Structure and method for contact pads having a recessed bondable metal plug over of copper-metallized integrated circuits

a technology of integrated circuits and contact pads, which is applied in the direction of semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems significant technological challenges, and the relative high resistivity of interconnecting aluminum now appears inferior to the lower resistivity of metals such as copper, so as to reduce the risk of aluminum smearing or scratching and electrical shorting, and facilitate the shrinking of the pitch of the contact pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

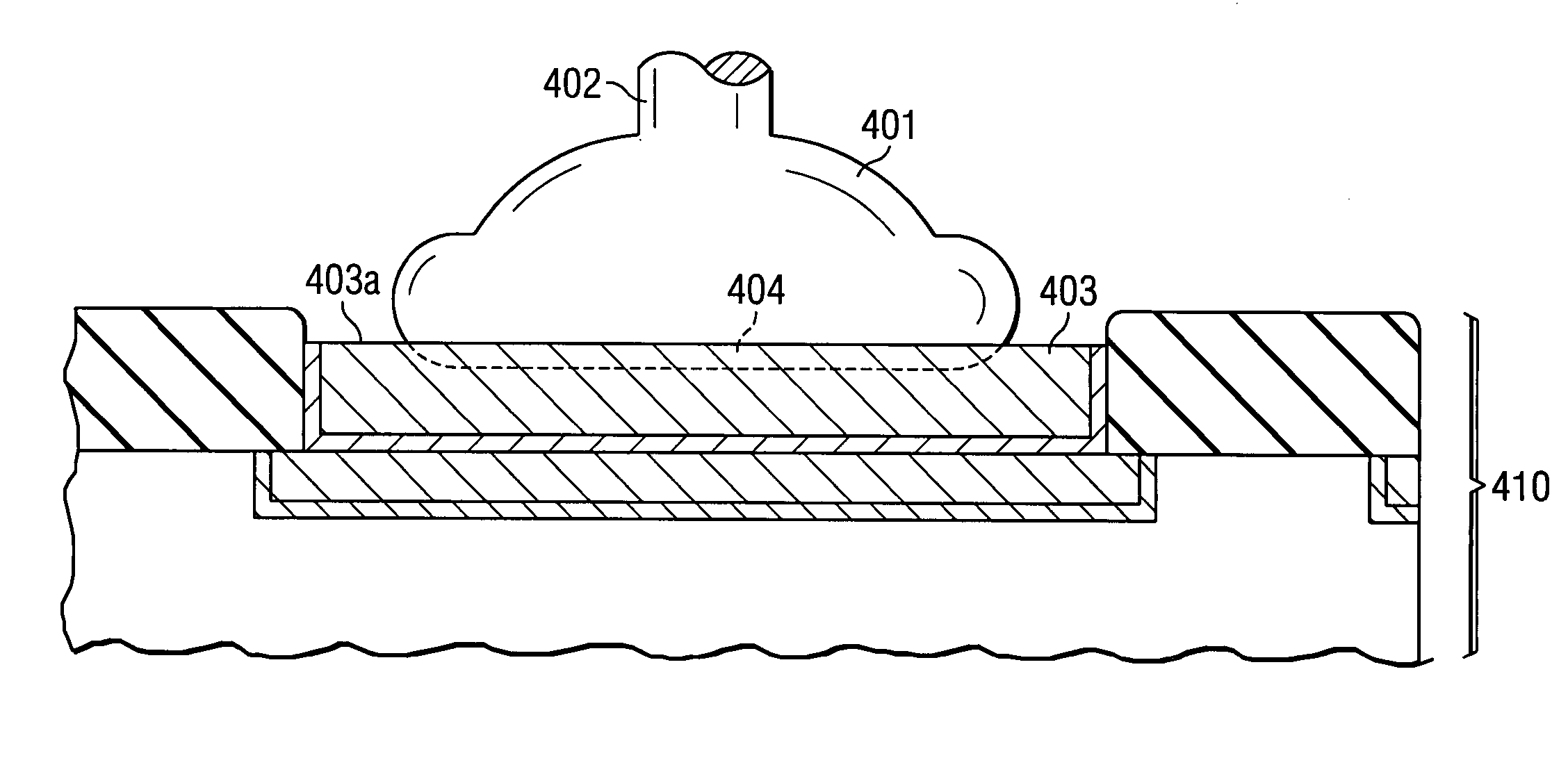

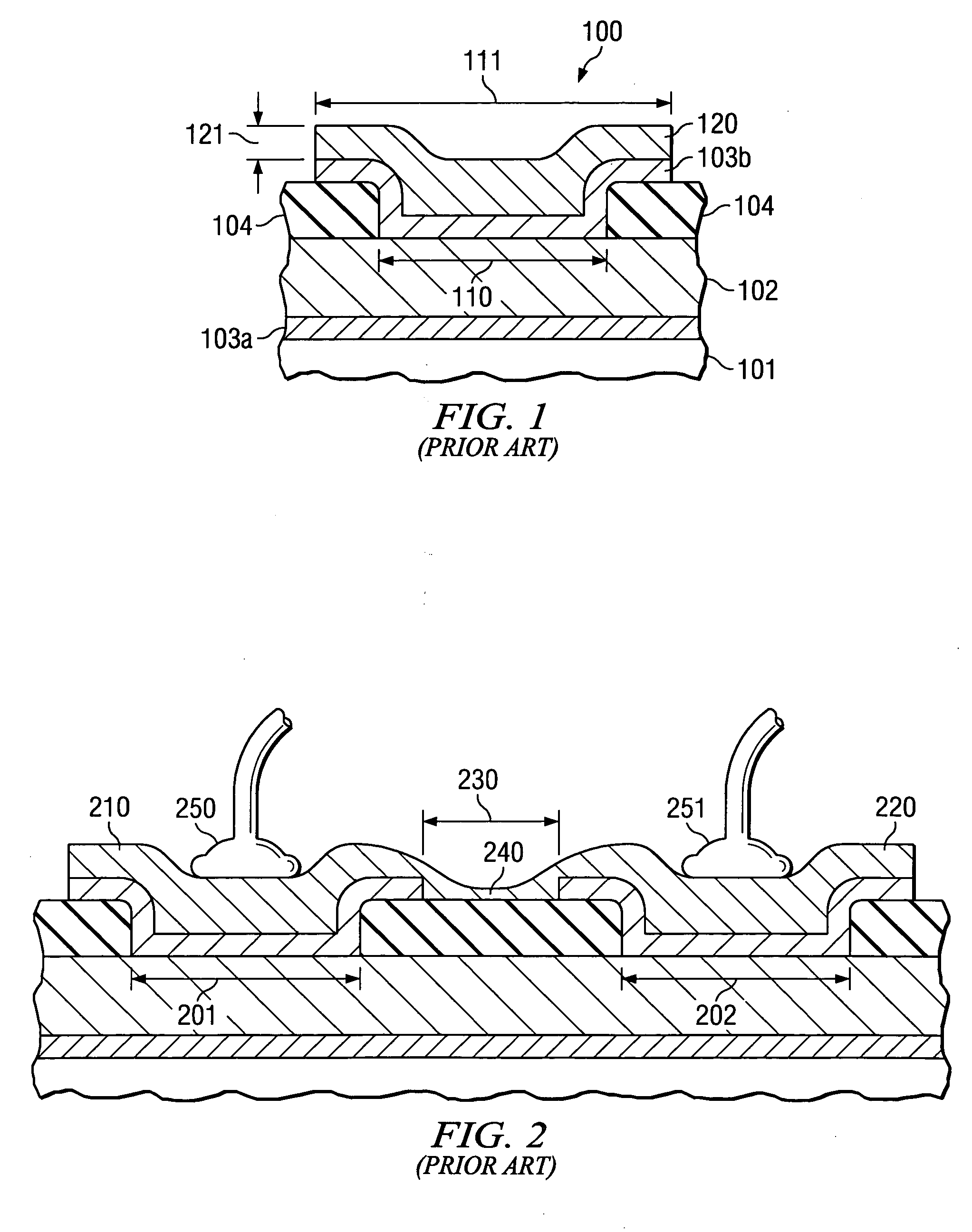

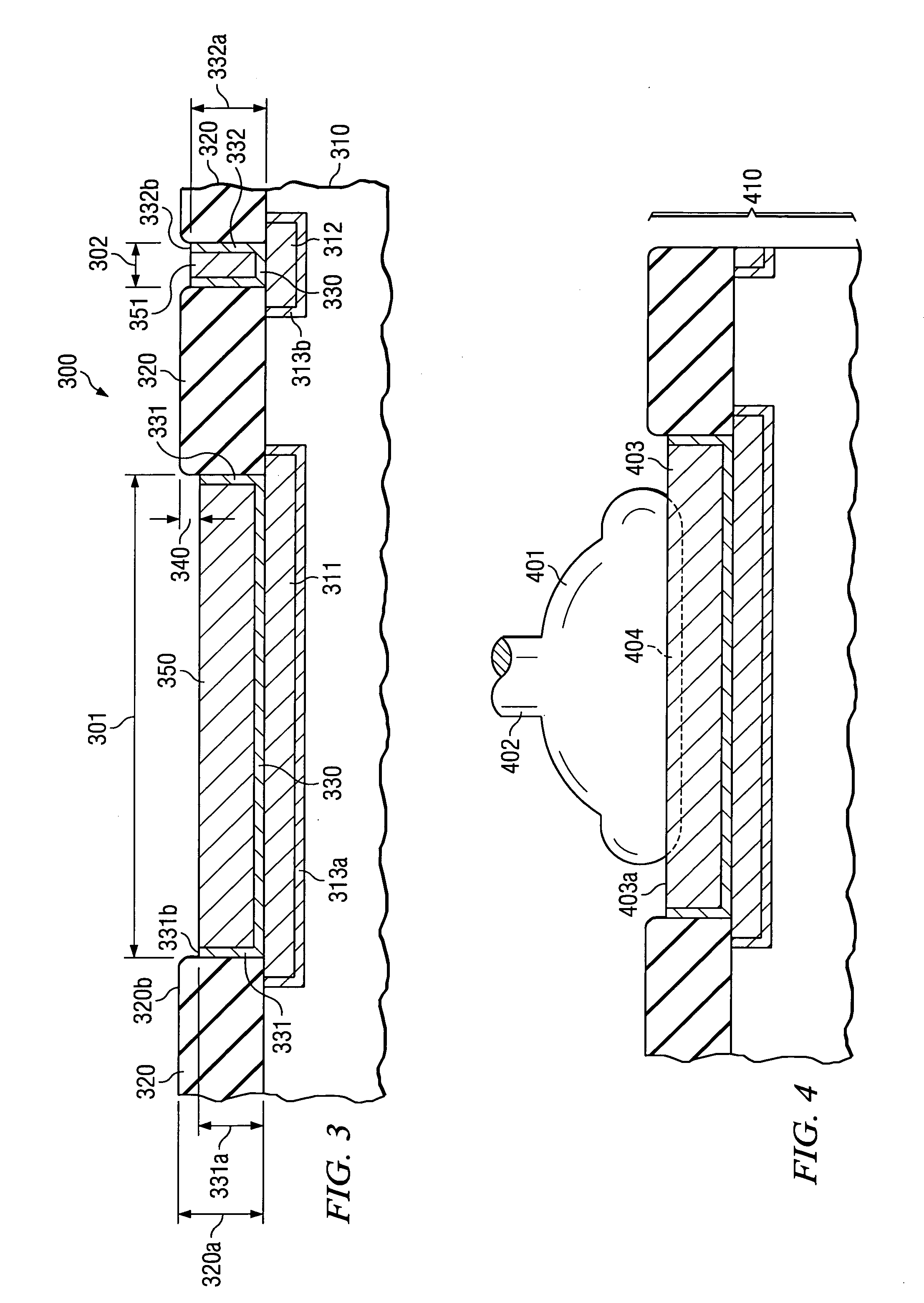

[0017] The technical advantages offered by the invention can be best appreciated by comparing an embodiment of the invention with the conventional method of wire-bonding a contact pad of an integrated circuit (IC) chip, which uses copper as interconnecting metal. An example of a conventional structure is depicted in FIG. 1. In the schematic cross section of an IC contact pad generally designated 100, 101 is an intra-level dielectric, which may consist of silicon dioxide, a low-k dielectric, or any other suitable insulator customarily used in ICs. 102 represents the top level IC copper metallization (thickness typically between 200 and 500 nm, contained by barrier layers 103a and 103b (typically tantalum nitride, typically 10 to 30 nm thick) from diffusing into other IC materials. In the essentially moisture-impermeable overcoat layer 104 (typically between 500 to 1000 nm of silicon nitride, silicon oxynitride, or silicon dioxide, single-layered or multi-layered) is contact window 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com