Patents

Literature

124results about How to "Reduced production cycle time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

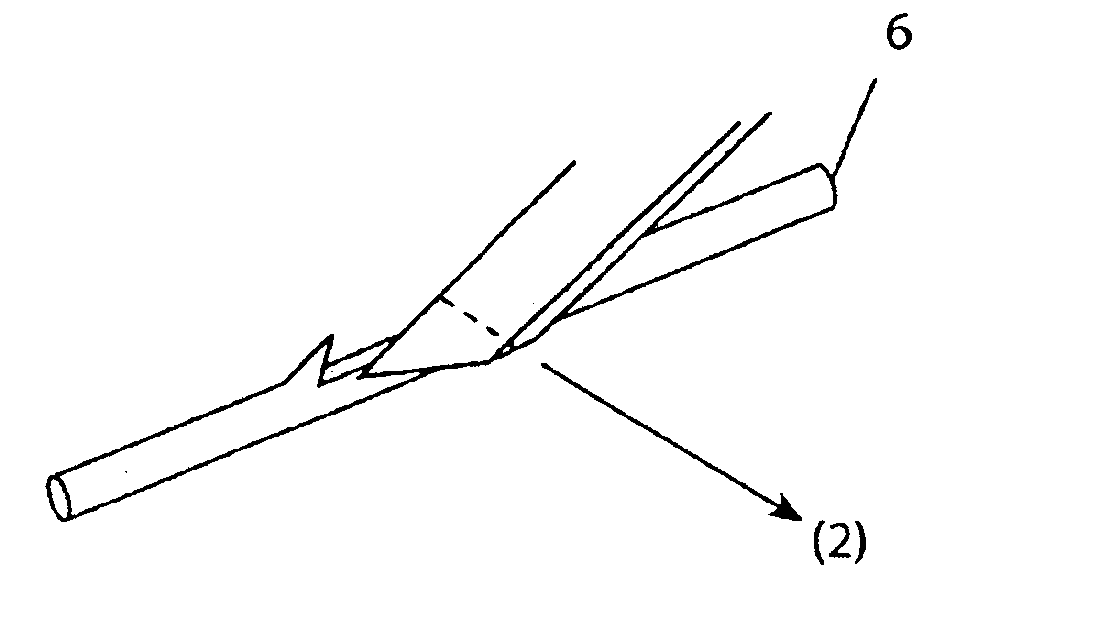

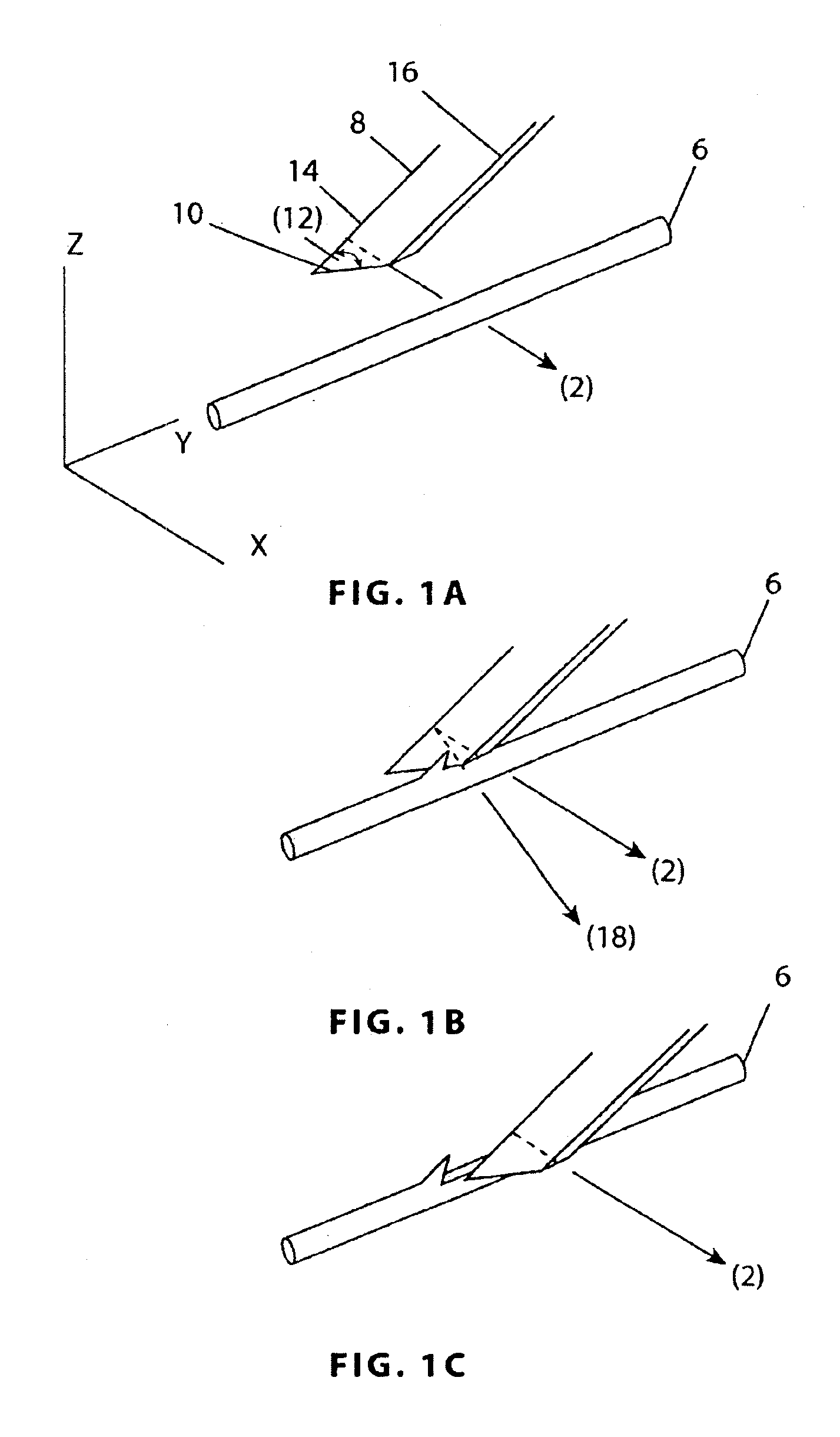

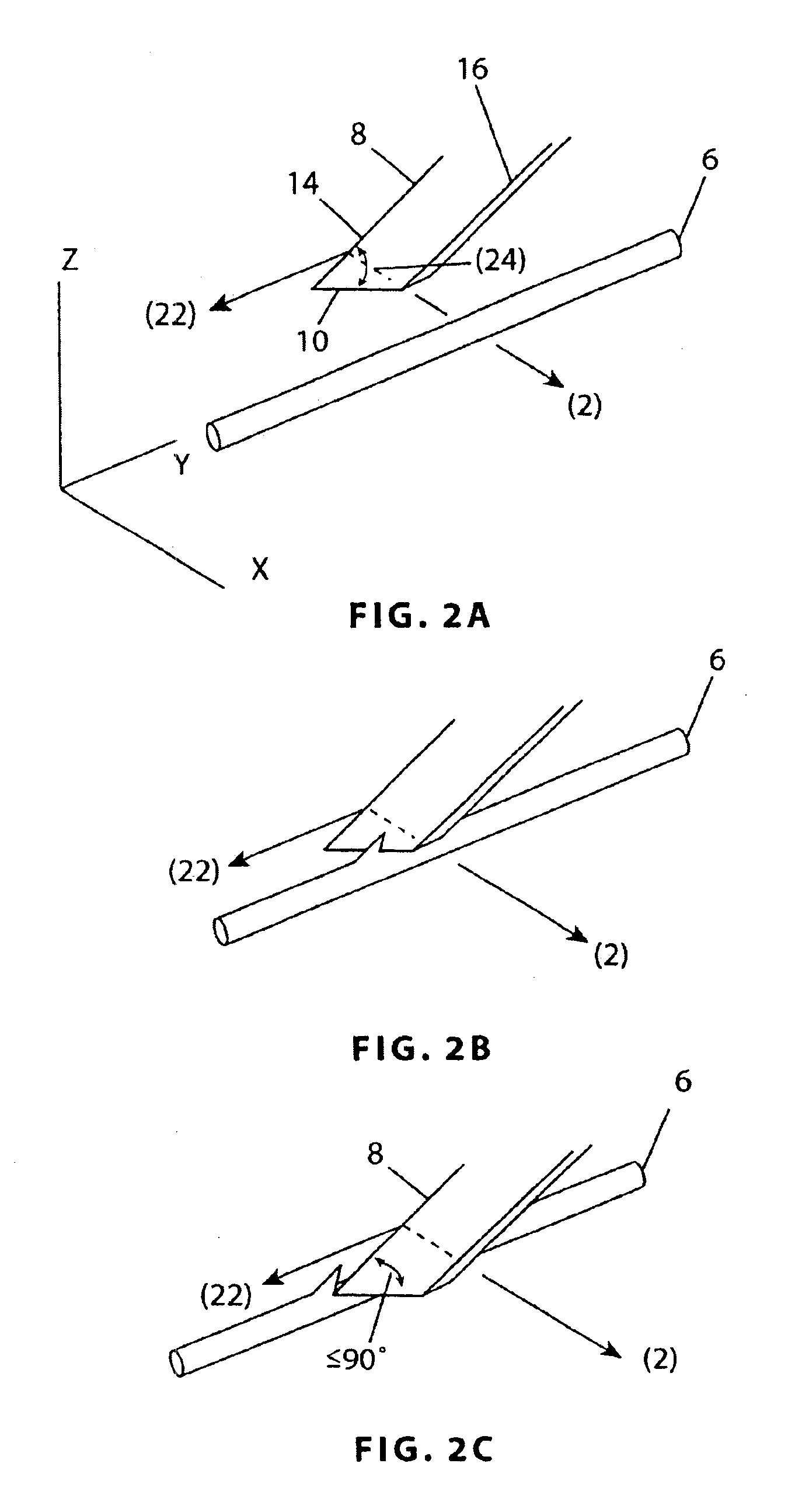

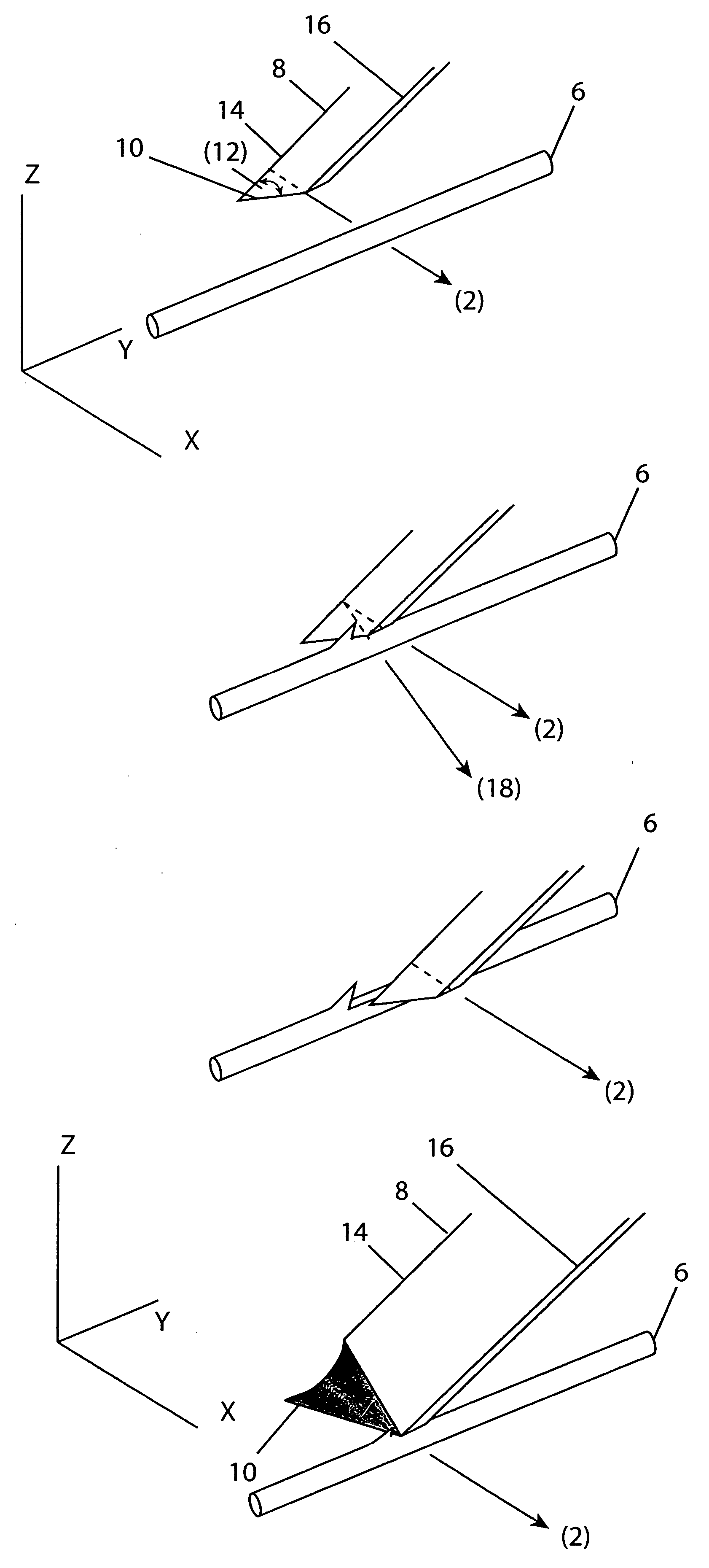

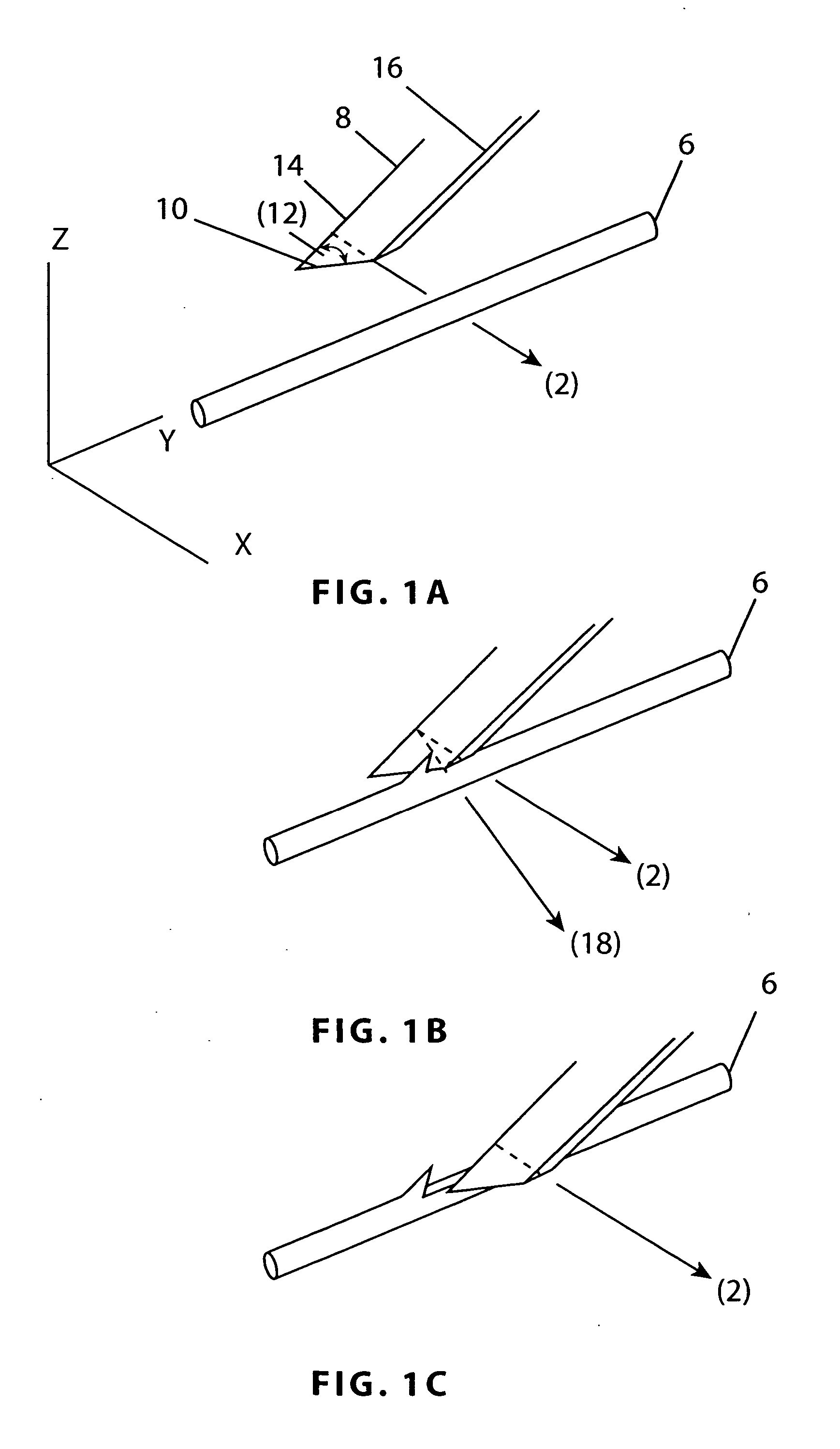

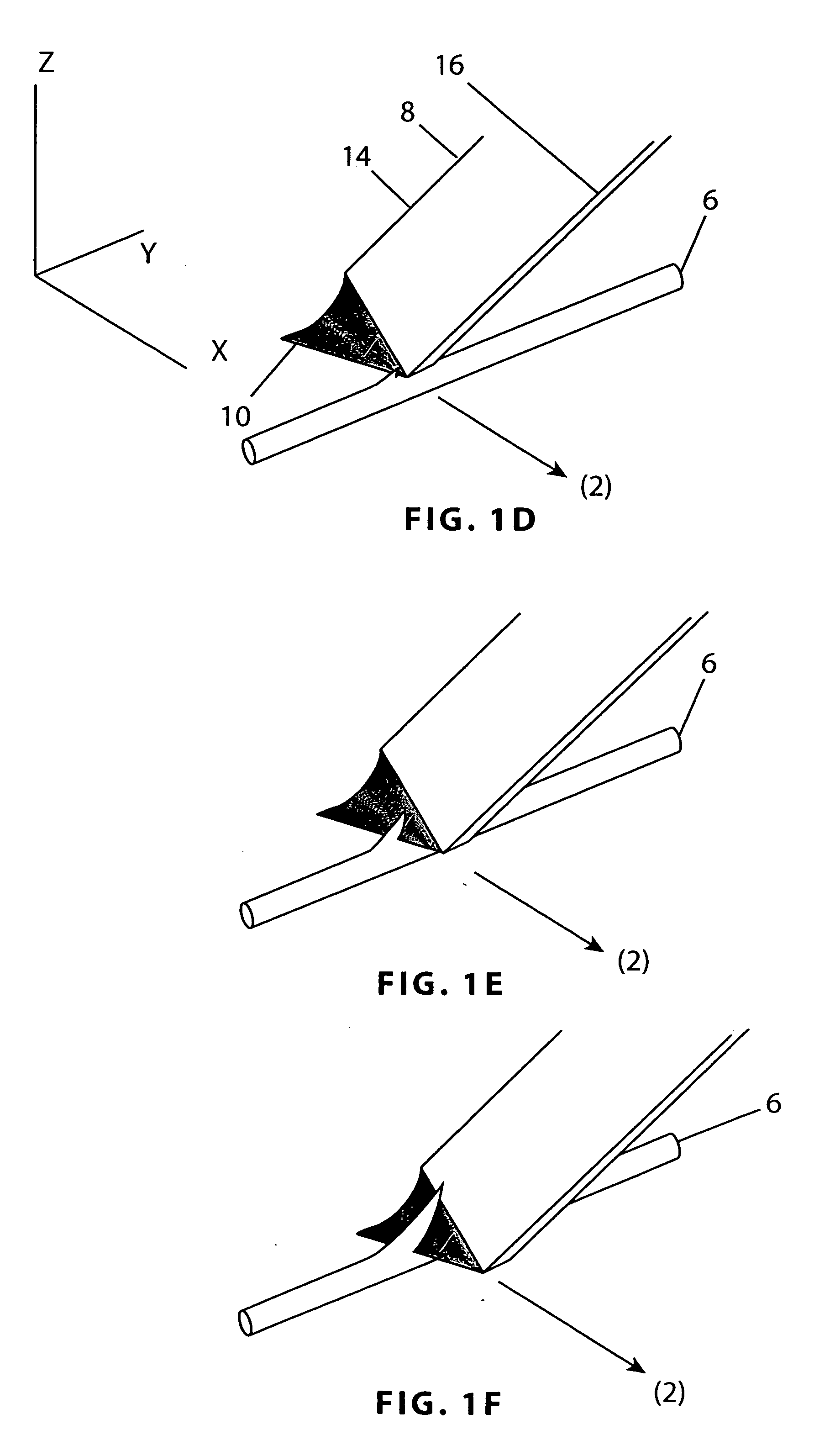

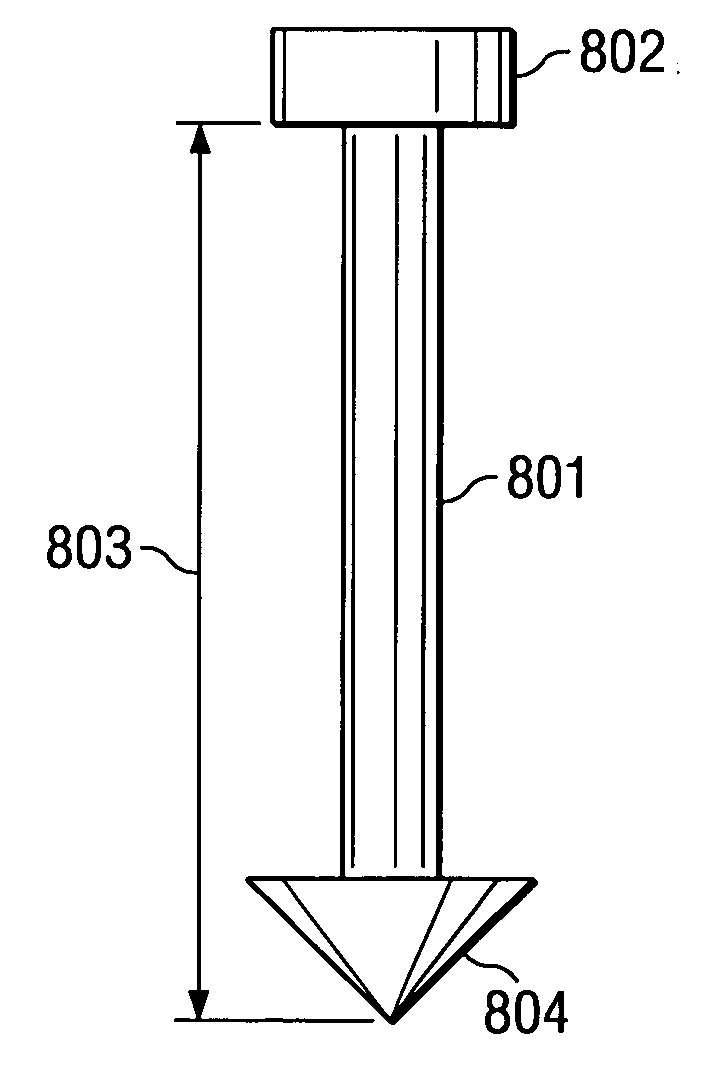

Method of forming barbs on a suture and apparatus for performing same

InactiveUS6848152B2Maximum anchoring propertyMore suitedSuture equipmentsSurgical needlesEngineeringBlade geometry

A method of making a barbed suture by varying the blade geometry and / or the movement of the blade when cutting a suture. The method can also be accomplished with a cutting device to create a plurality of barbs on the exterior of surgical suture. The barbs produced using the method with the cutting device can be the same or random configurations.

