Patents

Literature

168 results about "Penstock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A penstock is a sluice or gate or intake structure that controls water flow, or an enclosed pipe that delivers water to hydro turbines and sewerage systems. The term is inherited from the earlier technology of mill ponds and watermills.

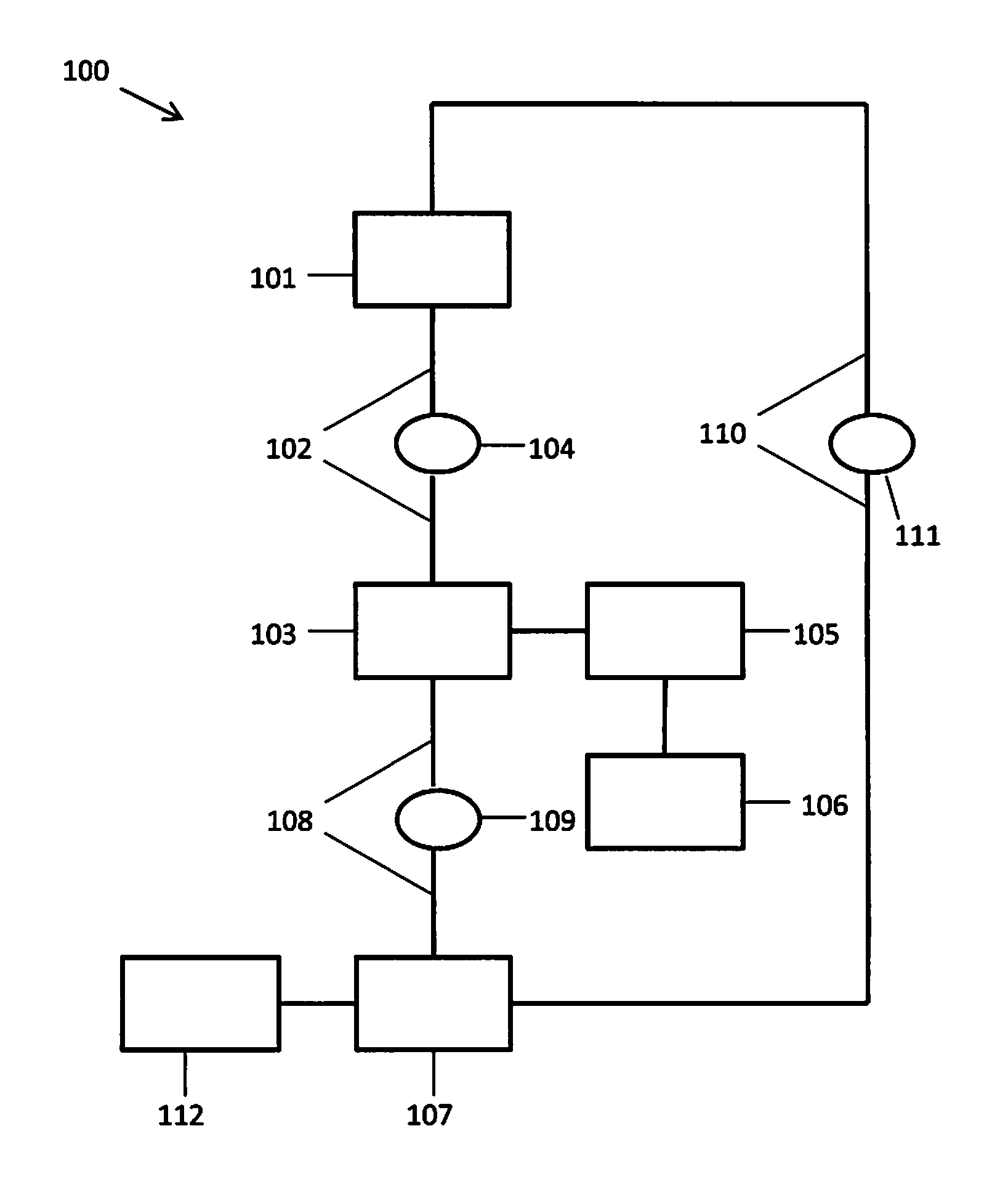

Multiple energy inputs hydropower system

InactiveUS20090152871A1Short construction timeKeep levelEngine componentsMechanical power devicesSaline waterDesalination

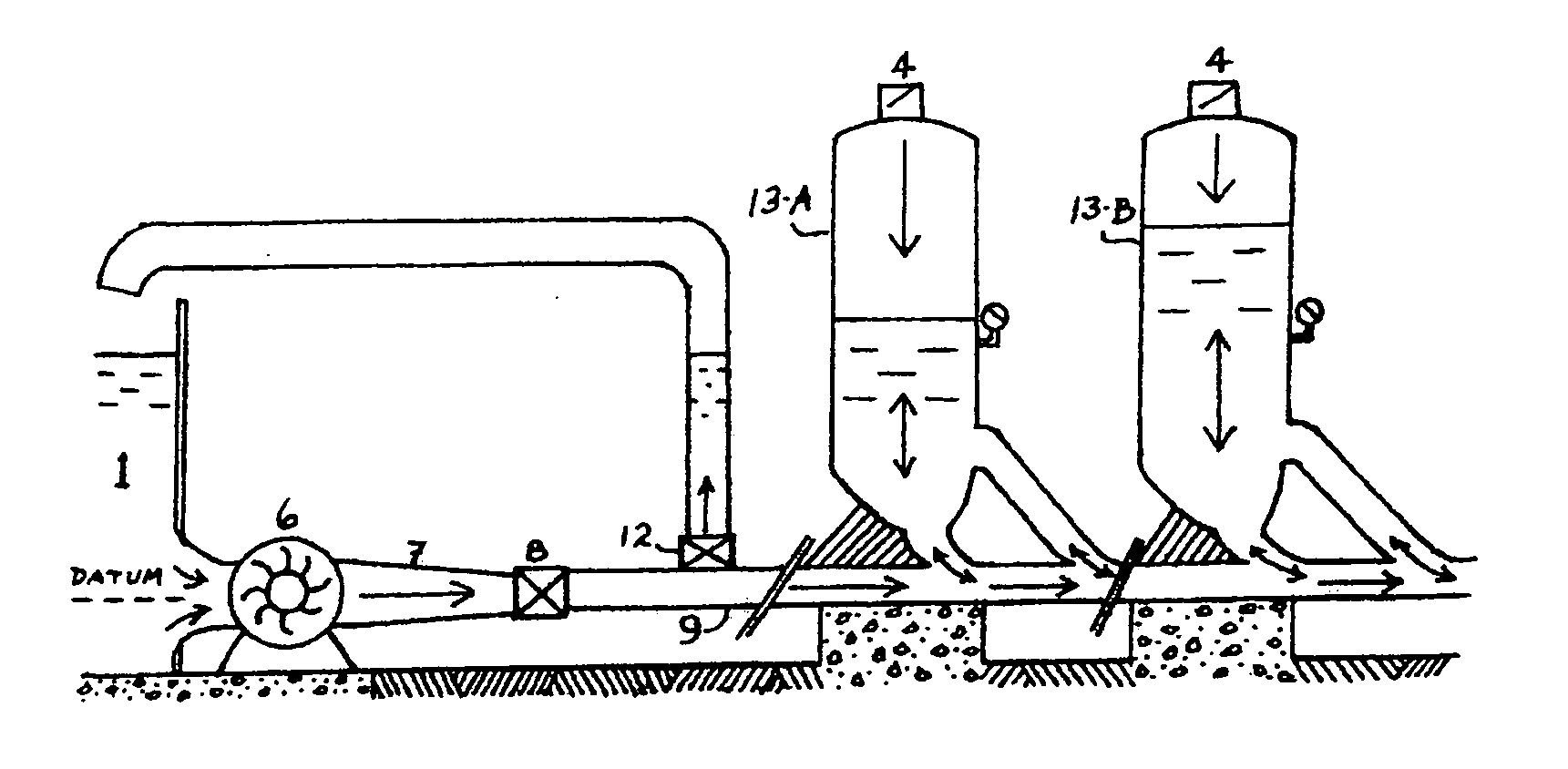

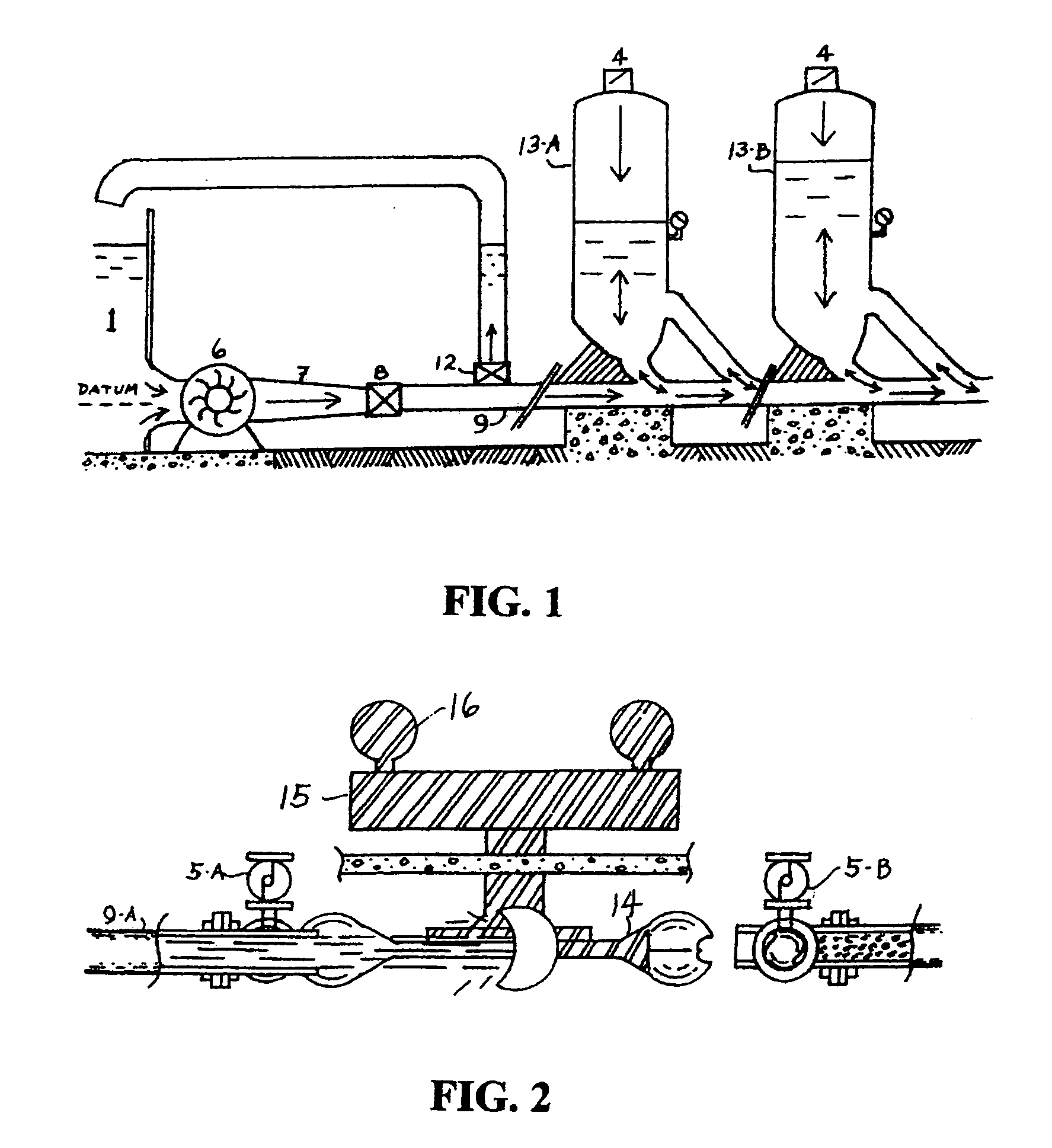

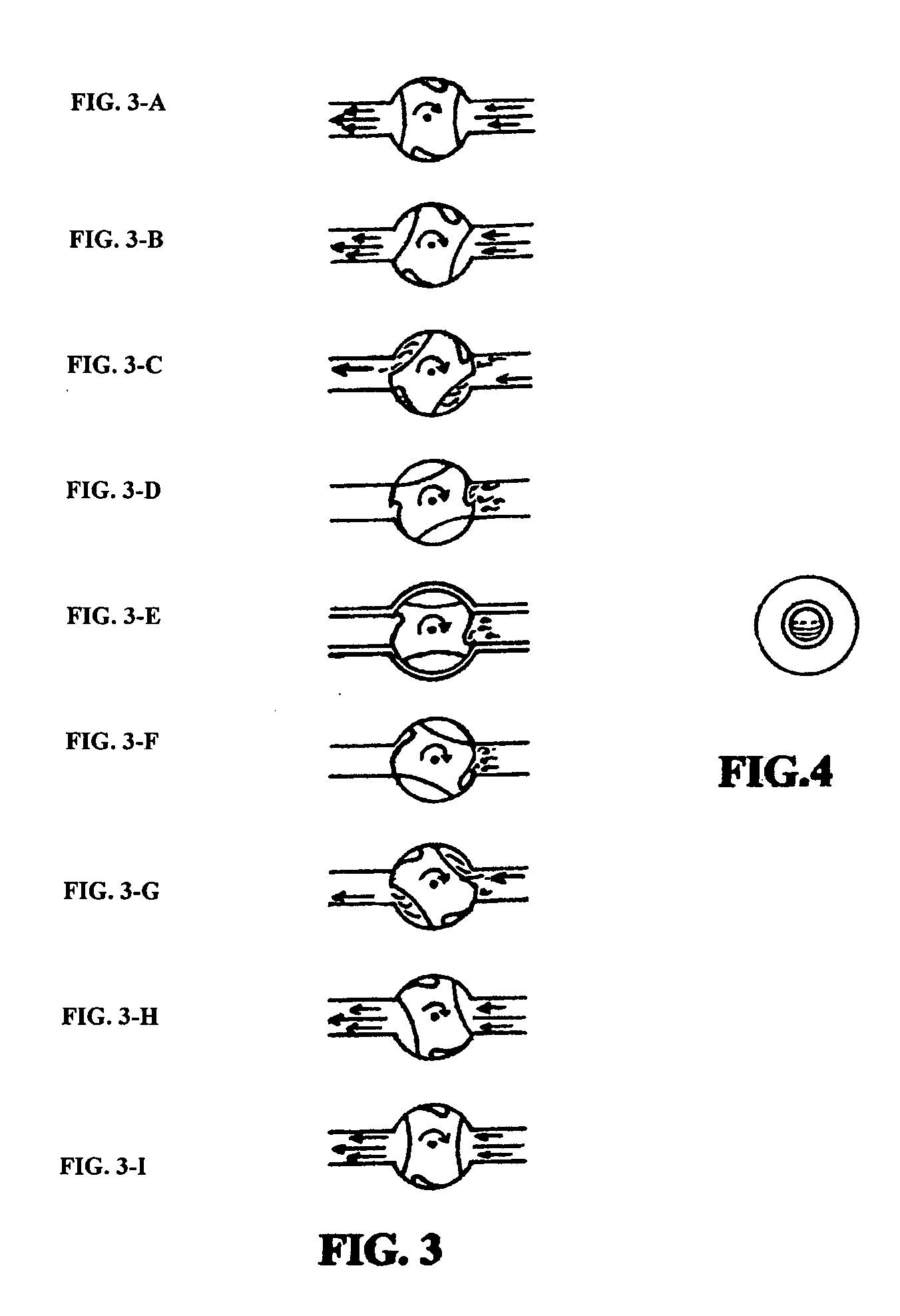

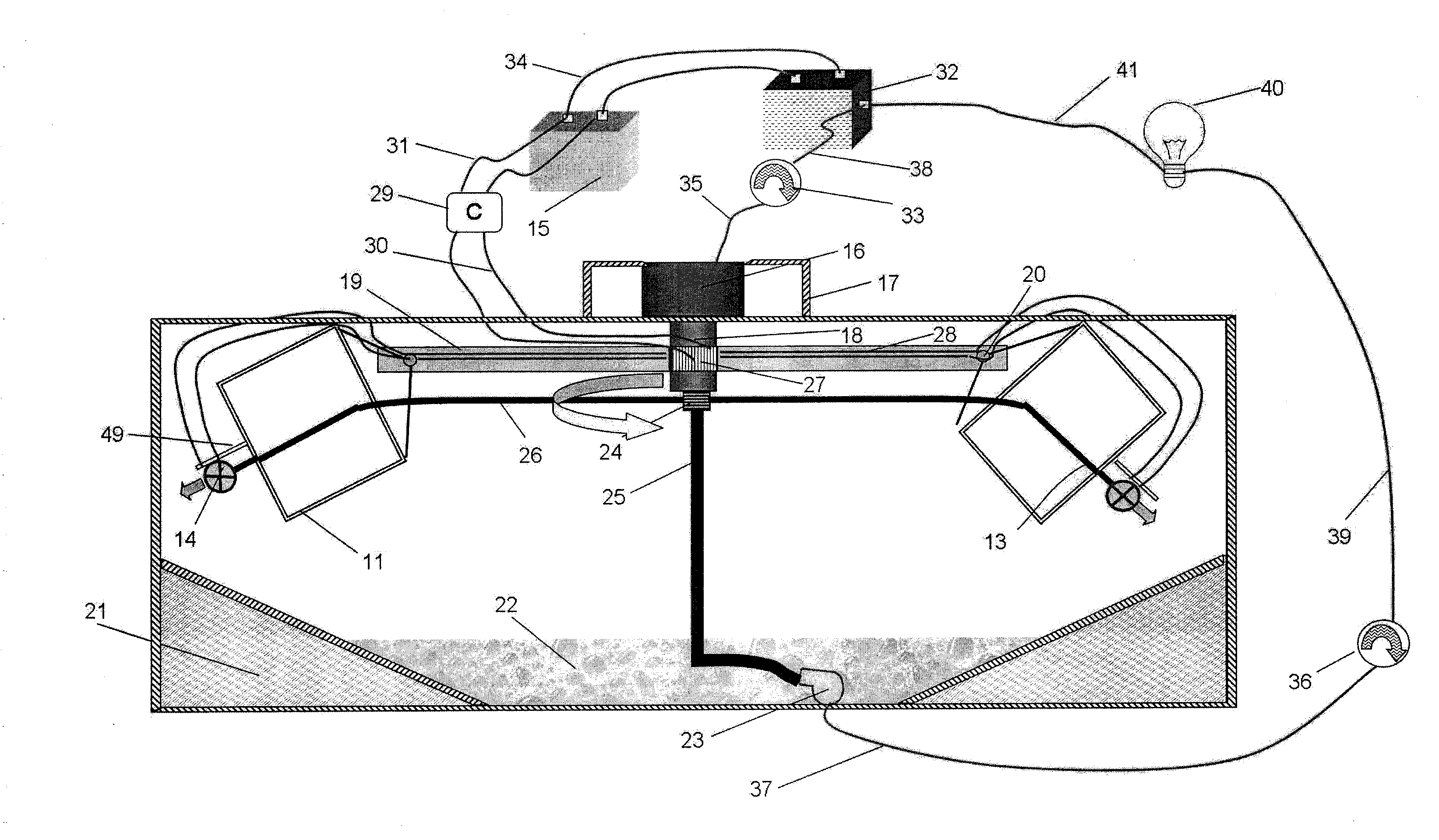

The present invention has incorporated a re-boosting pump to re-boost and to supply additional pressure energy input to a system periodically. The re-boosting pump gets its energy from a starting / re-boosting generator. This works to keep the level of the energy output sustainable.Another feature of the present invention is that it has incorporated a convergence recoil nozzle that utilizes a recoil force of the water jet. This recoil force which is equal in magnitude and opposite in direction, will push a piston that is inside a pressure chamber. This force is capable of doing different kinds of works, such as a pressurized liquid to add energy input to the system through a pressure pipe into the main penstock or it can be used as a pressure energy for the desalination of saline water.

