Patents

Literature

1017results about How to "Optimize process flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solvent composite and preparation method and use thereof

The solvent composition consists of sodium hydroxide 5-12 wt% and urea 8-20 wt% except water. The preparation process of the solvent composition is also provided. Water solution of sodium hydroxideand water solution of urea are mixed to compound the solvent composition; or sodium hydroxide is first compounded into water solution and urea is then added to compound the solvent composition. The solvent composition may be used in directly dissolving natural cellulose and regenerated cellulose to obtain transparent cellulose solution with high dissolubility and high concentration.

Owner:WUHAN UNIV

Semi-finished display panels

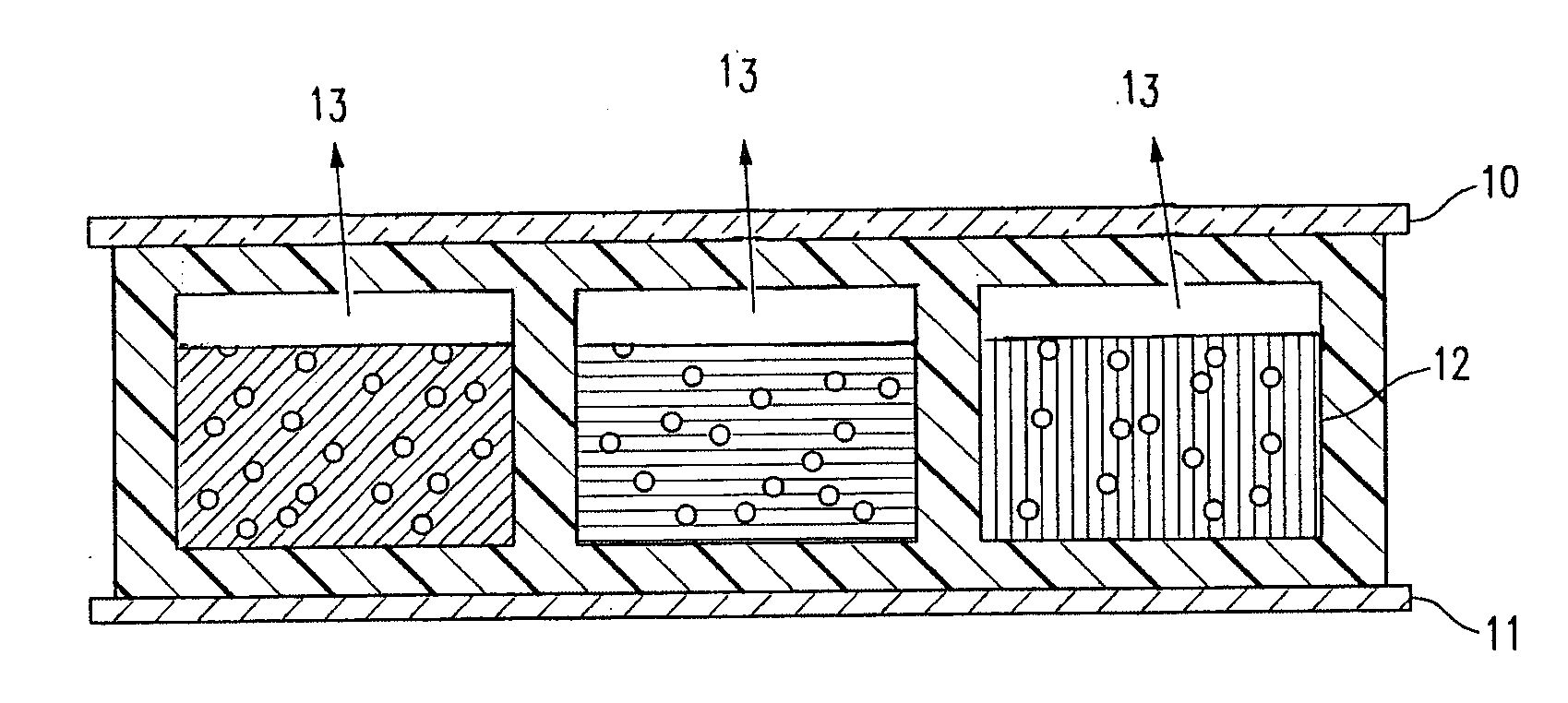

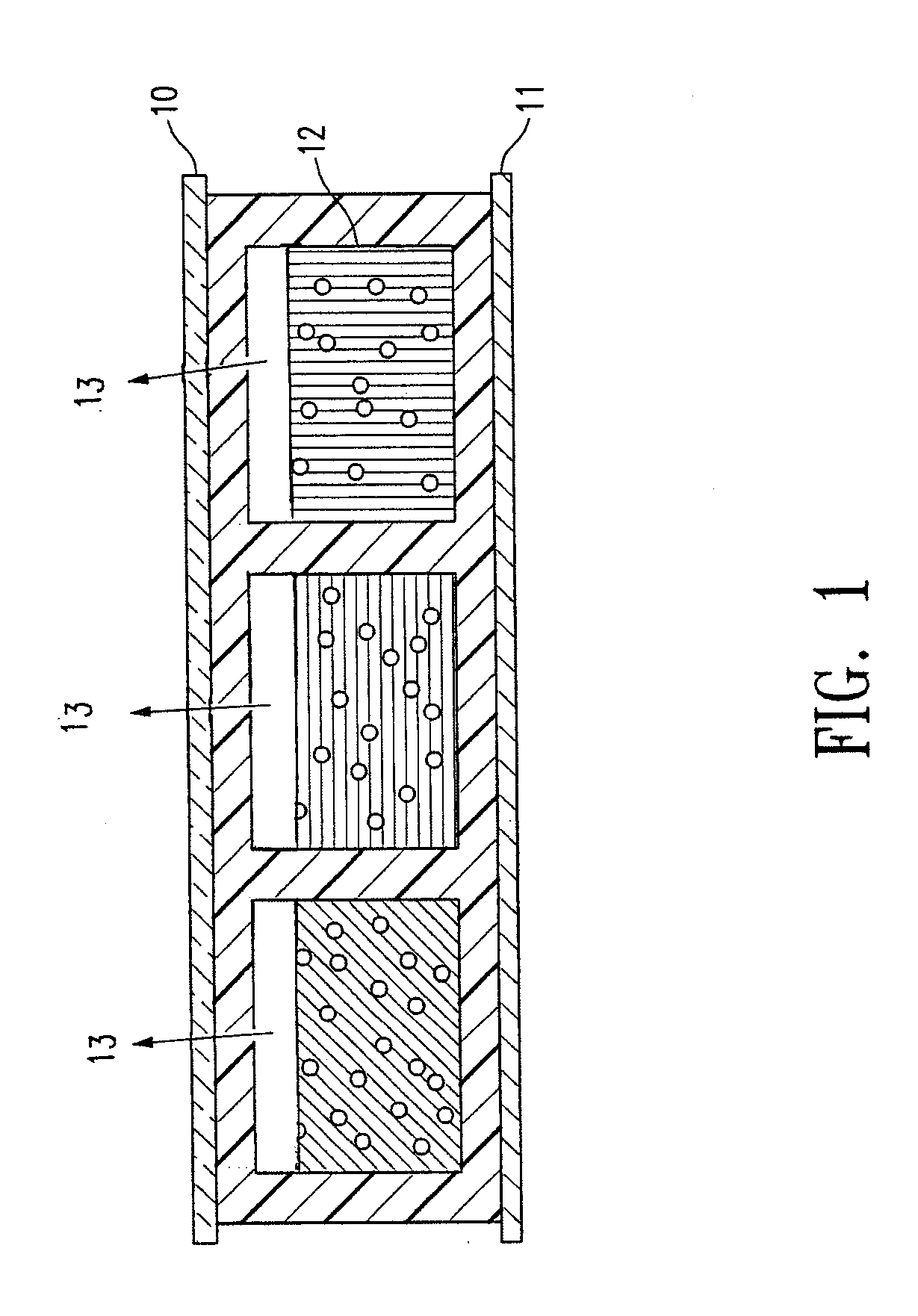

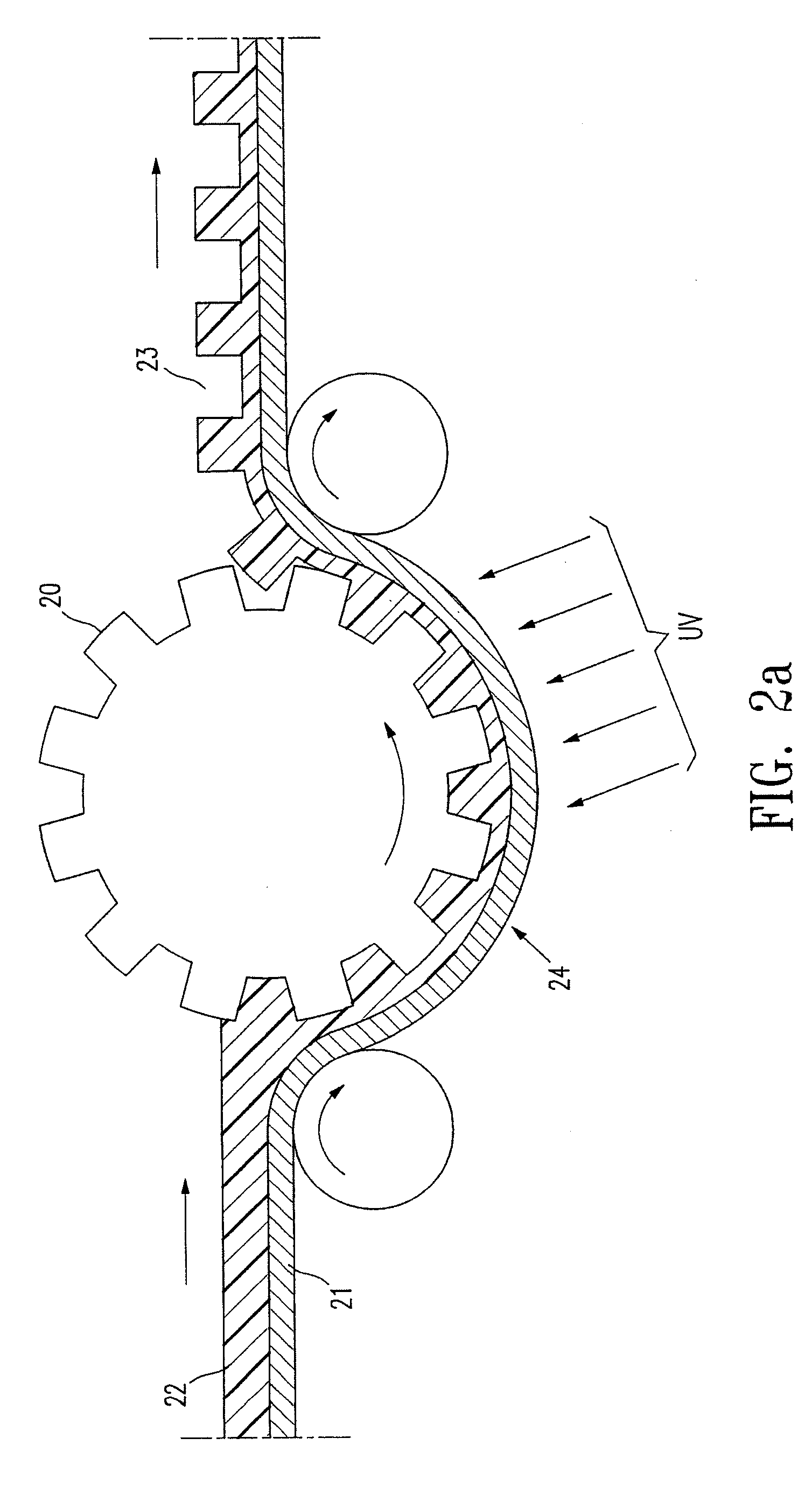

InactiveUS20070237962A1Improve opticalImprove physicomechanical propertyLayered productsElectrographic processes using photoelectrophoresisElectrical conductorEngineering

This application is directed to electrophoretic displays and semi-finished display panels comprising display cells prepared from the microcup and top-sealing technologies. The semi-finished display panel comprises an array of display cells sandwiched between two temporary substrate layers, between a temporary substrate layer and a conductor layer or between a temporary substrate layer and a permanent substrate layer, wherein said display cells are filled with an electrophoretic fluid and top-sealed with a polymeric sealing layer formed from a top-sealing composition which is being hardened while on top of the electrophoretic fluid.

