Full-automatic assembling machine for high-voltage large-current connector terminal and process method of full-automatic assembling machine

A high-current connector, fully automatic technology, applied in assembly machines, metal processing, manufacturing tools, etc., can solve problems such as overlapping and misalignment at the opening of the reed, affecting the performance of insertion and extraction force, and affecting the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

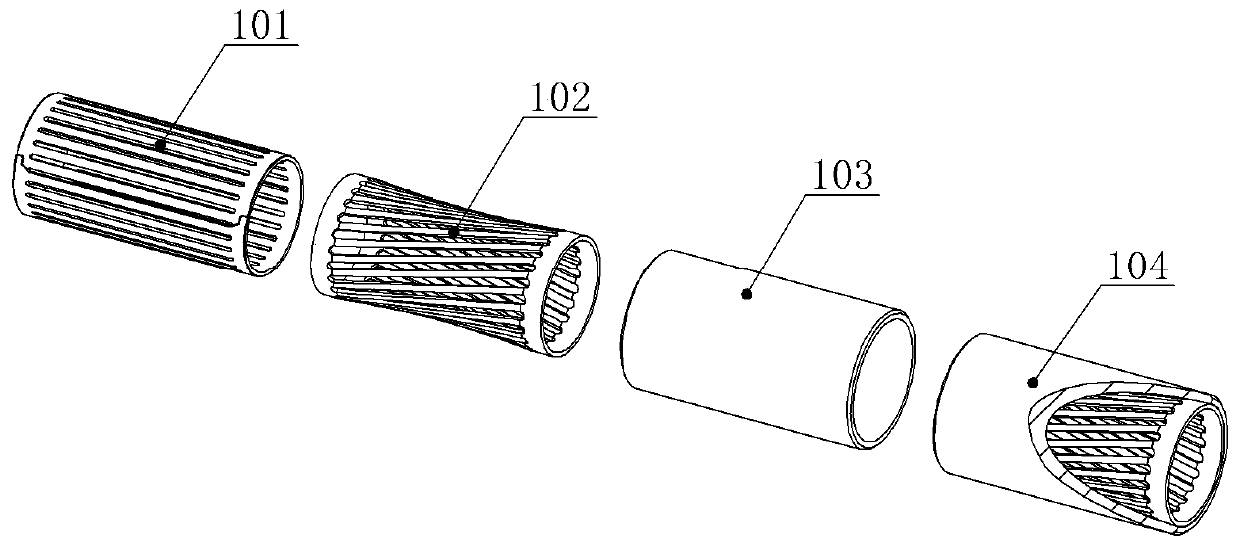

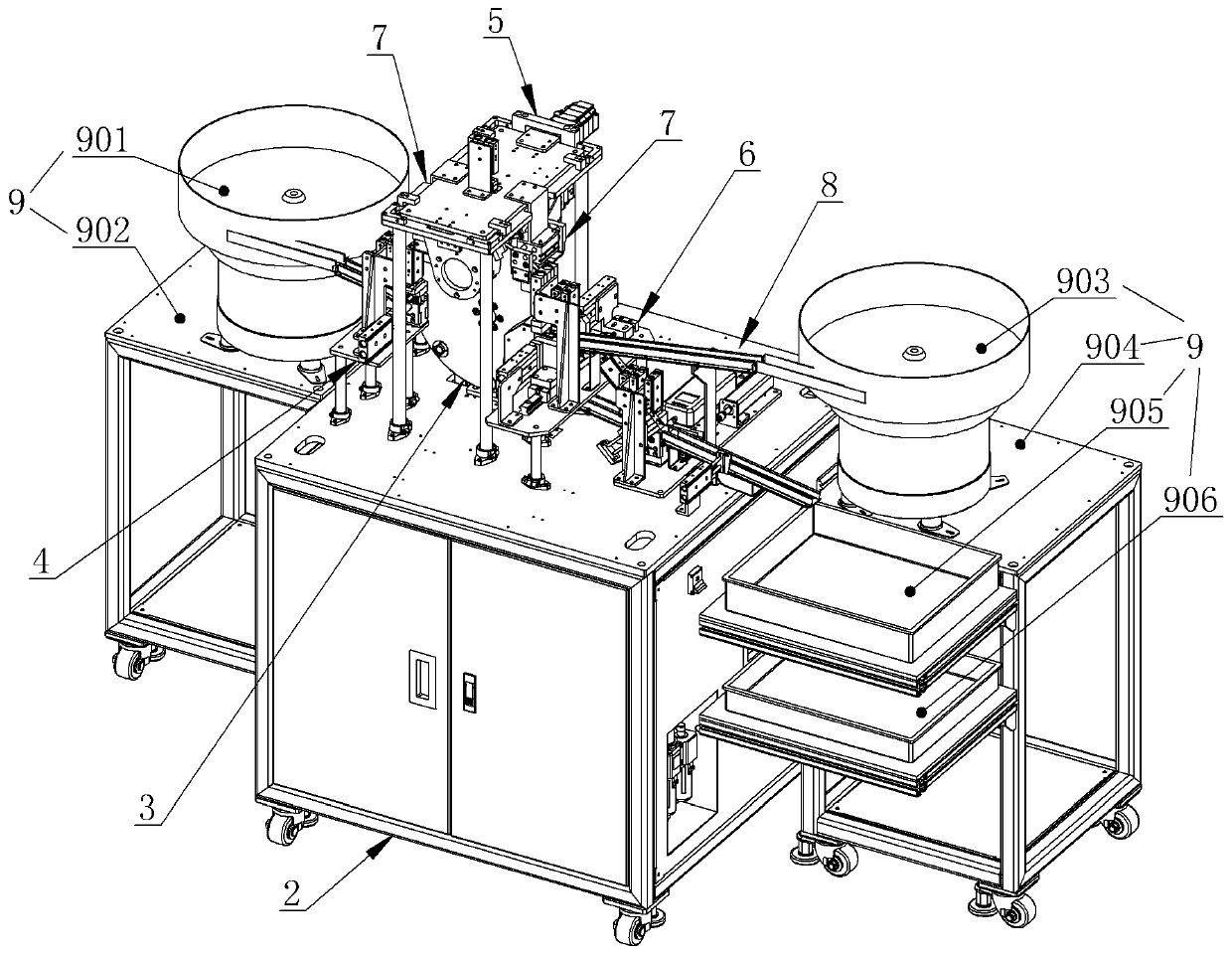

[0078] like figure 1 and figure 2 As shown, this embodiment is a high-voltage and high-current connector terminal automatic assembly machine, which is used to automatically twist the reed 101 to form a torsion spring 102 and assemble it with a copper