High-salinity high-hardness wastewater zero-discharging method

A high-hardness, zero-emission technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Energy consumption, easy membrane flux, and the effect of reducing membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The water quality characteristics of high-salt and high-hardness wastewater are: wastewater pH7.5, conductivity 10000μs / cm, COD cr 100mg / L, Na + 2000mg / L, Cl - 2500mg / L, total hardness (CaCO 3 ) 1500mg / L, dissolved silicon 50mg / L, NH 4 -N0mg / L.

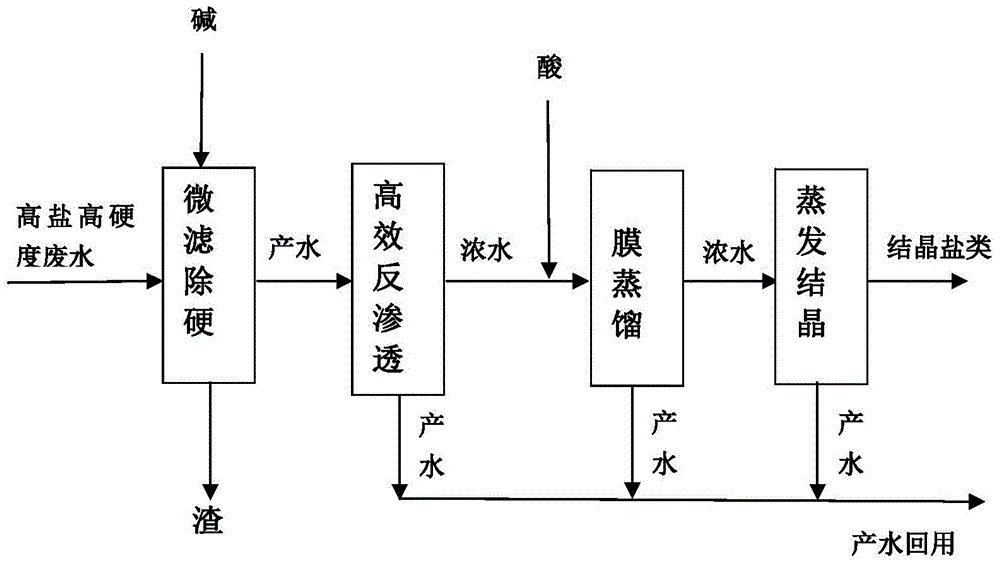

[0071] Such as figure 1 As shown, the treatment process of this high-salt and high-hardness wastewater is as follows:

[0072] (1) Microfiltration to remove hardness. Firstly, the pH of the high-salt and high-hardness wastewater was adjusted to 10.8 by adding sodium hydroxide, and the reaction time was 60 minutes. Afterwards, a PTFE Gore microfiltration membrane with a membrane pore size of 0.2 μm was used for microfiltration and filtration to remove high-salt and high-pressure wastewater. The hardness in the hardness wastewater can be obtained by microfiltration product water;

[0073] Among them, the Gore microfiltration flux is constant at 500L / m 2 h, under this constant flux, during the continuous 15-day operation, ...

Embodiment 2

[0083] The water quality characteristics of high-salt and high-hardness wastewater are: wastewater pH7.5, conductivity 10000μs / cm, COD cr 100mg / L, Na + 2000mg / L, Cl - 2500mg / L, total hardness (CaCO 3 ) 1500mg / L, dissolved silicon 50mg / L, NH 4 -N0mg / L.

[0084] Such as figure 1 As shown, the treatment process of this high-salt and high-hardness wastewater is as follows:

[0085] (1) Microfiltration to remove hardness. First, the pH of the high-salt and high-hardness wastewater was adjusted to 11 by adding sodium hydroxide, and the reaction time was 40 minutes. Afterwards, a PTFE Gore microfiltration membrane with a membrane pore size of 0.2 μm was used for microfiltration and filtration to remove high-salt and high-pressure wastewater. The hardness in the hardness wastewater is obtained by microfiltration to remove the hard product water;

[0086] Among them, the flux of microfiltration is constant at 400L / m 2 h, under this constant flux, during the continuous 15-day oper...

Embodiment 3

[0096] The water quality characteristics of high-salt and high-hardness wastewater are: wastewater pH 8.5, conductivity 15000μs / cm, COD cr 150mg / L, Na + 3000mg / L, Cl - 3500mg / L, total hardness (CaCO 3 )2200mg / L, dissolved silicon 80mg / L, NH 4 -N3mg / L.

[0097] Such as figure 1 As shown, the treatment process of this high-salt and high-hardness wastewater is as follows:

[0098] (1) Microfiltration to remove hardness. First, the pH of the high-salt and high-hardness wastewater was adjusted to 11 by adding sodium hydroxide, and the reaction time was 50 minutes. Afterwards, a PTFE Gore microfiltration membrane with a membrane pore size of 0.2 μm was used for microfiltration and filtration to remove high-salt and high-pressure wastewater. The hardness in the hardness wastewater can be obtained by microfiltration product water;

[0099] Among them, the flux of microfiltration is constant at 400L / m 2 h, under this constant flux, during the continuous 15-day operation, the op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com