Owner:CHING JOSE ONG

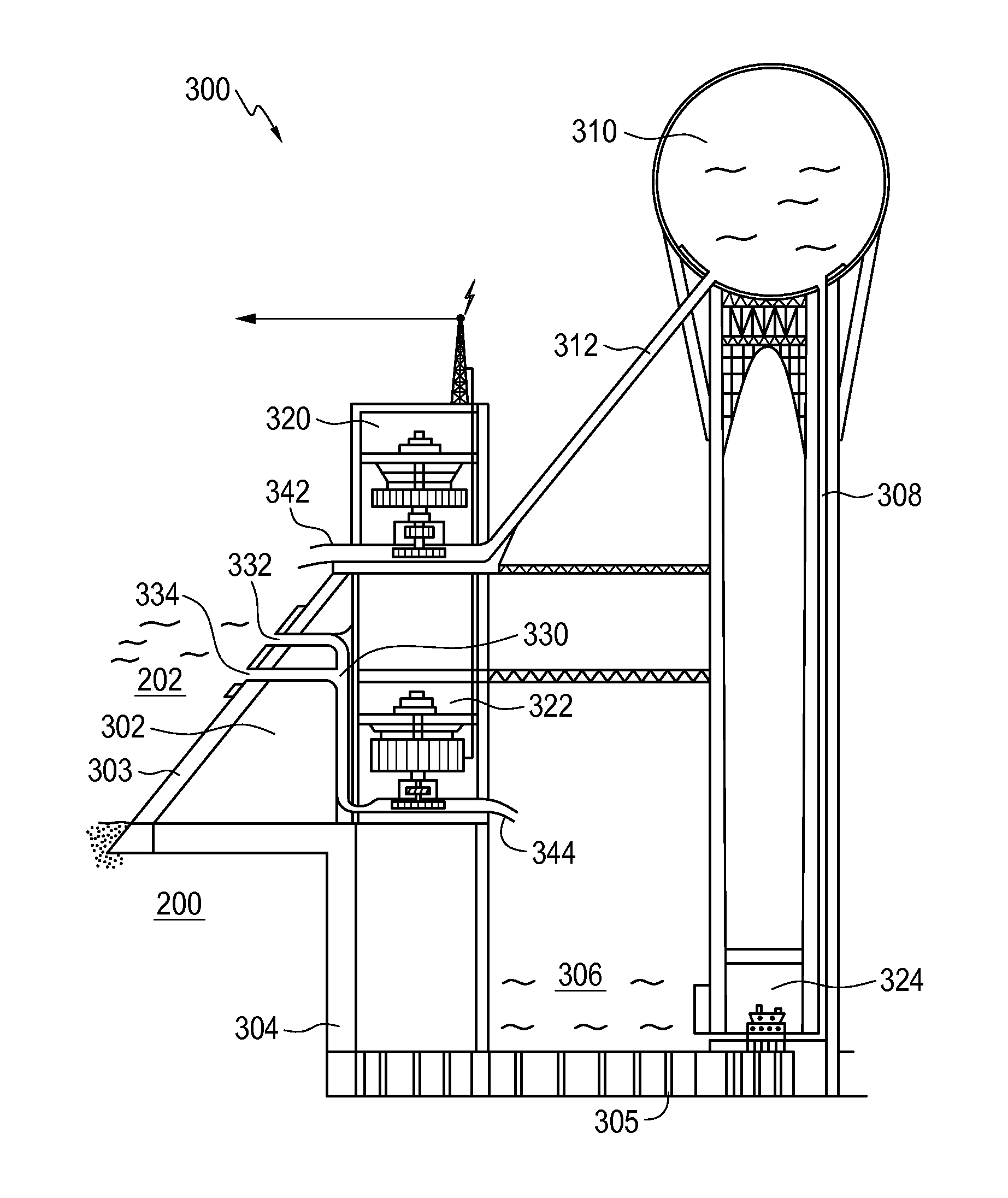

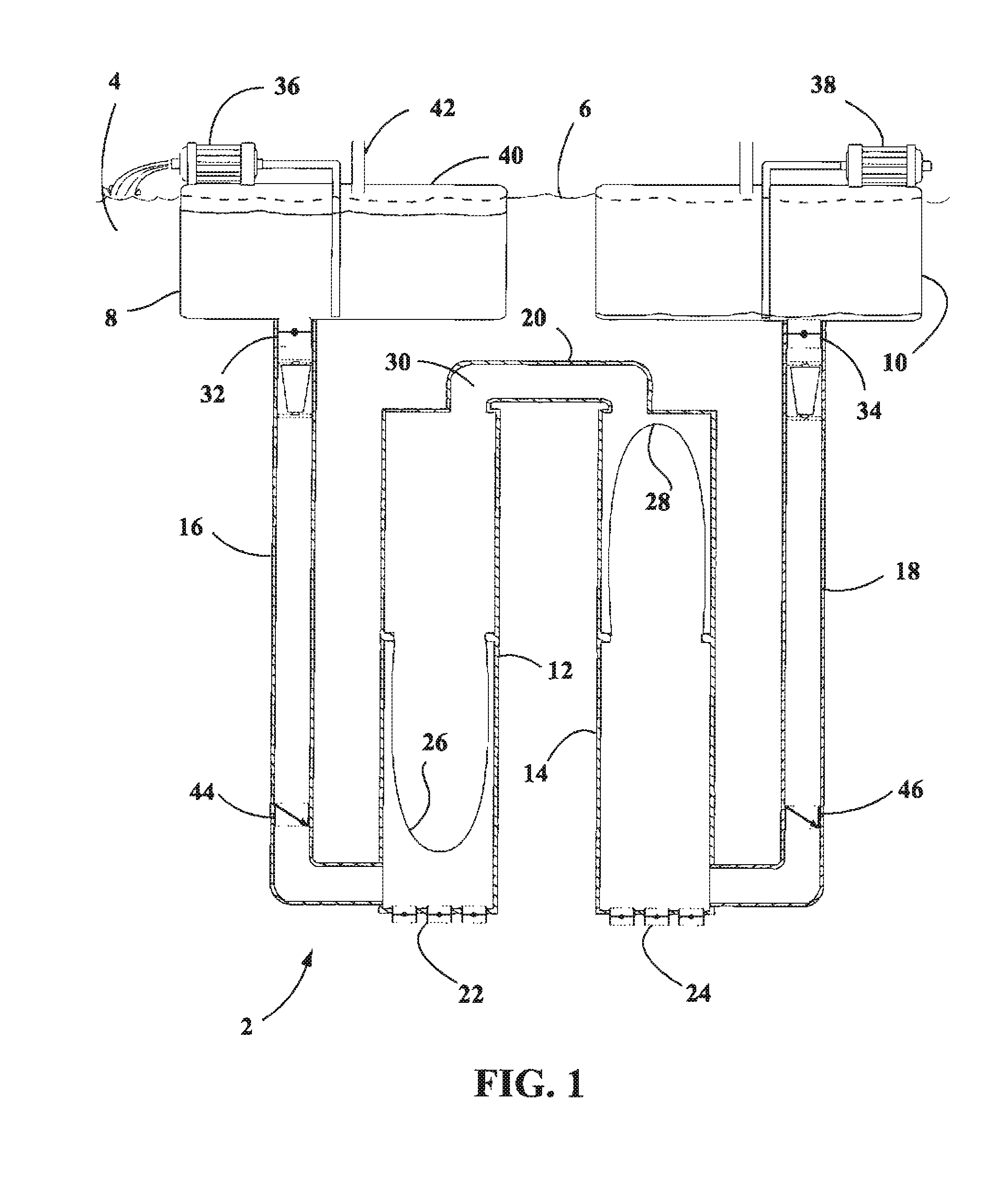

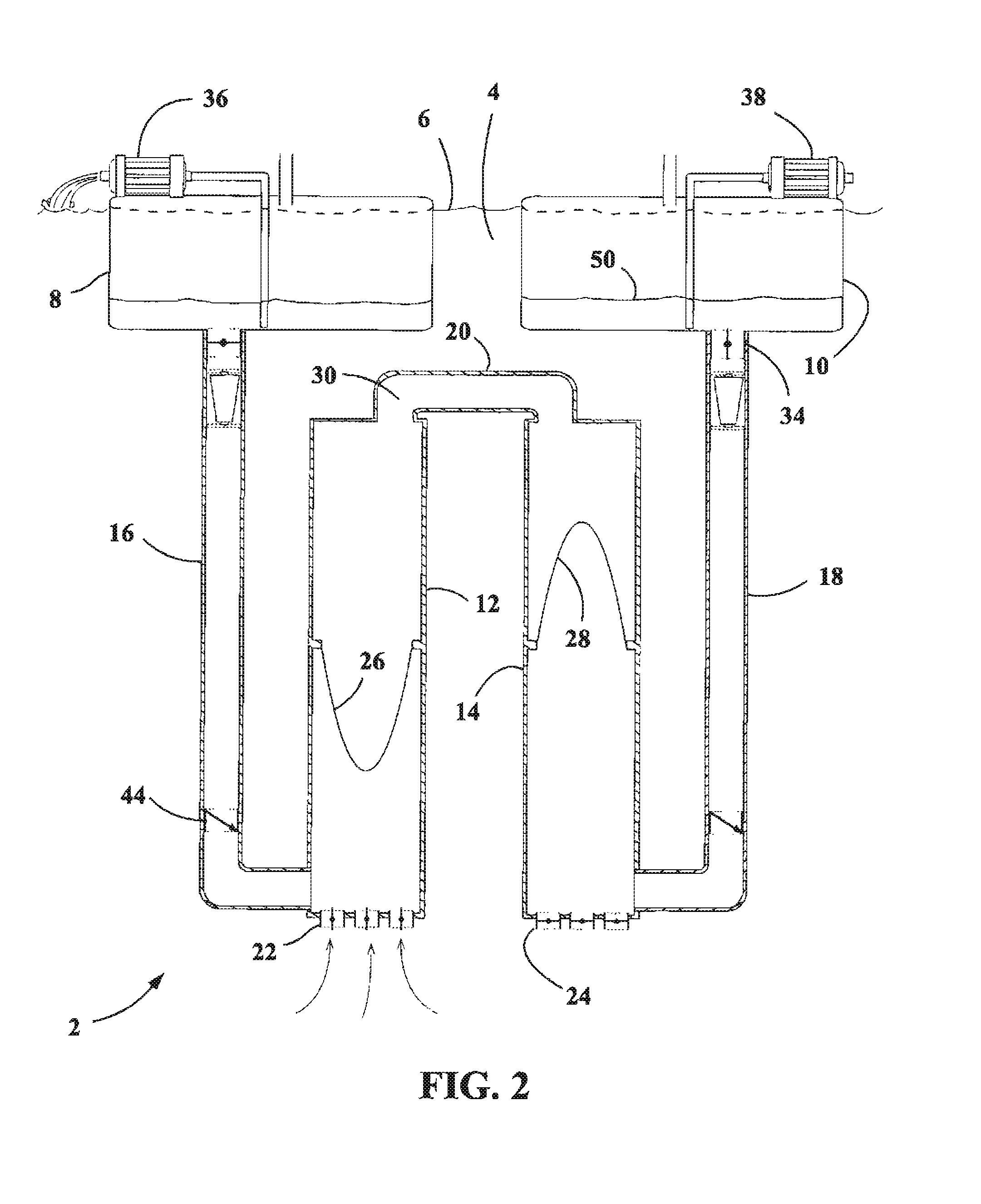

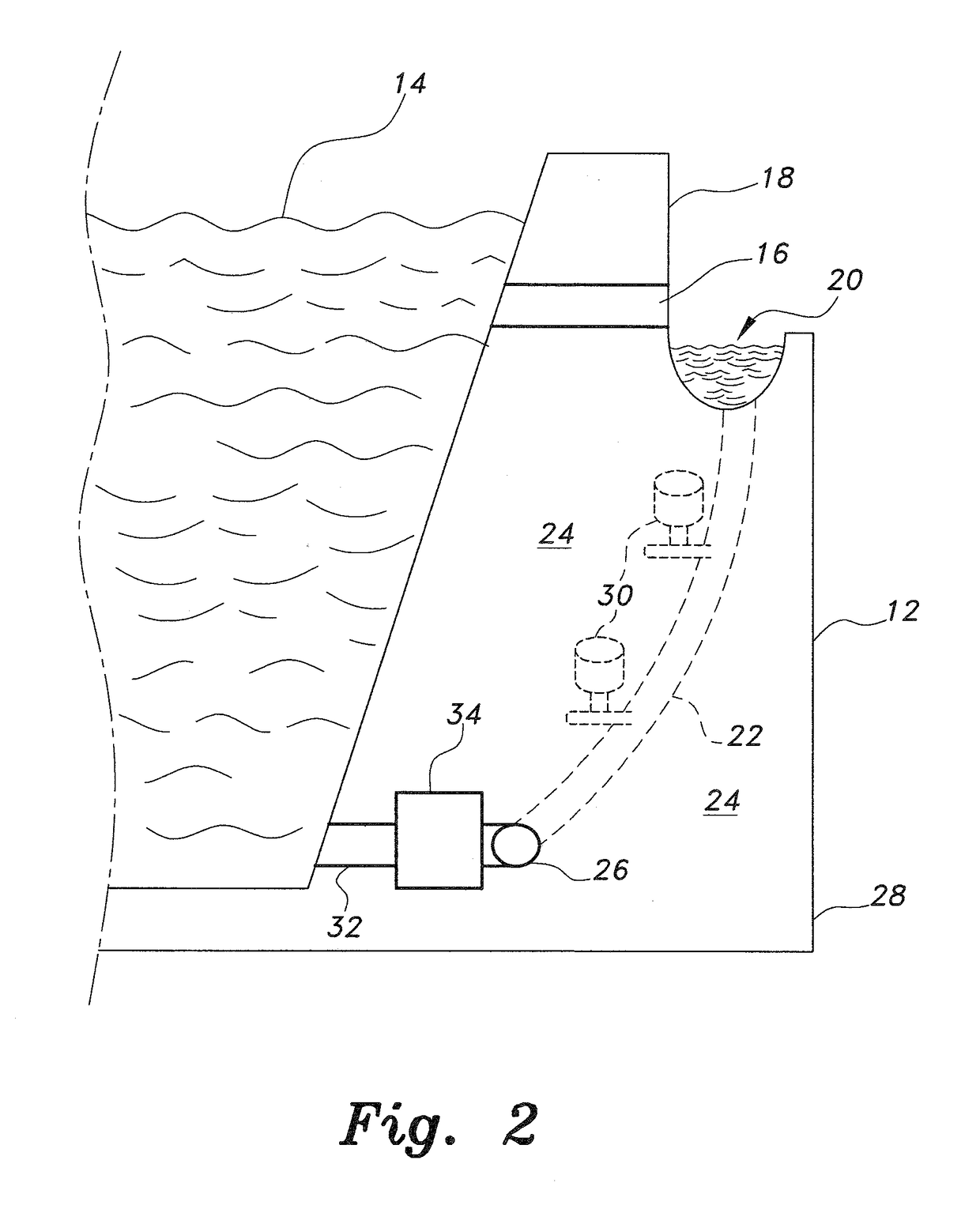

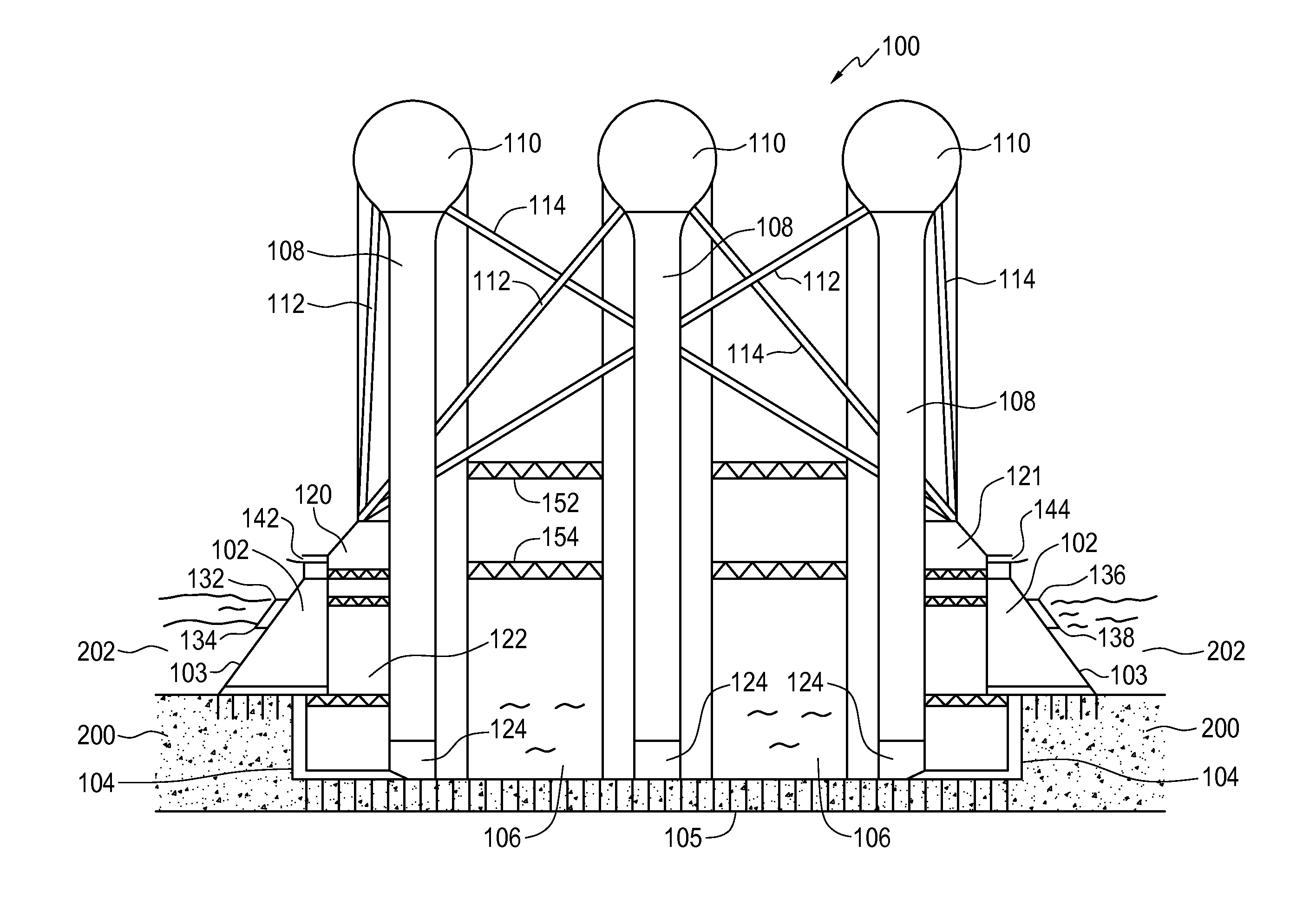

Hydro electric energy generation and storage structure

A hydro electric energy generation structure is disclosed. The structure comprises: a gravity wall forming a closed outer perimeter extending above an upper water level of an existing hydraulic reservoir, and extending below the reservoir floor; at least one water inlet hydraulically connecting a first penstock to a first turbine generator below the water inlet. The structure further comprises: at least one lower water storage reservoir within the perimeter of the gravity wall receiving water from the first turbine generator; at least one pump receiving water from the lower water storage reservoir and pumping it through a pump delivery conduit to at least one upper water storage reservoir above the gravity wall; at least one second penstock delivering water from the upper water storage reservoir to a second turbine generator below; and a tailrace for returning the water into the existing reservoir.

Owner:LEGACY MARK ROBERT JOHN

Metallocene geomembrane

InactiveCN101525452AImprove performanceReduce the temperatureLow-density polyethyleneLinear low-density polyethylene

The invention relates to a metallocene geomembrane which is used for railway laying, a refuse landfill, a tunnel, a penstock, a reservoir, a dyke, a sewage tank, an ecological tank, a landscape lake, an aquiculture tank and the seepage resistance and the water resistance of railway and highway engineering and is prepared by ingredients through a coextrusion machine. The metallocene geomembrane is characterized by comprising the following components by the weight percent: 64 to 73 of metallocene linearity low-density polyethylene, 24 to 32 of high-density polyethylene and 0.1 to 3 of assistant, wherein the assistant comprises a modifying assistant and a processing assistant, the modifying assistant is the antioxidant, and the processing assistant is carbon black or PPA. The Metallocene geomembrane has good puncture resistance, good,anti-tear property and high tensile strength.