Owner:CILAG GMBH INT

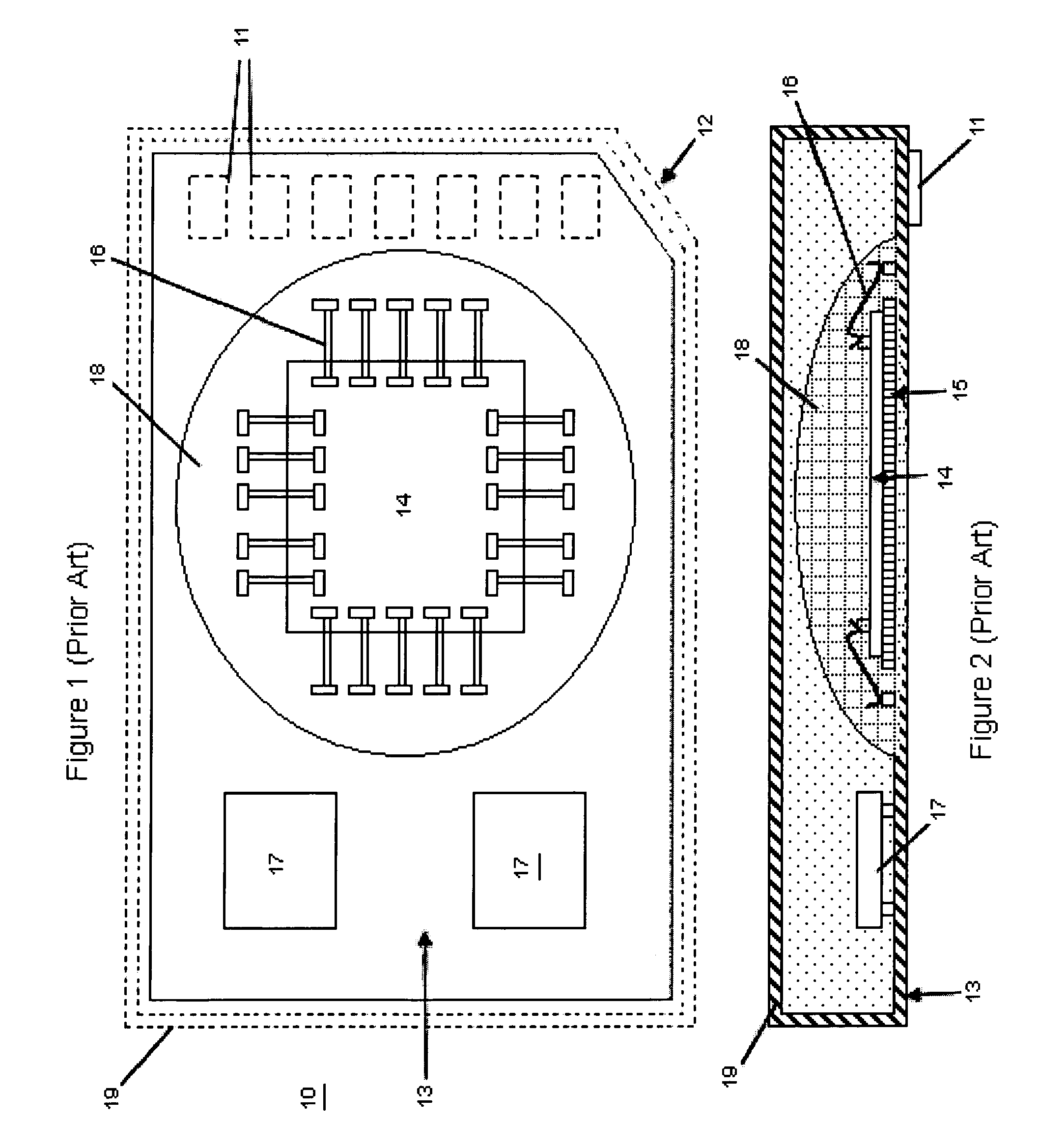

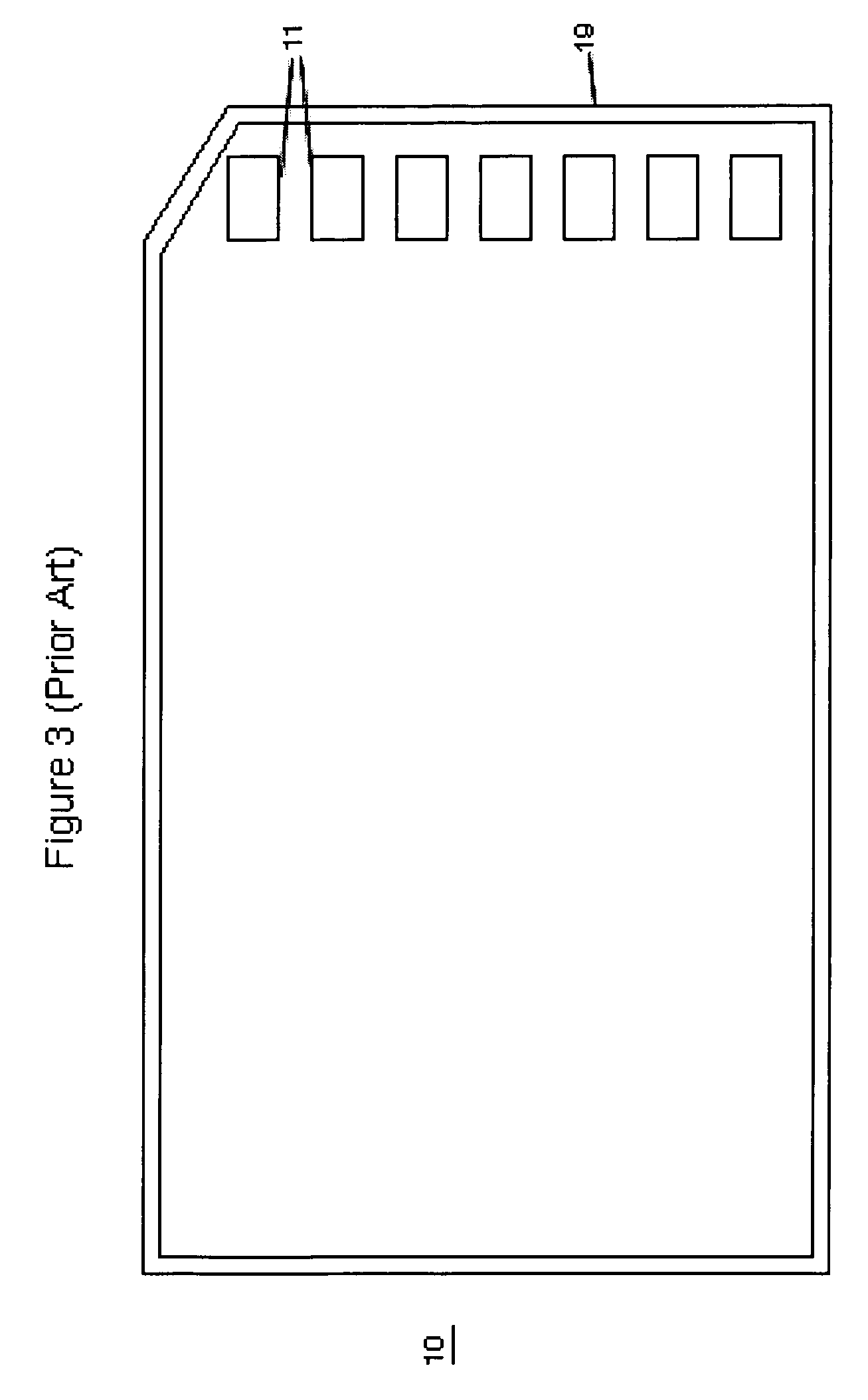

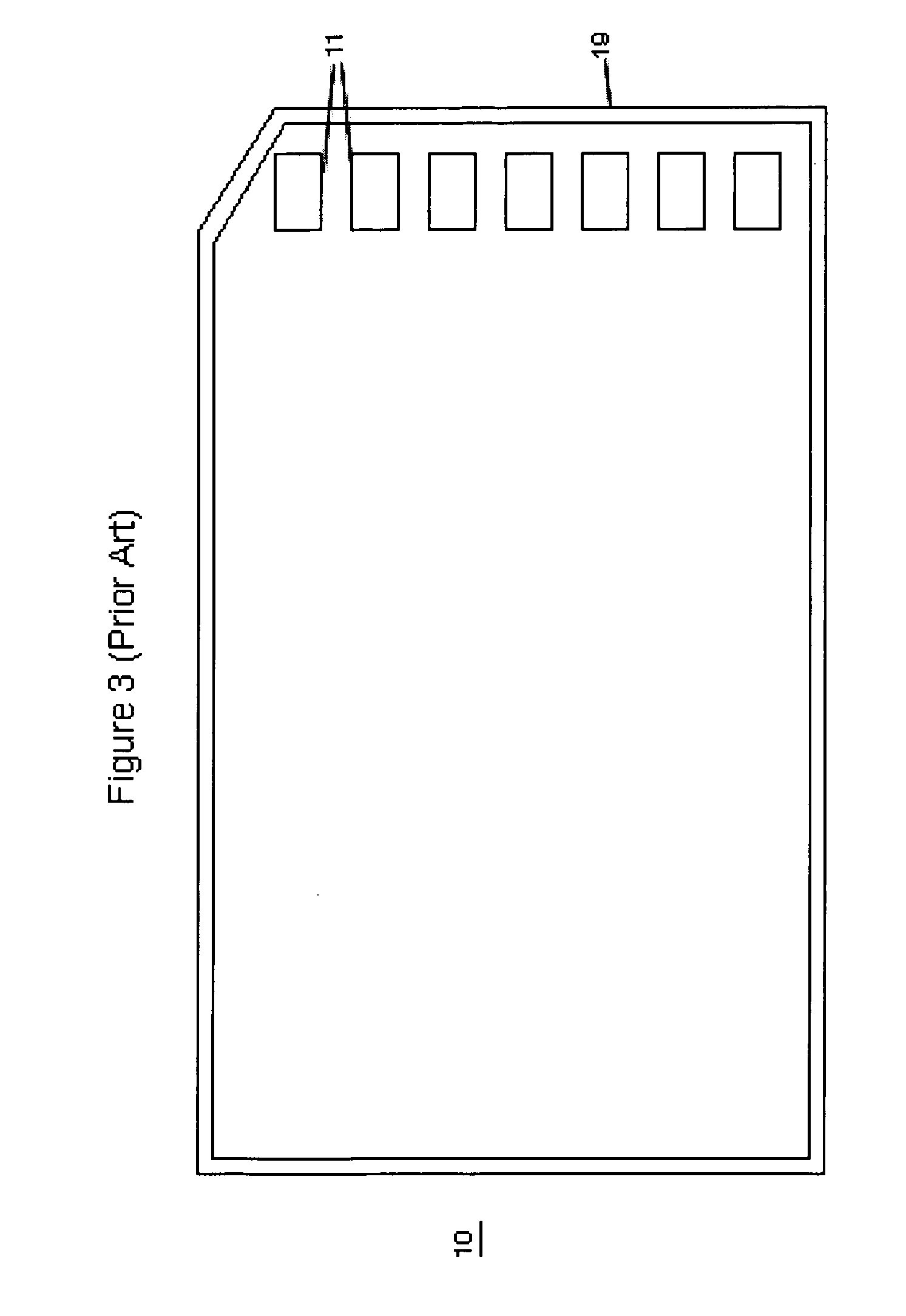

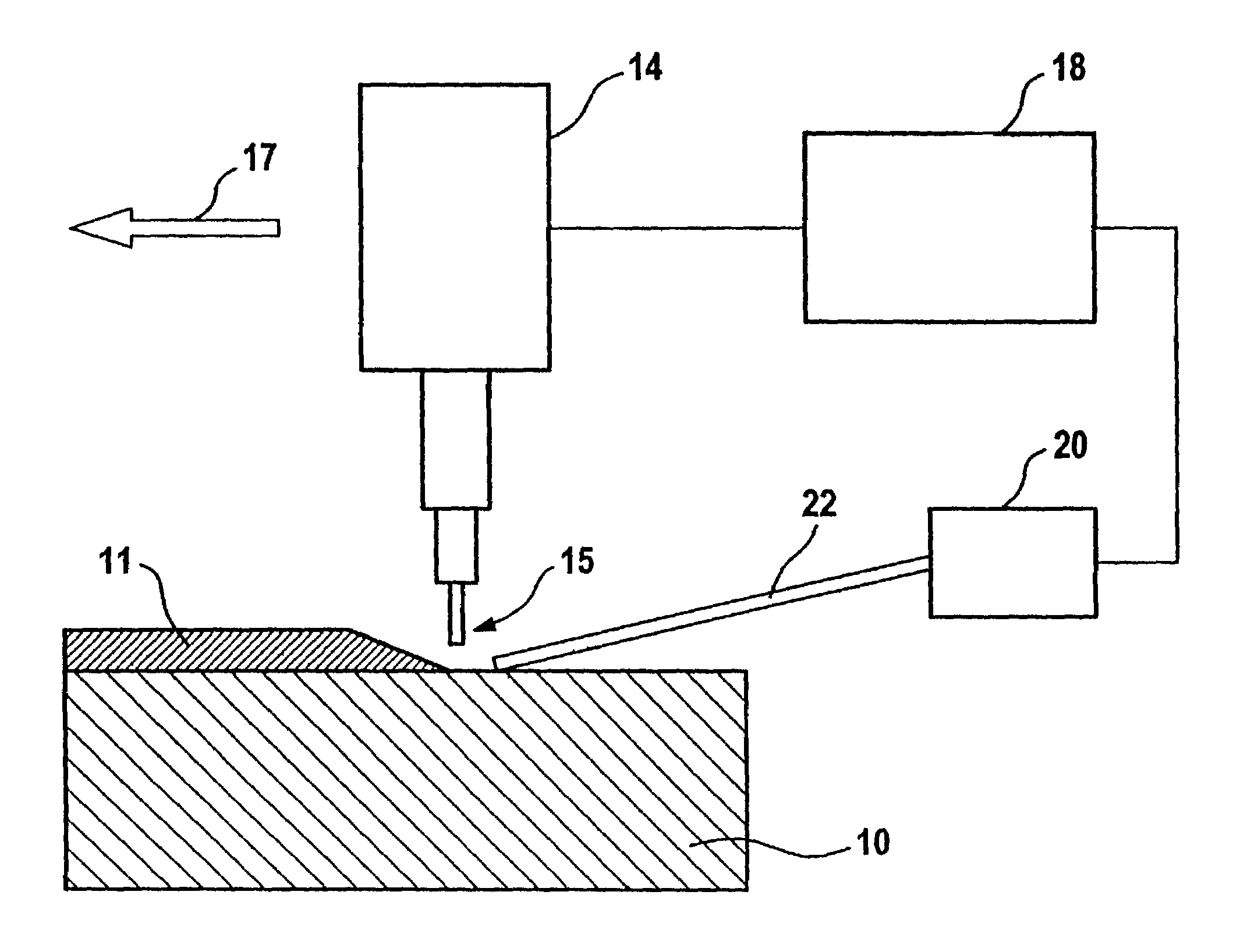

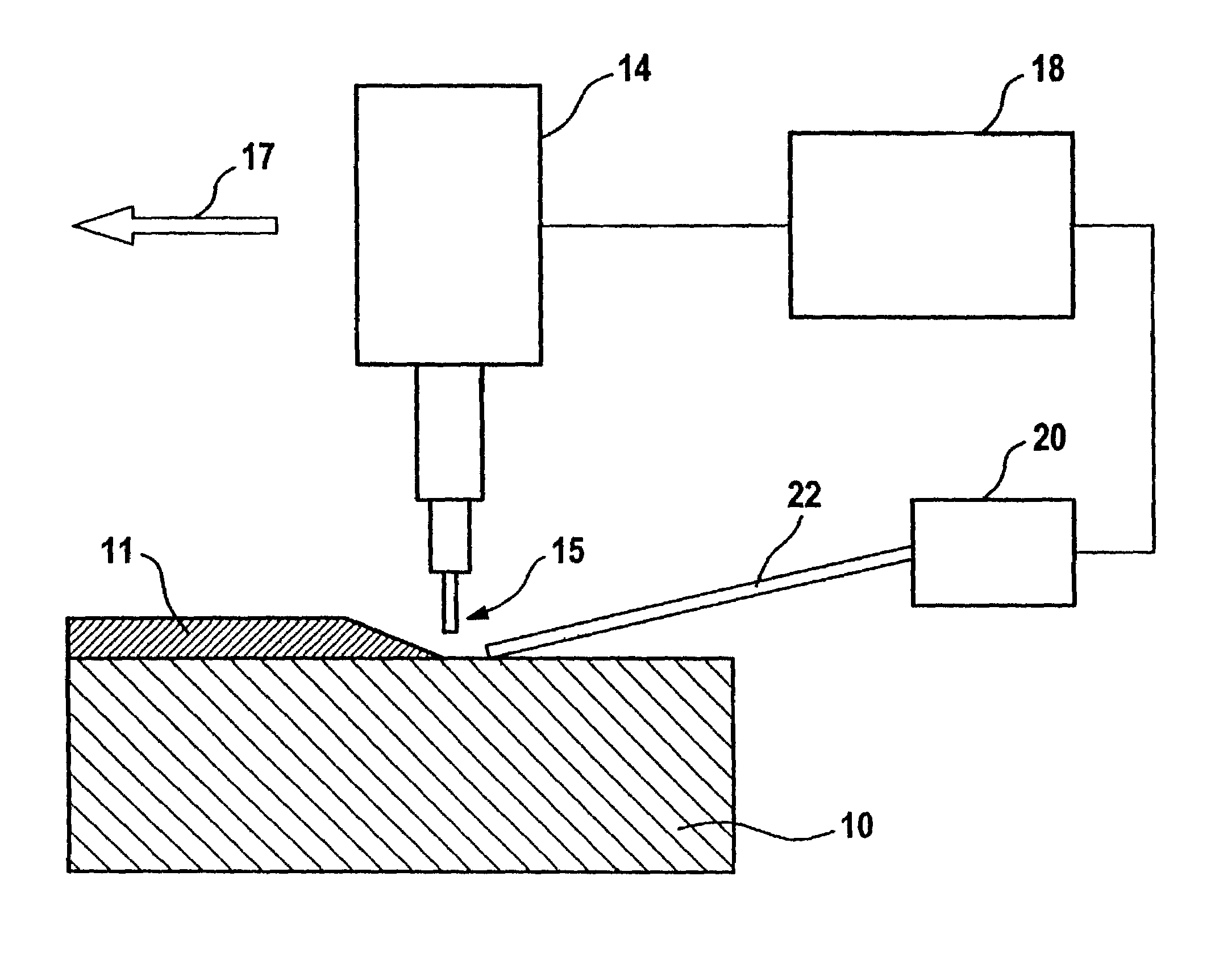

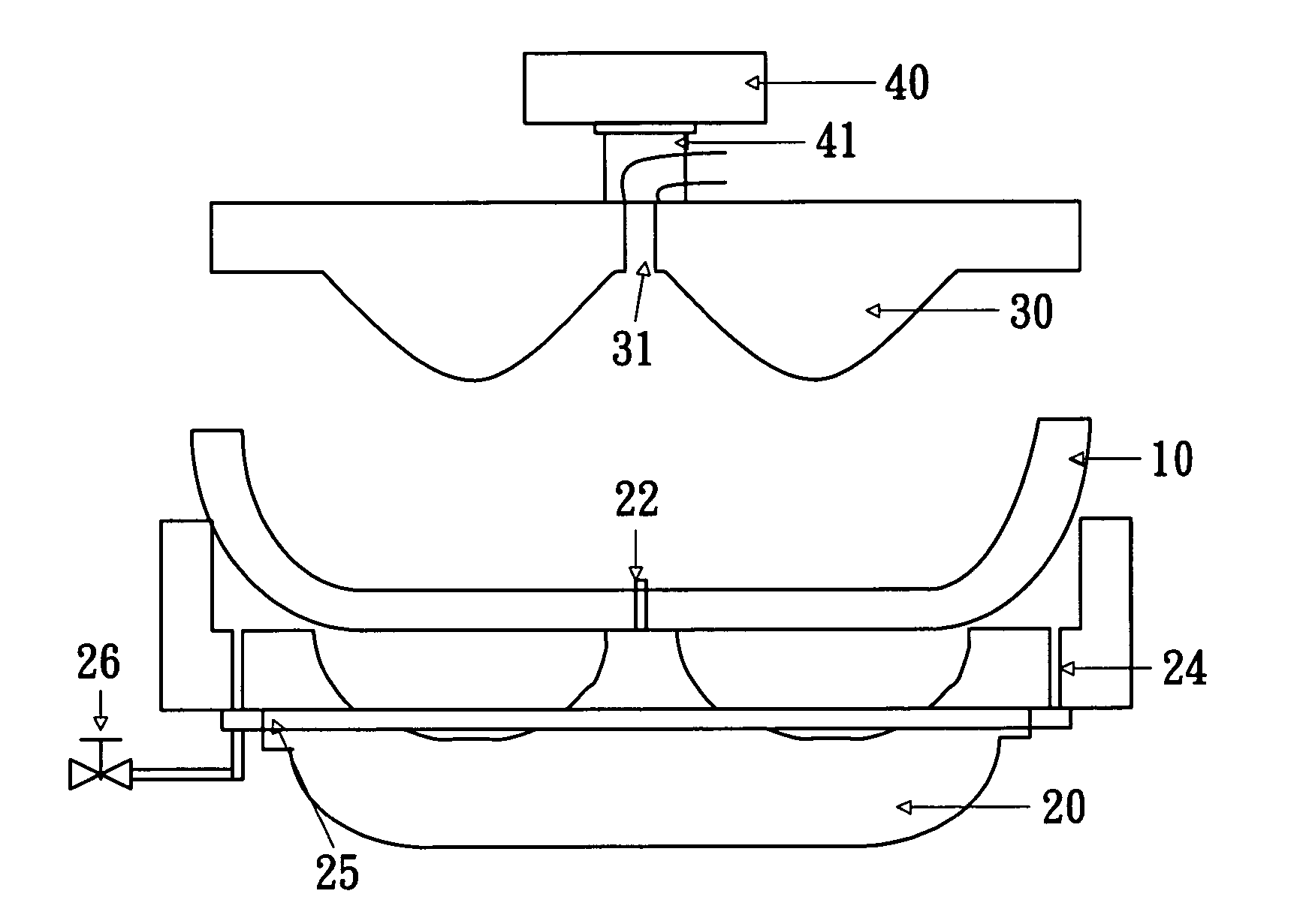

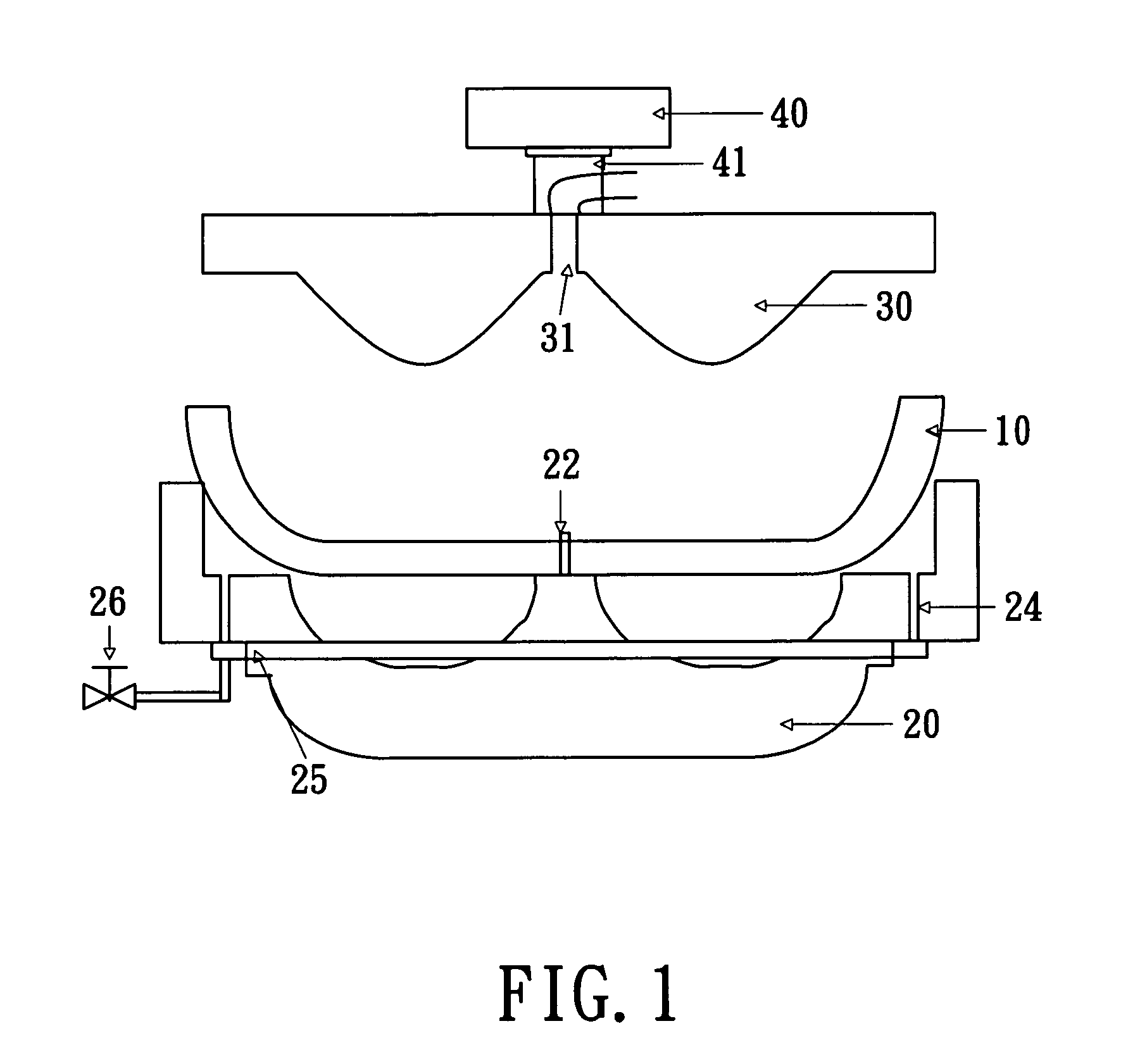

Method for making memory cards and similar devices using isotropic thermoset materials with high quality exterior surfaces

InactiveUS7225537B2Shorten the timeQuality improvementPrinted circuit assemblingLine/current collector detailsEngineeringInjection moulding

Memory Cards containing Integrated Circuits and other electronic components (e.g. resistors) in a variety of form factors having high quality external surfaces of polycarbonate, synthetic paper (e.g. Teslin), or other suitable material (e.g. PVC) can be made through use of injection molded thermoplastic material or thermosetting material that becomes the core layer of said Memory Cards and similar devices. The object of the invention is to provide the following properties to Memory Cards: rapid production cycle, high volume manufacturing throughput, security, electronics protection, better tamper resistance, durability, and highly reliable complex electronics encapsulation, achieved through a process utilizing low temperature and low pressure.

Owner:CARDXX

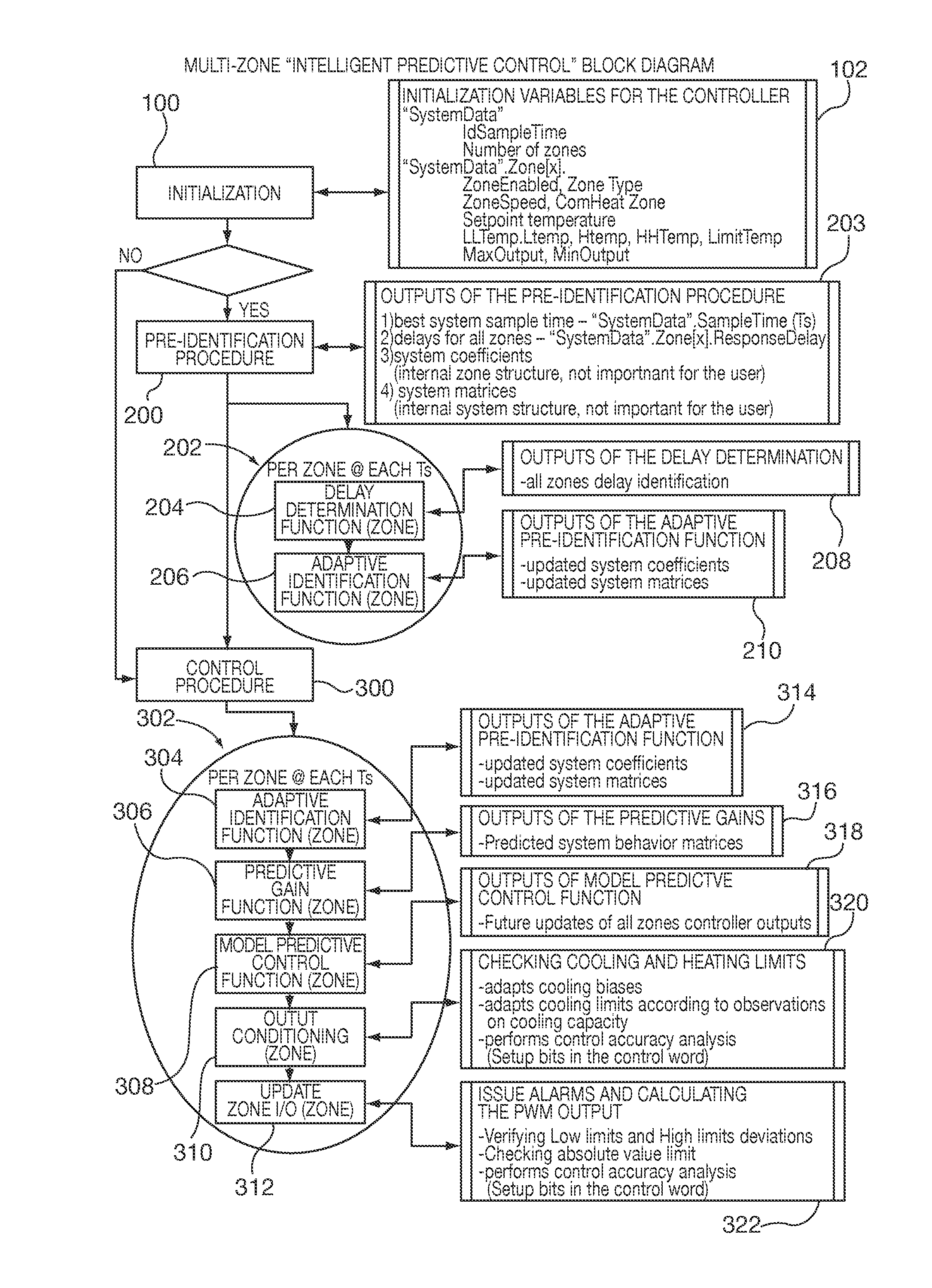

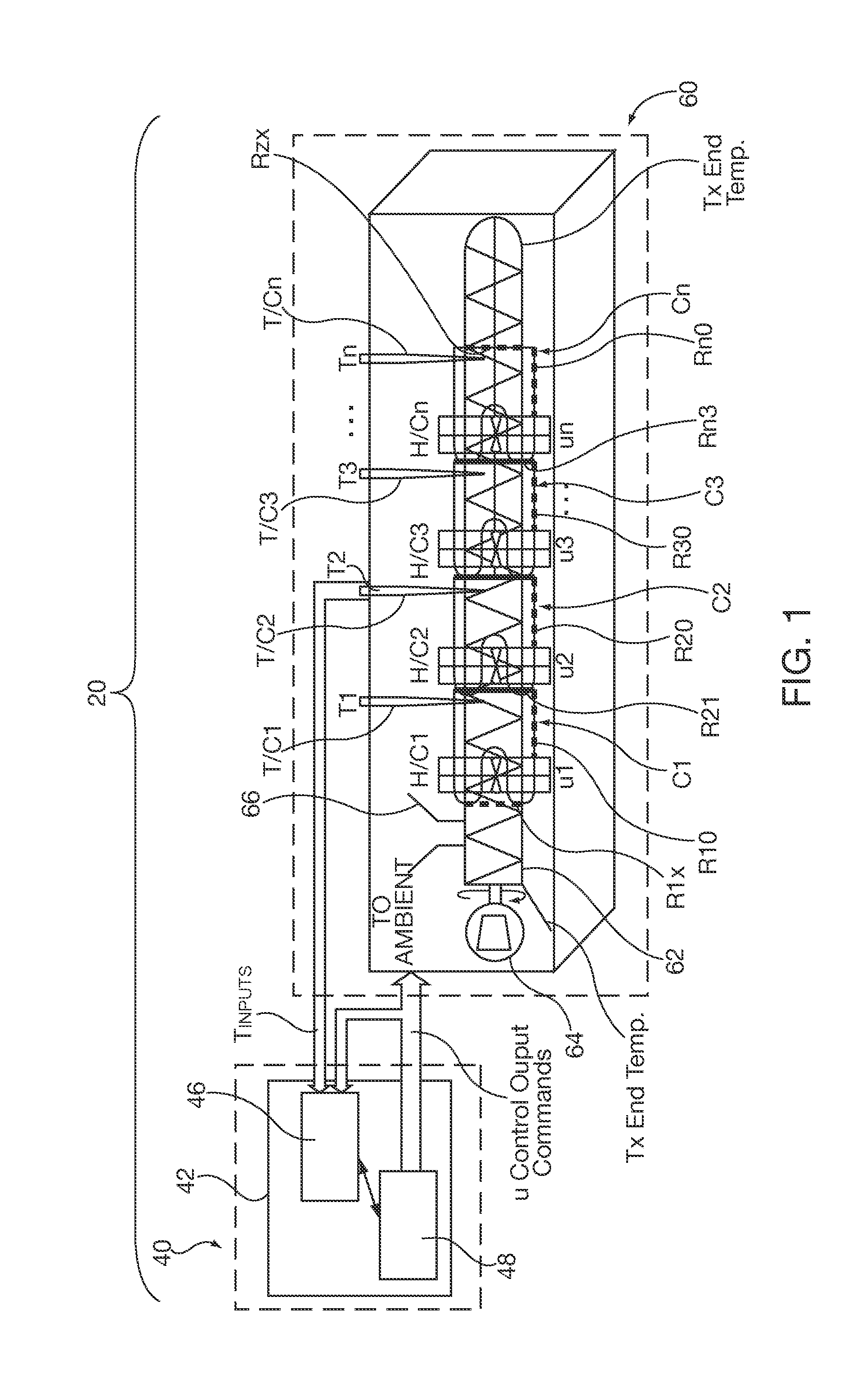

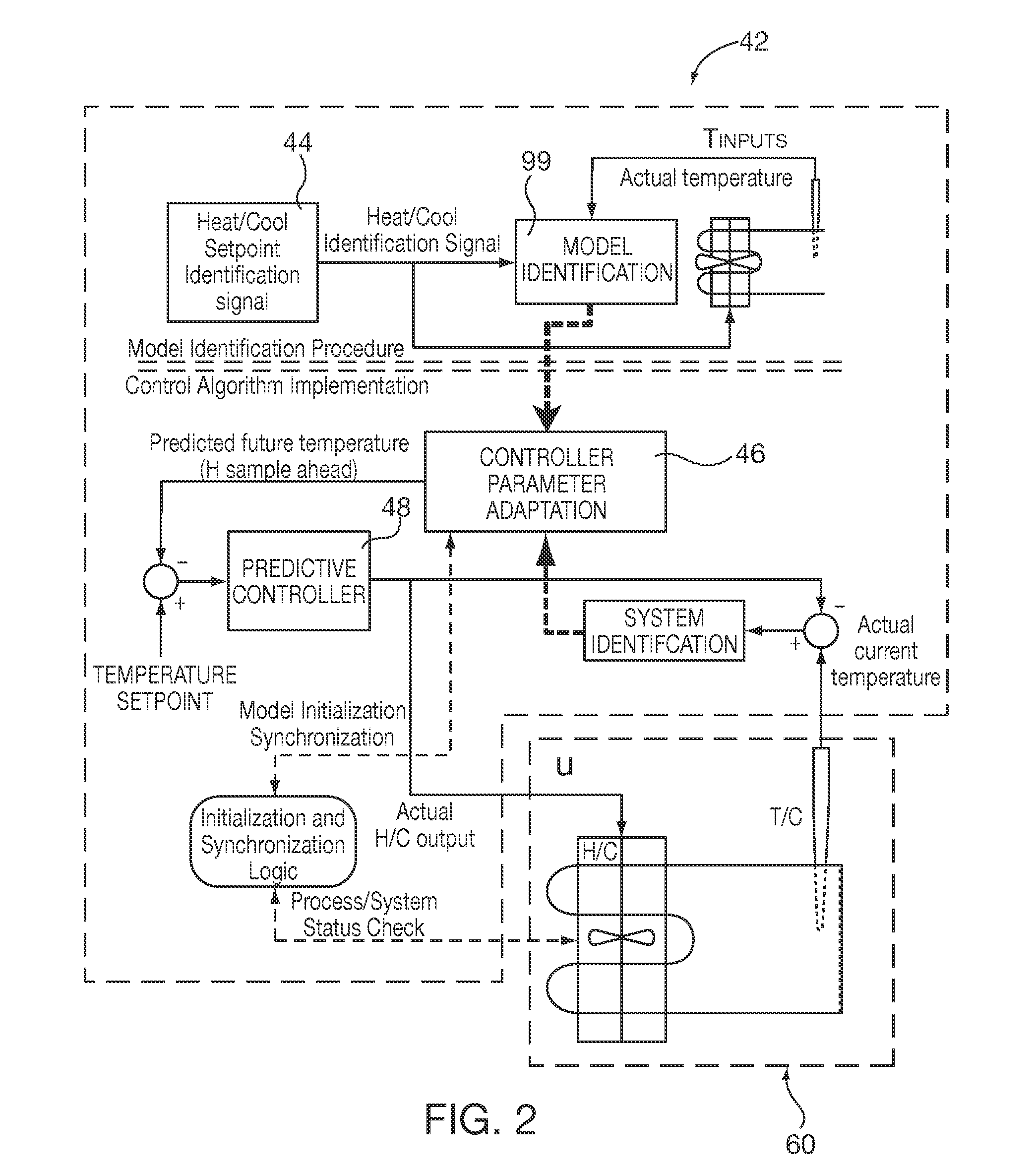

Method and apparatus of a self-configured, model-based adaptive, predictive controller for multi-zone regulation systems

InactiveUS20110022193A1Easy to addPrecise processingSampled-variable control systemsTravelling carriersHorizonPlastic injection molding

A control system simultaneously controls a multi-zone process with a self-adaptive model predictive controller (MPC), such as temperature control within a plastic injection molding system. The controller is initialized with basic system information. A pre-identification procedure determines a suggested system sampling rate, delays or “dead times” for each zone and initial system model matrix coefficients necessary for operation of the control predictions. The recursive least squares based system model update, control variable predictions and calculations of the control horizon values are preferably executed in real time by using matrix calculation basic functions implemented and optimized for being used in a S7 environment by a Siemens PLC. The number of predictions and the horizon of the control steps required to achieve the setpoint are significantly high to achieve smooth and robust control. Several matrix calculations, including an inverse matrix procedure performed at each sample pulse and for each individual zone determine the MPC gain matrices needed to bring the system with minimum control effort and variations to the final setpoint. Corrective signals, based on the predictive model and the minimization criteria explained above, are issued to adjust system heating / cooling outputs at the next sample time occurrence, so as to bring the system to the desired set point. The process is repeated continuously at each sample pulse.

Owner:SIEMENS IND INC

Method of forming barbs on a suture and apparatus for performing same

ActiveUS20040237736A1Maximum anchoring propertyMore suitedSuture equipmentsSurgical needlesEngineeringBlade geometry

A method of making a barbed suture by varying the blade geometry and / or the movement of the blade when cutting a suture is disclosed. The method can also be accomplished with a cutting device to create a plurality of barbs on the exterior of surgical suture. The barbs produced using the method with the cutting device can be the same or random configurations.

Owner:CILAG GMBH INTERNATIONAL

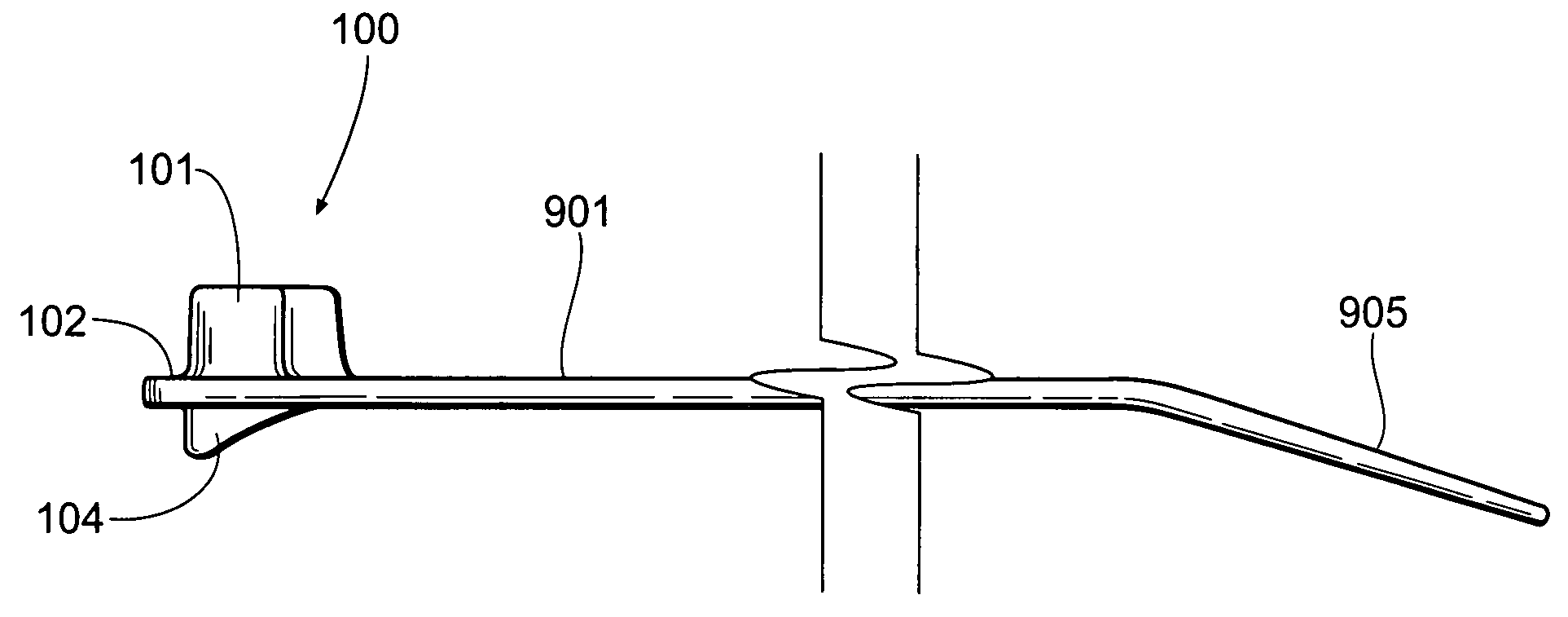

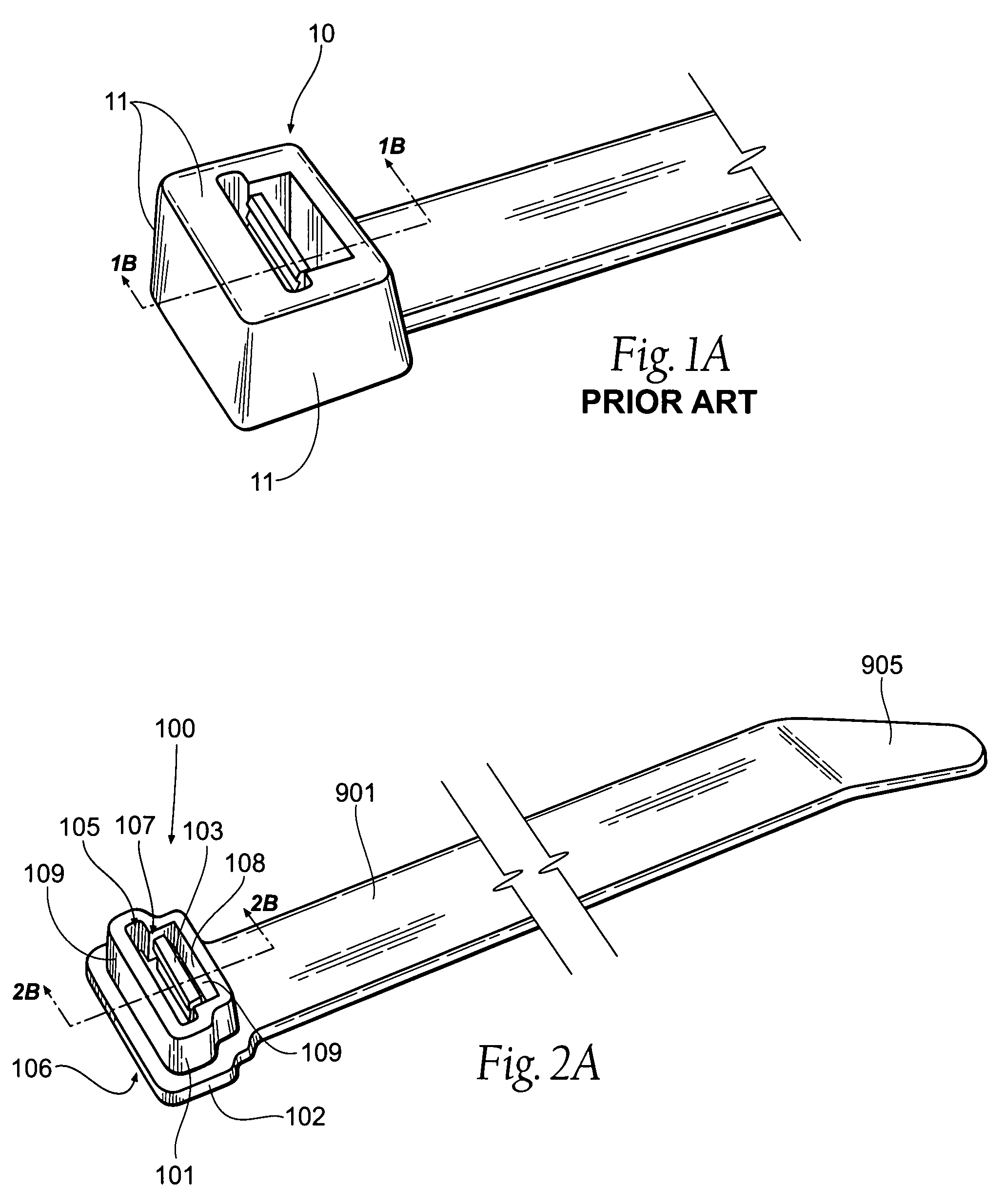

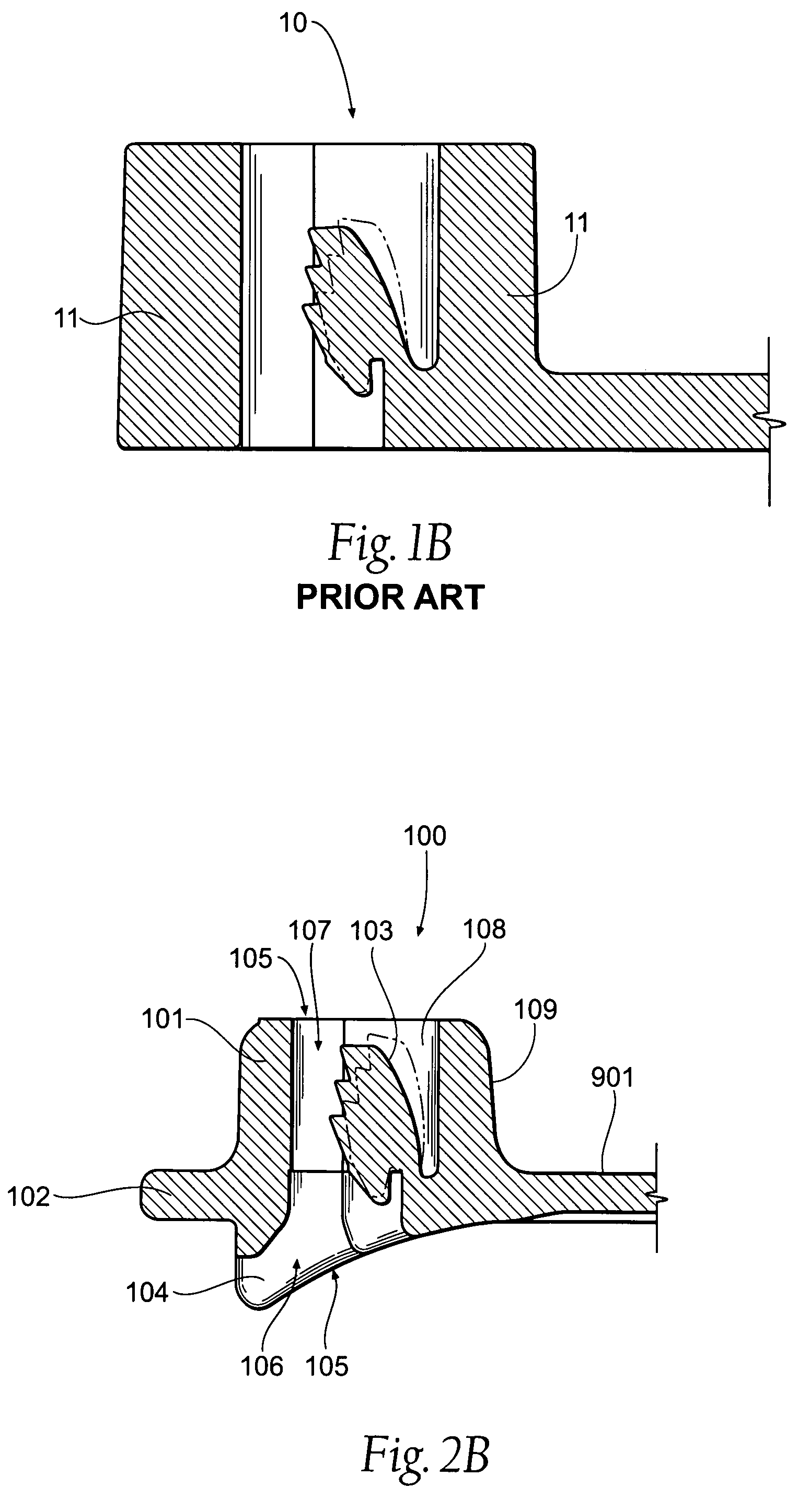

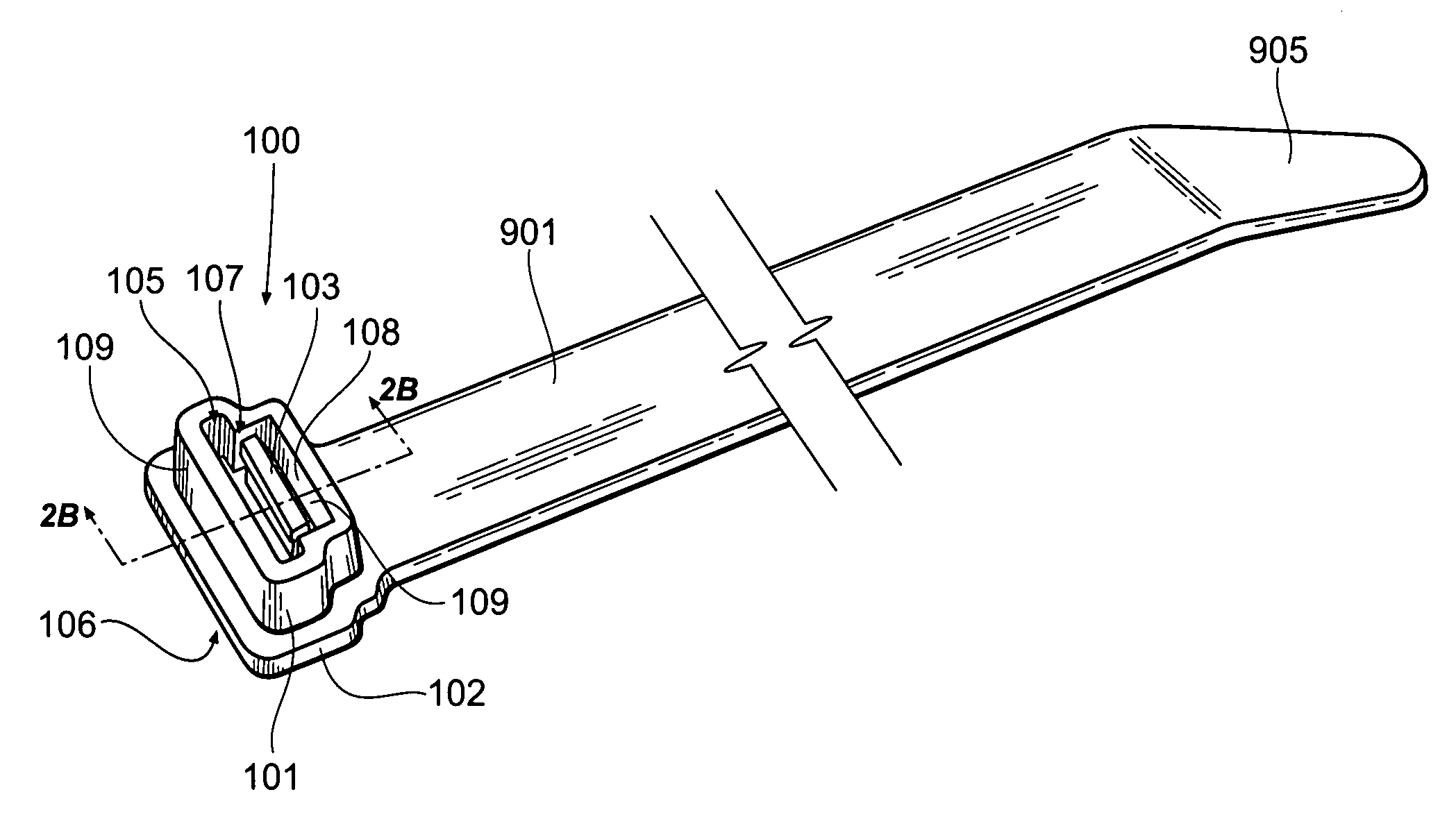

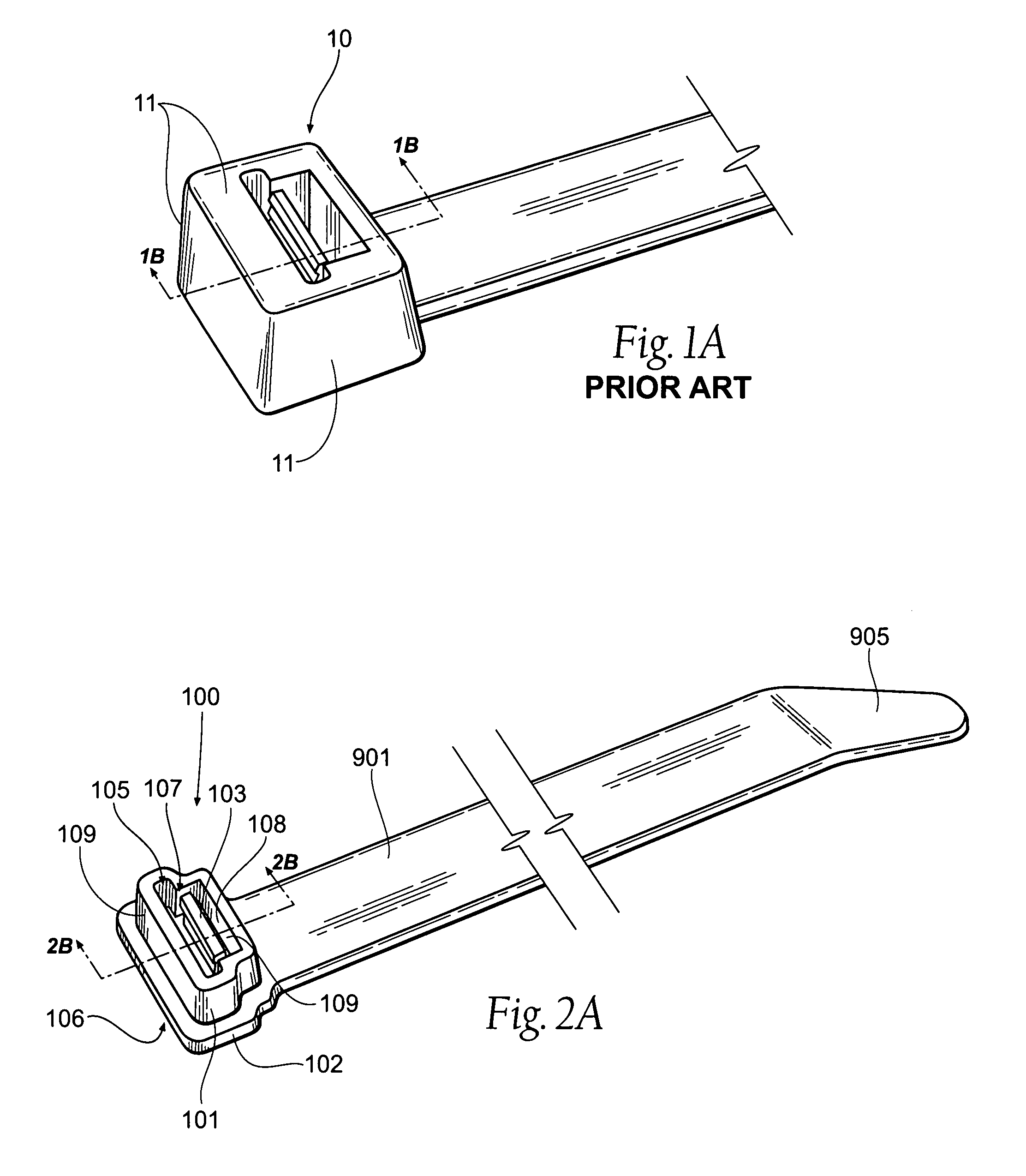

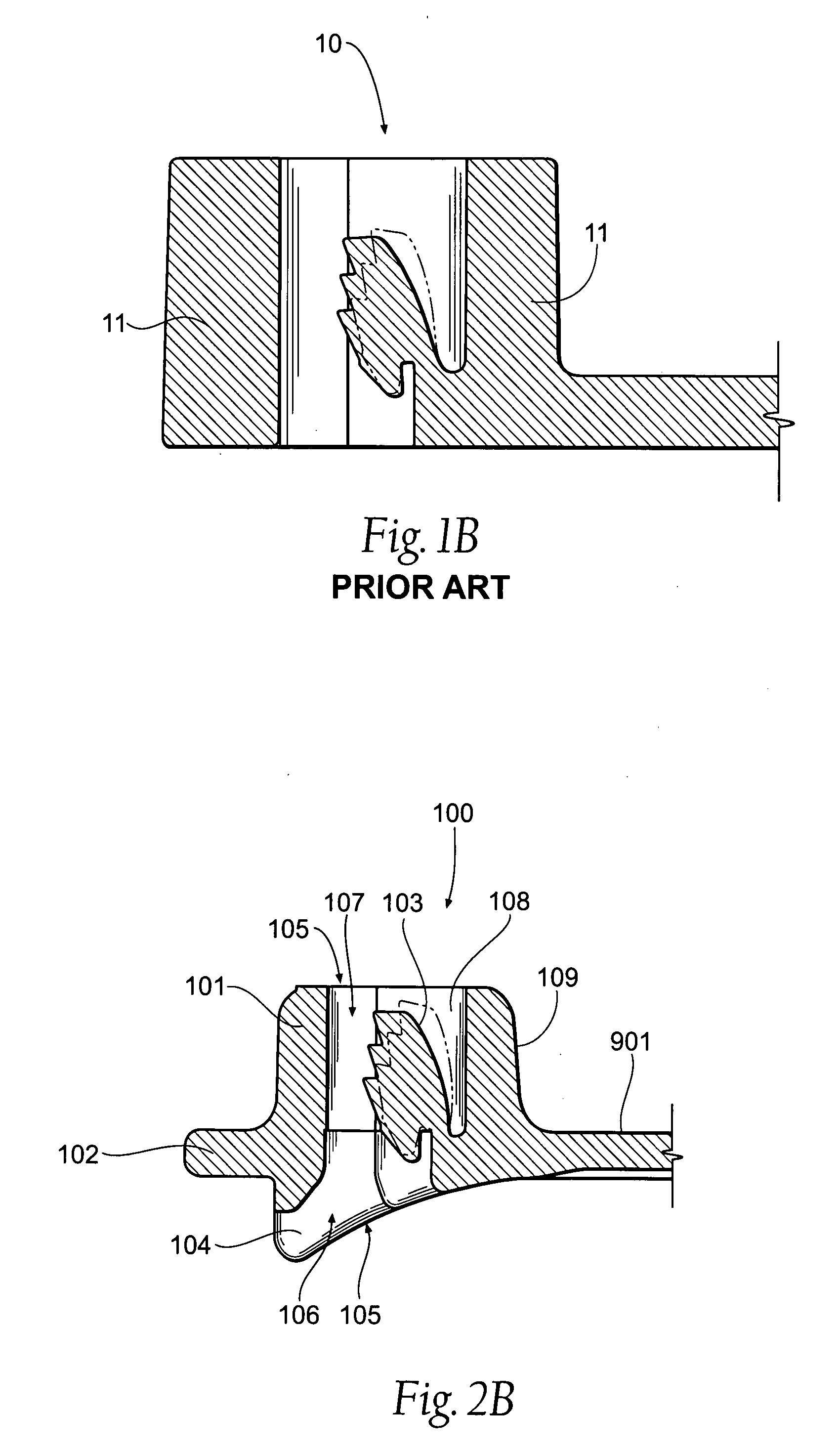

Element of a cable tie strap

ActiveUS7774905B2Reduce the amount requiredMaintain structural integritySnap fastenersPipe supportsCombined useMechanical engineering

A low profile locking tie head having a reduced wall thickness is provided for use in conjunction with a flexible strap. The low profile head comprises a wall, which circumferentially defines an opening, a reinforcement rib attached to the wall, and a pawl mechanism disposed at least partially inside the opening. A pair of clamping rails preferably provides a complete clamping surface, lowers the required tie head height, and assists in the transfer of force to the reinforcement rib. Further, a tie head retainer is provided to allow secure connection to a predetermined support structure.

