Intelligent excavating and repairing device for wood surface defects

A wood surface and defect technology, applied in the field of intelligent digging and repairing devices, can solve the problems of high labor cost, high risk, and easy to be affected by human subjective influence, and achieve the effect of low labor cost, high degree of automation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

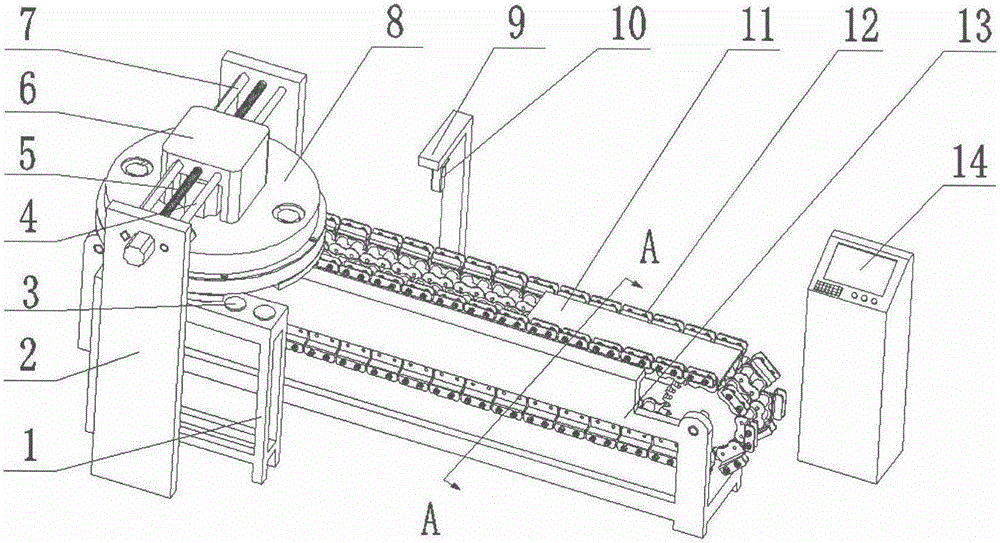

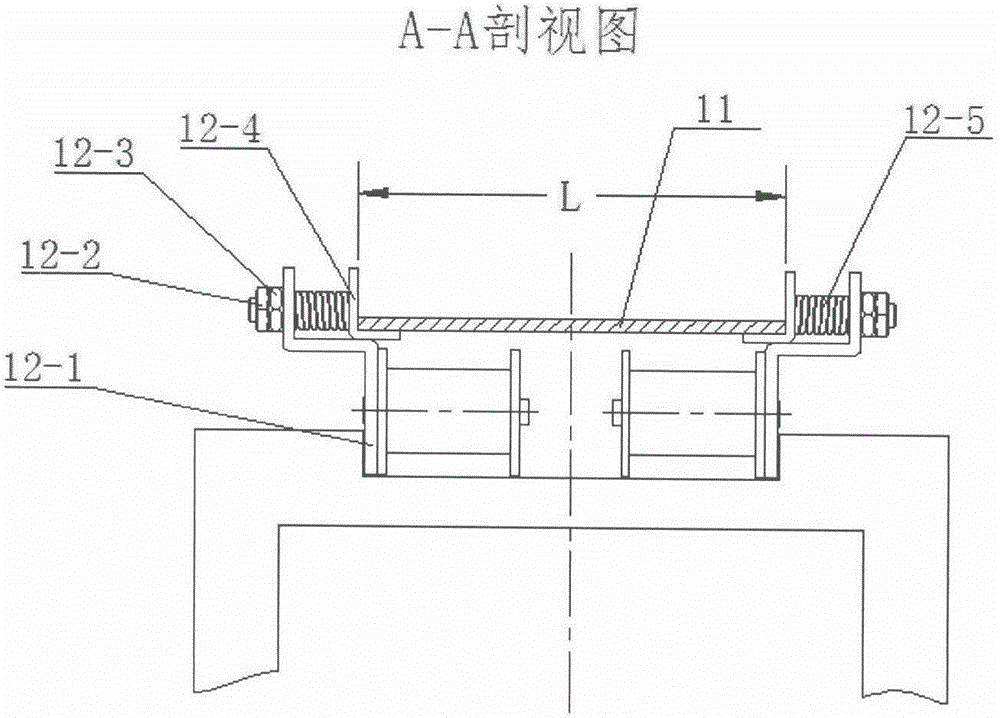

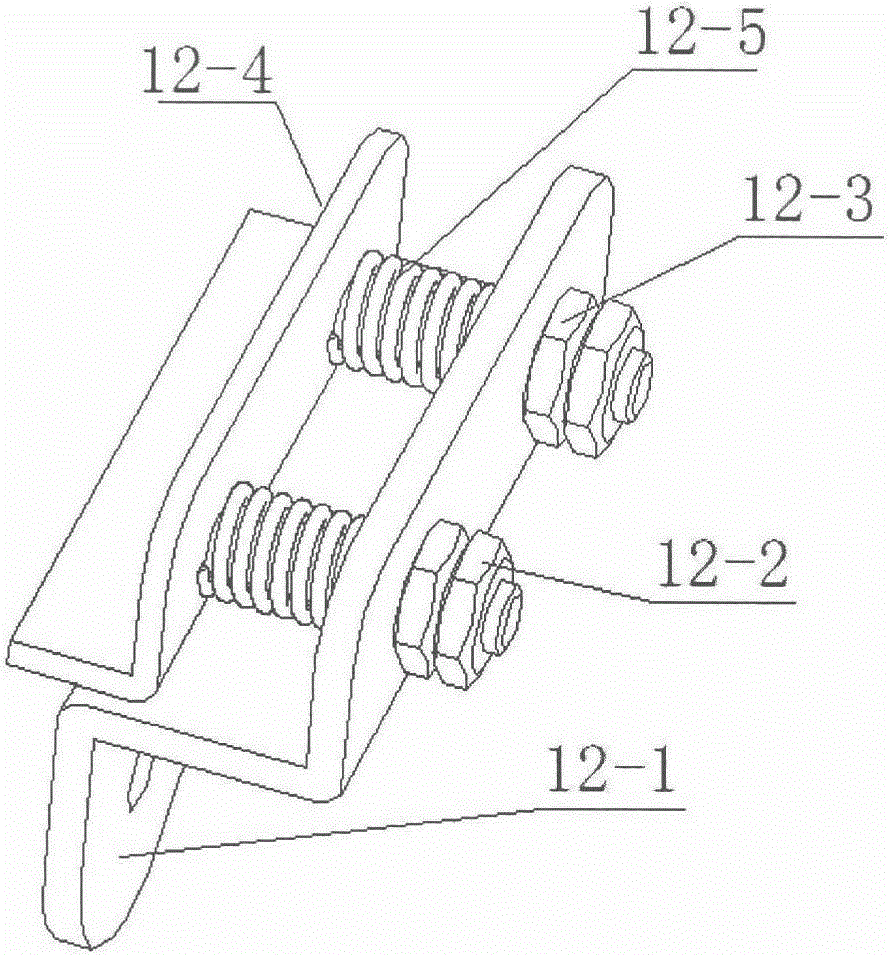

[0021]Place the plank to be processed (11) on the starting end of the conveyor chain (12), press it with a symmetrically installed clamping plate (12-4) with two cylindrical pins, and fix it on the conveyor chain (12); The glue-coated cork (3) of equal height is placed on the movable platform (1) at intervals; the operator presses the start button, and the control system starts to work, driven by the servo motor, the conveyor chain (12) drives the to-be-processed Plank (11) passes under the camera at a constant speed, and after the camera recognizes the surface defect of the plank to be processed, the control system in the operation console (14) records the defect position; ) to control the defect position of the plank to be processed (11) to stop under the support of the digging mechanism; the servo motor drives the screw (5) to rotate, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com