Owner:SIPIX IMAGING INC

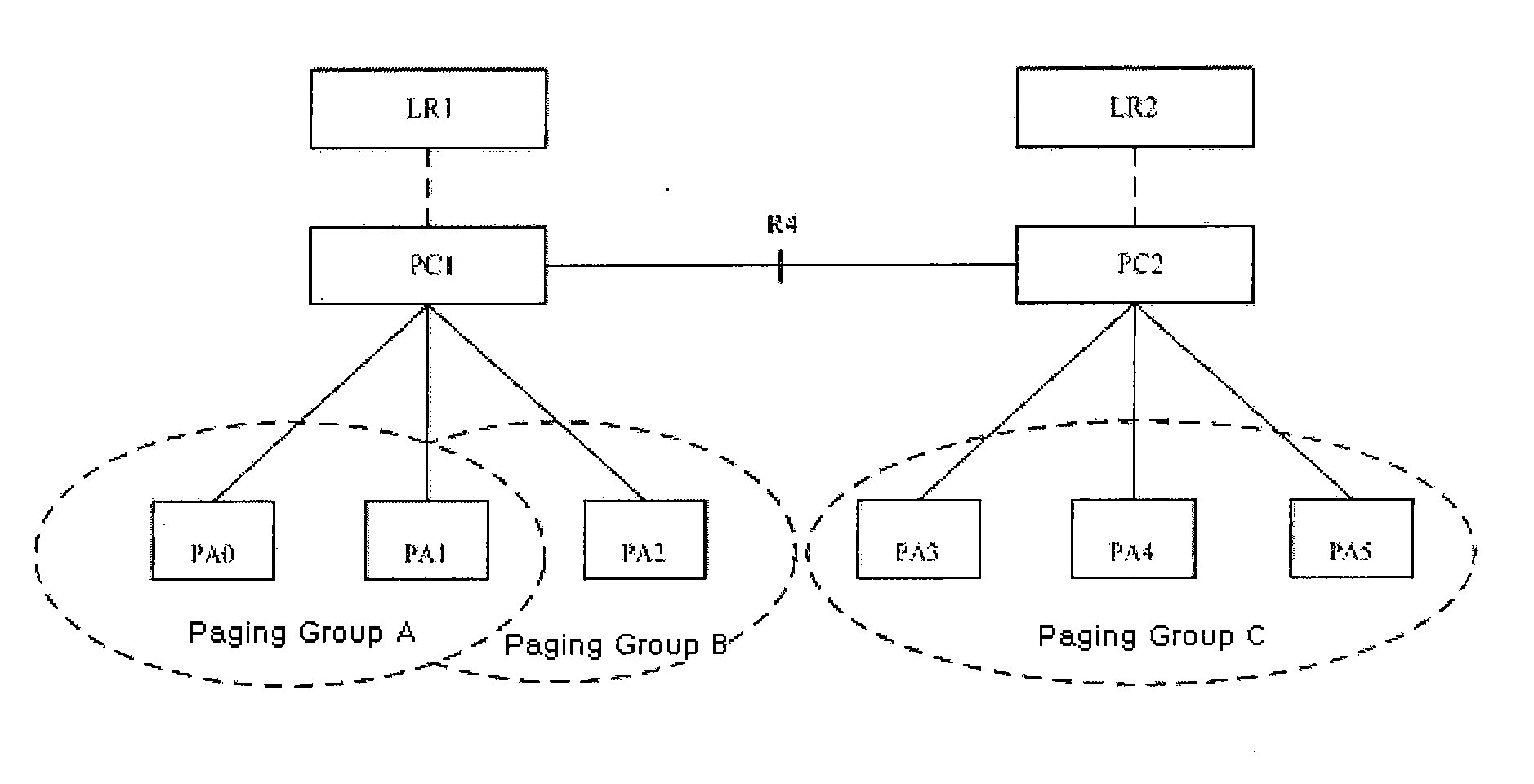

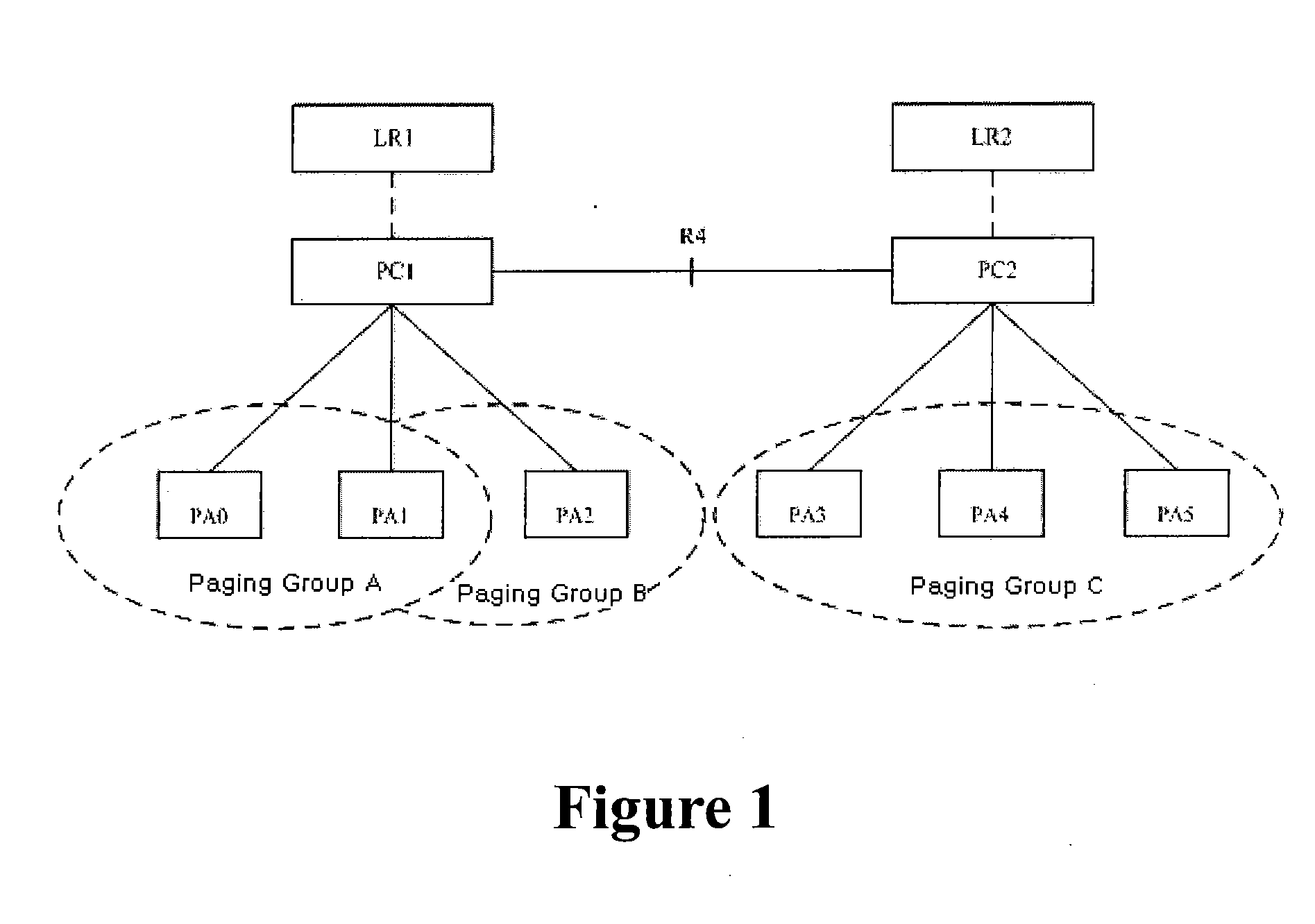

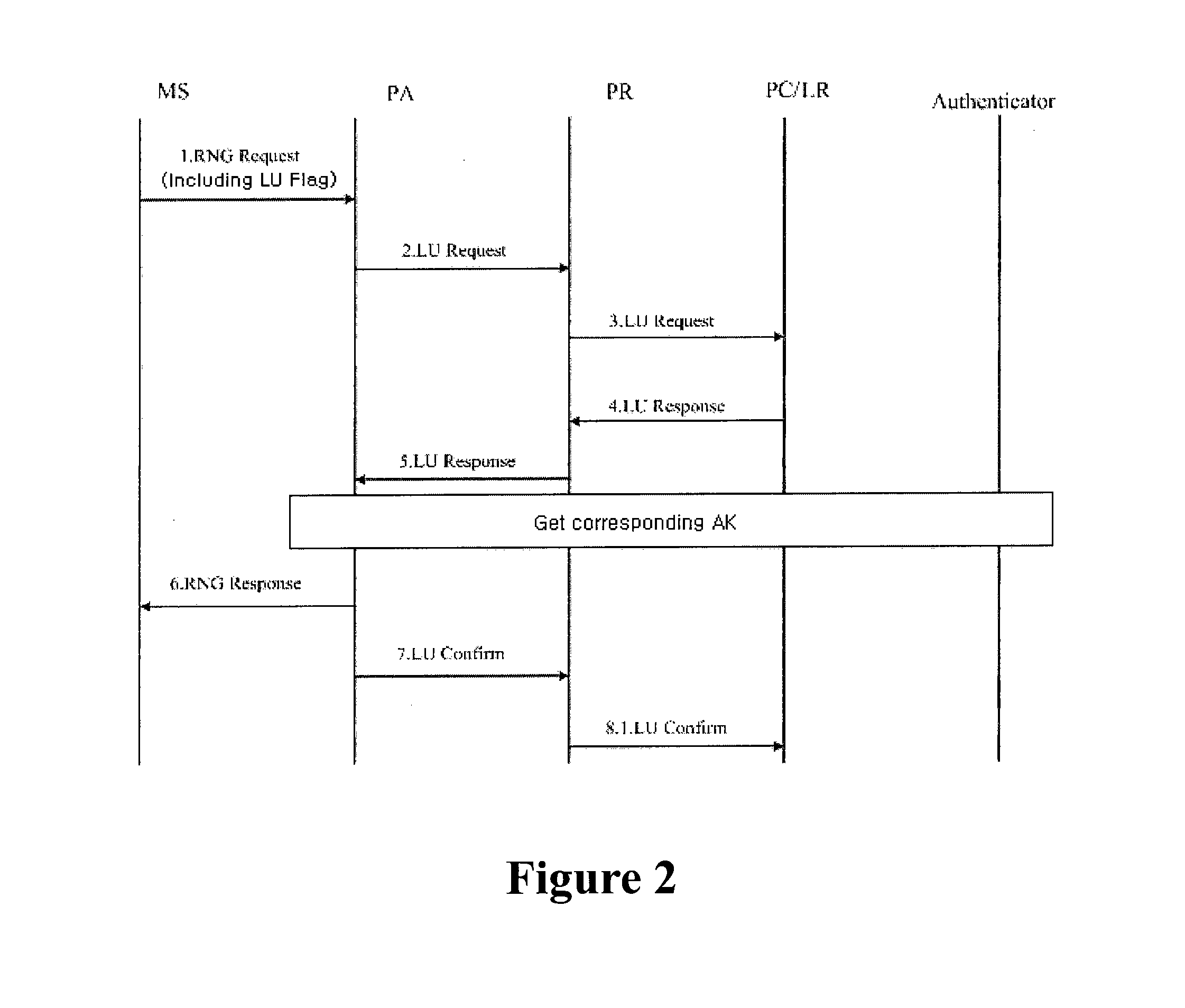

System and method for handling mobile station location update

InactiveUS20070218926A1Optimize process flowImproved location update success rateRadio/inductive link selection arrangementsWireless commuication servicesTelecommunicationsMobile station

The present invention relates to WiMAX communication technology, and particularly relates to a method and a system for handling Mobile Station location update in a WiMAX system, in order to solve the problems in the existing technology that a Paging Controller cannot perform a corresponding process based on the location update type of the Mobile Station, which results in location update low success rate. In the aforesaid technical proposal of the present invention, when a Paging Agent performs location update in a Mobile Station, it sends a location update request to a Paging Controller, and the location update request carries information indicating the Mobile Station location update type; after the Paging Controller successfully performs location update in the Mobile Station, it performs the corresponding process to the information indicating the location update type. The said location update type information is indicated through a corresponding flag bit set in the relevant message or an optional information unit.

Owner:HUAWEI TECH CO LTD

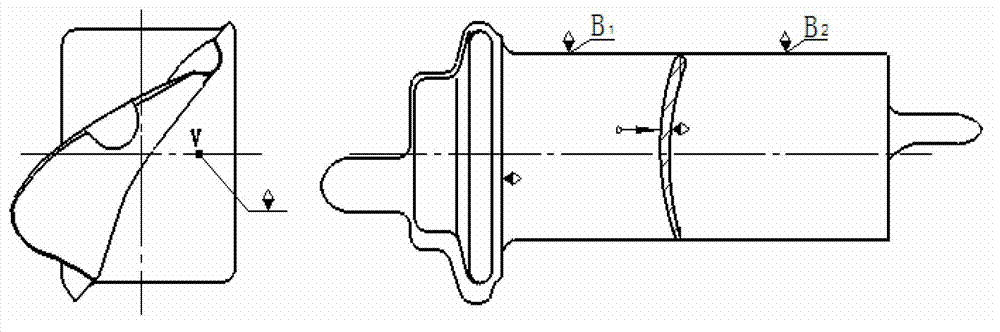

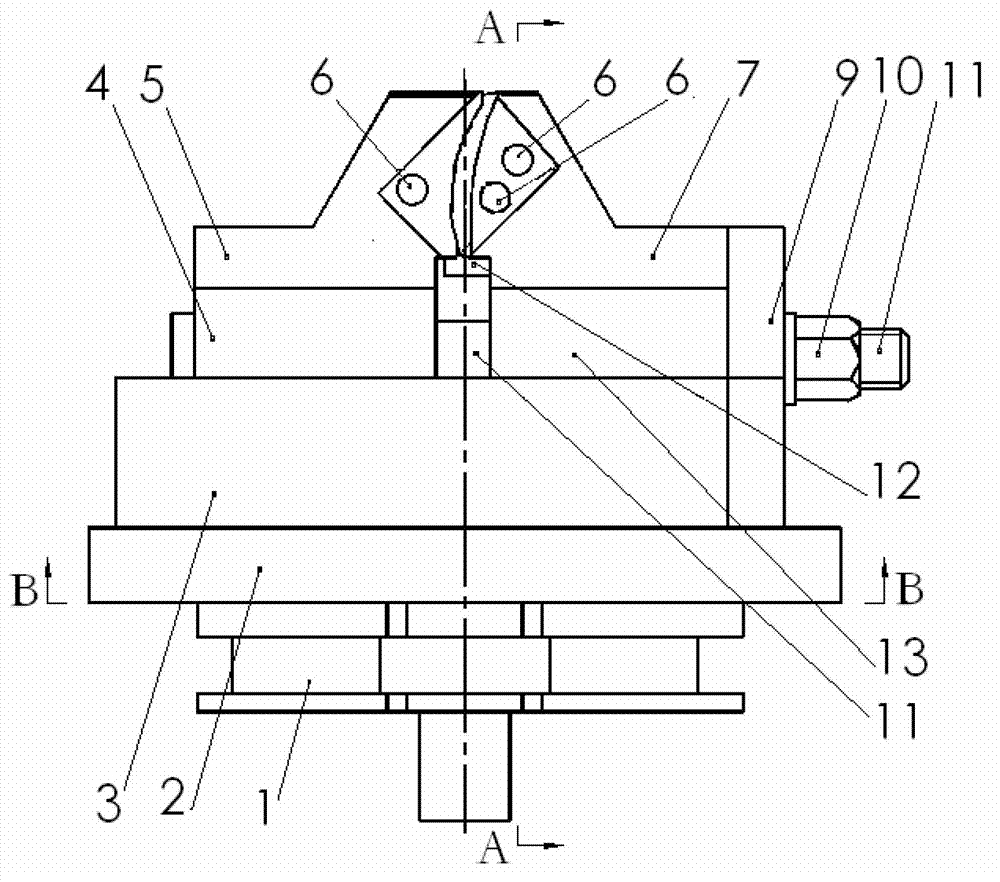

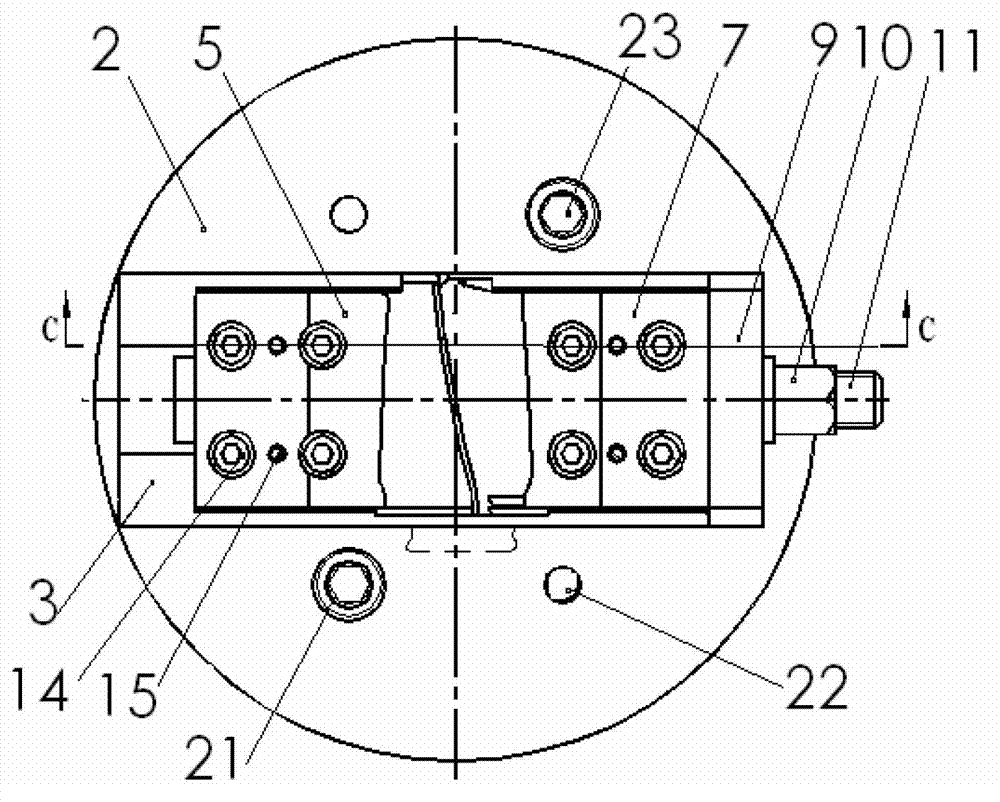

Method and clamp for moulding surface positioning clamping of finish forge blade

ActiveCN102773733AImprove rigidityImprove quality and efficiencyPositioning apparatusMetal-working holdersAdhesiveEngineering

The invention relates to a method and a clamp for moulding surface positioning clamping of a finish forge blade. According to the method, a vane is subjected to positioning clamping through a basin mounding surface of the blade, an inner side moulding surface of a blade root marginal plate, and a V point on the inner side mounting surface of the blade root marginal plate, by the positioning of an air inlet edge, and the clamping of a back mounding surface of the blade, as well as by using a high-accuracy positioning adhesive, and an adhesive coating method, and through a positioning block of the basin moulding surface of the blade and a clamping block of the back moulding surface of the blade. According to the method and the clamp, a satisfying contact area can be obtained by adoption of the high-accuracy adhesive, and the positioning rigidity of the blade is enhanced by adoption of the basin moulding surface of the blade, the inner side moulding surface of the blade root marginal plate and the V point on the inner side moulding surface of the blade root marginal plate for the positioning. According to the method and the device, the problems that the accurate positioning is difficult to realize and the moulding surface of the blade deforms or is damaged because the blade is thin, the blade body is small and the moulding surface is complex are solved. By the method and the device, the positioning accuracy of the mechanical processing of the blade is improved, and the technological process is optimized, so that the processing quality and the production efficiency of the blade are improved, the process is simple, the number of fixtures is reduced, the processing cycle is shortened, and the production cost is reduced.