Owner:HELLERMANNTYTON CORP

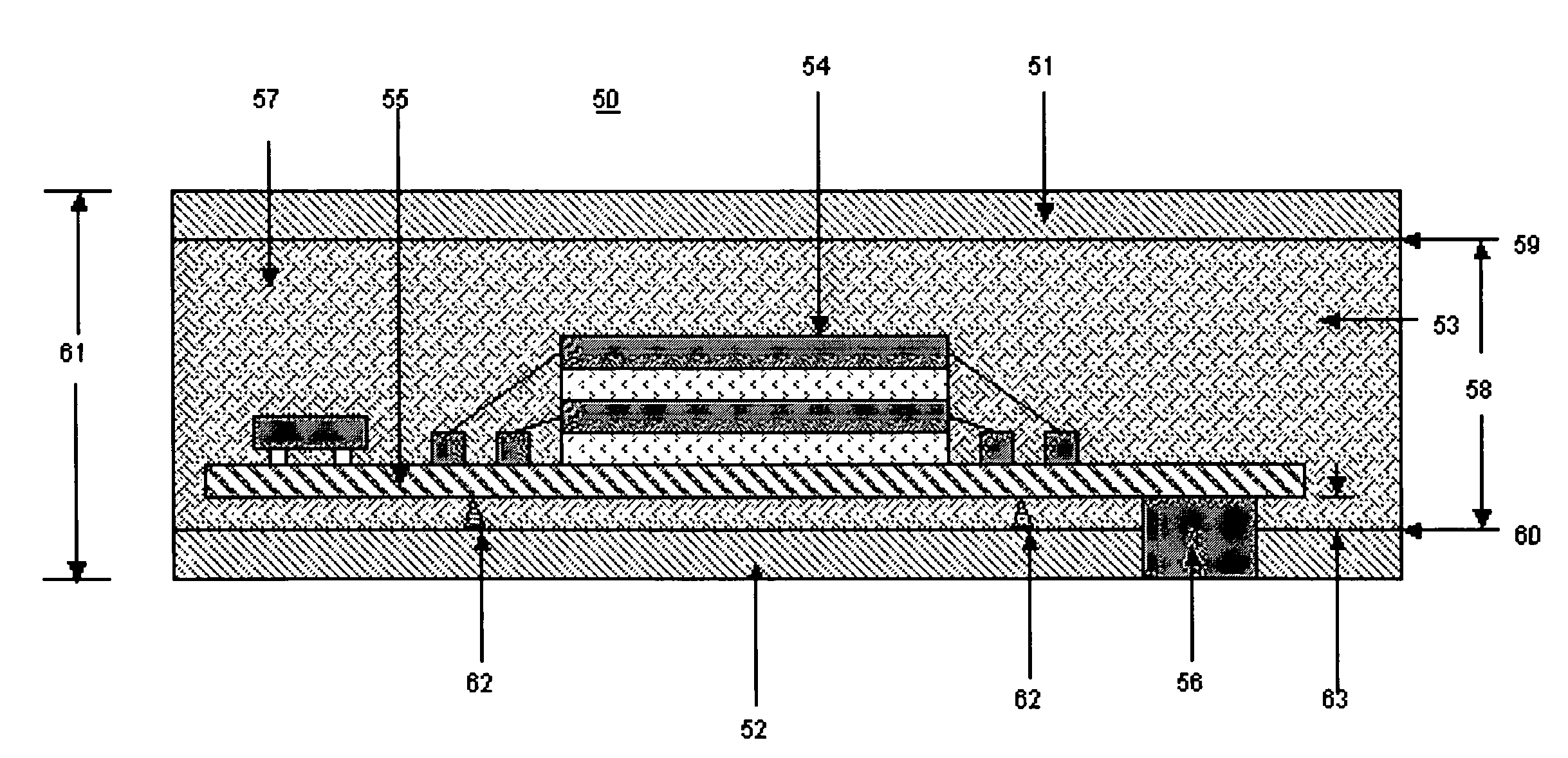

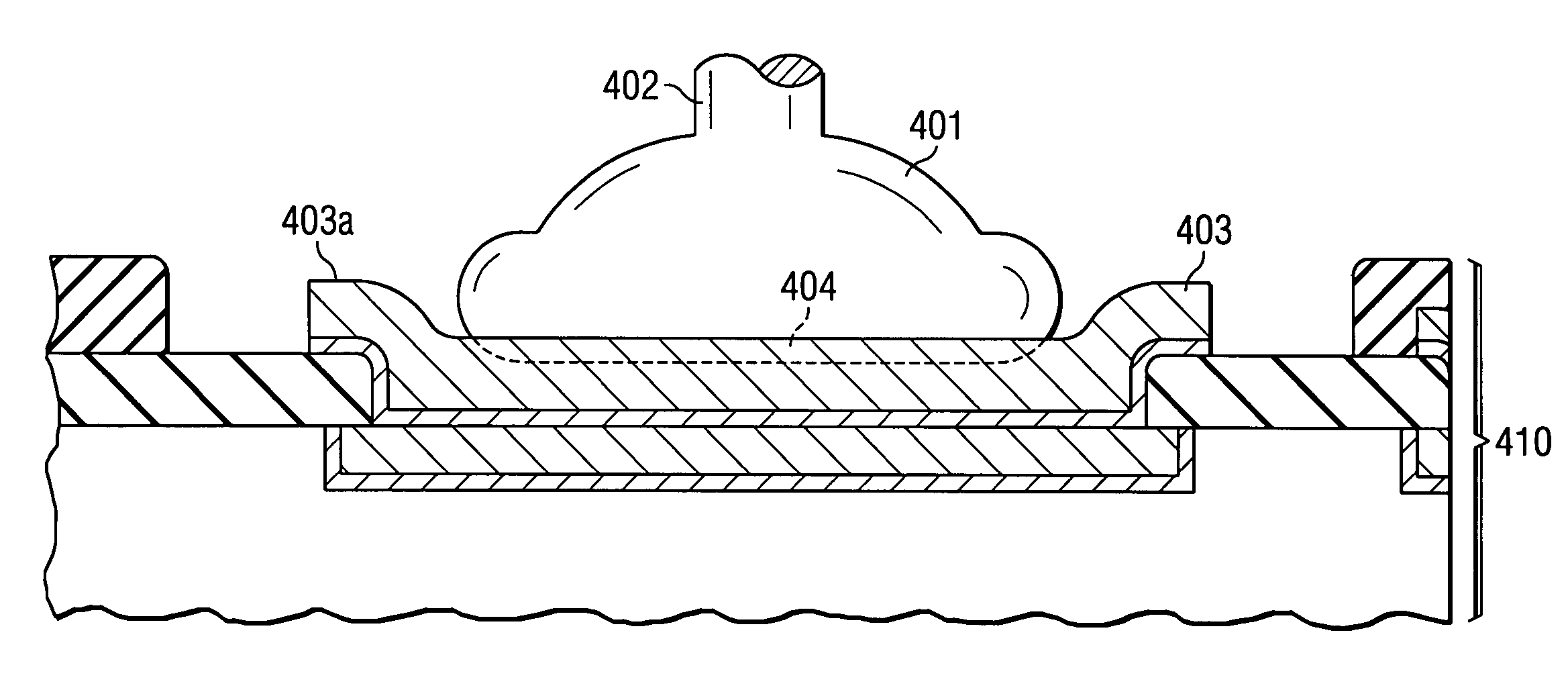

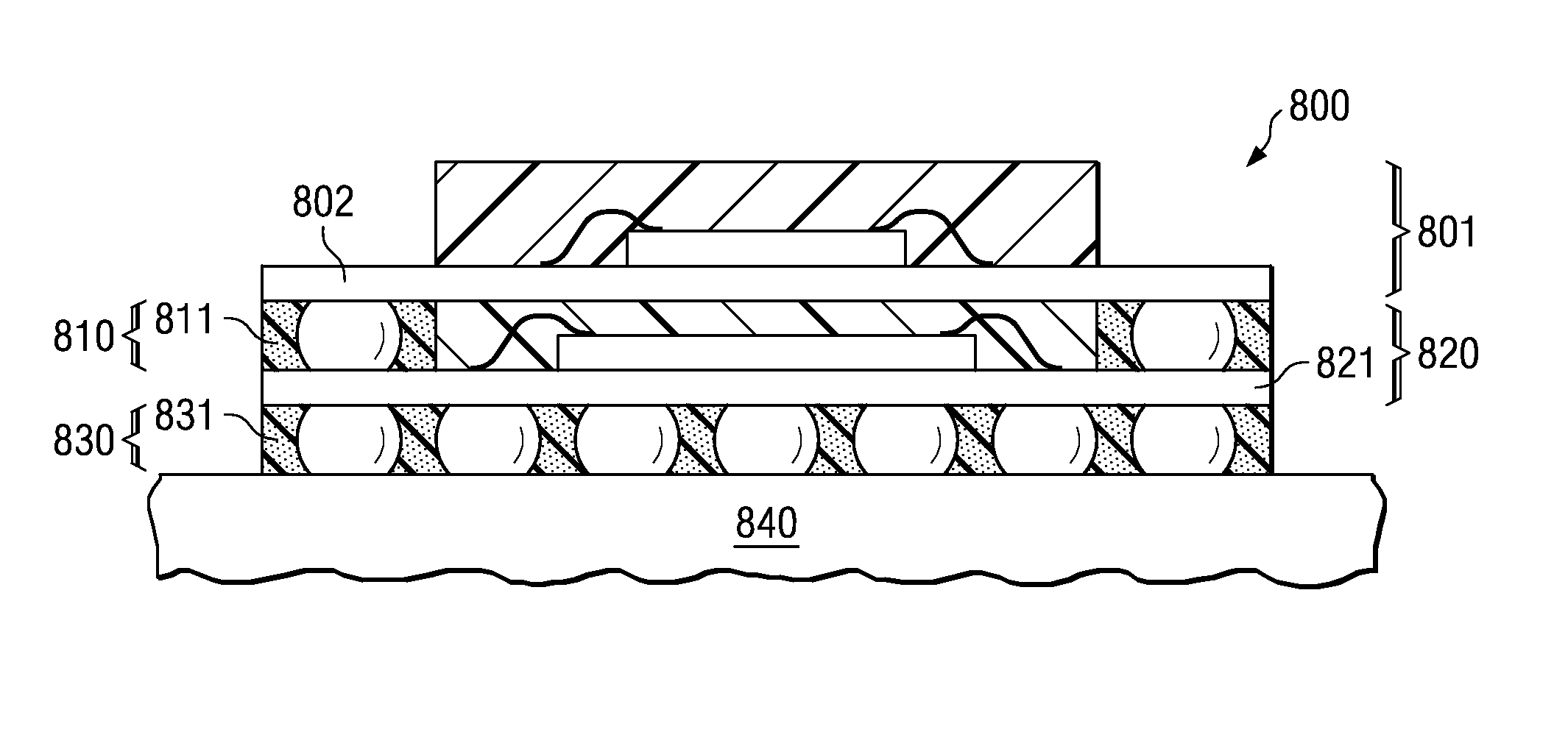

Flexible Circuit Assemblies without Solder and Methods for their Manufacture

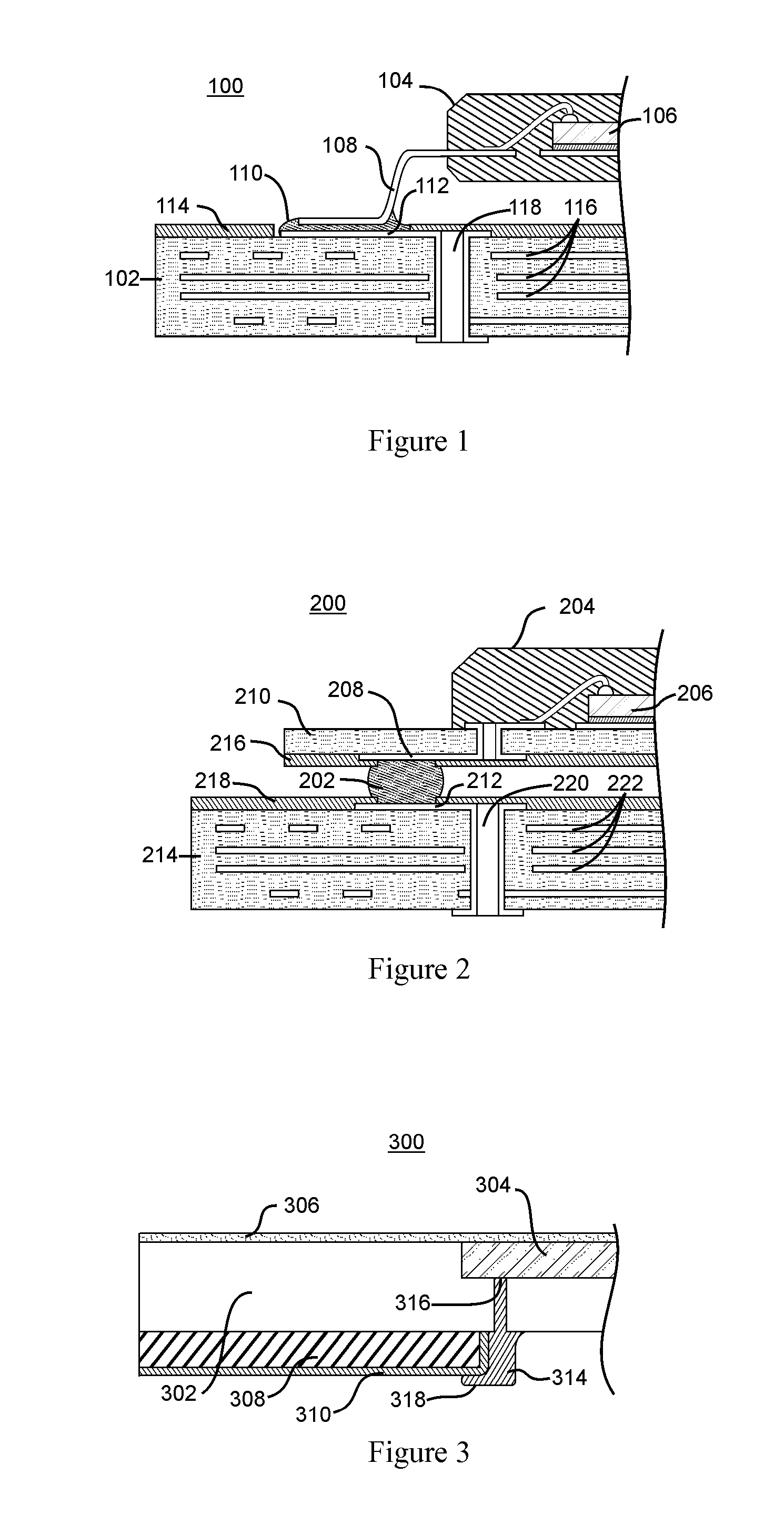

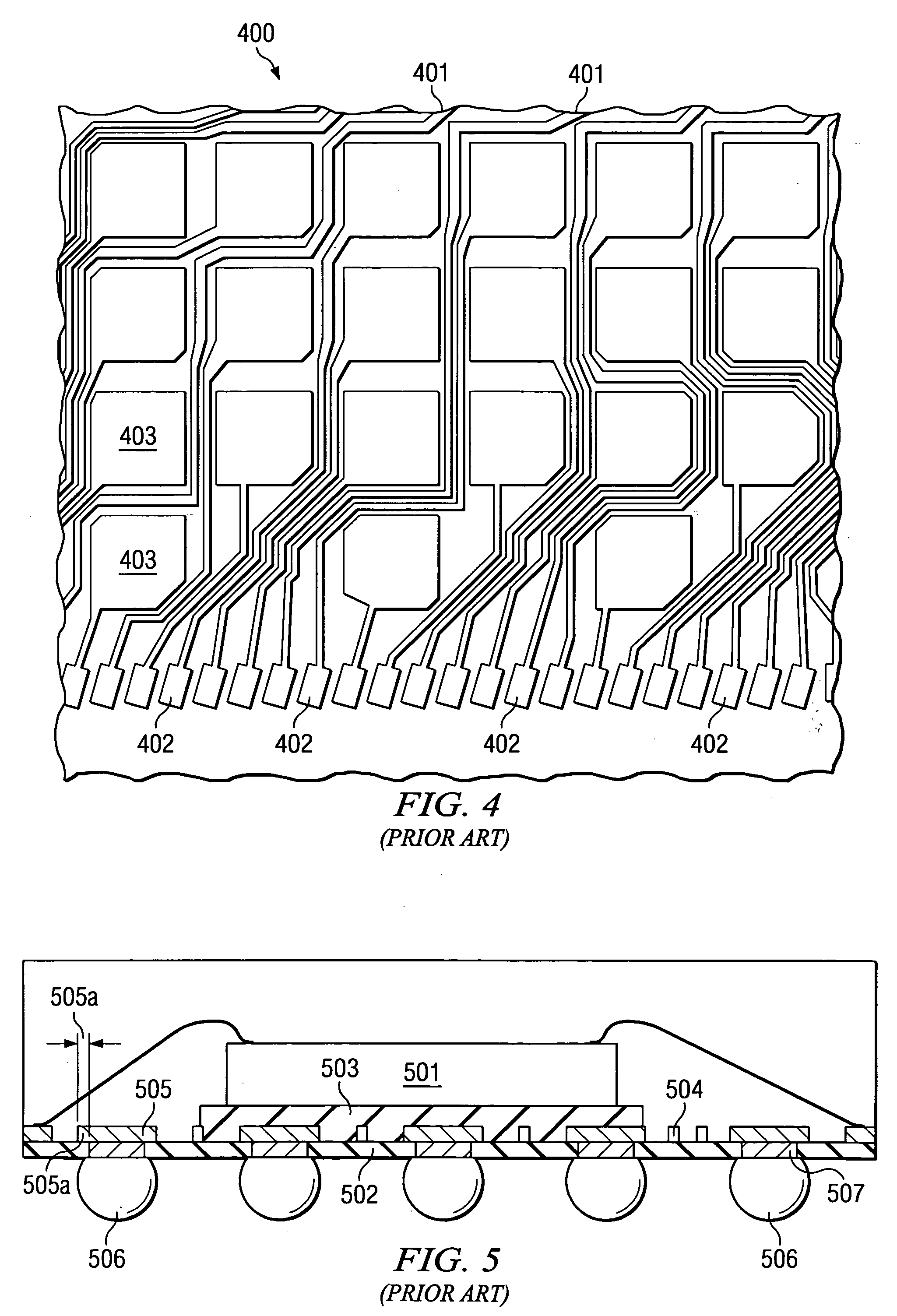

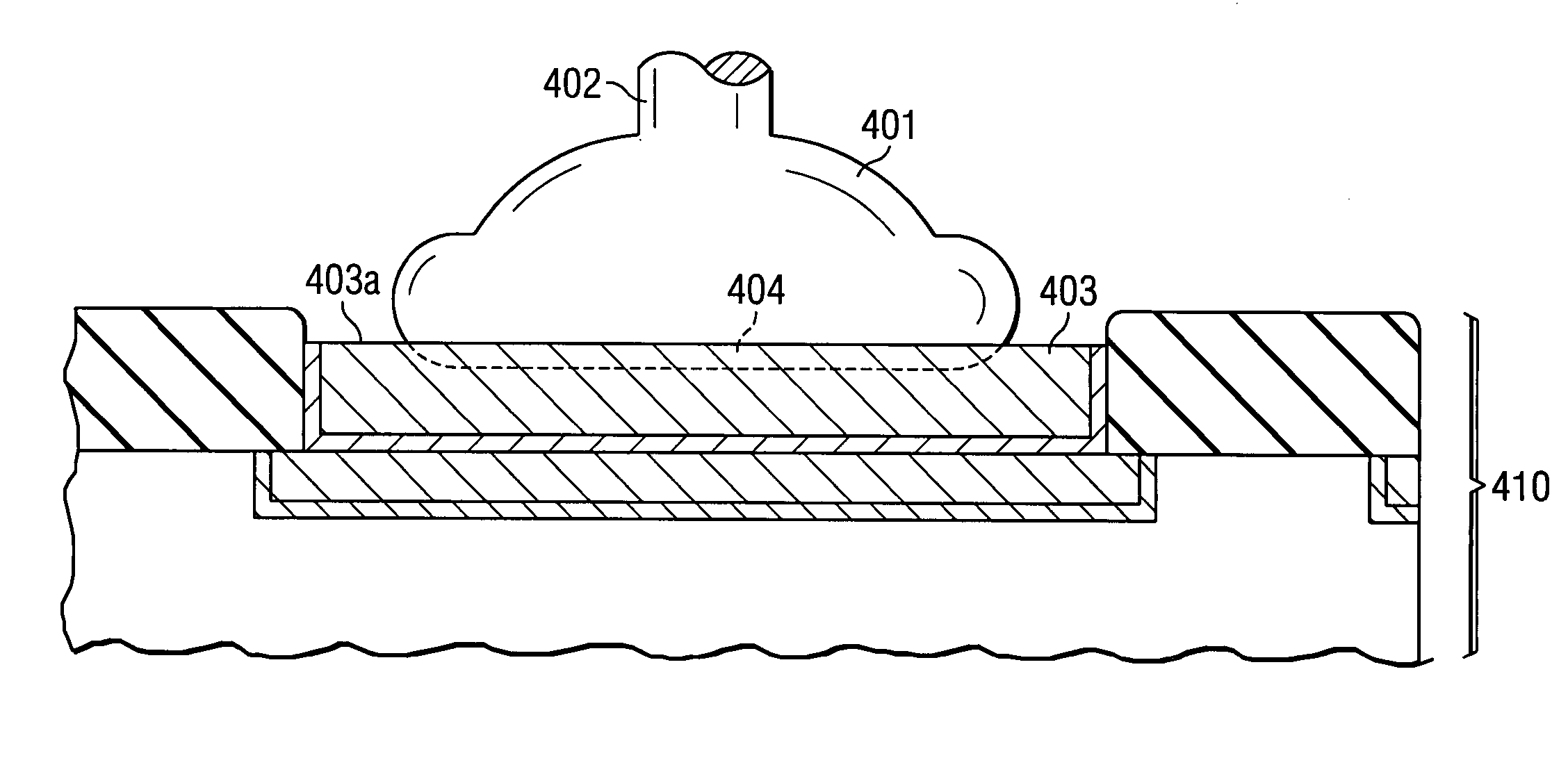

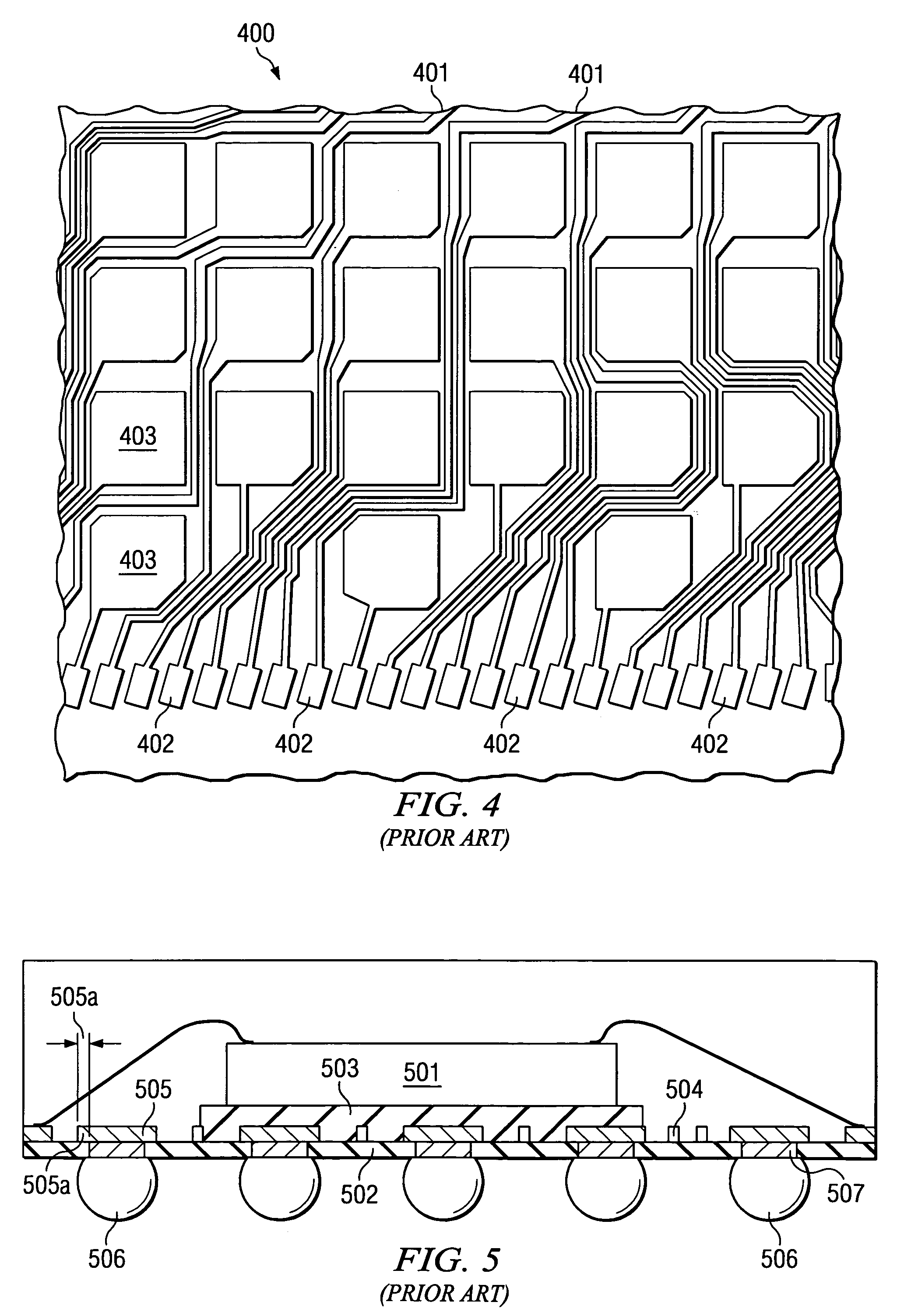

ActiveUS20100096166A1Reduced production cycle timeLow costPrinted circuit assemblingLamination ancillary operationsPlanar substrateFlexible circuits

The present invention provides an electronic assembly 400 and a method for its manufacture 800, 900, 1000 1200, 1400, 1500, and 1700. The assembly 400 uses no solder. Components 406 or component packages 402, 802, 804, 806 with I / O leads 412 are placed 800 onto a planar substrate 808. The assembly is encapsulated 900 with electrically insulating material 908 with vias 420, 1002 formed or drilled 1000 through the substrate 808 to the components' leads 412. Then the assembly is plated 1200 and the encapsulation and drilling process 1500 repeated to build up desired layers 422, 1502, 1702. The planar substrate 808 may be a flexible substrate 2016 allowing bending of an assembly 2000 to fit into various enclosures.

Owner:FJELSTAD JOSEPH CHARLES

Method for making memory cards and similar devices using isotropic thermoset materials with high quality exterior surfaces

InactiveUS20060162156A1Shorten the timeQuality improvementPrinted circuit assemblingLine/current collector detailsTamper resistancePolymer science

Memory Cards containing Integrated Circuits and other electronic components (e.g. resistors) in a variety of form factors having high quality external surfaces of polycarbonate, synthetic paper (e.g. Teslin), or other suitable material (e.g. PVC) can be made through use of injection molded thermoplastic material or thermosetting material that becomes the core layer of said Memory Cards and similar devices. The object of the invention is to provide the following properties to Memory Cards: rapid production cycle, high volume manufacturing throughput, security, electronics protection, better tamper resistance, durability, and highly reliable complex electronics encapsulation, achieved through a process utilizing low temperature and low pressure.

Owner:CARDXX

Method for removing coating from power unit components and device for carrying out the method

InactiveUS7452476B2Easy to implementPrevent removalVacuum gauge using ionisation effectsDecorative surface effectsFiberHigh energy

A method for the selective removal of one or more layers from a power unit component, e.g., a turbine blade of a heavy-duty turbine, using high-energy radiation of such a wavelength that the supplied energy is so strongly absorbed by the layer to be removed in each case that the removal threshold of the specific material of the layer to be removed is exceeded, while this removal threshold is not reached in the subsurface to be preserved, a spectrometer connected to a control unit via a light-conducting fiber cable such that the method-specific characteristic values are determinable by spectroscopic methods during the removal of the respective layer and are used for the self-regulating process limitation.