sleeve 103 to form a connector terminal 104, including a frame table 2, Station indexing device 3 , reed feeding device 4 , torsion spring device 5 , terminal assembly device 6 , clapping device 7 , terminal detection device 8 and vibration feeding device 9 . Through the assembly machine of this embodiment, automatic feeding, automatic material transfer, automatic torsion spring, automatic assembly, automatic detection of insertion and withdrawal force and screening of blanking can be realized, fully automatic assembly and production of connector terminals can be realized, and production efficiency can be significantly improved.

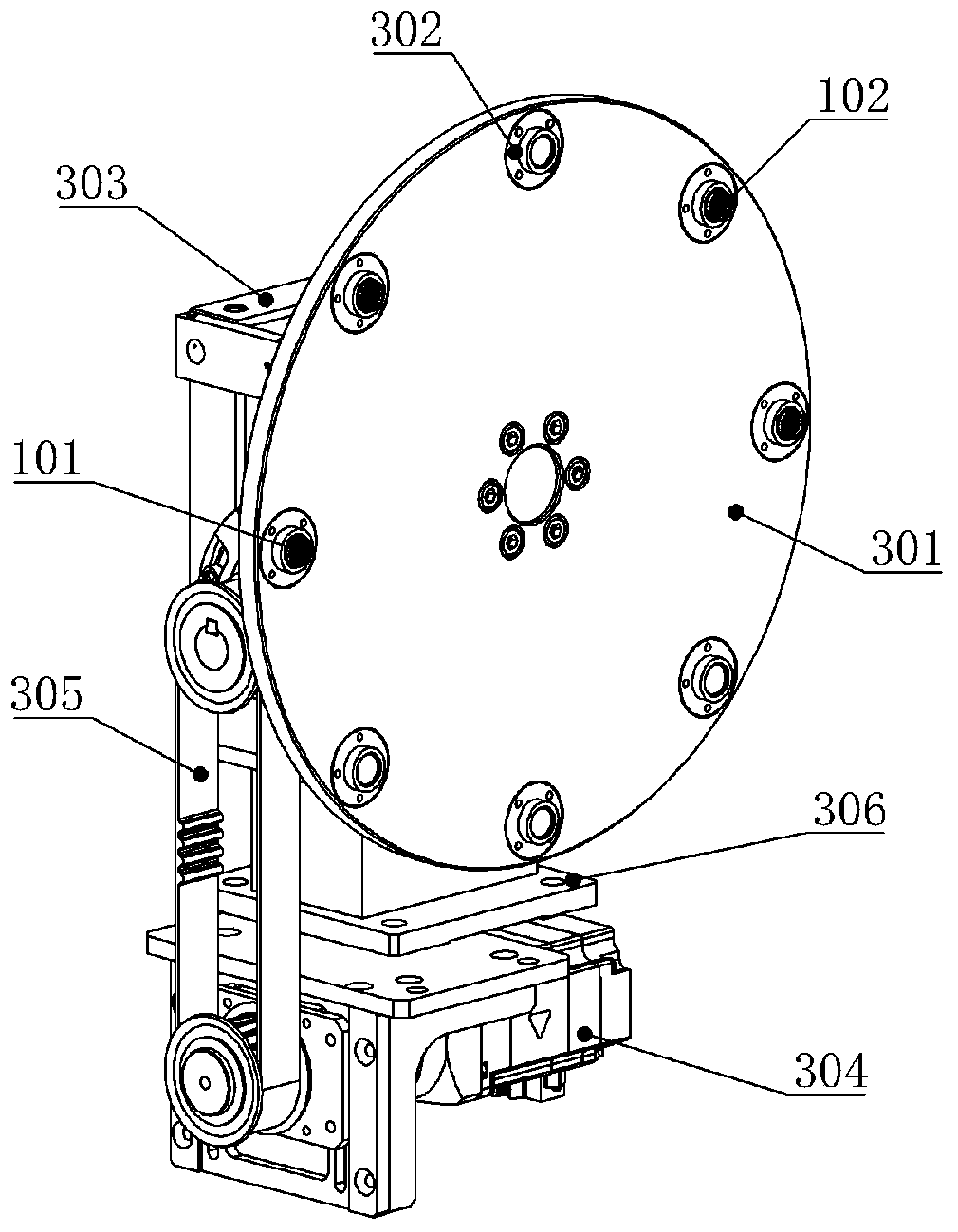

[0079] like figure 2 and image 3 As shown, the station indexing device 3 is installed on the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com