Owner:AECC AVIATION POWER CO LTD

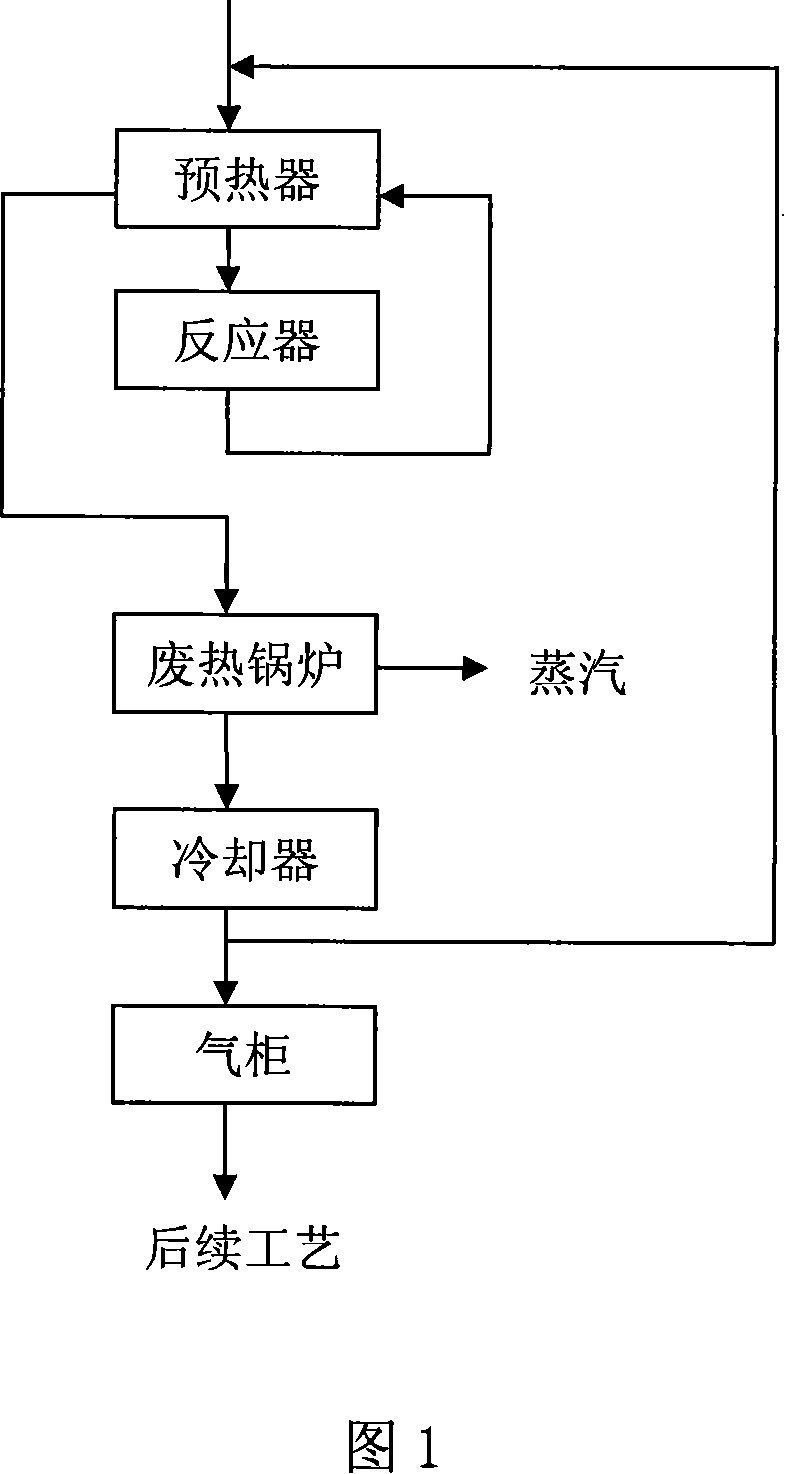

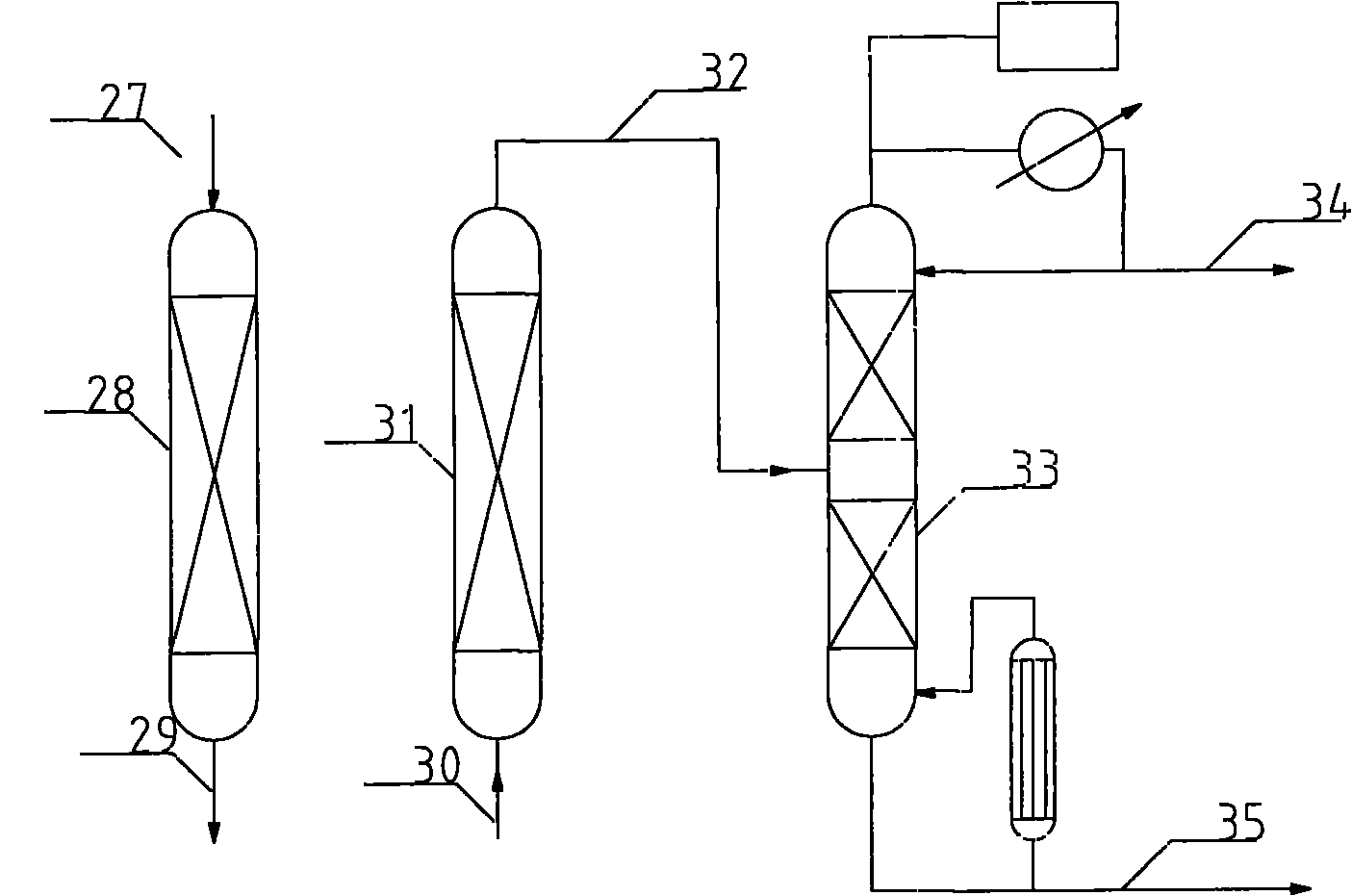

Sulfur-resistant catalytic deoxidization process for methane-rich gas

InactiveCN101139239ALow priceSulfur resistanceMetal/metal-oxides/metal-hydroxide catalystsChemical modification purification/separationReaction temperatureManganese

The present invention discloses a sulfur wearable and catalyzing and oxidizing method for gas abundant of firedamp; the raw material gas abundant of firedamp such as coal bed gas firstly passes through a preheater for preheating, and then enters a oxidizing reaction device; under the condition of 0-0.5MPa of pressure, 500-750 DEG C of reaction temperature, 1000-3000h-1of reaction air speed, the firedamp in the air is reacted with oxygen to produce carbon dioxide and water in manganese base sulfur wearable and catalyzing and oxidizing bed; at the same time, a small quantity of firedamp is decomposed to produce carbon and hydrogen gas; the carbon and the hydrogen after being decomposed are also reacted with oxygen so as to reach the purpose of getting rid of oxygen in the airs abundant of firedamp effectively. The present invention adopts much newer and more economical new catalyzer, which does not need to desulfurize firstly for the air; the air can directly enter the oxidization reaction device for oxidization. So the present invention can decrease the cost and simplify the technics process.

Owner:HAO HUA CHENGDU TECH

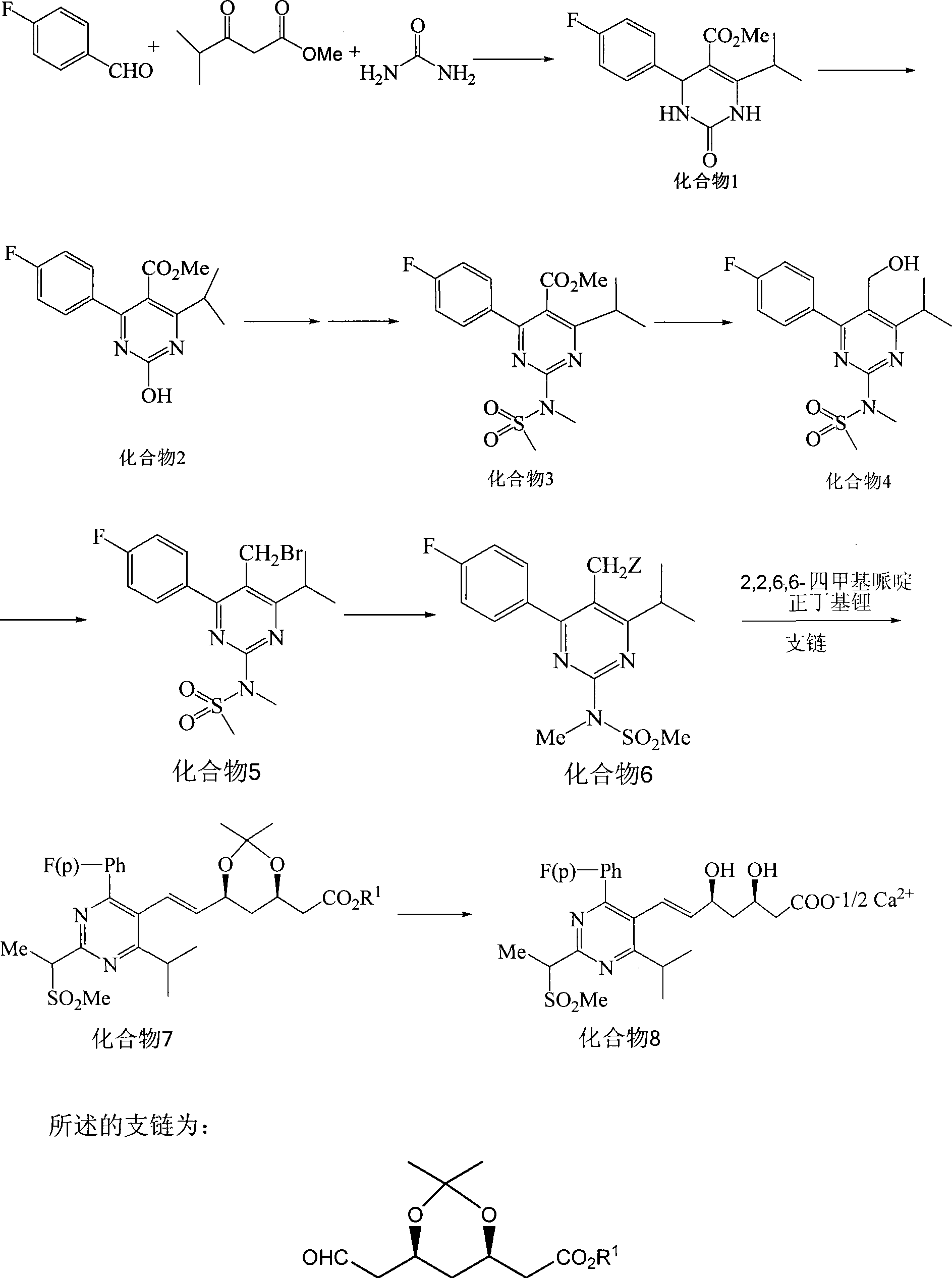

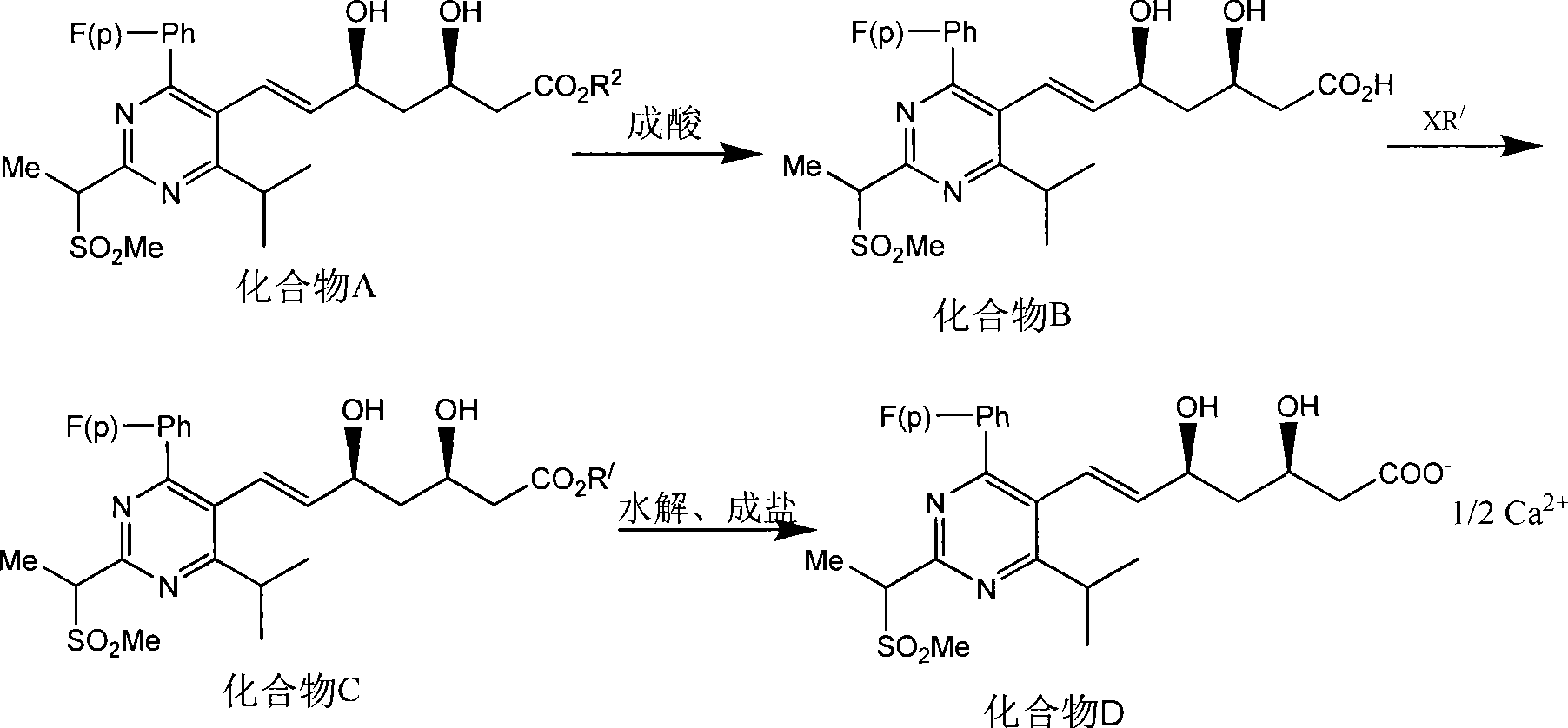

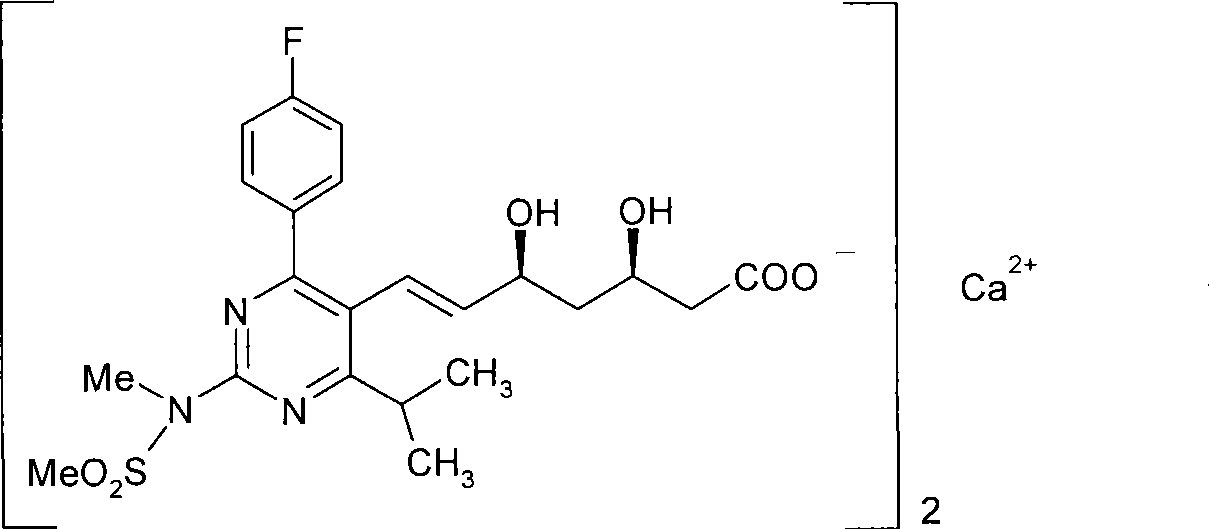

Method for synthesizing rosuvastatin intermediate and rosuvastatin

The invention provides a synthetic method of rosuvastatin calcium, which is characterized in that a compound 6 and branched chain react under the action of 2,2,6,6,-tetramethylpiperidine and n-butyl lithium to generate a compound 7, the reaction temperature is increased to minus 30 DEG C and the aspects such as reaction solvent and reaction reagent are improved so that the total reaction route has the advantages of mild condition, low device requirement and suitability for industrial production. Meanwhile, another improved synthetic route of rosuvastatin calcium comprises the following steps: converting esters into acids, synthesizing esters again, and synthesizing the rosuvastatin calcium. The rosuvastatin calcium purity is as high as 99.8%.

Owner:ENANTIOTECH CORP

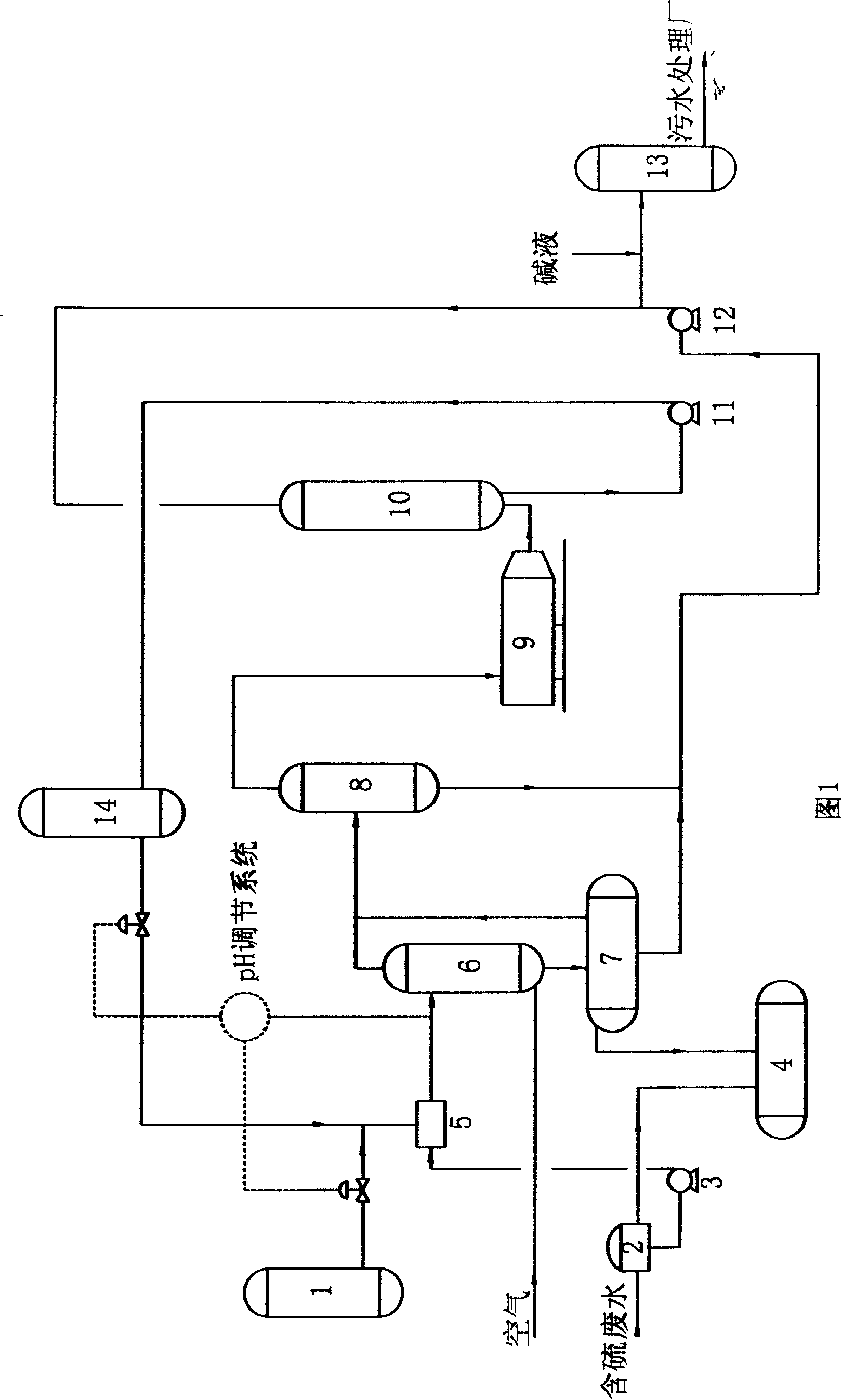

Method for treating sulfur-containing waste water

ActiveCN101239758ALess quantityLow costFatty/oily/floating substances removal devicesWater contaminantsWastewaterSewage

