High-concentration wastewater zero-discharging method

A concentrated wastewater, zero discharge technology, applied in the direction of energy wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve optimization problems, achieve light membrane pollution, solve difficult problems, important environmental benefits and The effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The main water quality characteristics of high-concentration wastewater are: wastewater pH7, conductivity 10000μs / cm, COD cr 100mg / L, Na + 2000mg / L, Cl - 2500mg / L, total hardness (CaCO 3 ) 1500mg / L, dissolved silicon 50mg / L, NH 4 -N0mg / L.

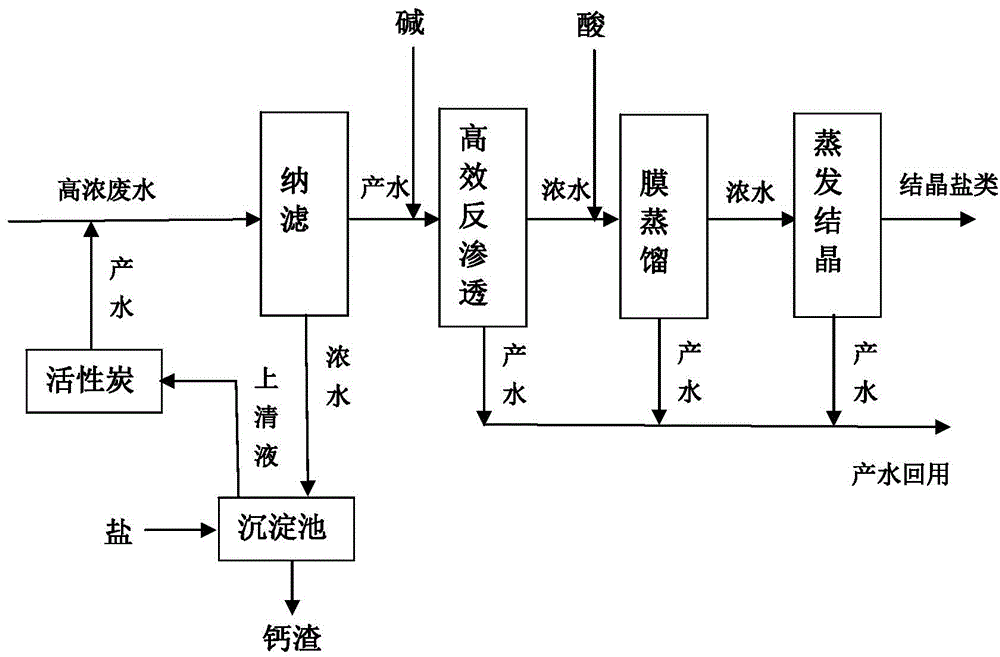

[0075] Such as figure 1 As shown, the treatment process of the high-concentration wastewater is as follows:

[0076] (1) Nanofiltration. The high-concentration wastewater enters the nanofiltration unit for nanofiltration treatment, removes multivalent ions such as hardness and some organic matter in the high-concentration wastewater, and obtains nanofiltration product water and nanofiltration concentrated water, and the nanofiltration product water enters step (2) for treatment. Sodium carbonate is added to the nanofiltration concentrated water to precipitate calcium ions to obtain calcium slag. The calcium slag is concentrated and dried, and the supernatant is adsorbed by powdered activated carbon, and then returned to the nan...

Embodiment 2

[0088] The main water quality characteristics of high-concentration wastewater are: wastewater pH7, conductivity 13000μs / cm, COD cr 150mg / L, Na + 2000mg / L, Cl - 2500mg / L, total hardness (CaCO 3 )2000mg / L, dissolved silicon 50mg / L, NH 4 -N0mg / L.

[0089] Such as figure 1 As shown, the treatment process of the high-concentration wastewater is as follows:

[0090] (1) Nanofiltration. The high-concentration wastewater enters the nanofiltration unit for nanofiltration treatment, removes multivalent ions such as hardness and some organic matter in the high-concentration wastewater, and obtains nanofiltration product water and nanofiltration concentrated water, and the nanofiltration product water enters step (2) for treatment. Sodium sulfate is added to the nanofiltration concentrated water to precipitate calcium ions to obtain calcium slag. The calcium slag is concentrated and dried, and the supernatant is adsorbed by granular activated carbon, and then returned to the nanofi...

Embodiment 3

[0102] The main water quality characteristics of high-concentration wastewater are: wastewater pH8, conductivity 15000μs / cm, COD cr 300mg / L, Na + 3000mg / L, Cl - 3500mg / L, total hardness (CaCO 3 )2500mg / L, dissolved silicon 80mg / L, NH 4 -N3mg / L.

[0103] Such as figure 1 As shown, the treatment process of the high-concentration wastewater is as follows:

[0104] (1) Nanofiltration. The high-concentration wastewater enters the nanofiltration unit for nanofiltration treatment, removes multivalent ions such as hardness and some organic matter in the high-concentration wastewater, and obtains nanofiltration product water and nanofiltration concentrated water, and the nanofiltration product water enters step (2) for treatment. Add a mixture of sodium carbonate and sodium sulfate to the nanofiltration concentrated water to precipitate calcium ions to obtain calcium slag. The calcium slag is concentrated and dried, and the supernatant is adsorbed by powdered activated carbon, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com