circuit, the first section arm is slidably arranged on the second section arm in a sleeving mode, and the first section arm can extend or retract relative to the second section arm so that the working radius of a lifting appliance can be adjusted, the lifting appliance has a large working range and is high in applicability, the two ends of the compensation mechanism are fixed to the first section arm and the second section arm correspondingly, and the compensation mechanism can extend in a bent mode and expand; and the oil circuit is formed in the compensation mechanism in a penetrating mode and used for being connected with the lifting appliance to supply oil to the lifting appliance. When the second section arm extends out relative to the first section arm, the compensation mechanism extending in the bent mode expands; and when the second section arm retracts relative to the first section arm, the expanding compensation mechanism extends in the bent mode, and compared with related technologies, falling of the oil circuit can be avoided.

Owner:JIANGSU LIUGONG MACHINERY

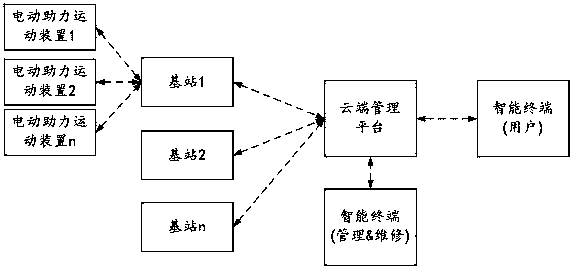

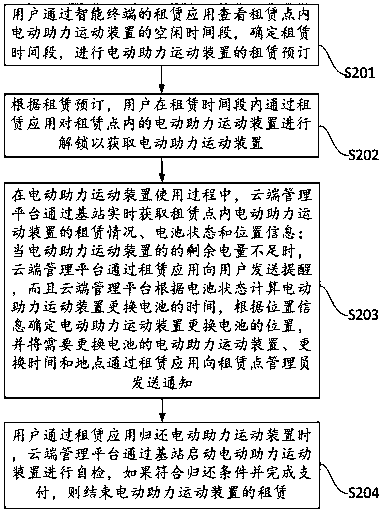

Electric power-assisted exercise device lease management method and system

ActiveCN111045398ASolve the problems of high operating costs and poor customer experienceImprove experienceElectrical testingSatellite radio beaconingAssisted exerciseElectrical battery

The invention provides an electric power-assisted exercise device lease management method and system. The method comprises the steps that: a user checks an idle time period of an electric power-assisted exercise device in a lease point through a lease application, and carries out lease reservation; the user unlocks the electric power-assisted exercise device through the leasing application; a cloud management platform obtains the lease condition, the battery state and the position information of the electric power-assisted exercise device, calculates battery replacement time of the electric power-assisted exercise device, determines a battery replacement position, and sends a notification including the electric power-assisted exercise device needing to replace the battery, the replacementtime and the replacement place to a lease point manager through the lease application; and when the user returns the device through the lease application, the cloud management platform starts the electric power-assisted exercise device to perform self-inspection, and if the return condition is met and payment is completed, leasing is ended. The position information and the battery state of the electric power-assisted exercise device can be monitored in real time, so that lease management is convenient and easy to maintain; and meanwhile, the user experience is also improved.