The present invention relates to a method for treating the sulfur-containing sewage. The industrial process of the invention is firstly adding sulfuric acid into the sulfur-containing sewage, adjusting pH value to 4-6, aerating with appropriate amount of air, facilitating the escaping of the H2S along with the air, and discharging the discharged water to the sewage treatment plant after adding alkali for neutralization. The aeration end gas containing H2S enters the incineration furnace or catalyzing burning reactor to generate SO2 and SO3, the SO2 and SO3 are absorbed by the absorption liquid to form a diluted acid. The generated diluted acid can be used back for adjusting pH to the sulfur-containing sewage, when the system operates normally basically no fresh sulfuric acid is added into the sulfur-containing sewage, the entire technique forms a closed system for treating the sulfur-containing sewage, the application range is broad and the cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oxygen-containing coal bed gas deoxidation catalyst and preparation thereof as well as applications

InactiveCN101322942ALow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsMordeniteAluminum silicate

The invention discloses a deoxidizing catalyst for a coal-seam gas containing oxygen and a preparation method as well as an application thereof. The deoxidizing catalyst of the invention consists of an active component, an active auxiliary and a porous carrier. The active component is the compound of Co; the active auxiliary is one or more compounds of Mn, Fe, Zn and Cu; the porous carrier is one or more of aluminum oxide, titanium oxide, zirconium oxide, magnesium oxide, calcium oxide, silicon oxide, a phosphor-aluminium molecular sieve, an A-typed molecular sieve, an X-typed molecular sieve, a Y-typed molecular sieve, a mordenite, a ZSM-5 zeolite, diatomaceous earth, kaolinite, natural clay, aluminum silicate and magnesium silicate; calculated by oxide, the weight percentage of the active component is 1 to 60 percent; the weight percentage of the active auxiliary is 1 to 50 percent; the rest is the carrier. The catalyst of the invention has certain sulfur-resistance performance, is applicable to the deoxidization treatment of coal-seam gas with an oxygen content of 3 to 6 percent (V / V) and is capable of causing the oxygen content in the coal-seam gas to be lower than 0.5 percent by deoxidization.

Owner:HAO HUA CHENGDU TECH

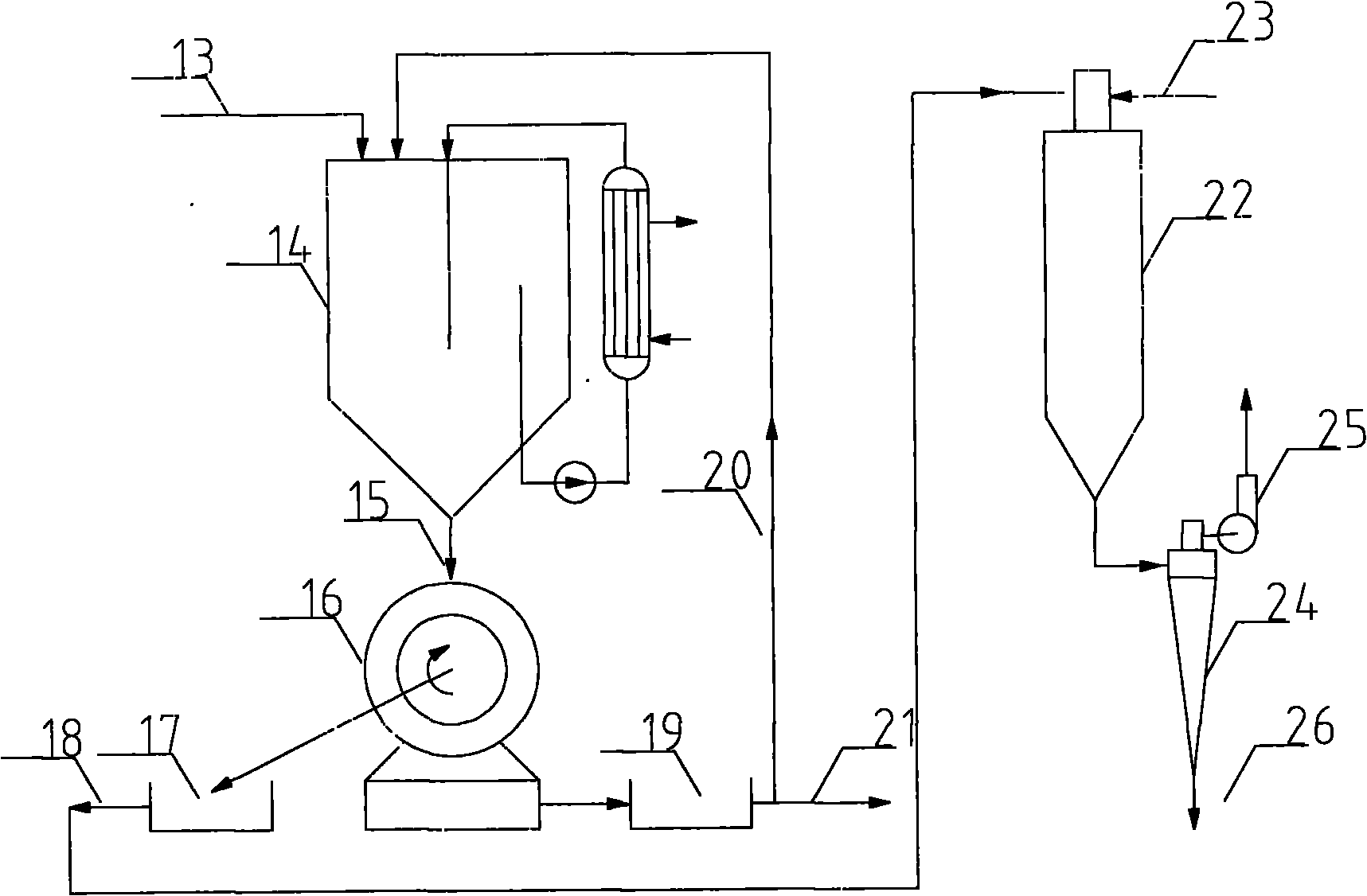

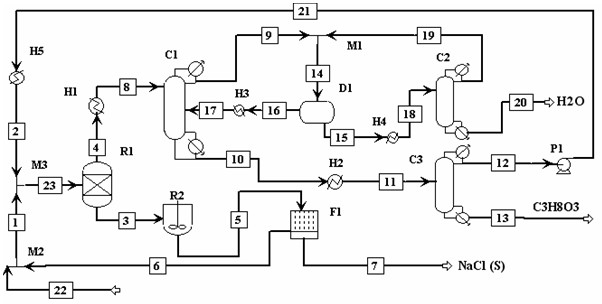

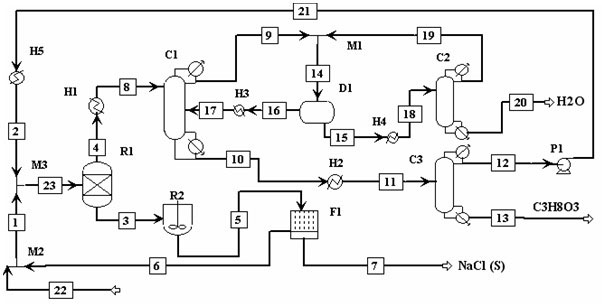

Method for processing wastewater produced in saponification cyclization step in epoxy chloropropane production method

ActiveCN101798154ARealize resourcesOptimize process flowWater contaminantsMultistage water/sewage treatmentEpoxyWastewater

The invention relates to a method for processing organic saponification high-salinity wastewater produced in the production processes of epoxy chloropropane and epoxy-propane. The processing method comprises the steps of concentration of organic high-salinity wastewater, crystallization of calcium chloride, purification and recycling, innocent treatment of mother liquid and the like. The method has simple and convenient technical process, easy operation and control, obvious economic benefit, and environmental protection; the recovery rate of calcium chloride can reach 98%, and the recovery rate of glycerine can reach 88%, thereby changing pollutant into resources.

Owner:NINGBO HUANYANG CHEM

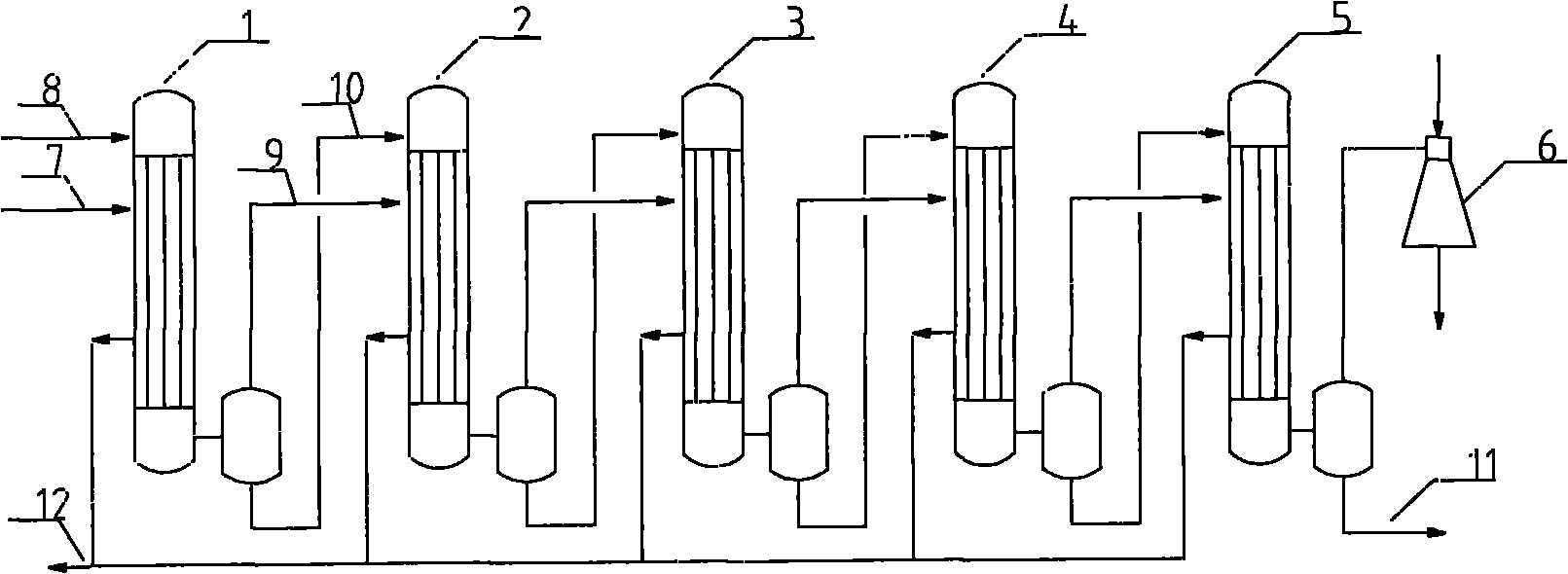

Process for preparing regenerated cellulose films and wires

The invention discloses a method for manufacturing cellulose film and silk. The cellulose is dissolved in mixed liquid 5-12wt% natrium oxyhydrogen and 8-20wt% ureophil, gets the cellulose liquid, then carries on film scratching and silk spraying to the cellulose, they are solidified in the solidifying bath, then the regenerated cellulose film and silk will be got after being cleaned. The cellulose thick liquid has excellent fiber textile performance and compactibiity of film, the regenerated cellulose has excellent light transmission and mechanical performance, the silk also has good mechanical performance. The method can obtain cellulose thick liquid by dissolving cellulose in room temperature. It has no contamination and its price is low, it is a kind of green manufacturing process.

Owner:WUHAN UNIV

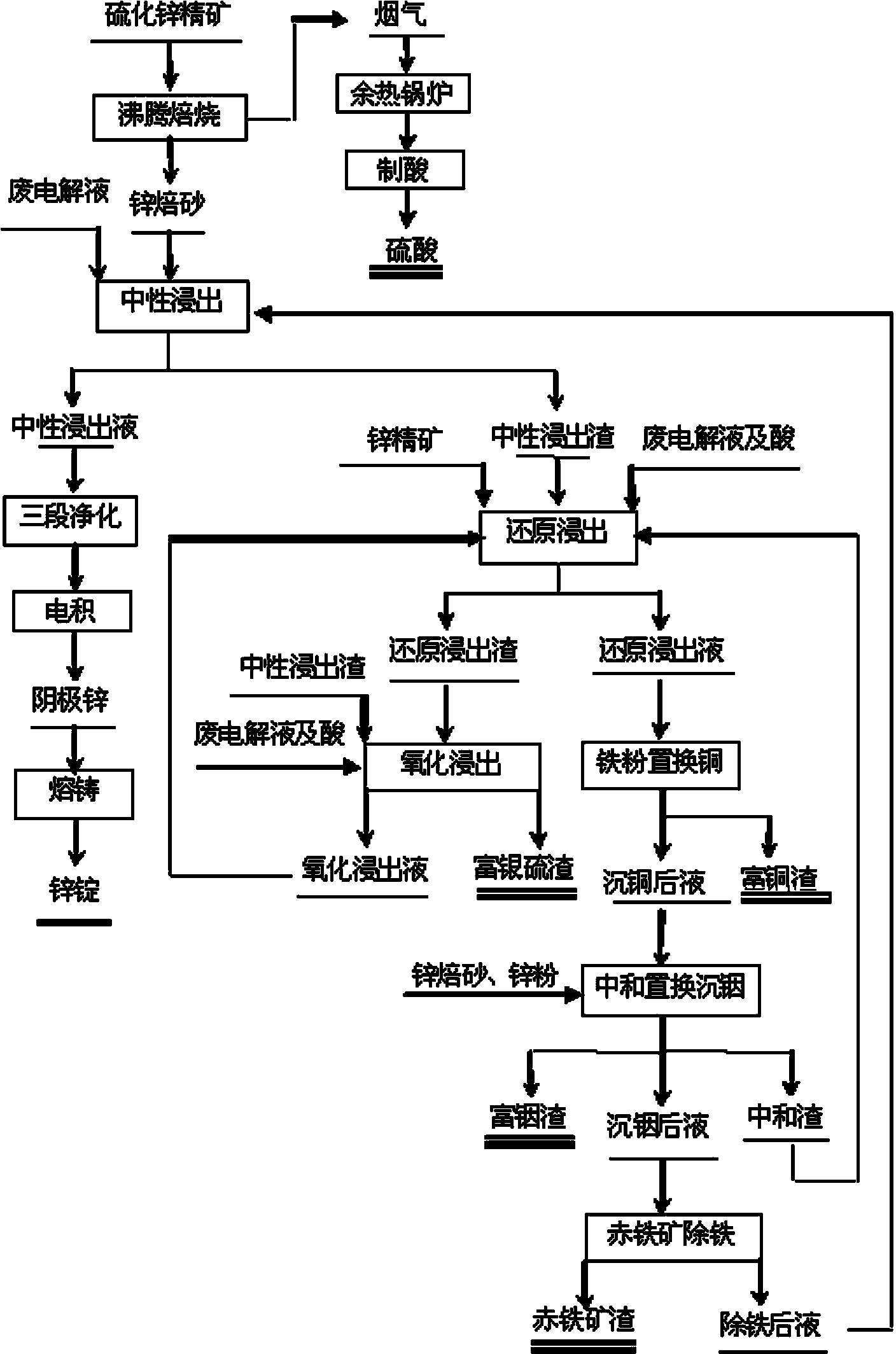

Method for individually processing high-iron zinc sulfide concentrate

ActiveCN103409622AThe process is highly targetedHigh enrichment ratioProcess efficiency improvementIndiumHydrometallurgy

The invention belongs to the technical field of hydrometallurgy, and particularly relates to a method for individually processing high-iron zinc sulfide concentrate. The method comprises a step of subjecting the high-iron zinc sulfide concentrate to calcination in a fluidized bed combustion boiler to obtain zinc calcine; a step of subjecting the zinc calcine to neutral leaching to produce neutral leaching solution and neutral leaching residue; a step of, after the neutral leaching residue and the high-iron zinc sulfide concentrate are mixed, successively performing reduction leaching and oxidation leaching, and circulating oxidation leaching solution to the reduction leaching to produce reduction leaching solution and silver-rich sulfur residue; a step of replacing the reduction leaching solution by using iron powder to precipitate copper and to produce copper-rich slag and solution after copper precipitation; a step of subjecting the solution after copper precipitation to pre-neutralization by using the zinc calcine, and then replacing by using zinc powder to precipitate indium and to produce indium-rich slag and solution after indium precipitation; and a step of bubbling oxygen into the solution after indium precipitation, heating and removing iron to obtain iron removal solution and hematite slag. The hematite slag can be utilized as a raw material for ironmaking. The method has strong pertinence, short technological process and high metal recovery yield, and the method is clean, efficient, energy-saving and environmental friendly. Separation and comprehensive utilization of zinc, indium, copper and iron are achieved.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

Process for removing bitter taste of momordica grosvenori extract

InactiveCN1907091AQuality improvementWide range of applicationsFood preparationIon-exchange membranesChemistry

The invention discloses an extracting method of bitter from Momordica grosvenori, which comprises the following steps: 1. adding Momordica grosvenori with 60-90% Momordica grosvenoritin in the pure water; dissolving to blend evenly to obtain Momordica grosvenori extract liquid; 2. proceeding positive and negative ion exchanging resin or composite ionic exchanging resin or negative and positive exchanging resin sequently to remove impurity; removing bitter material; 3. spraying to dry the powder of Momordica grosvenori extract.

