Sulfur-resistant catalytic deoxidization process for methane-rich gas

A methane gas, catalytic deoxidation technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc. High labor intensity, expensive catalyst and other problems, to achieve the effect of simple operation, cost saving and easy automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

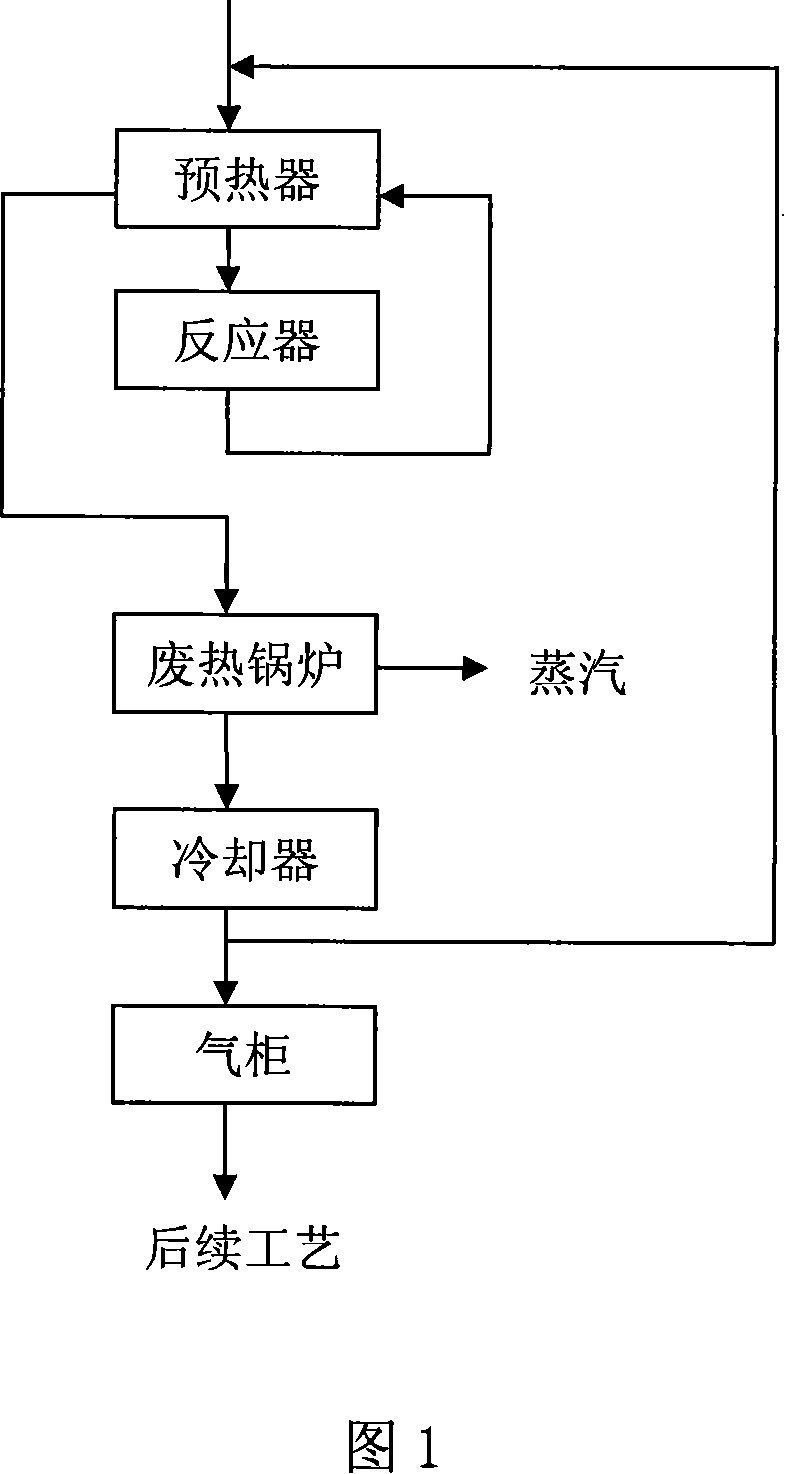

[0036] This embodiment is a sulfur-resistant catalytic deoxidation process for coalbed methane:

[0037] The raw coalbed methane is preheated by the preheater and directly enters the deoxidation reactor. Under the conditions of normal pressure and temperature of 500-550°C, the space velocity is 2500h -1 , in the catalyst bed, the methane in the coalbed methane reacts with oxygen to generate carbon dioxide and water, and at the same time a small amount of methane is cracked to produce carbon and hydrogen, and the carbon and hydrogen produced by the cracking react with oxygen, so as to effectively remove the oxygen in the coalbed gas In addition, by circulating the partially deoxidized and cooled coalbed methane to the raw coalbed methane before deoxidation, the oxygen content entering the reactor is adjusted to an appropriate range of 1-1.5%, and the reaction temperature is controlled within the range of 500-550°C.

[0038]The catalyst used in the deoxidation process of this ex...

Embodiment 2

[0043] This embodiment is a sulfur-resistant catalytic deoxidation process for coalbed methane:

[0044] The raw coalbed methane is preheated by the preheater and directly enters the deoxidation reactor. Under the conditions of normal pressure and temperature of 500-550°C, the space velocity is 1000h -1 , in the catalyst bed, the methane in the coalbed methane reacts with oxygen to generate carbon dioxide and water, and at the same time a small amount of methane is cracked to produce carbon and hydrogen, and the carbon and hydrogen produced by the cracking react with oxygen, so as to effectively remove the oxygen in the coalbed gas In addition, by circulating the partially deoxygenated and cooled coalbed methane to the raw coalbed methane before deoxidation, the oxygen content entering the reactor is adjusted to an appropriate range of 2.5-3%, and the reaction temperature is controlled within the range of 500-550°C.

[0045] The catalyst used in the deoxygenation process of th...

Embodiment 3

[0050] This embodiment is a sulfur-resistant catalytic deoxidation process for coalbed methane:

[0051] The raw coalbed methane is preheated by the preheater and directly enters the deoxidation reactor. Under the conditions of normal pressure and temperature of 600-650°C, the space velocity is 2000h -1 , in the catalyst bed, the methane in the coalbed methane reacts with oxygen to generate carbon dioxide and water, and at the same time a small amount of methane is cracked to produce carbon and hydrogen, and the carbon and hydrogen produced by the cracking react with oxygen, so as to effectively remove the oxygen in the coalbed gas In addition, by circulating partially deoxidized and cooled coalbed methane to raw coalbed methane before deoxidation, adjust the oxygen content entering the reactor to an appropriate range of 3.5-4%, and control the reaction temperature within the range of 600-650°C.

[0052] The catalyst used in the deoxidation process of this example is a ring-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com