Owner:MTU AERO ENGINES GMBH

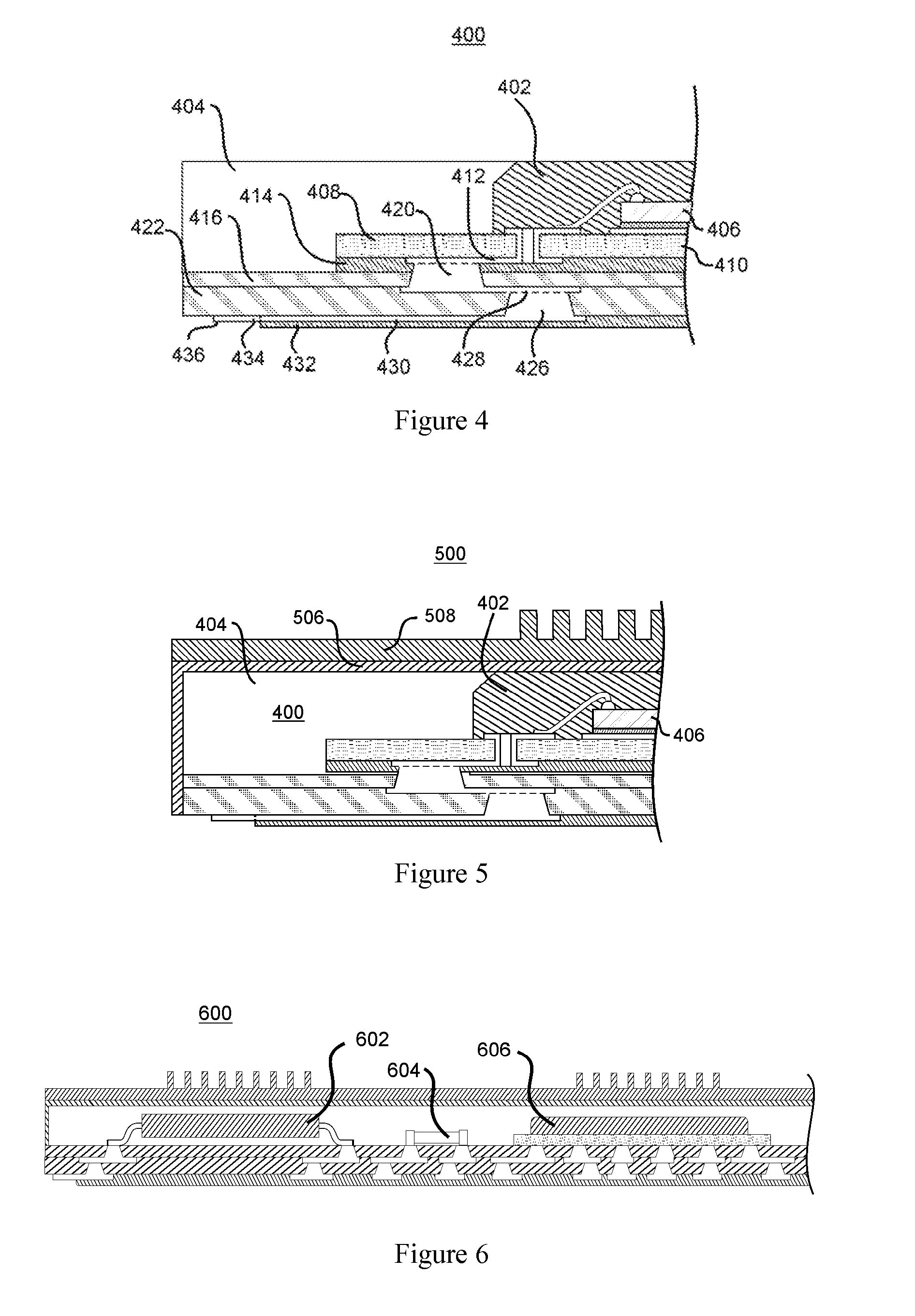

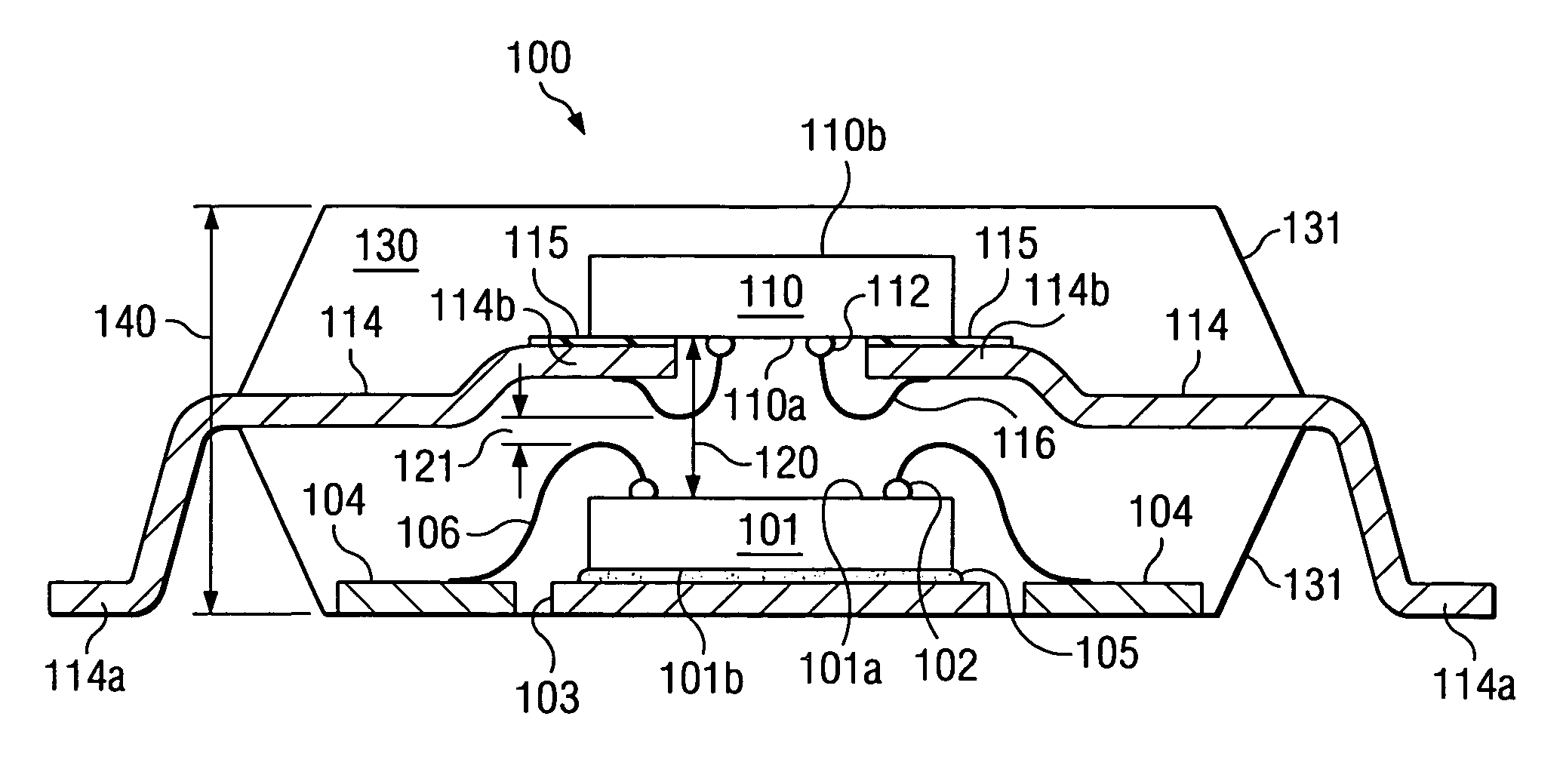

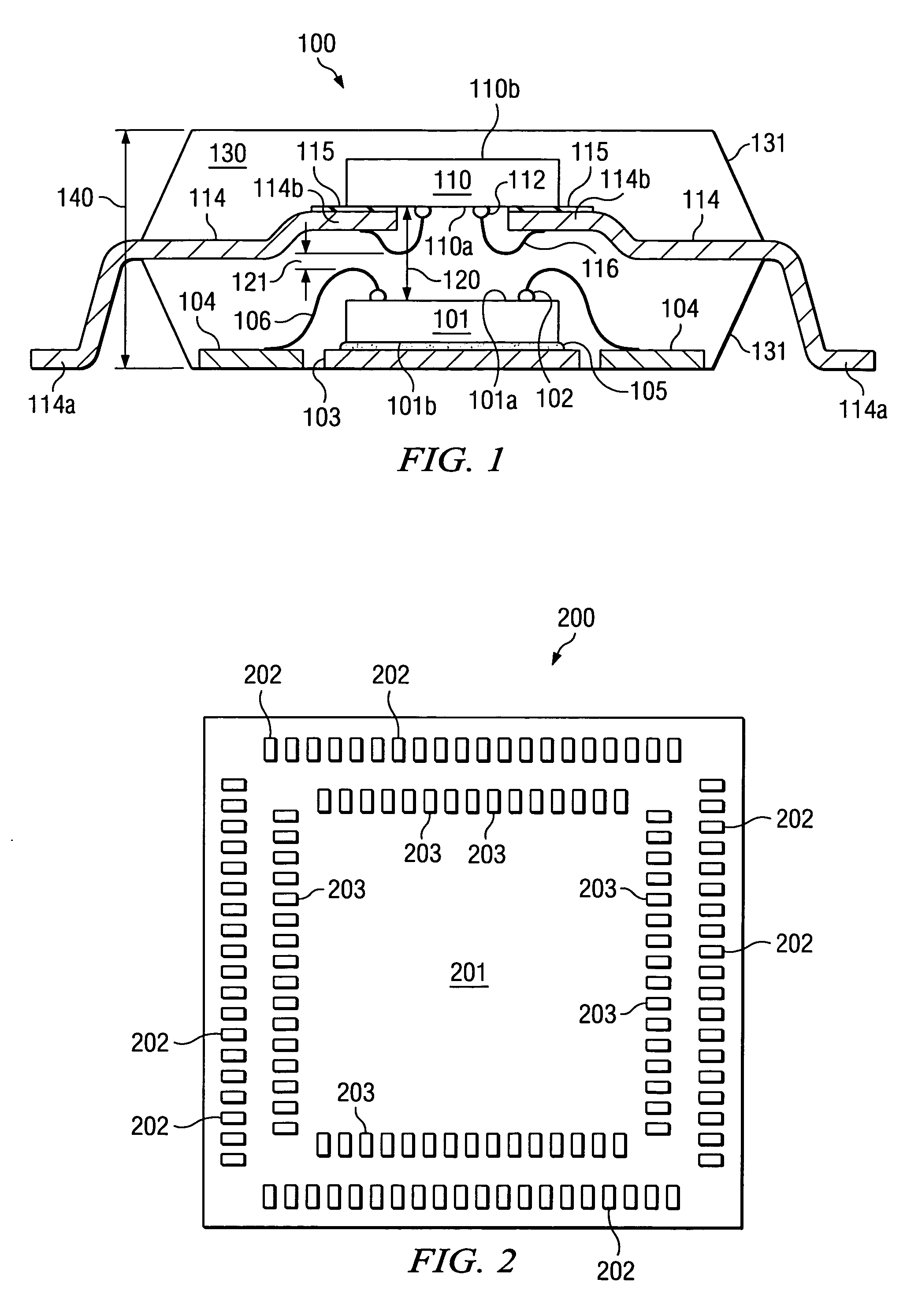

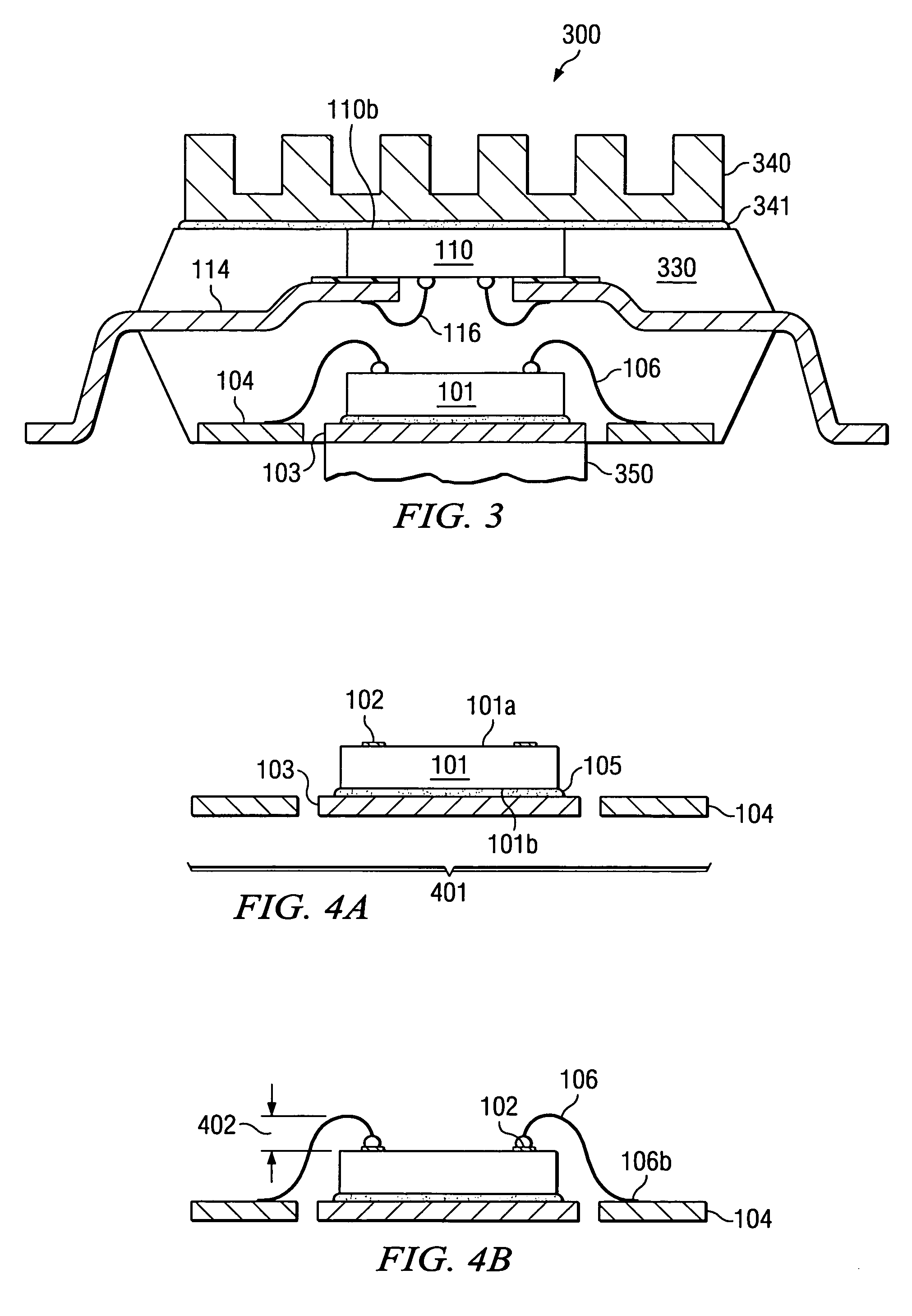

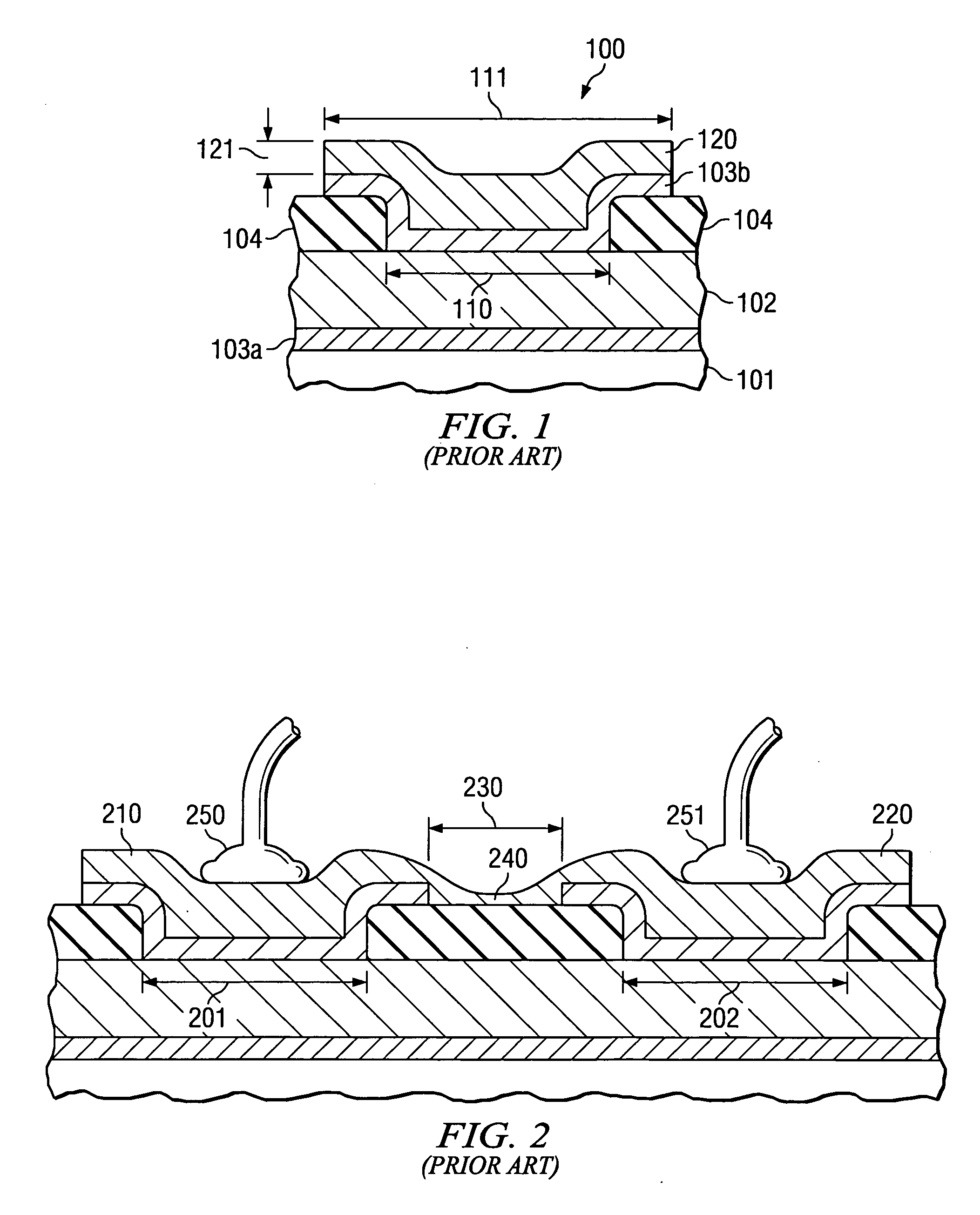

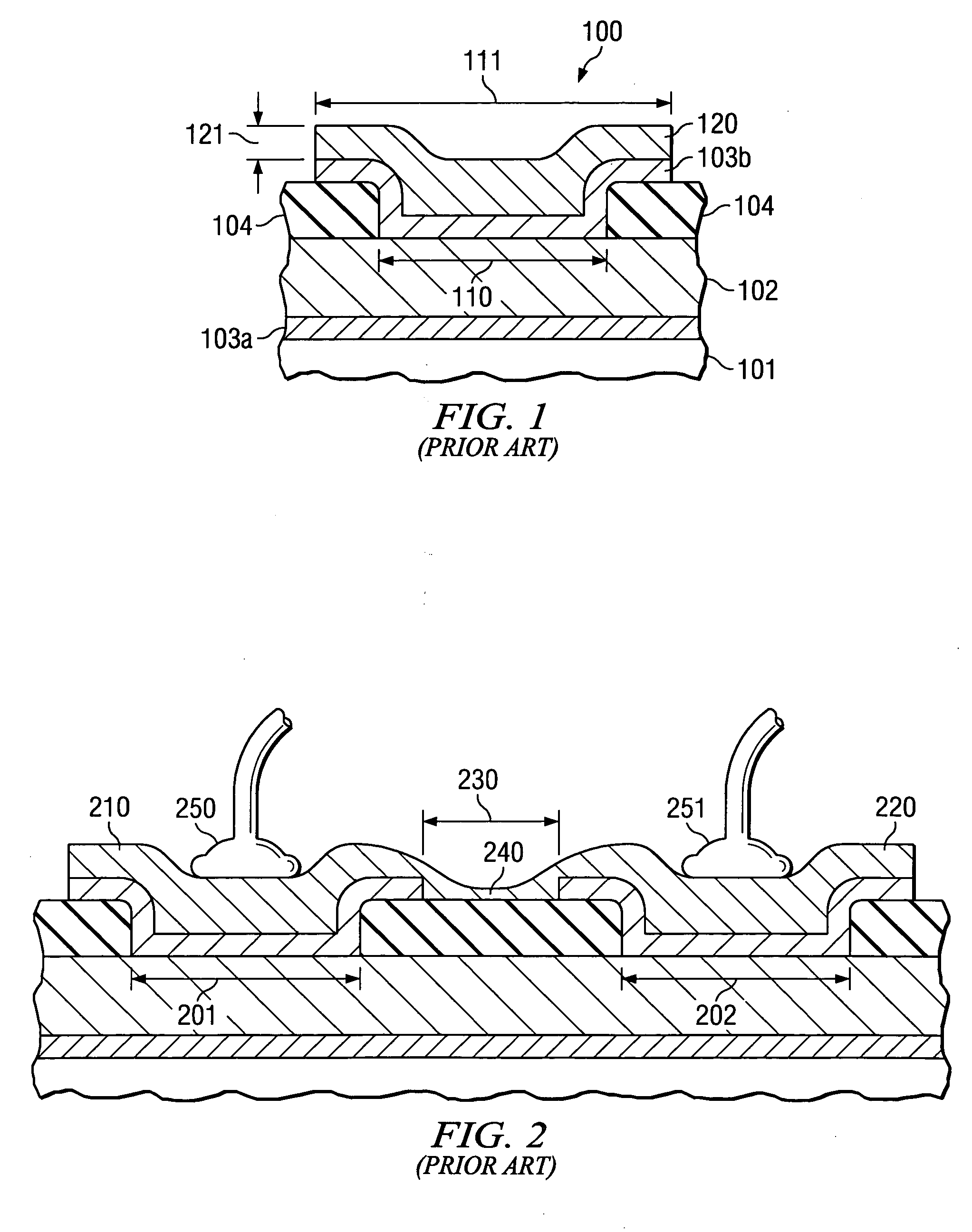

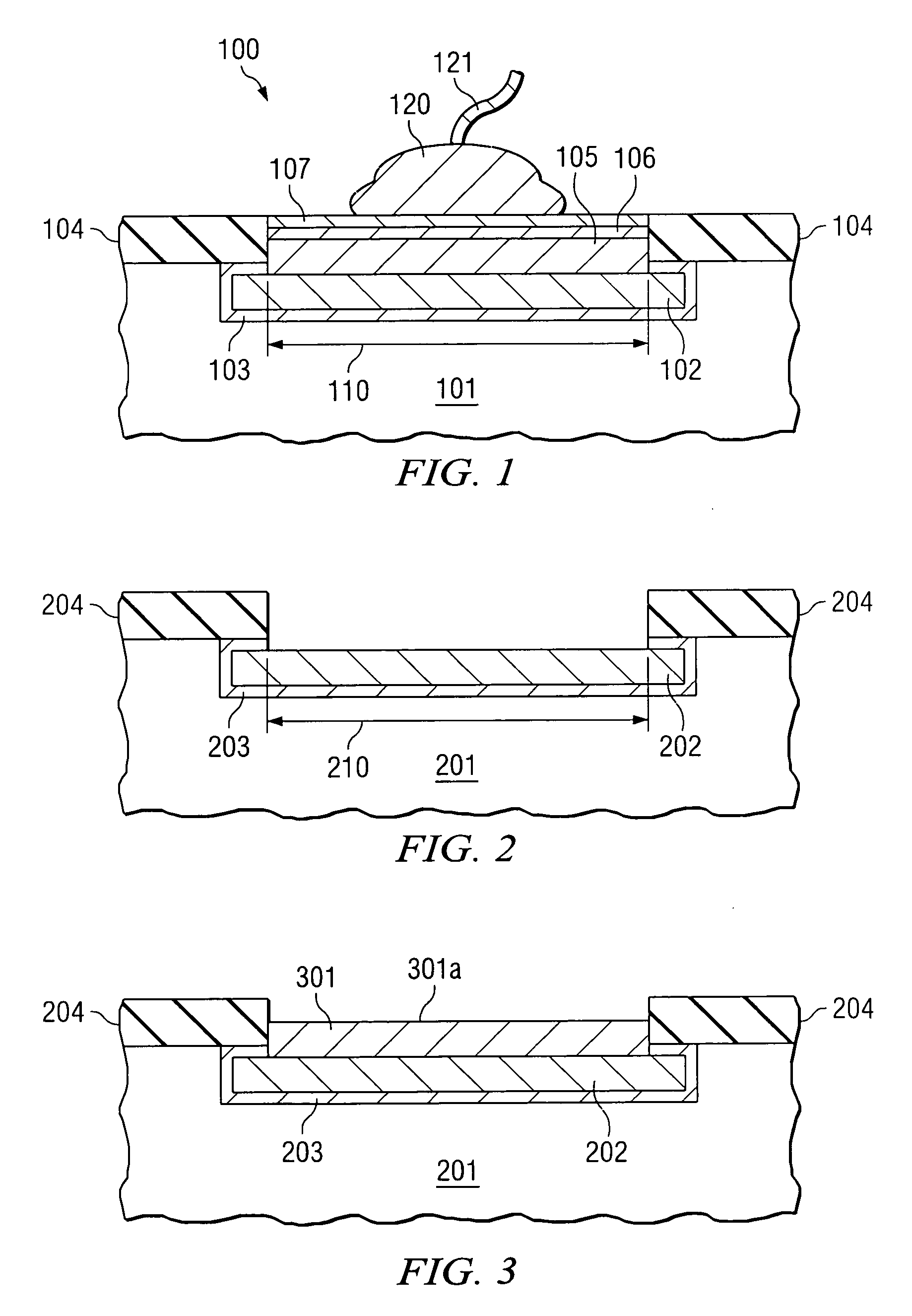

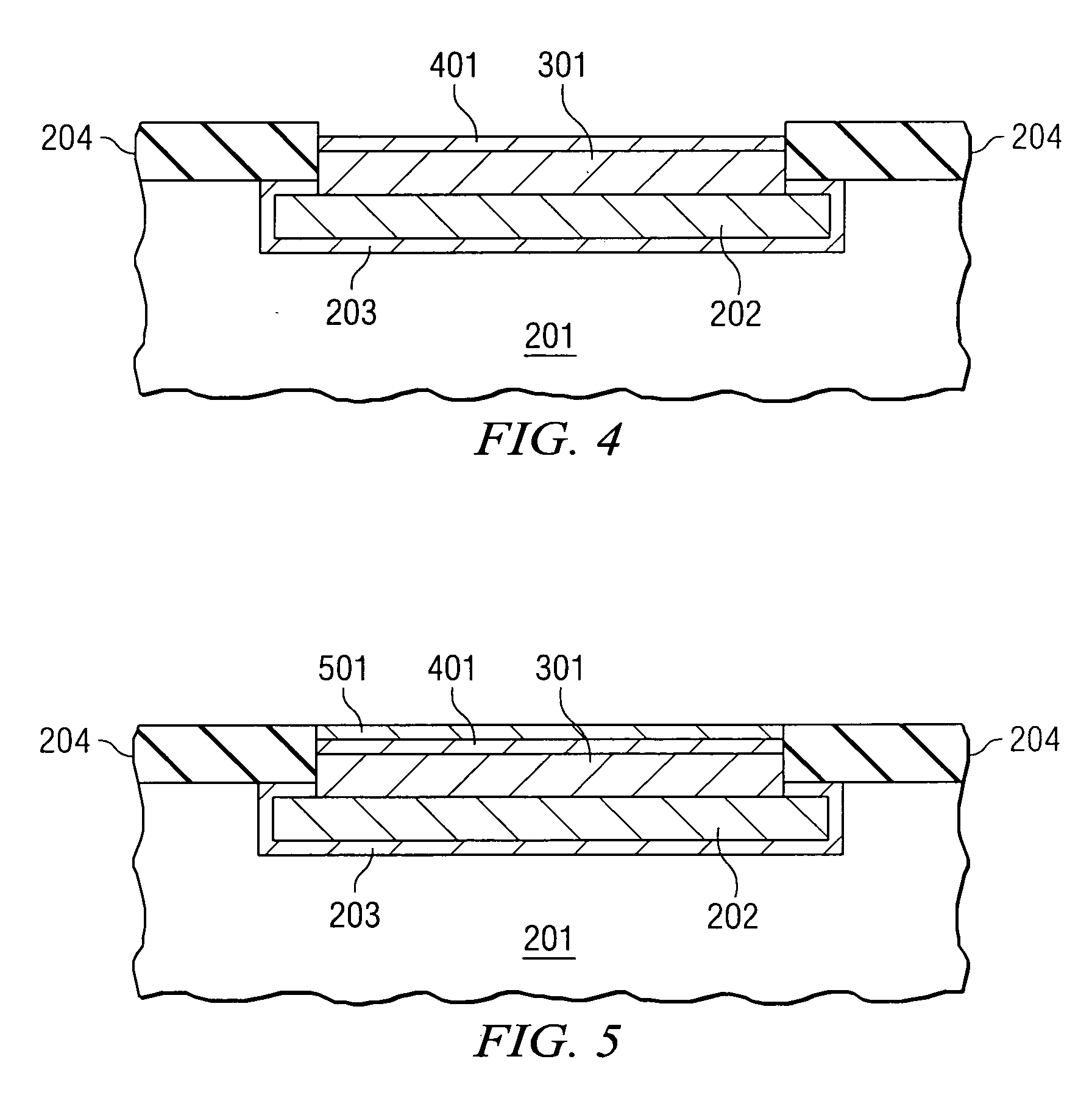

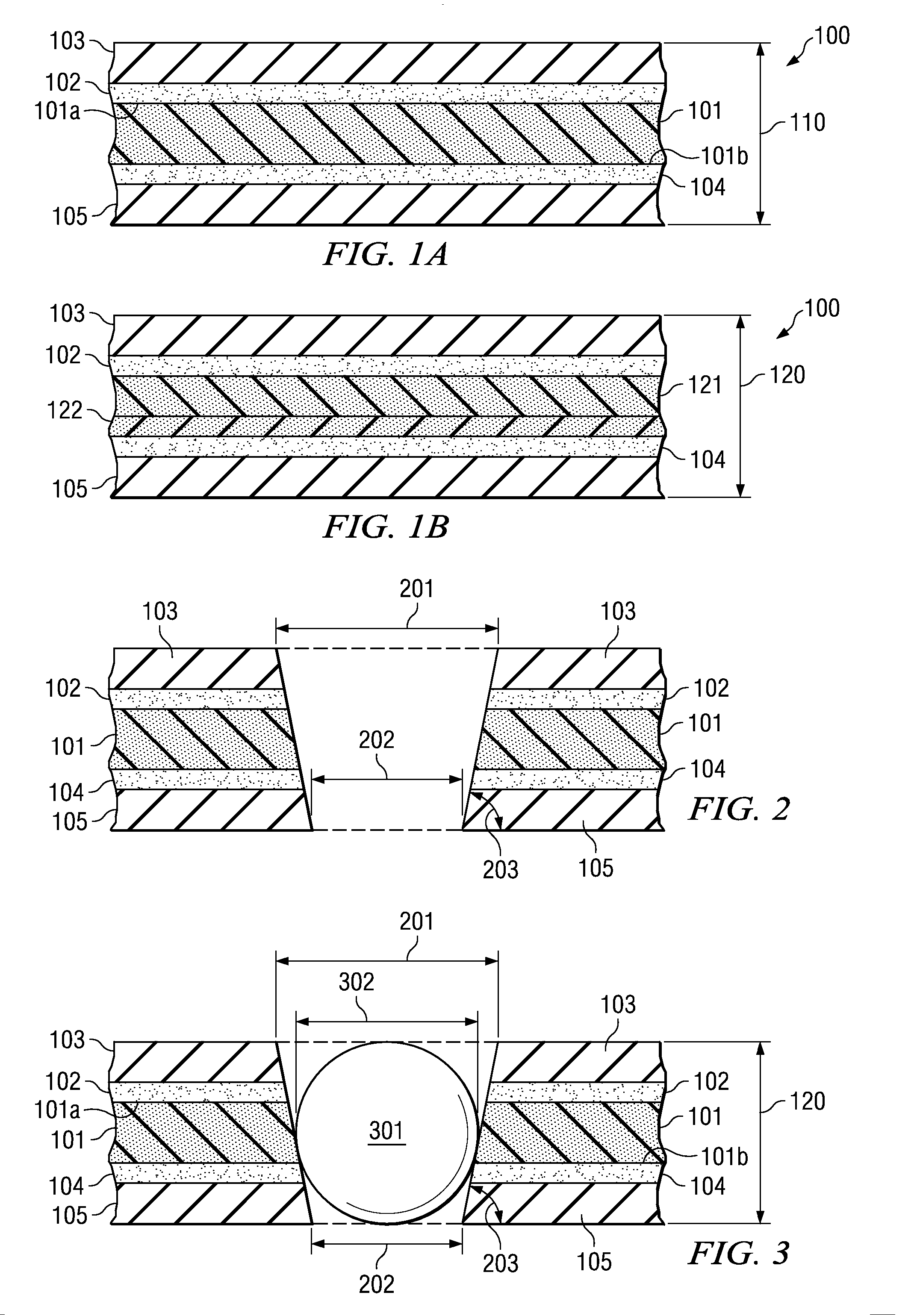

Flexible leaded stacked semiconductor package

InactiveUS20060091516A1High pin-countReduce consumptionSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

A multi-chip semiconductor device comprises two semiconductor assemblies vertically aligned so that the second active chip surface (110a) faces the first active chip surface (101a) and forms a gap (120) between the assemblies. Encapsulation material (130) fills the gap and couples the first and second assemblies together to form the multi-chip device (100). Lead portions of the first and second leadframes remain exposed from the encapsulation material. The exposed leads (104) of the first leadframe may be comprised for leadless assembly, and the exposed leads (114a) of the second leadframe may be formed coplanar with the first leads (104).

Owner:TEXAS INSTR INC

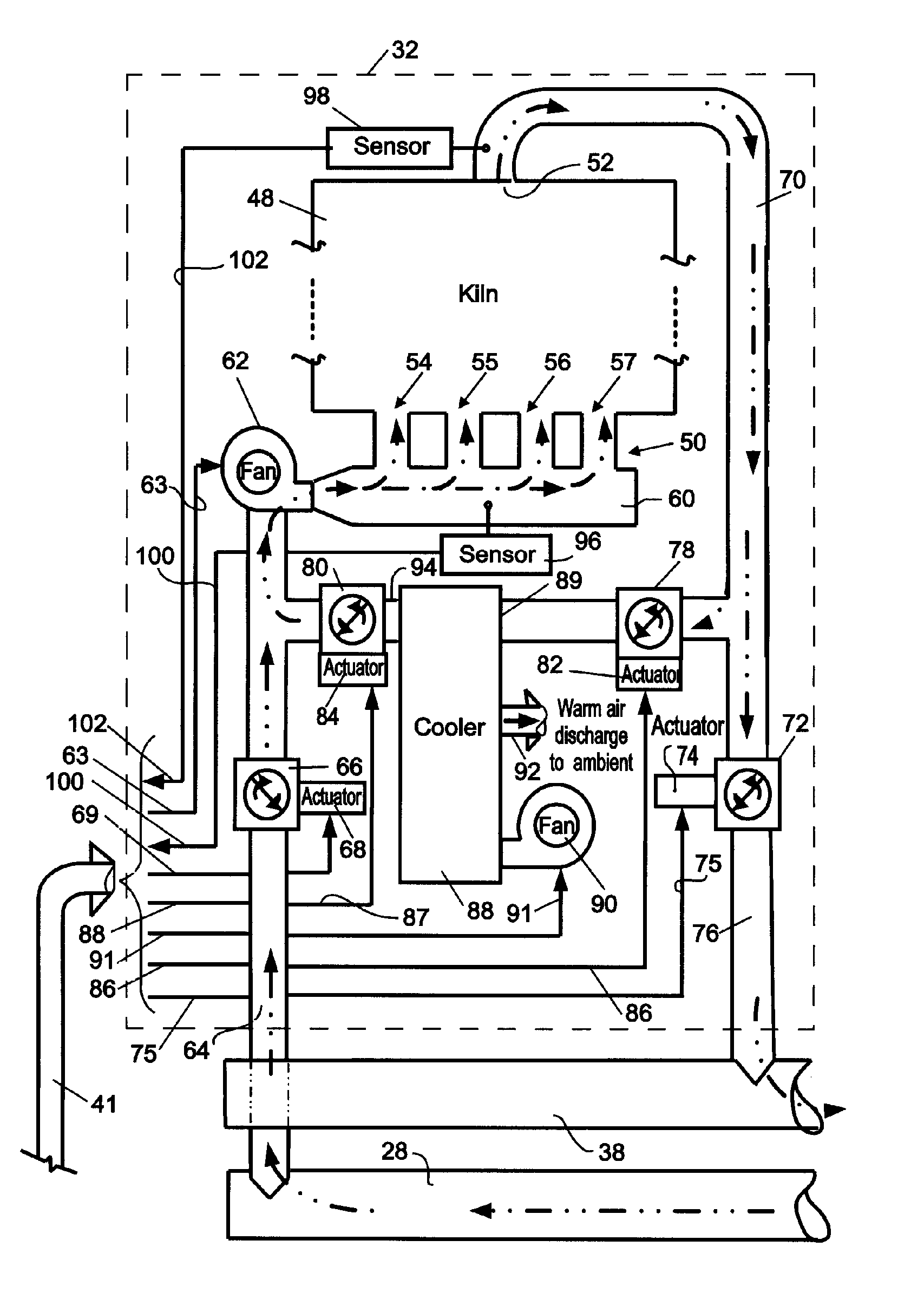

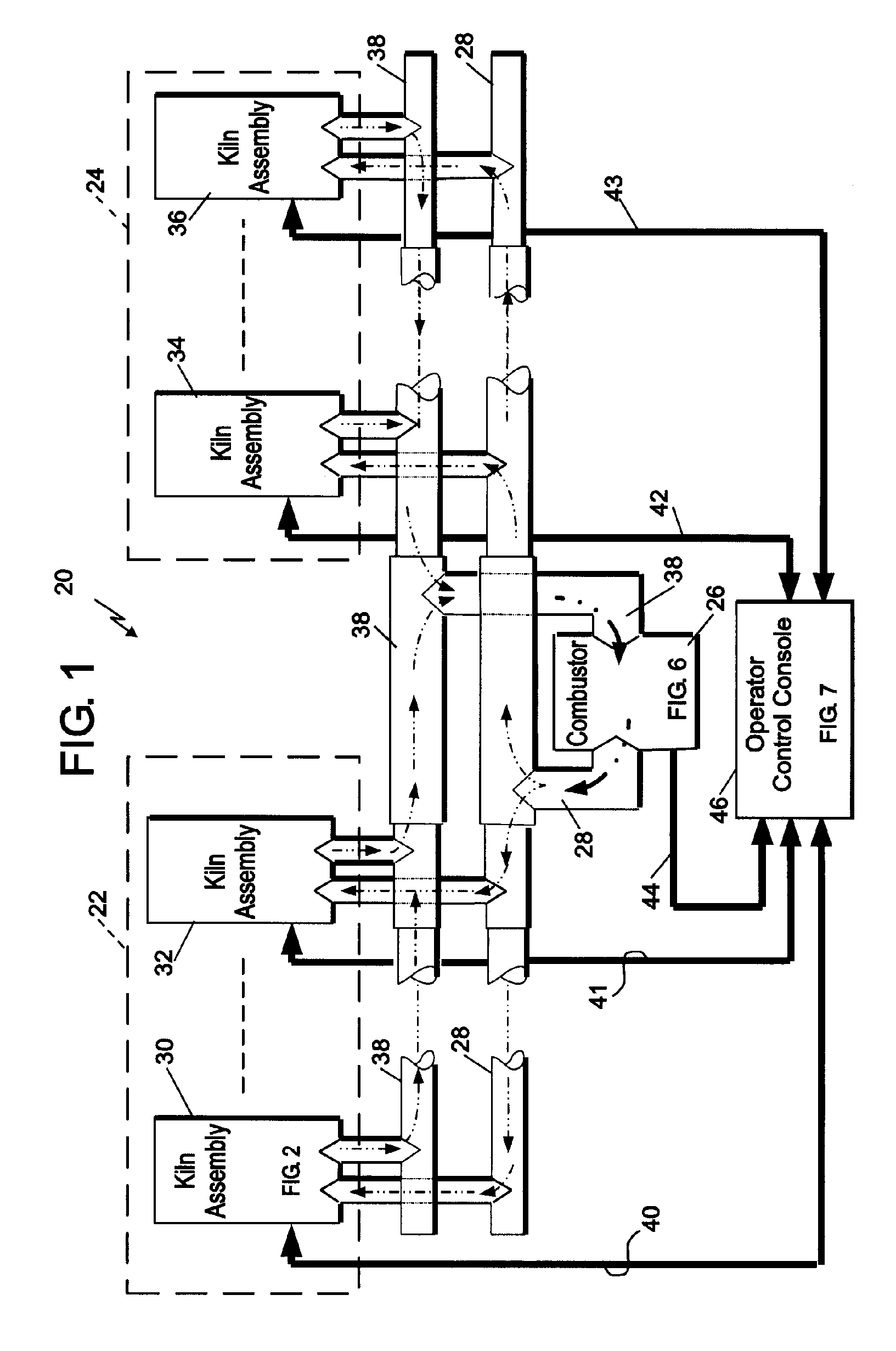

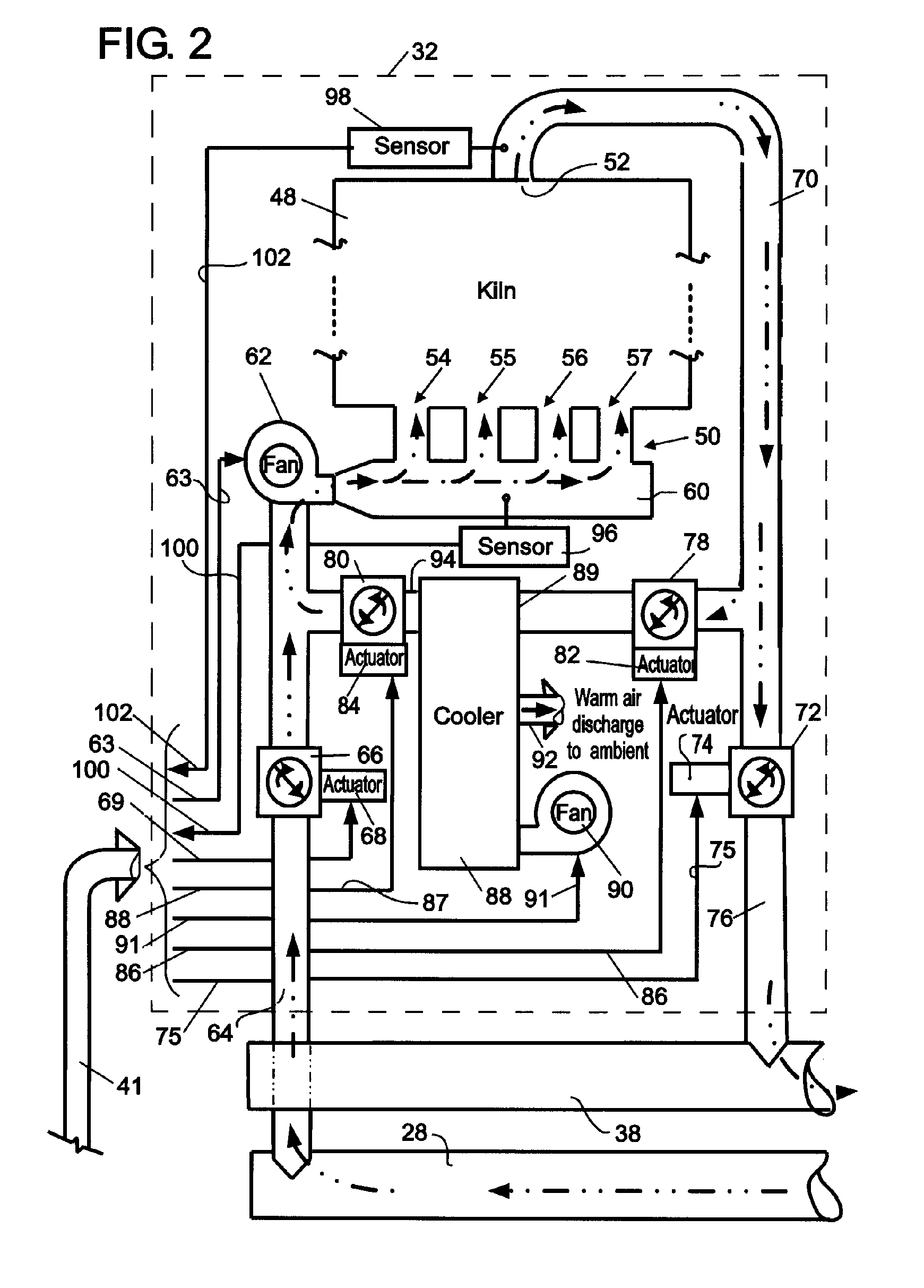

Method and apparatus for producing charcoal

InactiveUS20060280670A1Lower unit costProducing higher units of charcoal yieldDirect heating destructive distillationBiofuelsBatch processingCombustor

Apparatus for batch processing source material into charcoal in a battery of kilns, each of which use forced convection of process gases through the source material to shorten the process cycle time, and all of which use an external combustor to burn the process waste gases from each kiln to provide the primary source of applied energy for the process.