Owner:YUJET INT LTD

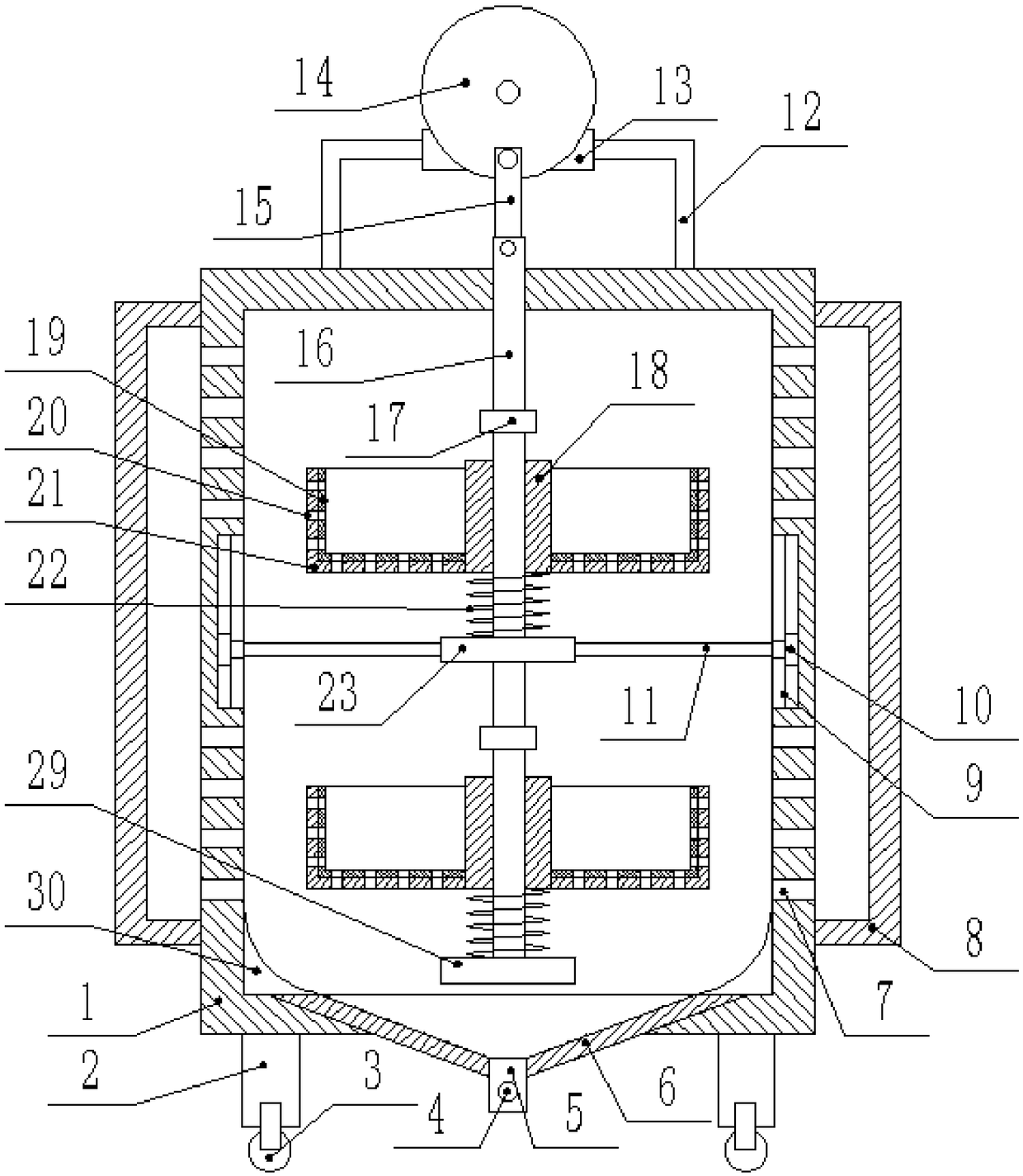

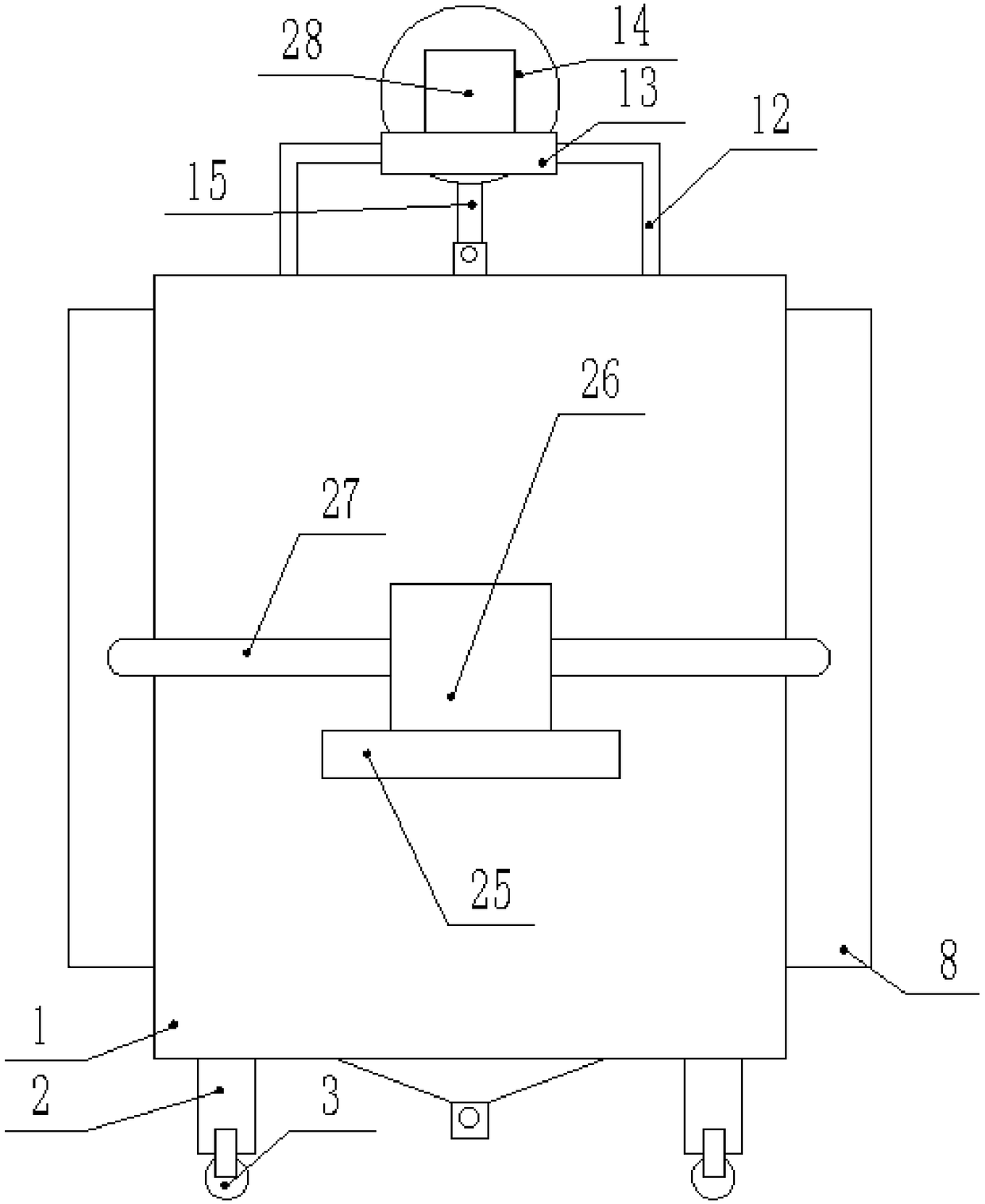

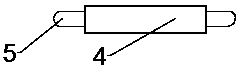

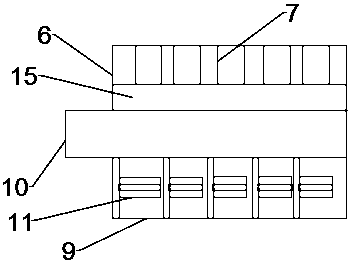

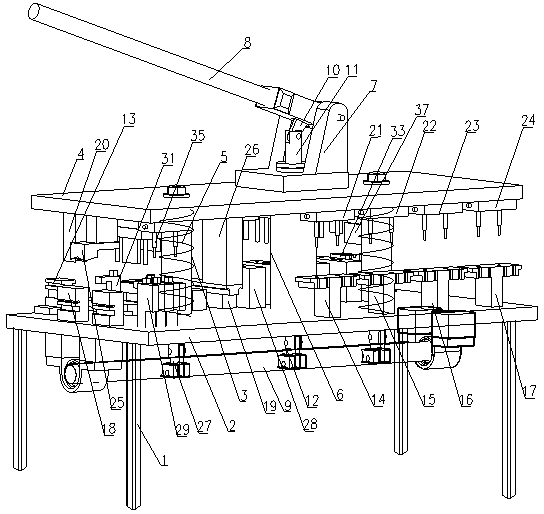

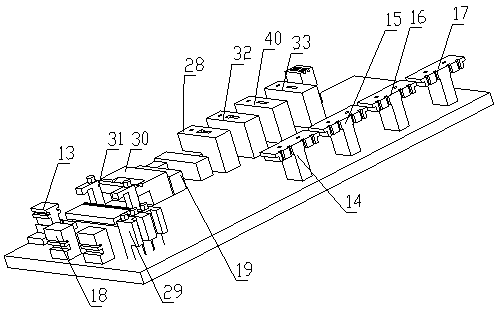

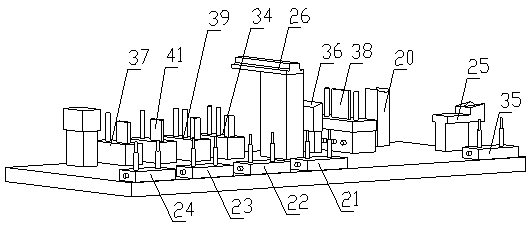

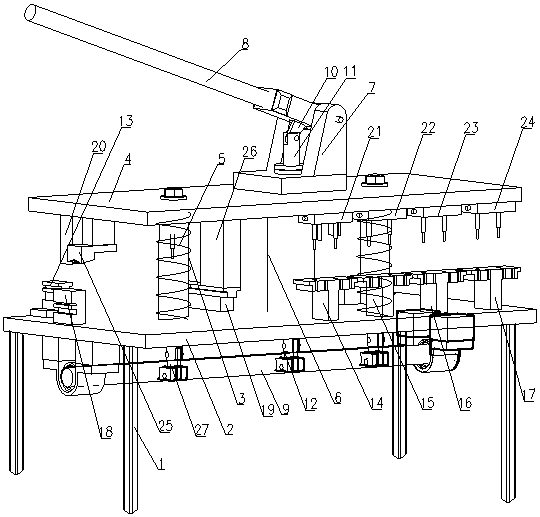

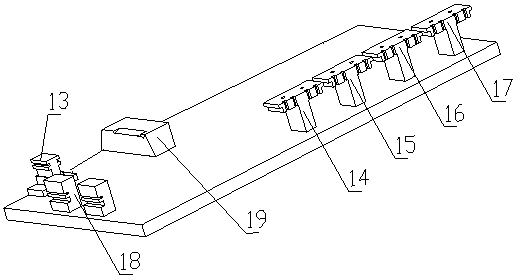

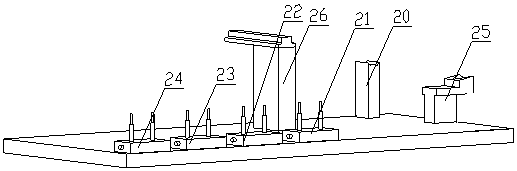

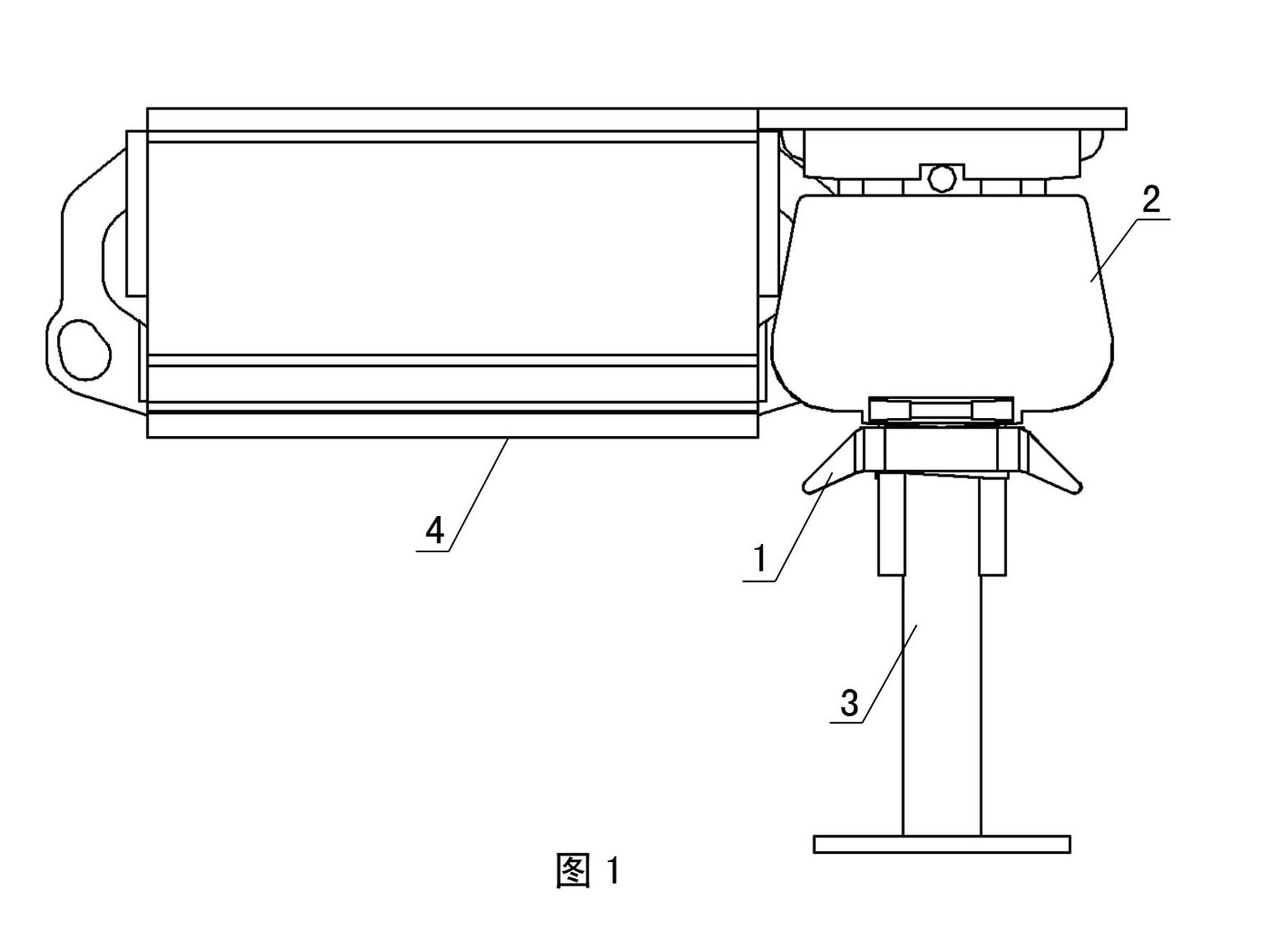

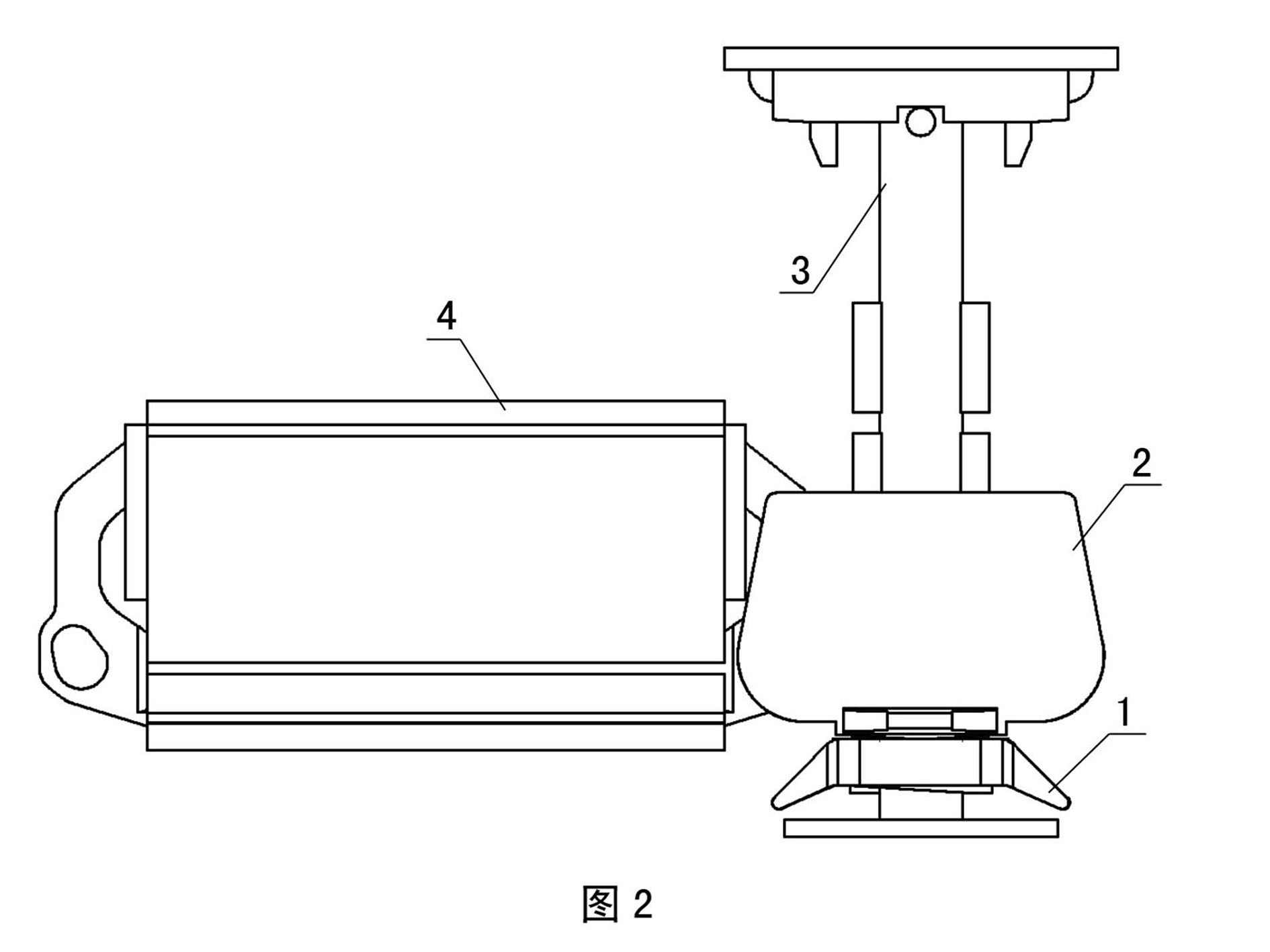

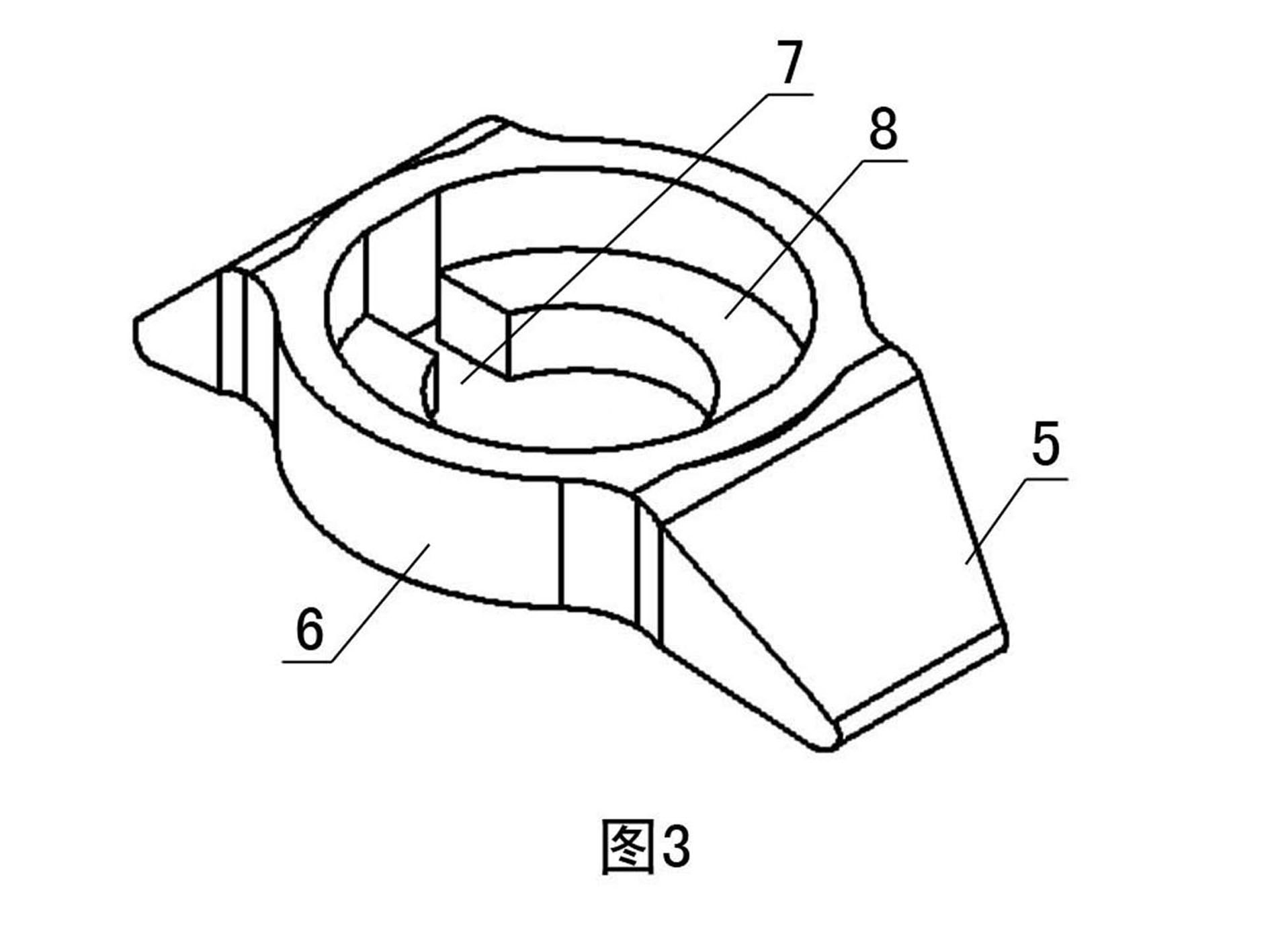

Manual stamping device

InactiveCN105251869AReduce the amount of handlingReduce labor intensityShaping toolsPerforating toolsEngineeringPulley

The invention relates to a manual stamping device which is used for stamping and milling of aluminum alloy door and window components. The manual stamping device comprises a rack, a lower mold plate, an upper mold plate, a sliding rod, a reset spring, a sliding sleeve, a hinge base, a lever, an eccentric shaft, a first connecting rod, a second connecting rod, a third connecting rod, a fourth connecting rod, a sliding wheel notch mold stamping base, a fan blade upper portion inner-side mold stamping base, a fan blade upper portion outer-side mold stamping base, a fan blade lower portion inner-side mold stamping base, a fan blade lower portion outer-side mold stamping base, a water flushing and draining hole mold base, a trimming mold base, an angle code hole opening mold base, a rib stamping mold base, a fan blade edge cutting mold base, a vertical hinged door lock hole opening mold base, a vertical hinged door pressing line cutting opening mold base, a fan blade hole opening mold, a sliding wheel notch stamping mold, a fan blade