Microcrystal glass manufactured by using tailing solid waste and manufacturing method thereof

A solid waste and glass-ceramic technology, which is applied in the field of construction engineering material manufacturing, can solve the problems of high cost of glass-ceramic raw materials, and achieve the effects of reduced production costs, simple process flow, and excellent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The composition of the weight percentage content of the glass-ceramics manufactured by tailings solid waste includes: SiO 2 50%, CaO 5%, MgO 8%, Al 2 o 3 15%, Na 2 O 8%, K 2 O8%, Fe 2 o 3 6%.

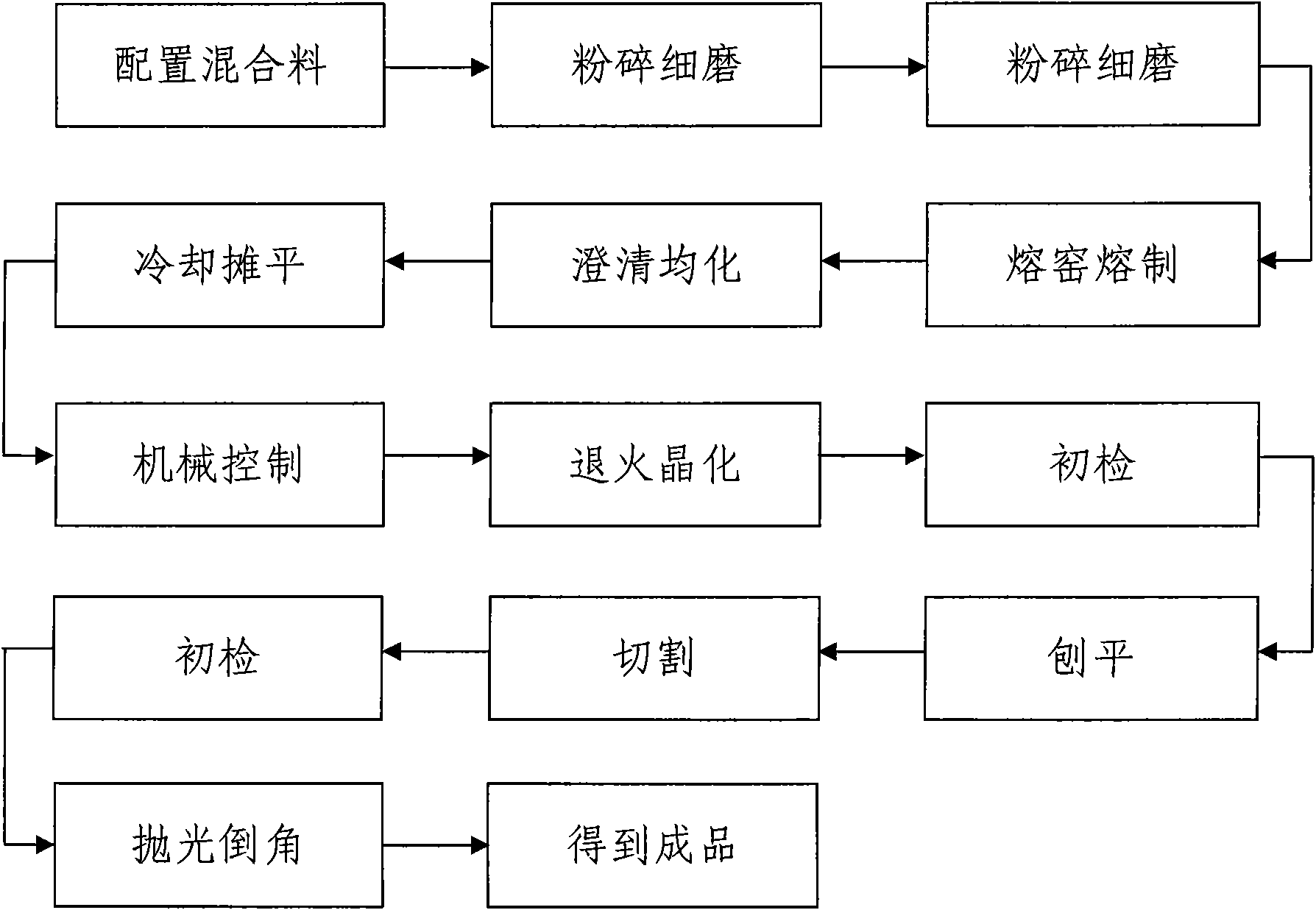

[0024] Such as figure 1 Shown, embodiment 1 of the present invention utilizes the production method of the crystallized glass that tailings solid waste is manufactured as follows:

[0025] (1) All raw materials are mechanically crushed with a gyratory crusher, and then finely ground by ball milling. The time of ball milling is 2 hours, and the particle size of 70% of the mixture after ball milling is controlled below 200 mesh.

[0026] (2) The finely ground mixture is subjected to vibration screening, and the screening grade is 200 mesh.

[0027] (3) The sieved mixed material is sent into the melting furnace, the melting temperature is controlled at 1650° C., and the melting time is 5 hours. After the mixture is melted into a liquid state, it is clarified and homogenized...

Embodiment 2

[0033] The composition of the weight percentage content of the glass-ceramics manufactured by tailings solid waste includes: SiO 2 60%, CaO 20%, MgO 6%, Al 2 o 3 5%, Na 2 O 6%, K 2 O 2%, Fe 2 o 3 1%.

[0034] Embodiment 2 of the present invention utilizes the production method of the glass-ceramics manufactured by tailings solid waste as follows:

[0035] (1) All raw materials are mechanically crushed with a gyratory crusher, and then finely ground by ball milling. The time of ball milling is 1.5 hours, and the particle size of 70% of the mixture after ball milling is controlled below 200 mesh.

[0036] (2) Vibration screening is carried out on the mixture obtained by fine grinding, and the grade of screening is 150 mesh.

[0037] (3) Send the sieved mixture into the melting furnace, the melting temperature is controlled at 1620° C., and the melting time is 3 hours. After the mixture is melted into a liquid state, it is clarified and homogenized and then flows into a t...

Embodiment 3

[0043] The composition of the weight percentage content of the glass-ceramics manufactured by tailings solid waste includes: SiO 2 58%, CaO 18%, MgO 3%, Al 2 o 3 7%, Na 2 O 2%, K 2 O 7%, Fe 2 o 3 5%.

[0044] Embodiment 3 of the present invention utilizes the production method of the glass-ceramics manufactured by tailings solid waste as follows:

[0045] (1) All raw materials are mechanically crushed with a gyratory crusher, and then finely ground by ball milling. The time of ball milling is 1 hour, and the particle size of 70% of the mixture after ball milling is controlled below 200 mesh.

[0046] (2) The finely ground mixed material is subjected to vibration screening, and the screening grade is 100 mesh.

[0047](3) Send the sieved mixture into the melting furnace, the melting temperature is controlled at 1600° C., and the melting time is 2 hours. After the mixture is melted into a liquid state, it is clarified and homogenized and then flows into a tin bath for mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com