Owner:NUCOR CORP

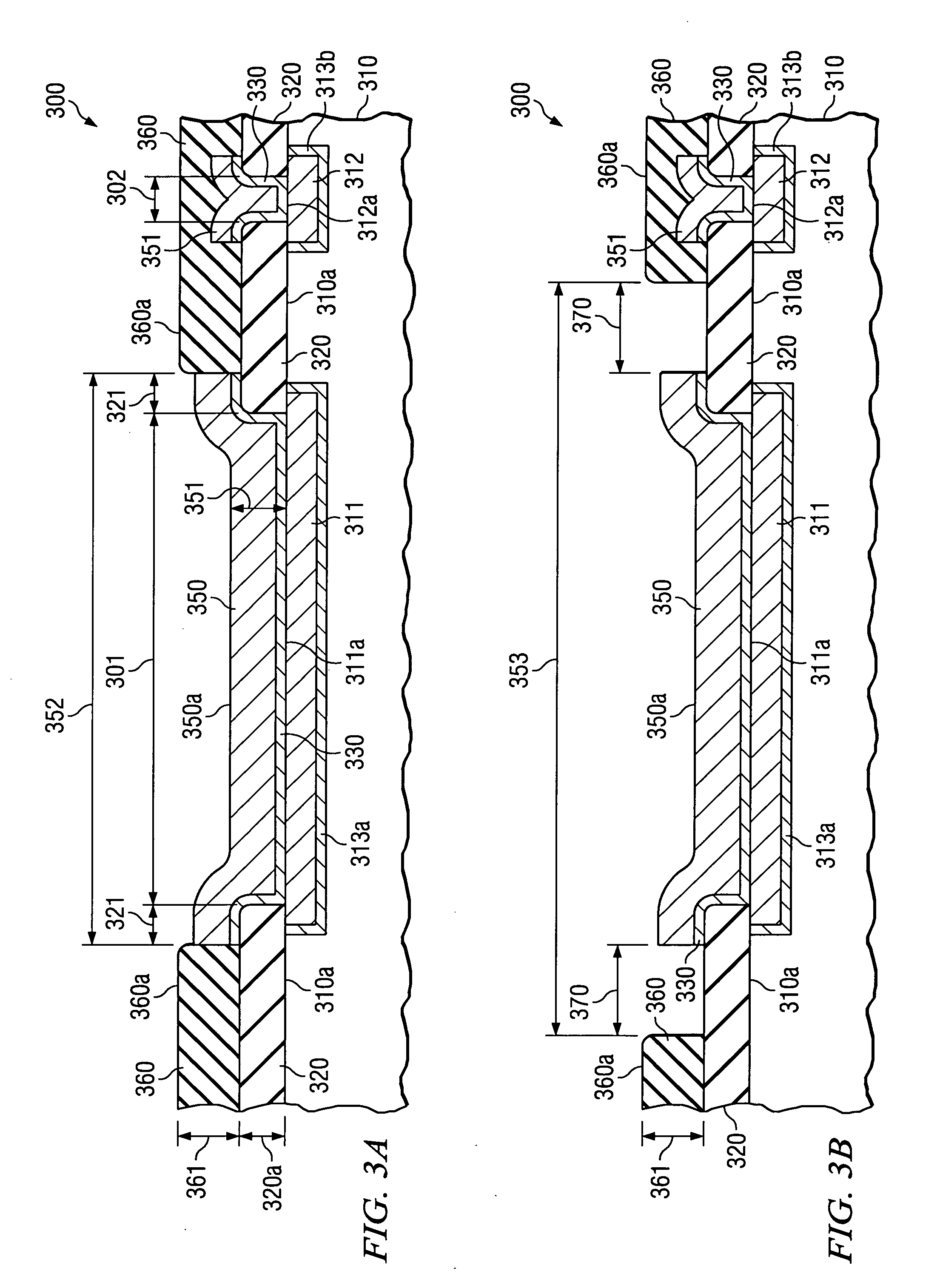

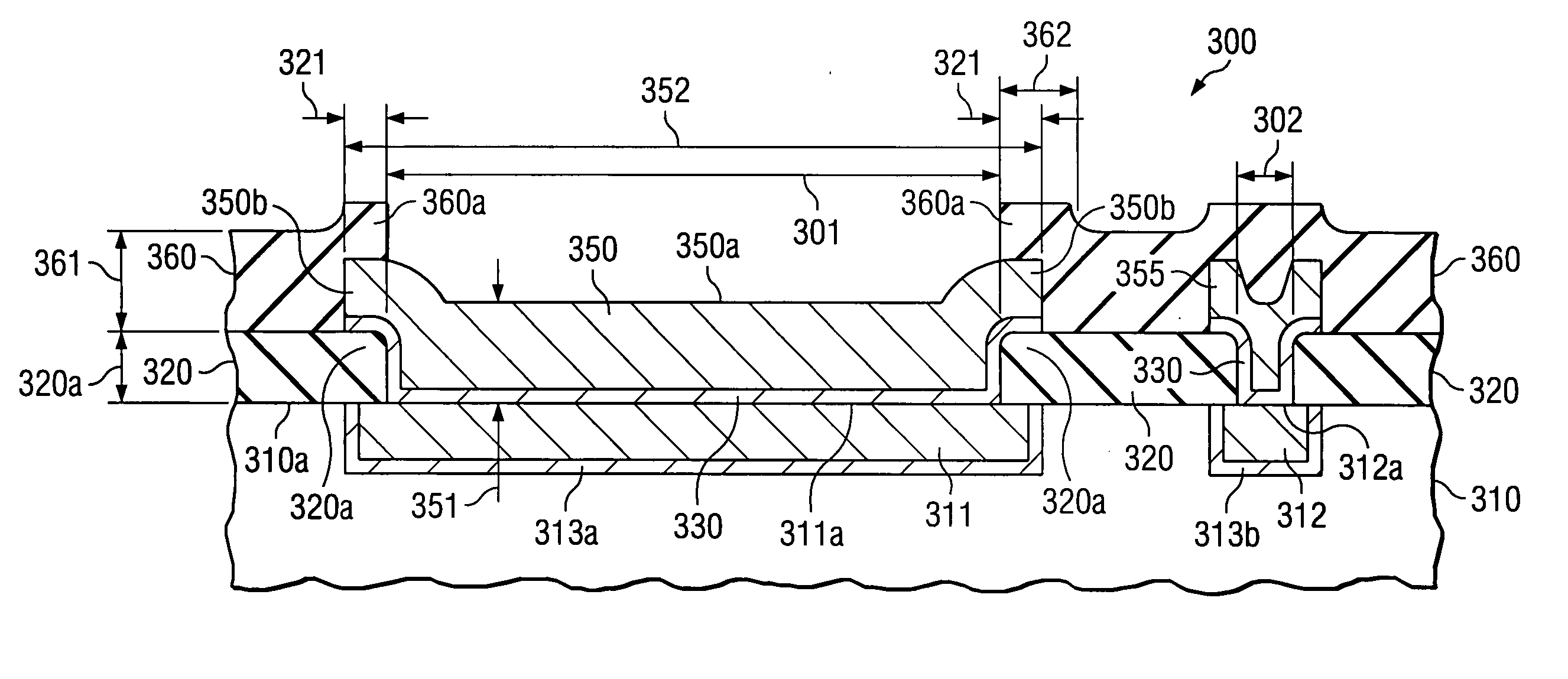

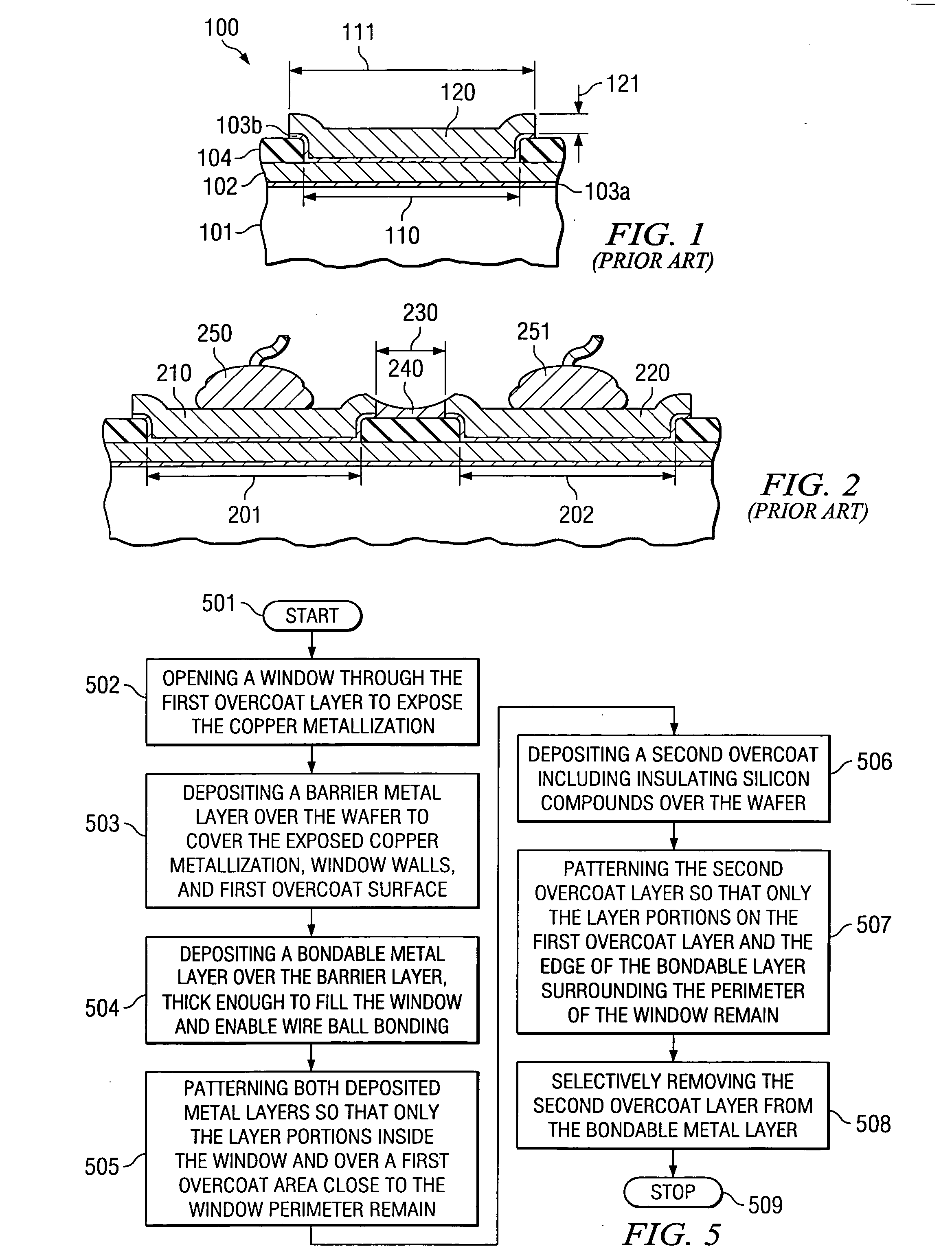

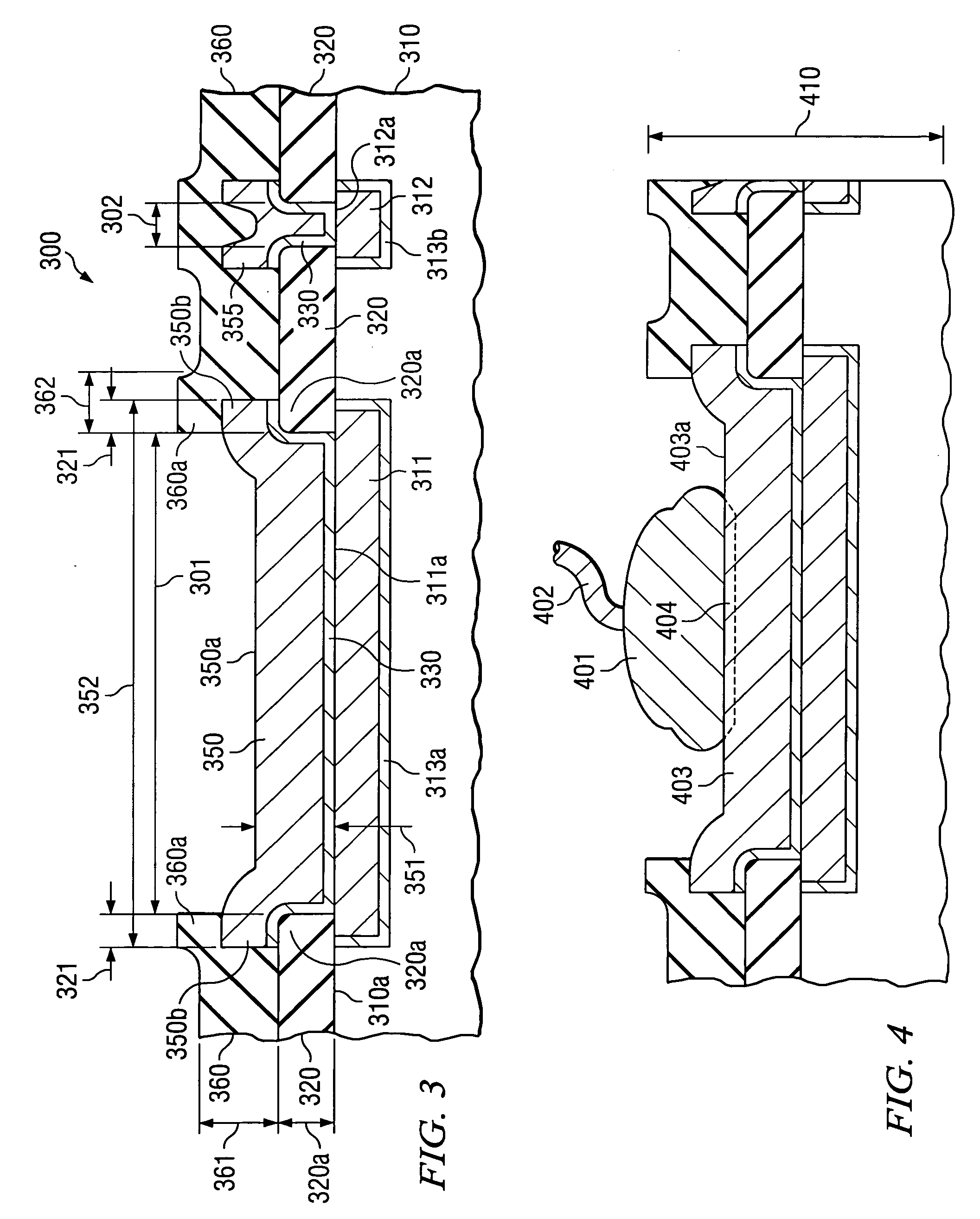

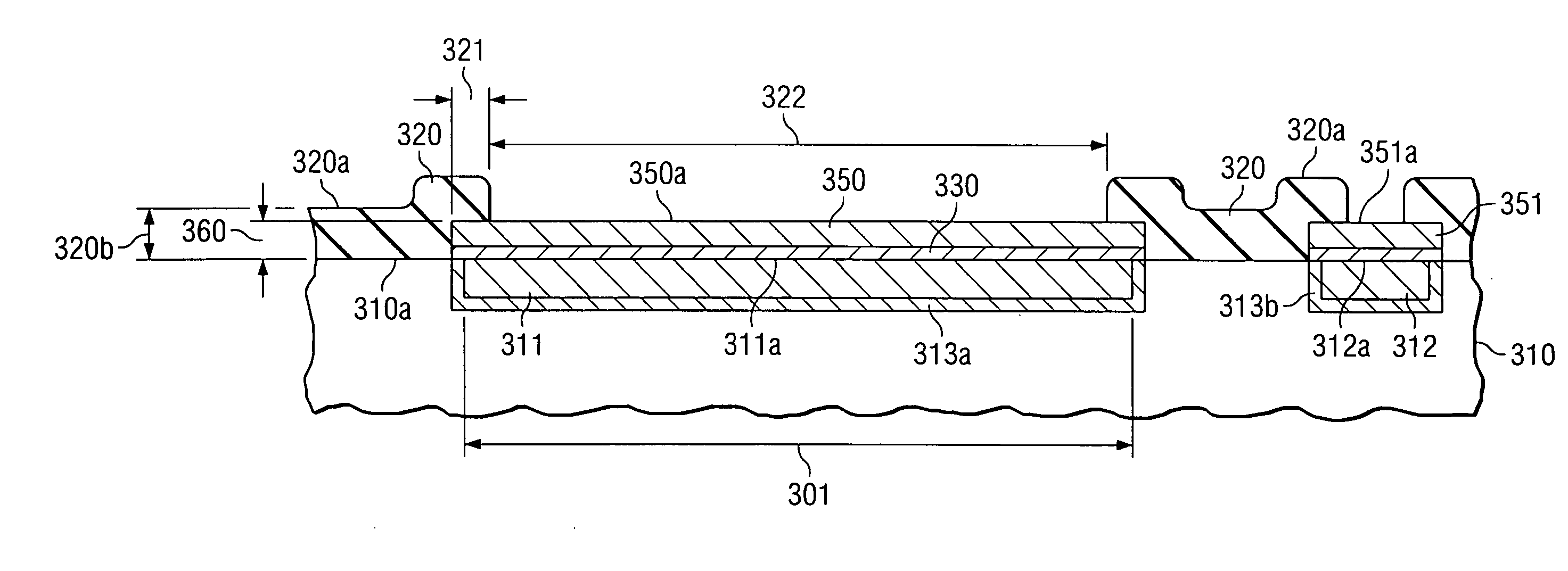

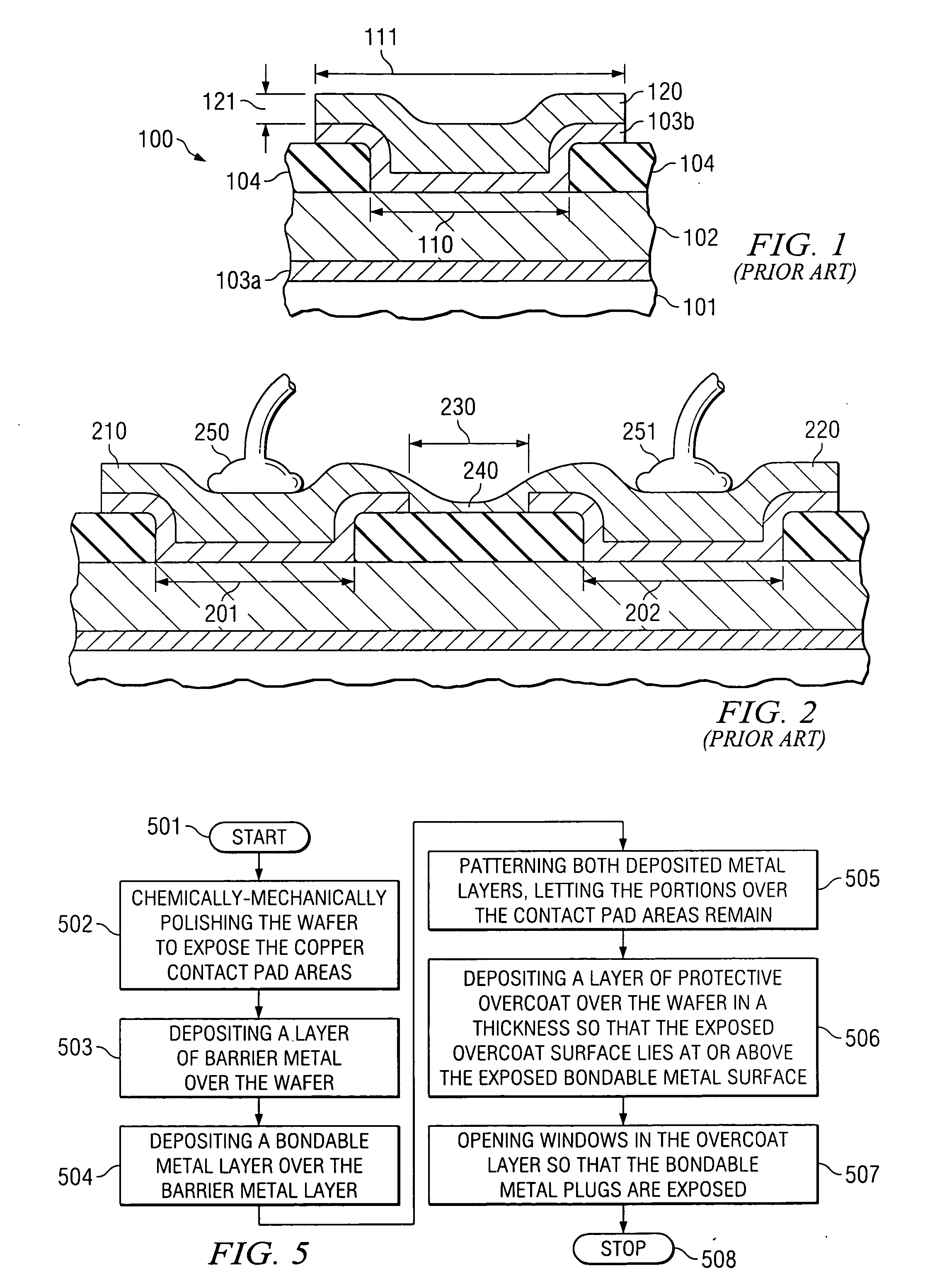

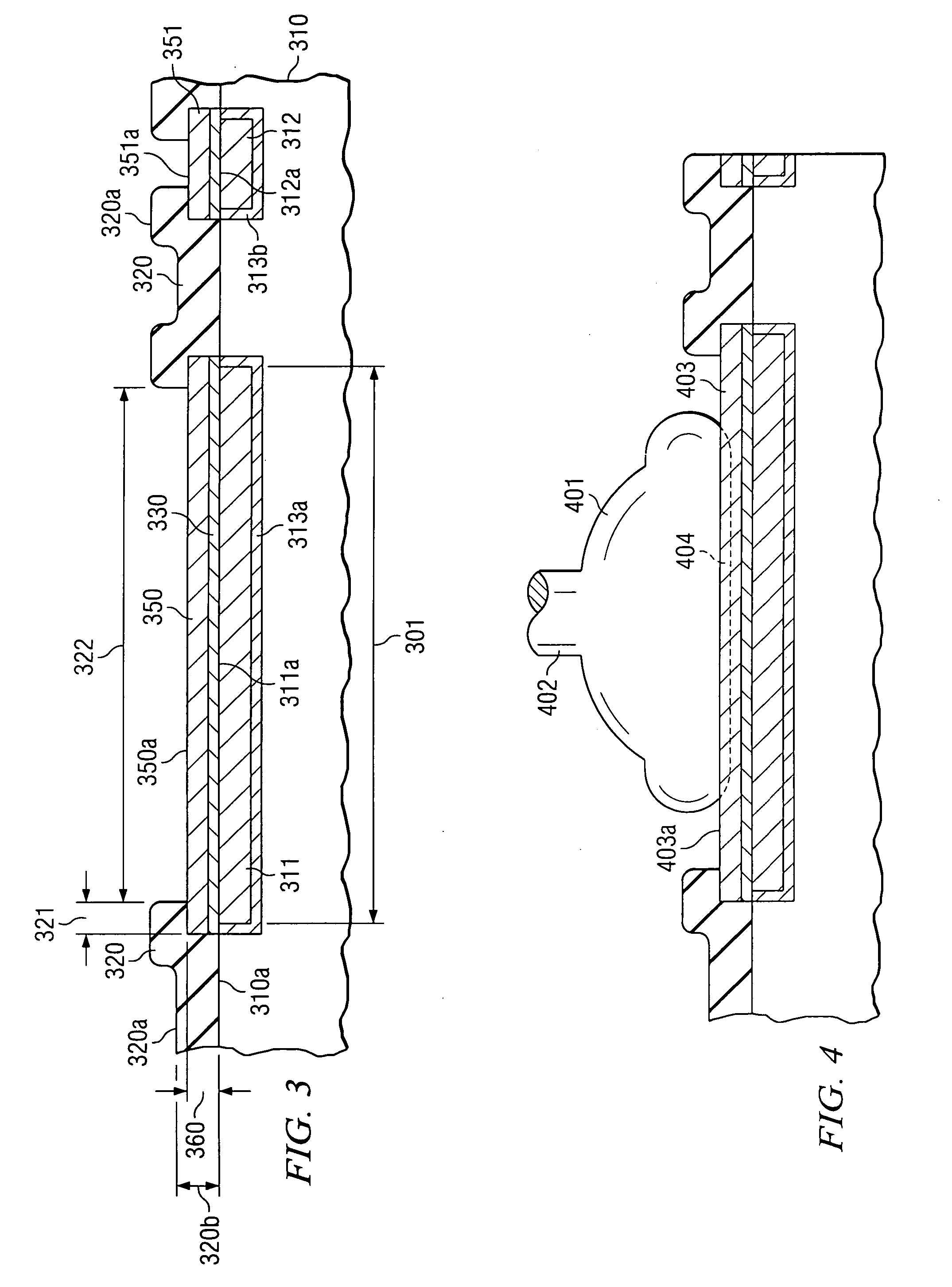

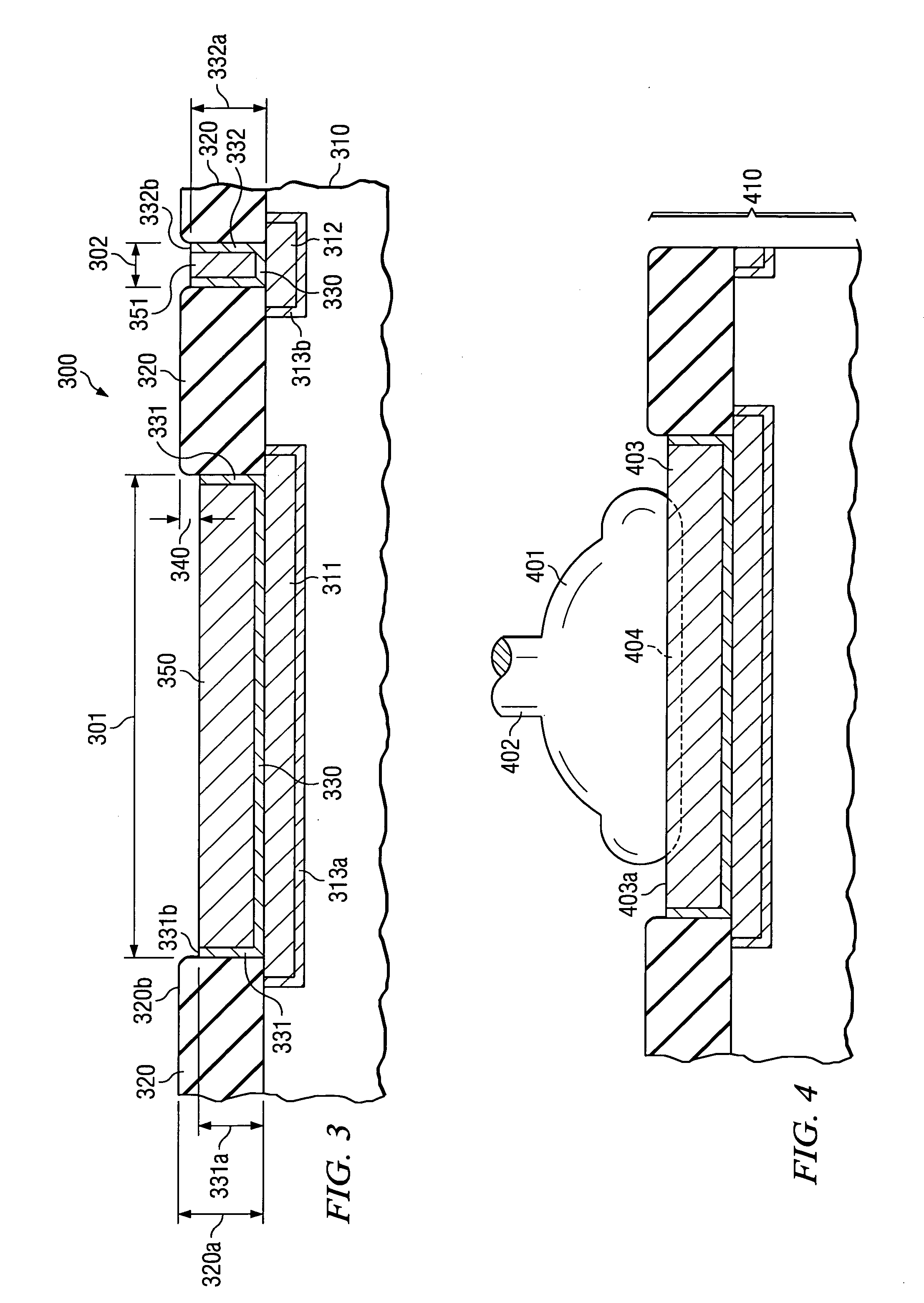

Structure and method for contact pads having a protected bondable metal plug over copper-metallized integrated circuits

ActiveUS20050224984A1Eliminate riskReduced production cycle timeSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectContact pad

An integrated circuit having copper interconnecting metallization (311, 312) protected by a first, inorganic overcoat layer (320), portions of the metallization exposed in windows (301, 302) opened through the thickness of the first overcoat layer. A patterned conductive barrier layer (330) is positioned on the exposed portion of the copper metallization and on portions of the first overcoat layer surrounding the window. A bondable metal layer (350, 351) is positioned on the barrier layer; the thickness of this bondable layer is suitable for wire bonding. A second, organic overcoat layer (360) is surrounding the window so that the surface (360a) of this second overcoat layer at the edge of the window is at or above the surface (350a) of the bondable layer. The second overcoat layer may be spaced (370) from the edge of the bondable metal layer.

Owner:TEXAS INSTR INC

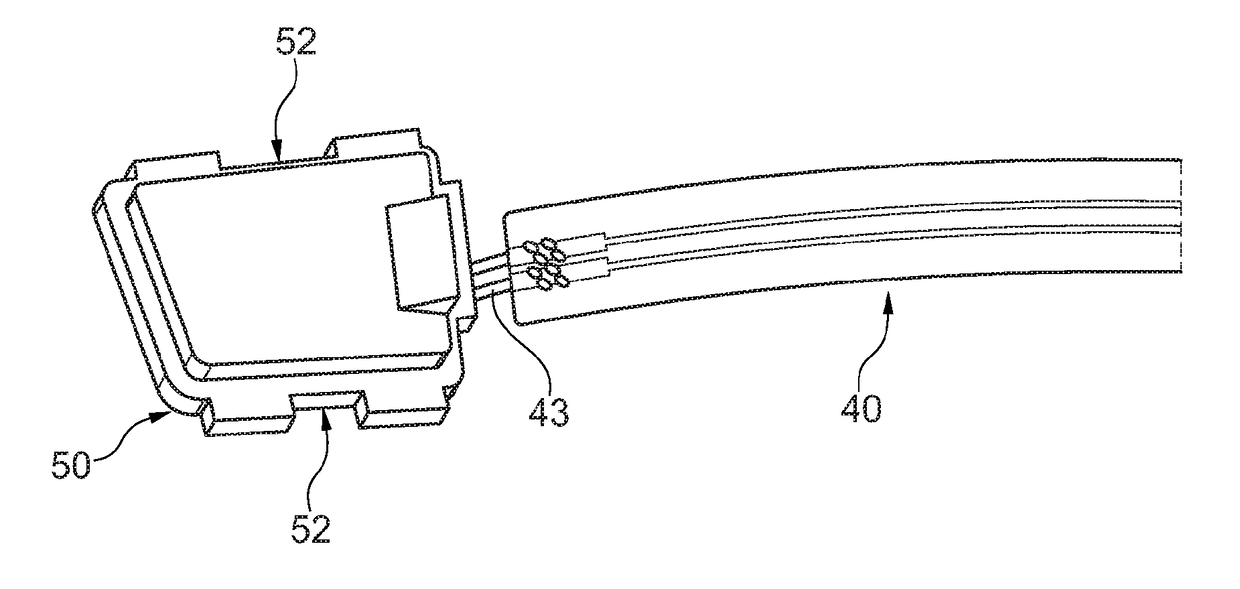

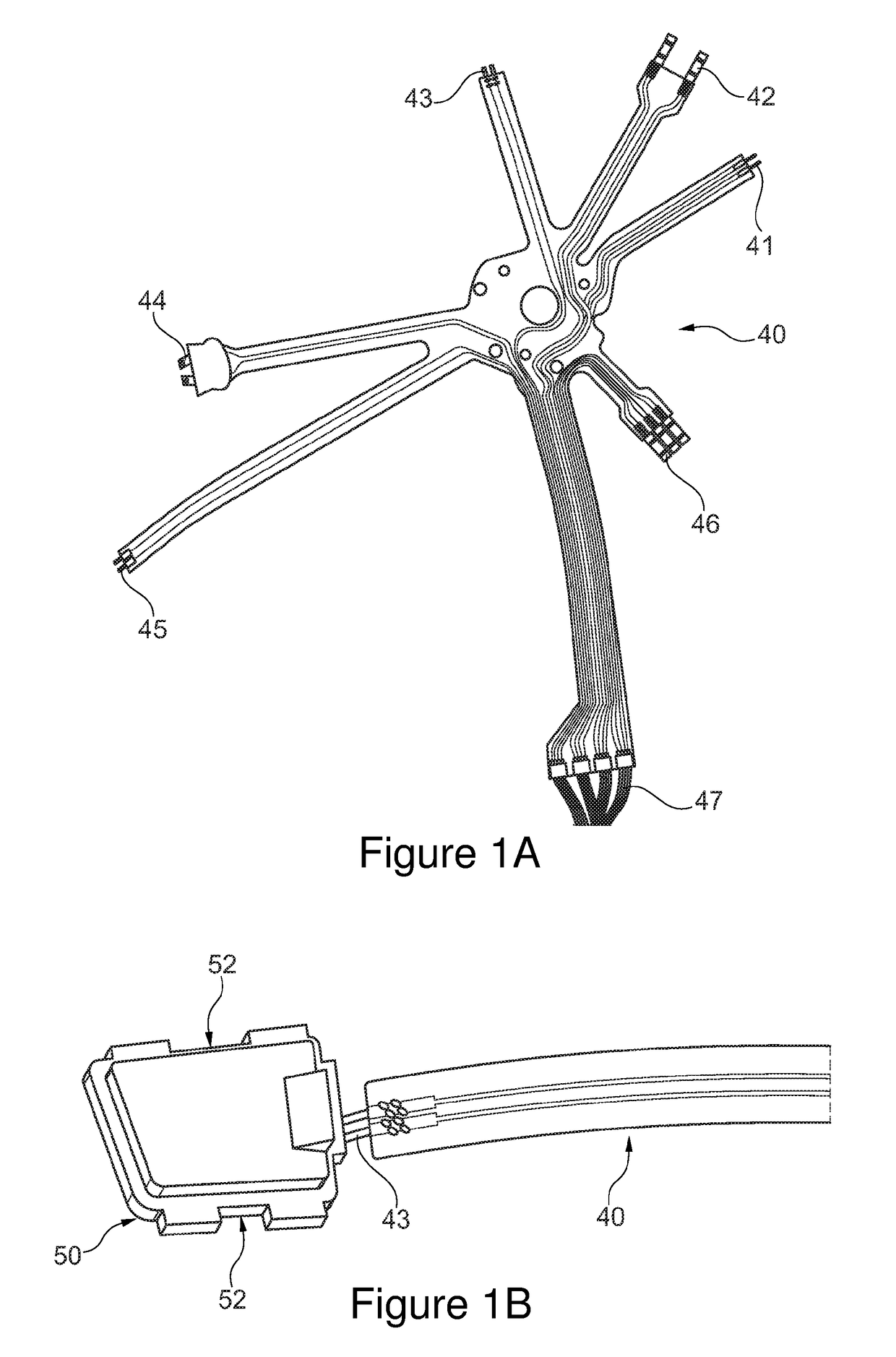

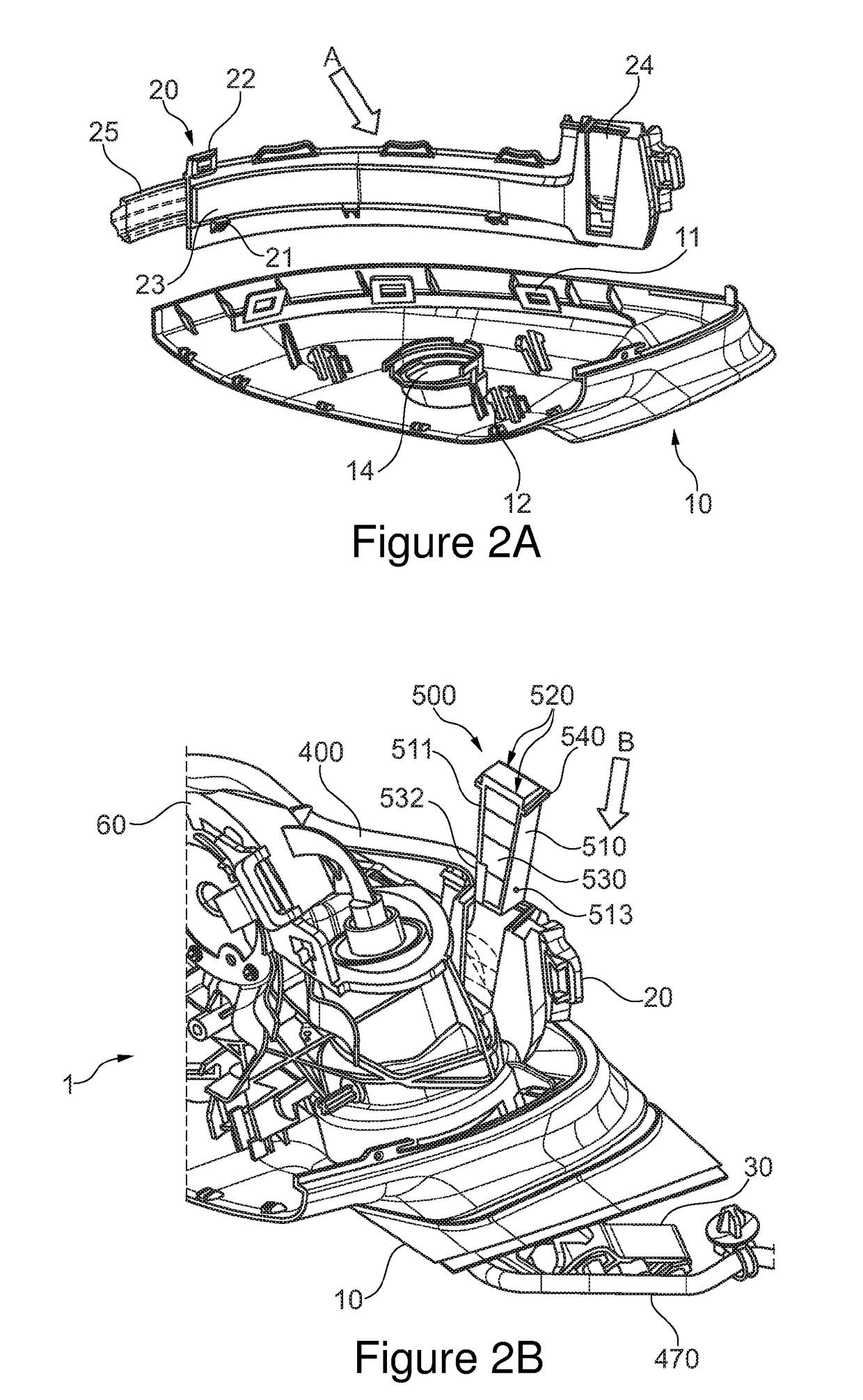

Method for manufacturing an automotive mirror

ActiveUS20170327167A1Easy to manufactureReduce maintenance costsProgramme-controlled manipulatorPrinted circuit detailsComputer moduleEngineering

A method for manufacturing an automotive mirror, in particular a side mirror, includes forming a printed circuit board as flexible printed circuit board with n+1 branches, nεN, providing n modules each including at least one electronic element housed within a plastic casting and connected to conducting paths on at least one of the surfaces of the plastic casting, and at least one standard gripping point, guiding structure, snap connection element and / or sealing member provided by the plastic casting, connecting up to n of said branches to one module each and connecting one branch to cables or a cable harness to be connected to a power supply and / or a control unit outside the mirror, providing mirror parts free of electronic elements, and assembling the mirror parts and the modules.

