Antibacterial and antistatic EVA/starch/PE composite foaming material and preparation method thereof

A compound foaming and antistatic technology, applied in the field of polymer materials, can solve the problems of single function and non-antibacterial and antistatic materials, and achieve the effects of high tear strength, broad application prospects and market demand, and scientific and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0018] Add the plasticized starch, EVA, PE, compatibilizer, elastomer, treated antibacterial agent, antistatic agent and other additives into the internal mixer, banbury at 90-130°C for 5-15min, and mix to obtain The plasticized composite material is kneaded at 60-90°C with an open mill, and mixed with a foaming agent and a crosslinking agent, and finally foamed at 160-190°C for 5-10 minutes with a flat vulcanizer. Obtain the antibacterial and antistatic EVA / starch / PE composite foaming material.

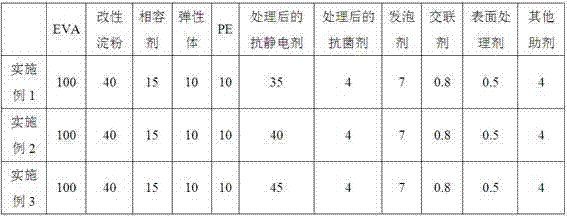

[0019] Table 1 Antibacterial and antistatic EVA / starch / PE composite foam material formula

[0020]

[0021] The compatibilizer is ethylene-acrylic acid copolymer and maleic anhydride grafted polypropylene, and the ratio of ethylene-acrylic acid copolymer and maleic anhydride grafted polypropylene is 4:1. The elastomer is ethylene-octene copolymer, the treated antistatic agent is treated carbon black, the treated antibacterial agent is surface-treated silver ion zeolite, and the s...

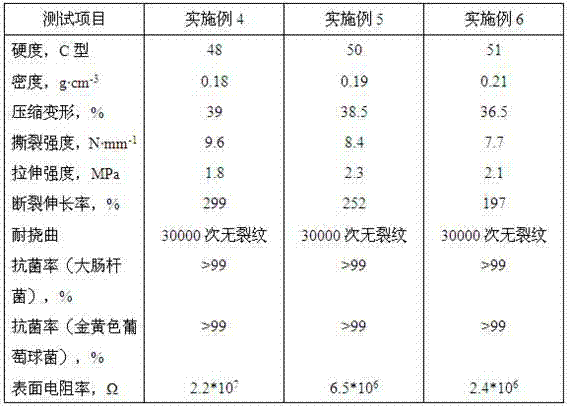

Embodiment 4-6

[0023] According to the composition of raw materials in Table 2, each raw material was taken, and the processing steps and process parameters were the same as in Example 1, to obtain an antibacterial and antistatic EVA / starch / PE composite foaming material.

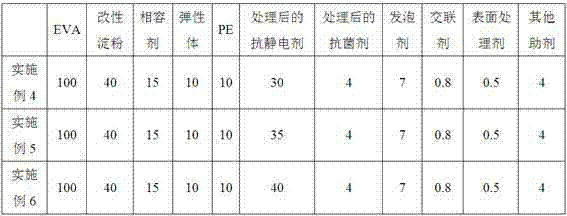

[0024] Table 2 Antibacterial and antistatic EVA / starch / PE composite foam material formula

[0025]

[0026] The compatibilizer is ethylene-acrylic acid copolymer and maleic anhydride grafted polypropylene, and the ratio of ethylene-acrylic acid copolymer and maleic anhydride grafted polypropylene is 4:1. The elastomer is ethylene-octene copolymer, the treated antistatic agent is treated carbon black and carbon fiber, and the ratio of treated carbon black to carbon fiber is 10:1. The treated antibacterial agent is surface-treated nano-silver antibacterial powder, the surface treatment agent is aluminate coupling agent and titanate coupling agent, and the ratio of aluminate coupling agent and titanate coupling agent is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com