Owner:SHANDONG TIANHE PLASTIC

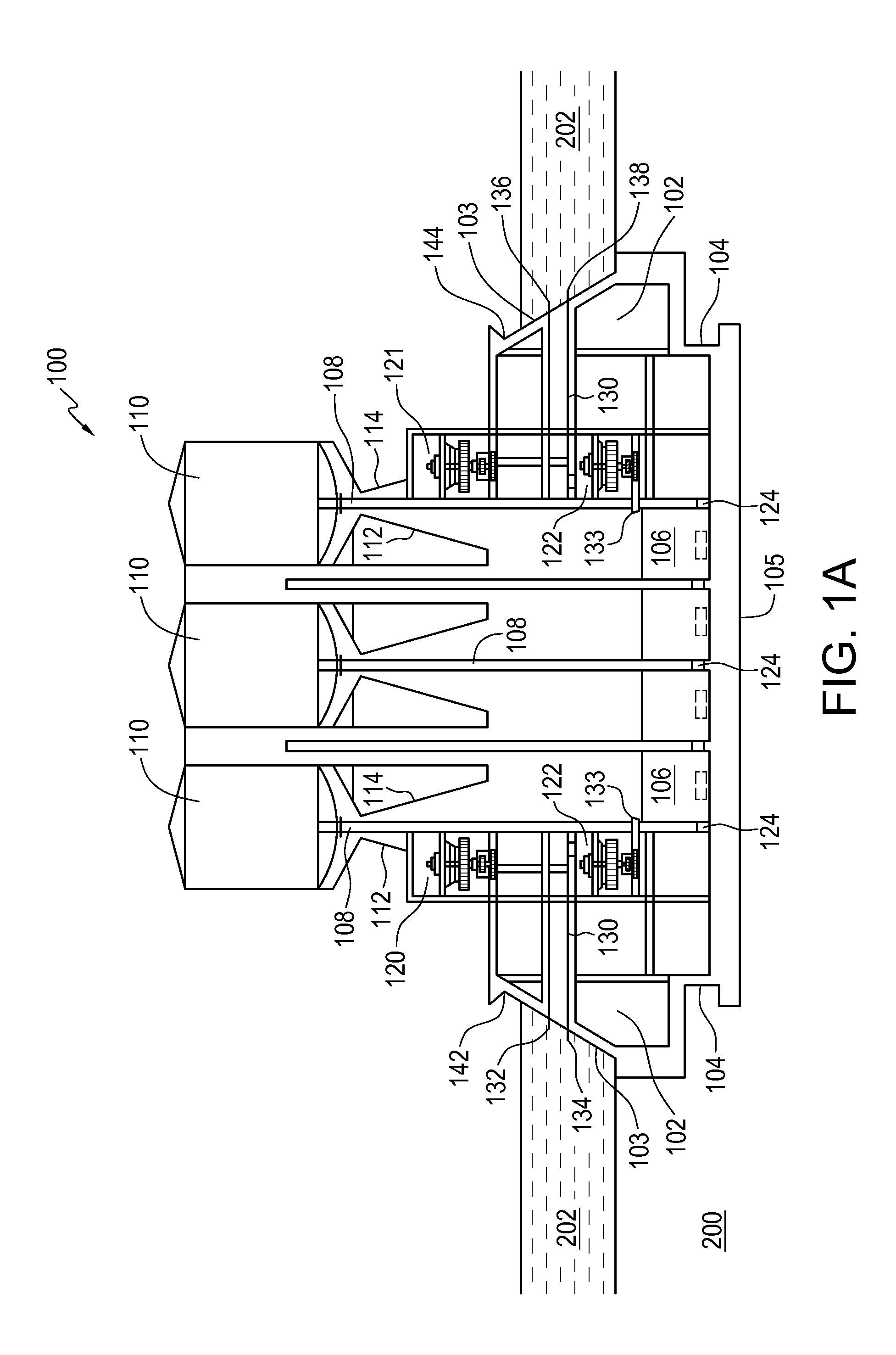

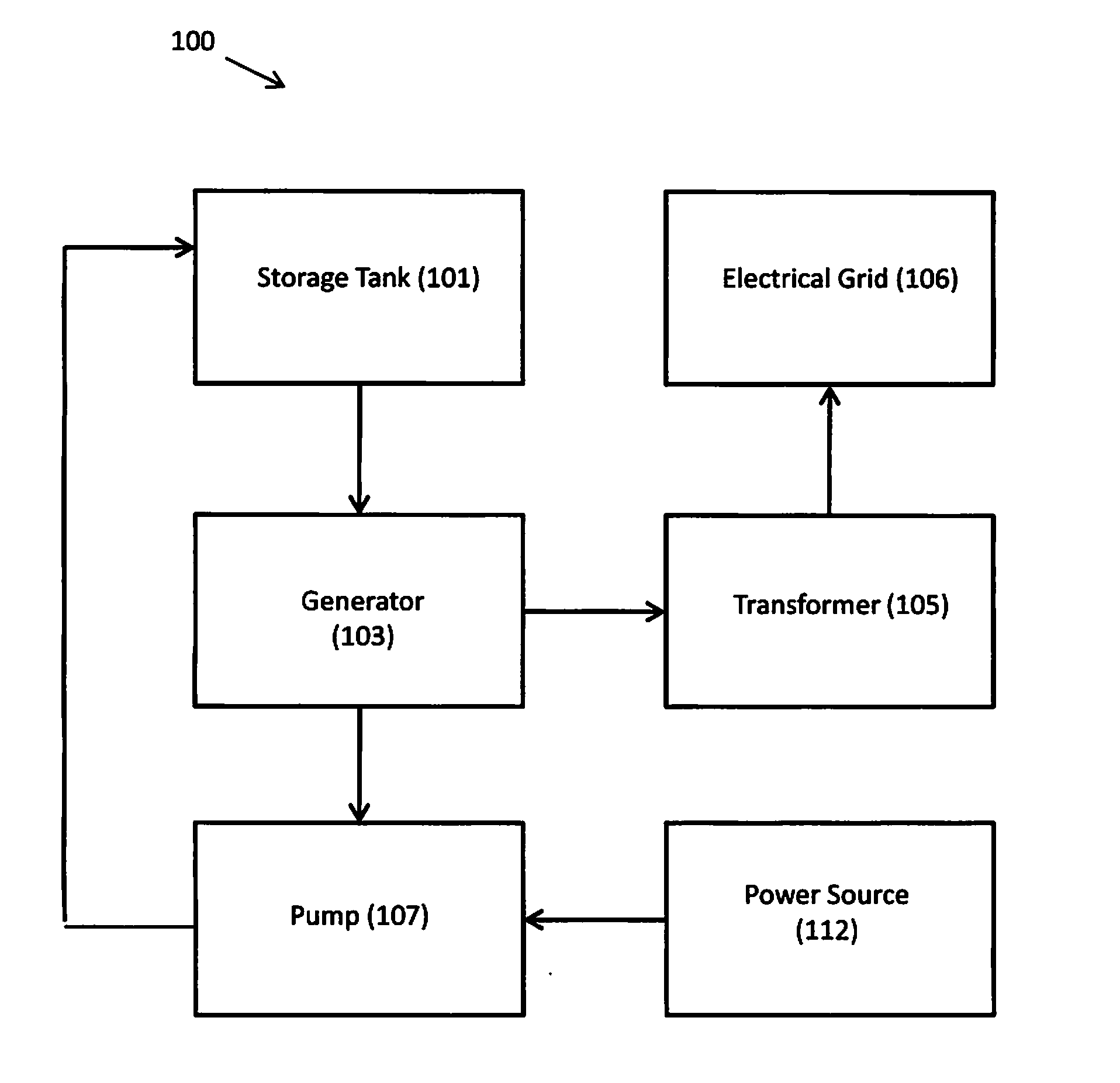

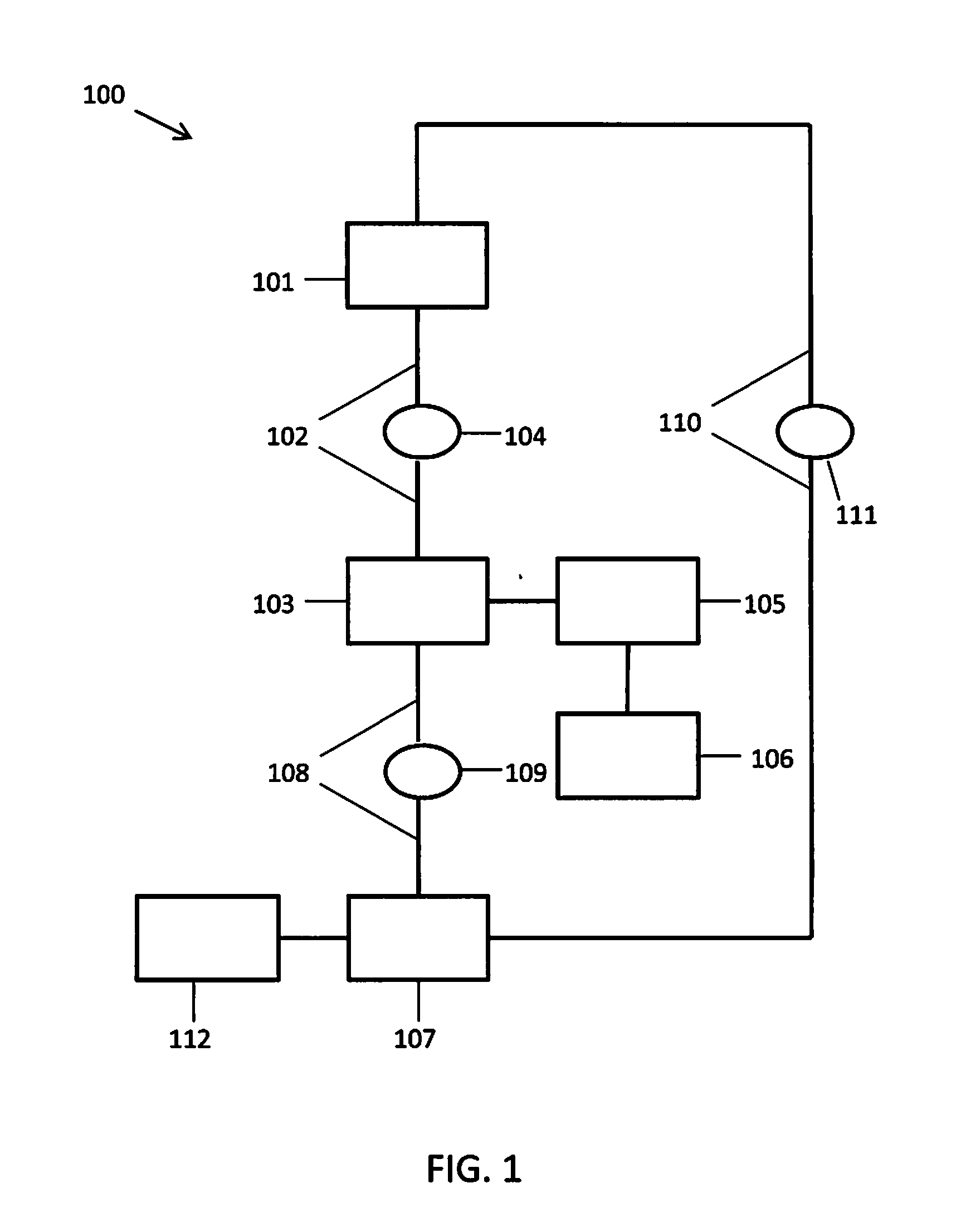

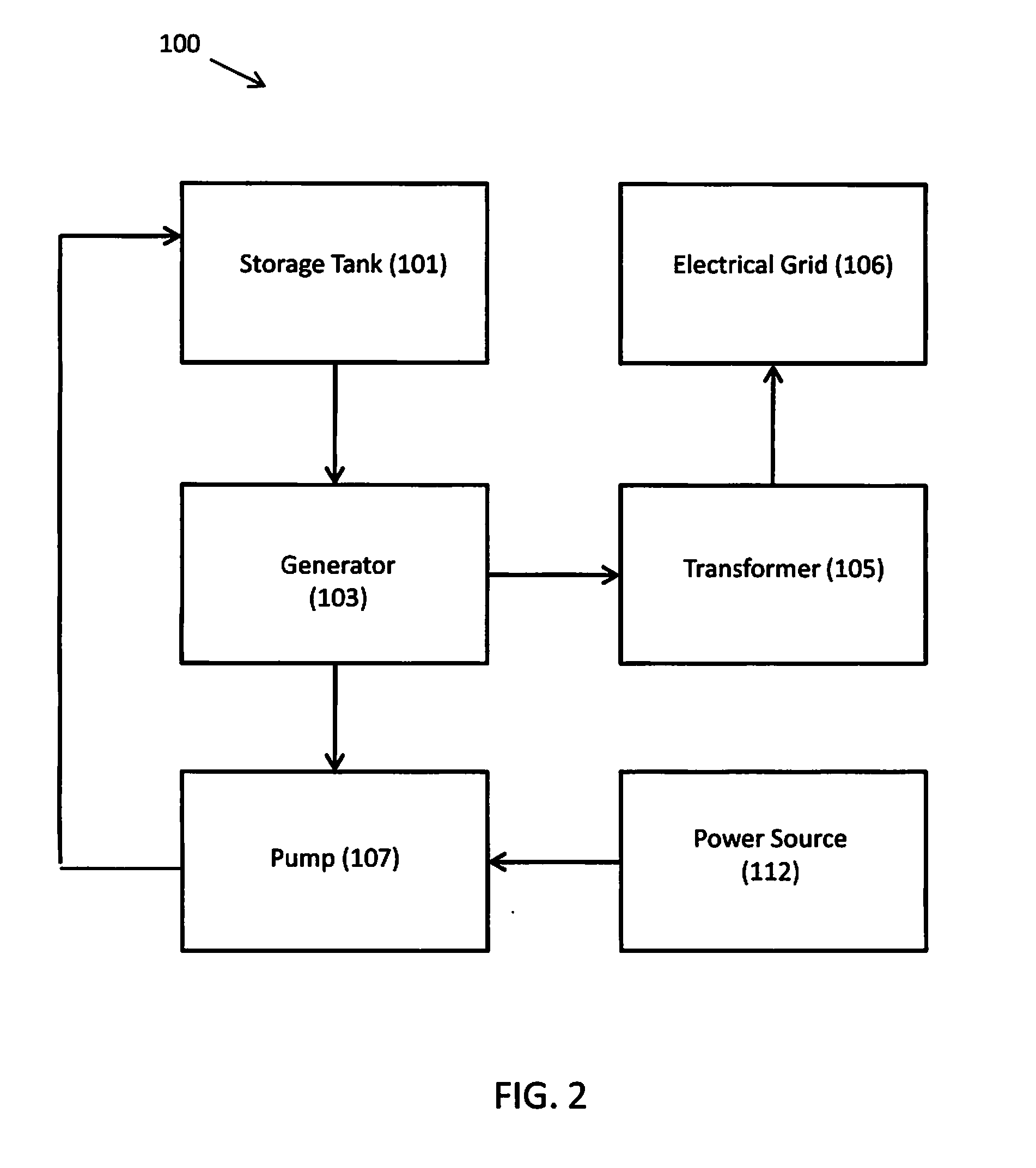

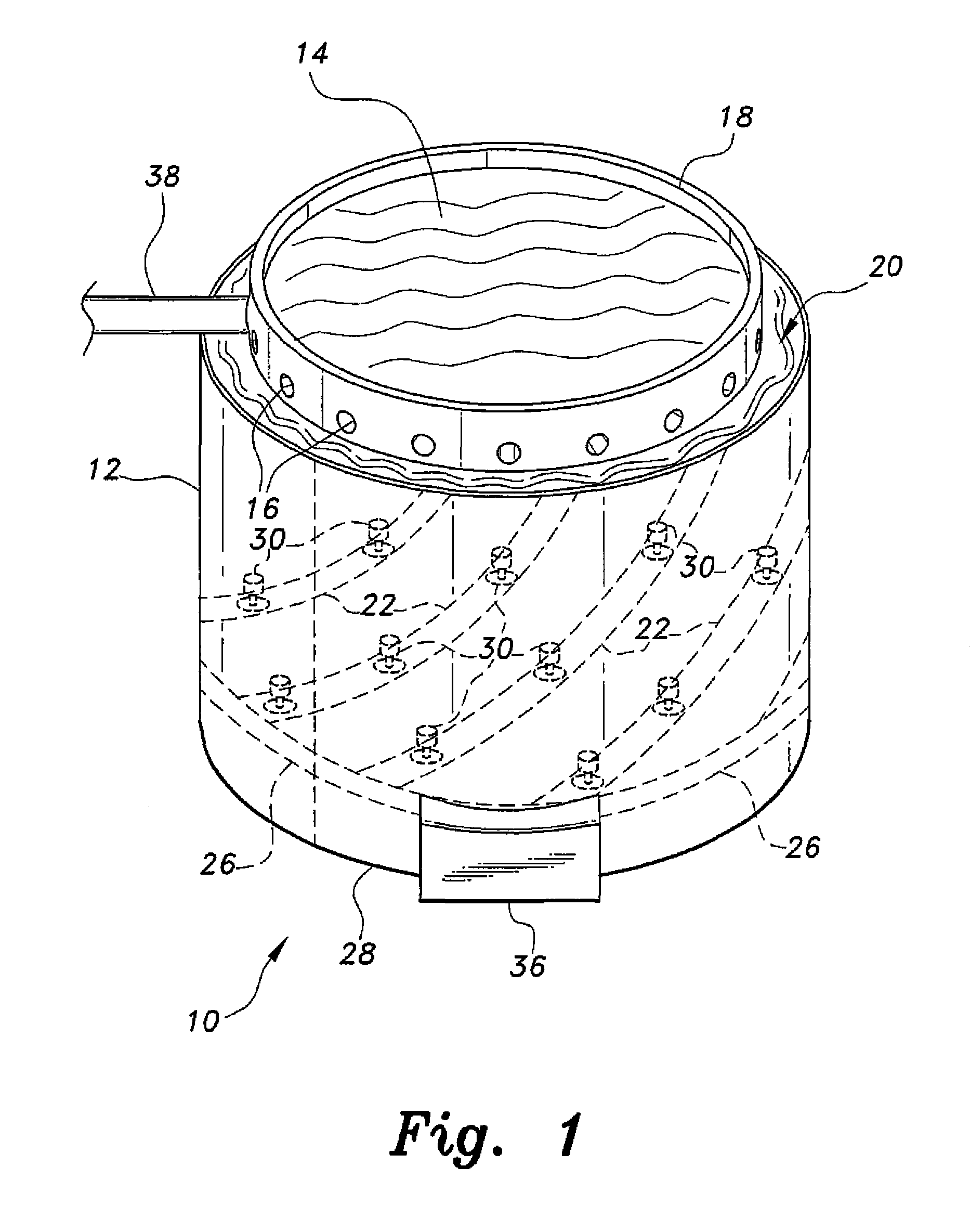

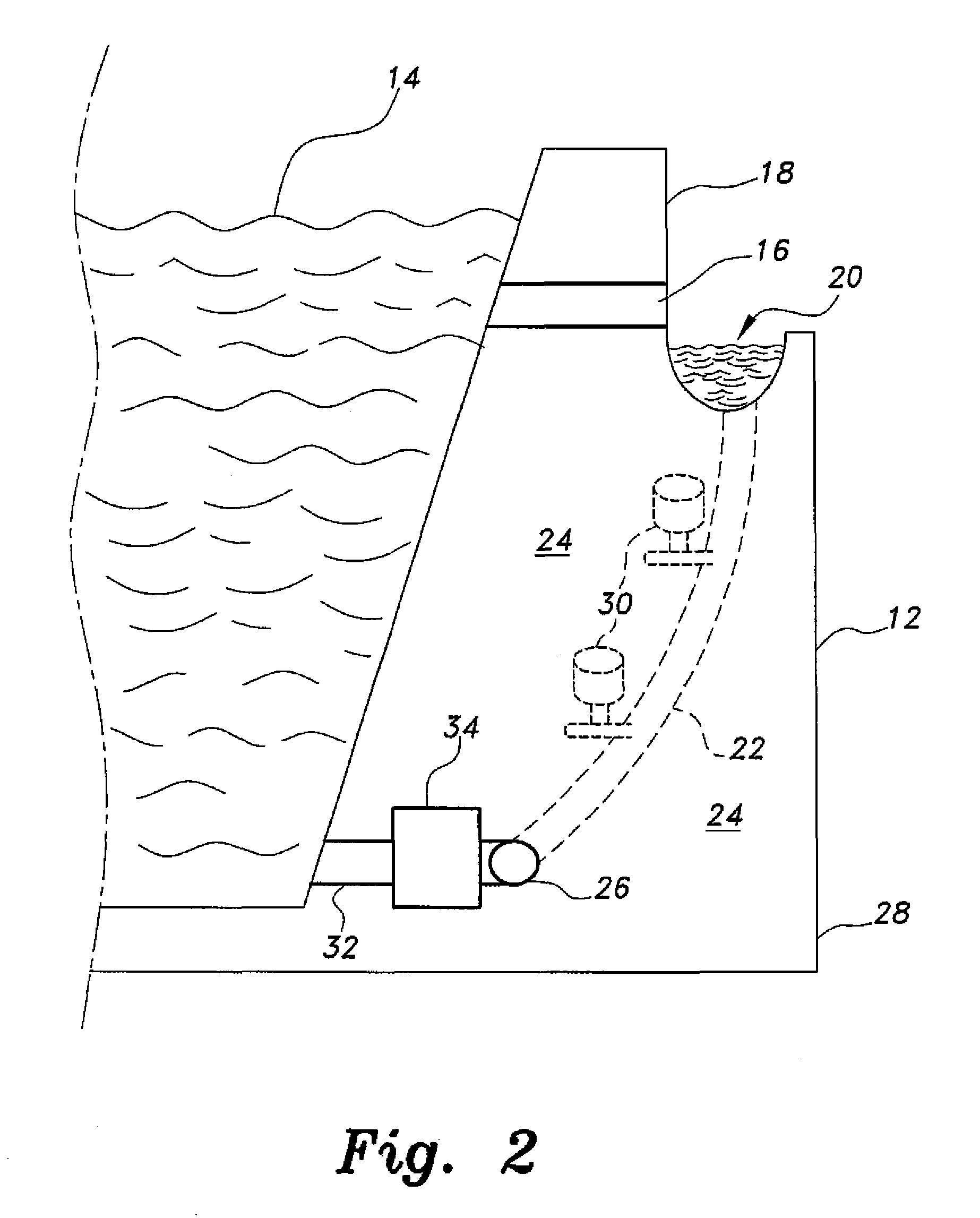

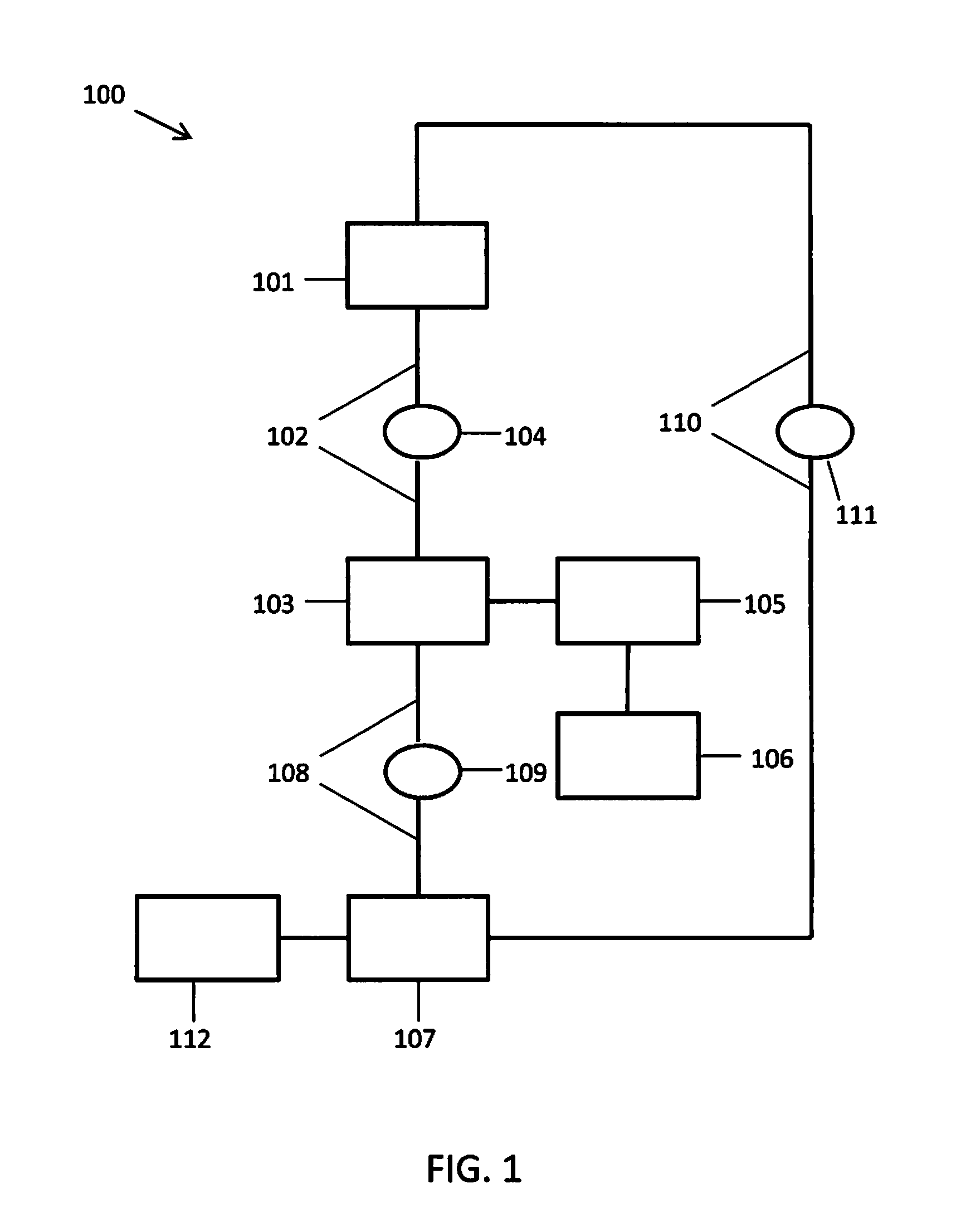

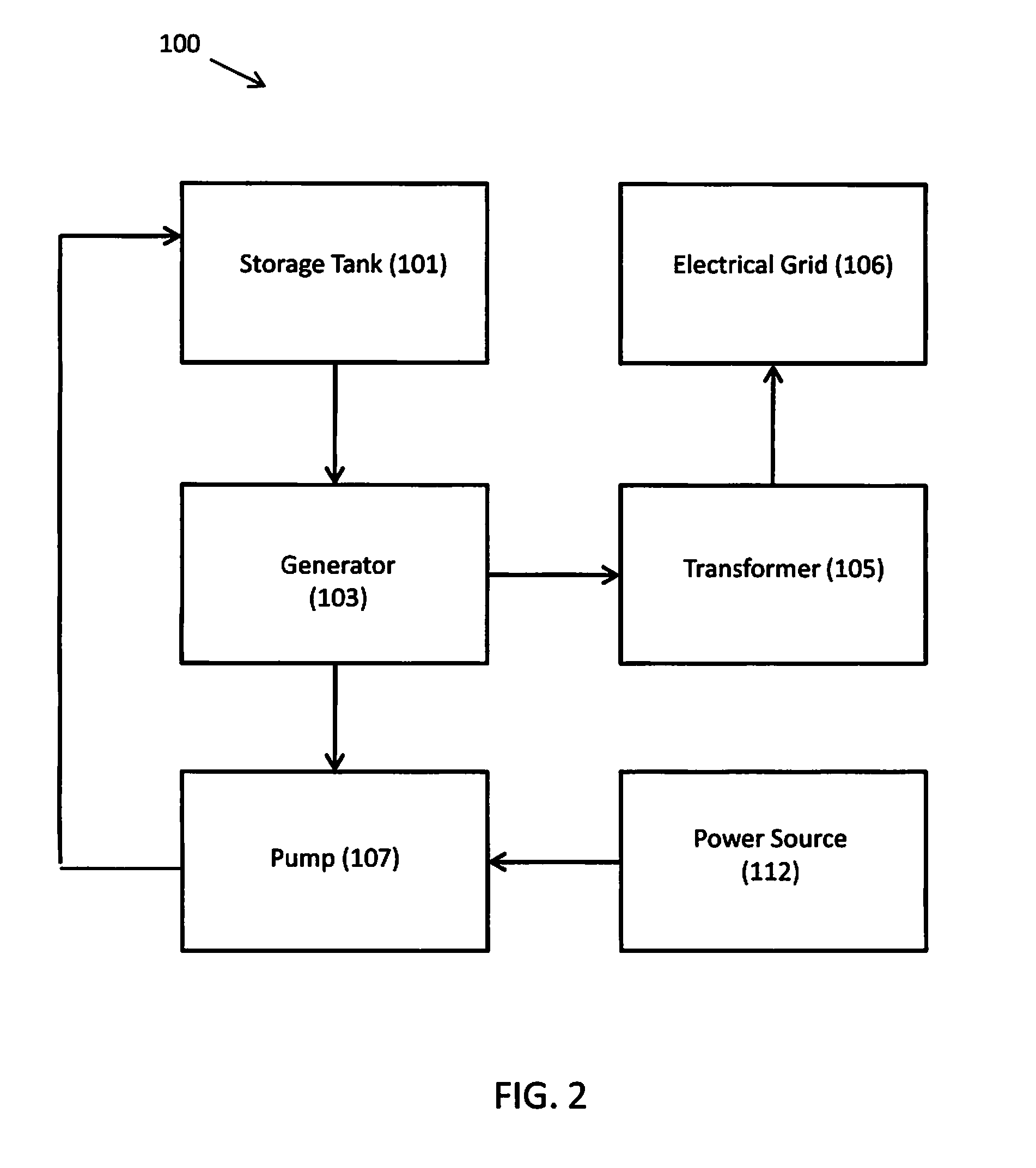

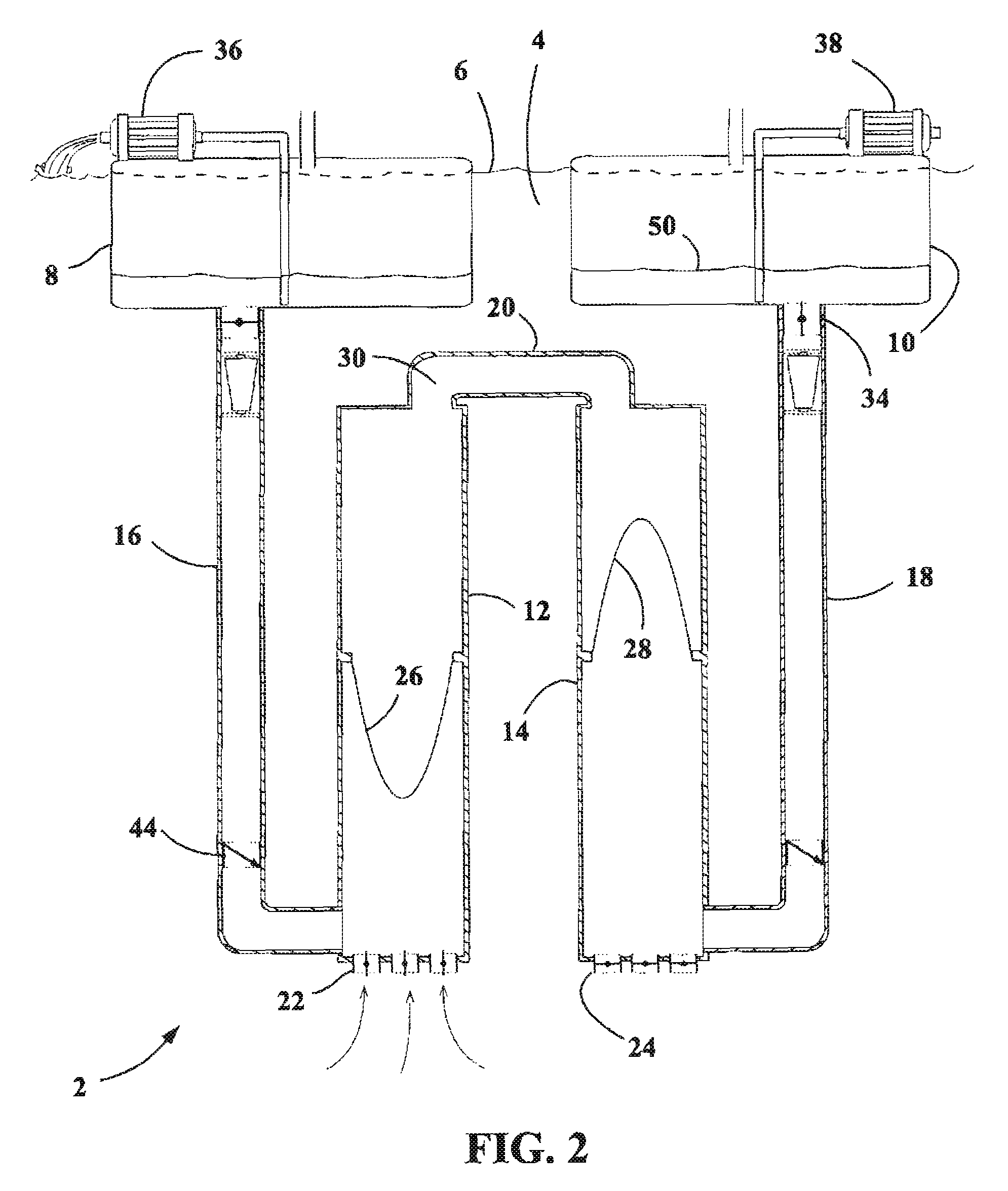

Hydroelectric Power System

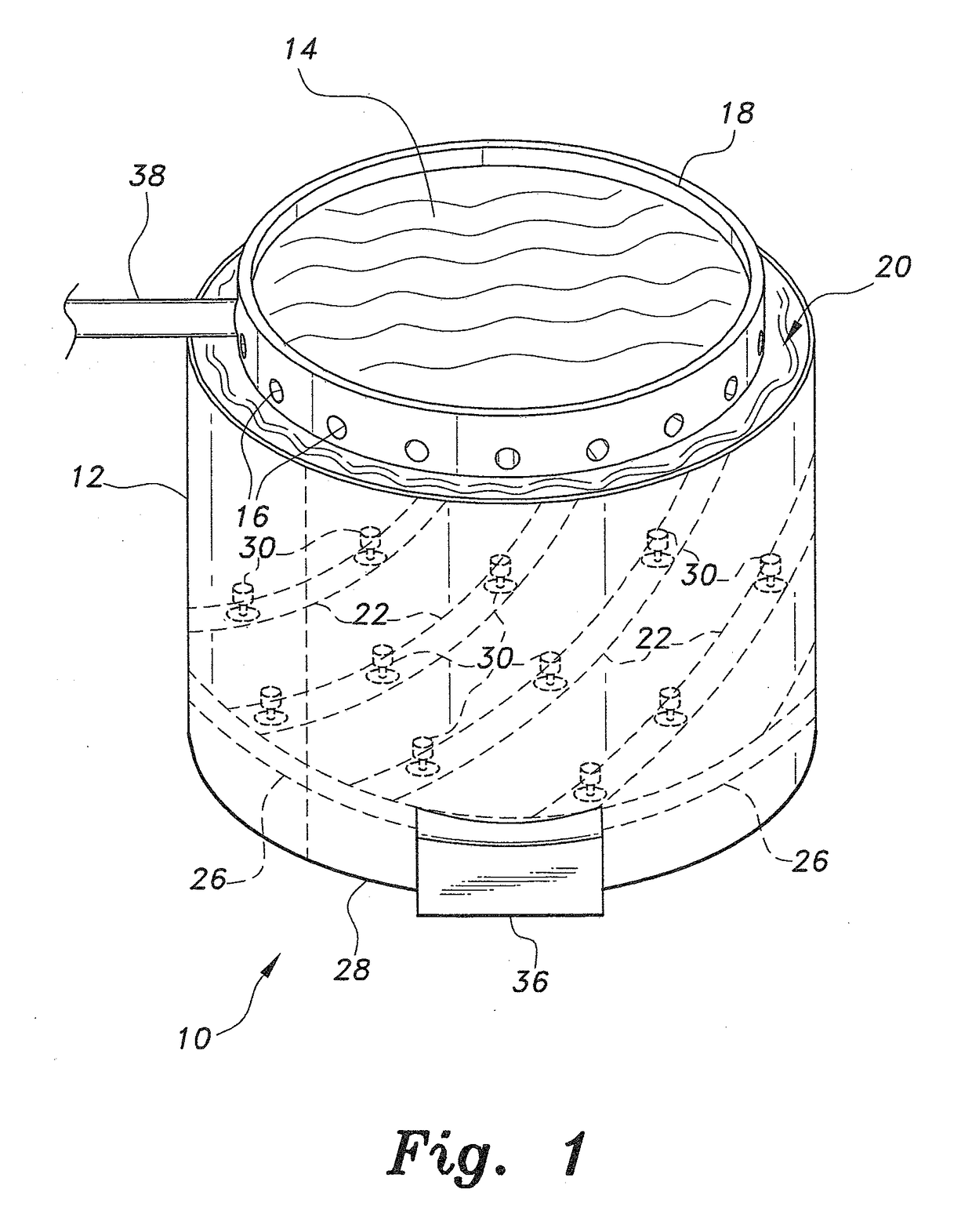

A hydroelectric power system is provided. The hydroelectric power system includes a storage tank; a fluid; a penstock; an electric turbine generator, a transformer, an electric power grid system; a pump, and connecting conduit. A method of generating hydroelectric energy is also provided.

Owner:CAMPBELL CHARLES E

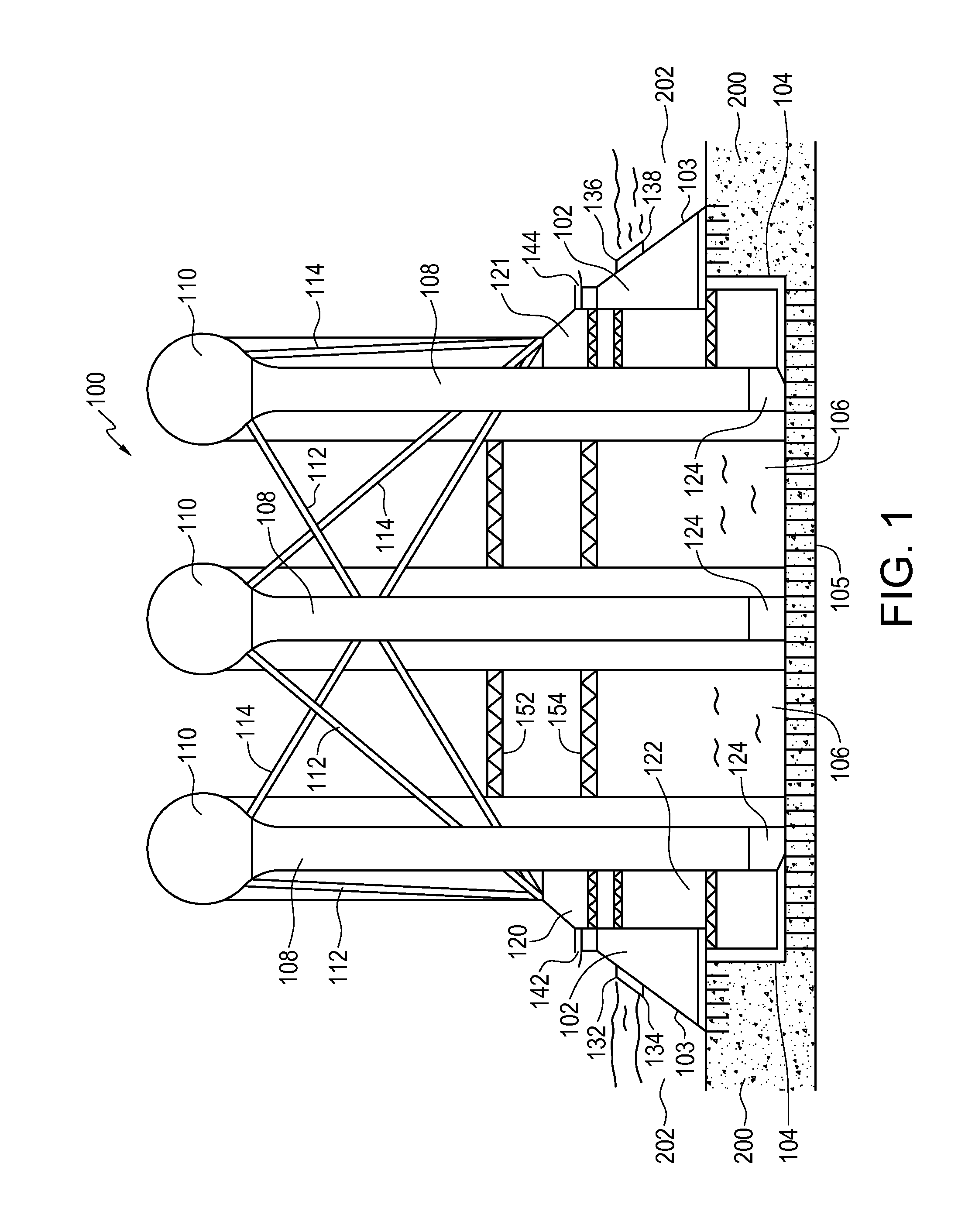

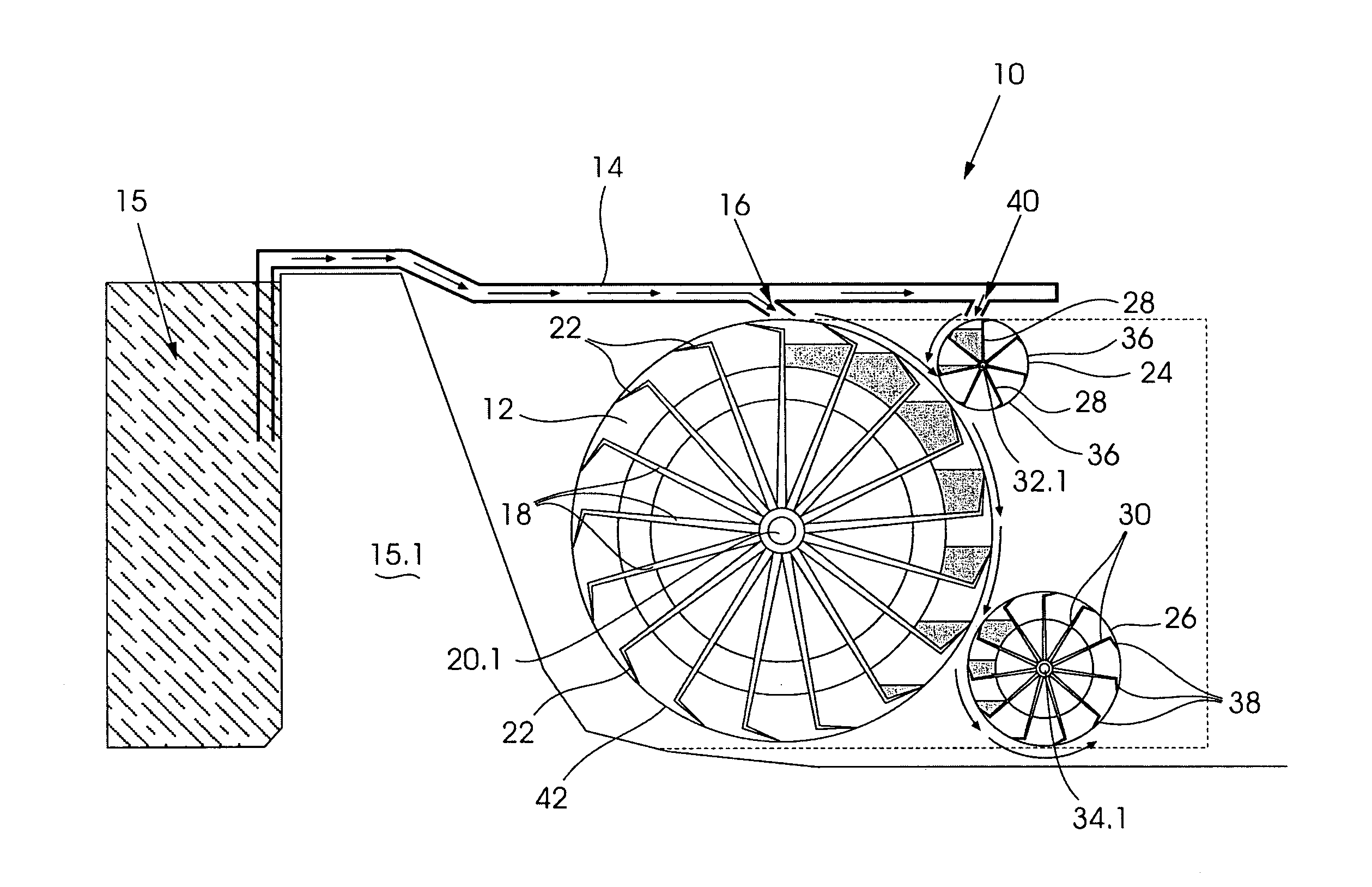

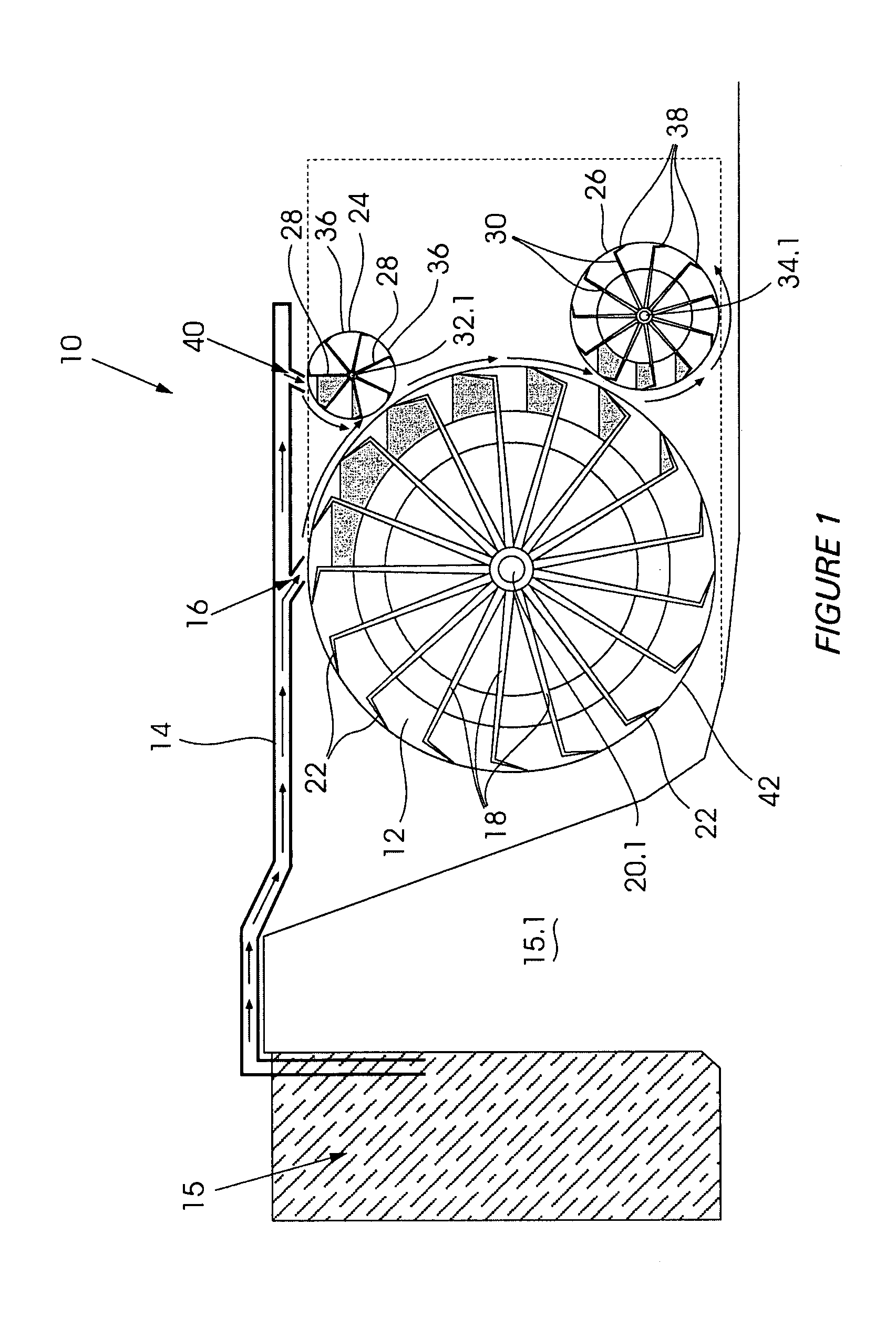

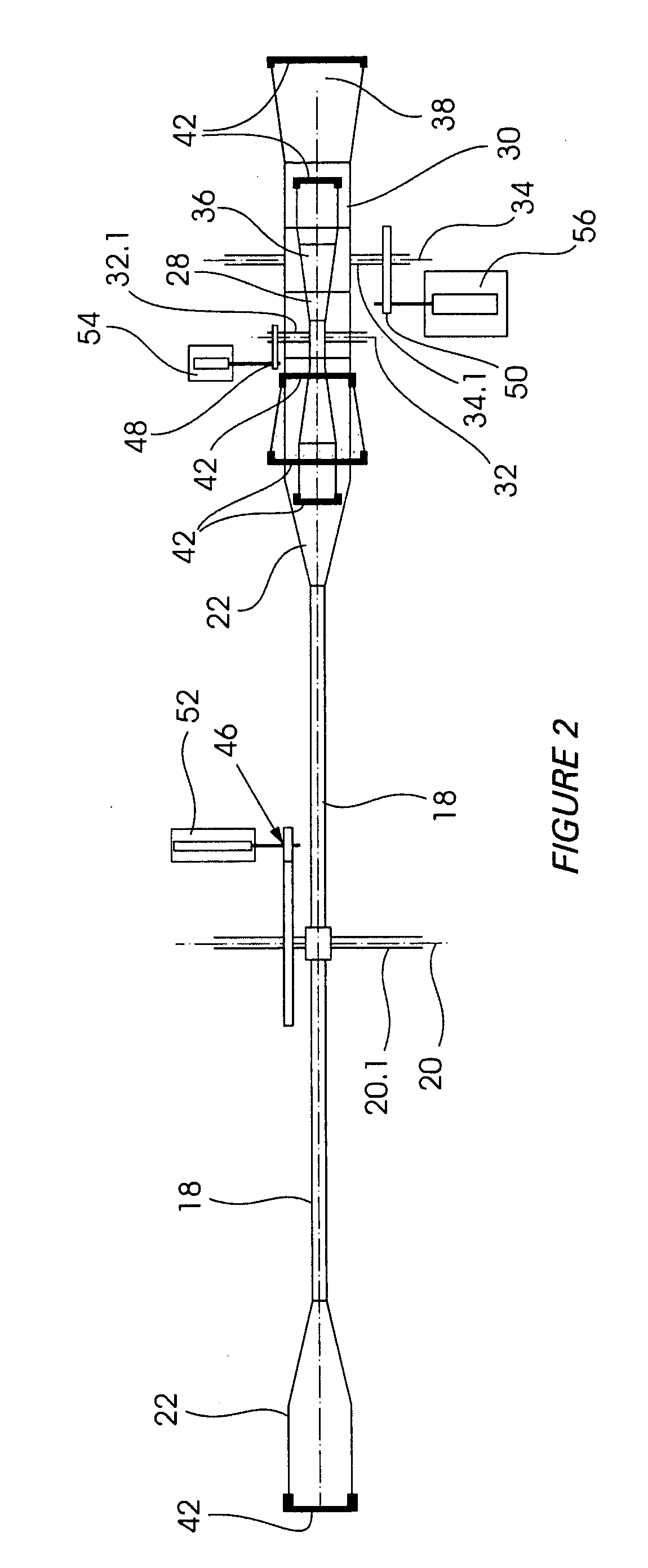

Energy generating system using a plurality of waterwheels

InactiveUS20110173976A1Improve efficiencyReduce energy lossEngine componentsMotorsPenstockEngineering

An energy generating system is provided, comprising a primary waterwheel for receiving water from a head penstock or upper pumping setup, the primary waterwheel comprising a plurality of radial arms rotatable about a primary axis, the radial arms terminating in water scoops for accommodating the water from the head penstock or upper pumping setup, the primary waterwheel defining head height. The system further comprises at least one additional waterwheel located within the head height of the primary waterwheel, the additional waterwheel also comprising a plurality of radial arms rotatable about an axis, the radial arms terminating in water scoops for accommodating either excess water from the head penstock or upper pumping setup or water that has spilled out of the water scoops of the primary waterwheel. In an example embodiment, the primary waterwheel and the at least one additional waterwheel are vertically orientated. In an example embodiment, the at least one additional waterwheel is smaller than the primary waterwheel.