Owner:SMR PATENTS S A R L

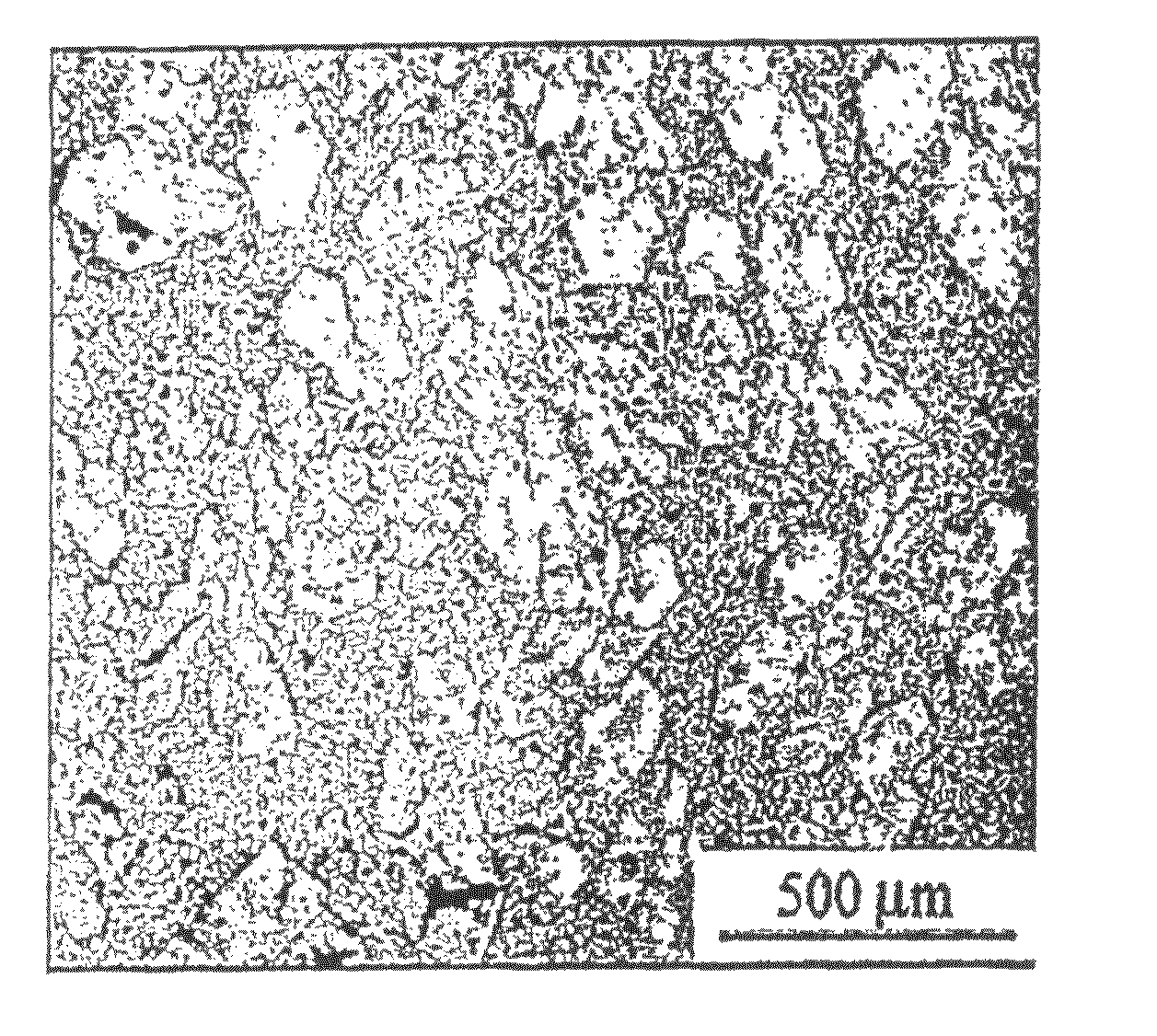

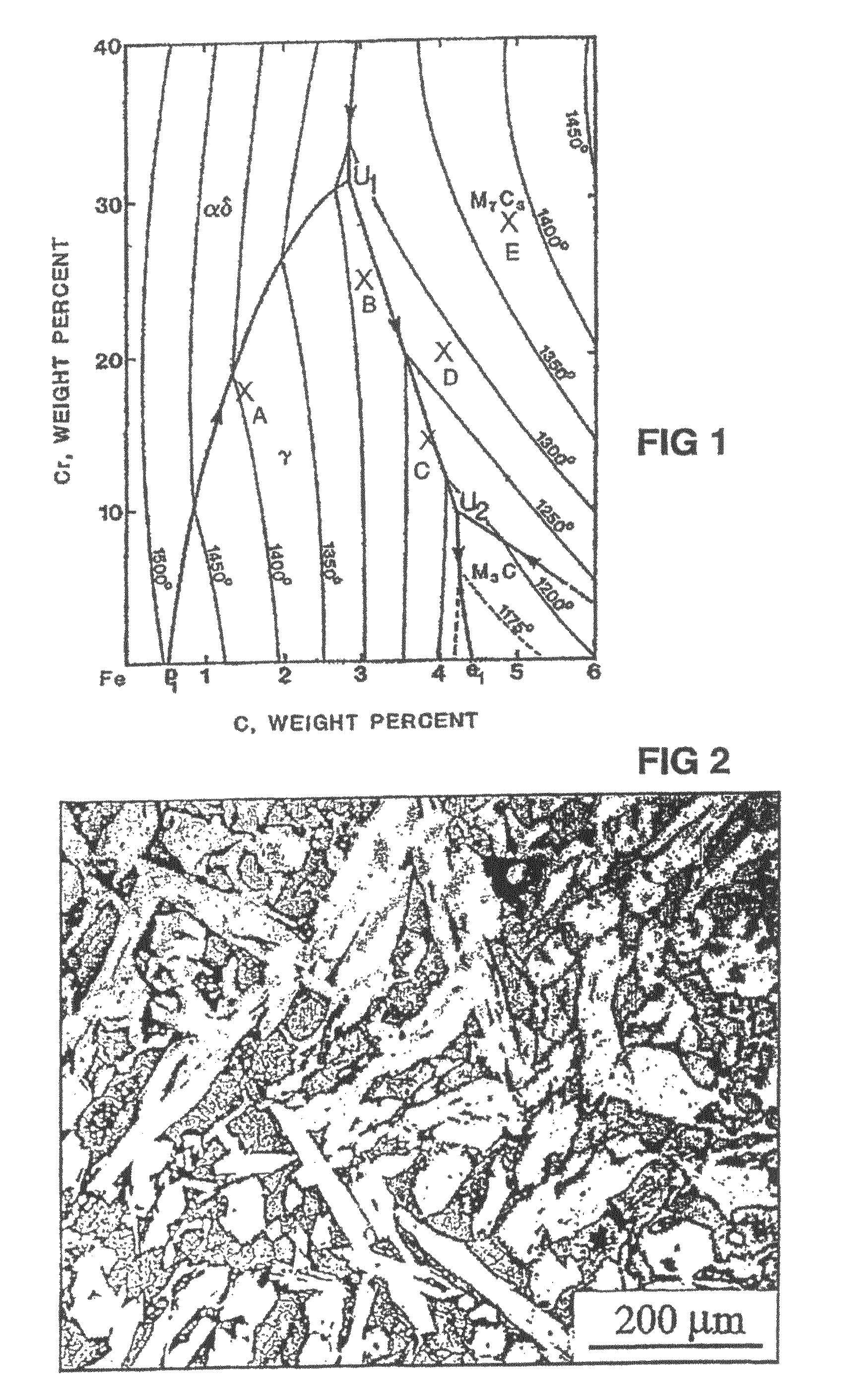

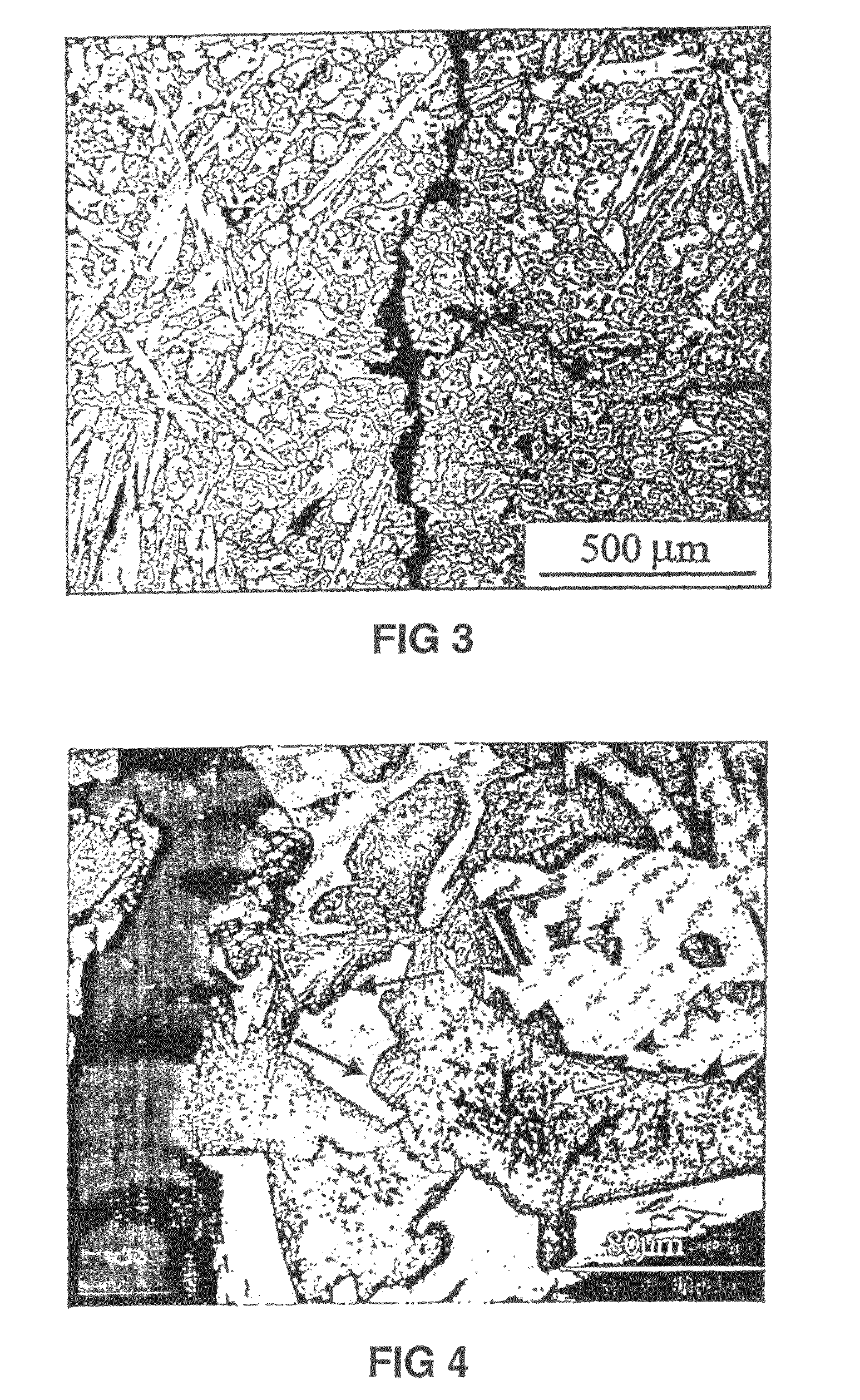

Wear resistant alloy and method of producing thereof

ActiveUS8187529B2Reduced risk of crackingImprove the level ofCooking-vessel materialsAngiosperms/flowering plantsWear resistantCrack free

Owner:GLOBAL TOUGH ALLOYS

Structure and method for contact pads having double overcoat-protected bondable metal plugs over copper-metallized integrated circuits

InactiveUS20050224987A1Eliminate riskReduced production cycle timeSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectContact pad

An integrated circuit having copper interconnecting metallization (311, 312) protected by a first overcoat layer (320), portions of the metallization exposed in windows (301, 302) opened through the thickness of the first overcoat layer. A patterned conductive barrier layer (330) is positioned on the exposed portion of the copper metallization and on portions of the first overcoat layer surrounding the window. A bondable metal layer (350, 351) is positioned on the barrier layer; the thickness of this bondable layer is suitable for wire bonding. A second overcoat layer (360) including insulating silicon compounds is positioned on the first overcoat layer so that the edge (362) of the second overcoat layer overlays the edge of the bondable layer positioned on the portions (321) of the first overcoat layer surrounding the window.

Owner:TEXAS INSTR INC

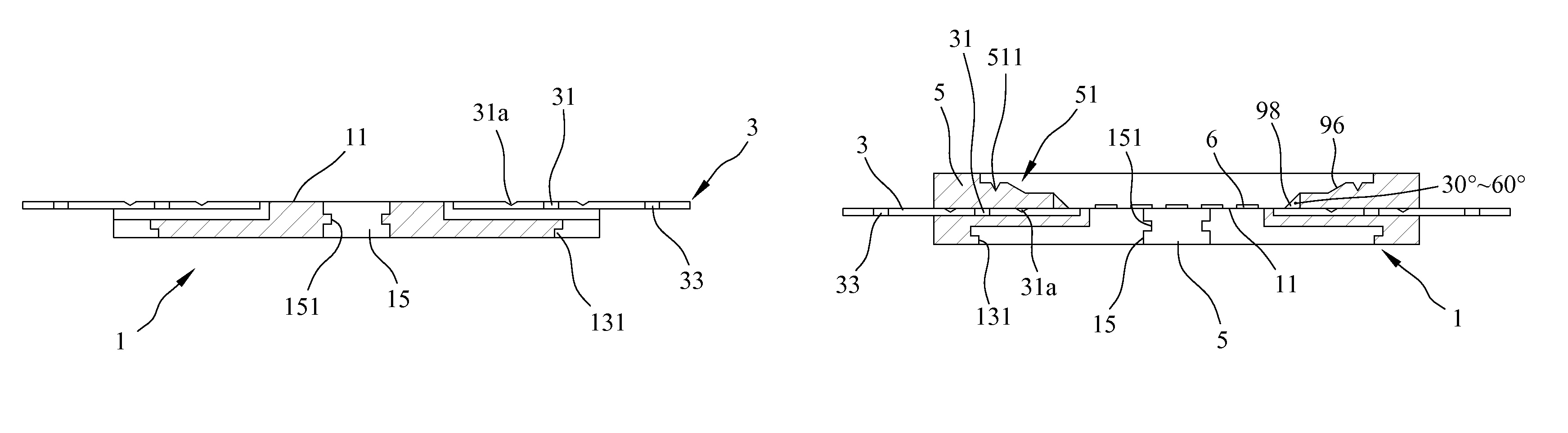

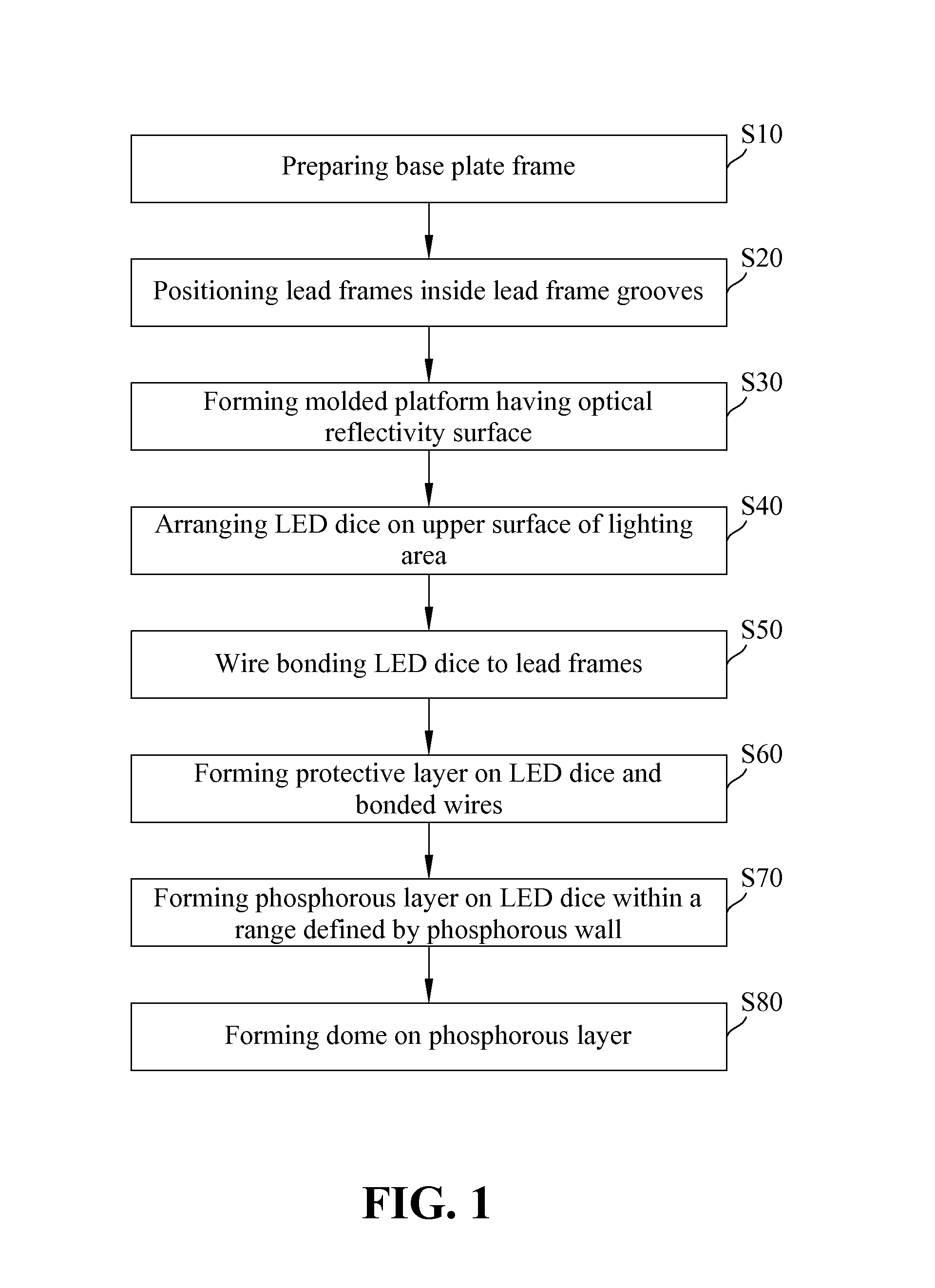

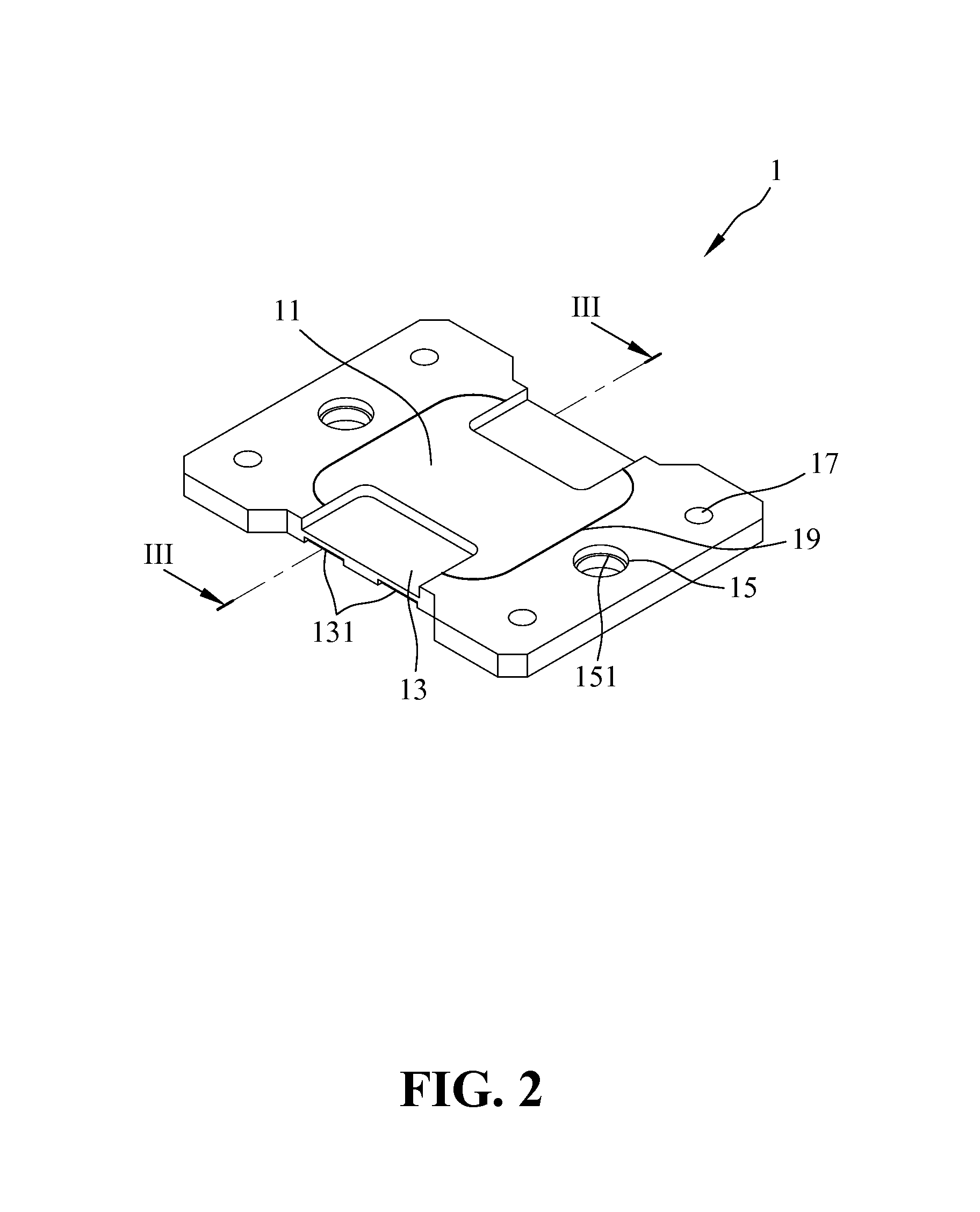

Method of assembling multi-layer LED array engine

InactiveUS7923271B1Production cost be saveShorten production cycle timeSolid-state devicesSemiconductor/solid-state device manufacturingChromiumInjection molding process

A method of assembling a multi-layer LED array engine is provided. The method includes the steps of: preparing a base plate frame comprising at least one lighting area, and two lead frame grooves; positioning two lead frames inside accommodating spaces defined in the two lead frame grooves, respectively; executing an injection molding process to form a molded platform on the base plate frame; configuring a thin layer of nickel or chromium; arranging a plurality of LED dice in an array form on an upper surface of the base plate frame; electrically coupling the LED dice to the lead frames by bonded wires; forming a protection layer on the LED dice and the bonded wires; forming a phosphorous layer on the protection layer, wherein the phosphorous layer is formed within a range defined by the phosphorous wall; and forming a dome on the upper surface of the molded platform by executing an injection molding process.

Owner:GEM WELTRONICS TWN CORP

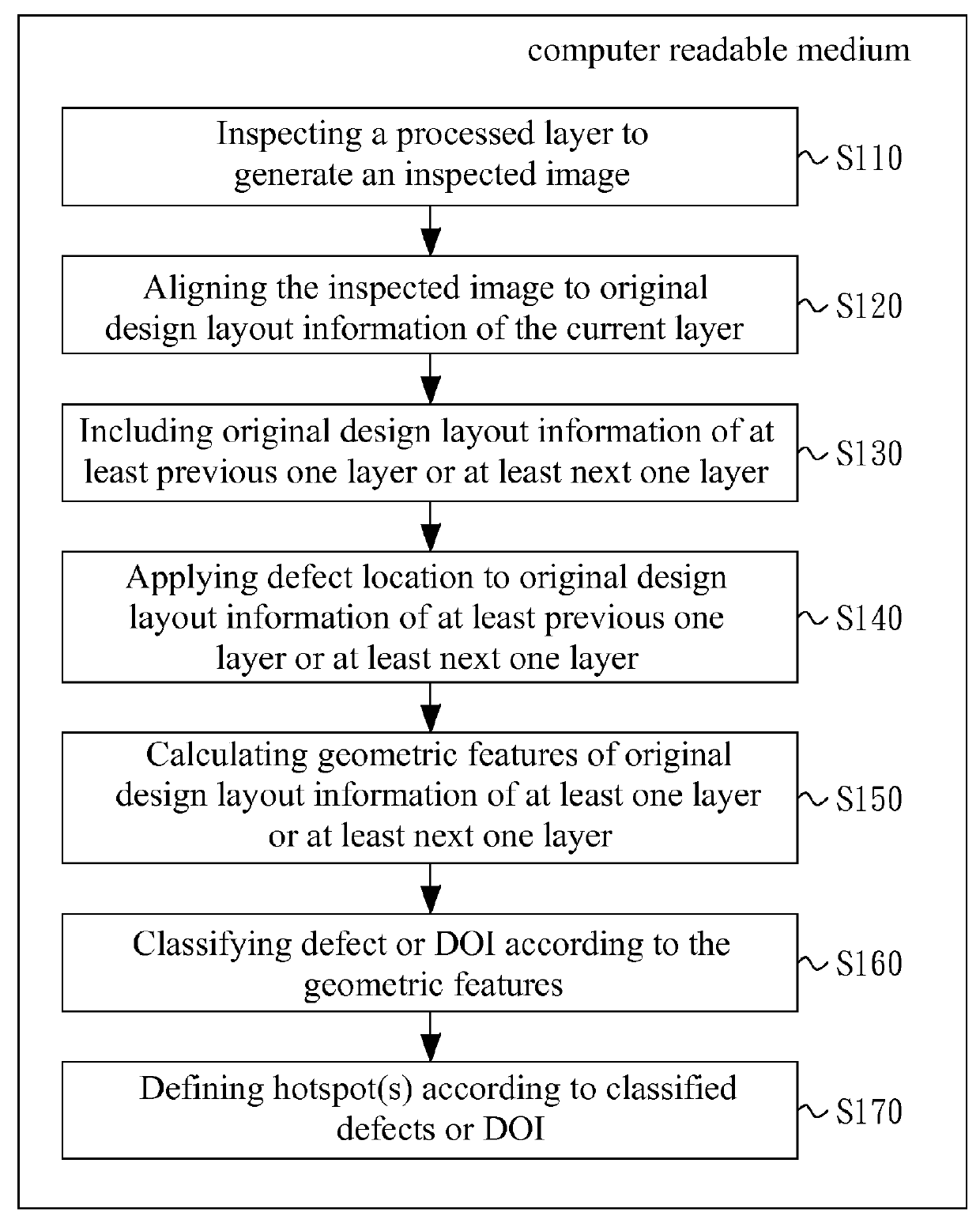

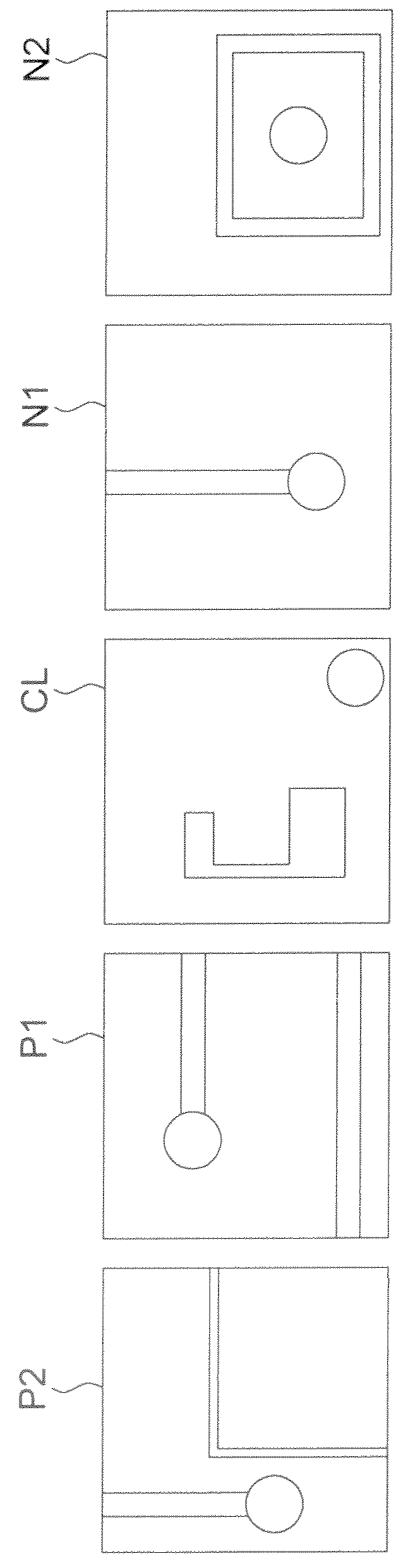

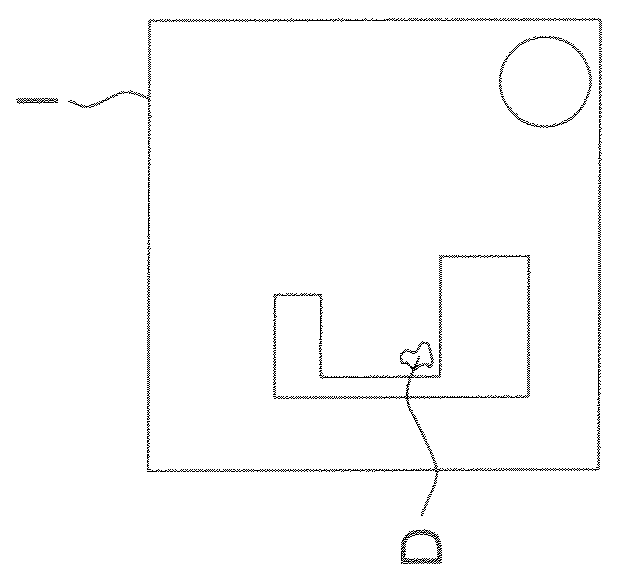

Methods for promoting semiconductor manufacturing yield and classifying defects during fabricating a semiconductor device, and computer readable mediums encoded with a computer program implementing the same

ActiveUS9251581B1Reduced production cycle timeIncrease and promote total yieldImage enhancementImage analysisComputer scienceSemiconductor

A method for promoting semiconductor manufacturing yield comprising the following steps and a computer readable medium encoded with a computer program implementing the method is provided. First, a processed layer is inspected to generate an inspected image with defects thereon. Next, the inspected image is aligned to an original design layout information of the processed layer. In addition, the defects are classified according to geometric features of the original design layout information of the processed layer and at least previous one layer and / or at least next one layer.

Owner:ASML NETHERLANDS BV

Structure and method for contact pads having an overcoat-protected bondable metal plug over copper-metallized integrated circuits

InactiveUS20060094228A1Eliminate riskReduced production cycle timeSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsCopper interconnectContact pad

A metal structure for a contact pad of an integrated circuit (IC), which has copper interconnecting metallization (311). A portion (301) of this metallization is exposed to provide a contact pad to the IC. A conductive barrier layer (330) is positioned on the exposed portion o the copper metallization. A plug (350) of bondable metal, preferably aluminum between about 0.4 and 1.4 μm thick, is positioned on the barrier layer. A protective overcoat layer (320) surrounds the plug and has a thickness (320b) so that the exposed surface (322) of the plug lies at or below the exposed surface (320a) of the overcoat layer. Optionally, a portion (321) of the overcoat layer between about 0.1 and 0.3 μm wide may overlap the perimeter of the plug.

Owner:LI LEI +1

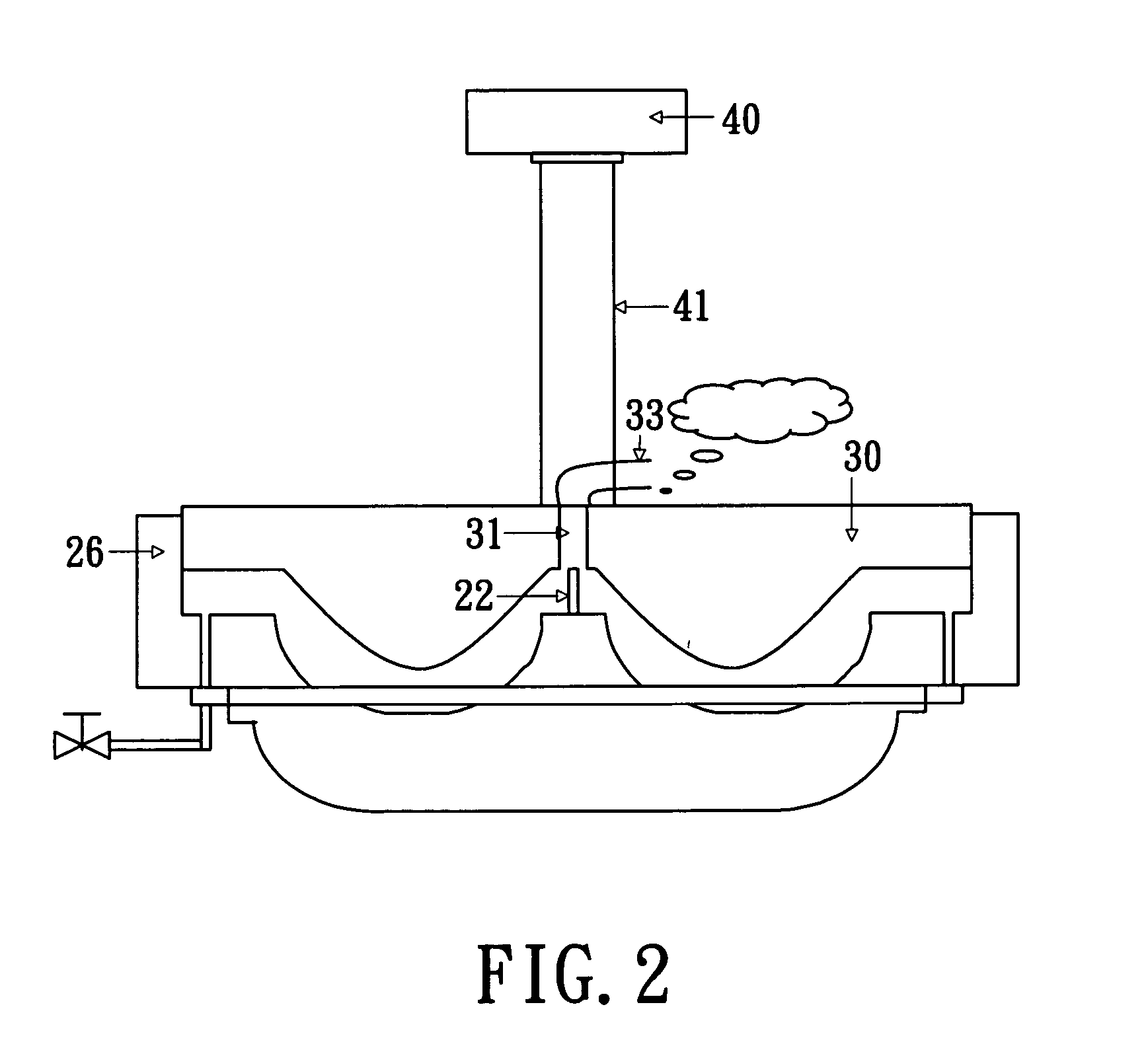

Method for preparing brassiere cup

An improved method of preparing molded seamless breast pads, cups, fronts and the like for use in brassieres and other garments is described. Polyurethane foam sheet, which still contains free isocyanates in its urethane matrix, is sliced from a freshly made foam bun, and placed between the mold parts. The mold parts are then closed by a hydraulic press. Steam is injected through holes in one mold part, and flows throughout the compressed polyurethane foam. Exhaust steam is emitted from holes in the other mold part. Moisture and heat from the steam then accelerate reactions with the free isocyanates and further cure the polyurethane foam material. The polyurethane foam material is therefore molded into the shape of mold parts cavity.

Owner:HSUEH PAN TING

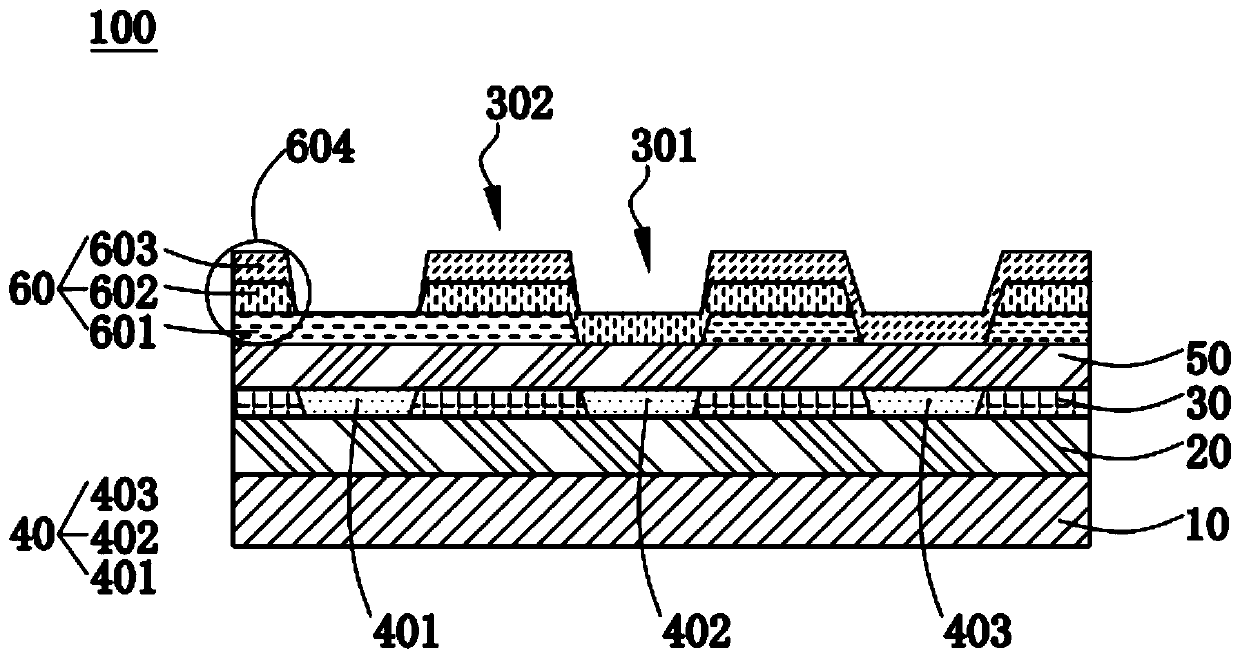

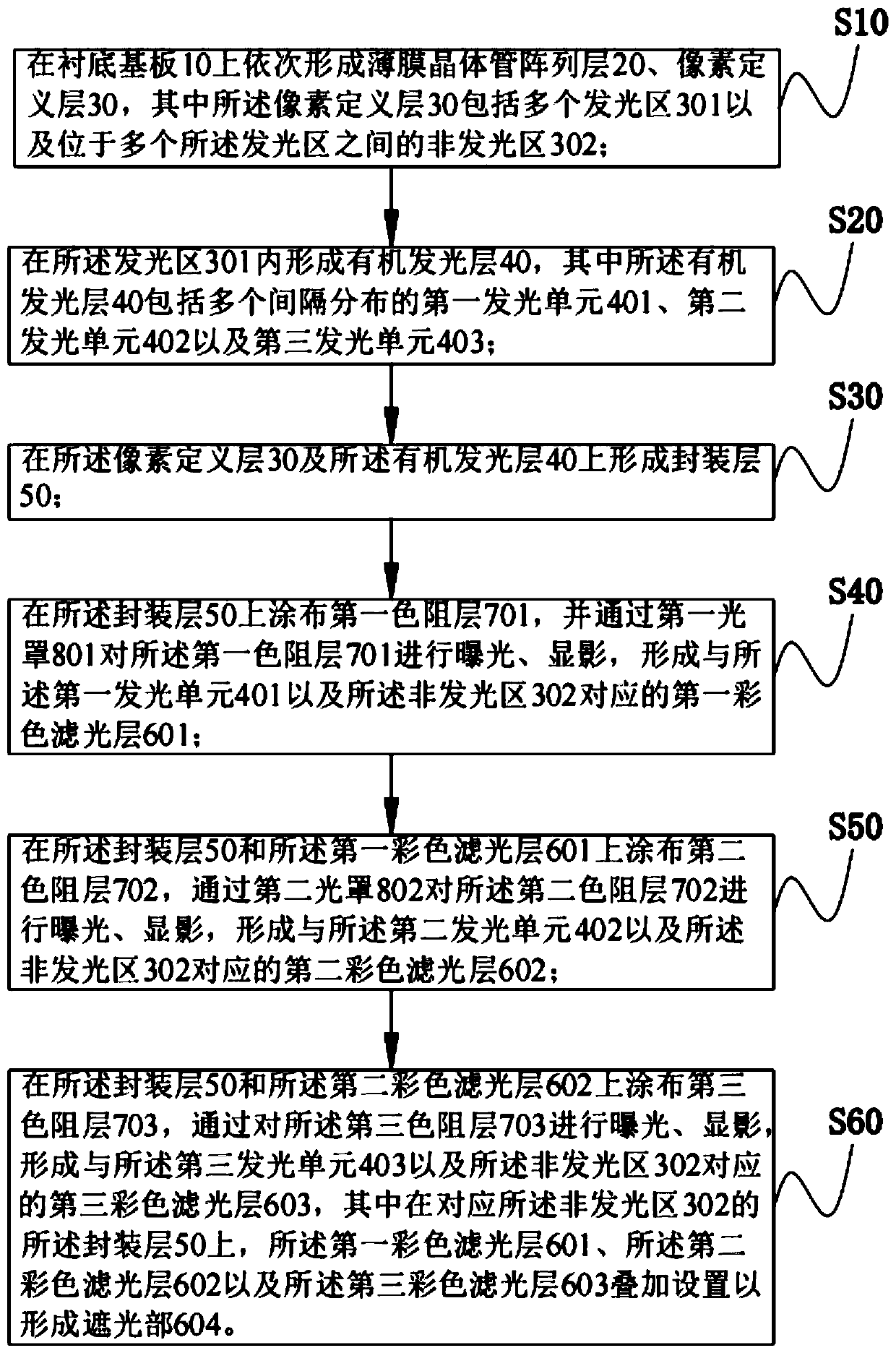

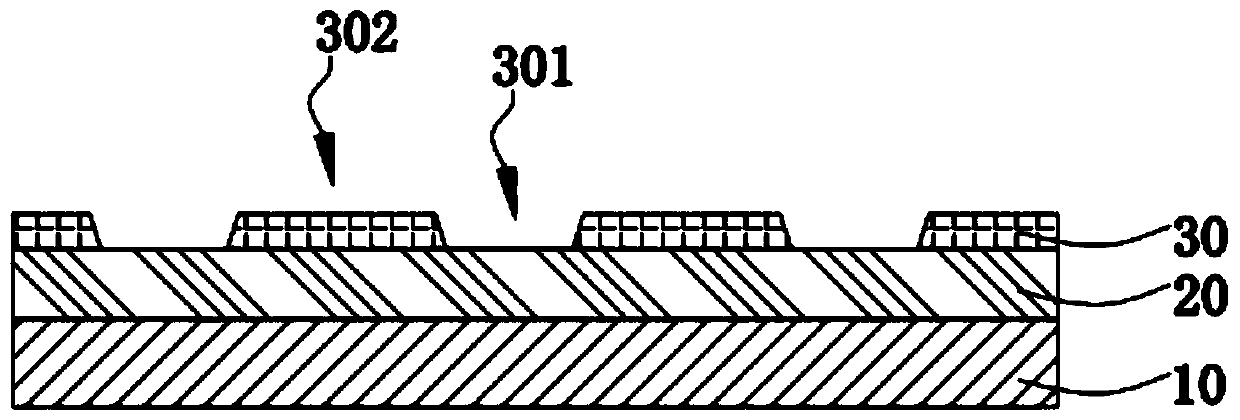

OLED display panel and manufacturing method thereof

InactiveCN110707132AGood optical performanceImprove bending performanceSolid-state devicesSemiconductor devicesTransistor arrayColor film

