OLED display panel and manufacturing method thereof

A display panel and manufacturing method technology, applied in the direction of electrical components, diodes, electric solid devices, etc., can solve the problems of increasing the luminous efficiency of OLED devices, increasing the encapsulation layer to block water and oxygen pressure, and complicated manufacturing processes, so as to improve the optical effect and bending performance, reducing the risk of luminous efficiency reduction or failure, and optimizing the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

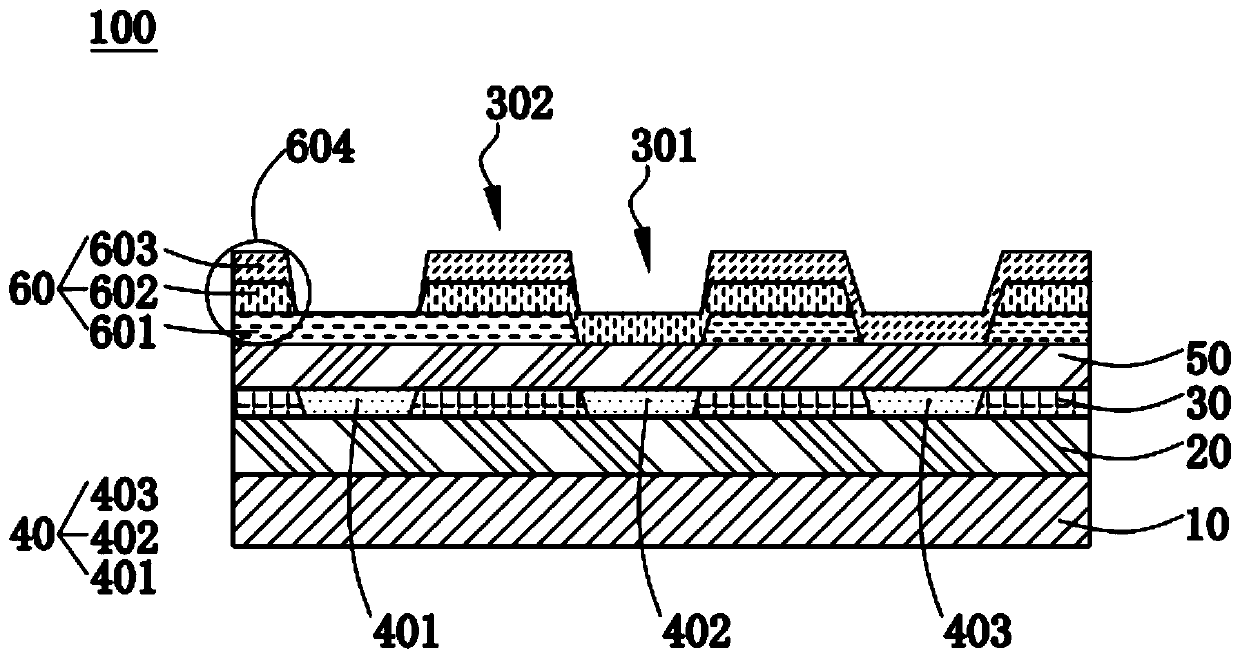

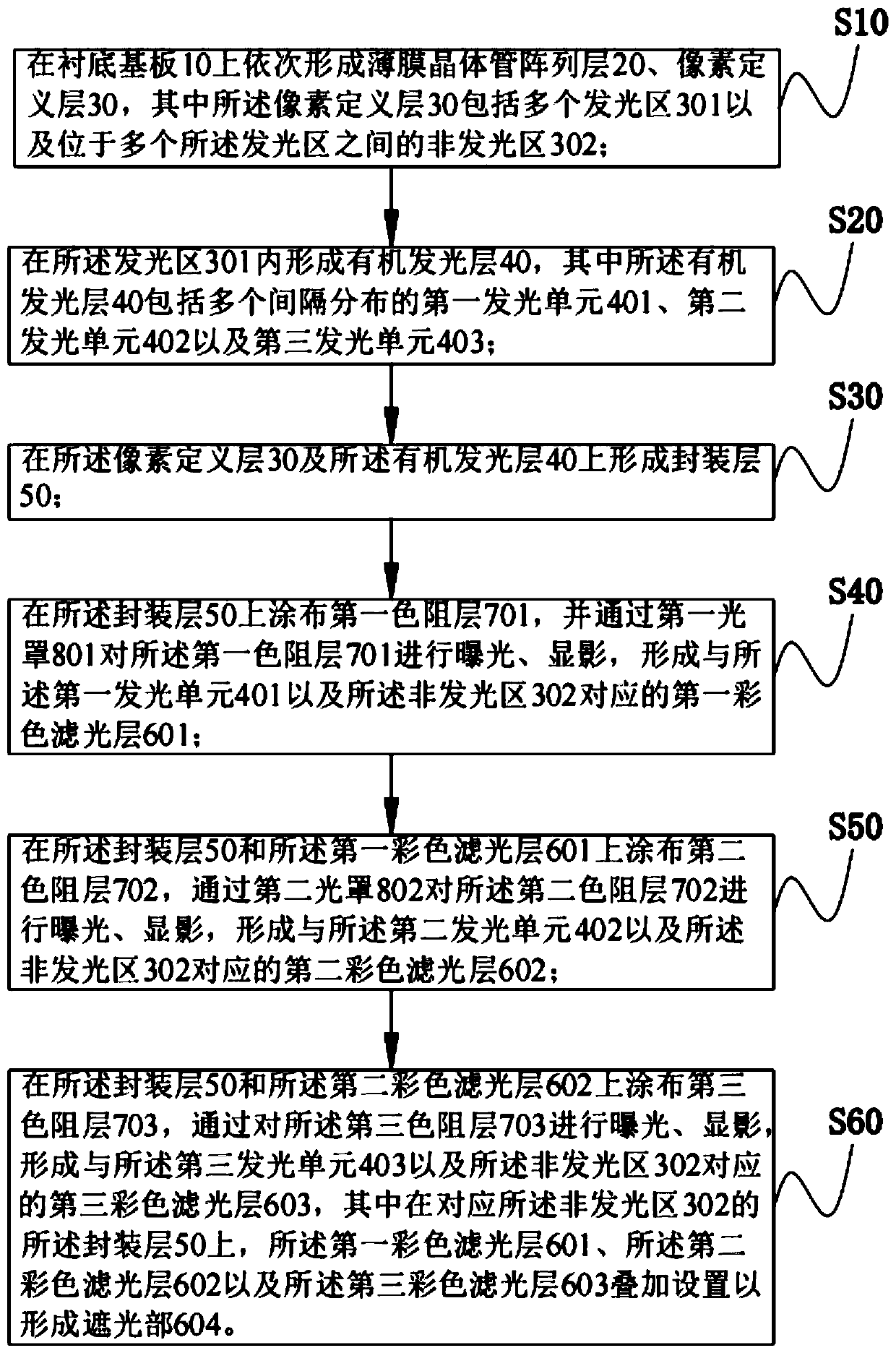

[0056] see figure 2 First of all, it needs to be explained that the embodiment of the present disclosure takes the first color filter layer 601, the second color filter layer 602, and the third color filter