upper portion inner-side stamping mold, a fan blade upper portion outer-side stamping mold, a fan blade lower portion inner-side stamping mold, a fan blade lower portion outer-side stamping mold, a water flushing and draining hole mold, a trimming mold, an angle code hole opening mold, a rib stamping mold, a fan blade edge cutting stamping mold, a vertical hinged door lock hole opening mold, a vertical hinged door pressing line cutting opening mold and a fan blade hole opening stamping mold. The sliding wheel notch mold stamping base, the fan blade upper portion inner-side mold stamping base, the fan blade upper portion outer-side mold stamping base, the fan blade lower portion inner-side mold stamping base, the fan blade lower portion outer-side mold stamping base, the water flushing and draining hole mold base, the trimming mold base, the angle code hole opening mold base, the rib stamping mold base, the fan blade edge cutting mold base, the vertical hinged door lock hole opening mold base, the vertical hinged door pressing line cutting opening mold base and the fan blade hole opening mold are connected to the lower mold plate; and the sliding wheel notch stamping mold, the fan blade upper portion inner-side stamping mold, the fan blade upper portion outer-side stamping mold, the fan blade lower portion inner-side stamping mold, the fan blade lower portion outer-side stamping mold, the water flushing and draining hole mold, the trimming mold, the angle code hole opening mold, the rib stamping mold, the fan blade edge cutting stamping mold, the vertical hinged door lock hole opening mold, the vertical hinged door pressing line cutting opening mold and the fan blade hole opening stamping mold are connected to the upper mold plate.