The invention provides an OLED display panel and a manufacturing method thereof. The OLED display panel comprises a substrate, a thin film transistor array layer, a pixel definition layer, an organiclight-emitting layer, a packaging layer and a color film layer, the color film layer comprises a first color filter layer, a second color filter layer and a third color filter layer. The first color filter layer, the second color filter layer and the third color filter layer are sequentially stacked to form a shading part to replace a black matrix; process flow is optimized, cost of the productionequipment, the photomask and the material is greatly reduced, the risk that the luminous efficiency of the OLED device is reduced or fails after the photoetching process is reduced, the pixel definition layer also has the shading effect, and the optical effect and the bending performance of the OLED display panel can be further improved by combining the pixel definition layer with the shading part.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

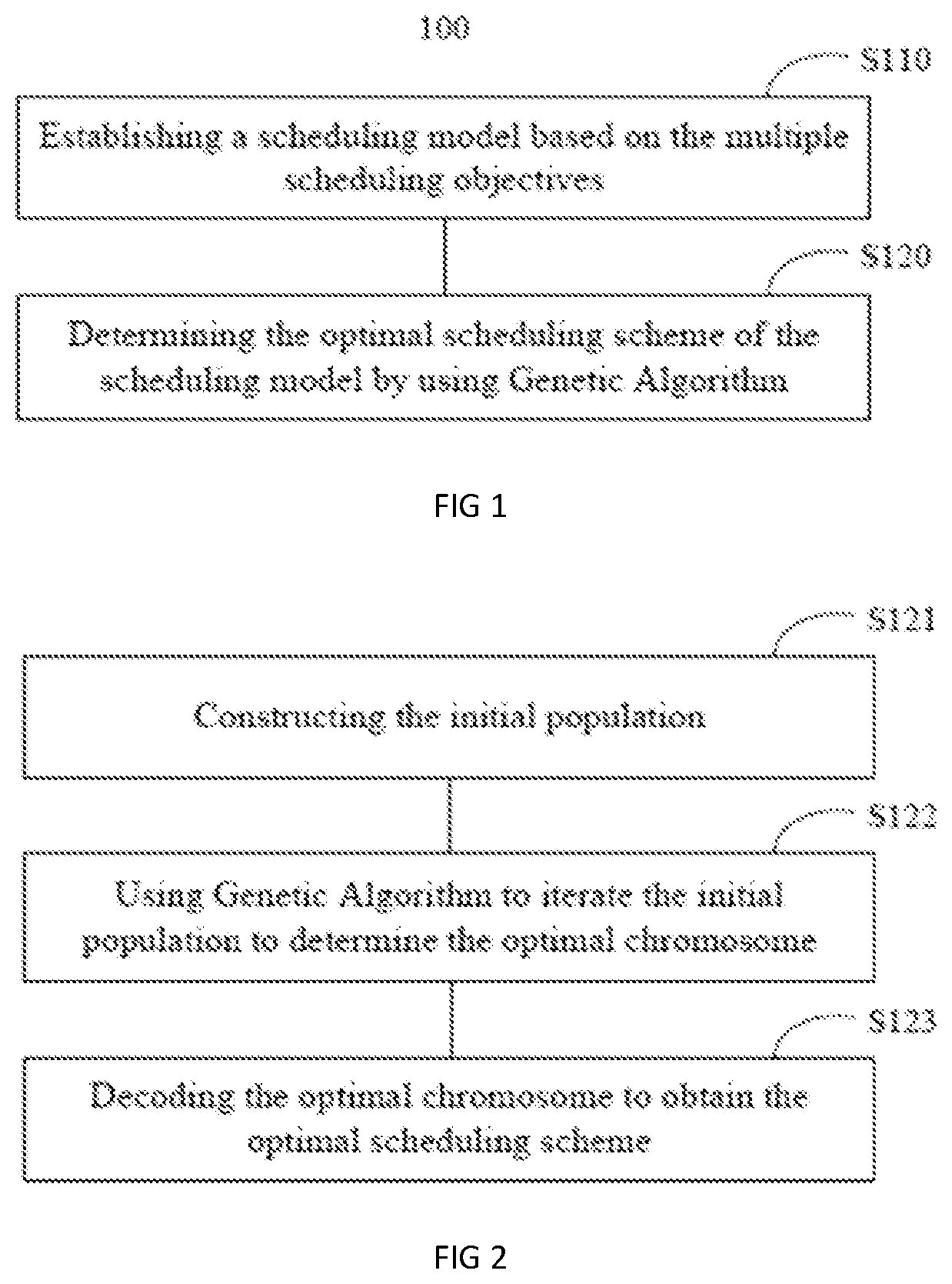

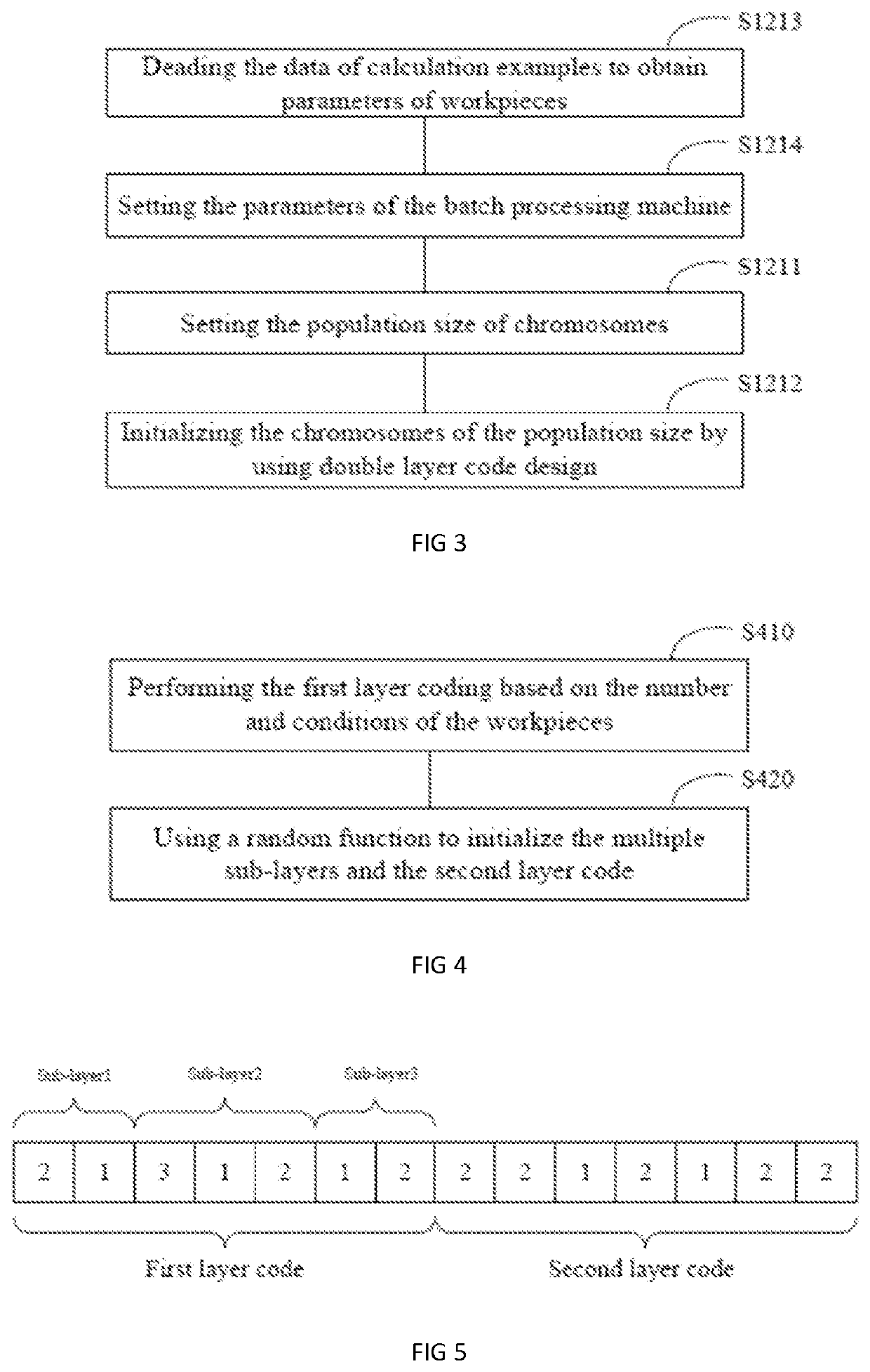

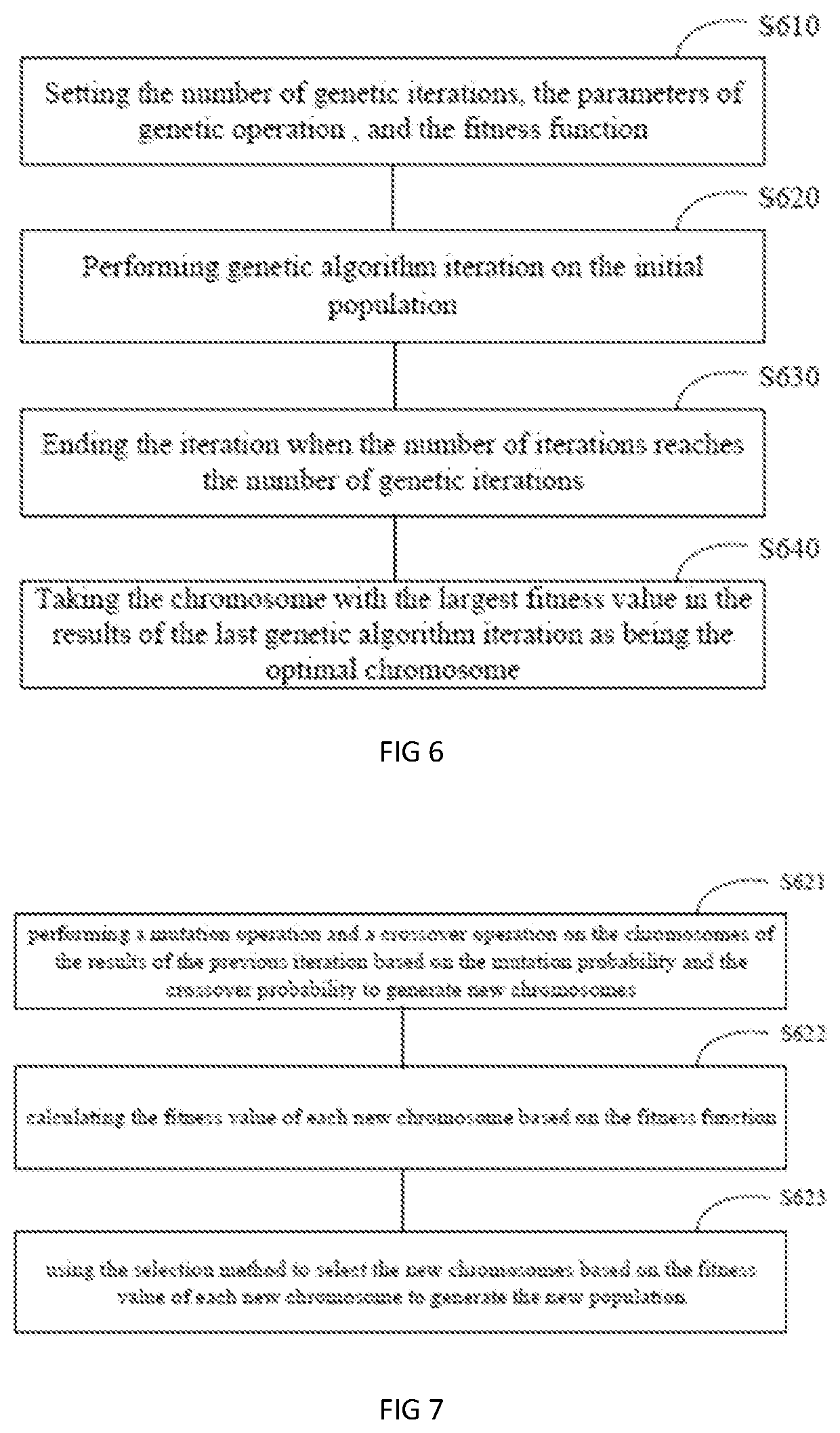

Scheduling method and device for batch processing machine

PendingUS20210335639A1Good effectReduced production cycle timeSemiconductor/solid-state device manufacturingResourcesBatch processingOptimal scheduling

The invention provides a scheduling method for batch processing machines, which is suitable for scheduling of workpieces on multiple batch processing machines in a manufacturing factory. The scheduling method for batch processing machines includes: establishing a scheduling model based on multiple scheduling objectives of the multiple batch processing machines and the workpieces, and the multiple scheduling objectives include meeting the delivery date of the workpieces, improving the capacity utilization rate and batch size of the batch processing machine, reducing the final production cycle time of the workpieces, and using Genetic Algorithm to determine the optimal scheduling scheme of the scheduling model.

Owner:SHANGHAI HUALI INTEGRATED CIRCUIT CORP

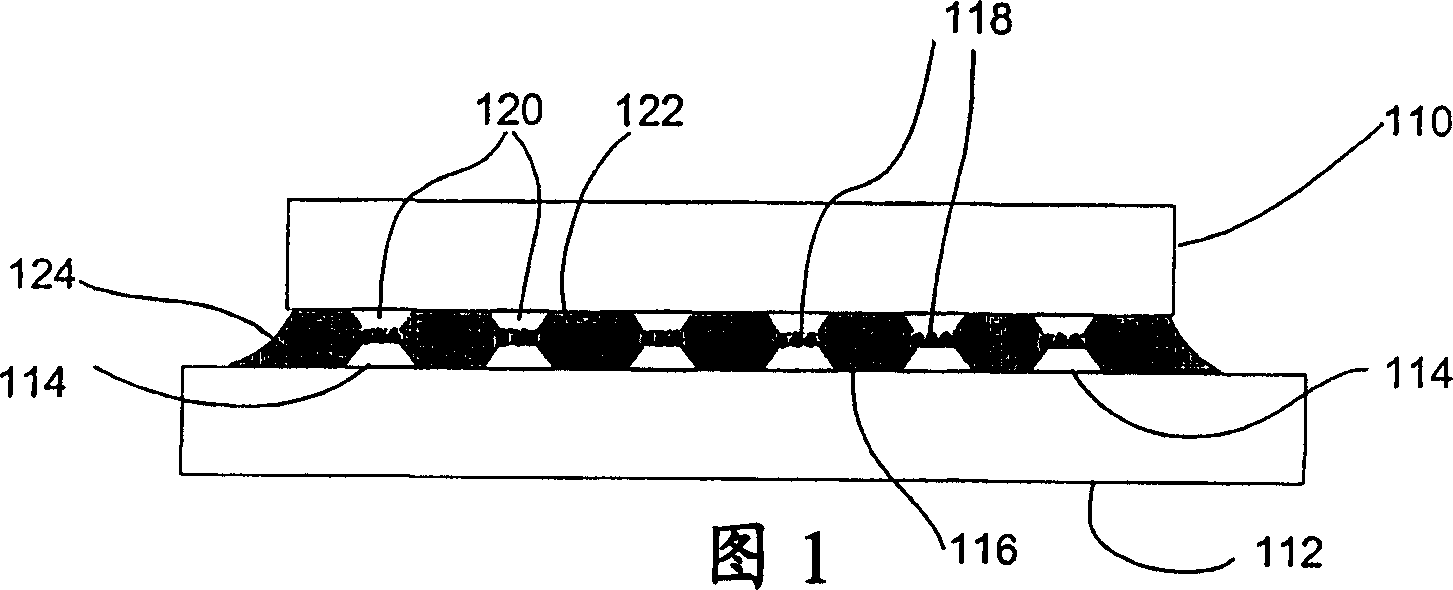

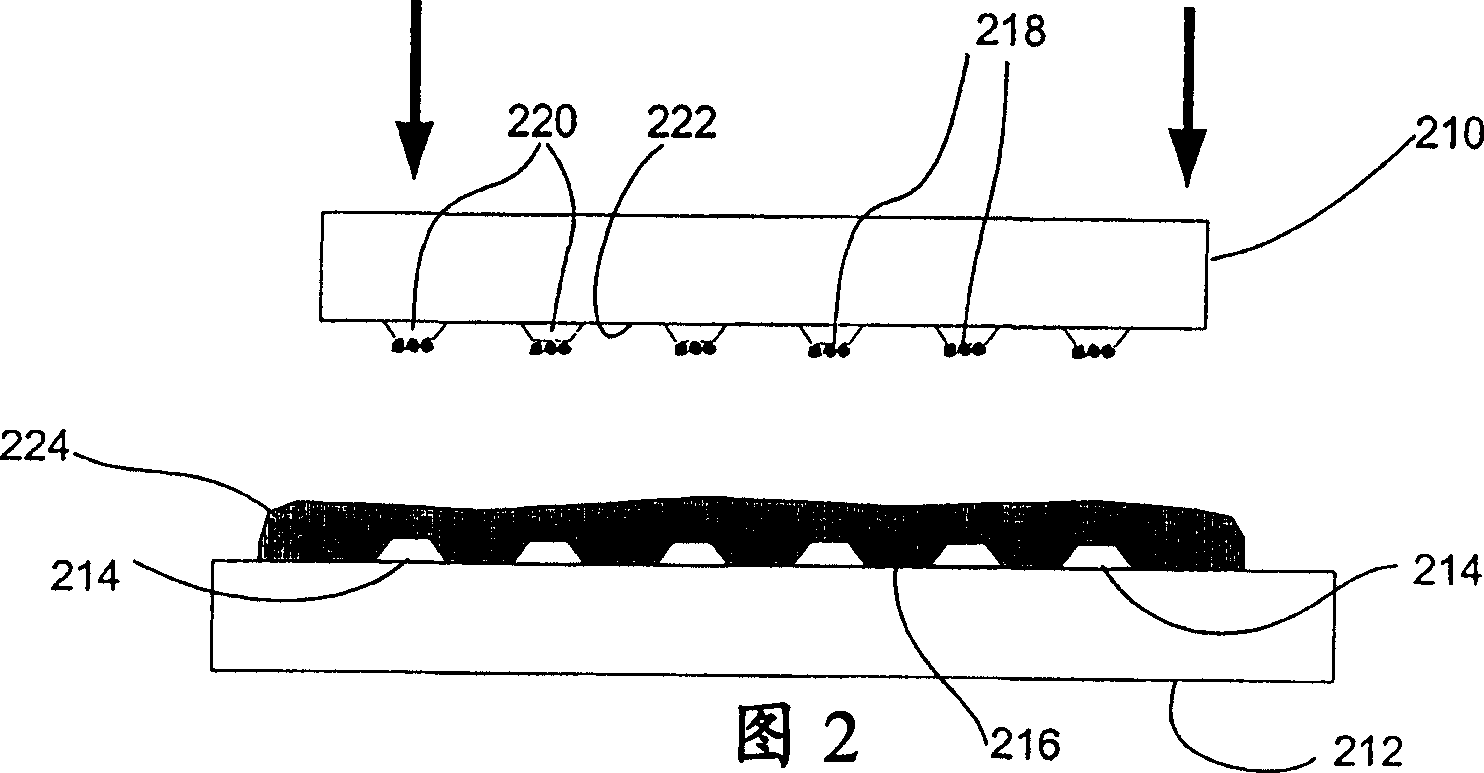

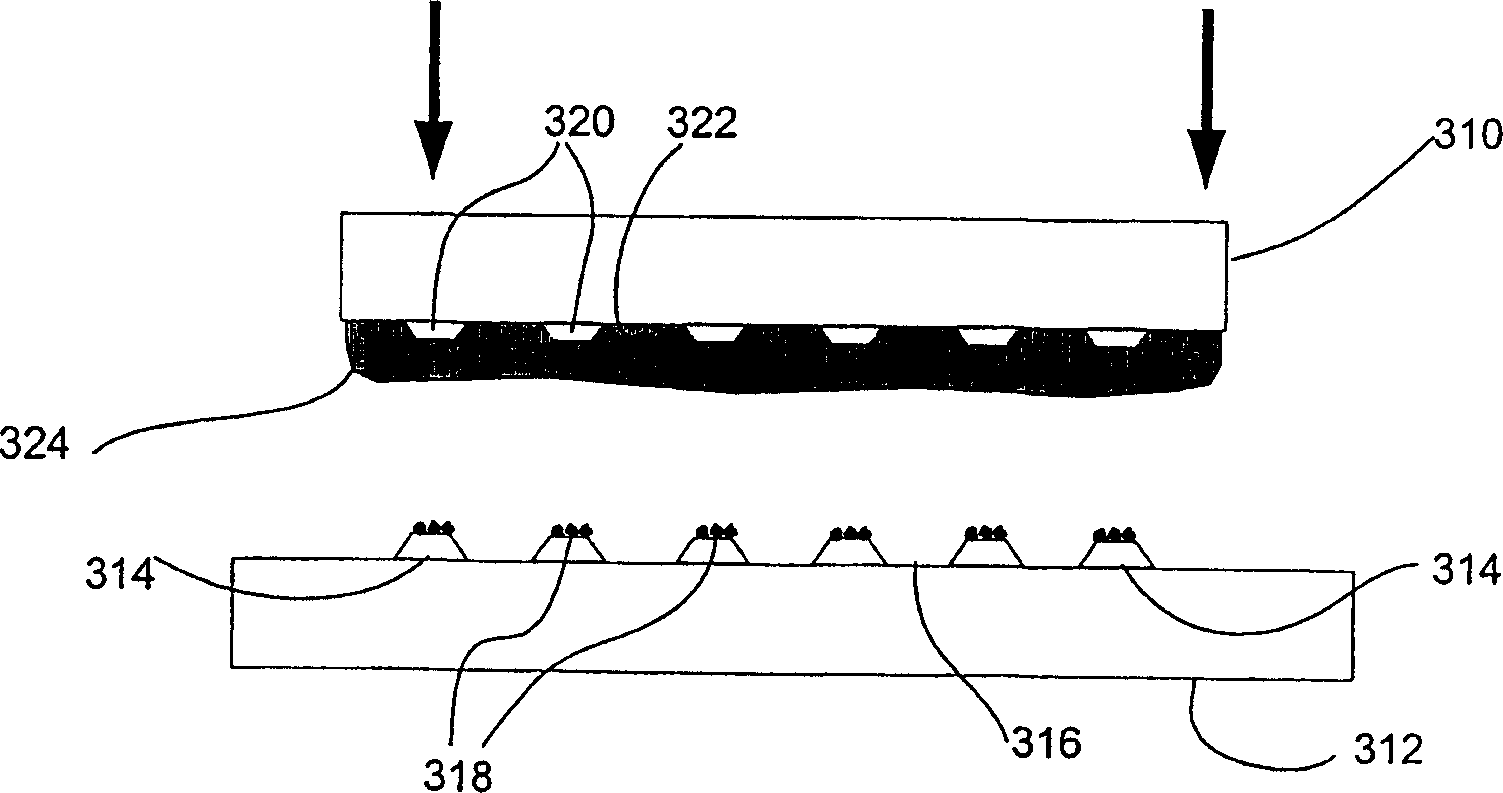

Electrical component assembly and method of fabrication

InactiveCN1620725ASimplify the assembly processImprove electrical performancePrinted circuit assemblingSemiconductor/solid-state device detailsElectronic componentElectroplating

An electrical component assembly and method of manufacturing the same, wherein particles (318) are fixed to a metal surface (314) and pressure is applied to cause the particles to penetrate at least one metal contact surface (314). In one method, hard particles (318) are applied to one of the metal surfaces (314) by electroplating the particles in an electroplating bath. In another approach, hard particles (318) are applied to a non-conductive adhesive layer (324) positioned between the electronic component (310) and the substrate (312). Once pressure is applied to the electronic component (310) or substrate (312), a permanent, conductive bond is formed.

Owner:NANOPIERCE TECH

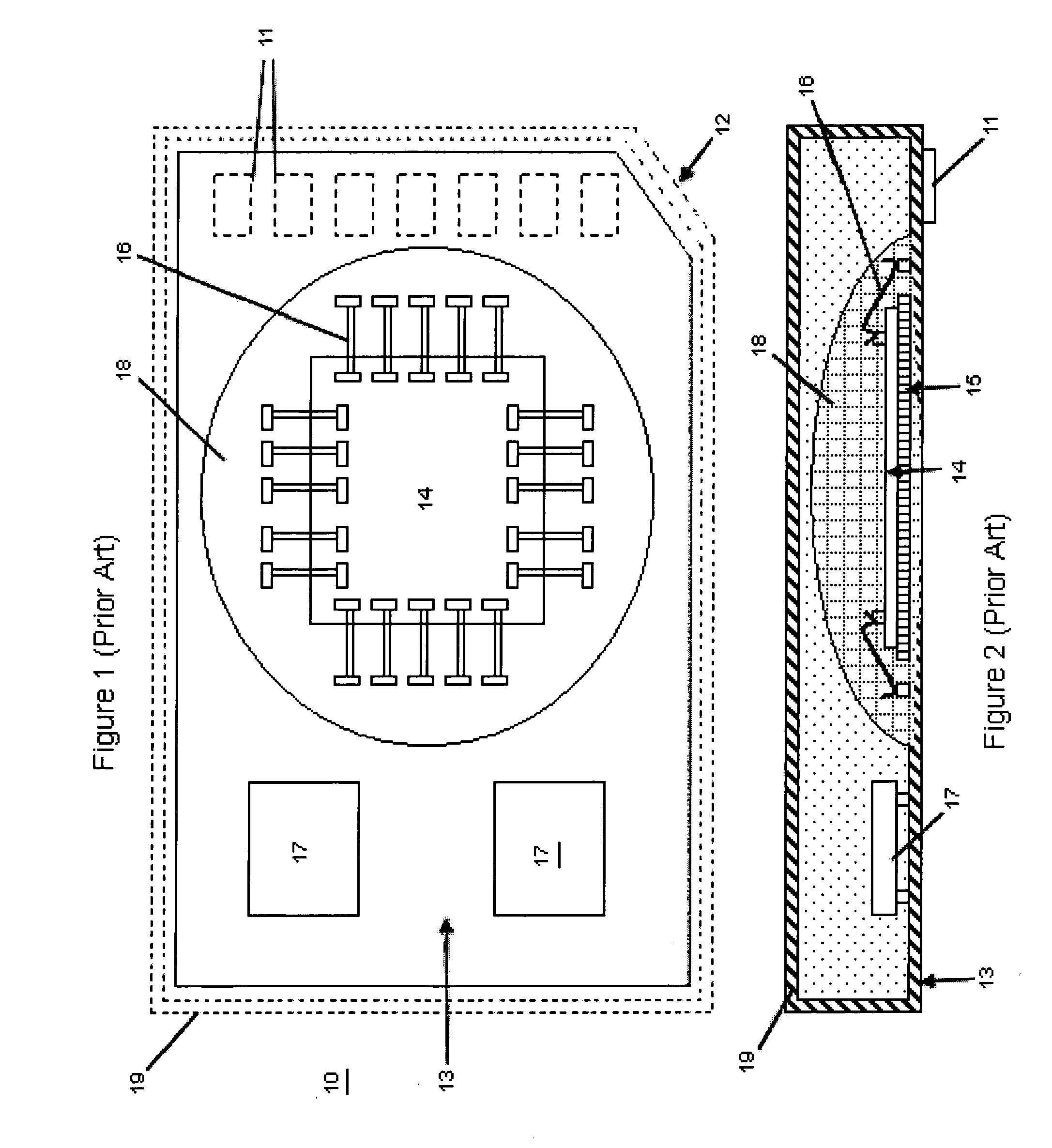

Semiconductor package having a grid array of pin-attached balls

ActiveUS20060021795A1Raise countImprove electrical performanceFinal product manufactureSemiconductor/solid-state device detailsContact padAdhesive

Semiconductor chip (1101) of a ball grid array device (1100) is mounted onto tape substrate (1102) using attach adhesive (1103). The metal layer on the top surface of substrate (1102) uses between about 30% to 90% of its area for connecting lines (1104), and only the remainder for members / rings (1105) and terminals (1106). Routing of differential pair signals and large numbers of signals on a single layer tape package are feasible. This embodiment creates an inexpensive high performance tape ball grid array package for chip-scale devices. Terminals (1106) serve the connection (by bonding wires or reflow bumps) to the chip contact pads. Inserted in members / rings (1105) are the conductive pins (1107), which serve as anchors for the solder bodies / balls (1108). Pins (1107) are substantially insensitive to the thermomechanical stresses, which occur in device (1100) during assembly, testing and operation.

Owner:TEXAS INSTR INC

Element of a cable tie strap

ActiveUS20080189916A1Reduce the amount requiredReduced production cycle timeSnap fastenersPipe supportsCombined useEngineering

A low profile locking tie head having a reduced wall thickness is provided for use in conjunction with a flexible strap. The low profile head comprises a wall, which circumferentially defines an opening, a reinforcement rib attached to the wall, and a pawl mechanism disposed at least partially inside the opening. A pair of clamping rails preferably provides a complete clamping surface, lowers the required tie head height, and assists in the transfer of force to the reinforcement rib. Further, a tie head retainer is provided to allow secure connection to a predetermined support structure.

Owner:HELLERMANNTYTON CORP

Structure and method for contact pads having a recessed bondable metal plug over of copper-metallized integrated circuits

InactiveUS20050206007A1Reduce riskImprove assembly yieldSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectContact pad

A metal structure for an integrated circuit, which has copper interconnecting metallization (311) protected by an overcoat layer (320). A portion of the metallization is exposed in a window (301) opened through the thickness of the overcoat layer. The metal structure comprises a patterned conductive barrier layer (330) positioned on the copper metallization, wherein this barrier layer forms a trough with walls (331) conformal with the overcoat window. The height (331a) of the wall is less (between 3 and 20%) than the overcoat thickness (320a), forming a step (340). A plug (350) of bondable metal, preferably aluminum, is positioned in the trough and has a thickness equal to the trough wall height (331a).

Owner:TEXAS INSTR INC

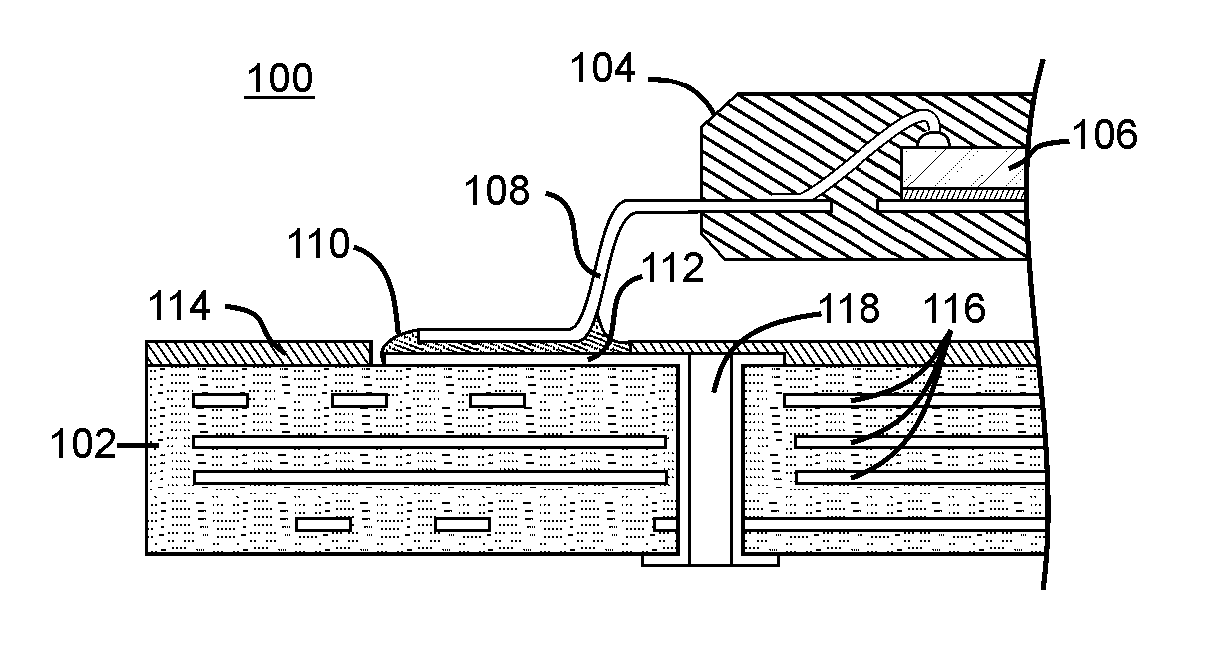

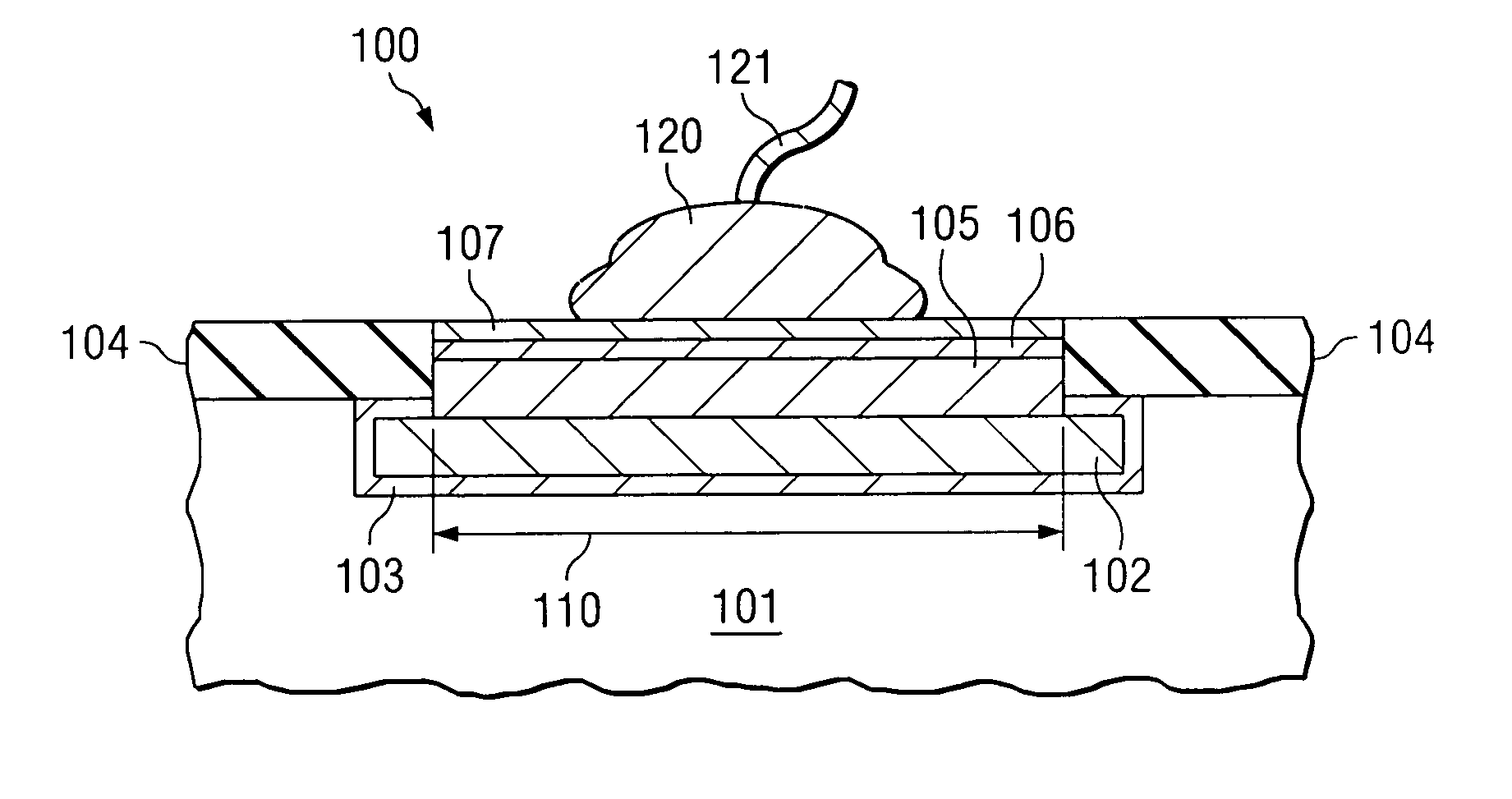

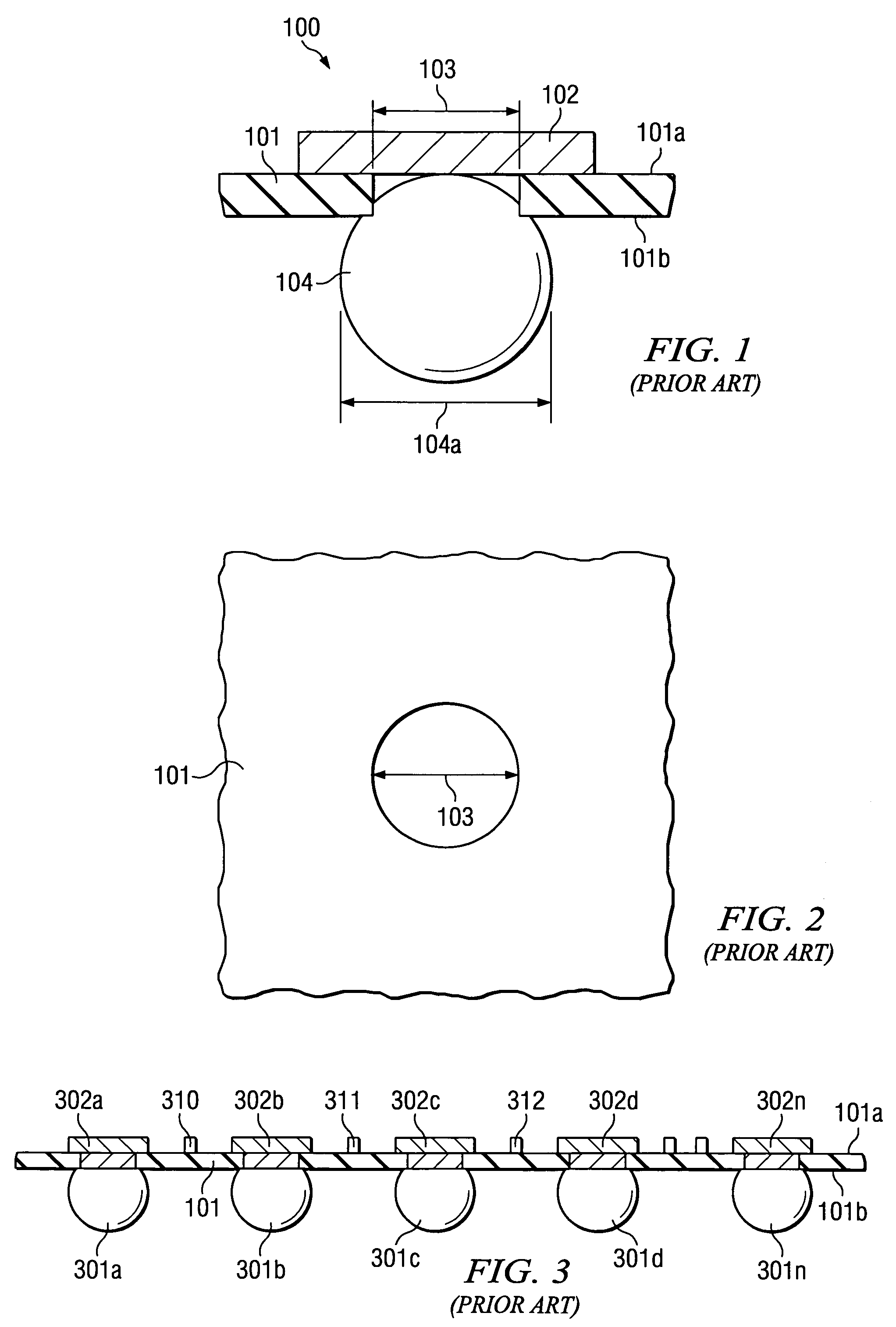

Copper-metallized integrated circuits having electroless thick copper bond pads

ActiveUS20070031697A1Low cost methodImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingContact padDevice material

A metal structure (100) for a contact pad of a semiconductor device, which has interconnecting traces of a first copper layer (102). The substrate is protected by an insulating overcoat (104). In the structure, the first copper layer of first thickness and first crystallite size is selectively exposed by a window (110) in the insulating overcoat. A layer of second copper (105) of second thickness covers conformally the exposed first copper layer. The second layer is deposited by an electroless process and consists of a transition zone, adjoining the first layer and having copper crystallites of a second size, and a main zone having crystallites of the first size. The second thickness is selected so that the distance a void from the second layer can migrate during the life expectancy of the structure is smaller than the combined thicknesses of the first and second layers. A layer of nickel (106) is on the second copper layer, and a layer of noble metal (107) is on the nickel layer.

