Method for preparing high-purity siliceous reinforcing agent by using rice hull ash as raw material

A technology of rice husk ash and white carbon black, which is applied in the direction of silicon dioxide and silicon oxide, can solve the problems of wasting resources, polluting the environment, and low value itself, and achieves the effects of eliminating pollution, simple operation, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

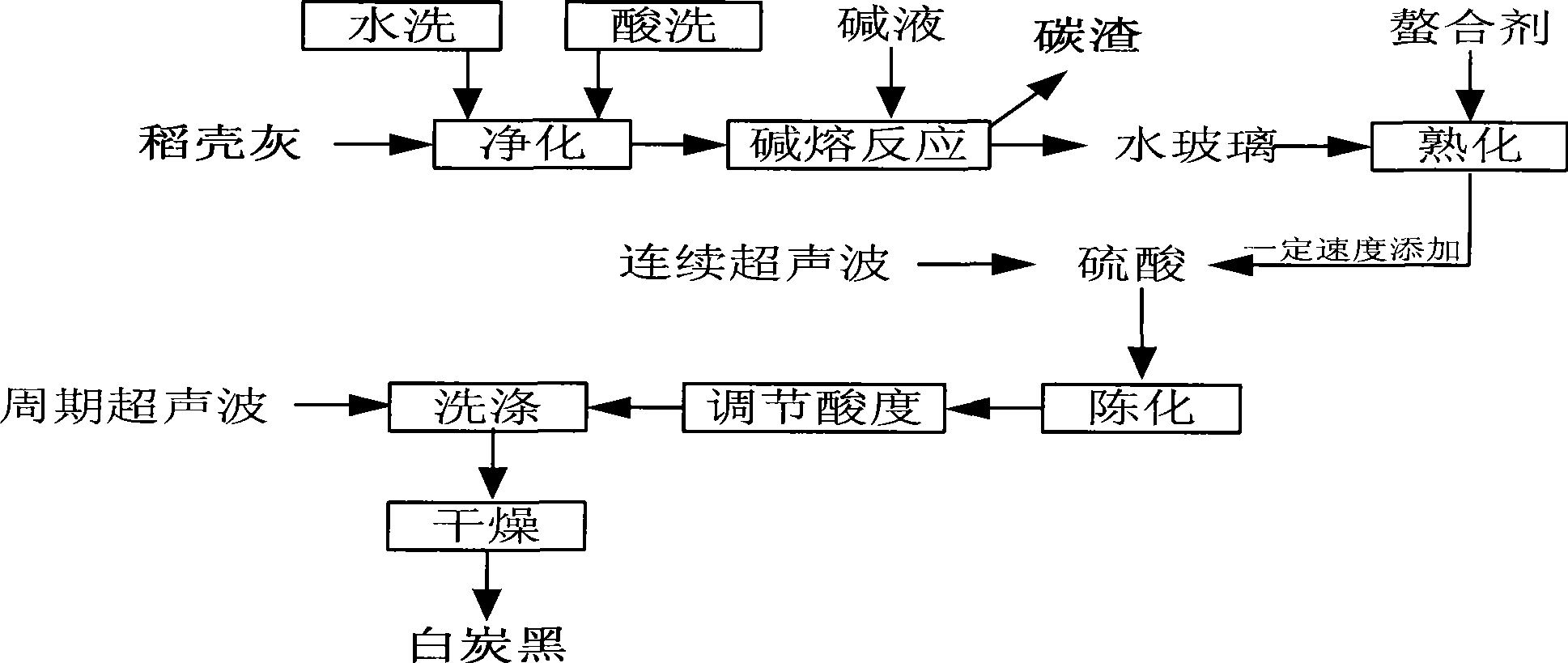

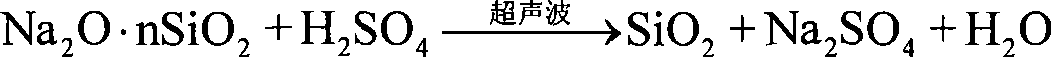

Method used

Image

Examples

Embodiment 1

[0026] 1. Take 1000g of rice husk ash and pass it through a 100-mesh sieve, take 5L of deionized water, wash the rice husk ash and water for 20 minutes under constant stirring, and then centrifuge at a centrifugal speed of 3000rpm. After repeating the steps of washing and centrifuging twice, the concentration Pickle with 5L of 0.1mol / L hydrochloric acid for 2 hours, then filter and wash with water until the washing liquid is neutral (pH6.5), and then dry the washed rice husk ash in an oven at 90°C;

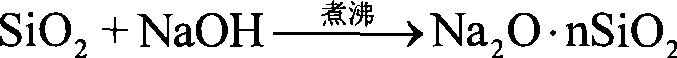

[0027] 2. Take 10g of washed and dried rice husk ash and mix it with 100mL of sodium hydroxide solution, the concentration of lye is 1.0mol / L, boil to 100°C for 2 hours, stir continuously during the reaction; then suction filter, and then use 100°C Wash with boiling water until the pH value is 6.5, collect the filtrate and washing liquid and concentrate in a vacuum rotary evaporator to obtain water glass. The concentration conditions are: temperature 50°C, rotation speed 300r / min, ...

Embodiment 2

[0032] 1. Take 1500g of rice husk ash and pass it through a 100-mesh sieve, take 5.5L of deionized water, wash the rice husk ash and water for 30 minutes under constant stirring, and then centrifuge at 3000rpm, repeat the steps of washing and centrifuging 3 times, use Pickle with 5.5L of hydrochloric acid with a concentration of 0.1mol / L for 2.5h, then filter and wash with water until the washing liquid is neutral (pH7.0), and then dry the washed rice husk ash in an oven at 90°C ;

[0033] 2. Take 12.5g of washed and dried rice husk ash and mix it with 125mL of sodium hydroxide solution, the concentration of lye is 1.5mol / L, boil to 100℃ for 2.5h, stir continuously during the reaction; Wash with boiling water at 100°C until the pH value is 7.0, collect the filtrate and washing liquid and concentrate in a vacuum rotary evaporator to obtain water glass. The concentration conditions are: temperature 55°C, rotation speed 300r / min, vacuum degree 0.1×10 5 Pa;

[0034] 3. Dilute th...

Embodiment 3

[0038] 1. Take 2000g of rice husk ash and pass it through a 100-mesh sieve, take 6L of deionized water, wash the rice husk ash and water for 40 minutes under constant stirring, and then centrifuge at a centrifugal speed of 3000rpm. After repeating the washing and centrifuging steps 4 times, the concentration Pickling with 6L of 0.1mol / L hydrochloric acid for 3 hours, and then washing with suction and water until the washing liquid is neutral (pH7.5), and then drying the washed rice husk ash in an oven at 90°C;

[0039] 2. Mix 15g of washed and dried rice husk ash with 150mL of sodium hydroxide solution, the concentration of lye is 2.0mol / L, boil to 100°C for 3 hours, stir continuously during the reaction; Wash with boiling water until the pH value is 7.5, collect the filtrate and washing liquid and concentrate in a vacuum rotary evaporator to obtain water glass. The concentration conditions are: temperature 60°C, rotation speed 300r / min, vacuum degree 0.1×10 5 Pa;

[0040] 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com