Owner:湖南盛世美景门窗工程有限公司

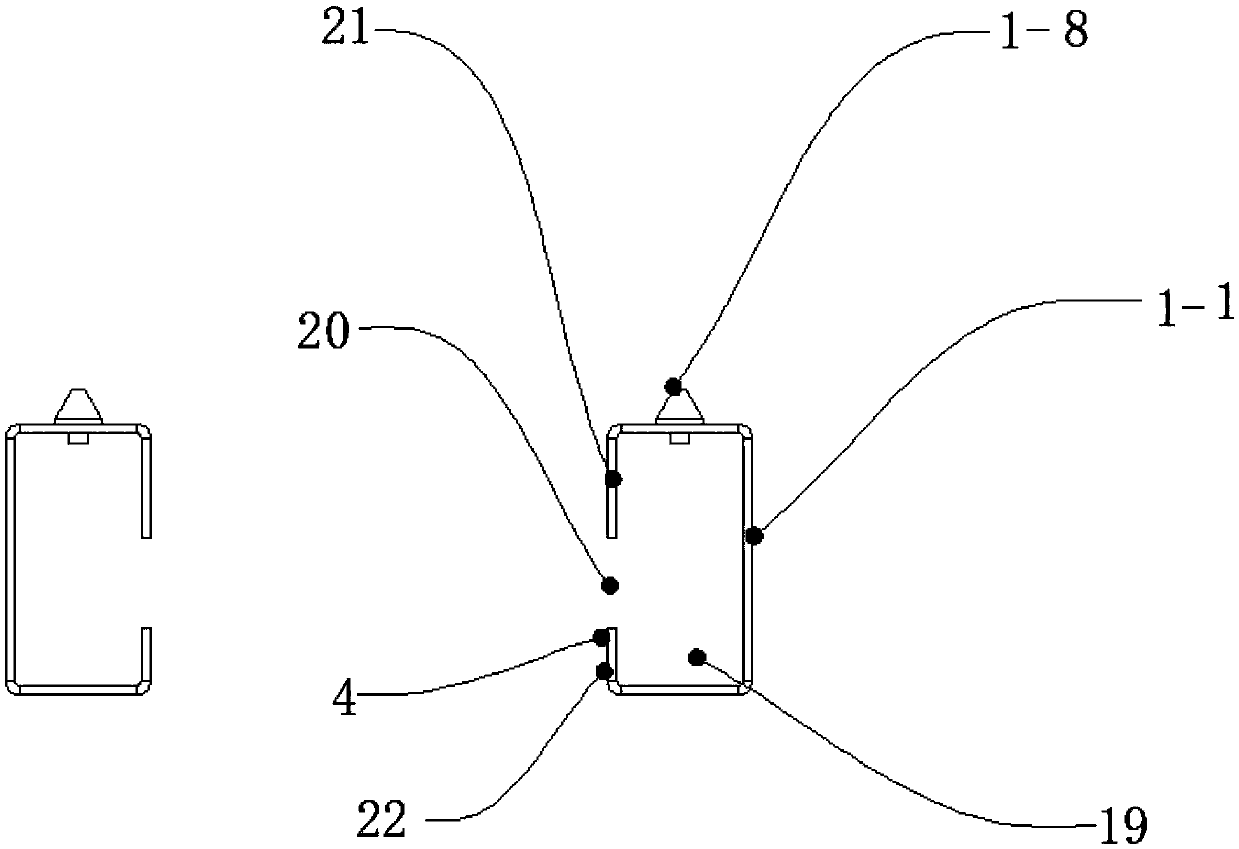

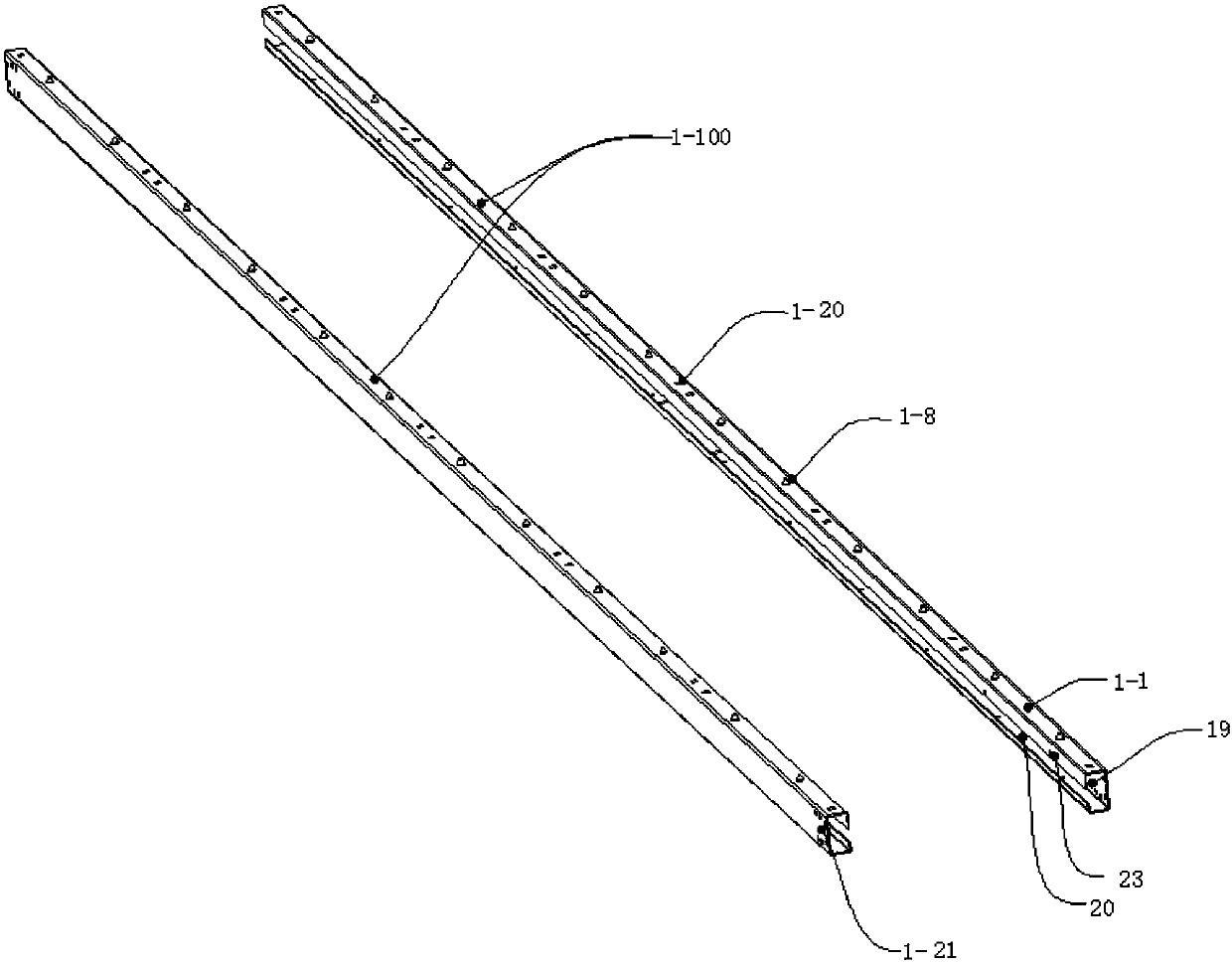

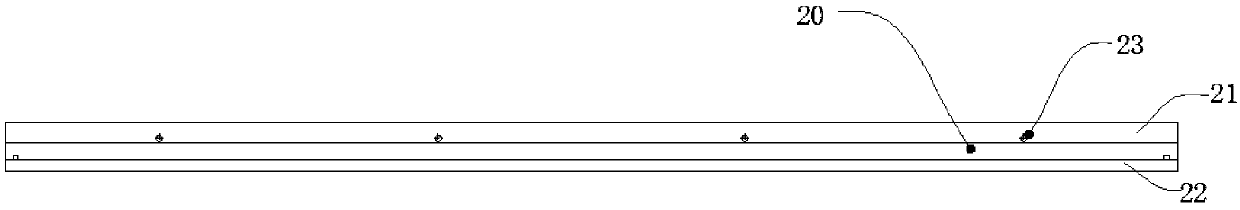

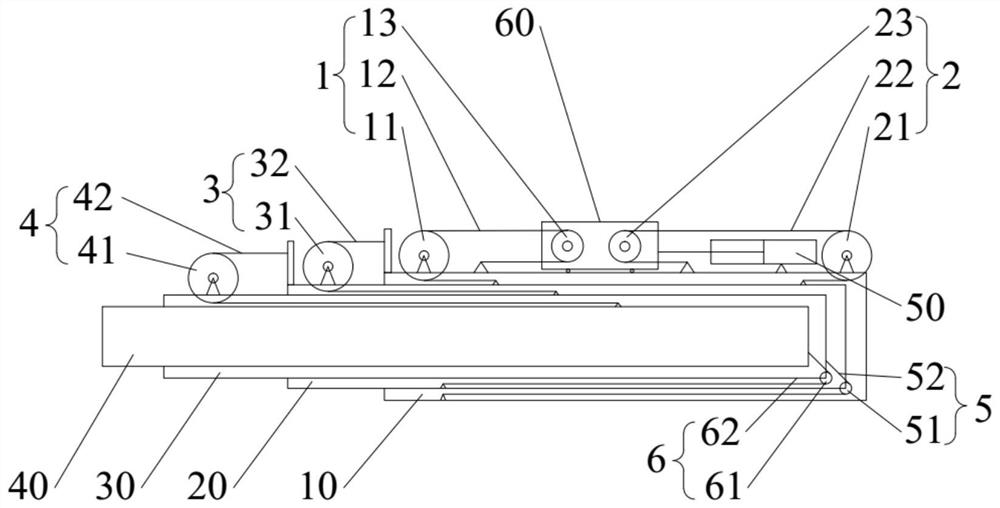

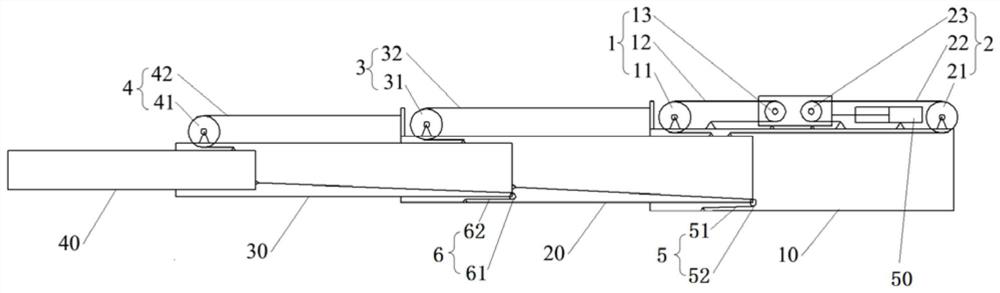

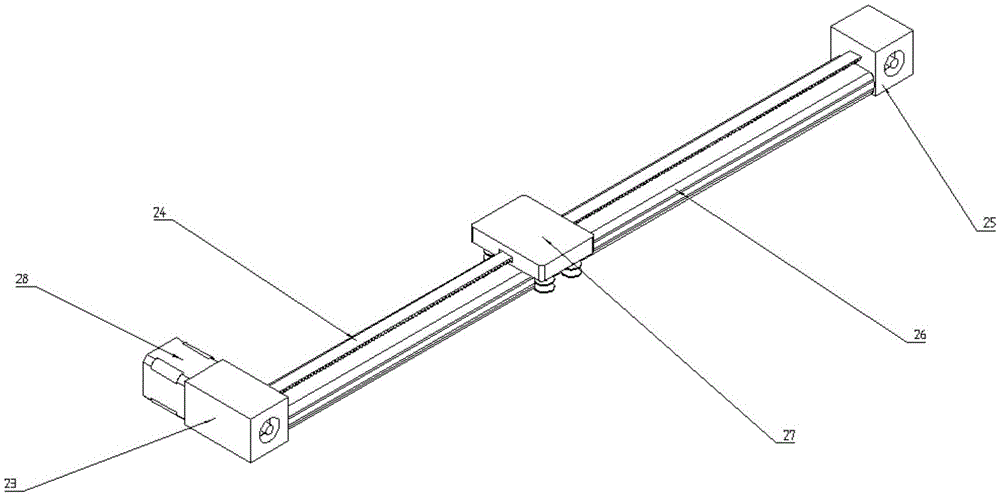

Manual stamping device for processing parts of aluminum alloy doors and windows

A manual stamping device for processing parts of aluminum alloy doors and windows comprises a rack (1), a lower die plate (2), an upper die plate (4), a reset spring (5), a sliding sleeve (6), a hinge support (7), a lever (8), an eccentric shaft (9), a first connection rod (10), a second connection rod (11), a third connection rod (12) and a fourth connection rod (27), a pulley opening punching die holder (13) connected onto the lower die plate (2), a punching die holder (14) for the inner side of the upper portion of a fan, a punching die holder (15) for the outer side of the upper portion of the fan, a punching die holder (16) for the inner side of the lower portion of the fan, a punching die holder (17) for the outer side of the lower portion of the fan, a drain hole punching die holder (18), an edge punching die holder (19), a pulley opening punching die (20) connected onto the upper die plate (4), a punching die (21) for the inner side of the upper portion of the fan, a punching die (22) for the outer side of the upper portion of the fan, a punching die (23) for the inner side of the lower portion of the fan, a punching die (24) for the outer side of the lower portion of the fan, a drain hole punching die (25) and an edge punching die (26).

Owner:湖南盛世美景门窗工程有限公司

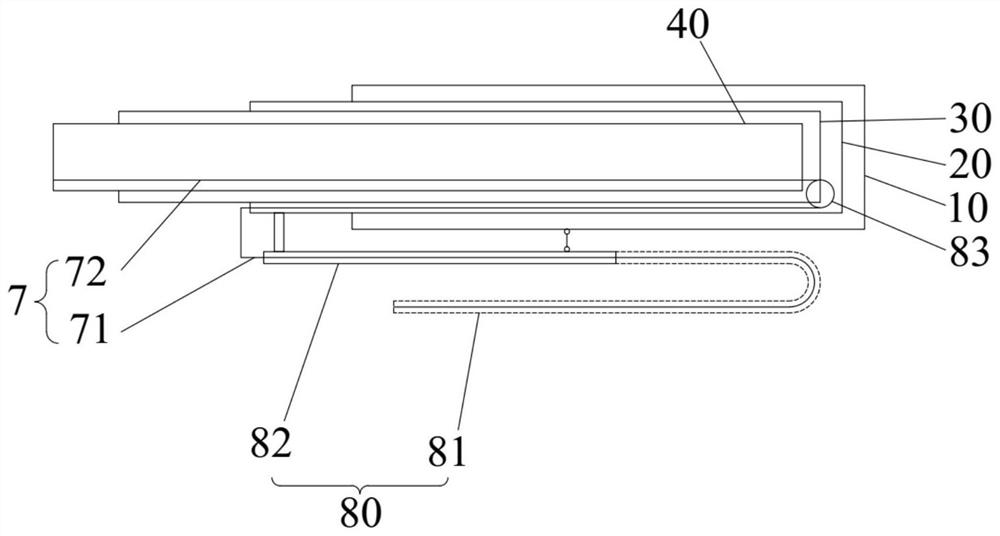

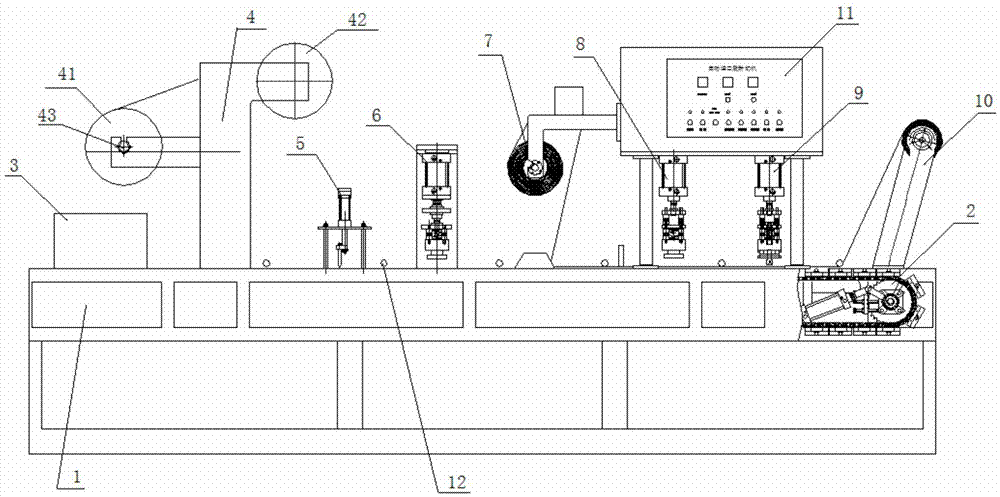

Full-automatic production system and method for ostomy bag

InactiveCN105437618AMake sure not to wrinkleMake sure not to stretchEnvelopes/bags making machineryComposite filmPhotoelectric sensor

The invention discloses a full-automatic production system for an ostomy bag. The full-automatic production system for the ostomy bag comprises a horizontal workbench which is provided with a transmission part. A chassis feeding device is arranged on the left side of the transmission part, and a waste film wrap-up device is arranged on the right side of the transmission part. A film roll supplying device, a positioning ironing piece, a chassis ironing piece, a composite-film-roll supplying device, an ostomy edge-ironing piece and an ostomy sealing and cutting piece are arranged from left to right in sequence above the transmission part. The film roll supplying device, the positioning ironing piece, the chassis ironing piece, the composite-film-roll supplying device, the ostomy edge-ironing piece and the ostomy sealing and cutting piece are electrically connected with an electrical apparatus controller on the horizontal workbench. Photoelectric sensors are arranged in the positions, on one side of the transmission part, under the positioning ironing piece, under the chassis ironing piece, under the ostomy edge-ironing piece and under the ostomy sealing and cutting piece. The electrical apparatus controller controls the transmission part, the positioning ironing piece, the chassis ironing piece, the ostomy edge-ironing piece and the ostomy sealing and cutting piece to operate. According to the full-automatic production system and method for the ostomy bag, the production efficiency is improved, the cost is reduced, each process is effectively connected, and all processes are controlled through the electrical apparatus controller synchronously, so that the material carrying amount is reduced, and man-made quality risks are reduced.