Owner:TEXAS INSTR INC

Method for preparing formed polyurethane foam materials and formed polyurethane foam materials therefrom

InactiveUS20060154567A1Solve Porosity InsufficiencyExcellent color fastness against UV lightBrassieresCorsetsPorosityPolyol

This invention relates to a novel method for the preparation of polyurethane foam materials suited for seamless breast pads, cups, fronts and the like for use in brassieres and other garments. Polyurethane foam is produced from aliphatic isocyanates and polyols. The aliphatic polyurethane foam is reticulated to remove all celled membranes and sliced into sheet with a thickness greater than the thicker wall of the finished brassiere cup. The sliced aliphatic polyurethane foam sheet is then pressed between mold parts of a female mold part and a male mold part. The mold parts are closed and pressed whereby the aliphatic polyurethane foam material is molded into the exact shape of the mold cavity. The molded aliphatic polyurethane foam material can be used as seamless breast pads, cups, fronts and the like in brassieres and other garments and expresses superior non-yellowing properties over previous aromatic polyurethane brassiere pads and improved breathability and porosity.

Owner:JUNG SHUN

Semiconductor package having a grid array of pin-attached balls

ActiveUS7462783B2Raise countImprove electrical performanceFinal product manufacturePrinted electric component incorporationContact padSignal on

Owner:TEXAS INSTR INC

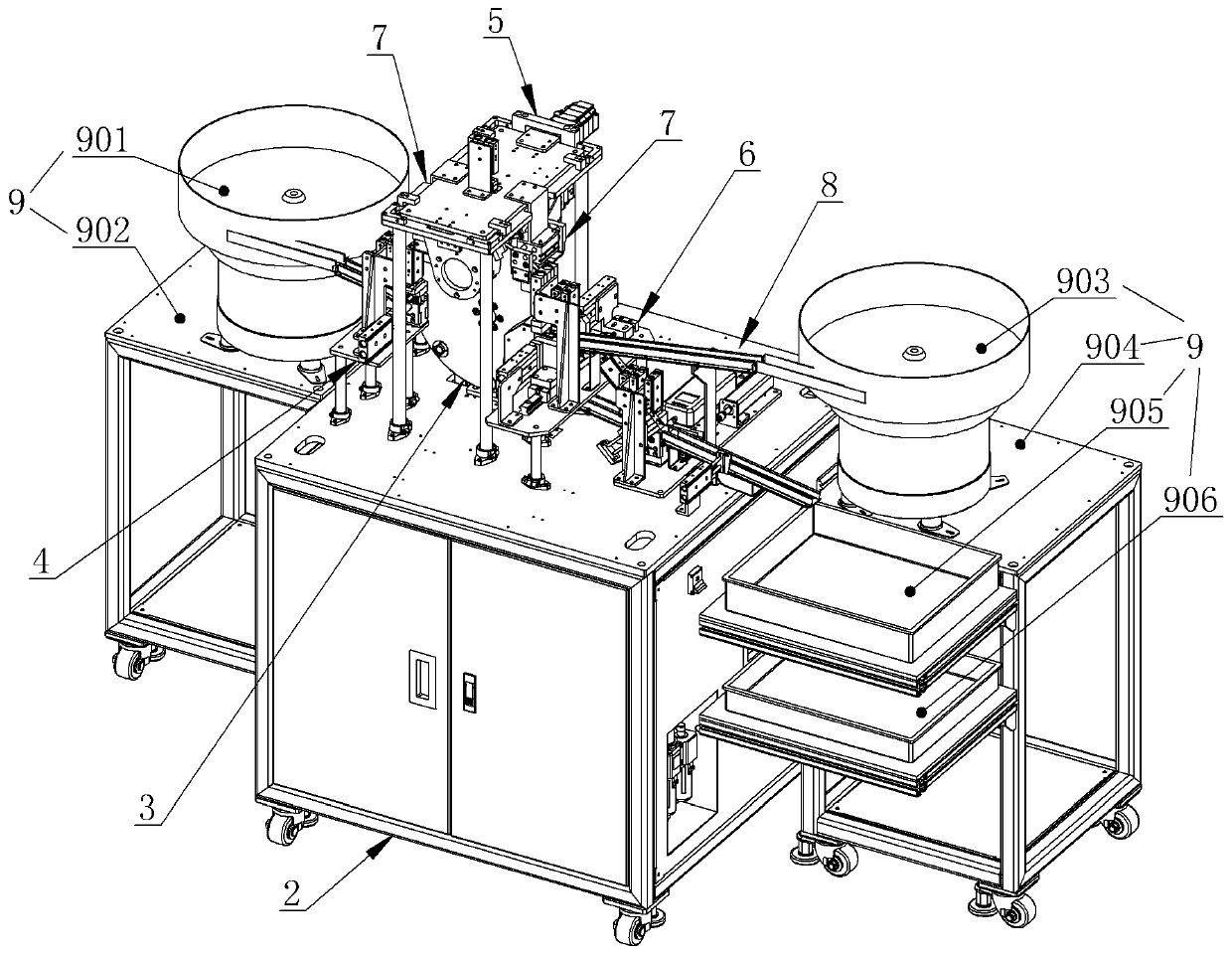

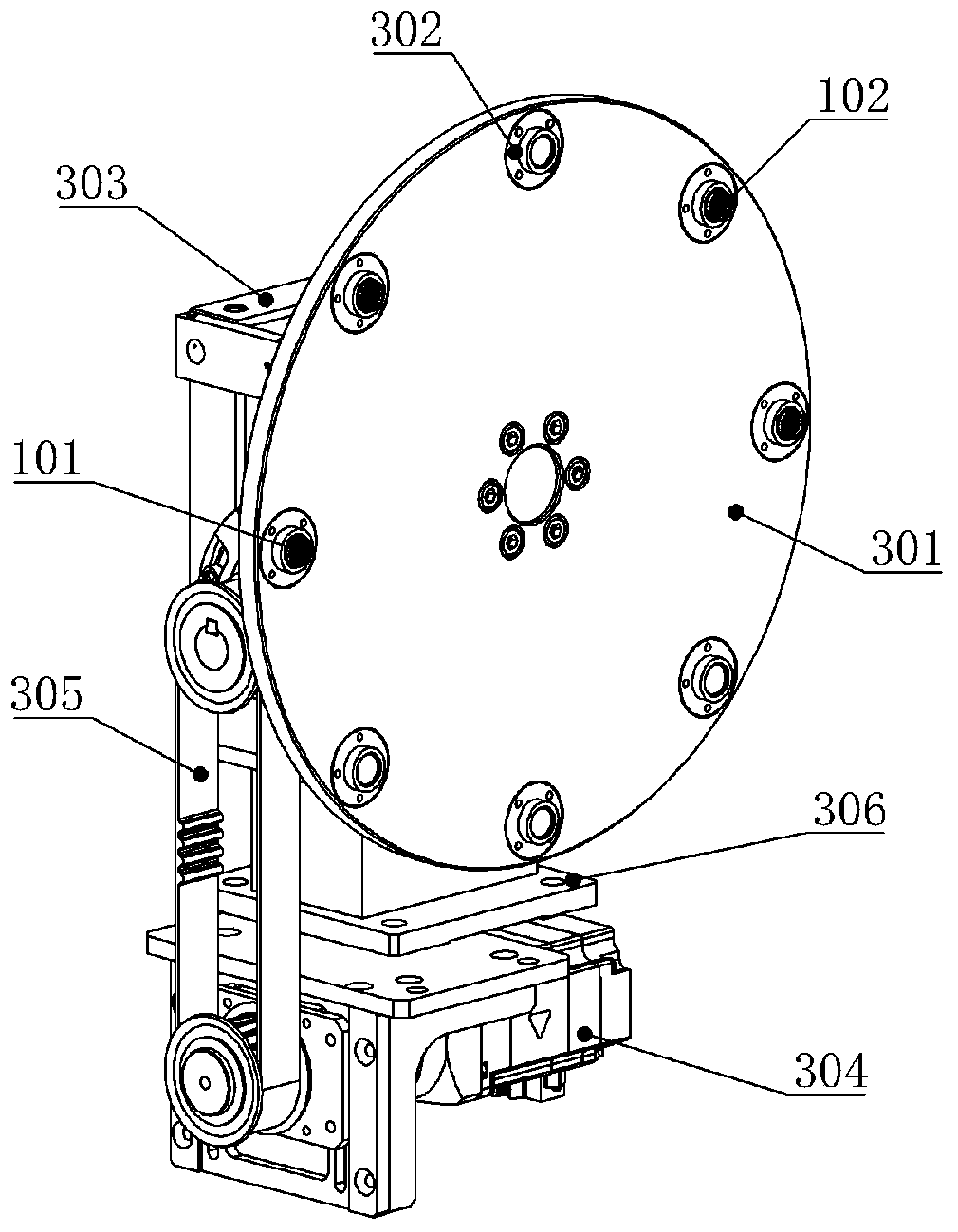

Full-automatic assembling machine for high-voltage large-current connector terminal and process method of full-automatic assembling machine

PendingCN110802404AReduce occupancyAvoid oxidation and blackeningAssembly machinesMetal working apparatusStatistical analysisTorsion spring

The invention discloses a full-automatic assembling machine for a high-voltage large-current connector terminal and a process method of the full-automatic assembling machine. The assembling machine comprises a rack table, a station indexing device, a reed feeding device, a torsion spring device, an aligning device, a terminal assembling device, a terminal detection device and a vibration feeding device. A plurality of clamps which correspond to the reed feeding device, the torsion spring device, the aligning device and the terminal assembling device one by one are uniformly arranged on the outer circumference of the station indexing device. Stations corresponding to the clamps can carry out parallel simultaneous processing. The torsion spring device can accurately control the torsion angleto adjust the torsion spring deformation amount. The terminal detection device can automatically detect the terminal plugging force and screen unqualified products. Statistical analysis is carried out on the plugging force detection result, and an adjustment basis is given out for the torsion spring angle. The full-automatic assembling machine can achieve automatic feeding, automatic material transferring, automatic torsion spring, automatic assembly and automatic plugging force detection, screening and discharging, full-automatic assembly production of connector terminals is realized, and production efficiency is remarkably improved.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

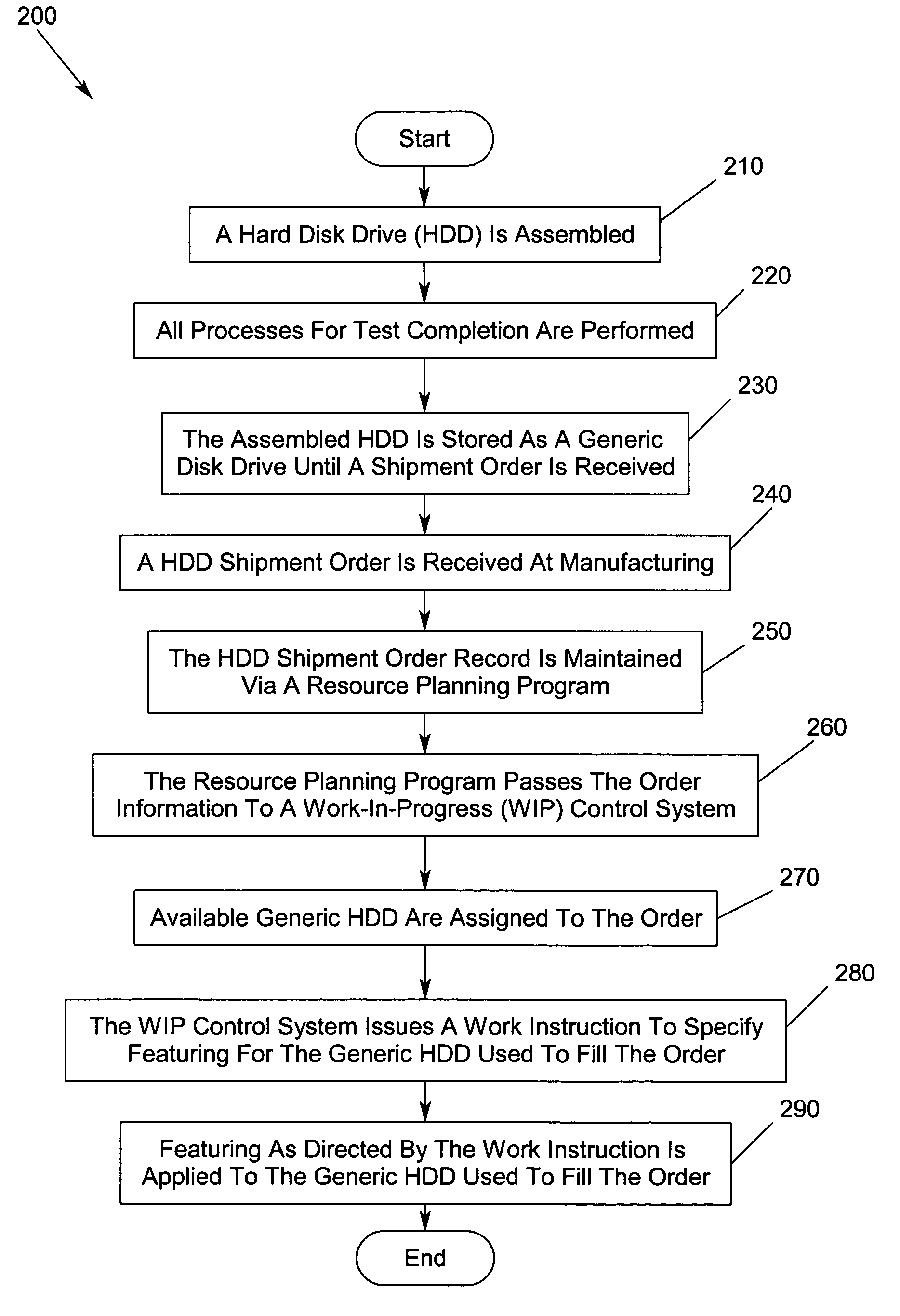

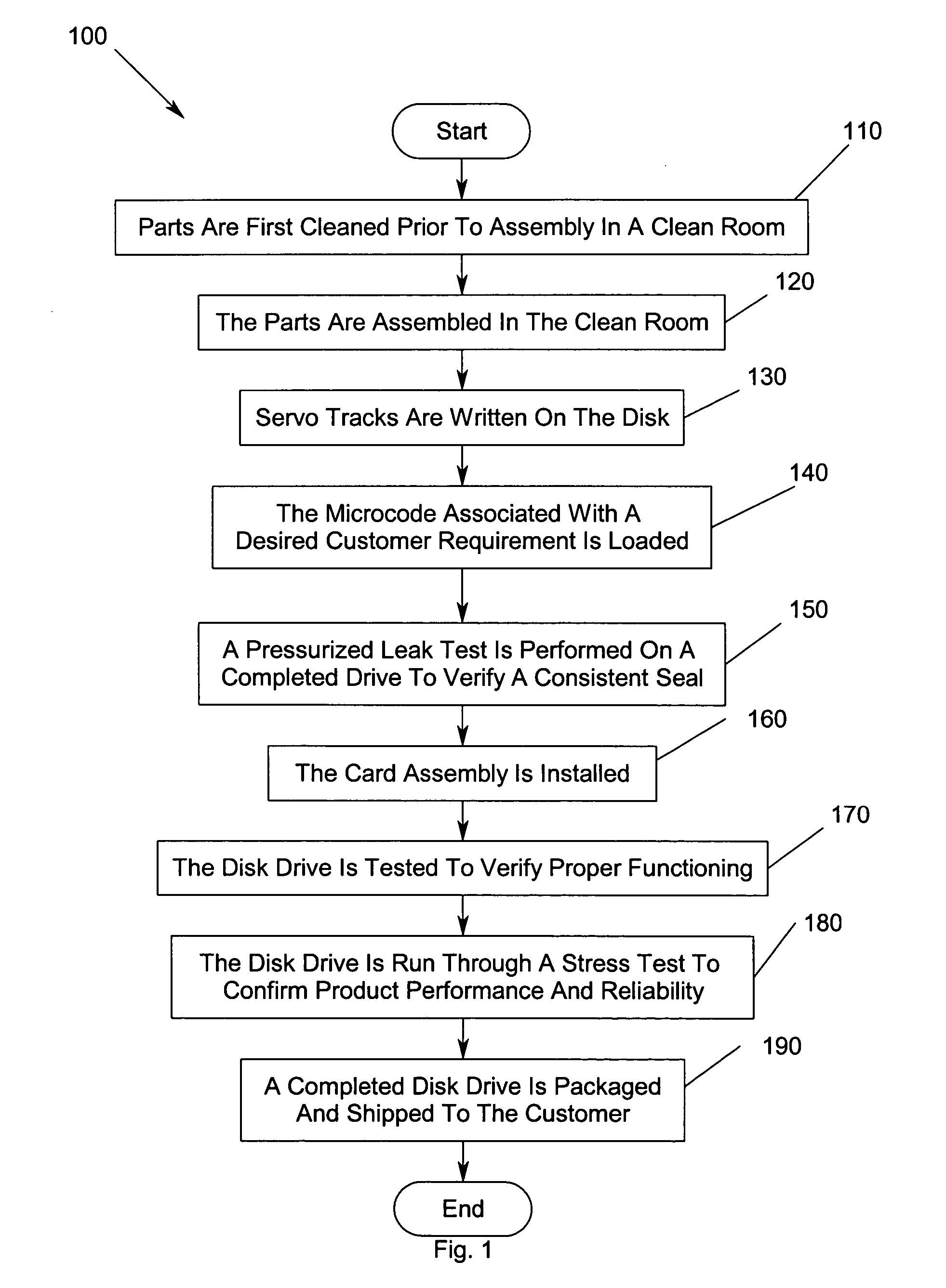

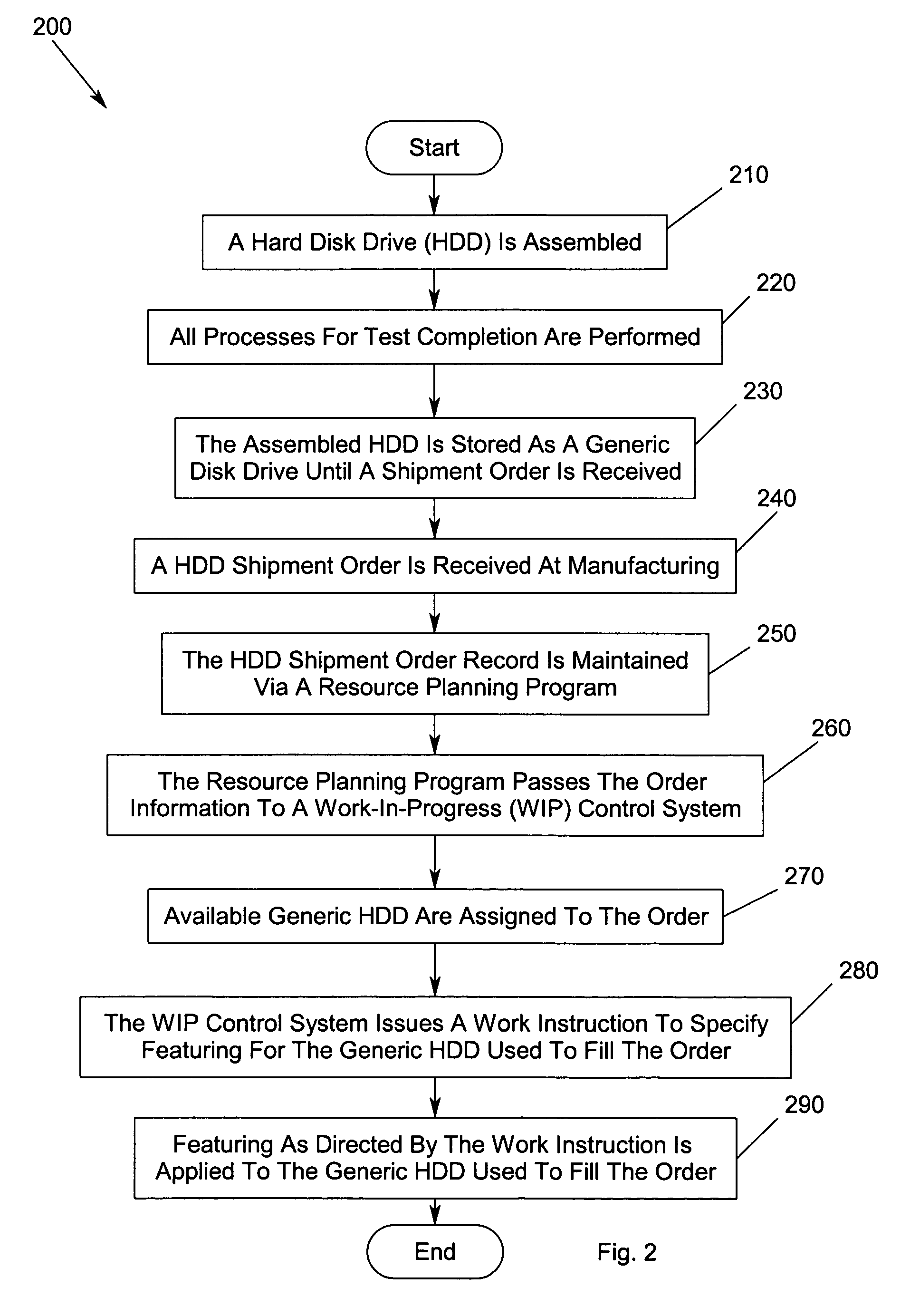

Method and system for reducing production cycle time of a hard disk drive and a generic hard disk drive ready for customization

InactiveUS20060200262A1Reduced production cycle timeProduction cycle time of hardCarrier constructional parts dispositionSpecial data processing applicationsCustomer requirementsHard disc drive

A method and system for reducing production cycle time of a hard disk drive and a generic hard disk drive ready for customization. A generic disk drive is provided for stocking until a shipment order is issued. When a shipment order defining customer requirements is received, a generic disk drive from stock is pulled from stock. Then, the generic disk drive is featured to meet the customer requirements.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

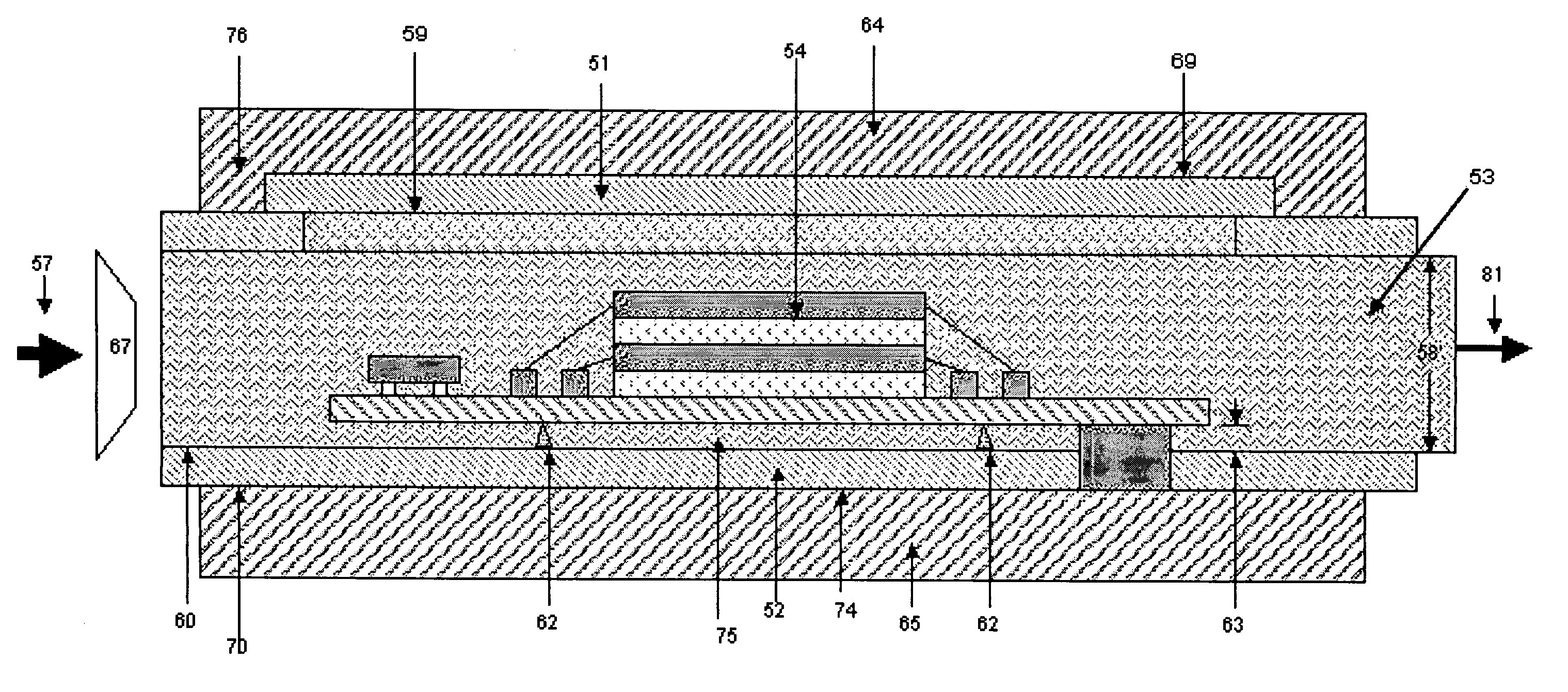

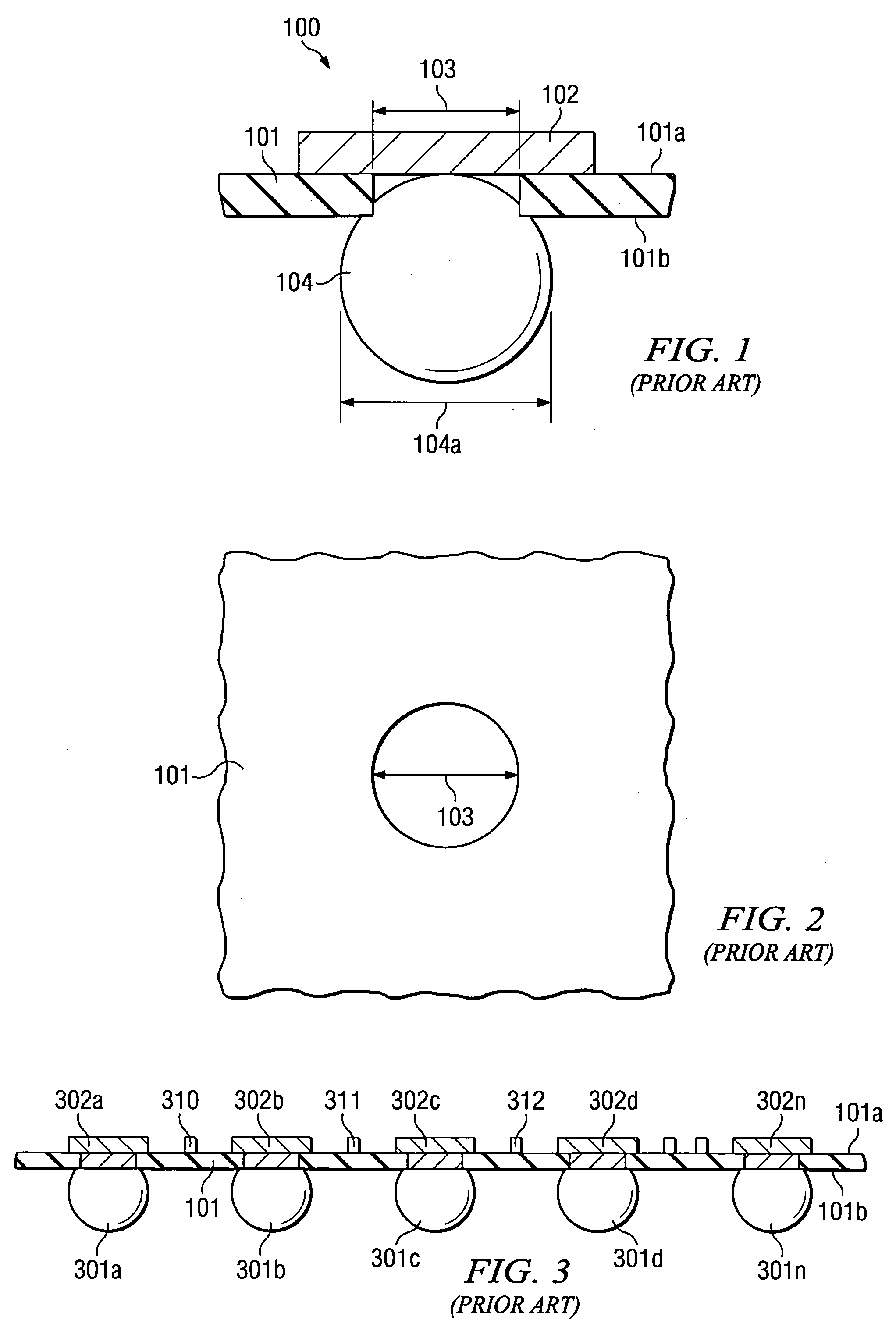

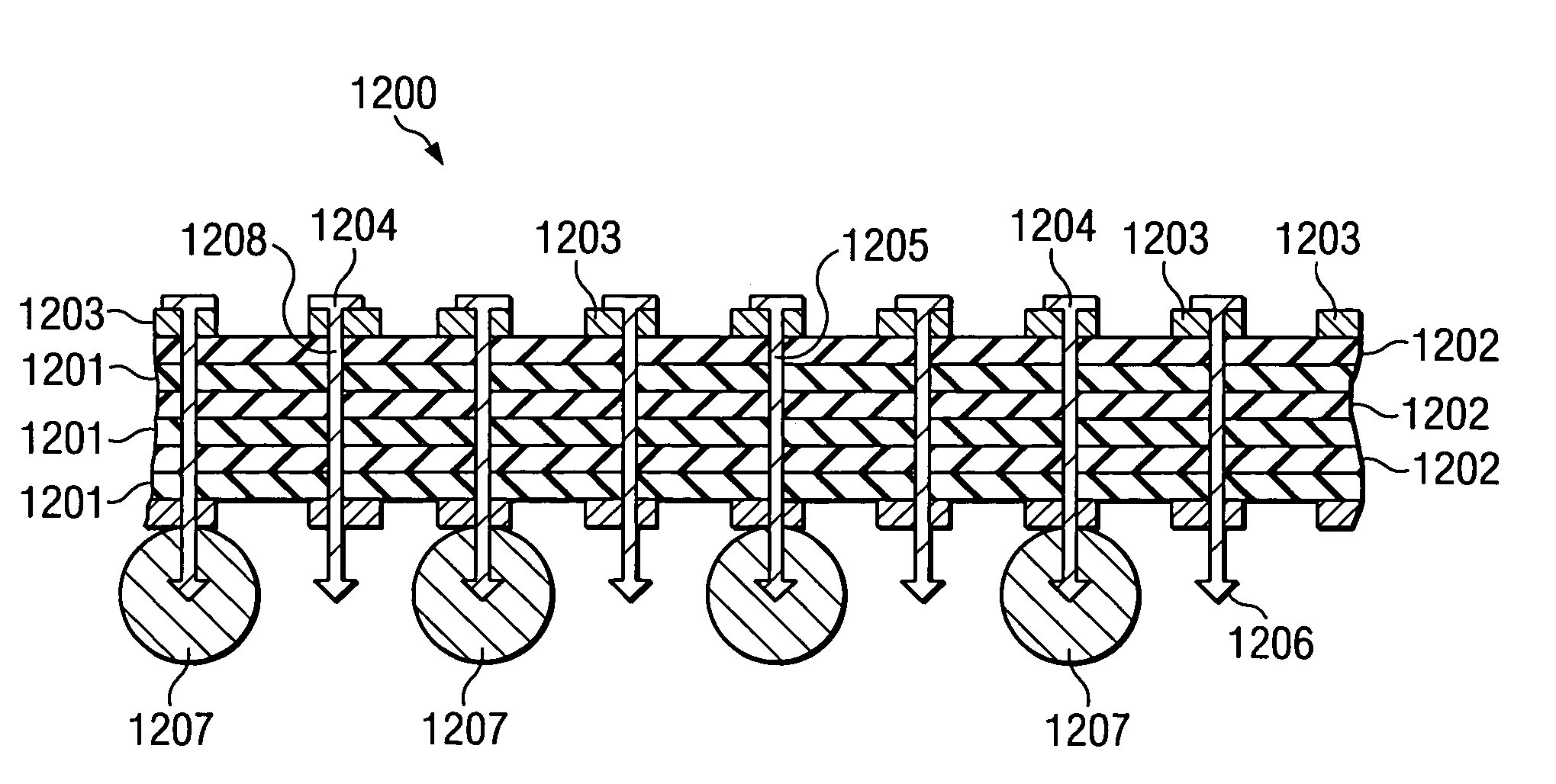

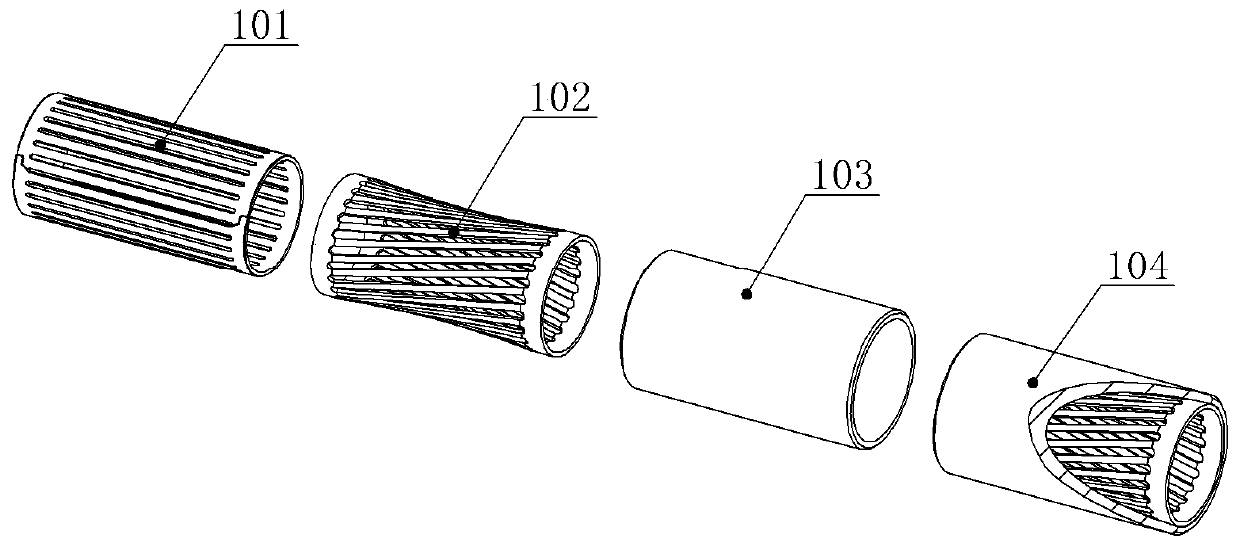

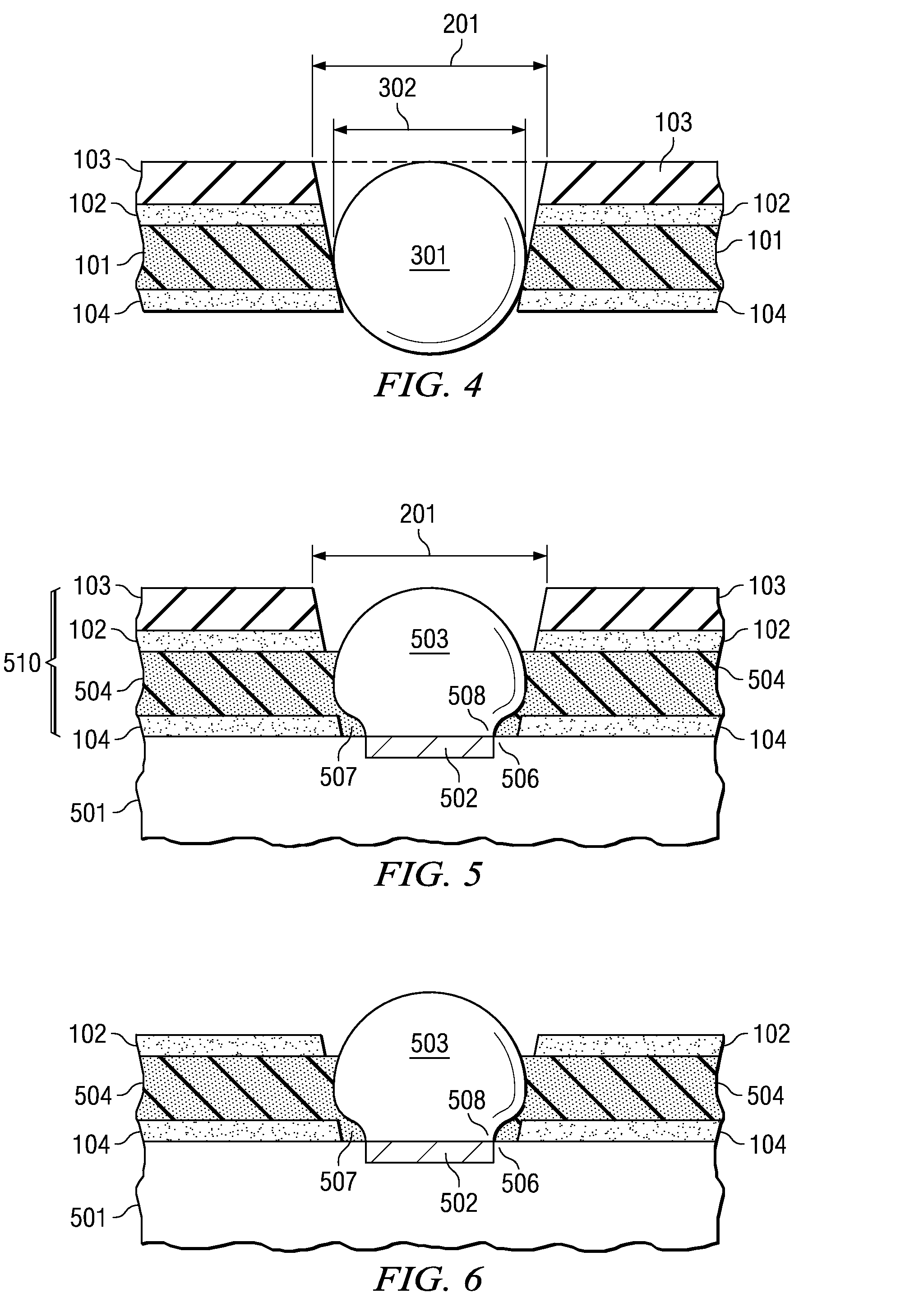

Flip-attached and underfilled stacked semiconductor devices

InactiveUS20070170599A1Reduce thermomechanical stressSimple process flowFinal product manufactureSemiconductor/solid-state device detailsDevice materialMagnetic tape

A tape for use as a carrier in semiconductor assembly, which has one or more base sheets 101 of polymeric, preferably thermoplastic, material having first (101a) and second (101b) surfaces. A polymeric adhesive film (102, 104) and a foil (103, 105) of different, preferably inert, material are attached to the base sheet on both the first and second surface sides; they thus provide a thickness (120) to the tape. A plurality of holes is formed through the thickness of the tape; the holes are preferably tapered with an angle between about 70° and 80° with the second tape surface. A reflow metal element (301), with a preferred diameter (302) about equal to the tape thickness, is held in each of the holes.

Owner:TEXAS INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com