Treatment method of glycerin wastewater containing salt

A treatment method and technology for wastewater, which are applied in heating water/sewage treatment, extraction water/sewage treatment, water/sewage multi-stage treatment, etc. Operation and Control, Reduced Production Costs, Environmentally Friendly Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

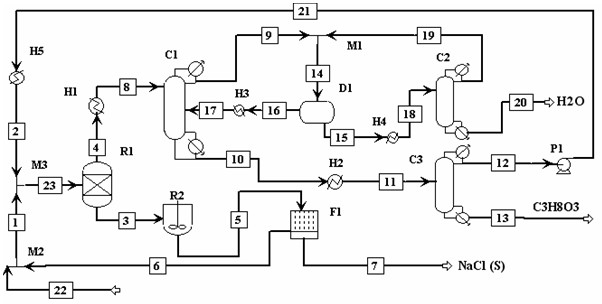

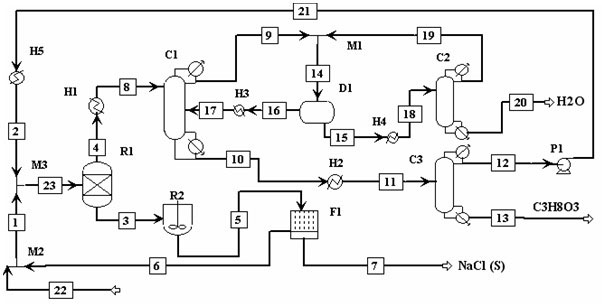

Method used

Image

Examples

Embodiment 1

[0025] The amount of n-butanol in this example is 2.5 times that of the production wastewater. The process flow is established according to the accompanying drawings, and the specific logistics connection is referred to the introduction of the process flow in the summary of the invention. Wastewater feed 22 (flow 1395.2kg / hr, water 56%, glycerol 26%, sodium chloride 18%) and filtrate 6 in filter F1 (flow 1668.8kg / hr, water 55%, glycerol 27%, sodium chloride accounted for 15%, n-butanol accounted for 3%) mixed into waste water circulation mixture material 1 (flow rate 3064kg / hr), and n-butanol circulation stream 2 (flow rate 7500kg / hr) in the third mixer M3 mixed in the middle to form waste water and solvent mixture 23 (flow rate 10564kg / hr) and enter the extraction tower R1. Operate at atmospheric pressure at a temperature of 30°C. In the extractor R1, the output extraction tower lower layer stream 3 (flow rate is 1921.7kg / hr, water accounts for 55%, glycerol accounts for 27...

Embodiment 2

[0030] The amount of n-butanol in this example is 1.3 times that of the production wastewater. The process flow is established according to the accompanying drawings, and the specific logistics connection is referred to the introduction of the process flow in the summary of the invention. Wastewater feed 22 (flow 792.1kg / hr, water 56%, glycerol 24%, sodium chloride 20%) and filter F1 filtrate 6 (flow 2297.9kg / hr, water 55%, glycerol 27%, sodium chloride accounted for 15%, n-butanol accounted for 3%) mixed into waste water circulation mixture material 1 (flow rate 3090kg / hr) and n-butanol circulation stream 2 (flow rate 3911.5kg / hr) in the third mixer M3 Mixed in, form waste water, solvent mixture 23 (flow rate 7010kg / hr) enter extraction tower R1. Operate at atmospheric pressure at a temperature of 50°C. In the extractor R1, the output extraction tower lower layer stream 3 (flow rate is 2443.5kg / hr, water accounts for 51%, glycerol accounts for 25%, sodium chloride accounts ...

Embodiment 3

[0035] The amount of n-butanol in this example is 3.3 times that of the production wastewater. The process flow is established according to the accompanying drawings, and the specific logistics connection is referred to the introduction of the process flow in the summary of the invention. Wastewater feed 22 (flow 1841.9kg / hr, water 56%, glycerol 18%, sodium chloride 26%) and filtrate 6 in filter F1 (flow 1208.1kg / hr, water 55%, glycerol 27%, sodium chloride accounted for 15%, n-butanol accounted for 3%) mixed into waste water circulation mixture material 1 (flow rate 3050kg / hr) and n-butanol circulation stream 2 (flow rate 9932.5kg / hr) in the third mixer M3 Mixed in, form waste water, solvent mixture 23 (flow rate 13010kg / hr) enter extraction tower R1. Operated at atmospheric pressure at a temperature of 70°C. In the extractor R1, the output extraction tower lower layer stream 3 (flow rate is 1533.0kg / hr, water accounts for 43%, glycerol accounts for 21%, sodium chloride acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com