Owner:MEADON SEAN BRIAN +1

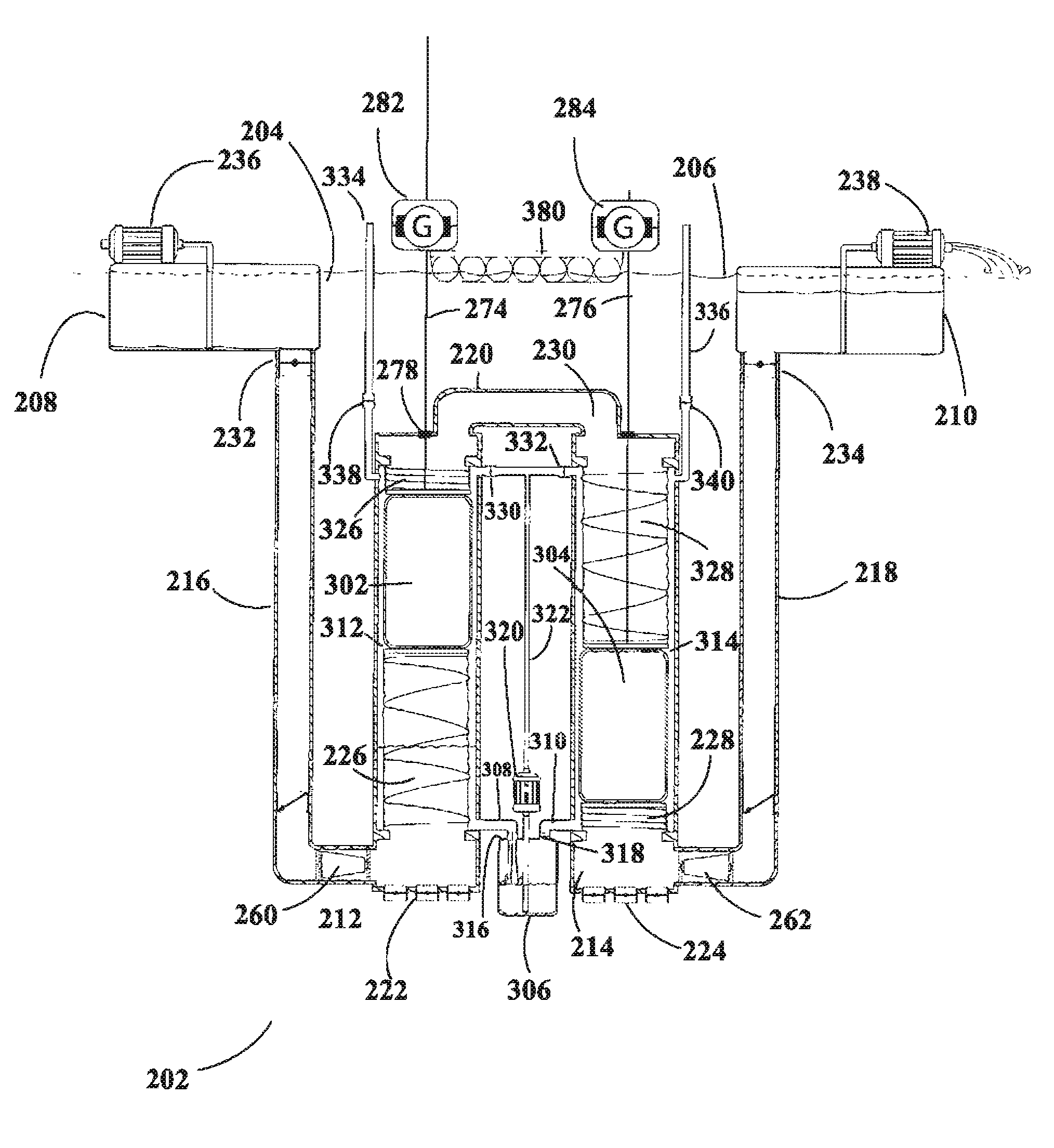

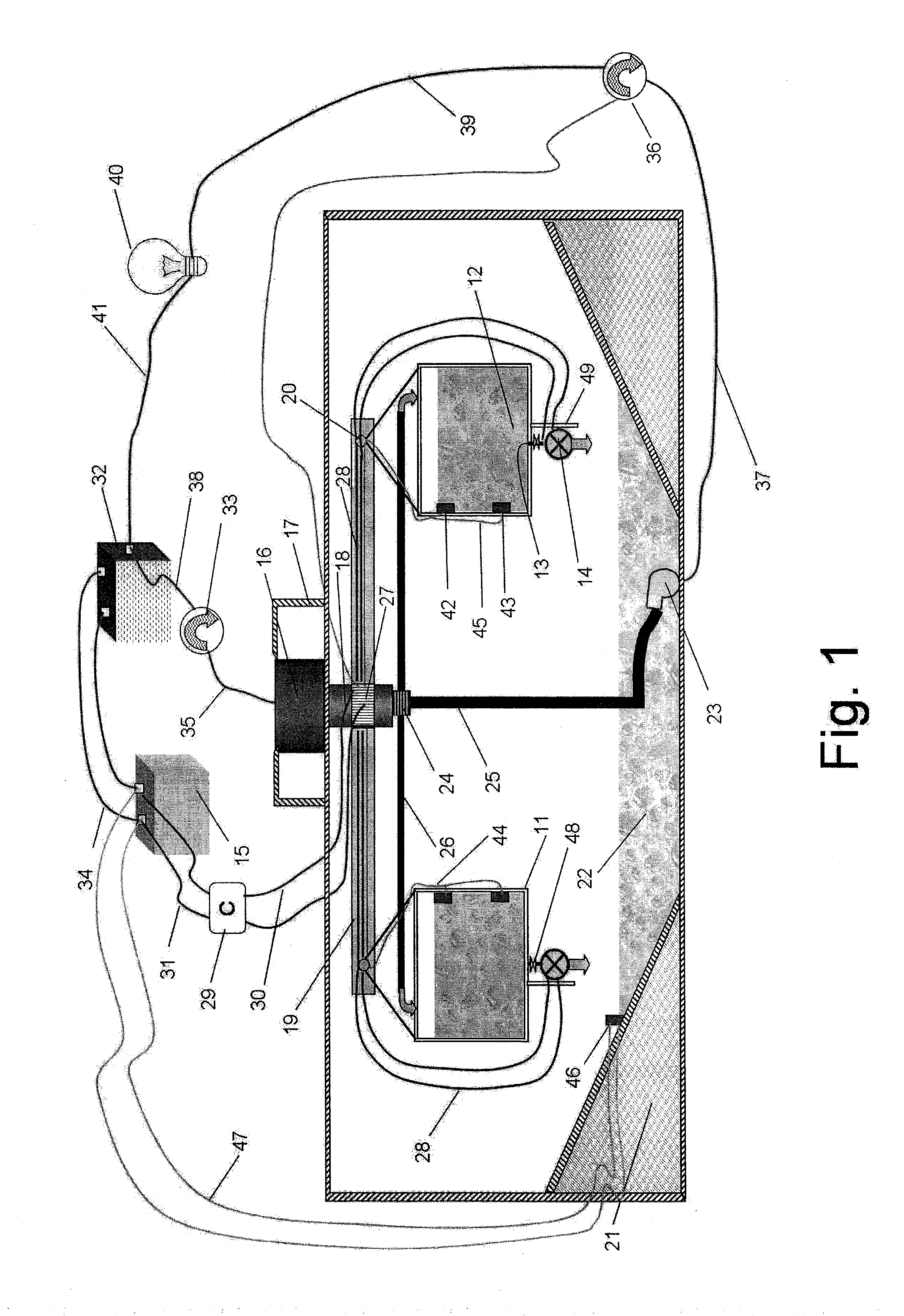

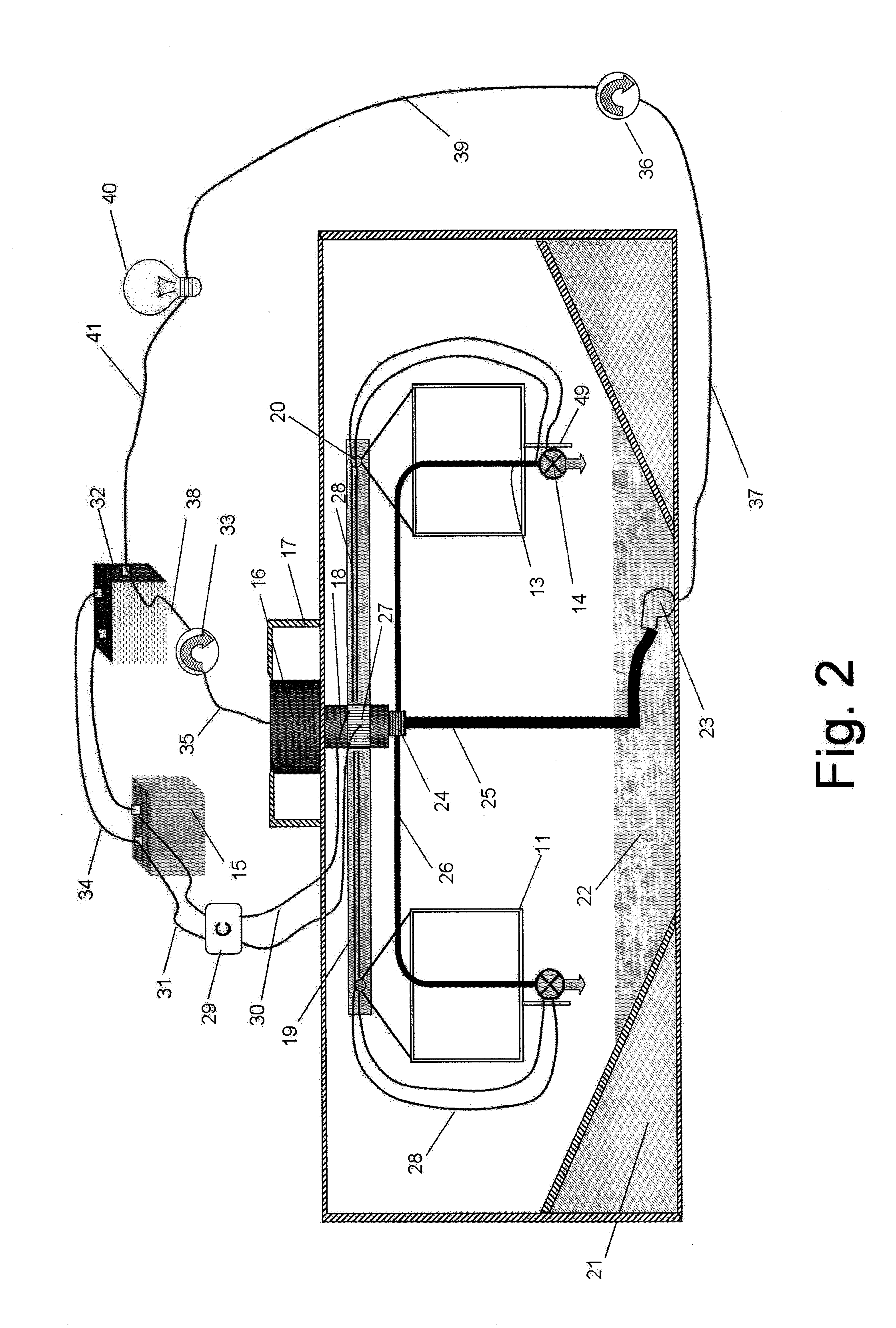

Power generator

InactiveUS20140130497A1Improve efficiencyMaintain volumeHydro energy generationEngine componentsWorking fluidConstant power

The power plant disclosed is an engine that derives its usefulness in the pursuit of energy generation by utilizing hydrostatic pressure differentials found or created in various liquids, gases or solutions, such as but not limited to water and air. It is generally provided as a two-stroke piston cycle power generating system, wherein the actions of the pistons perform work or replenish working fluid from a lower head to a higher head, and can be utilized to generate power, pump fluids, or perform work, for example. Multiple power generating systems are interconnected to provide continuous and constant power generation through a penstock and turbine system.

Owner:ANTEAU MARK R

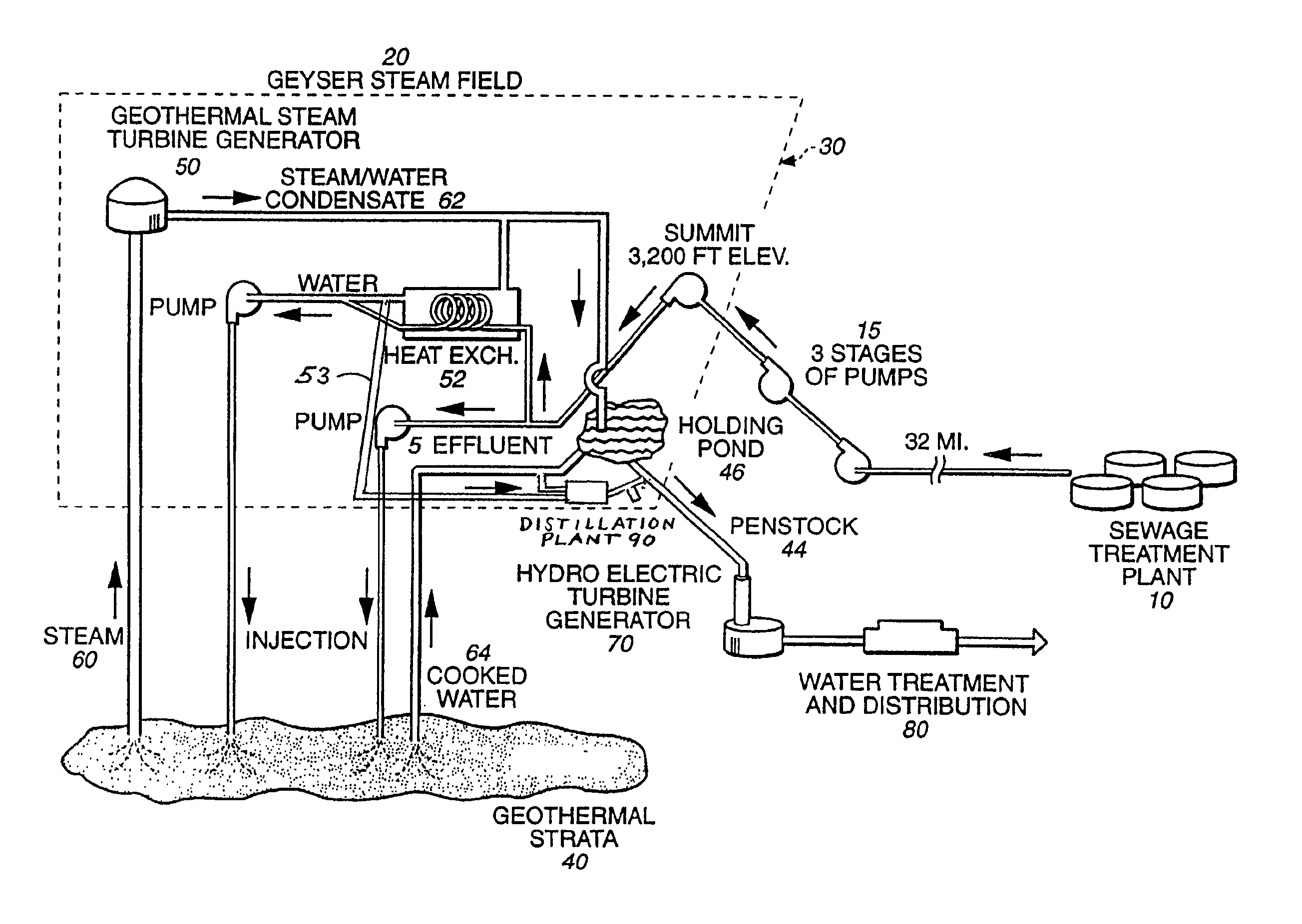

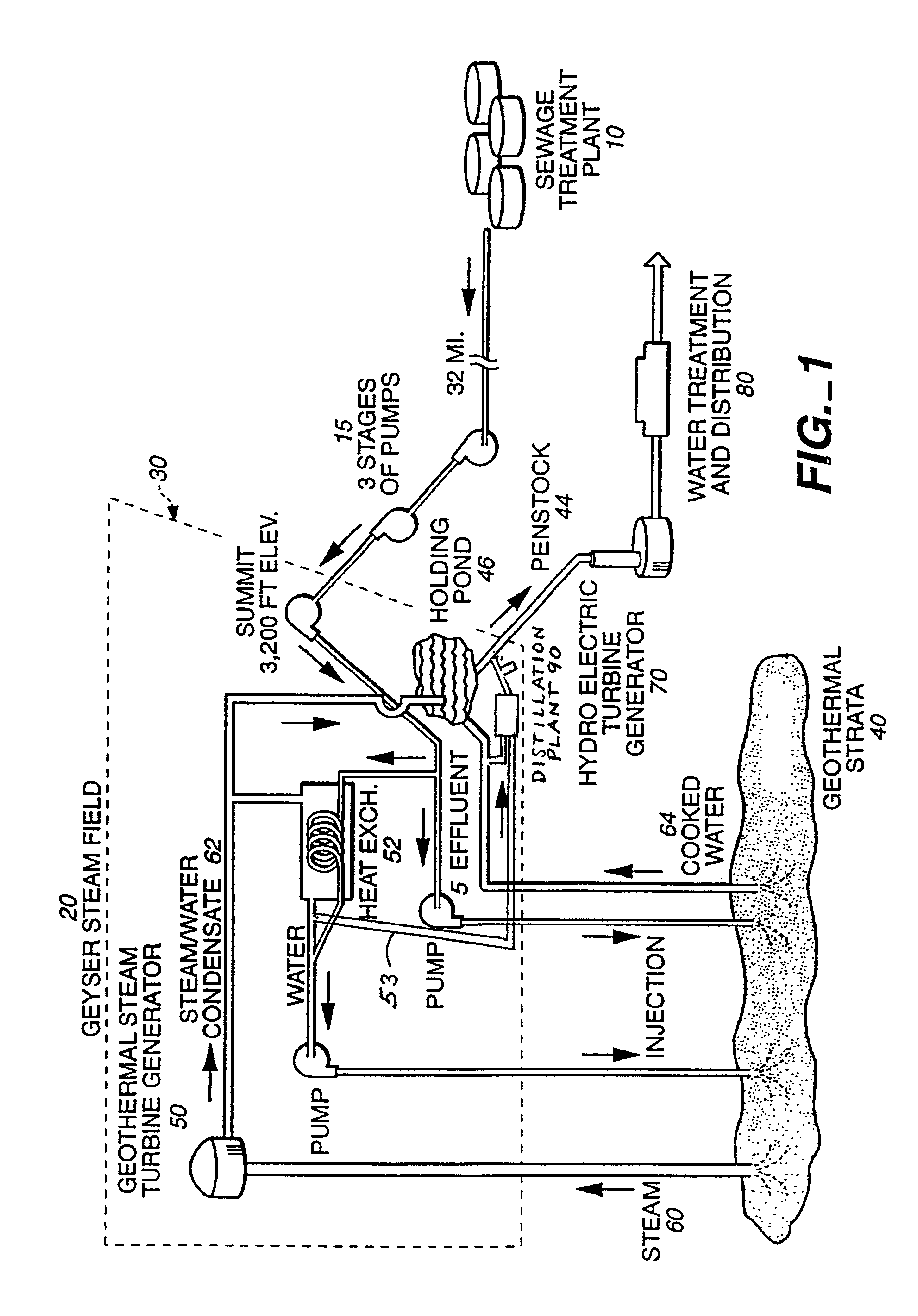

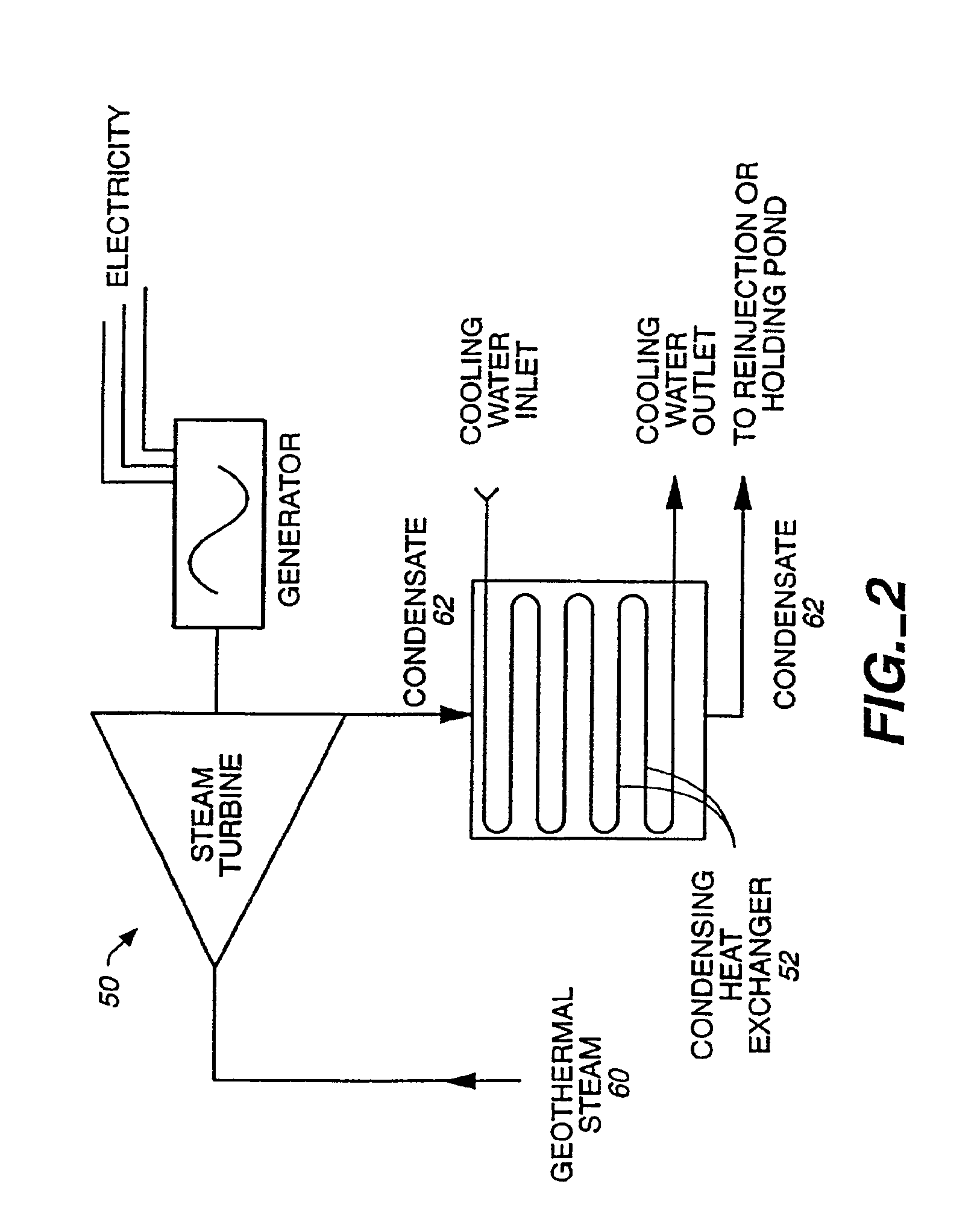

Method of combining wastewater treatment and power generation technologies

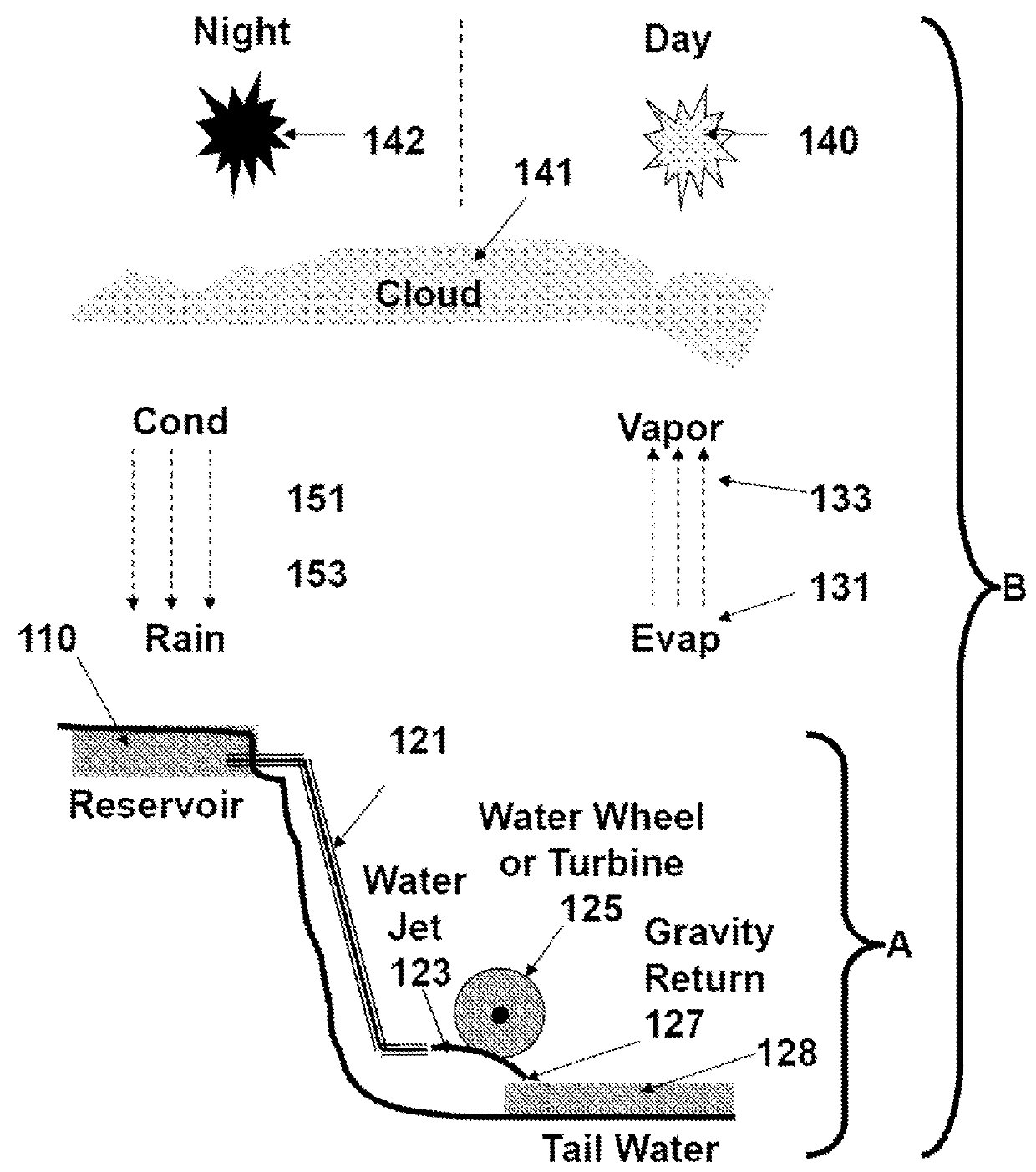

InactiveUS6862886B2Cost of such pumpIncrease valueOther heat production devicesGeothermal energy generationHigh elevationPenstock

Applicant's preferred embodiment utilizes municipal wastewater effluent to replenish a depleted geothermal field. Condensate produced by expanding steam produced in the geothermal field through a steam turbine-generator may be pooled with cooked water collected from said field, and then directed through a penstock from a higher elevation to a lower elevation where further energy is extracted through a traditional hydroelectric turbine-generator. The cooked water and condensate may be treated to produce potable water and / or distributed for public consumption either before or after being directed to the hydroelectric turbine-generator. The effluent is pumped up to the geothermal field during off-peak periods of electric consumption, and the hydroelectric generation is accomplished during periods of peak electric demand. A fraction of the effluent may be used as cooling water for the steam turbine-generator and its associated condenser before injection into the geothermal field. At least a portion of the pipeline to transport the wastewater effluent is preferably routed along an undisturbed riverbed and / or through an excavated tunnel.

Owner:STEWART LEONARD L

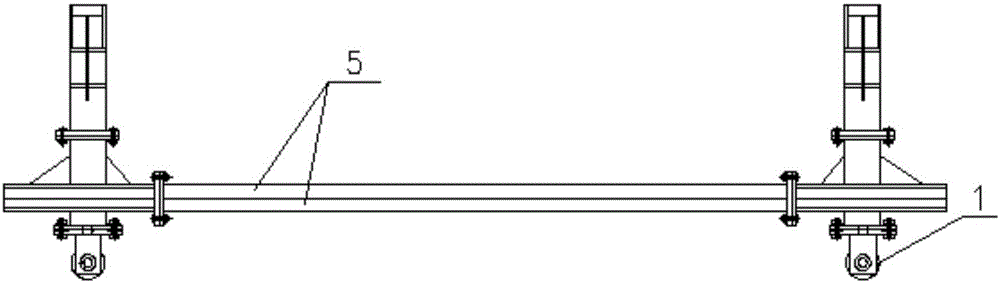

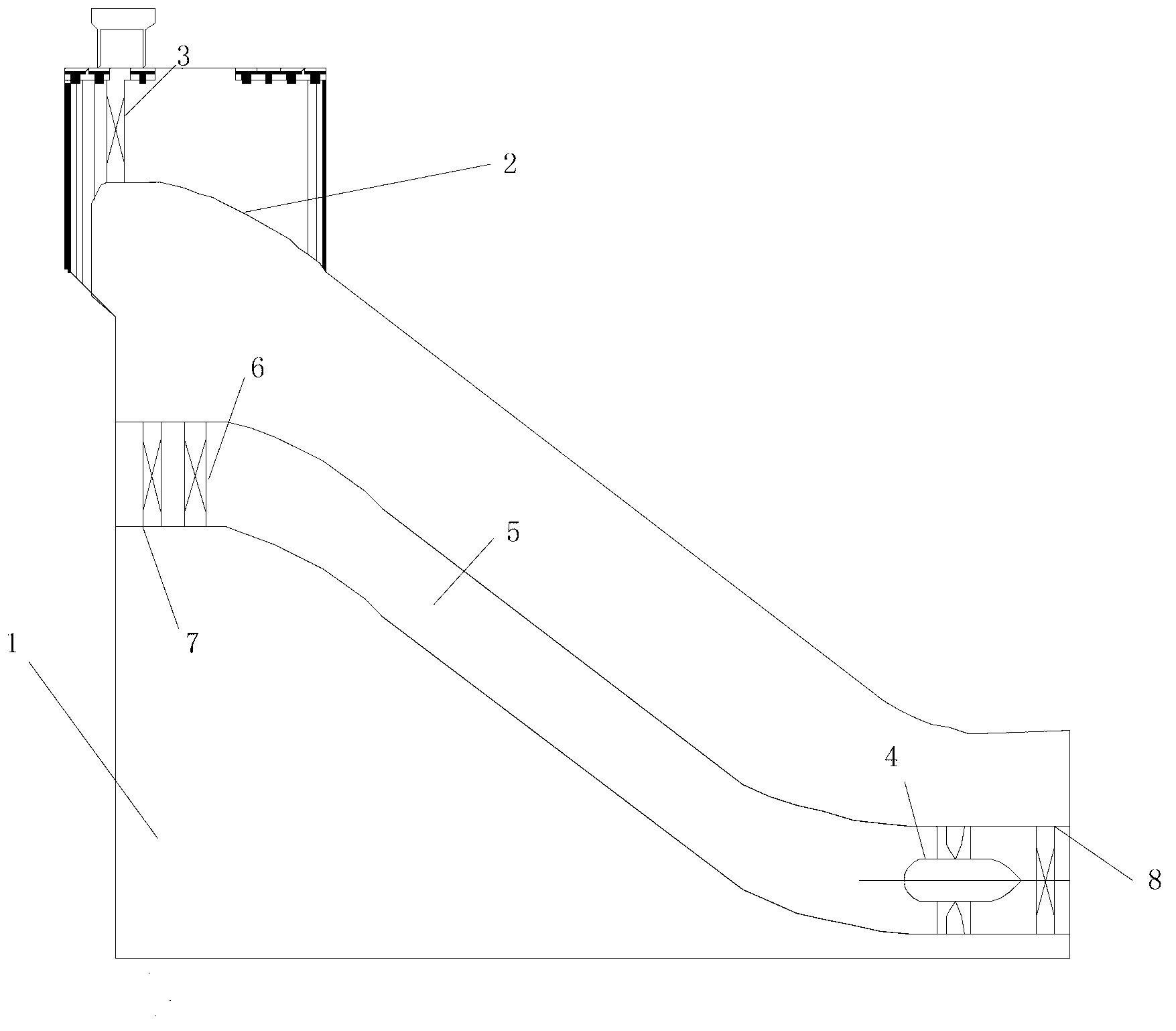

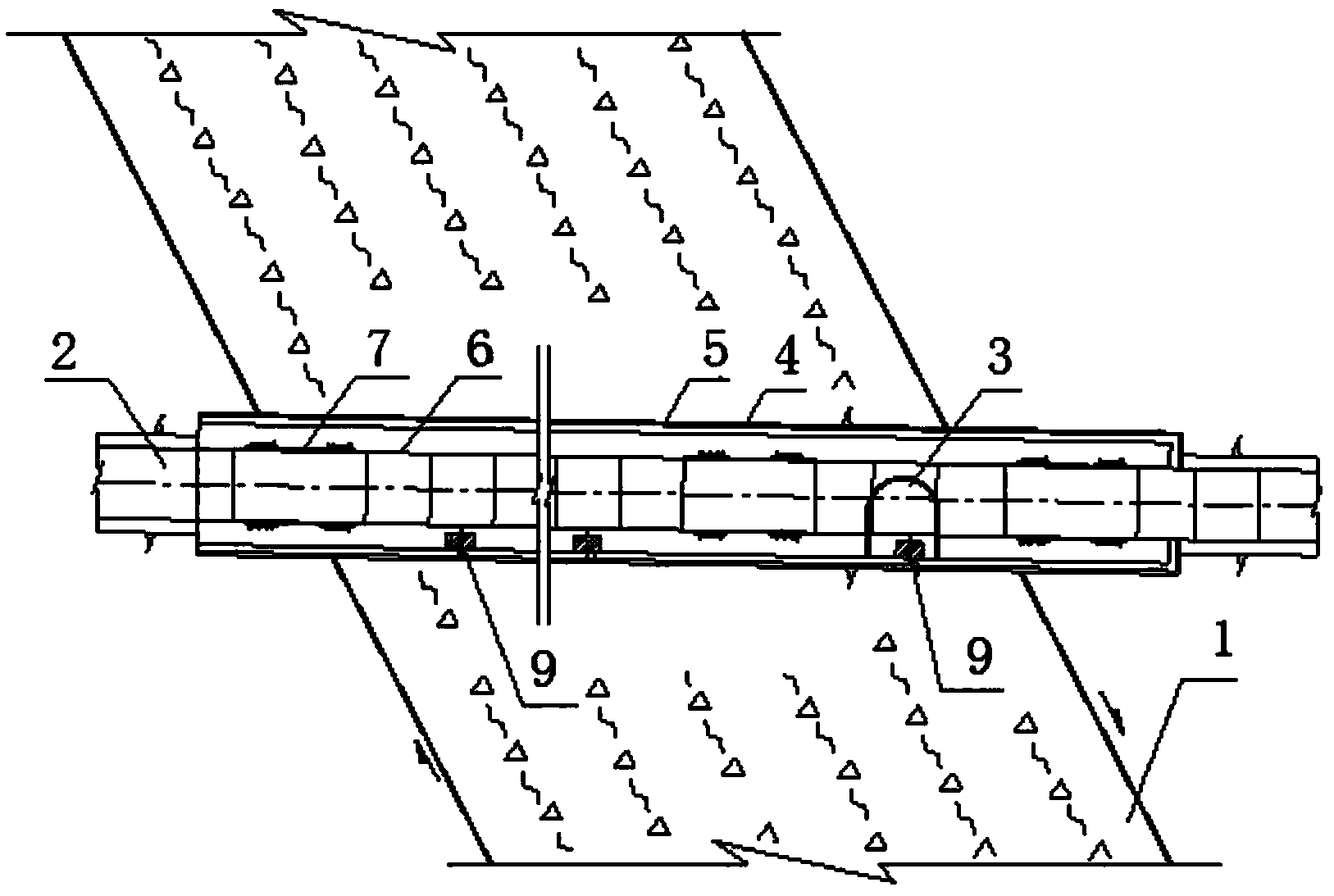

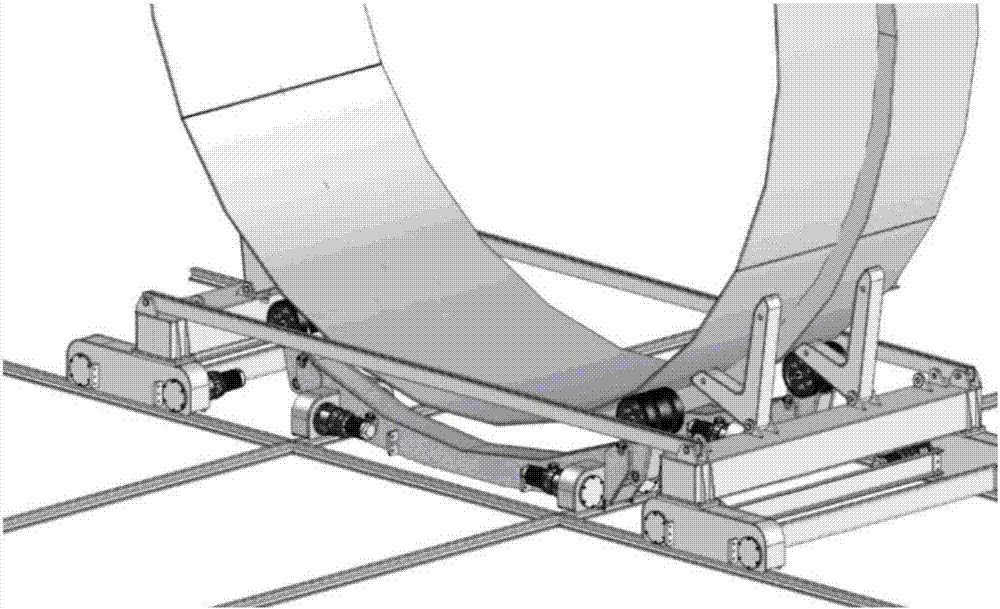

High-slope large-scale steel penstock mounting and unloading device and steel penstock mounting method