Owner:湖北汇特生物医药技术有限公司

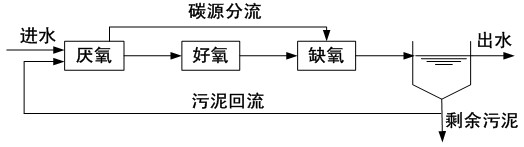

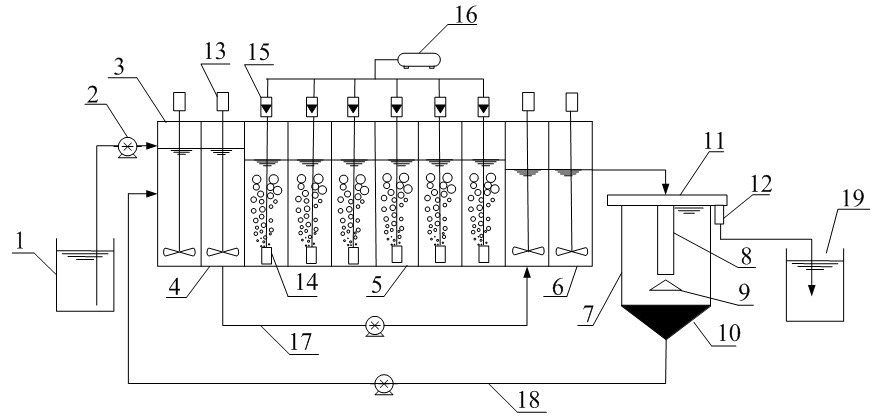

Rear denitrifying sewage treatment device and process

InactiveCN102153236AImprove utilization efficiencyImprove nitrogen and phosphorus removal efficiencyTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSludgeAir pump

The invention discloses a rear denitrifying sewage treatment device and process. A water inlet bucket, a biochemical tank, a sedimentation tank and a water outlet bucket are connected with each other in sequence; the biochemical tank comprises three parts, such as an anaerobic zone, an aerobic zone and an anoxic zone; blenders are arranged in the aerobic zone and the anoxic zone; the anaerobic zone is connected with the anoxic zone by a carbon source shunt pipe; an aerator is arranged in the aerobic zone; the aerator, a gas flowmeter and a gas pump are connected with each other in sequence; the sedimentation tank comprises a central pipe, a reflective plate, a tank body, a water outlet weir and a water outlet; and the bottom of the sedimentation tank is connected with the anaerobic zone of the biochemical tank by a sludge backflow pipe. By using a single-sludge system, the device and process, disclosed by the invention, operate in the form of continuous flow according to an anaerobic-aerobic-anoxic mode. A mixed solution rich in polyhydroxyalkanoate in the anaerobic zone is shunted to the aerobic zone to provide phosphorus-accumulating bacteria with a carbon source so that the denitrifying phosphorus removal is realized in the aerobic zone. The device and process, disclosed by the invention, have the advantages of good nitrogen and phosphorus removal effect, simple process flow, low operation energy consumption, high carbon source utilization rate and the like, and are applicable to treatment of sewage (wastewater) with low C / N (Carbon / Nitrogen) ratio and low C / P (Carbon / Phosphorus) ratio.

Owner:ZHEJIANG UNIV

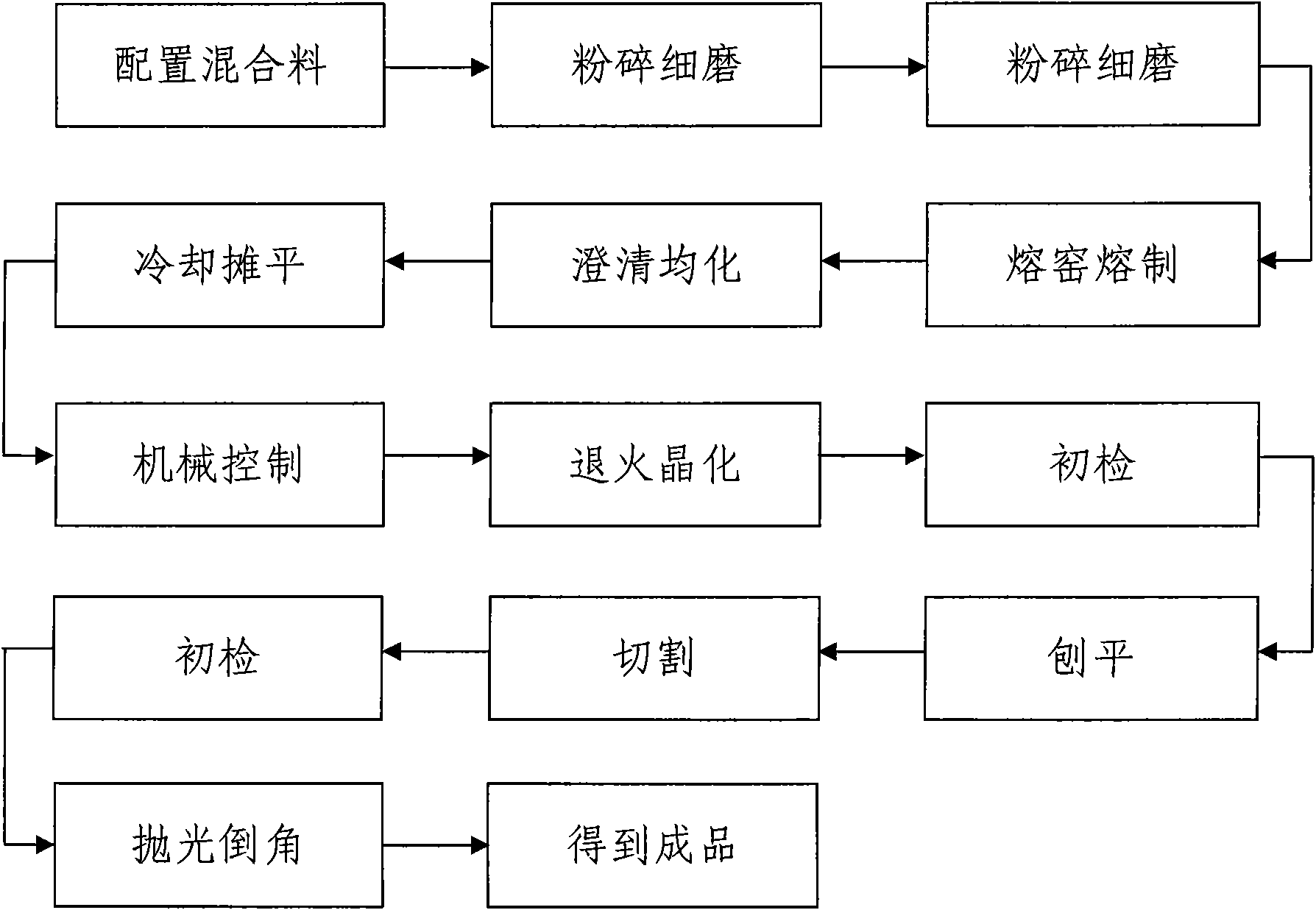

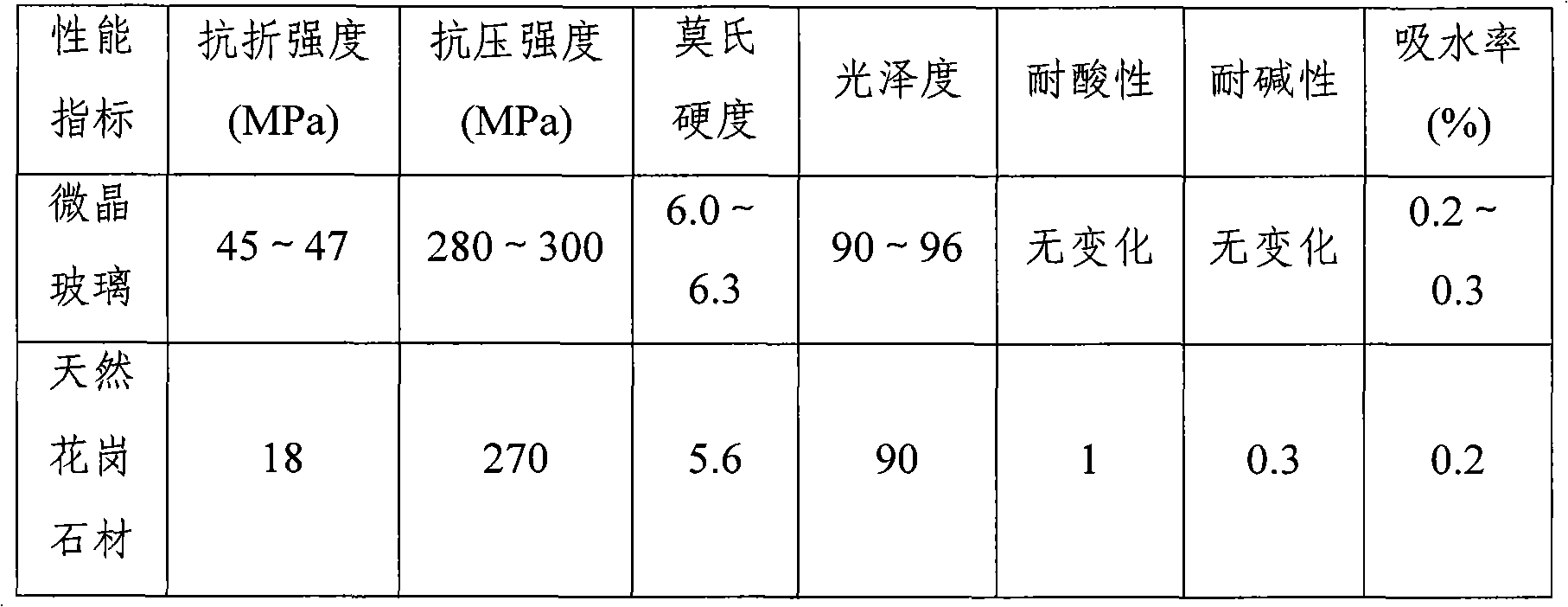

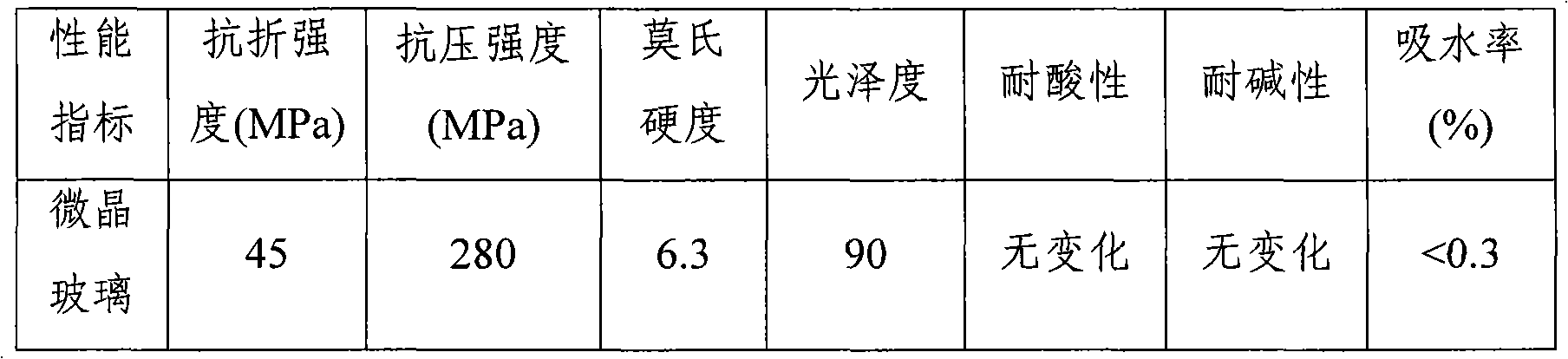

Microcrystal glass manufactured by using tailing solid waste and manufacturing method thereof

The invention relates to the manufacturing field of construction engineering material, and specifically discloses microcrystal glass manufactured by using tailing solid waste and a manufacturing method thereof. The microcrystal glass comprises the following components in percent by weight: 50 to 60% of SiO2, 5 to 20% of CaO, 3 to 8% of MgO, 35 to 15% of Al2O3, 2 to 8% of Na2O, 2 to 8% of K2O and 1 to 6% of Fe2O3. The microcrystal glass manufactured by effectively using tailing solid waste as primary production material has the compressive strength, rupture strength, hardness, acid-alkali resistance, glossiness and other indexes reaching or exceeding the level of top-grade natural granite. The microcrystal glass has the advantages of simple and convenient technological flow, significantly reduced production cost and excellent product quality, and can be extensively popularized in building decoration.

Owner:淮安乔氏建材发展有限公司

Carbon nano tube composite carbon crystal paint and method for preparing carbon crystal electric heating material from same

InactiveCN101914347AStrong far infrared radiationHigh electrothermal conversion efficiencyChemical industryPolyurea/polyurethane coatingsFiberCarbon fibers

The invention discloses a carbon nano tube composite carbon crystal paint and a method for preparing a carbon crystal electric heating material from the same, wherein the carbon crystal composite paint is prepared from carbon nano tubes, modified ball milling short carbon fibers, resin paints, infrared emission powder and the like; and the carbon crystal electric heating material is prepared by spraying or scratching the paint into a film on a planar template (paper base template, plastic template and the like), and compositing with an aging proof high molecular material to obtain the planar electric heating material. The carbon crystal composite paint and the carbon crystal electric heating material have strong far-infrared radiation, high electric heating conversion efficiency, small surface temperature difference, good corrosion resistance, weather resistance and aging resistance and high safety, can be compatible with concrete, can be used as a heating product for buildings, and can also be processed into various electric heating products, such as an electric heating plate, an electric heating carpet, a dry wardrobe, a foot warmer, a food warmer and the like.

Owner:龚亮 +1

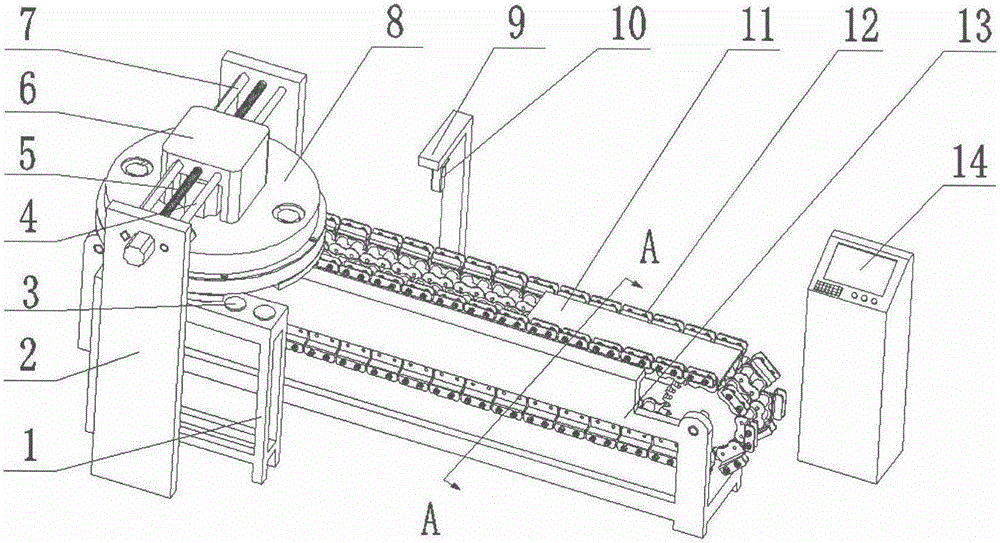

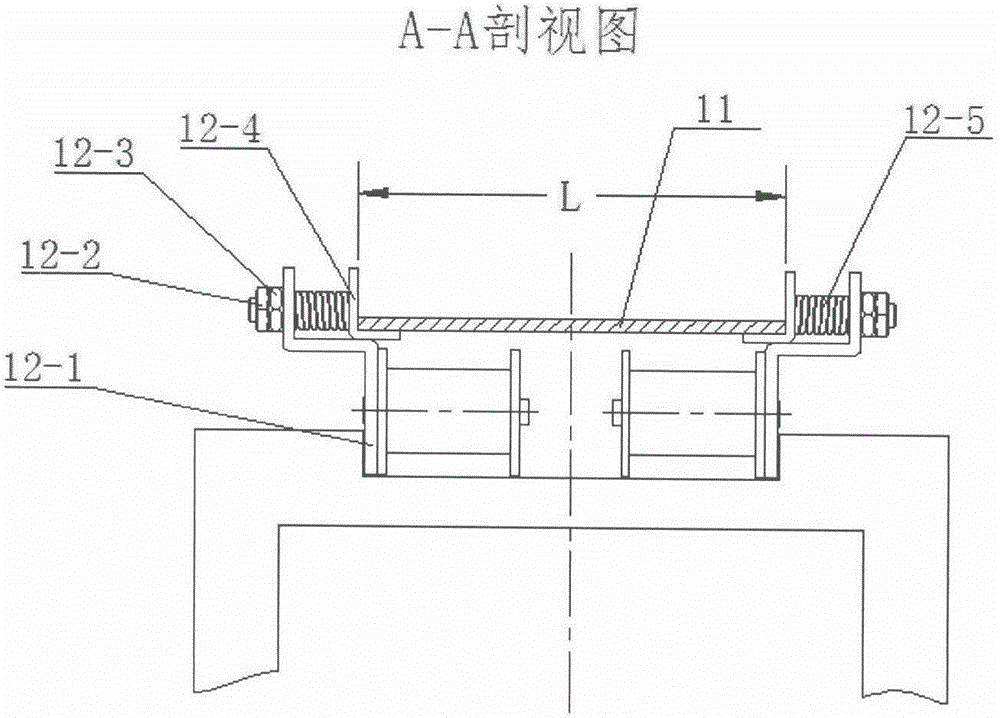

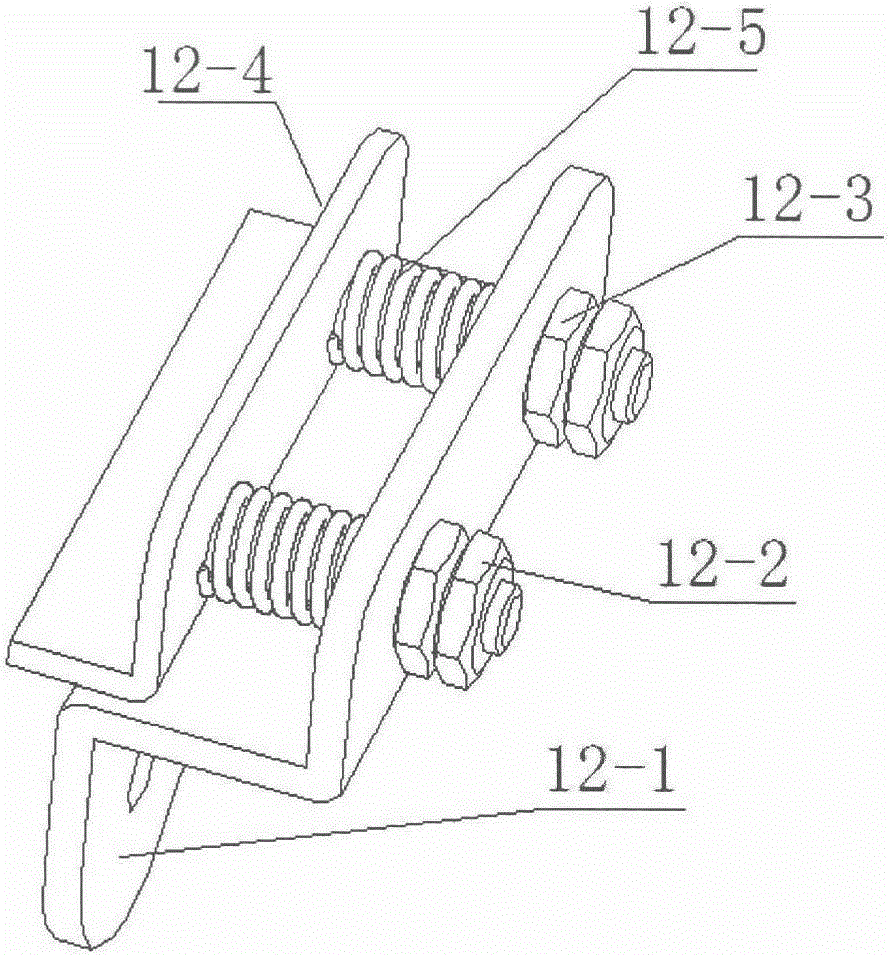

Intelligent excavating and repairing device for wood surface defects

ActiveCN105291213AHigh functional integrationOptimize process flowEdge grinding machinesIrregularity removal devicesEngineeringWood plank