Owner:ZHEJIANG ANSHENG MEDICAL MATERIALS TECH

Drying treatment mechanism for hardware

InactiveCN110749170AImprove securityEfficient dryingDrying gas arrangementsDrying chambers/containersComputer hardwareUltraviolet lights

The invention discloses a drying treatment mechanism for hardware, and relates to the technical field of hardware fittings. The mechanism comprises a box body, the four corners of the bottom end of the box body are fixedly connected with supporting legs, wheels are fixedly mounted at the bottom ends of the supporting legs, cover bodies are arranged on the two side walls of the box body, a box dooris arranged on one side of the box body, the box door is hinged to the box body, the box door is provided with a plurality of air outlet holes, the other side wall of the box body is fixedly connected with a second transverse plate, and the top surface of the second transverse plate is fixedly connected with an air heater. The upper inner wall of the box body is provided with an ultraviolet lampfor disinfection, the hardware is disinfected during drying, and the safety performance of the device is improved. A protective cover is arranged on the outer side of the ultraviolet lamp, so that thesafety performance of the device is improved.

Owner:湖北中琛窑炉设备有限公司

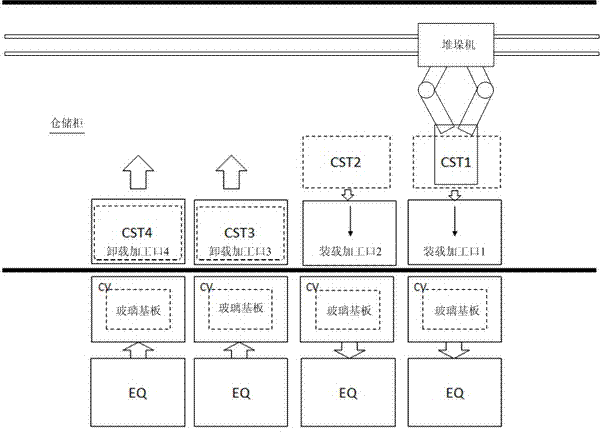

Substrate transfer facility and transfer method

ActiveCN103531508AReduced production cycle timeReduce the amount of handlingSemiconductor/solid-state device manufacturingConveyor partsEngineeringProduction cycle

The invention relates to a substrate transfer facility and a transfer method, wherein the facility comprises a cartridge for loading substrates and a transfer machine for transferring the cartridge, and a first processing chamber and a second processing chamber which are used for processing the cartridge are sequentially arranged along a direction perpendicular to the moving direction of the transfer machine; and the substrate transfer facility also comprises a first conveyer belt which is arranged between the first processing chamber and the second processing chamber and used for driving the cartridge to move from the first processing chamber to the second processing chamber. By implementing the invention, the technical processes of the first processing chamber and the second processing chamber can be fulfilled as long as the transfer machine transfers the cartridge to an inlet without intermediate processing, consequently, the transfer load of the transfer machine is reduced, the substrate production cycle is shortened, and productivity is increased.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Supporting method of carboniferous system geologic structure in-zone breaking country rock roadway

ActiveCN103122768BEffective control of deformationControl deformationMine roof capsAnchoring boltsTectonicsFactor of safety

Owner:DATONG COAL MINE GRP

Automatic seedling replenishment mechanical operation device

The invention discloses a mechanical operation device for automatically filling gaps with seedlings. The device comprises a rack, a walking module, a mechanical arm module, a transplanting mechanical paw, a control box, an industrial camera and a computer, wherein the device is arranged on a track of an operation seedbed; the walking module is arranged at the bottom of the rack, and is used for driving the device to move on the track; the industrial camera is capable of automatically shooting a seeding tray; the computer is used for processing a shot picture, and obtaining seedling-missing positions on an operation seeding tray; the transplanting mechanical paw is arranged on the mechanical arm module; the mechanical arm module is used for driving the transplanting mechanical paw to reach the position needing work according to an instruction; and the mechanical arm module is matched with the transplanting mechanical paw, and is used for transplanting healthy seedlings into the seedling-missing positions on the operation seeding tray from a standby seeding tray, to finish the operation for automatically filling gaps with seedlings. According to the device disclosed by the invention, the inconvenience that the operation seeding tray needs to be moved to seedling filling equipment by manpower to fill gaps with seedlings in rows in traditional seedling filling equipment is avoided; the carrying capacity is reduced; and double hands of workers are liberated.

Owner:ZHEJIANG UNIV

Early-dismantling support of aluminum alloy top plate

InactiveCN101864835BConstruction safety is not affectedFaster turnaroundForms/shuttering/falseworksSheet steelHigh stress

The invention provides an early-dismantling support of an aluminum alloy top plate which comprises a support main body and a template support connected on the support main body, wherein the support main body consists of a vertical steel pipe, a lower connecting plate welded on the lower end of the vertical steel pipe, an upper support plate welded on the upper end of the vertical steel pipe and limit sheets welded at the middle part of the vertical steel pipe; the vertical steel pipe is sheathed with a jacking which is formed by casting cast steel; and the vertical steel pipe between the jacking and the upper support plate is also sheathed with a slide support which is formed by welding steel plates. The early-dismantling support has the advantages of fast and convenient dismantling, highworking efficiency, simple structure, high stress intensity, convenient and flexible operation, easily mastered construction process, accelerated construction progress and shortened construction period.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

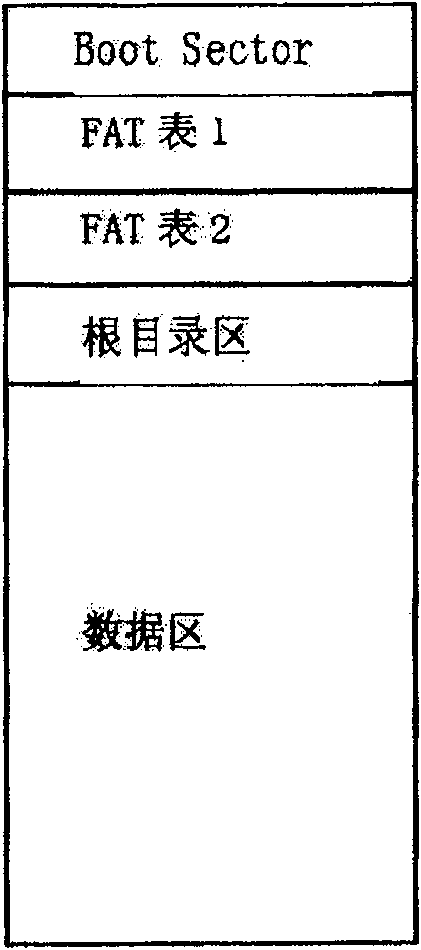

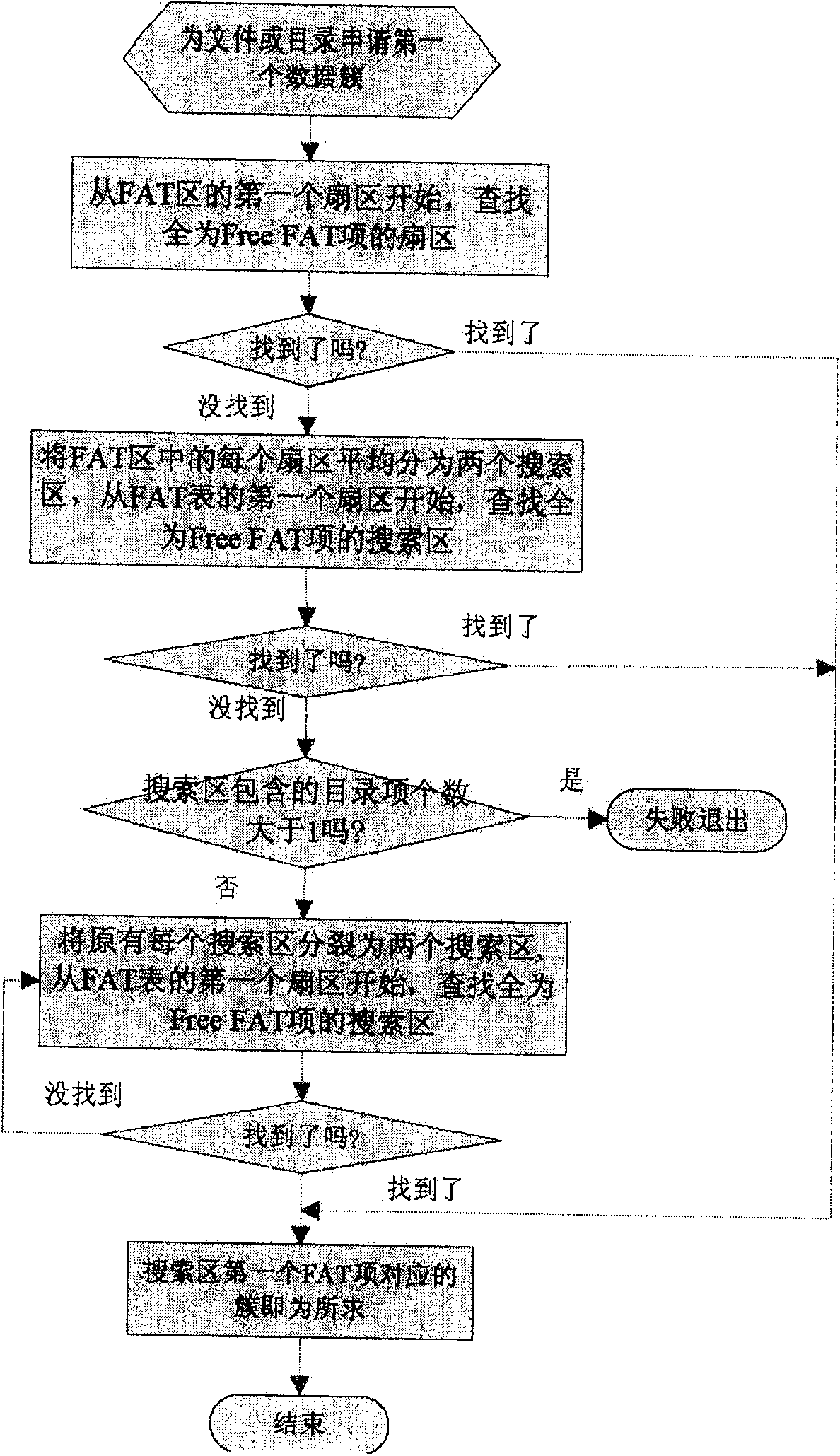

Method for applying cluster on Flash storage medium

ActiveCN100580668CExtended service lifeReduce the amount of handlingSpecial data processing applicationsMemory systemsFile systemRequirements clustering

This invention relates to one Flash memory media method to require cluster, which comprises the following steps: when FAT file system due to data adding and the first requirement cluster, firstly finding the fan area of whole Free and the initial FAT item relative cluster as one to be required; if not, then folding the fan area by half; if there is , then the half area initial FAT item cluster is to be required; if not then folding as 1 / 4 till finding the FAT item.