ActiveCN106151682ASolve the difficulty of installationSimple structural designPipe laying and repairTerrainPenstock

The invention discloses a high-slope large-scale steel penstock mounting and unloading device which comprises a trolley with a rotary part, a rail and a traction device for dragging the trolley. A high-slope large-scale steel penstock mounting method comprises the following steps: (1) carrying out foundation measurement and rail laying; (2) designing and arranging the traction device; (3) manufacturing and mounting the trolley and carrying out a load test; (4) transporting steel penstocks to unloaded positions; (5) swerving the trolley and the steel penstocks; (6) unloading the steel penstocks at a first abrupt slope section; (7) swerving the trolley and the steel penstocks at a gentle slope plane; (8) unloading the steel penstocks at a second abrupt slope section; (9) putting the steel penstocks in position; and (10) disassembling and moving out the trolley. According to the high-slope large-scale steel penstock mounting and unloading device and the high-slope large-scale steel penstock mounting method, the technological problems including laying of the rail and the traction device for mounting the steel penstocks at a complicated massif terrain, design of the mounting and unloading device, horizontal transportation, right-angle swerving, unloading in a high-slope, plane swerving and in-position unloading of the steel penstocks can be solved, construction is safe and efficient, and economy and practicality are realized.

Owner:CHINA GEZHOUBA GRP MECHANICAL & ELECTRICAL CONSTR

Hydroelectric power generating system

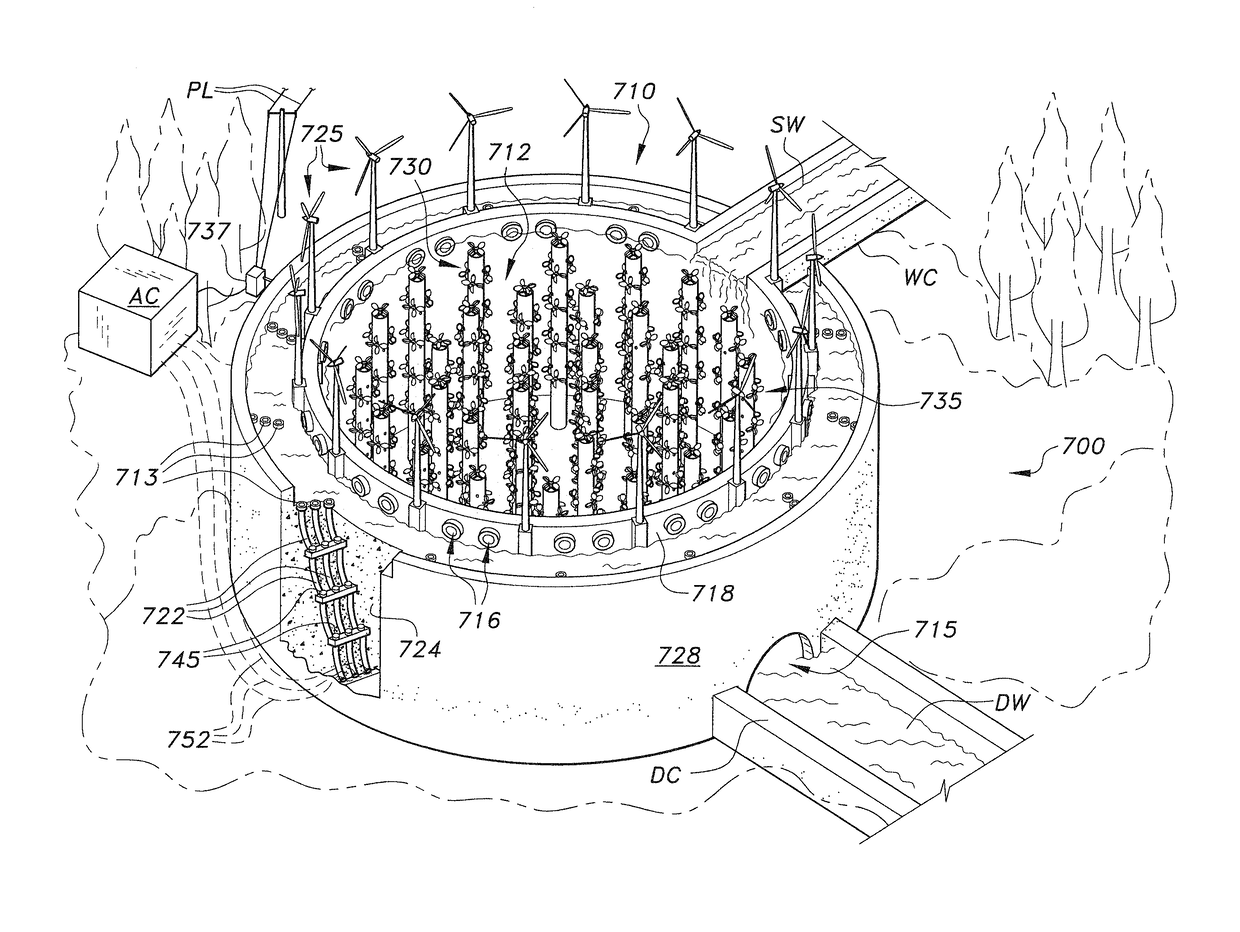

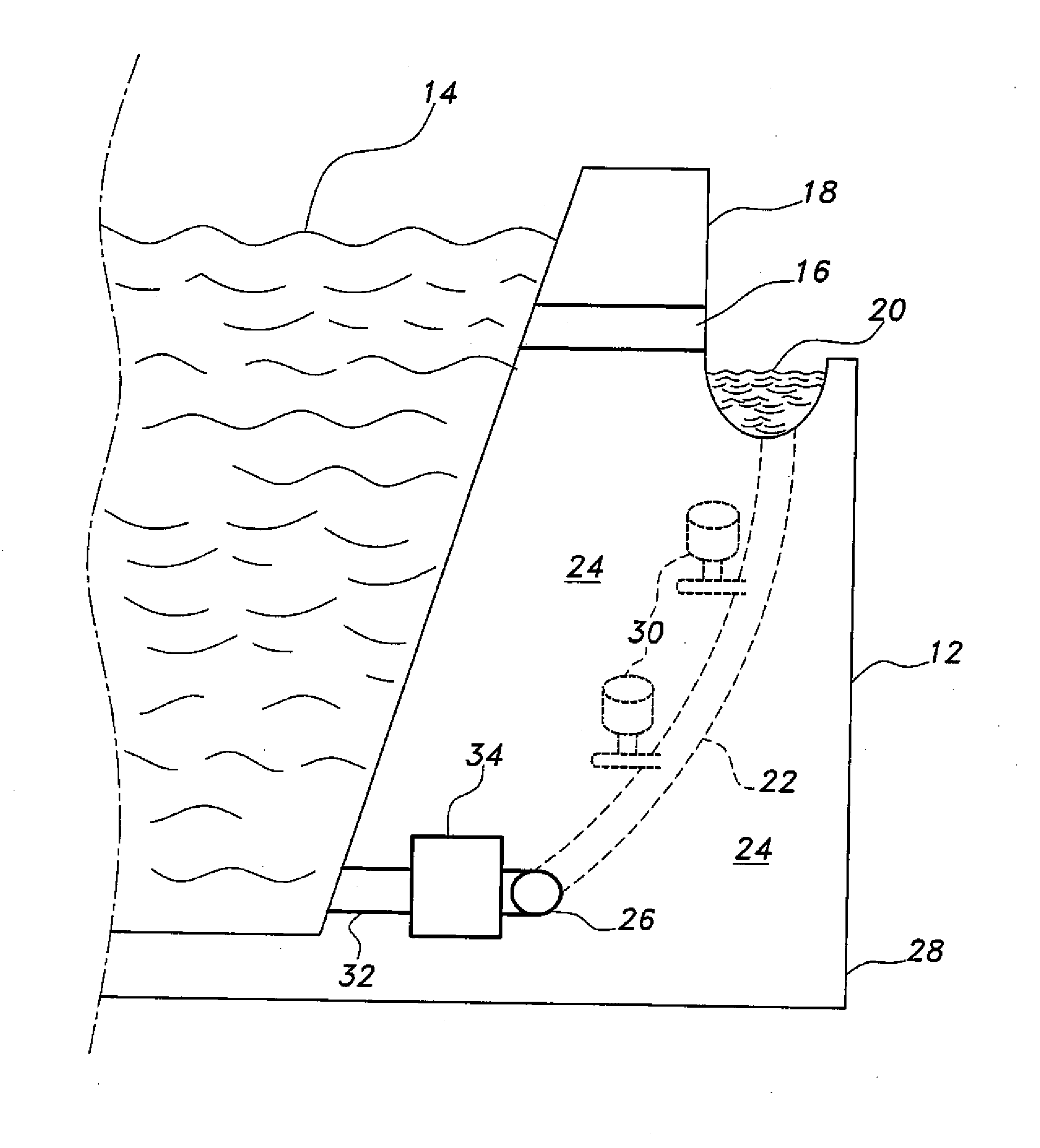

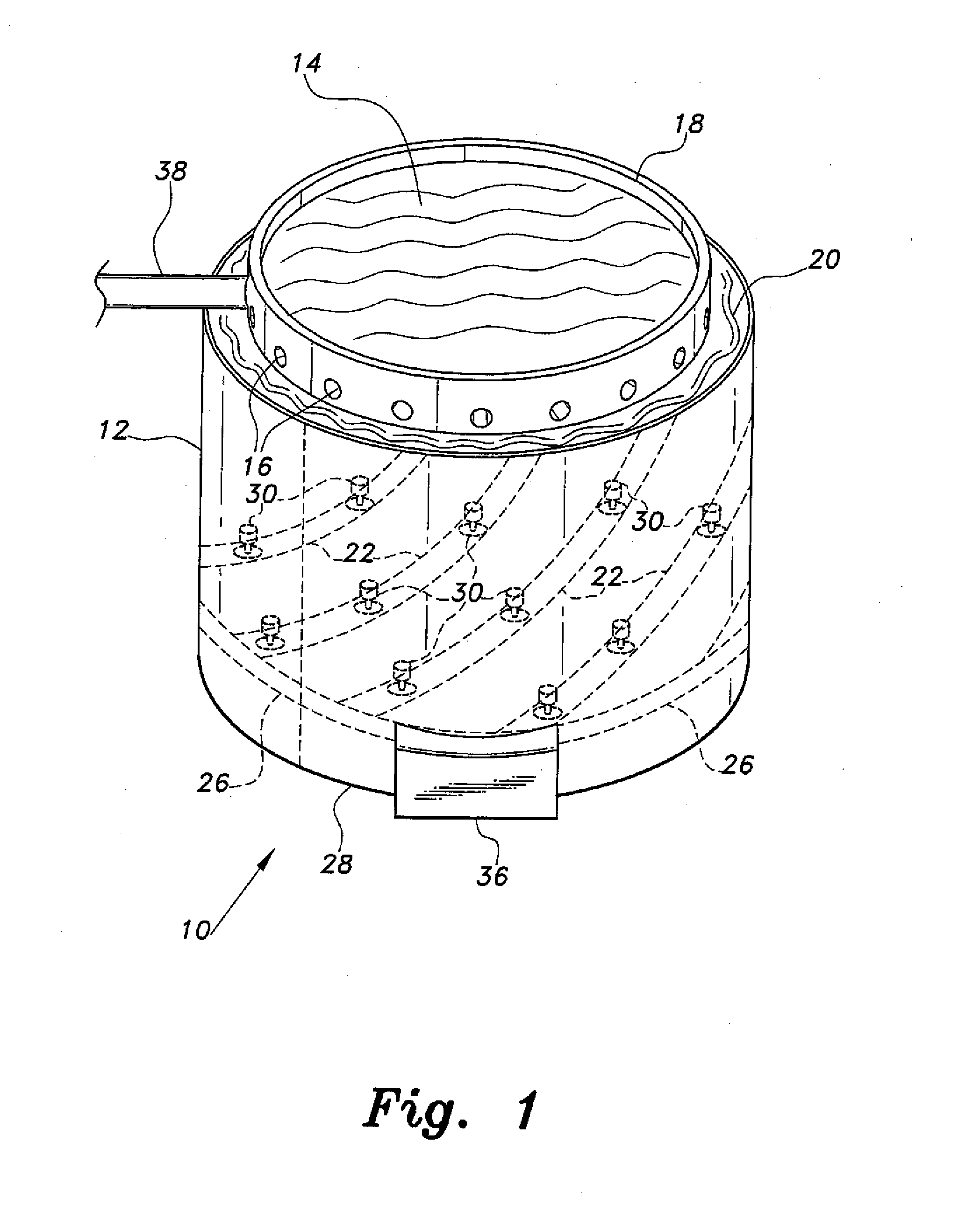

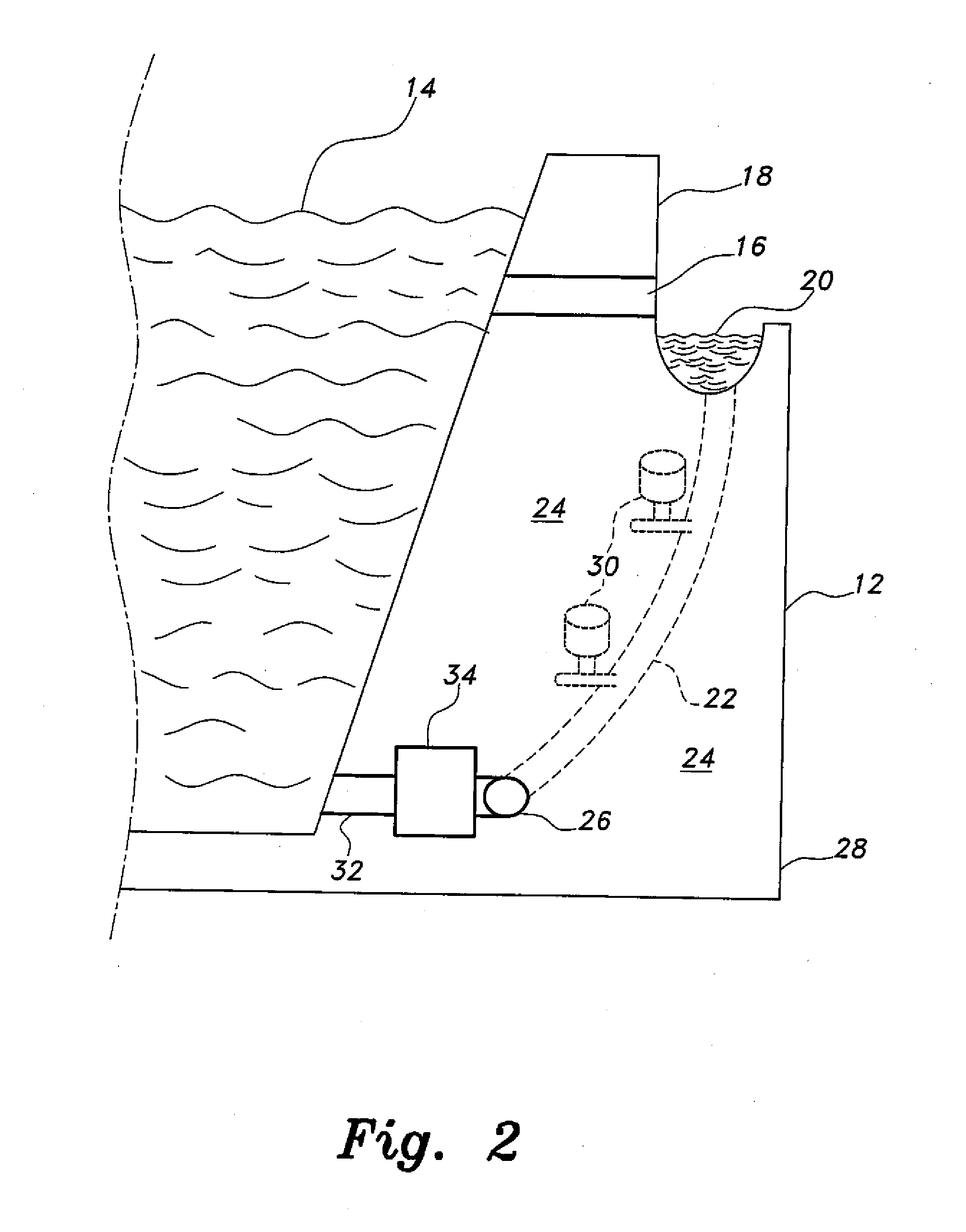

The hydroelectric power generating system incorporates a man-made dam structure configured to completely enclose a body of water. The dam is preferably filled by pumping seawater into the reservoir defined by the encircling dam. A circumferential canal feeds water to one or more penstocks. Each penstock has one or more hydroelectric turbine generators installed therealong. The penstocks feed an enclosed circumferential channel about the base of the dam. The channel delivers water to a pump that pumps the water back into the bottom of the reservoir. An auxiliary hydroelectric power generating system disposed within the dam utilizes the water exiting from the lower end of the penstocks for additional production of energy. While this system results in a net loss of energy, the system can make use of surplus power to drive the return pump during periods of low electrical demand in order to replenish the reservoir.

Owner:BARAKAT YASER K

Method for repairing and constructing trenchless large caliber water feeding penstock

ActiveCN101109475AMature construction technologyReliable construction technologyPipe elementsPenstockWater quality

The invention provides a construction method for repairing a pressure water supply pipe with big diameter without excavating. The method comprises such procedures as clearing scale in the old pipe, laying an inner lining pipe, connecting, inspecting and pressure testing the pipe, etc. The method is characterized in that, the laying of the inner lining pipe is to pass a glass steel & sand pipe and a steel pipe in diameter slightly smaller than that of the former mother pipe into the former mother pipe, a glass steel & sand pipe is used at pipe section without branch, and a steel pipe is used at pipe section needing branch; between the inner lining pipe sections, a joint of sealing and connecting function is provided. The construction method in the invention is relatively simple, the process is mature, economic and practical, and a repaired pipe has the advantages of the small resistance in delivering liquid, the good resistance to corrosion, the long service life and the no water pollution.

Owner:上海水务建设工程有限公司

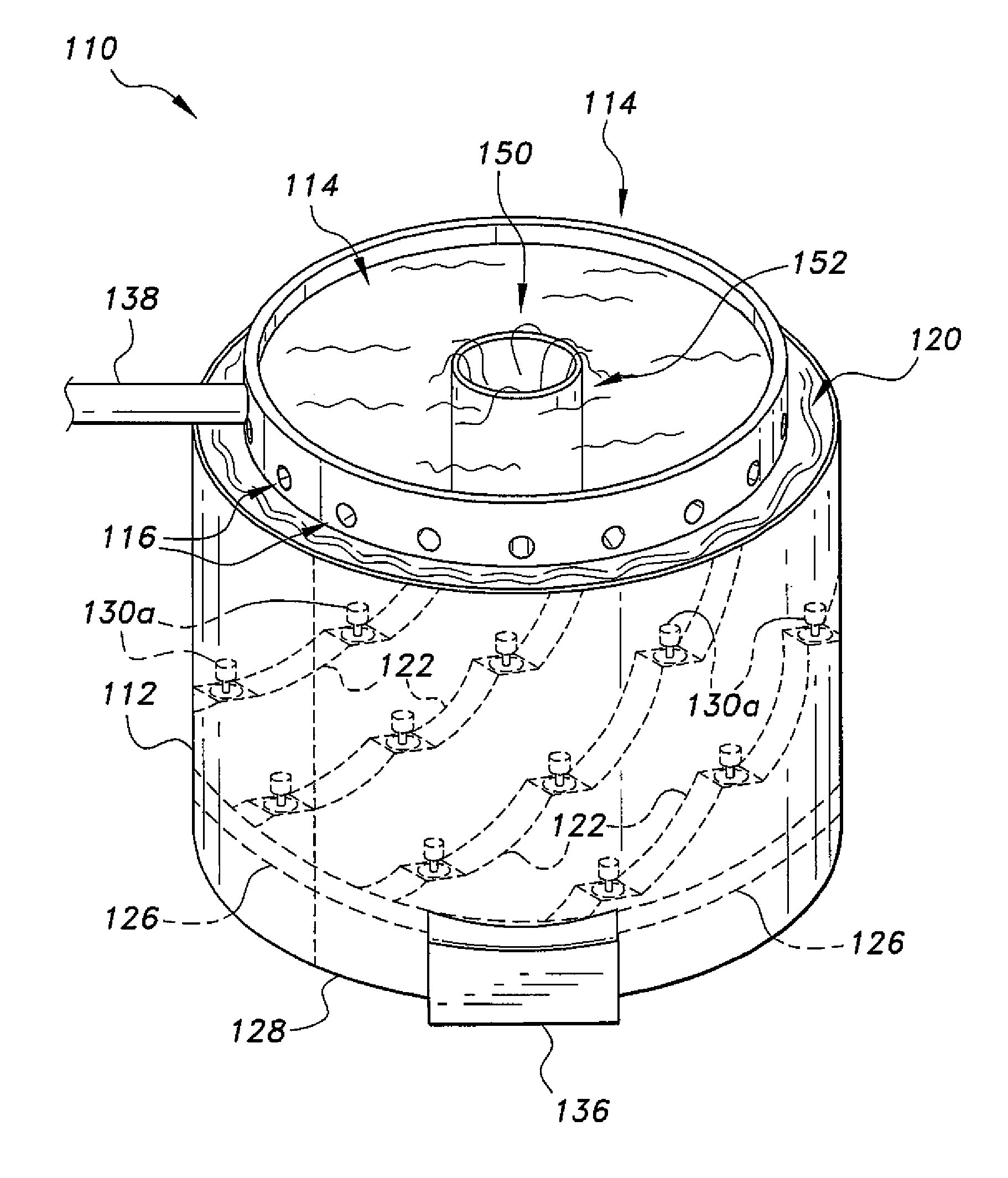

Hydroelectric power generating system

The hydroelectric power generating system includes a reservoir for retaining a body of water and an outer vessel that surrounds a peripheral wall of the reservoir. A circumferential canal extends between an upper portion of the reservoir peripheral wall and the outer vessel. One or more penstocks extend below the canal between the reservoir and the outer vessel. Each penstock has one or more hydroelectric turbine generators installed therealong. A plurality of primary wind turbines can be disposed on a peripheral wall of the reservoir and a plurality of air columns can be disposed within the reservoir to generate auxiliary power.

Owner:BARAKAT YASER

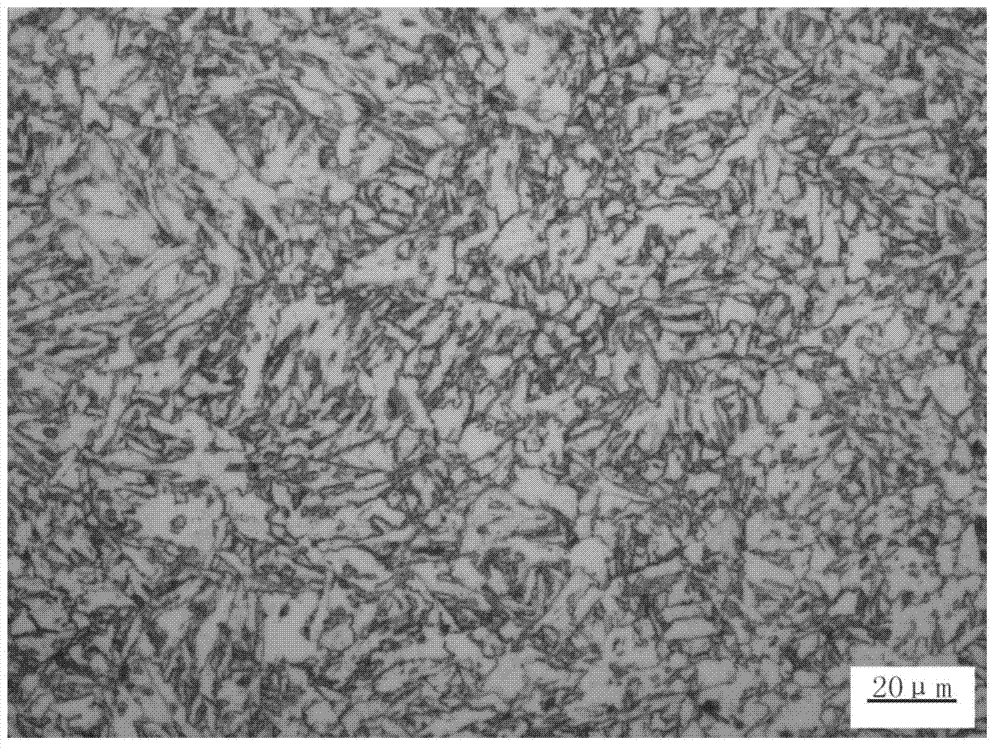

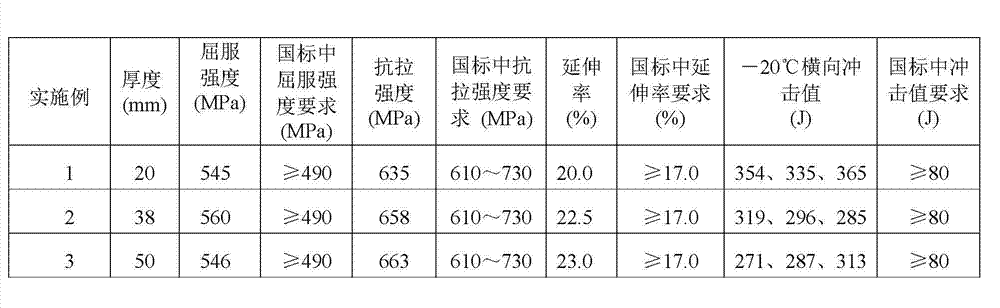

Technique for manufacturing steel plate for 600MPa hydropower steel penstock

InactiveCN103045965AImprove plasticityImprove low temperature impact toughnessHeat treatment process controlTemperingPenstock

The invention provides a technique for manufacturing a steel plate for a 600MPa hydropower steel penstock. The steel plate comprises the following chemical components in weight percentage: 0.06-0.09% of C, 0.20-0.40% of Si, 1.4-1.6% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.02-0.04% of Nb, 0.20-0.40% of Ni, 0.10-0.30% of Cr, 0.10-0.30% of Mo, 0.03-0.05% of V, 0.01-0.02% of Ti and the balance of Fe and inevitable impurities. Through a low-carbon microalloying design, a thermo-mechanical control process (TMCP) and a tempering process (T), a metallographic structure mainly based on a tempered bainite is ultimately obtained, thus achieving good matching of strength, plasticity, toughness and weldability, reducing the production cost and improving the production efficiency. The steel plate is mainly used for manufacturing the hydropower penstock.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

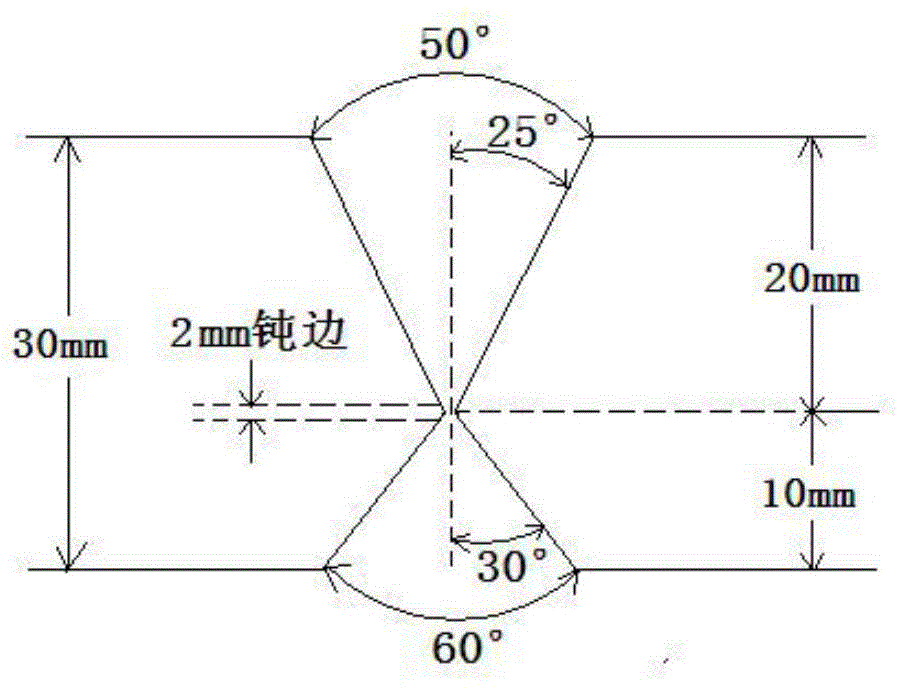

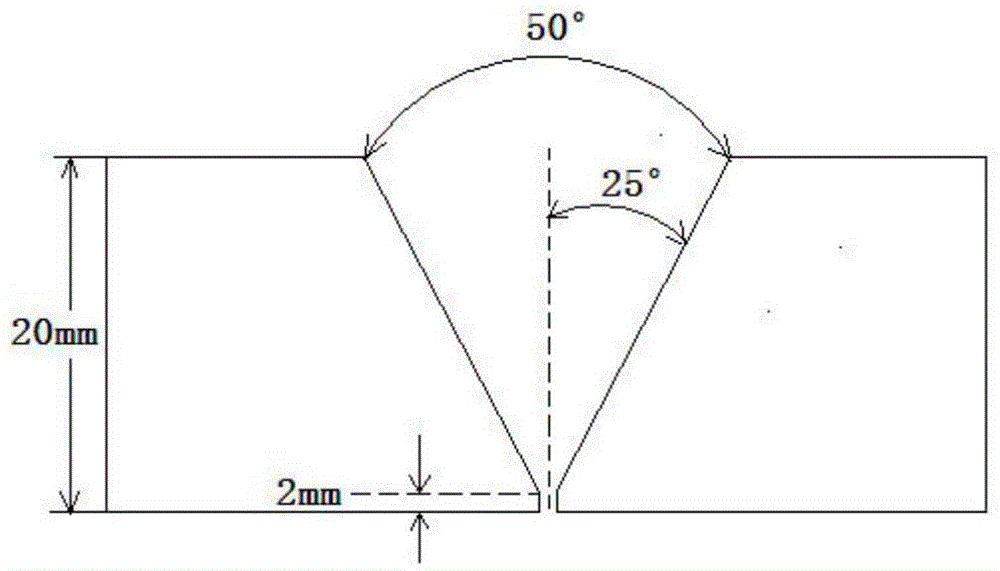

Welding wire special for high-strength steel penstock submerged-arc welding

InactiveCN104162748AEnsure safetyMeet site construction requirementsArc welding apparatusWelding/cutting media/materialsPenstockHigh strength steel

The invention discloses a welding wire special for high-strength steel penstock submerged-arc welding and belongs to the field of welding materials. The welding wire comprises, by weight, 0.08%-0.2% of C, 0.1%-0.3% of Si, 1.5%-2.5% of Mn, 1.5%-3.5% of Ni, 0%-0.5% of Cr, 0.5%-1.0% of Mo, 0%-0.05% of Al, 0%-0.2% of Nb, 0%-0.2% of V, 0%-0.2% of Ti, 0%-0.01% of B, 0%-0.005% of O, 0%-0.01% of N, 0%-0.01% of S, 0%-0.01% of P, and the balance Fe and inevitable impurity elements. The welding wire is matched with a hydroelectric steel penstock made of a 100kg-grade steel plate, and when the welding wire is matched with alkaline welding flux, the requirements of a welded joint of the hydroelectric steel penstock made of the 100kg-grade steel plate that welded joint tensile strength is higher than or equal to 950 MPa, minus 60 DEG C ballistic work is higher than or equal to 47 J and 0 DEG C ballistic work is higher than or equal to 100 J can be met.

