A zero-discharge method for high-salt wastewater

A high-salt wastewater, zero-discharge technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Realize the effect of resource disposal and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The main water quality characteristics of high-salt wastewater are: wastewater pH7, conductivity 10000μs / cm, COD cr 0 mg / L, Na + 2000mg / L, Cl - 2500mg / L, total hardness (CaCO 3 ) 200mg / L, alkalinity (as CaCO 3 Total) 100mg / L, dissolved silicon 0mg / L.

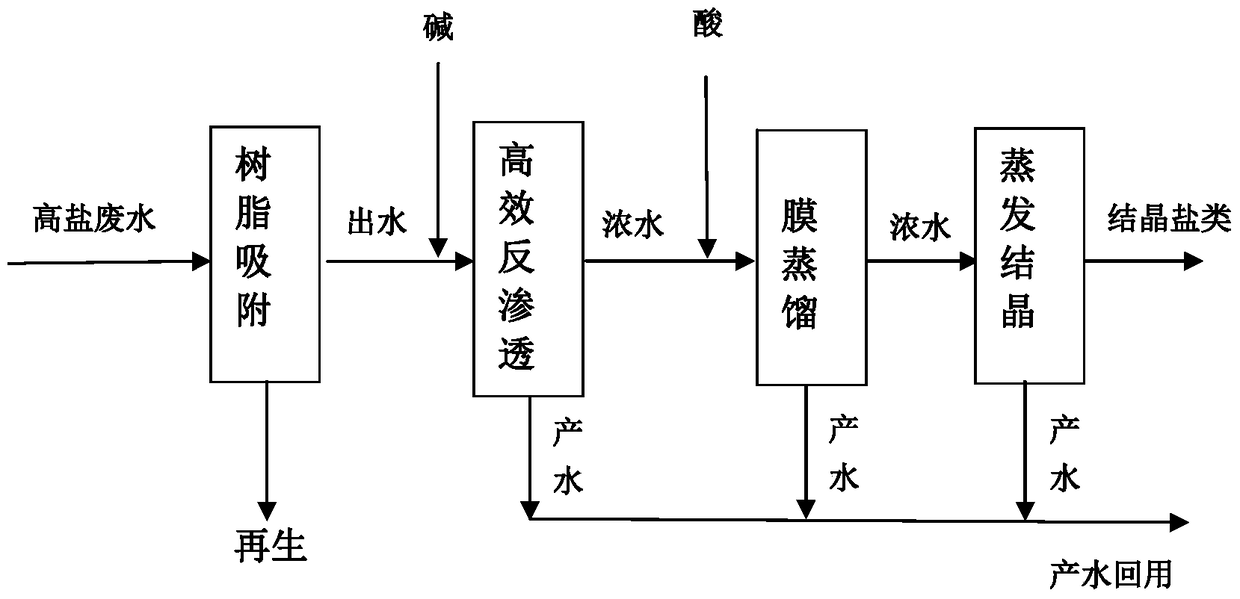

[0075] Such as figure 1 As shown, the treatment process of this high-salt wastewater is as follows:

[0076] (1) Resin adsorption. First, enter the high-salt wastewater into the resin adsorption unit for resin adsorption treatment, remove hardness and a small amount of organic matter in the high-salt wastewater, and obtain effluent after resin adsorption;

[0077] Wherein, the resin adopts a first-grade weakly acidic cation exchange resin, and the operating flow rate of the resin adsorption unit is 4BV / h; under this operating condition, the hardness of the water produced by resin adsorption is less than 10mg / L; after the resin is saturated, 5% hydrochloric acid is used Perform elution and regeneration, the regenera...

Embodiment 2

[0087] The main water quality characteristics of high-salt wastewater are: wastewater pH7.5, conductivity 15000μs / cm, COD cr 50mg / L, Na + 3000mg / L, Cl - 3500mg / L, total hardness (CaCO 3)500mg / L, alkalinity (as CaCO 3 Total) 150mg / L, dissolved silicon 20mg / L.

[0088] Such as figure 1 As shown, the treatment process of this high-salt wastewater is as follows:

[0089] (1) Resin adsorption. First, enter the high-salt wastewater into the resin adsorption unit for resin adsorption treatment, remove hardness and a small amount of organic matter in the high-salt wastewater, and obtain effluent after resin adsorption;

[0090] Wherein, the resin adopts a first-grade weakly acidic cation exchange resin, and the operating flow rate of the resin adsorption unit is 6BV / h; under this operating condition, the hardness of the water produced by resin adsorption is less than 10mg / L; after the resin is saturated, 7% hydrochloric acid is used Perform elution and regeneration, the regener...

Embodiment 3

[0100] The main water quality characteristics of high-salt wastewater are: wastewater pH8, conductivity 20000μs / cm, COD cr 100mg / L, Na + 4000mg / L, Cl - 5000mg / L, total hardness (CaCO 3 ) 1000mg / L, alkalinity (as CaCO 3 Total) 300mg / L, dissolved silicon 50mg / L.

[0101] Such as figure 1 As shown, the treatment process of this high-salt wastewater is as follows:

[0102] (1) Resin adsorption. First, enter the high-salt wastewater into the resin adsorption unit for resin adsorption treatment, remove hardness and a small amount of organic matter in the high-salt wastewater, and obtain effluent after resin adsorption;

[0103] Wherein, the resin adopts two-stage weakly acidic cation exchange resins, and the resin adsorption water after the first-stage resin adsorption is about to enter the second-stage resin adsorption, and the operating flow rate of the resin adsorption unit is 8BV / h; under these operating conditions, the resin adsorption The hardness of the produced water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com