layer 603 as an example for illustration and description. Yes, but the embodiments of the present disclosure should not be limited thereto. The manufacturing method of the OLED display panel 100 provided by the disclosed embodiment includes the following steps:

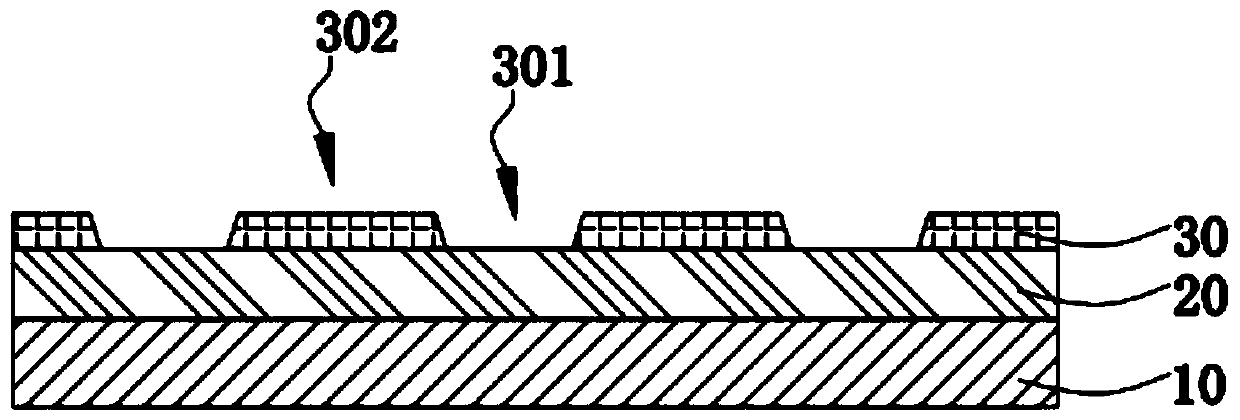

[0057] S10: sequentially forming a thin film transistor array layer 20 and a pixel definition layer 30 on the base substrate 10, wherein the pixel definition layer 30 includes a plurality of light-emitting regions 301 and non-light-emitting regions 302 between the plurality of light-emitting regions;

[0058] Specifically, please refer to image 3 , providing a base substrate 10, the material of the base substrate 10 is PI, the thin film transistor array layer 20 is formed on the base substrate 10, and the thin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com