An intelligent excavating and repairing device for wood surface defects is characterized in that glue-coated wood plugs with the same diameter and height are arranged on a mobile platform at intervals, a wood plate to be processed is placed on a conveying chain and passes from the area below a camera, and after the camera recognizes the surface defects of the wood plate to be processed, a system transmits the message to a control system of an operating console; the control system conveys the defect part of the wood plate to be processed to the area below an excavating and repairing mechanism support according to the operation speed of the conveying chain, a drilling cutter of a rotating cutter plate assembly completes defect excavation, a sucking device of the rotating cutter plate assembly completes wood plug filling, then a drying device of the rotating cutter plate assembly completes drying, a polishing device of the rotating cutter plate assembly completes polishing, and finally the excavating and repairing work of the surface defects at the defect part of the wood plate to be processed is completed intelligently; the conveying chain drives the wood plate to be processed to continue moving forwards, and then intelligent excavating and repairing of next surface defect of the wood plate to be processed can be carried out. Compared with existing excavating and repairing technologies, the intelligent excavating and repairing device has the advantages that the technological process of wood excavating and repairing is optimized, the automation degree is high, the operation is easy, the safety is high, and the labor cost is low.

Owner:NANJING FORESTRY UNIV

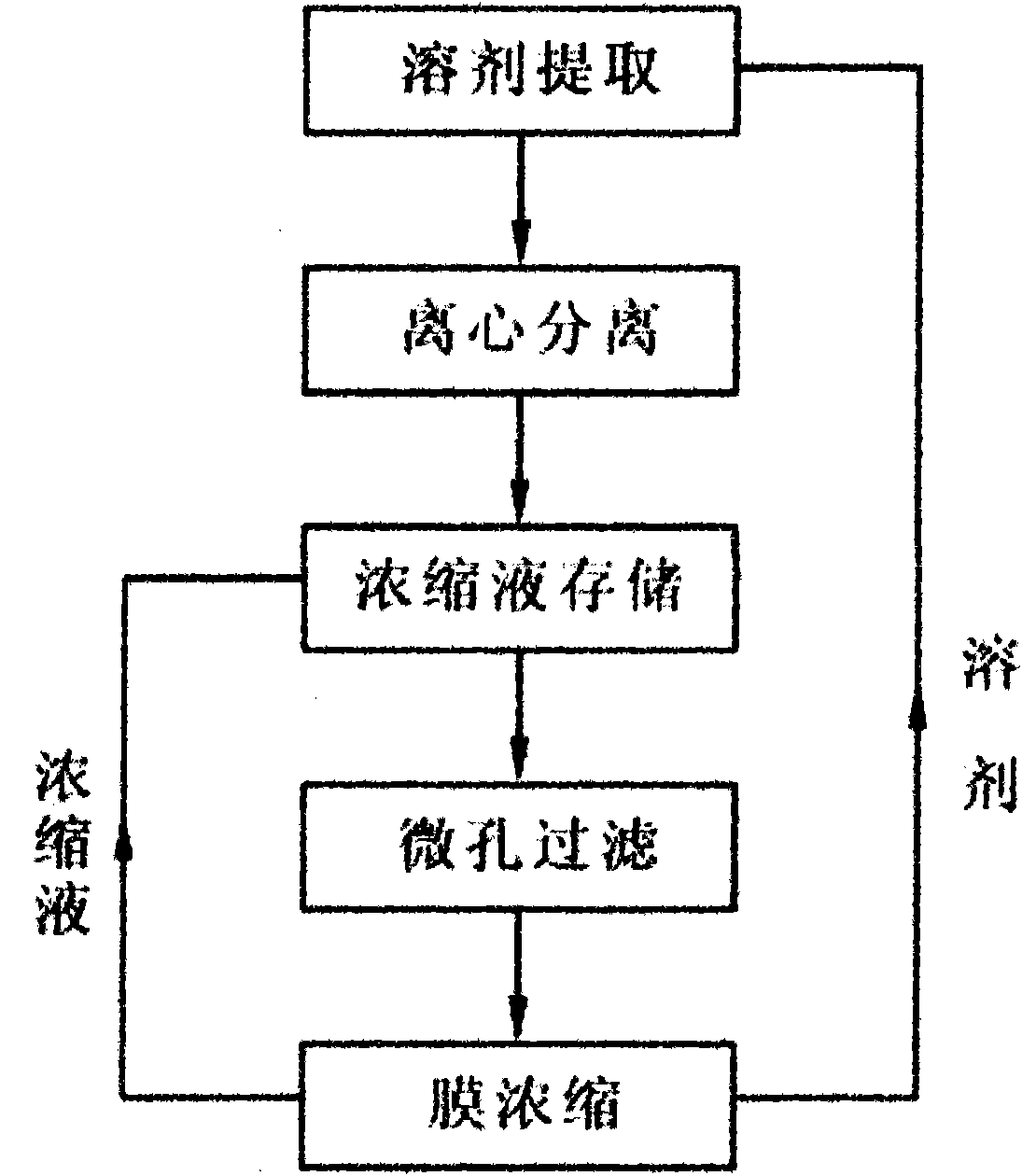

Energy-saving concentration process for extracting active ingredients of plants and concentration device thereof

ActiveCN101879380AReduce oxidative denaturationReduce lossesAntibacterial agentsUltrafiltrationThermal energyProcess systems

The invention discloses an energy-saving concentration process for extracting active ingredients of plants and a concentration device thereof. The process of the invention comprises the steps of solvent extraction, centrifugal separation, filtration and film concentration. The concentration device comprises an extraction device, a centrifugal separation device, a filtration device and a film concentration device which form a closed circulation system. By using a film centrifugal separation technology for replacing the evaporation method of the prior art for concentrating, the concentration device of the invention has the advantages of simple structure and high working efficiency; the active ingredients of plants are concentrated without being heated; compared with the prior art, the energy is saved by more than 90%; and simultaneously, oxidative degeneration and loss of the active ingredients are reduced, the extraction rate is higher, and the quality is better. In the invention, a closed process system of extraction, separation and concentration is formed, and a heat exchange device is arranged in the closed process system, thereby being favorable for improving the utilization rate of heat energy.

Owner:云南活草堂生物科技有限公司

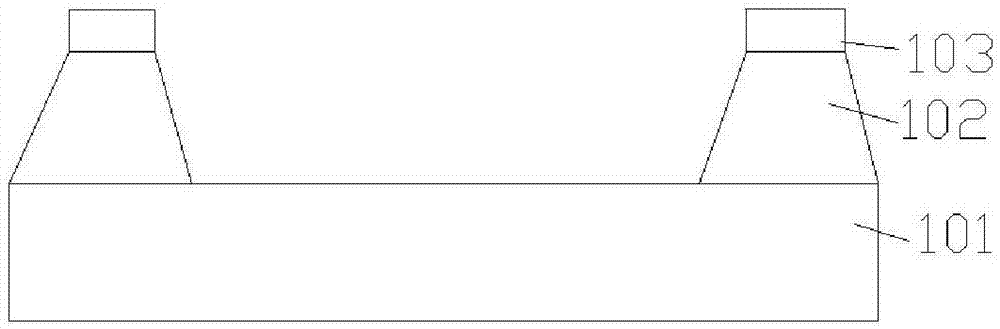

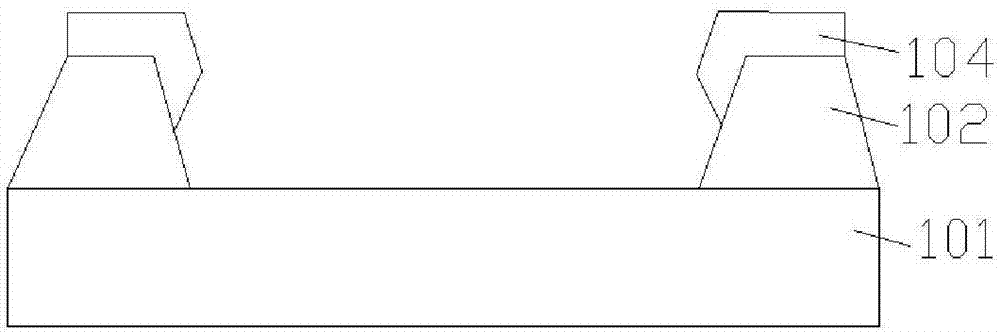

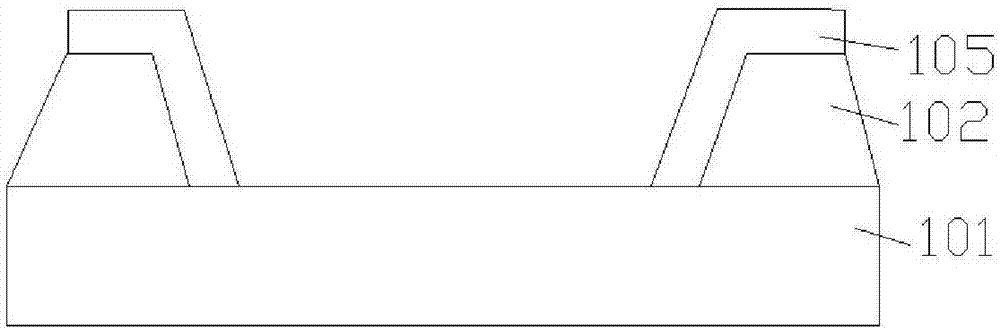

Pixel defining layer and manufacturing method thereof

ActiveCN107248523AEasy to prepareReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

According to the invention, a first defining layer of a pixel defining layer comprises dam bodies locally covering a substrate; second defining layers are arranged at the tops of the dam bodies; and the second defining layers are made of a lyophobic material. A manufacturing method of the pixel defining layer disclosed by the invention comprises the steps of: preparing the first defining layer on the substrate; preparing one layer of lyophobic material on the substrate and the first defining layer; and by the etching process, removing the lyophobic material between the dam bodies to obtain the second defining layers covering the dam bodies of the first defining layer. According to the pixel defining layer disclosed by the invention, hydrophobic layers are arranged at the tops of the dam bodies, and a material of the substrate has the lyophilic property, so that the requirements for top lyophobicity and bottom lyophilic property of the pixel defining layer are met; and the manufacturing method of the pixel defining layer disclosed by the invention is simple, low in manufacturing cost and very simple and convenient in process flow.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

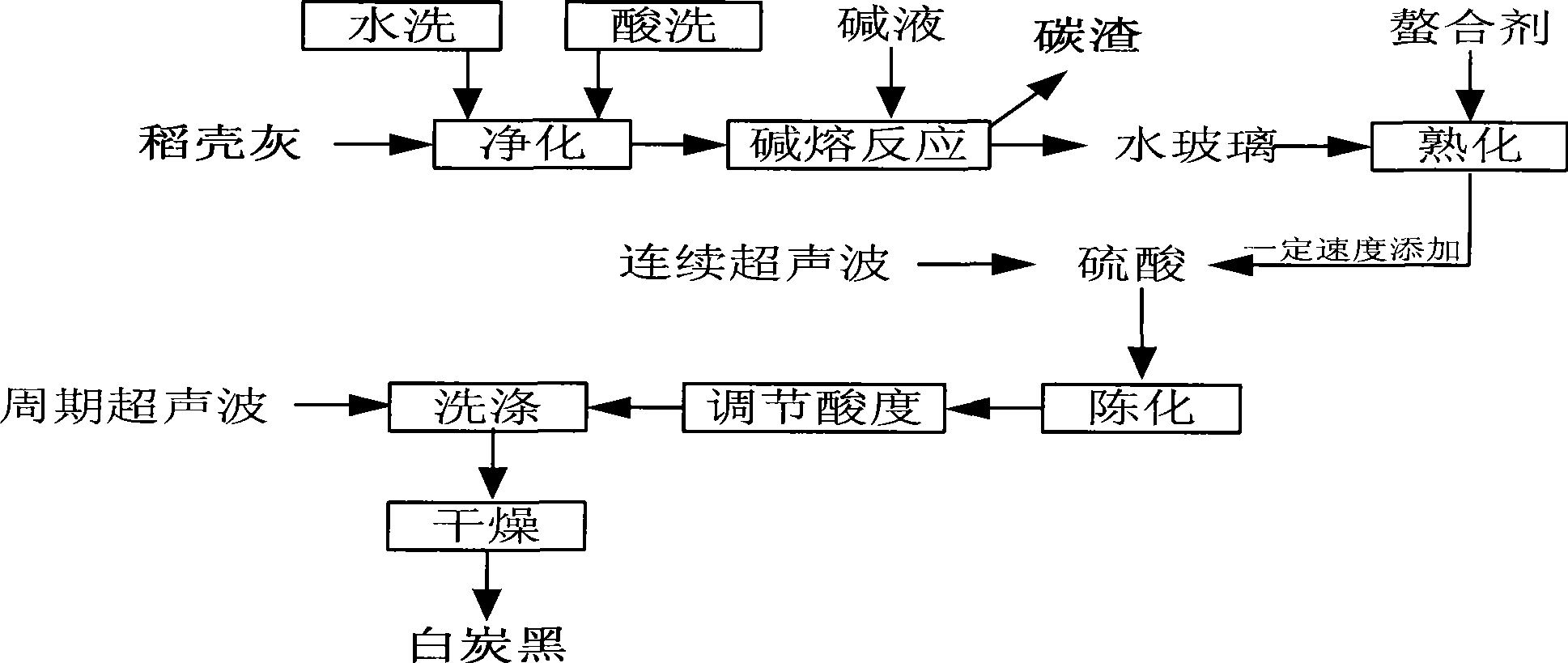

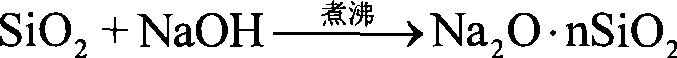

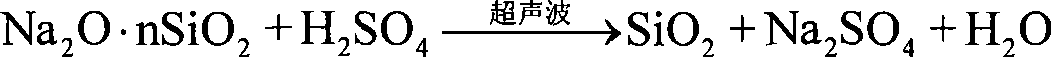

Method for preparing high-purity siliceous reinforcing agent by using rice hull ash as raw material

The invention relates to a method for preparing high purity silica white by using rice husk ash as a raw material, belonging to the field of fine inorganic chemical technology. The invention is characterized by comprising the following steps: taking the rice husk ash and water for washing under constant stirring, separation, pickling, leaching, and then undertaking washing till the lavage liquid is neutral and drying; taking the dried rice husk ash for being mixed and reacted with the sodium hydroxide solution, through leaching and washing; collecting filtrate and washing liquid so as to be condensed and obtain water glass; diluting the water glass which is obtained from the condensation and adding metal ion chelating agent, and next carrying out precipitation reaction after being fully dissolved, then a sediment is obtained by centrifugal separation; using ultrasound-assisted washing treatment, and then undertaking centrifugal separation and repeated washing; placing the washed sediment into a drying oven and then crushing and packaging the sediment so as to obtain the silica white product. The invention has simple process flow, easy operation, can improve the purity of the silica white, and is suitable for commercial process; moreover, the heavy metal content is less, which can completely replace or is even better than the market silica white product and also eliminates the environmental pollution of the rice husk ash.