Owner:KONKA GROUP

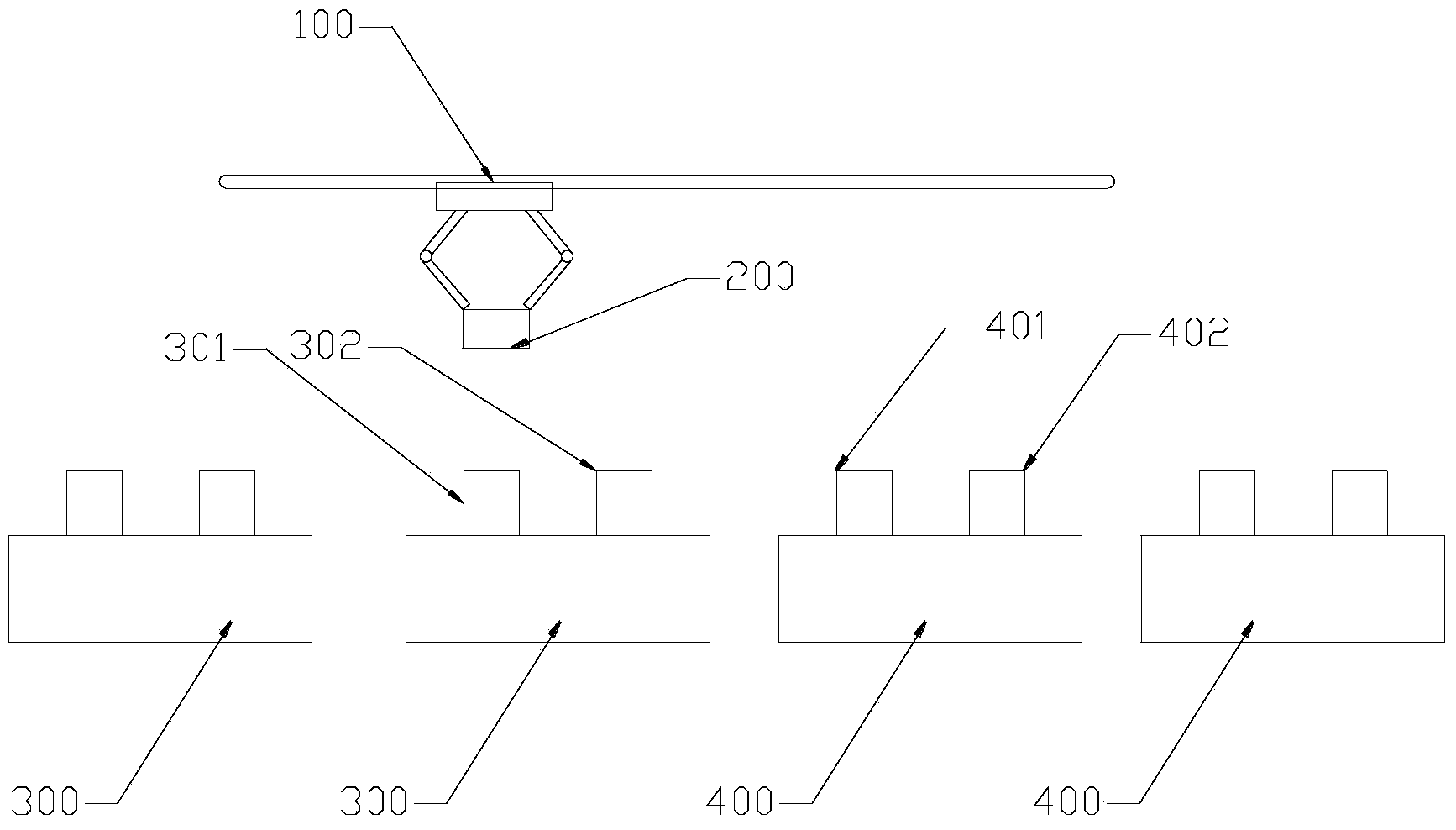

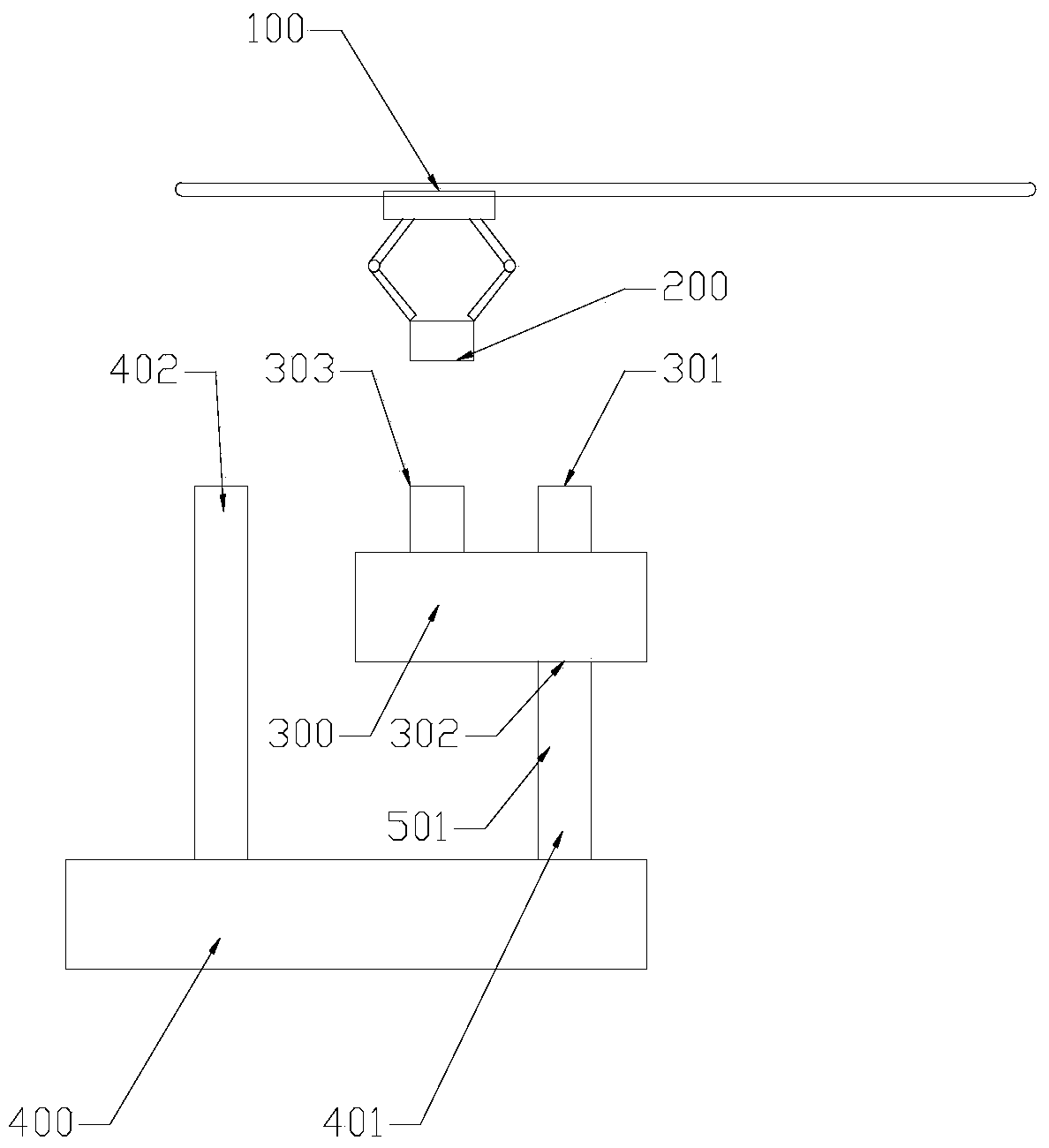

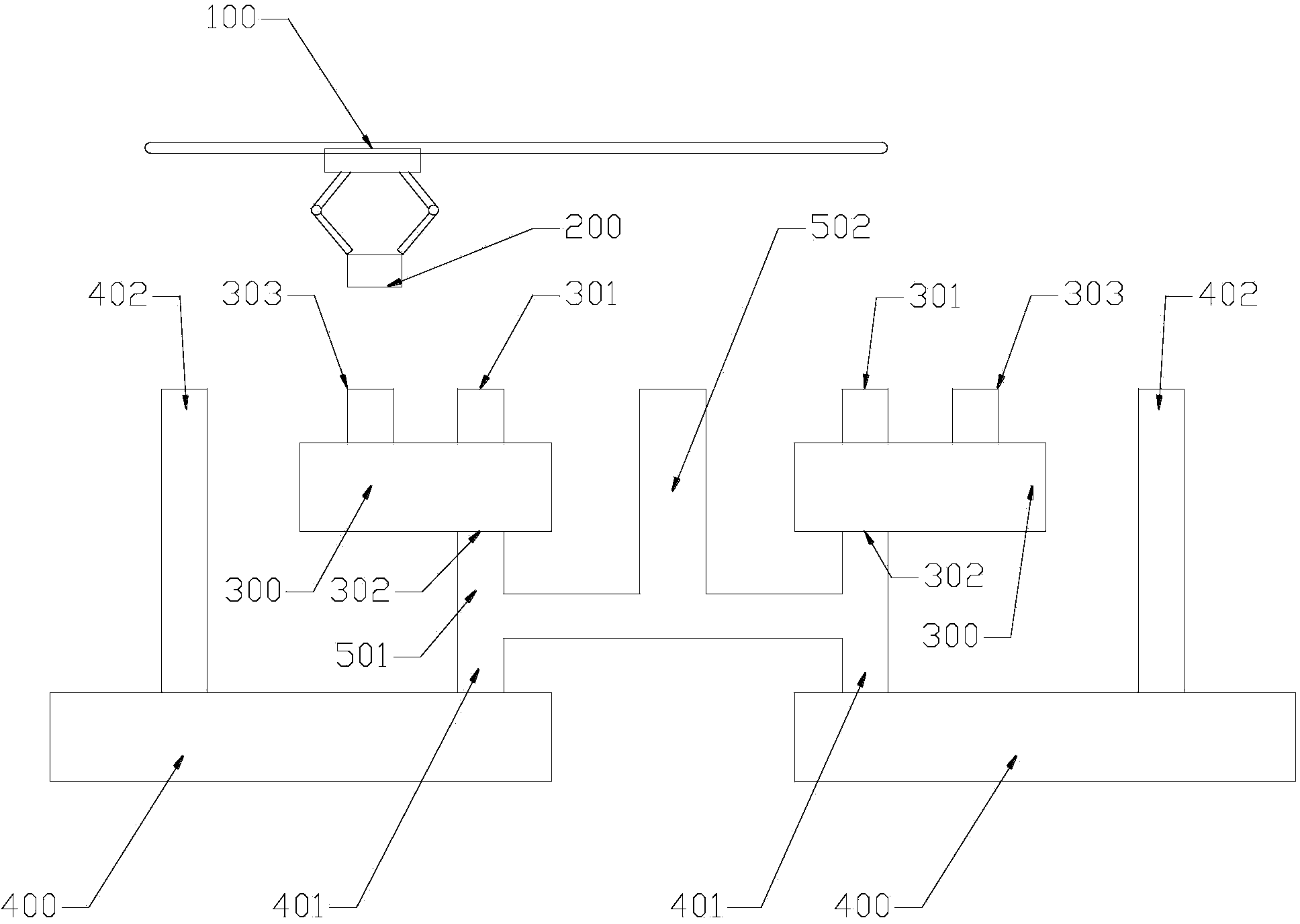

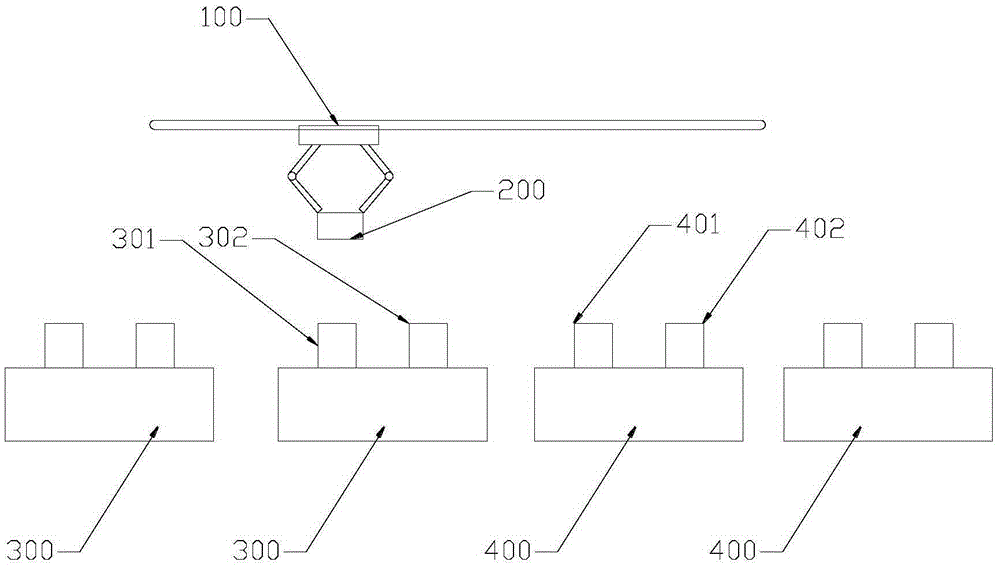

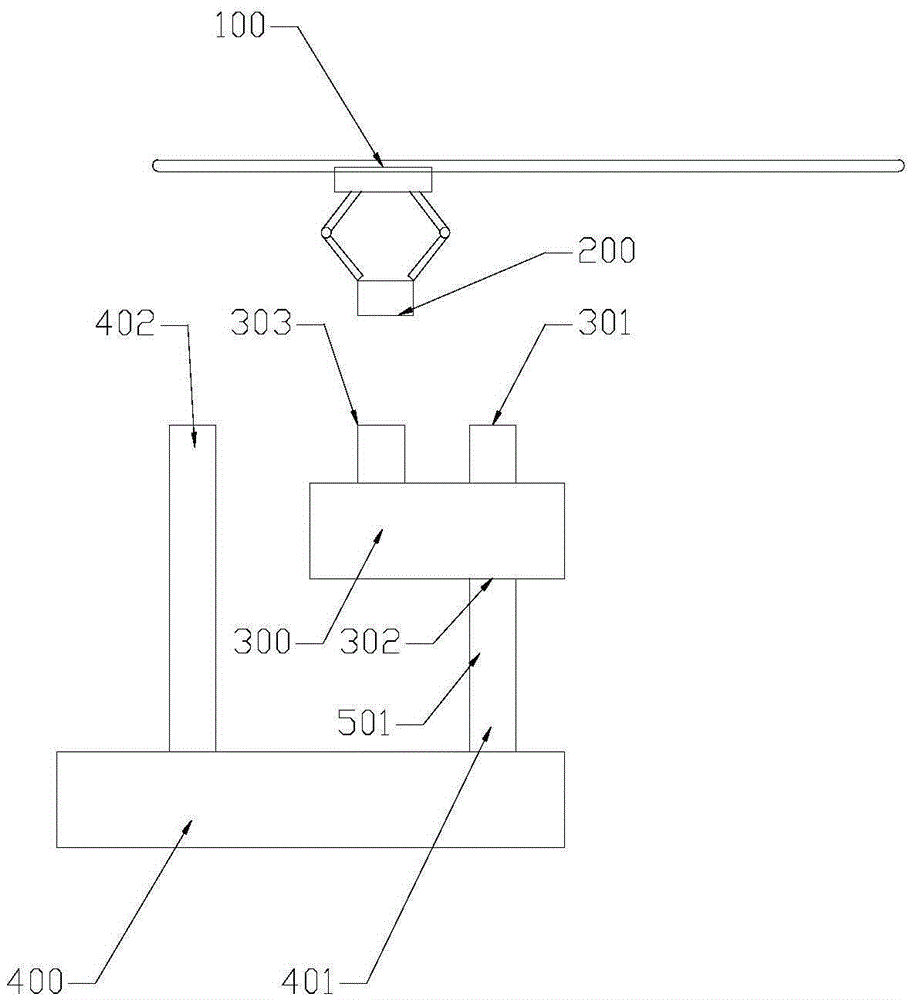

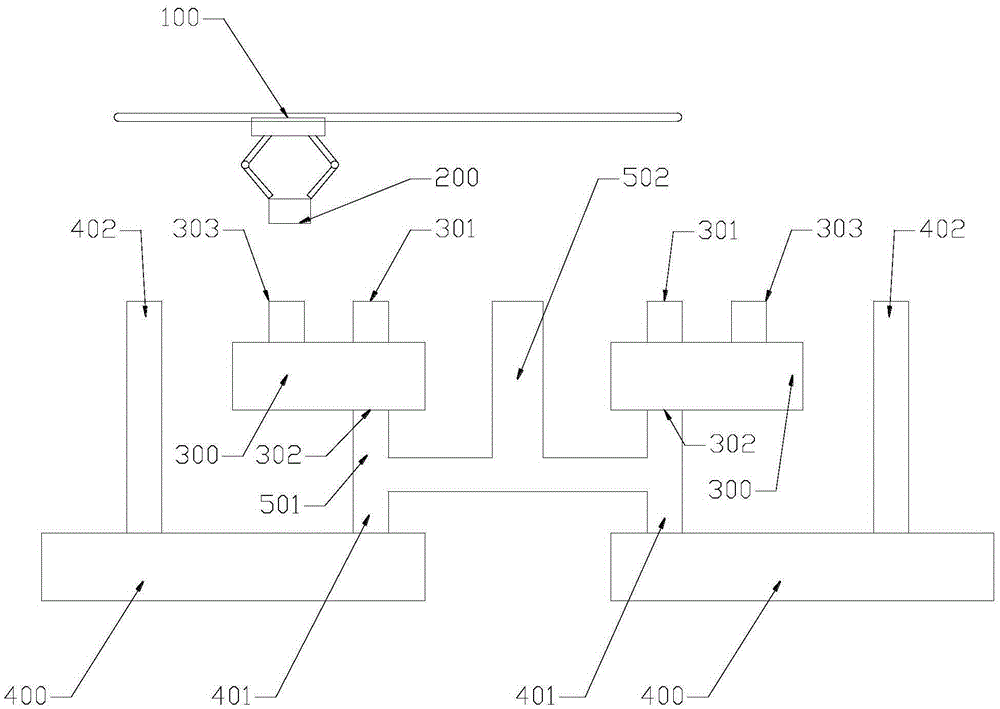

Substrate transportation equipment and transportation method

ActiveCN103531508BReduced production cycle timeReduce the amount of handlingSemiconductor/solid-state device manufacturingConveyor partsEngineeringProduction cycle

A substrate transporting device, comprising a cartridge (200) for loading a substrate, and a crane (100) for transporting the cartridge; a first handling chamber (300) and a second handling chamber (400) for handling the cartridge are sequentially disposed in a direction perpendicular to the crane moving direction; a first conveyer belt (501) for moving the cartridge from the first handling chamber to the second handling chamber is disposed between the first handling chamber and the second handling chamber. The crane only needs to transport a cartridge to an input port without further crane handling in the flow, thus reducing transport workload, shortening a substrate production cycle, and improving productivity. Also provided is a substrate transporting method.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

A production line for sausage packaging

ActiveCN107054784BReduce physical laborReduce the amount of handlingConveyorsControl devices for conveyorsProduction lineSpray nozzle

The invention relates to a production line for sausage packaging. The problems that the space using rate is low, the labor amount of workers is large, and stations are not synchronous are solved. According to the technical scheme, the production line comprises a section shearing machine provided with an oil spraying machine, a double-layer conveying belt is arranged behind the section shearing machine, and a vacuum package machine is arranged behind the double-layer conveying belt; the section shearing machine comprises a first working table provided with a first hanging bracket and a second hanging bracket, the first hanging bracket is