Production line for sausage packaging

A technology of production line and sausage, which is applied in the direction of packaging, transportation and packaging, and special packaging objects, etc., can solve problems such as difficulty in ensuring food hygiene, affecting product quality, and high labor intensity, so as to avoid the risk of dumping and spilling, and reduce the risk of dumping and The risk of spillage and the effect of reducing manual repetitive labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

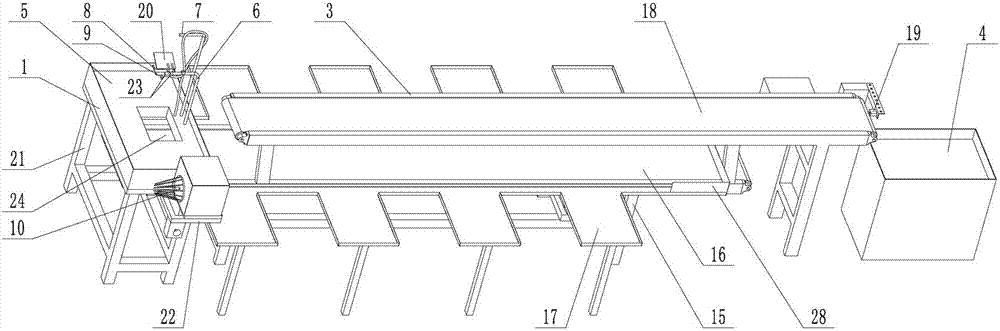

[0030] Embodiment 1, the present invention includes a knuckle cutter, including a knuckle cutter 1, a fuel injection machine 2 is installed on the knuckle cutter 1, and the fuel injection machine 2 is used to control the flow of salad oil, and a double layer is placed behind the knuckle cutter 1 Conveyor belt 3, the second workbench 5 on both sides of the upper conveyor belt 3 is the bagging area for workers, and the bagging is completed on the second workbench 5. After the bagging is completed, the double-layer conveyor belt 3 transports the product to the rear vacuum packaging machine 4 places for vacuum packaging;

[0031] Described section shearing machine 1 comprises the first workbench 5, the first hanger 6 and the second hanger 7 of inverted "L" shape are fixedly installed on the upper surface of the first workbench 5, and the first hanger 6 is installed with A cutting board 8 is fixed horizontally, and a nozzle 9 is arranged below the cutting board 8, and the nozzle 9 ...

Embodiment 2

[0034] Embodiment two, on the basis of embodiment one, described cutting plate 8 is provided with notch, and the position of notch is arranged on the opposite side of cutting plate 8 and the fixed edge of first hanger 6, and described cutting plate 8, a cover plate 20 is installed above, and the cover plate 20 completely covers the cutting plate 8, effectively preventing splashing caused by pulling during work. There is a gap between the cover plate 20 and the cutting plate 8, and the first workbench 5 is placed On the first support 21, an auxiliary support 22 is fixedly installed on one side of the first support 21, and a third driving device is fixedly installed on the auxiliary support 22, and the third driving device drives the reel 10. The nozzle 9 is connected to the first hanger 6 is fixed with cable ties 23, and the second pipeline 13 for conveying salad oil is installed on the nozzle 9, and the first workbench 5 is provided with a through hole 24, and the through hole ...

Embodiment 3

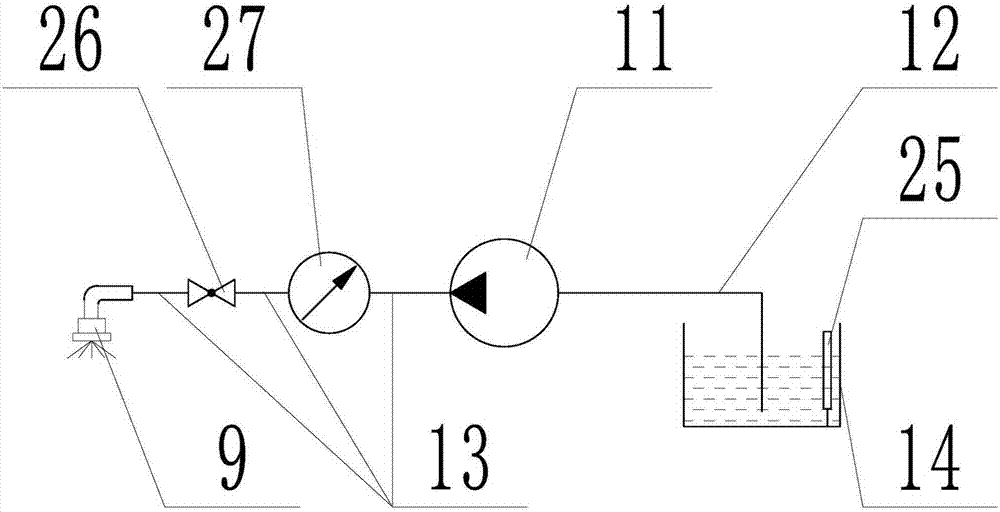

[0035] Embodiment 3. On the basis of Embodiment 1, a first sensor 25 is installed in the cavity of the oil cylinder 14 to detect the amount of oil in the oil cylinder 14. There is a switch 26 between the oil pump 11 and the nozzle 9. The switch 26 is installed on the second pipeline 13 , there is a pressure gauge 27 between the oil pump 11 and the switch 26 , and the pressure gauge 27 is installed on the second pipeline 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com