Owner:JIANGNAN UNIV

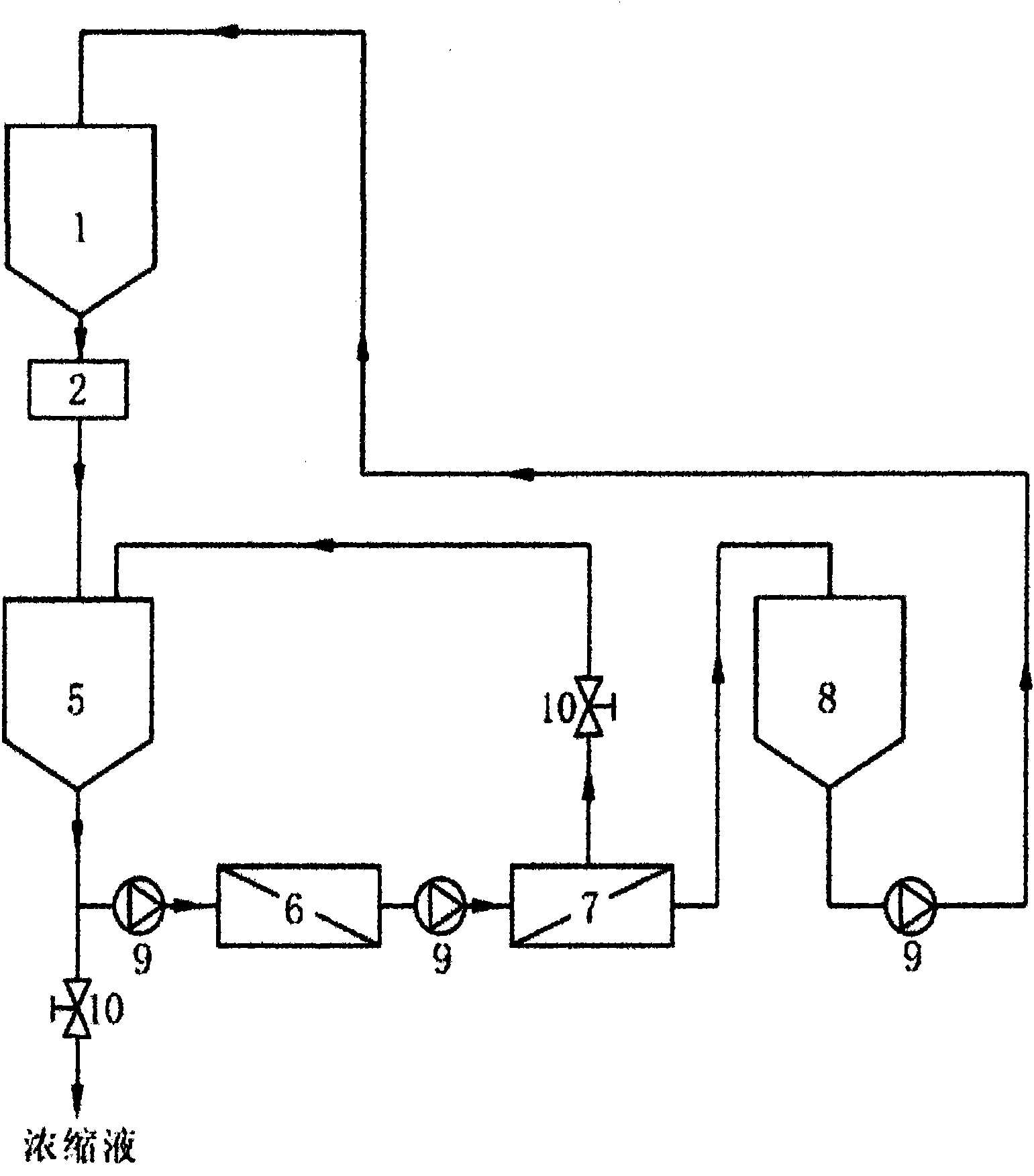

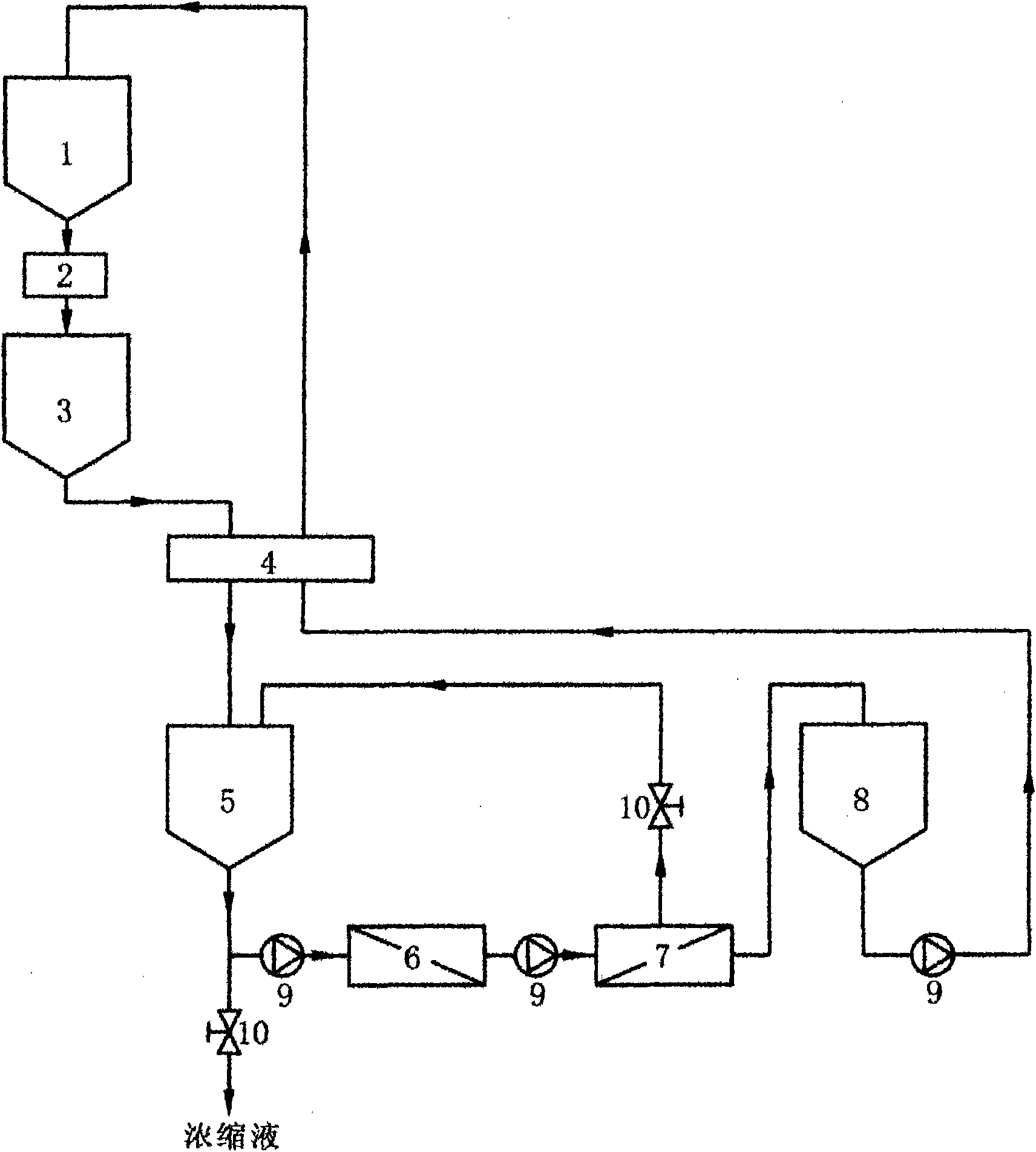

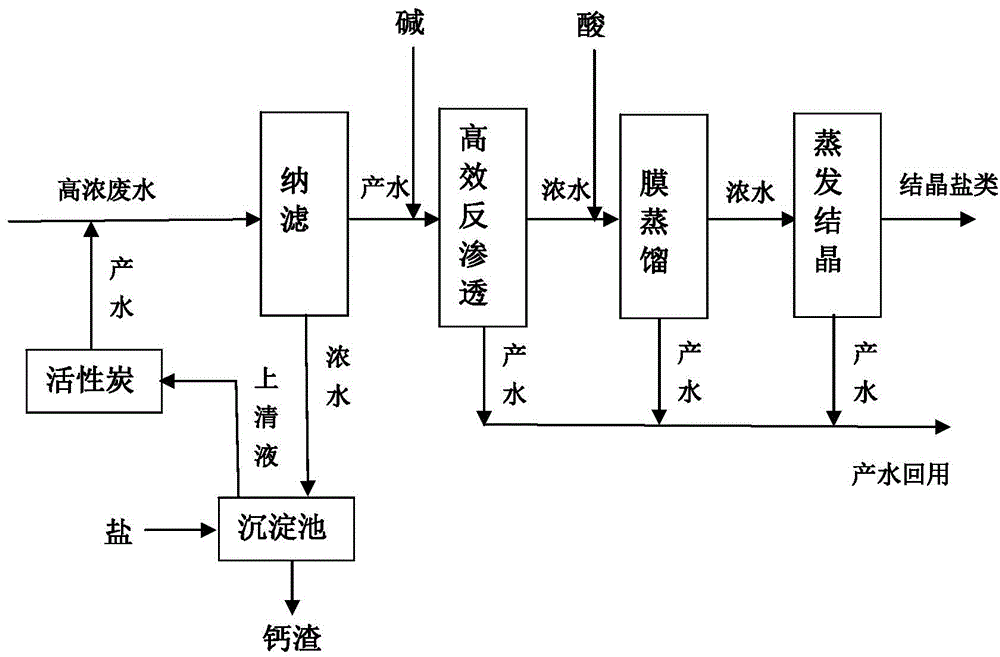

High-concentration wastewater zero-discharging method

ActiveCN105198143ARealize in-depth treatment and even zero discharge problemsEfficient reverse osmosis treatmentEnergy based wastewater treatmentMultistage water/sewage treatmentHigh concentrationReverse osmosis

The invention relates to the field of industrial wastewater treatment, in particular to a high-concentration wastewater zero-discharging method. Accoridng to the method, a 'nanofiltration + efficient reverse osmosis + membrane distillation + evaporative crystallization' method is adopted to treat high-concentration wastewater. Firstly, nanofiltration is adopted to remove hardness, multivalent ions and parts of organic matter in the high-concentration wastewater so as to obtain nanofiltration producing water and nanofiltration concentrated water, then an efficient reverse osmosis technology is adopted to conduct deep concentration treatment on the nanofiltration producing water, deep concentration treatment is conducted on the obtained efficient reverse osmosis concentrated water through membrane distillation to obtain membrane-distillation concentrated water, further evaporative crystallization treatment is performed to enable salt solids in the membrane-distillation concentrated water to crystallize out, and centralized drying disposal is performed, wherein salt is added into the nanofiltration concentrated water to perform precipitation treatment so as to obtain calcium residues, supernate obtained after precipitation is subjected to activated carbon adsorption and then is mixed with the high-concentration wastewater, and the mixed liquid is fed into a nanofiltration unit for circular treatment. By means of the high-concentration wastewater zero-discharging method, water resources are recycled to the most degree while the problem of high-concentration wastewater discharging is solved, and zero discharging of high-concentration wastewater is basically achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

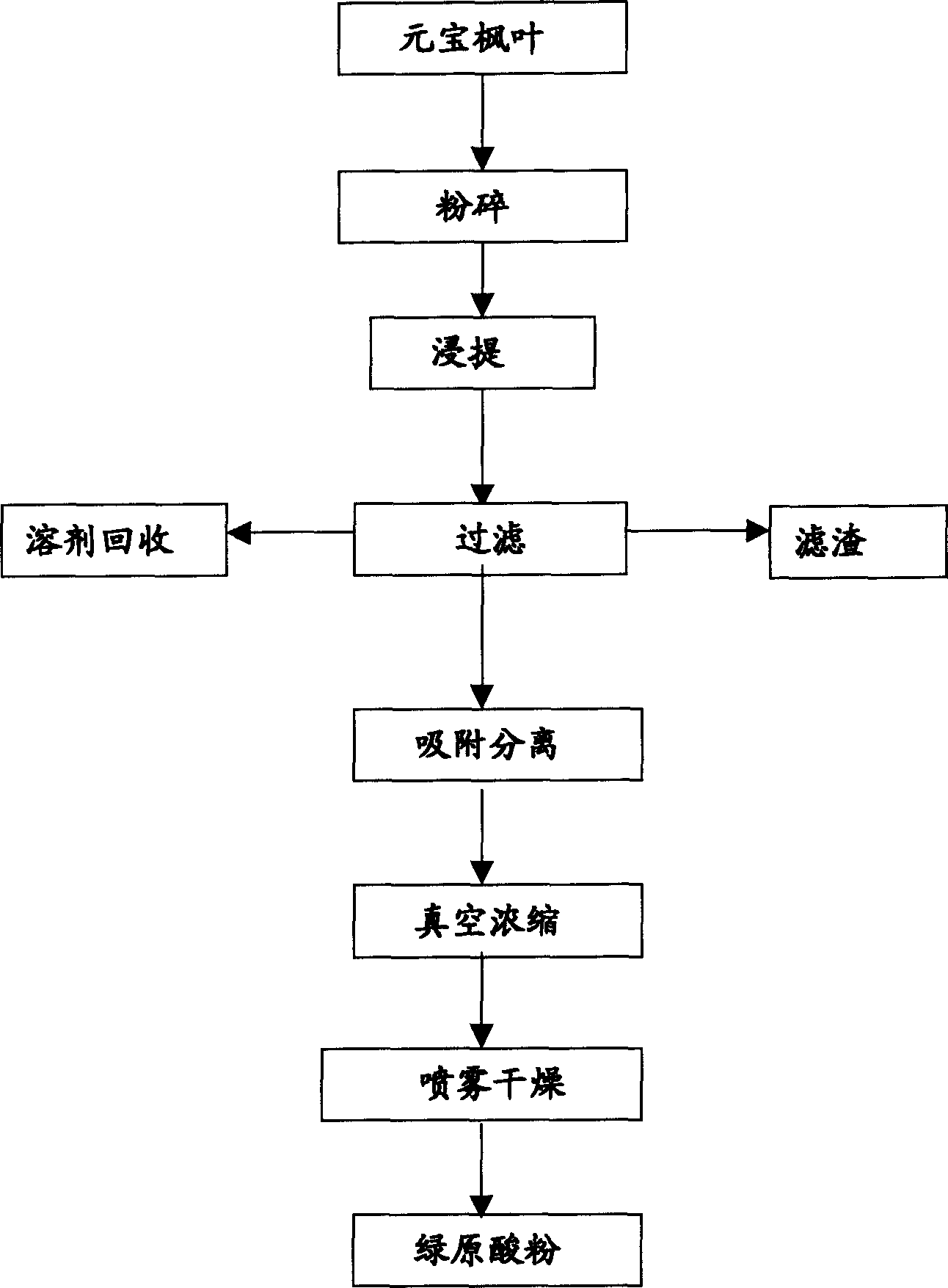

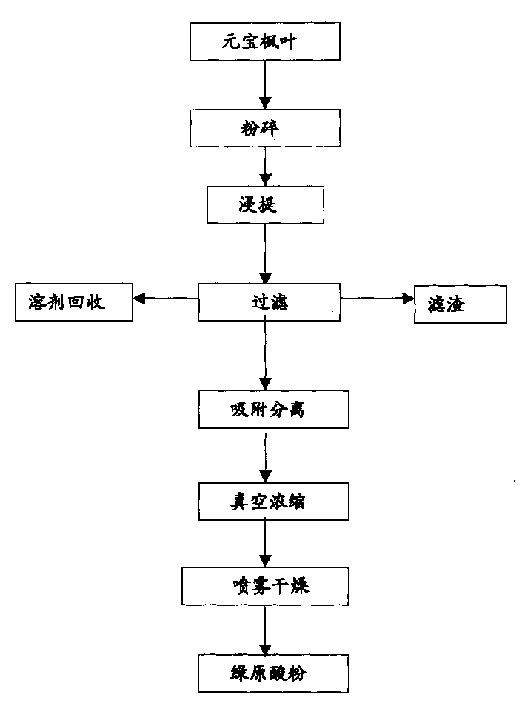

Technology for extracting chlorogenic acid from shoe-shaped maple leaves

InactiveCN1524843AImprove leaching rateGood effectOrganic compound preparationCarboxylic acid esters separation/purificationLiquid ratioChlorogenic acid

The invention relates to a process for extracting medicinal herb component, specifically a process for extracting chlorogenic acid from shoe-shaped ingot maple leaves, wherein low-temperature extraction is employed and under the conditions of controlled time, pH value and feed liquid ratio. The advantages of the process are high leaching ratio, simplicity of operation, low cost, and no toxin.