provided with a cutting plate, a spraying nozzle is arranged below the cutting plate, and a reel is arranged on one side of the first working table; the oil spraying machine comprises an oil pump provided with a first pipe and a second pipe, an oil cylinder is arranged at the other end of the first pipe, and the second pipe is connected with the spraying nozzle; and the double-layer conveying belt comprises a second support provided with a lower-layer conveying belt, a plurality of second working tables are arranged on the two sides of the lower-layer conveying belt, and an upper-layer conveying belt is arranged above the lower-layer conveying belt. The production line is reliable in performance, ingenious in conception and convenient to maintain, the space using rate of a packaging workshop is improved, the labor amount of workers in the workshop is reduced, and the overall production efficiency is obviously improved.

Owner:漯河市谊加谊食品有限公司

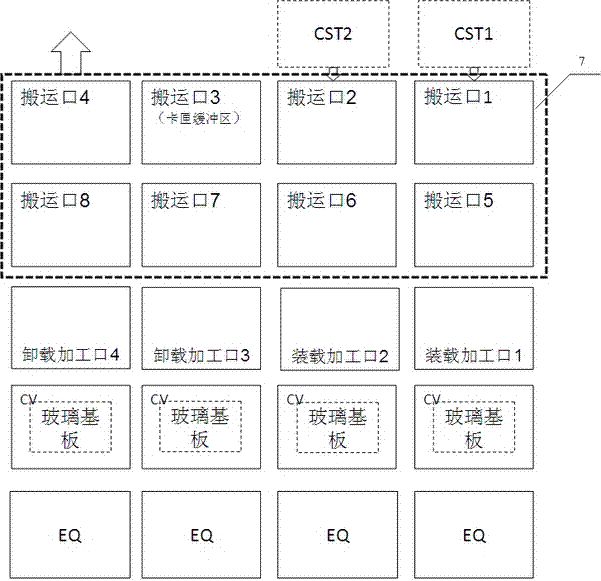

A device and method for transporting cassettes

ActiveCN102951401BReduce the amount of handlingSolve the bottleneck of excessive handling volumeSemiconductor/solid-state device manufacturingStorage devicesStacker

A cassette conveying device and method, used for conveying a cassette between the cranes of stockers, load ports and unload ports; a conveying port area (7) is disposed at the front section of the load ports and the unload ports; a horizontal conveying mechanism and a vertical conveying mechanism are disposed in the conveying port area (7), so that an empty cassette at the load port can be conveyed to the predetermined unload port. The method and device can reduce the amount of cassette conveying of a crane in a stocker, thus effectively solving the bottleneck of high amount of cassette conveying of the cranes in existing stockers, and improving productivity.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

An abnormal group identification method, device and smart chip

ActiveCN112990446BAchieve compressionSmall footprintDigital data information retrievalCharacter and pattern recognitionComputation processEngineering