Owner:SHOUGANG CORPORATION

Eco-friendly subsidiary dam capable of improving gas supersaturation

ActiveCN102852122AGuaranteed to workReduce supersaturationBarrages/weirsWater-power plantsRiver routingPenstock

The invention relates to an eco-friendly subsidiary dam capable of improving gas supersaturation generated during flood discharge and energy dissipation of large-sized hydraulic and hydroelectric engineering, comprising a dam body. The downstream face of the dam body is an overflow surface, a gate is arranged on a dam crest to control the outflow rate on the overflow surface so that the maximal water depth of the outflow of the overflow surface does not exceed 5m; a backward step of the dam body adopts the continuous type, and meanwhile, the flow over spillway is smoothly connected with the downstream water flow, so that the gas supersaturation water body is positioned at the upper layer of a downstream river course to accelerate the escape speed of the gas supersaturation water body; and the inner part of the dam body is provided with a penstock to guide the water in a water cushion pool to the lower reaches. The eco-friendly subsidiary dam capable of improving gas supersaturation can reduce water saturation when water passes through a low-head water turbine, reduces the supersaturation of the water of the downstream river course, and effectively controls the influence of gas supersaturation caused by flood discharge of the dam on the aquatic organism of the lower reaches.

Owner:CHINA THREE GORGES CORPORATION

Hydroelectric power system

A hydroelectric power system is provided. The hydroelectric power system includes a storage tank; a fluid; a penstock; an electric turbine generator, a transformer, an electric power grid system; a pump, and connecting conduit. A method of generating hydroelectric energy is also provided.

Owner:CAMPBELL CHARLES E

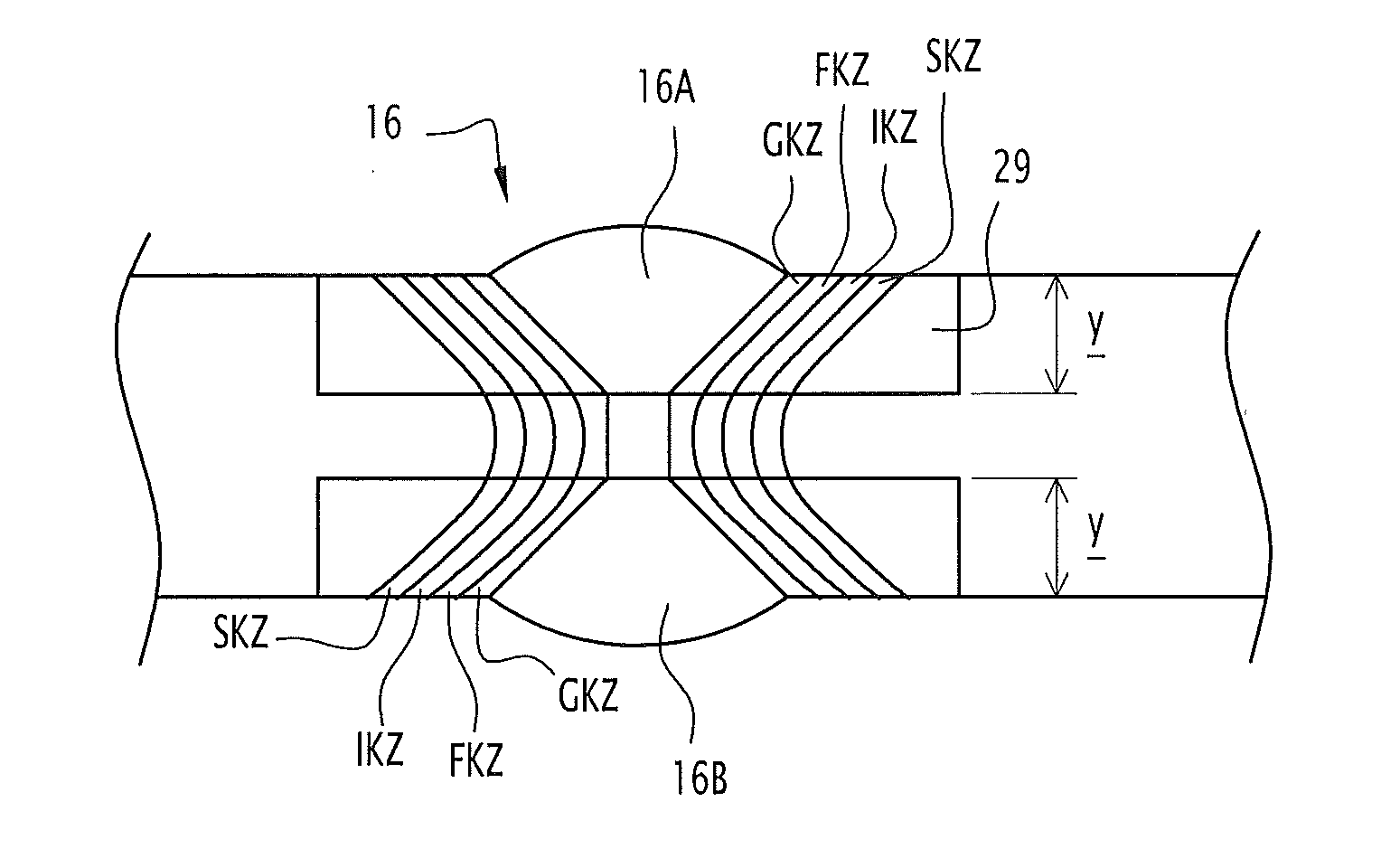

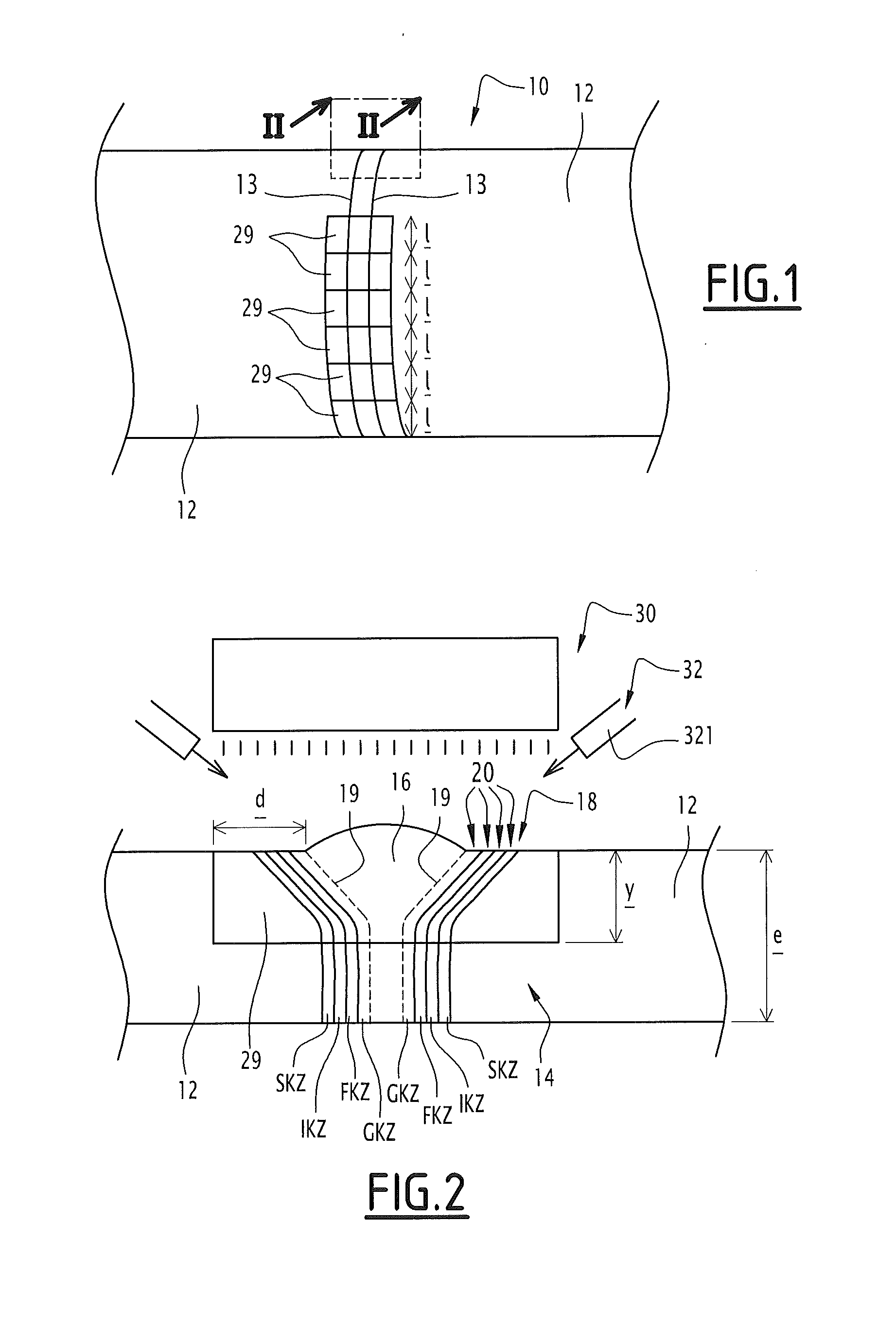

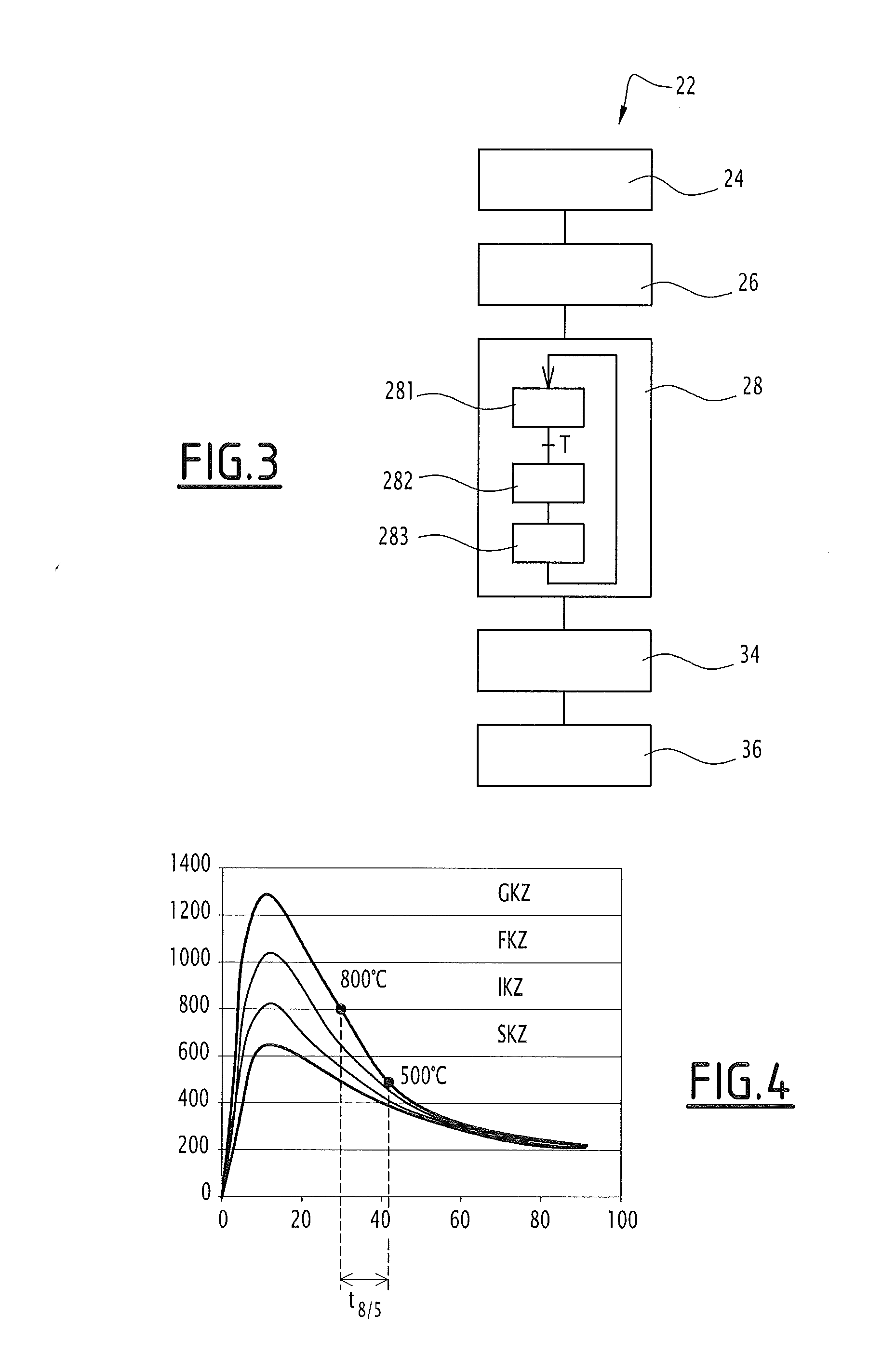

Method for welding two edges of one or more steel parts to each other including a heat treatment step after the welding step: penstock obtained with such a method

The present application describes a method for welding two parts to each other. The two parts are made from steel having a high thermomechanical yield strength. The welding method includes a welding step in which a weld bead is created inducing a heat-affected zone to appear. The method also includes a heat treatment step having a heating step, during which at least one portion of the weld bead and the HAZ is gradually heated to a treatment temperature; then a holding step in which the portion of the weld bead and the HAZ is kept at the treatment temperature; then a cooling step in which the HAZ and the weld bead are gradually cooled and pass from the austenitic transformation end temperature to the martensitic transformation end temperature of the steel of the parts in a time between 7.5 s and 8.5 s, and pass from the austenitic transformation end temperature to the martensitic transformation end temperature in a time shorter than 15.5 s. The present application also describes a penstock obtained with such a method.