Owner:杨凌元宝枫生物制品有限公司

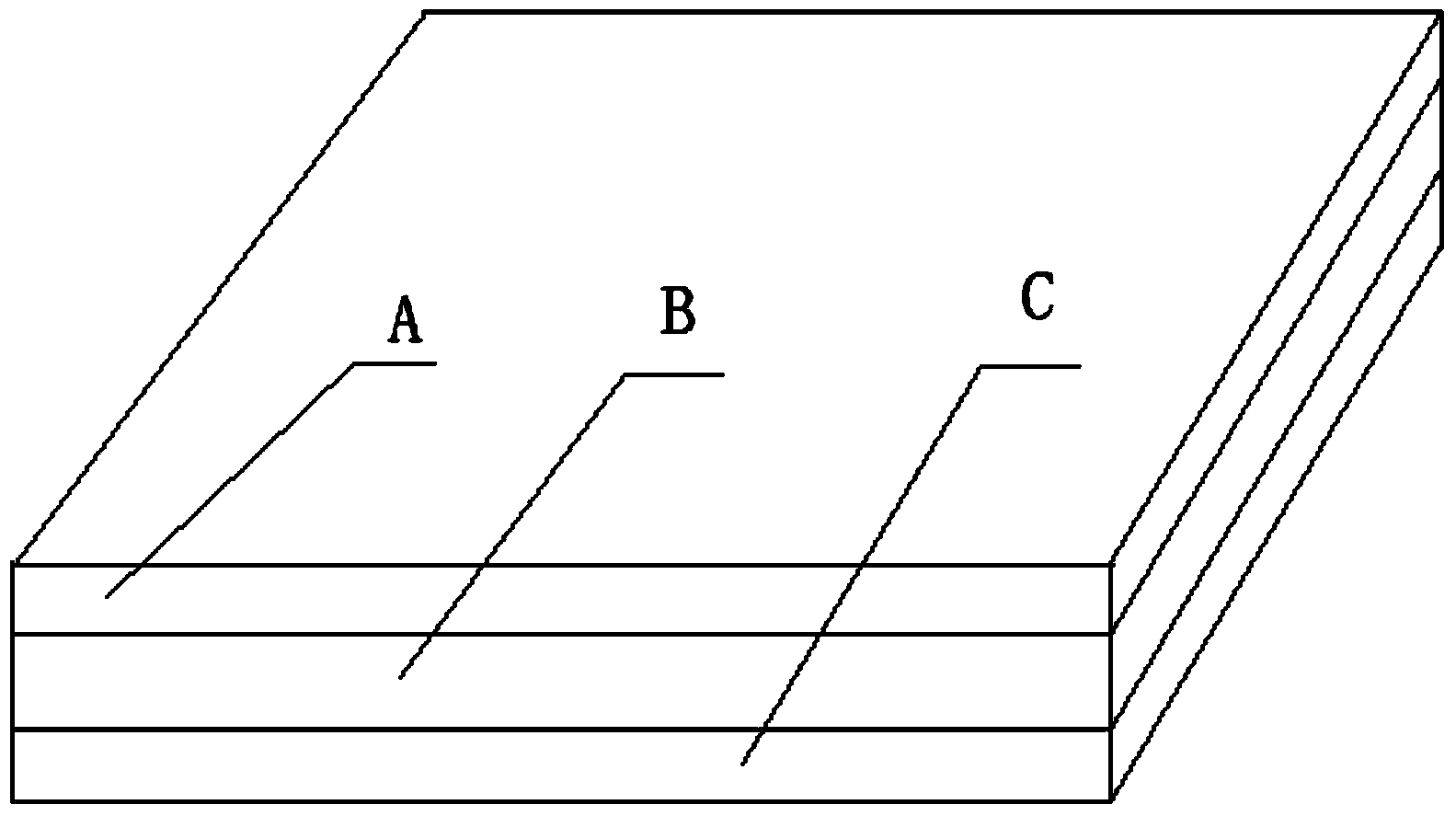

Compound type light heat-preservation decorative ceramic external wall tile and manufacturing method thereof

ActiveCN104005528ARich surface decoration effectReduce pollutionCovering/liningsSolid waste managementAbsorption rate3D printing

The invention discloses a compound type light heat-preservation decorative ceramic external wall tile and a manufacturing method of the compound type light heat-preservation decorative ceramic external wall tile. The external wall tile is composed of three layers, the lower layer is a surface decorative layer, the middle layer is a closed air hole heat-preservation layer, and the upper layer is an open air hole structural layer. All materials are mixed, distributed three times according to layers (the lower layer, the middle layer and the upper layer), formed at one time, dried and sintered through laser, edges are cut off, and the surface is decorated (in an ink-jet printing or 3D-printing mode). Uniform and fine sealed air holes can be formed in the compound type light heat-preservation decorative ceramic external wall tile, the water absorption rate is 0.3-2 percent, the air hole rate reaches 40-60 percent, the extension strength is 60-80 MPa, the heat conduction coefficient is 0.2-0.7 W / (M.K), and the compound type light heat-preservation decorative ceramic external wall tile has good heat-preservation, heat-insulating, waterproof and flame retardant properties, has a decorative effect, is firmly combined with a wall body, is convenient to construct, and is safe and reliable to use.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing biological organic fertilizer from sludge serving as raw material and application of biological organic fertilizer

InactiveCN102167629AReduced effectivenessOptimize process flowBio-organic fraction processingClimate change adaptationInorganic fertilizerAnaerobic digestion

The invention belongs to the field of biological organic fertilizers, and in particular relates to a preparation method for a biological organic fertilizer by taking sludge as a raw material, and application of the biological organic fertilizer. The preparation method comprises a heavy metal passivation process, a material mixing process, an aerobic fermentation process, an anaerobic digestion process and a sieving and dividing process. The process flows are simple and convenient, the sludge is taken as the raw material, the effectiveness of heavy metals is reduced by a metal passivator, aerobic and anaerobic double-flow fermentation is combined, the obtained fertilizer integrates an organic fertilizer, an inorganic fertilizer and a biofertilizer and has the characteristics of no pollution, long effect, quick effect, synergism and the like, the investment scale is small, the invention is favorable for promotion and application, and a new way for harmless, reductive and regenerative treatment of sludge is provided.

Owner:王斌

Method for preparing arsenic trioxide by using arsenic-containing waste water

InactiveCN101125682ASimple processSave raw materialsWater/sewage treatmentArsenic compoundsFiltrationSlurry

The invention relates to a method to produce arsenic trioxide with waste water containing arsenium, which takes waste water containing arsenium as raw material to produce arsenic trioxide. A. alkali is added to remove impurities, cupric salt is added, the pH value of the solution is adjusted to 4-14 by alkali and green copper arsenite or copper arsenate precipitate is prepared; B. the prepared green copper arsenite or copper arsenate precipitate is made into slurry by water or sulphuric acid solution; sulfur dioxide is pumped into or sulphite is added to be reacted, arsenious acid solution and pink filtration residue are obtained after filtration; C. arsenious acid solution is crystallized, filtered and dried to get arsenic trioxide powder. The invention has the advantages of simple process, saving raw materials, reducing cost and high recovery yield.

Owner:CENT SOUTH UNIV

Treatment method of glycerin wastewater containing salt

InactiveCN102503014AOptimize process flowEasy to operateOrganic compound preparationHydroxy compound preparationEpoxyFluid phase

The invention discloses a treatment method of glycerin wastewater containing salt. Glycerin waste water containing salt produced during different production processes is added in normal butanol with the amount being 1.3 to 3.3 times of wastewater quantity; with the addition of normal butanol, under the normal pressure and the temperature of 30 to 70 DEG C, salt in glycerin wastewater containing salt is separated out by crystallization, the liquid phase is divided into an upper organic phase and a lower water phase; the upper organic phase contains 0.3 percent of salt, and is rectified, normalbutanol is recovered, and water is removed at the same time, so that 99.9 percent of pure glycerin serving as a product is obtained; and the lower water phase is filtered, filtrate flows back to an extraction tower for retreatment, and crystallized sodium chloride is washed and recovered. The treatment method has the advantages of simple and convenient process flow, easiness in operation and control, and environmental friendliness; and glycerin and sodium chloride in wastewater can be recycled, so that the production cost can be reduced effectively. The invention is especially suitable for byproducts in epoxide resin production, glycerin byproducts in oil and glycerin chemical production and wastewater treatment of glycerin byproducts in biodiesel production.

Owner:ZHEJIANG UNIV

Multi-function plastic particles, preparation method and application

The invention relates to the technical field of plastic particles, in particular to the multi-function plastic particles, a preparation method and application. The multi-function plastic particles comprise an essence, a resin, a polyethylene wax and kaolin, and are characterized by comprising the following components in percentage by mass: 21 to 26 percent of essence or essential oil, 48 to 53 percent of thermoplastic resin, 2 percent of polyethylene wax and 22 to 26 percent of kaolin and 22 to 26 percent of silicon dioxide. In the particles, more essences with a lower boiling point and some pure natural essential oil can be added into various plastics, and the selection of the essence and the plastic is not limited any longer; and when the plastic sends fragrance, the plastic also has the functions of all kinds of essential oil, such as mildew proofing and mothproofing, refreshing, tibia releasing and the like, and the plastic product has long-time pure fragrance, so that the service life of the plastic product with fragrance is prolonged, the technical steps of the prior art are simplified under the condition of not influencing the quality, the technical flow of the prior art is optimized, the investment is reduced, the fragrance adding effect is better, and the product is suitable for multiple resins.

Owner:BESTSCENT SHANGHAI FINE CHEM

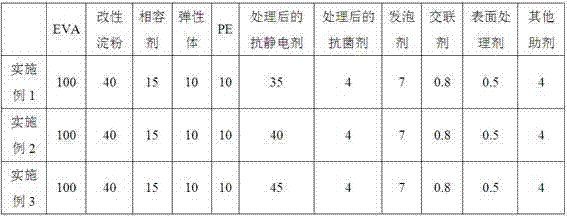

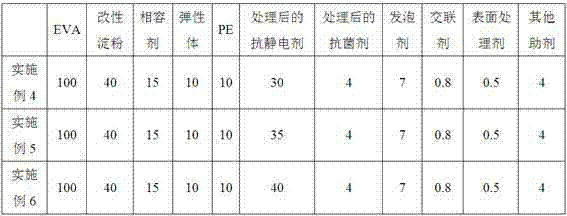

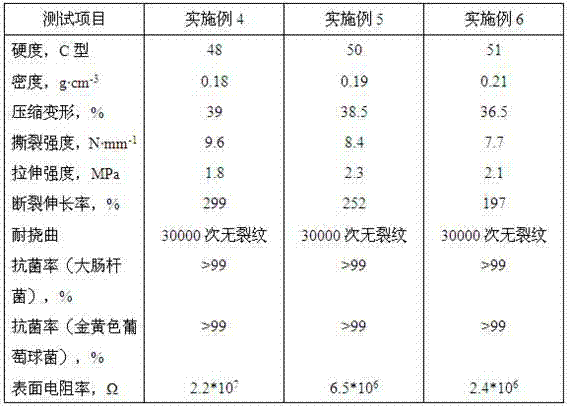

Antibacterial and antistatic EVA/starch/PE composite foaming material and preparation method thereof

The invention discloses an antibacterial and antistatic EVA (ethylene-vinyl acetate) / starch / PE (polyethylene) composite foaming material and a preparation method thereof. The antibacterial and antistatic EVA / starch / PE composite foaming material is prepared by: subjecting completely degradable starch and EVA, PE, a compatibilizer, as well as an elastomer to blending in a Banbury mixer, and adding functional additives, i.e. an antibacterial agent and an antistatic agent, and an inorganic filler, a cross-linking agent, a foaming agent and other aids. According to the invention, the antibacterial agent and the antistatic agent are blended into the foaming material, and the formula is scientific and reasonable, so that the product has both antibacterial and antistatic properties, and can satisfy life and some special environments.

Owner:福州市福通高新材料有限公司

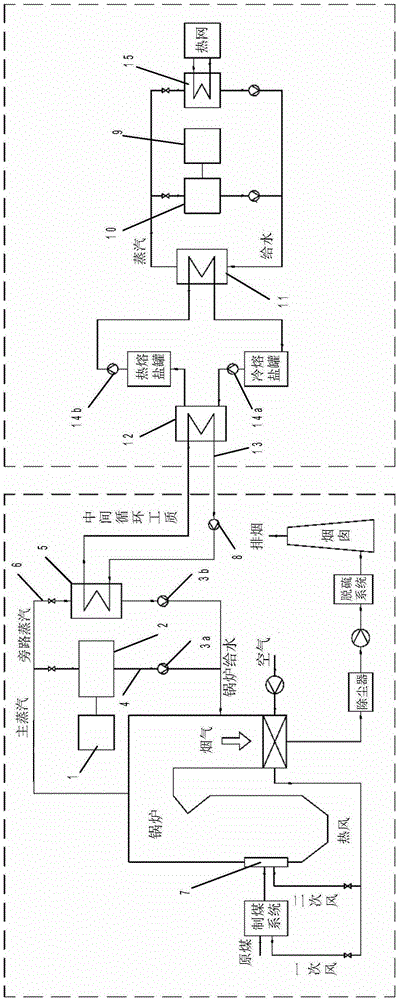

Thermal power generation system and method with fused salt energy storage, power supply and heat supply functions

InactiveCN105351018AThe system process is simpleLess process equipmentHeat storage plantsSteam engine plantsThermal energyThermal energy storage

The invention discloses a thermal power generation system and method with fused salt energy storage, power supply and heat supply functions. By arranging a bypass steam pipeline, a high-pressure condenser and a molten salt heater, excess steam heat energy generated by the load change of a power grid can be stored though molten salt. When the peak load of the power grid is reached, a molten salt energy storage power generation subsystem can participate in peak regulation of power supply of the power grid. In this way, the problems of peak regulation of the power grid, low utilization rate of power equipment and the like are solved, it is guaranteed that the power generation efficiency of the power generation system is equal to that of an existing thermal power generating unit, and the thermal power generation system and method have the outstanding advantages that energy storage and variable-load power supply are achieved, and high-efficiency power generation is guaranteed.

Owner:SHANGHAI YUANMENG ELECTRIC POWER ENERGY TECH CONSULTING CENT

Combined technology for milling and grinding tooth parts of spiral taper gear

InactiveCN1958216AEasy to process and adjustSmall shapeFurnace typesHeat treatment process controlEngineeringSpiral bevel gear

A grinding and abrading combined technology for machining the teeth of a pair of drive and driven spiral bevel gears includes such steps as forging, heat treating in advance, turning the raw teeth, grinding the primary locating position, milling spiral teeth, machining before heat treating (including tapping, chamfering and washing of driven gear and chamfering, milling spline and spiral threads and wash of drive gear, fine grinding, abrading between the drive and driven gears in a pair, and numbering them.

Owner:ZHUZHOU GEAR CO LTD

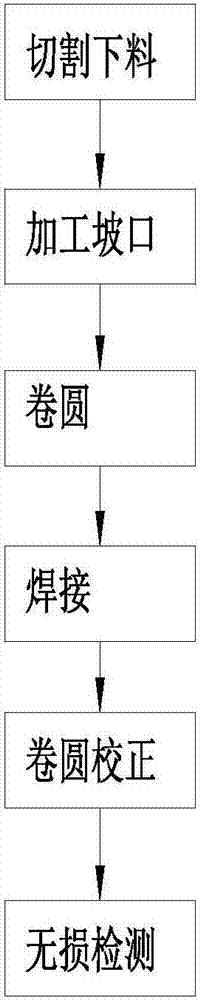

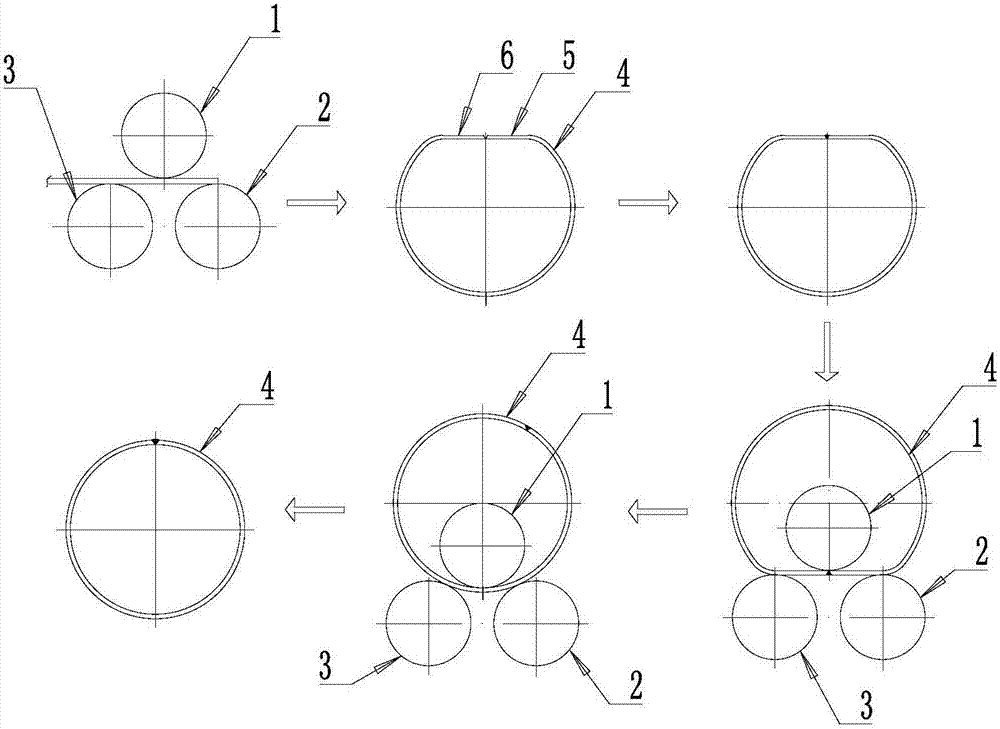

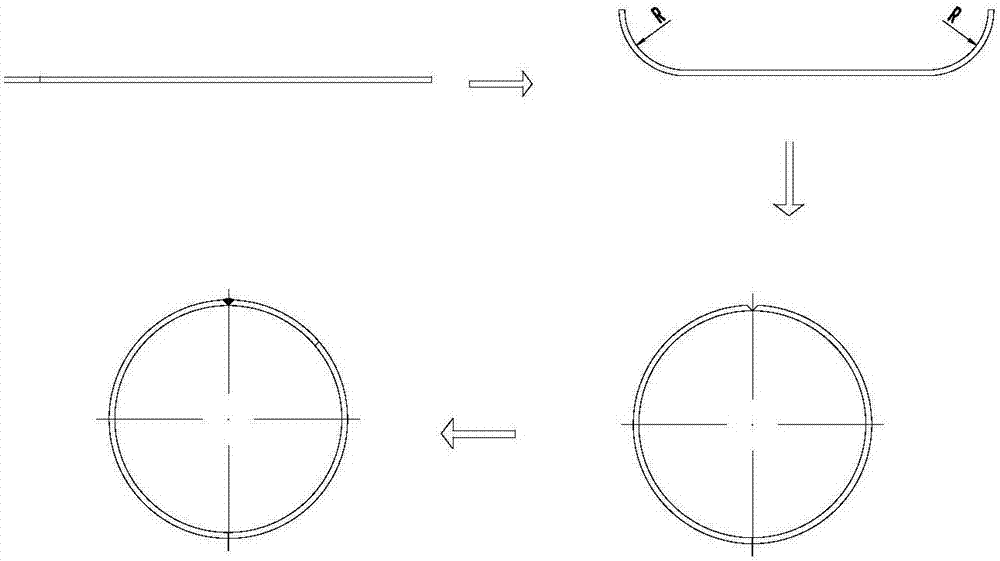

Barrel non-prebending rolling forming process

The invention relates to a round forming process without pre-bending for a cylindrical body, which belongs to the field of round forming for boilers, pressure vessels, pipelines, air ducts and other cylindrical bodies. Including the following steps: (1) cutting and blanking: cutting and blanking the plate according to the size required by the process; (2) rolling: using a plate rolling machine to roll the plate cut in step (1); (3) welding: the step (2) Weld the side seam of the cylindrical body formed by the middle rolling; (4) Rolling correction: use a plate rolling machine to perform rolling correction on the processed barrel in step (3). The process of the invention is simple, the common plate rolling machine can meet the process requirements, and the cost of the enterprise is reduced.

Owner:SHANDONG MEILING CHEM EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com