Owner:中诚华隆计算机技术有限公司

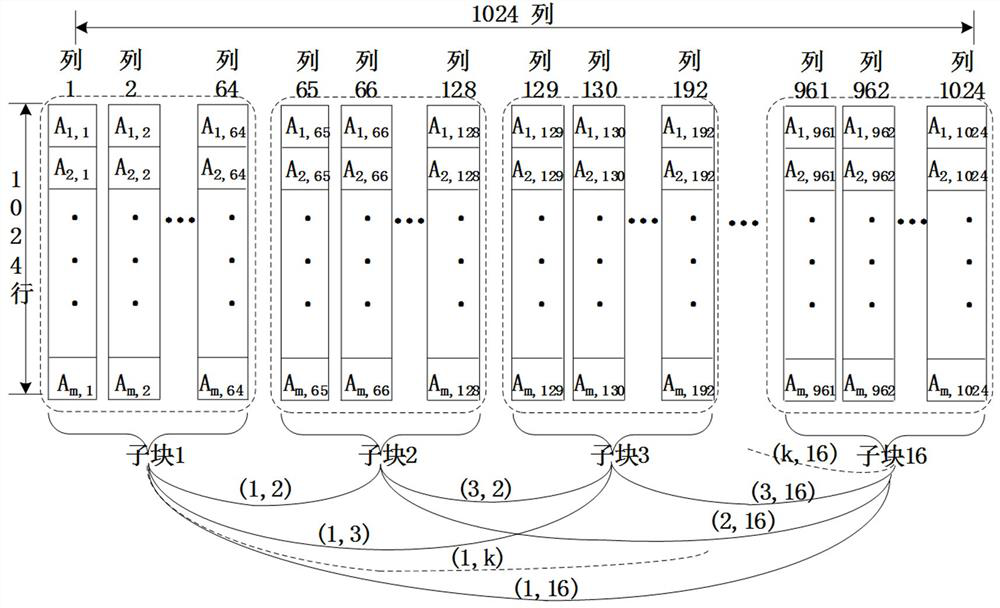

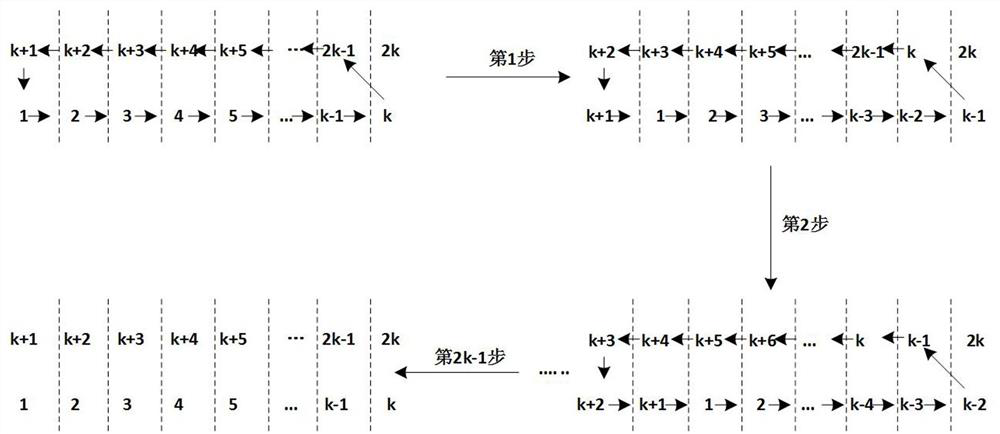

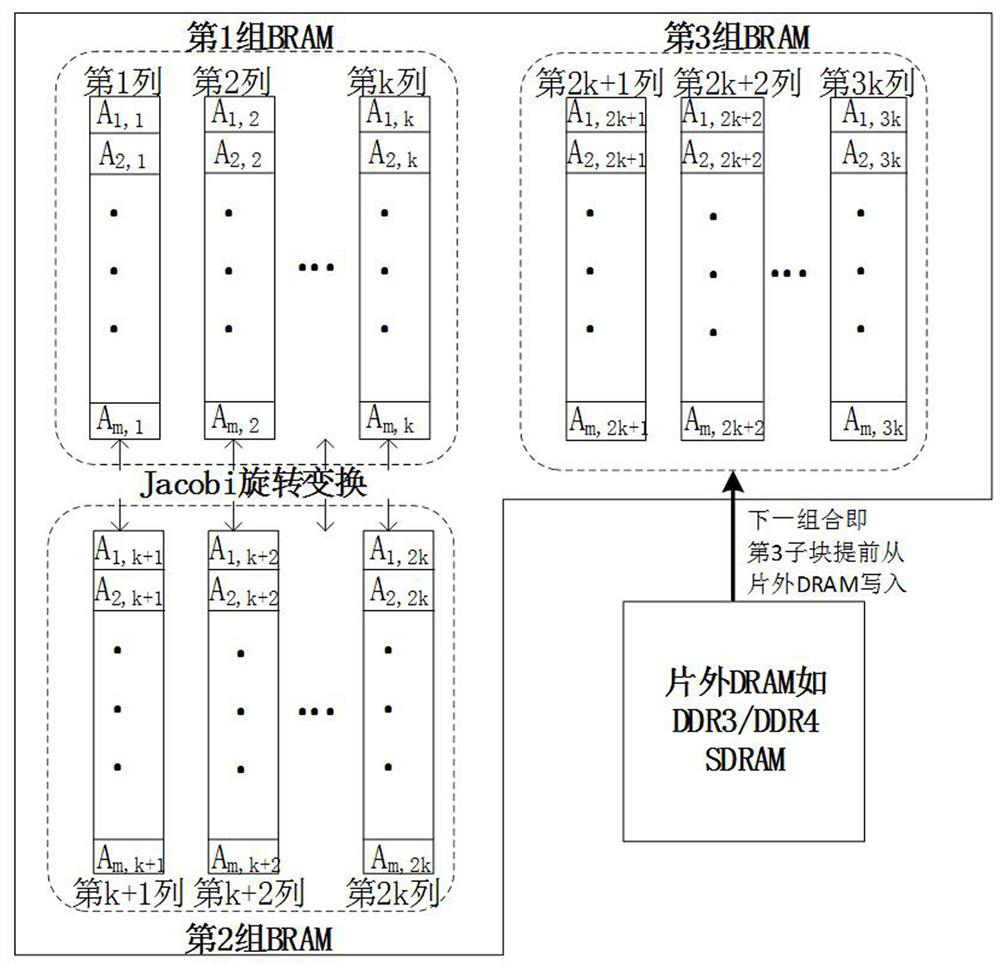

A Method for FPGA Accelerated Realization of Singular Value Decomposition of Matrix

ActiveCN113536228BCombination rules are simple and clearEasy to develop and implementComplex mathematical operationsSingular value decompositionMultiplexing

The invention discloses an FPGA accelerated implementation method of singular value decomposition of a matrix. The method firstly divides a matrix of m rows×n columns stored in an off-chip DRAM into p=n / k sub-blocks according to a group of k column vectors. , the p sub-blocks are alternately combined in pairs in order to obtain a small-sized matrix of m rows × 2k columns and write it into the internal BRAM of the FPGA, and further perform unilateral Jacobi rotation transformation, and half of the column vectors in the obtained calculation results are written back to the slice Outside the DRAM, the other half of the column vectors will continue to be combined with the next sub-block to obtain a new m-row×2k-column matrix, and the above operations will be repeated on the FPGA, until p sub-blocks are combined in pairs to perform a full round of unilateral Jacobi rotation Transformation; perform the above operations multiple times until the convergence condition is satisfied, that is, the singular value decomposition of the large-size matrix with m rows×n columns is completed. The present invention adopts a divide-and-conquer decomposition strategy and an implementation mode of alternate combination between sub-blocks, which improves the data multiplexing rate, reduces frequent data transfer, and reduces the bandwidth pressure of on-chip and off-chip data transmission.

Owner:ZHEJIANG LAB

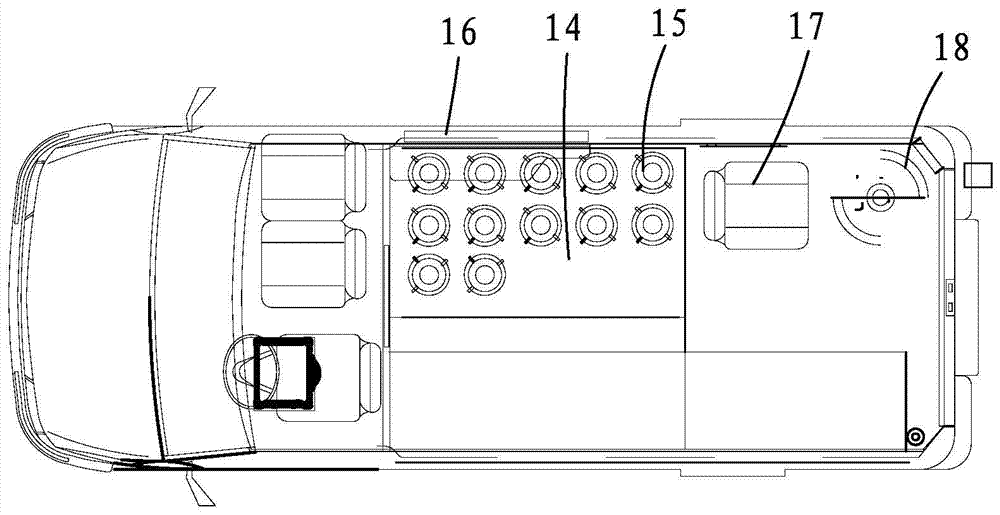

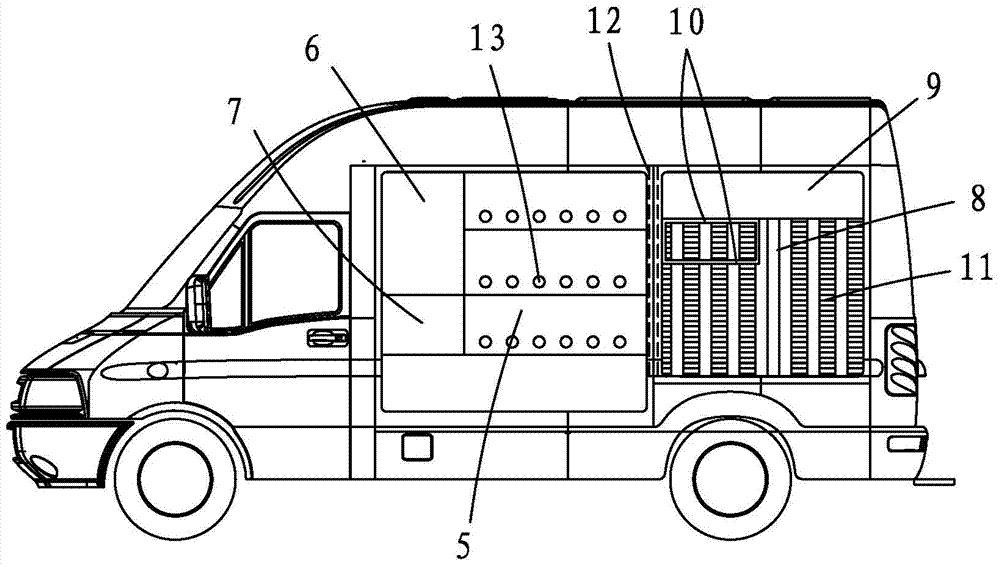

Scale Online Testing Platform

ActiveCN105181105BReduce the amount of handlingEmission reductionWeighing apparatus testing/calibrationHydraulic cylinderFuel tank

The scale online testing platform includes a car, the car includes a carriage, the rear of the carriage is provided with a door, and two upper lift doors are opened on one side of the carriage, and the door of the front lift door on the left side of the carriage is There is a multi-layer shelf structure under the inner frame, which is used to place the oil pipe winding device and the cantilever beam; there is a container under the door inner frame of the rear upper door on the left side of the carriage, which is used to place high-precision instruments, intelligent hydraulic servo control device, fuel tank; the top of the container is a tool cabinet, and its opening is inside the compartment; a hanger is provided at the lower left of the tool cabinet, on which the high-precision instrument is placed, and the intelligent hydraulic pressure gauge is fixed at the lower right of the container. The servo control device, and the fuel tank; the right side of the carriage is provided with a steel frame area, and the surface of the steel frame area is provided with a round hole groove, and a hydraulic cylinder and a sensor group are placed in the round hole groove. The invention provides a large weighing instrument inspection vehicle for verification which is convenient for moving and transporting.

Owner:FUJIAN METROLOGY INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com