Owner:ALSTOM RENEWABLE TECH

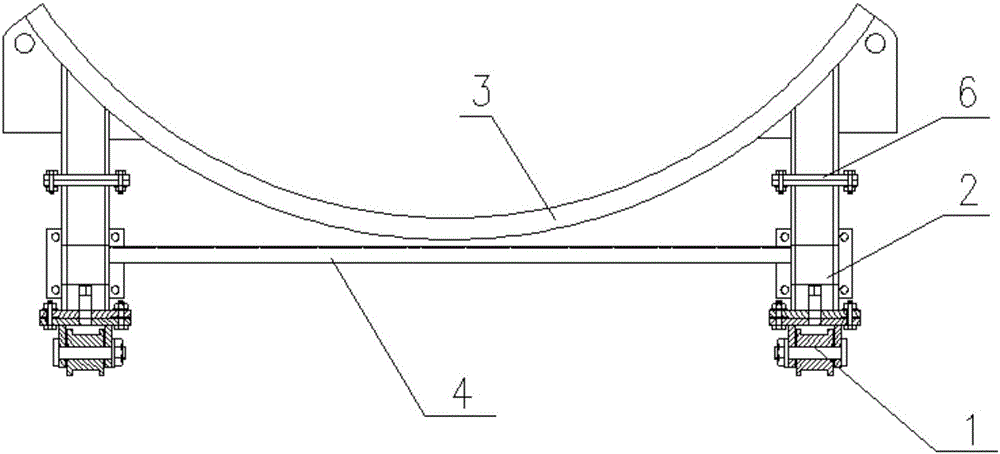

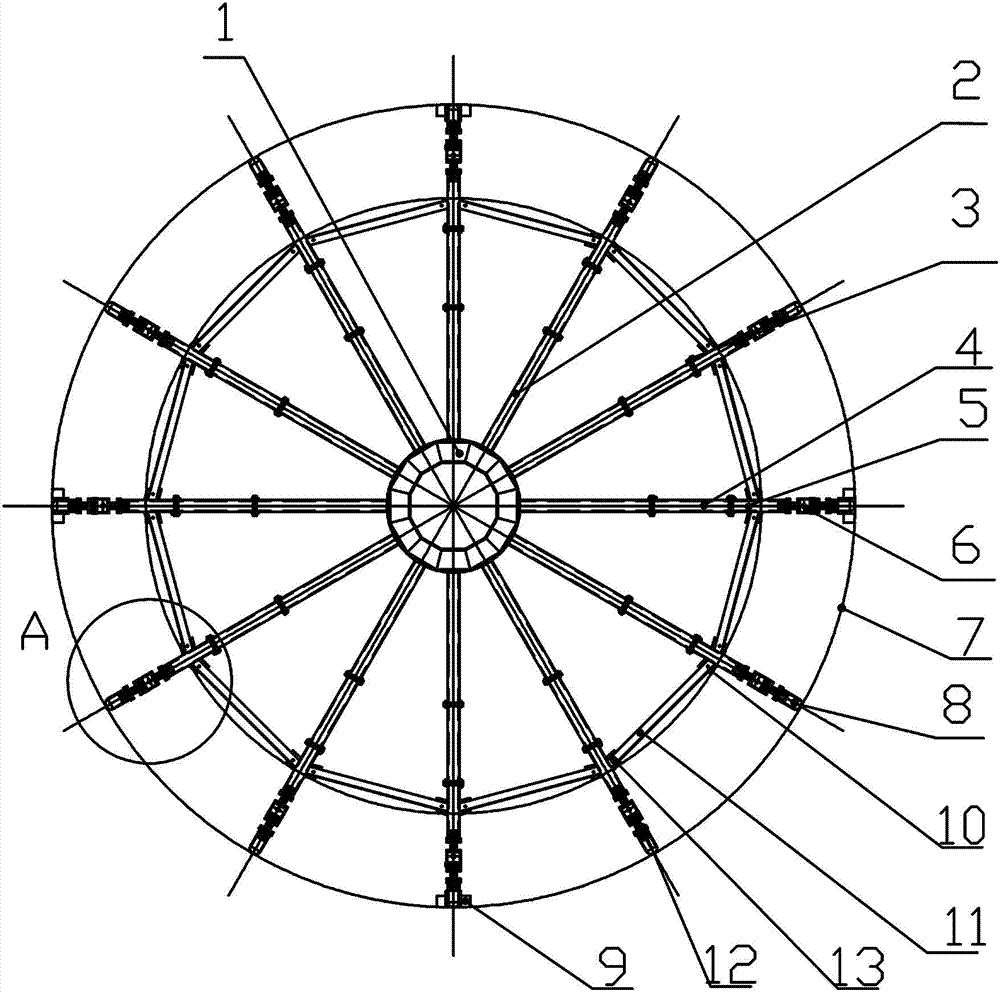

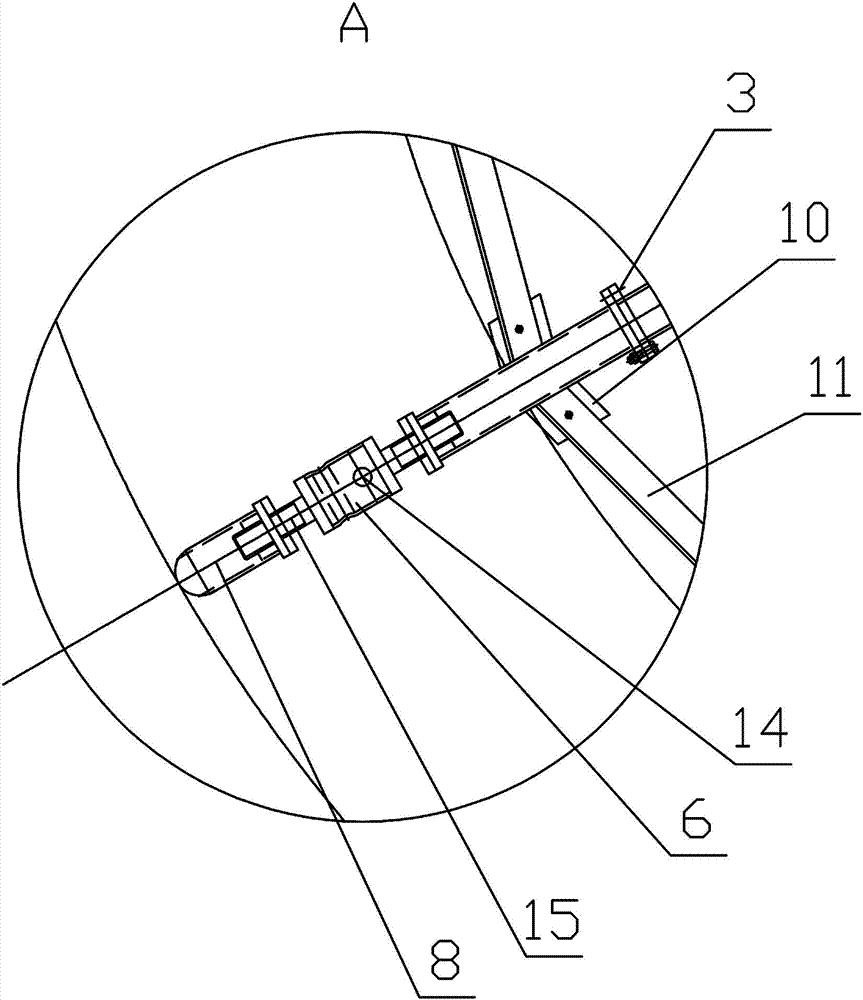

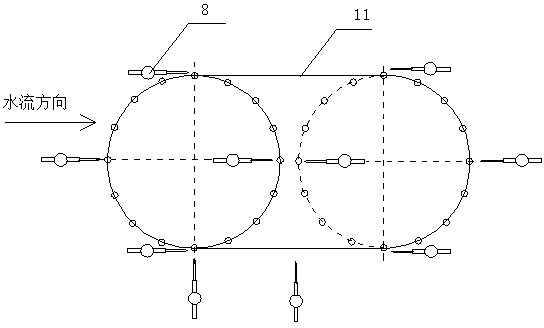

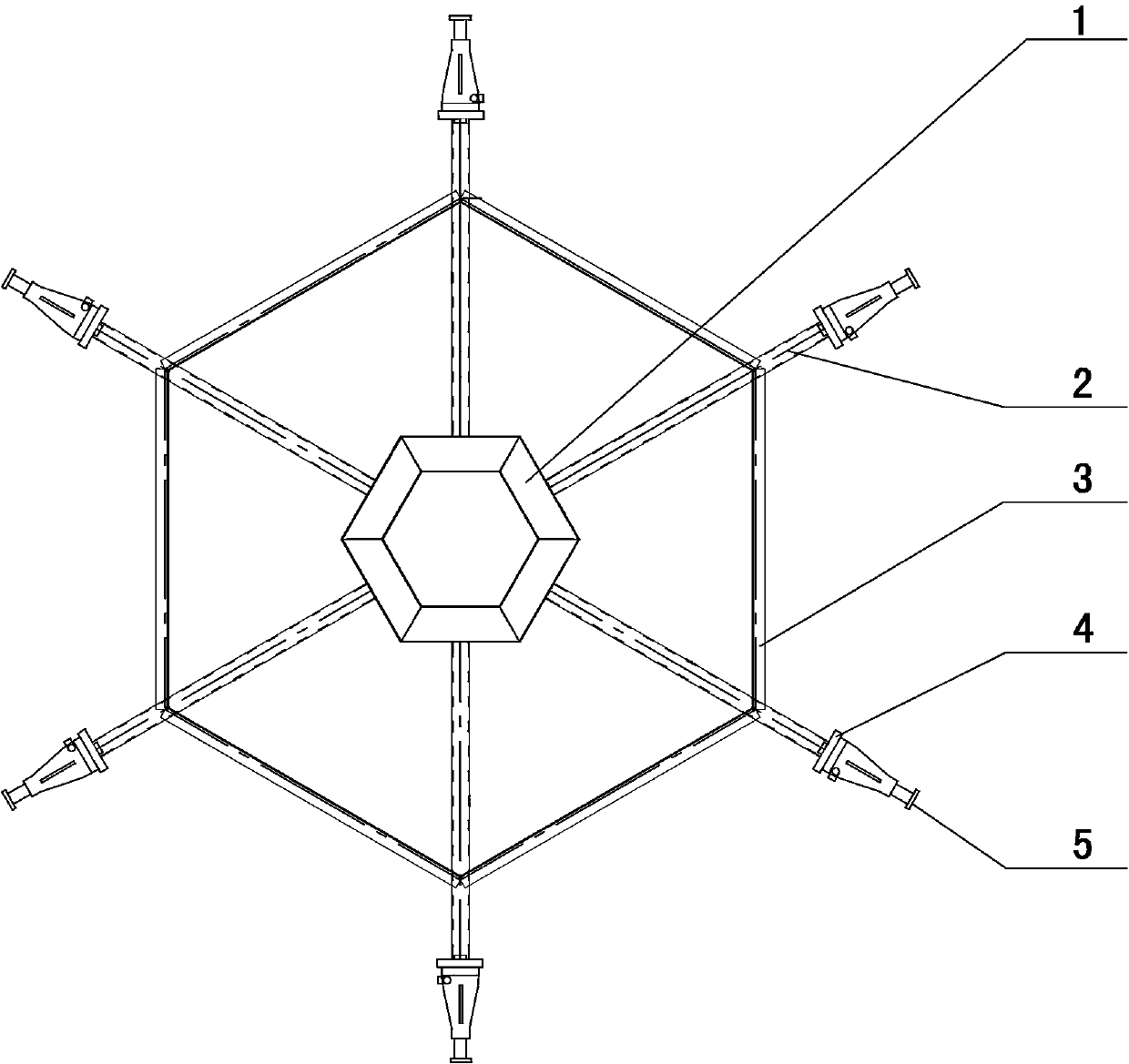

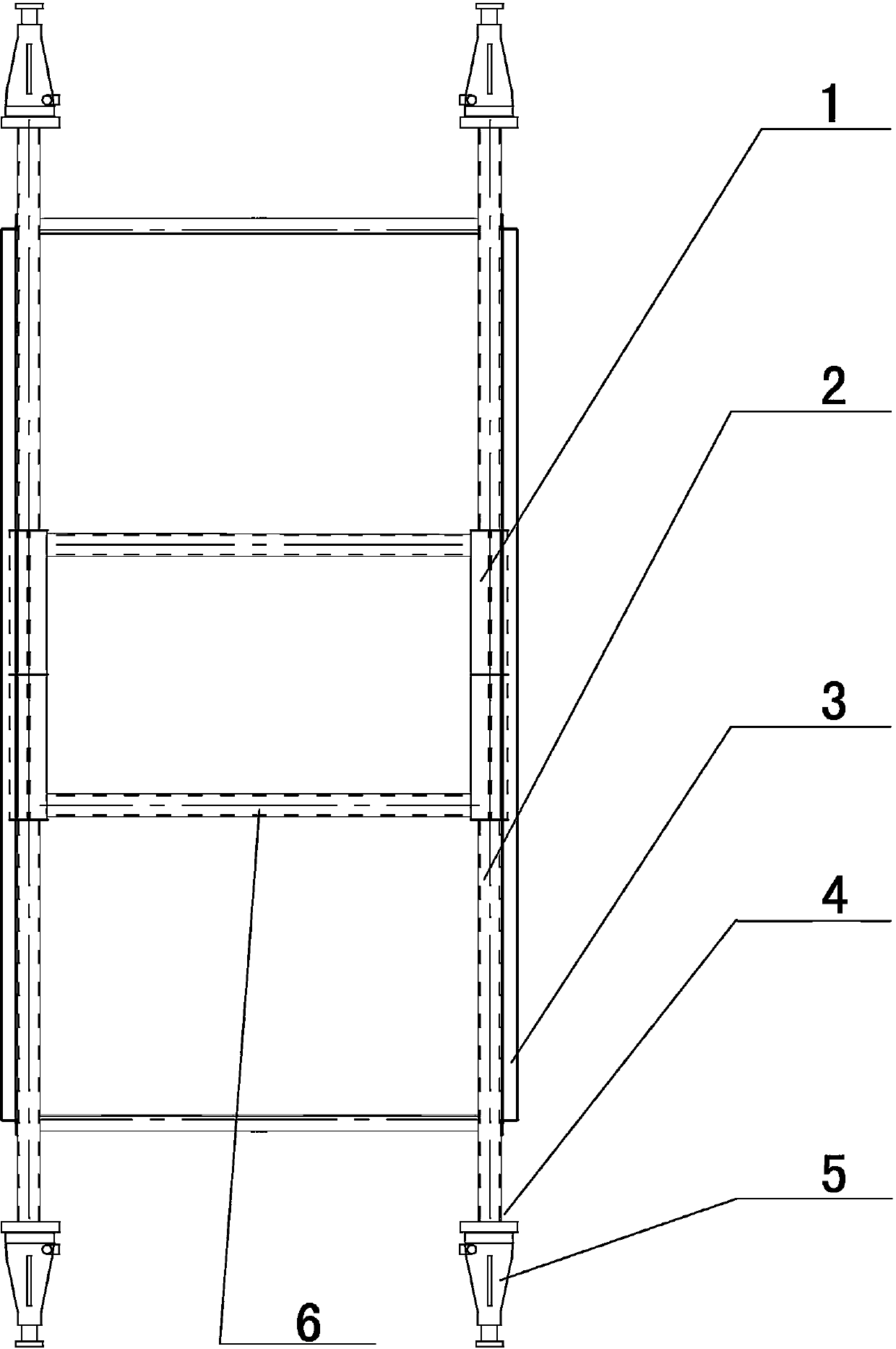

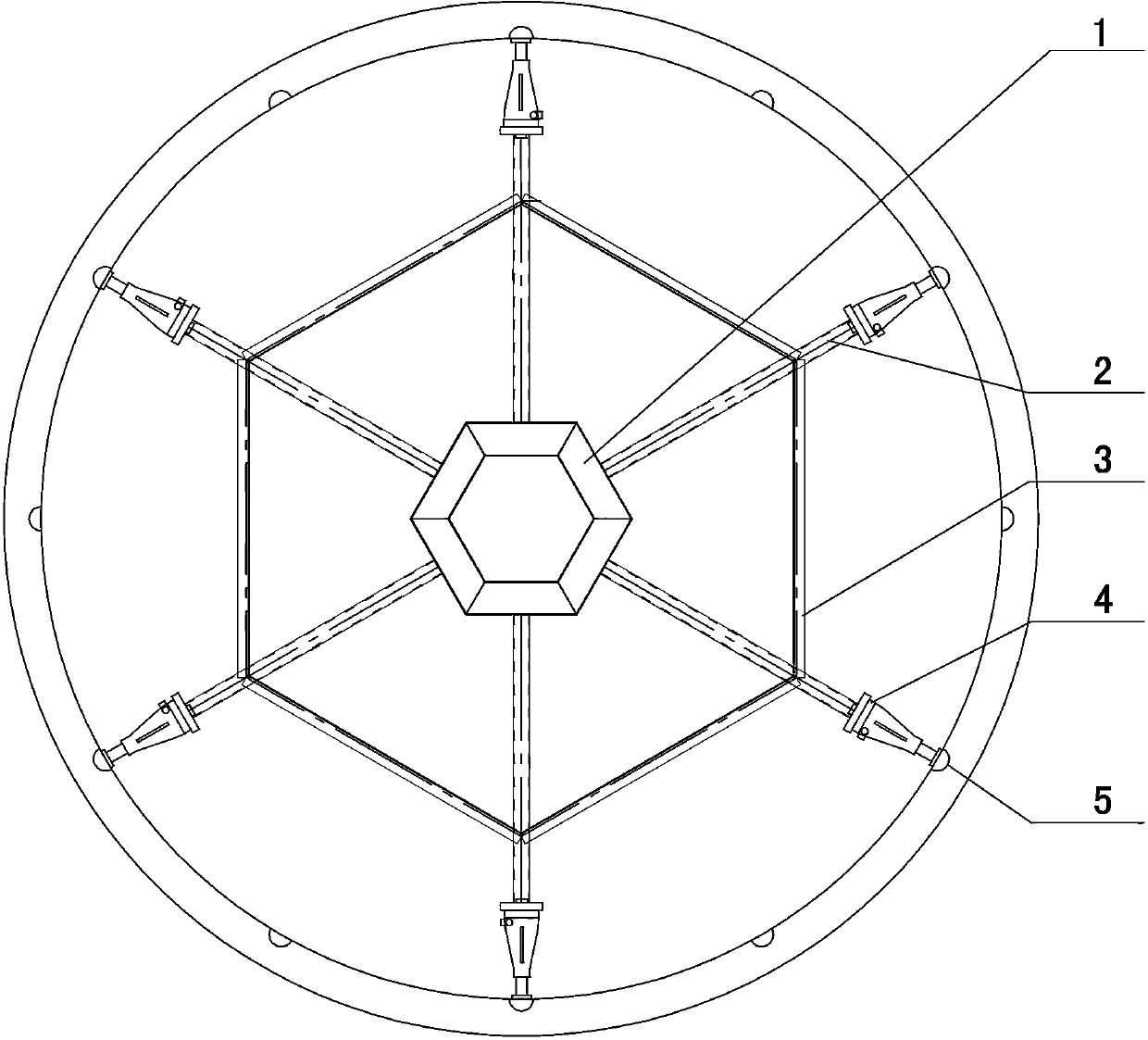

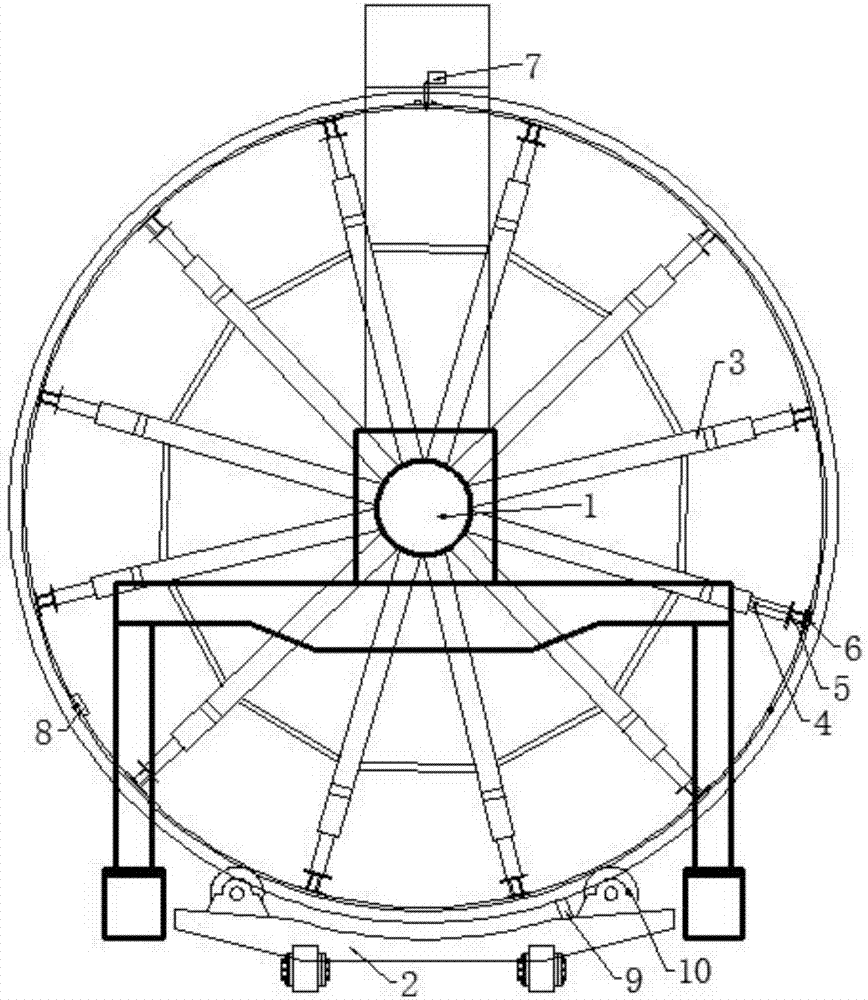

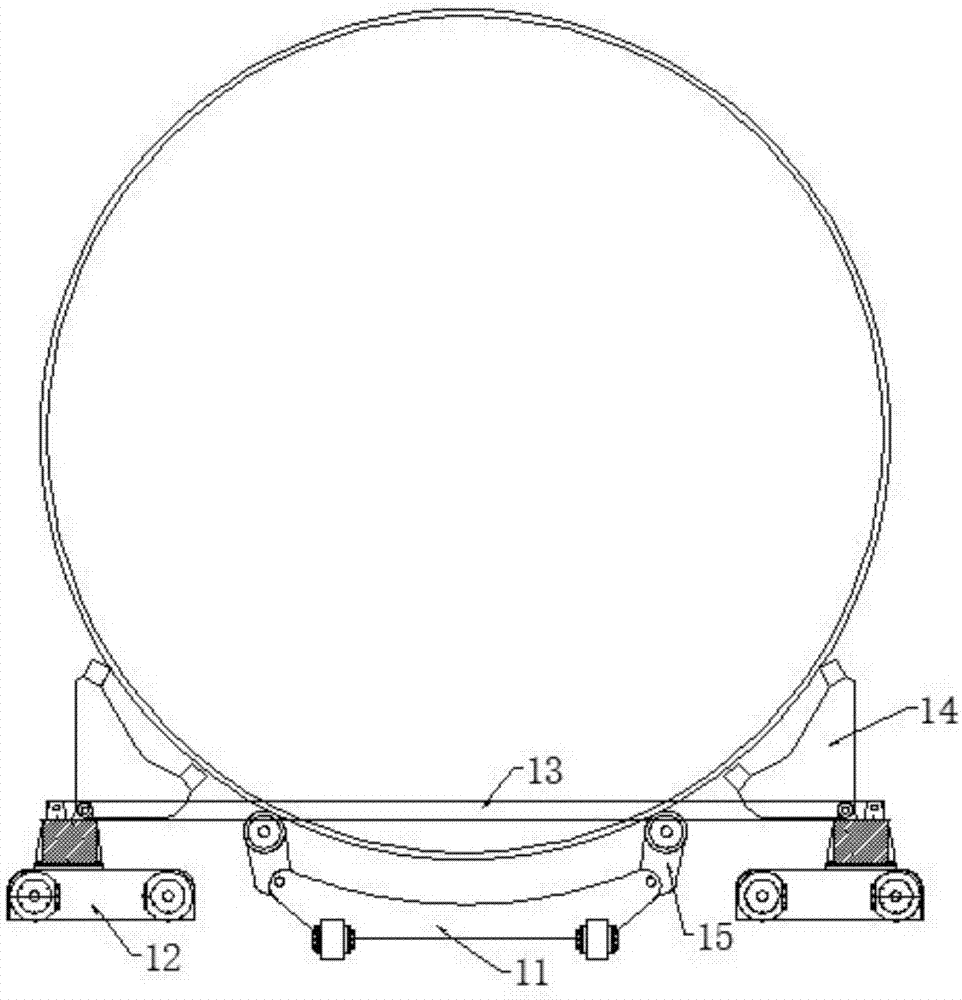

Device for roundness adjustment and supporting of penstock

A device for roundness adjustment and supporting of a penstock comprises an inner hub, wherein a plurality of supporting rod assembles are arranged on the outer circumference of the inner hub; each supporting rod assembly comprises at least three supporting rods including a supporting rod connected with the inner hub, an end supporting rod arranged at an end and in contact with the penstock, and an adjusting supporting rod connecting the supporting rod with the end supporting rod; studs are arranged at two ends of the adjusting supporting rod; and internal threads are formed in the supporting rod and the end supporting rod in corresponding positions. The device provided by the invention has the advantages that the roundness of the penstock can be adjusted conveniently; error caused by deformation of a component can be compensated; repeated use is convenient; the structure is simple; the mounting and the adjustment are convenient; the stress is reliable; the mounting and the disassembly are convenient; and the device also can be used for internal supporting during second stage concrete pouring.

Owner:CHINA GEZHOUBA GROUP CO LTD

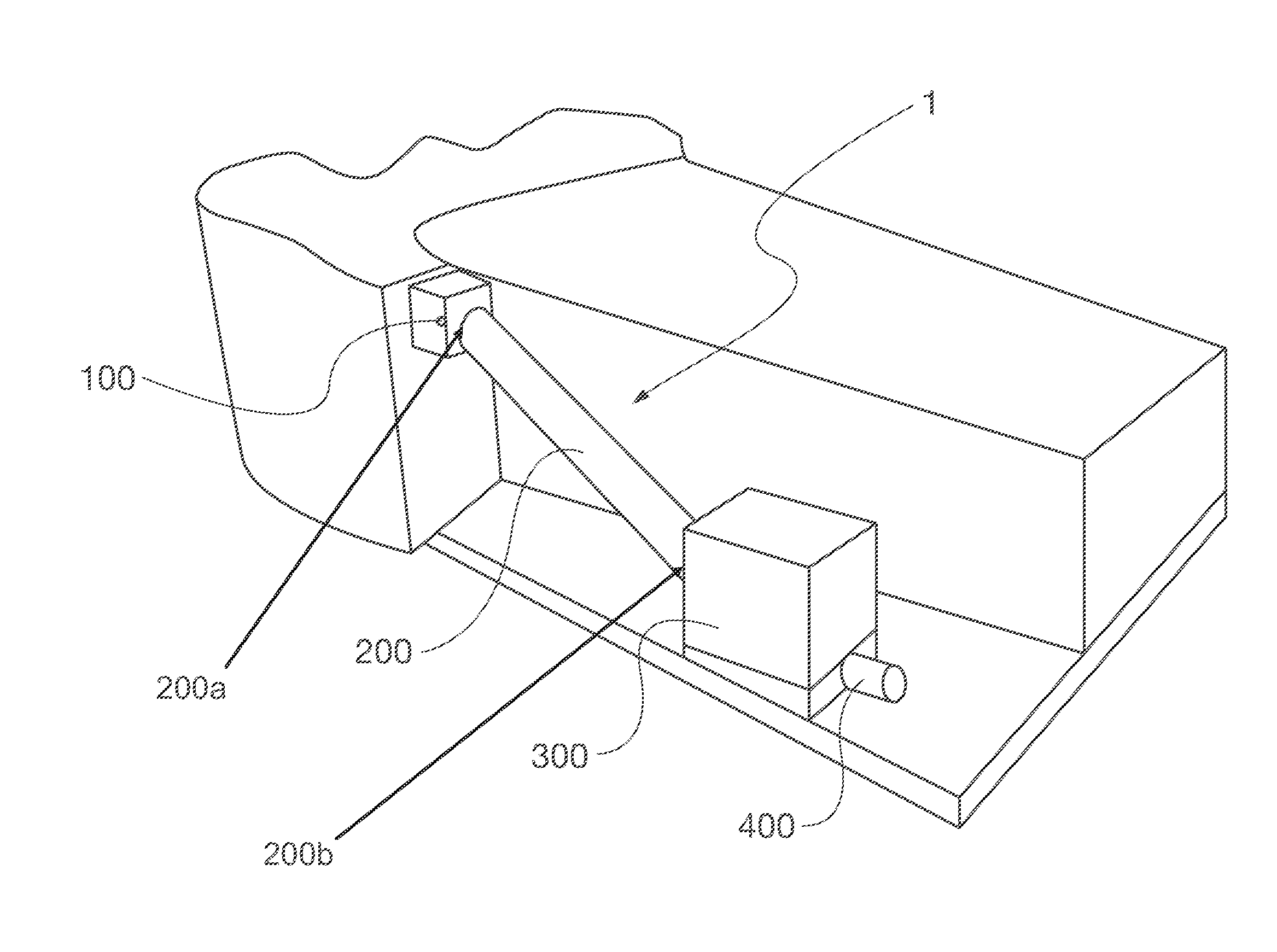

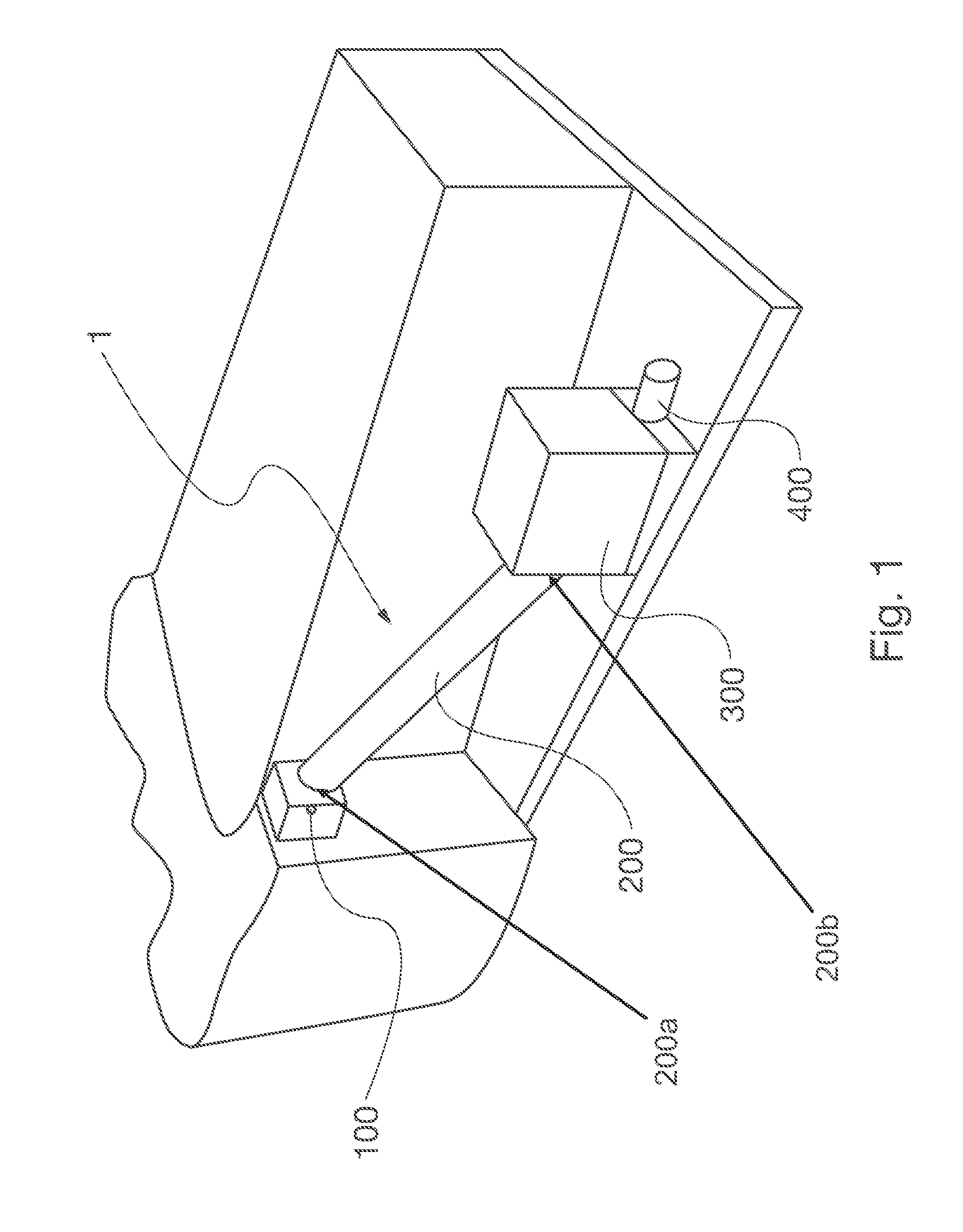

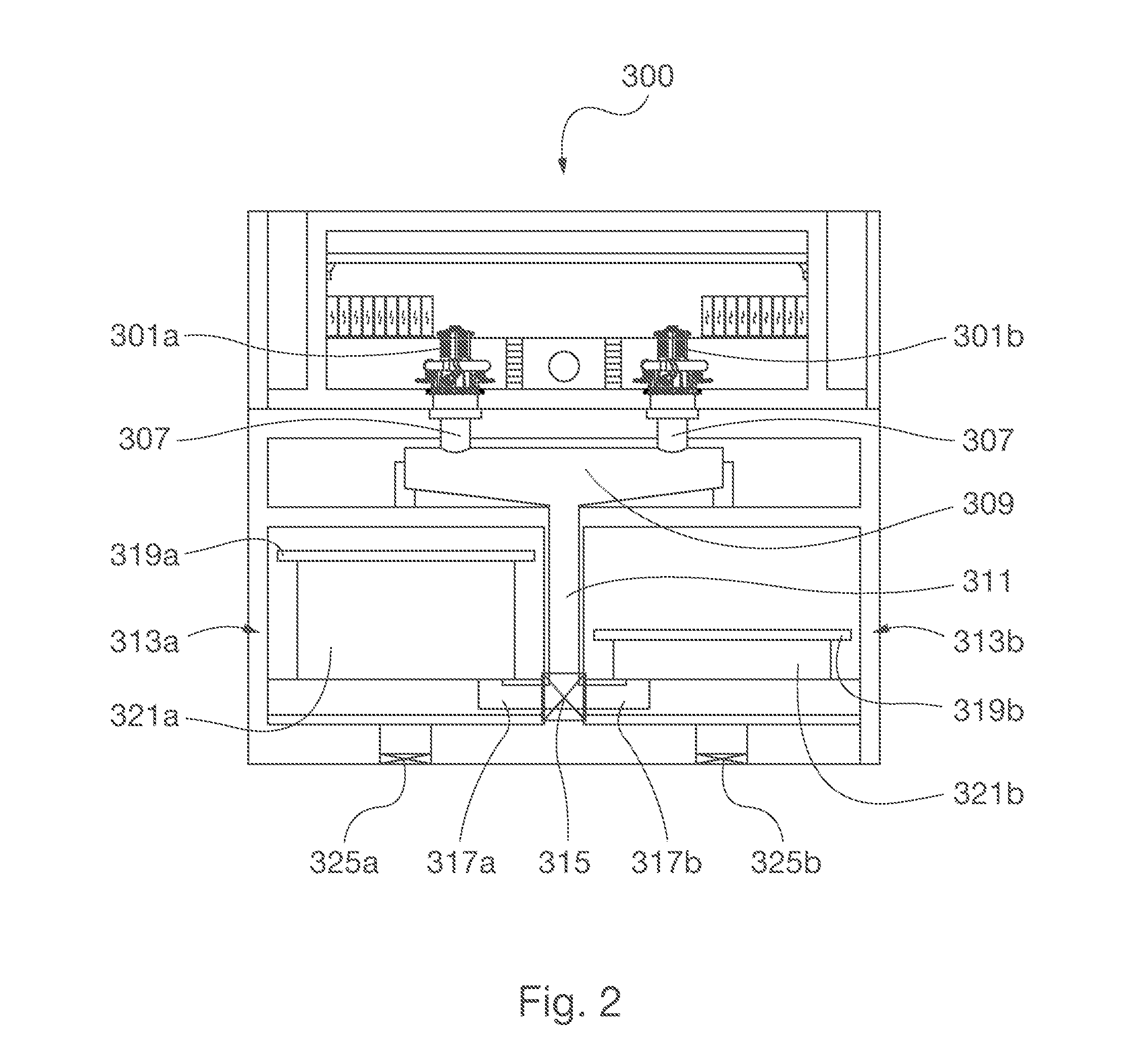

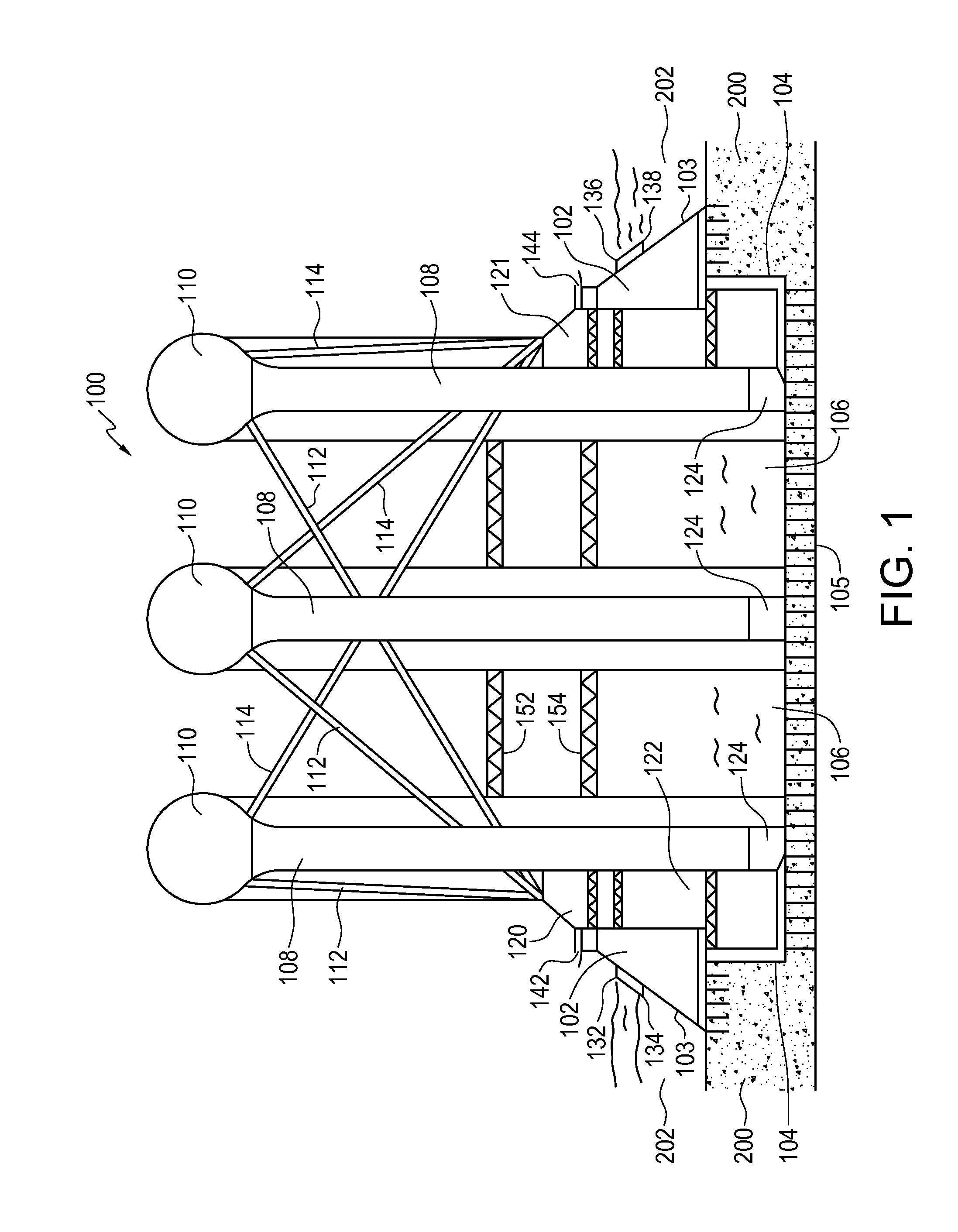

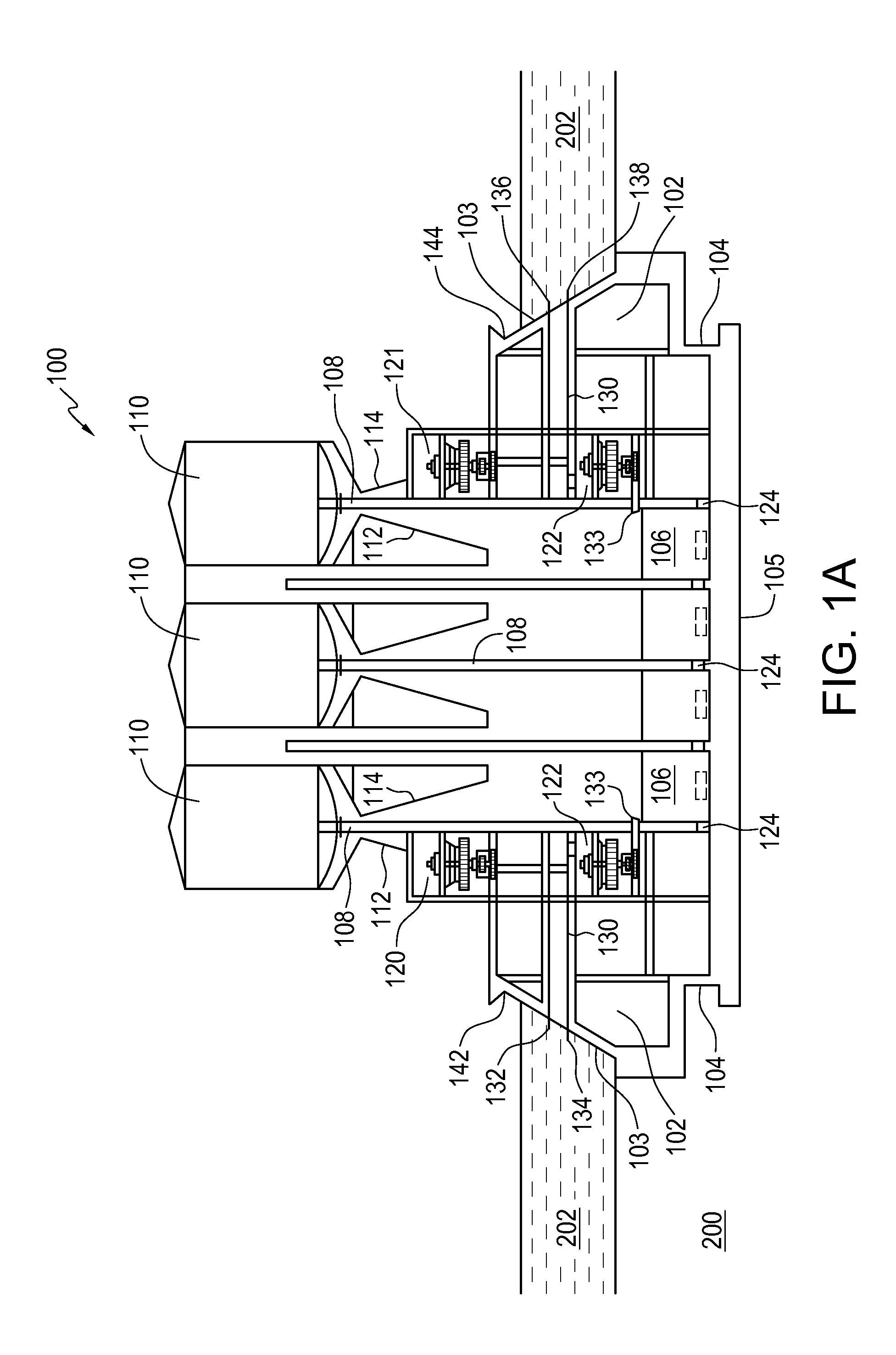

Unit for a hydroelectric power plant and modular hydroelectric power plant comprising said unit

InactiveUS20120200089A1Sufficient speedEfficient dischargeFluid couplingsMachines/enginesPower stationPenstock

The present invention refers to a underwater unit (1) for a hydroelectric power plant and a modular hydroelectric power plant (2) comprising a plurality of such units. The unit (1) according to the invention uses the principle of functioning of the traditional hydroelectric power plants and comprises a penstock (200) which involves a “head” of at least 100 m, and preferably of about 150-300 m, and carries elevated kinetic energy water masses from the surface of a water basin down to one or more turbines (301a-301f) provided in depth under the surface of the basin itself, so as to transfer the kinetic energy from the water to said turbines and to transform then the kinetic energy into electric power. Thanks to the use of variable volume discharge tanks (313a,313b) positioned downstream the turbines, it is possible to easily and effectively return the water masses used for the actuation of turbines themselves to the surrounding environment.

Owner:DEANDREA LUCA

Hydro electric energy generation and storage structure

ActiveUS20130257057A1Addressing Low Power RequirementsReduced Power RequirementsGas turbine plantsEngine componentsWater storagePenstock

A hydro electric energy generation structure is disclosed. The structure comprises: a gravity wall forming a closed outer perimeter extending above an upper water level of an existing hydraulic reservoir, and extending below the reservoir floor; at least one water inlet hydraulically connecting a first penstock to a first turbine generator below the water inlet. The structure further comprises: at least one lower water storage reservoir within the perimeter of the gravity wall receiving water from the first turbine generator; at least one pump receiving water from the lower water storage reservoir and pumping it through a pump delivery conduit to at least one upper water storage reservoir above the gravity wall; at least one second penstock delivering water from the upper water storage reservoir to a second turbine generator below; and a tailrace for returning the water into the existing reservoir.

Owner:LEGACY MARK ROBERT JOHN

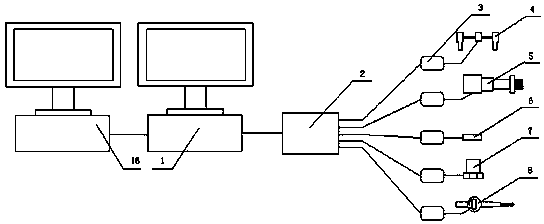

Steel penstock and expansion joint operating parameter automatic monitoring system and evaluation method thereof

Owner:HOHAI UNIV

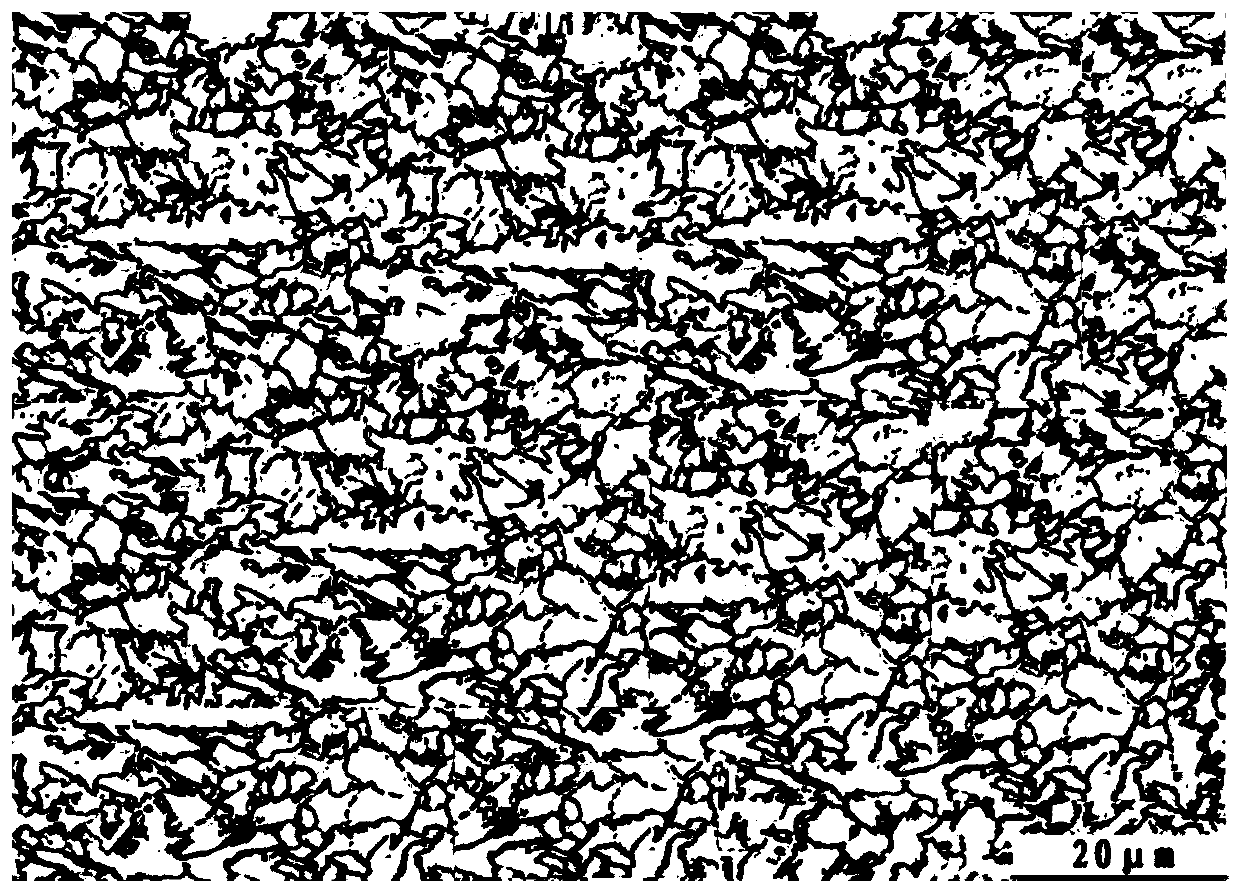

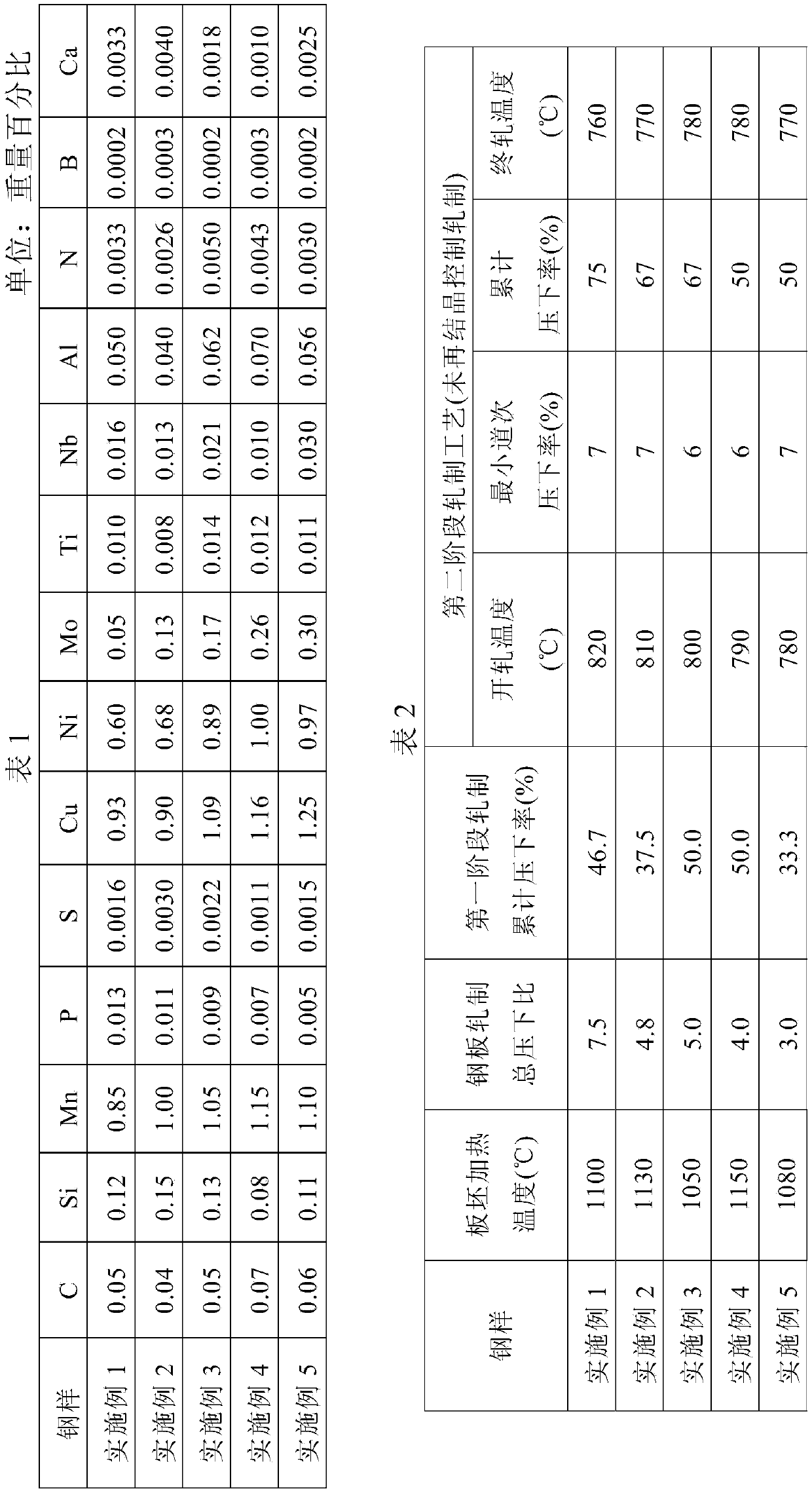

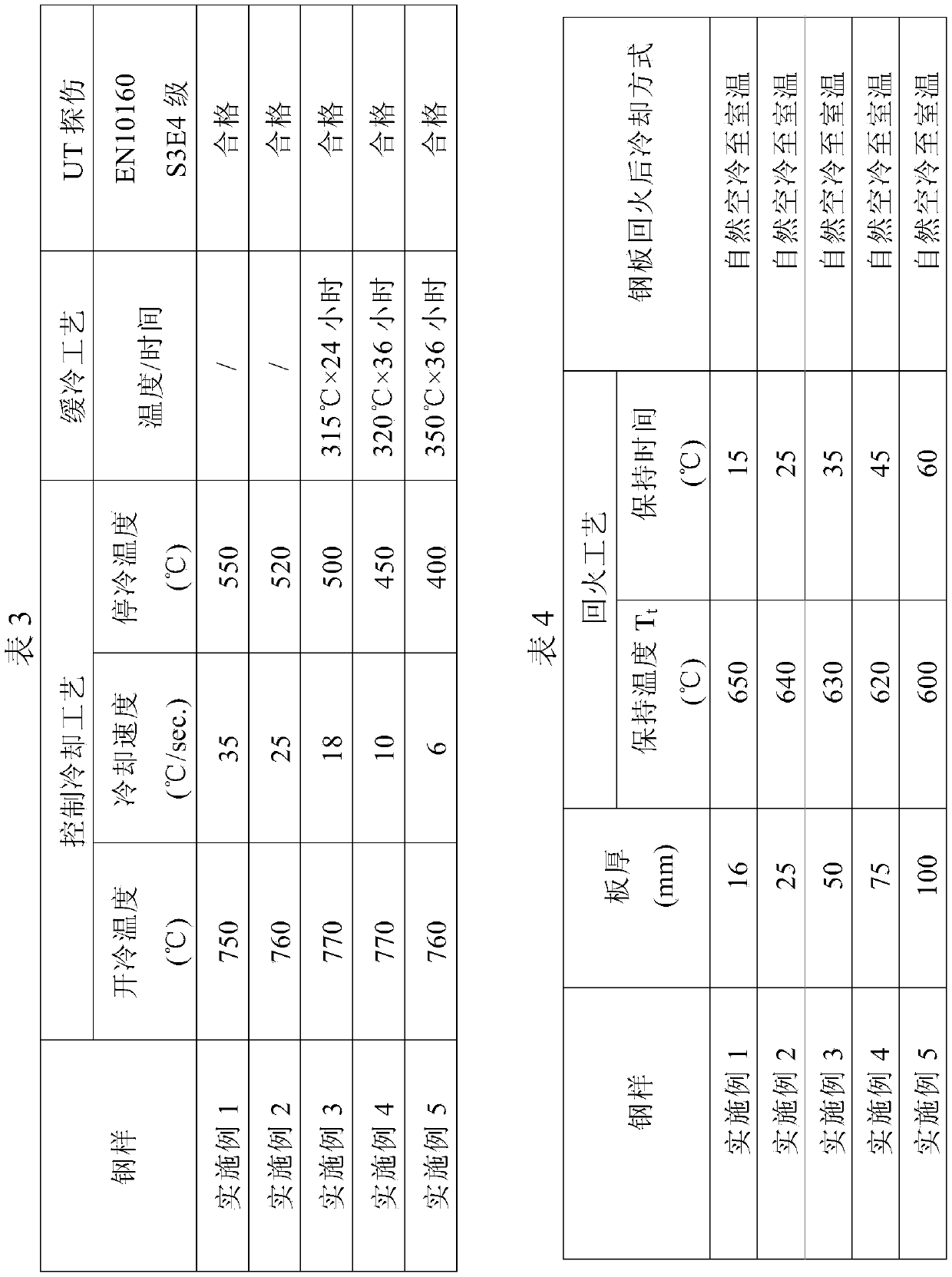

Seawater corrosion-resistant steel plate with high crack arrest and anti-strain aging embrittlement properties and manufacturing method thereof

The invention discloses a seawater corrosion resistant steel plate with high crack arrest and strain aging embrittlement resistance characteristics and a manufacturing method thereof. The seawater corrosion resistant steel plate is prepared from the compositions in percentage by weight: 0.040-0.070% of C, less than or equal to 0.15% of Si, 0.85-1.15% of Mn, less than or equal to 0.013% of P, lessthan or equal to 0.0030% of S, 0.90-1.20% of Cu, 0.60-1.00% of Ni, 0.05-0.30% of Mo, 0.010-0.030% of Nb, 0.008-0.014% of Ti, 0.040-0.070% of Al, less than or equal to 0.0050% of N, less than or equalto 0.0003% of B, 0.0010-0.0040% of Ca and the balance of Fe and inevitable impurities. The steel plate has high strength, excellent low-temperature toughness, the crack arresting characteristic and the strain aging embrittlement resistance characteristic, further has excellent seawater corrosion resistance, can withstand large heat input welding, is particularly suitable for icebreaker shells, offshore platforms, sea-crossing bridges, ocean wind tower structures, hydroelectric metal structures (pressure steel pipes, volutes, steel bifurcated pipes and hydraulic turbine metal components), pressure vessels and the like in ice sea areas, and can achieve stable mass industrial production.

Owner:BAOSHAN IRON & STEEL CO LTD

Hydroelectric power generating system

InactiveUS20140197640A1Reduction in sea levelPractical to provideHydro energy generationMachines/enginesPenstockEngineering

The hydroelectric power generating system incorporates a man-made dam structure configured to completely enclose a body of water. The dam is preferably filled by pumping seawater into the reservoir defined by the encircling dam. A circumferential canal feeds water to one or more penstocks. Each penstock has one or more hydroelectric turbine generators installed therealong. The penstocks feed an enclosed circumferential channel about the base of the dam. The channel delivers water to a pump that pumps the water back into the bottom of the reservoir. While this system results in a net loss of energy, the system can make use of surplus power to drive the return pump during periods of low electrical demand in order to replenish the reservoir.

Owner:BARAKAT YASER K

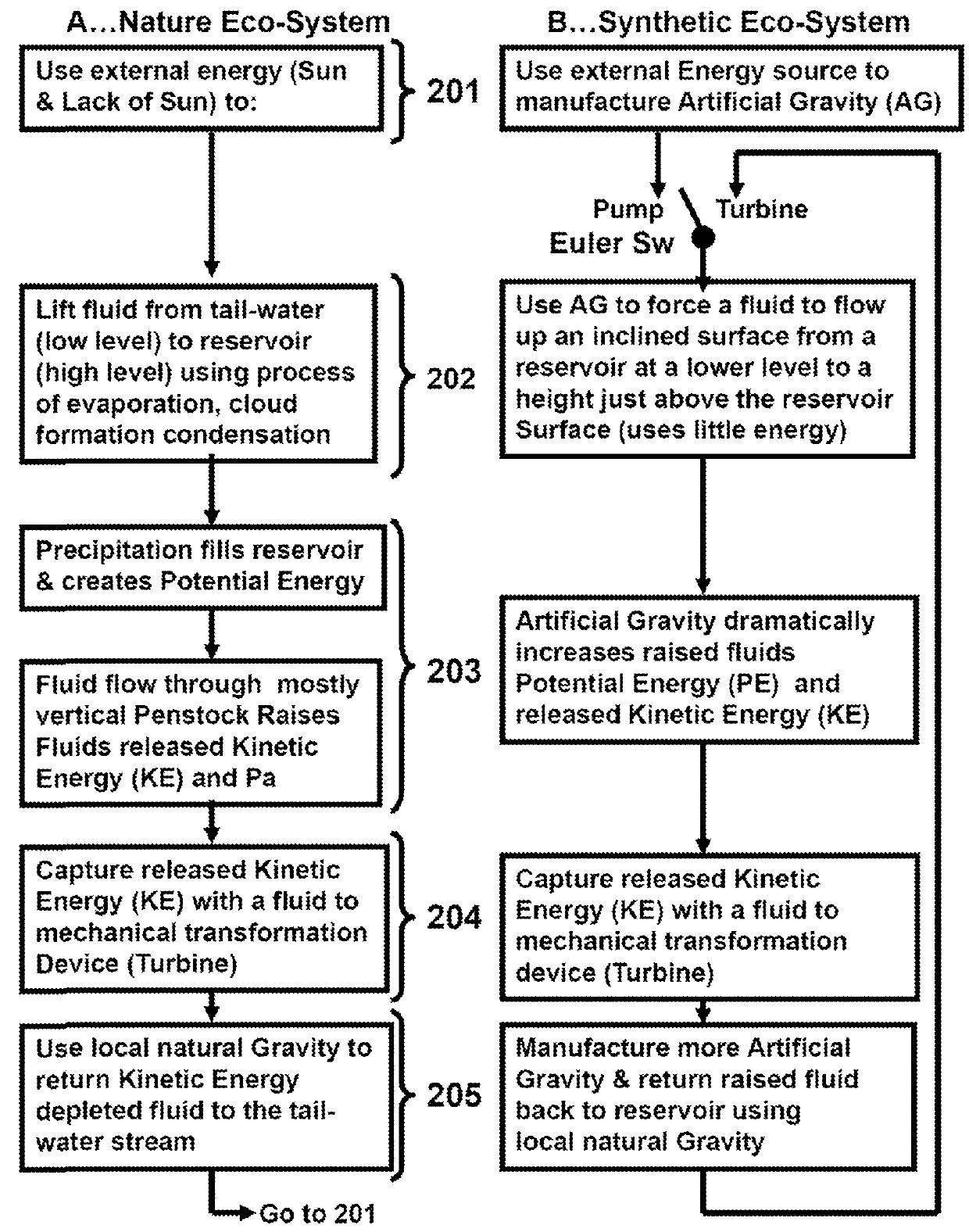

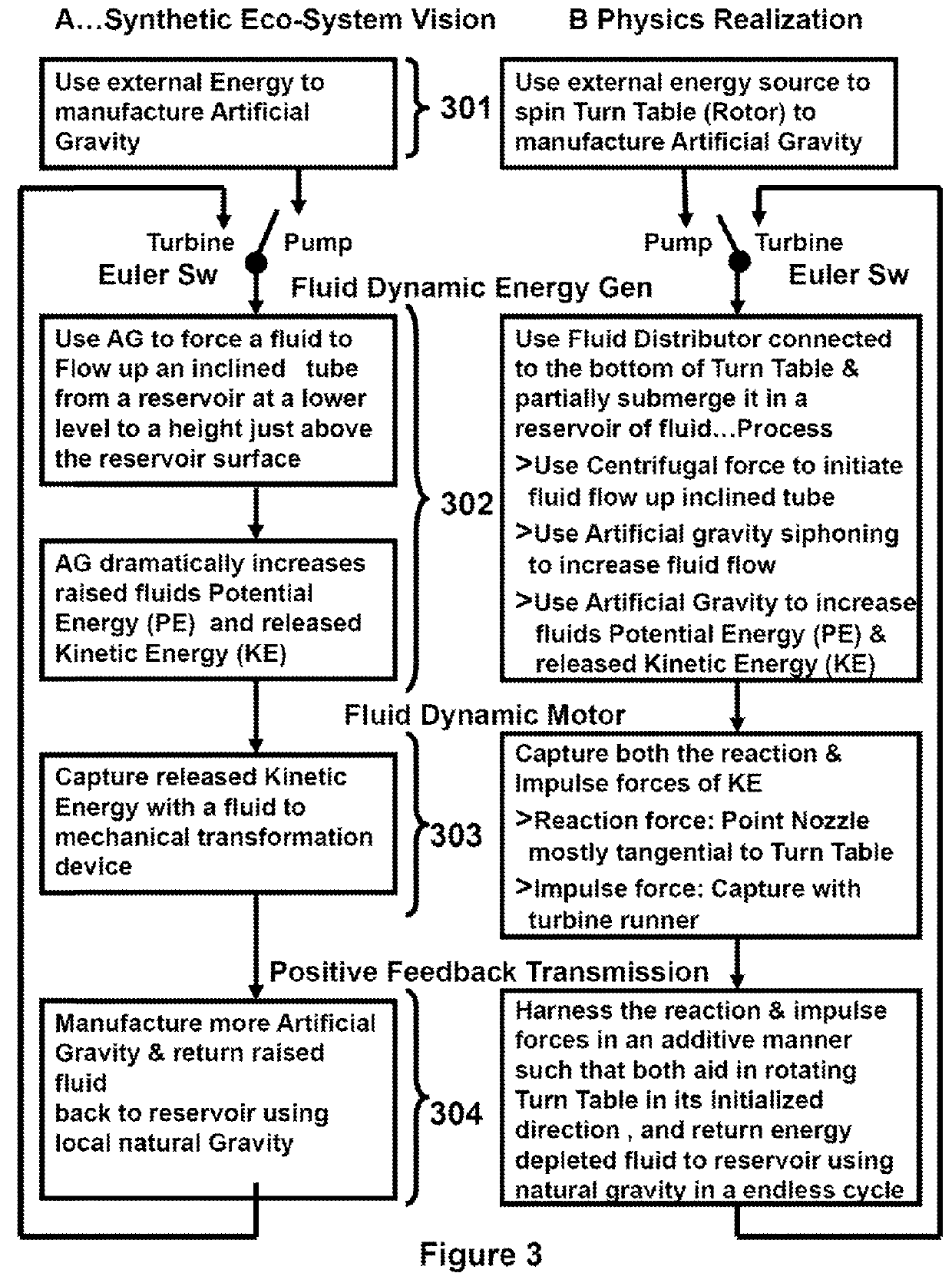

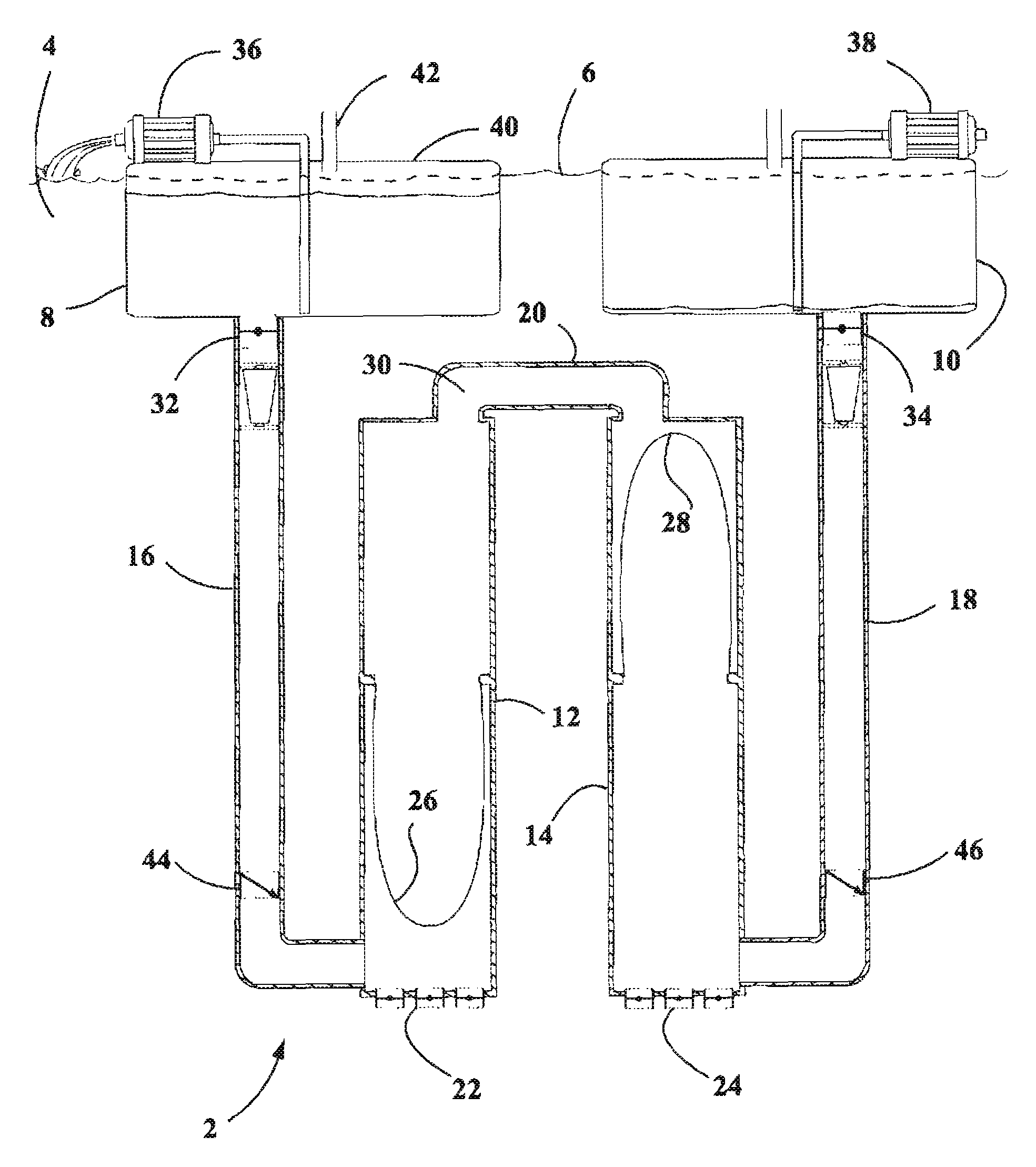

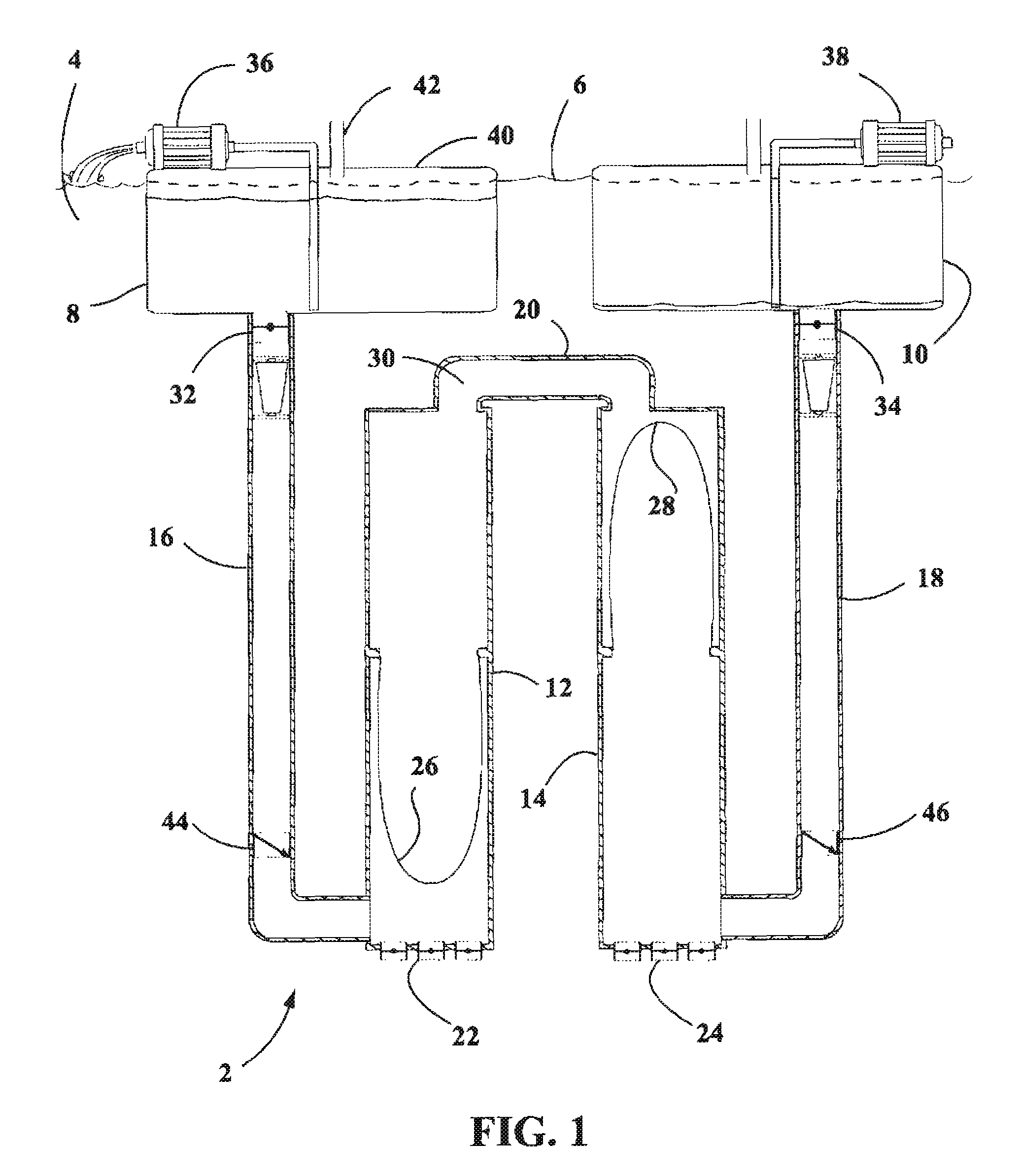

System and method for artificial gravity fueled fluid dynamic energy generator or motor

An Artificial Gravity Fueled Fluid Dynamic Day Energy Generator / Motor that initially uses external power to spin a partially submerged low drag fluid distributor rotor that uses centrifugal force to cause fluid to flow from the center of rotation, through a plurality of Euler contoured penstocks, in a true radial direction through a high “g” artificial gravity field, which dramatically increases the fluid's kinetic energy and releases available power, before it is guided out tangentially from the distributor via a plurality of nozzles symmetrically located at a small height just above the reservoir surface (near zero lift). As the frequency of the rotor is increased linearly the fuel Artificial Gravity increases exponentially, as does the fluid dynamic available power Pa. Turbine runners on the rotor assembly capture the available power, and a positive feedback mechanical transmission couples the captured rotational power to the I / O shaft in its initialized direction.

Owner:PRILL ROBERT S

Power generator

The power plant disclosed is an engine that derives its usefulness in the pursuit of energy generation by utilizing hydrostatic pressure differentials found or created in various liquids, gases or solutions, such as but not limited to water and air. It is generally provided as a two-stroke piston cycle power generating system, wherein the actions of the pistons perform work or replenish working fluid from a lower head to a higher head, and can be utilized to generate power, pump fluids, or perform work, for example. Multiple power generating systems are interconnected to provide continuous and constant power generation through a penstock and turbine system.

Owner:ANTEAU MARK R

Hydraulic tunnel structure spanning large-scale active fault zone

The invention relates to a hydraulic tunnel structure spanning a large-scale active fault zone and belongs to the technical field of water conservancy and hydropower application. According to the technical scheme, the hydraulic tunnel structure comprises an active fault spanning section, a buried type steel penstock section with two connected ends and an overhaul tunnel communicated with the active fault spanning section in the longitudinal direction of a tunnel, a combined type lining structure is adopted in the active fault spanning section, the active fault spanning section is composed of an outer layer structure and an inner layer structure in the radial direction of the tunnel, the outer layer structure comprises a one-stage annular support and a one-stage annular lining on the outer side in the radial direction, the one-stage annular support and the one-stage annular lining are of reinforced concrete lining structures, and the inner layer structure comprises a combined lining structure with steel pipes and corrugate telescopic joints, wherein the steel pipes and the corrugate telescopic joints are connected in series alternatively. The hydraulic tunnel structure spanning the large-scale active fault zone is safe and convenient to construct, has the good seismic capacity and the capacity for resisting large-scale fault creep diastrophism damage and is high in safety.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

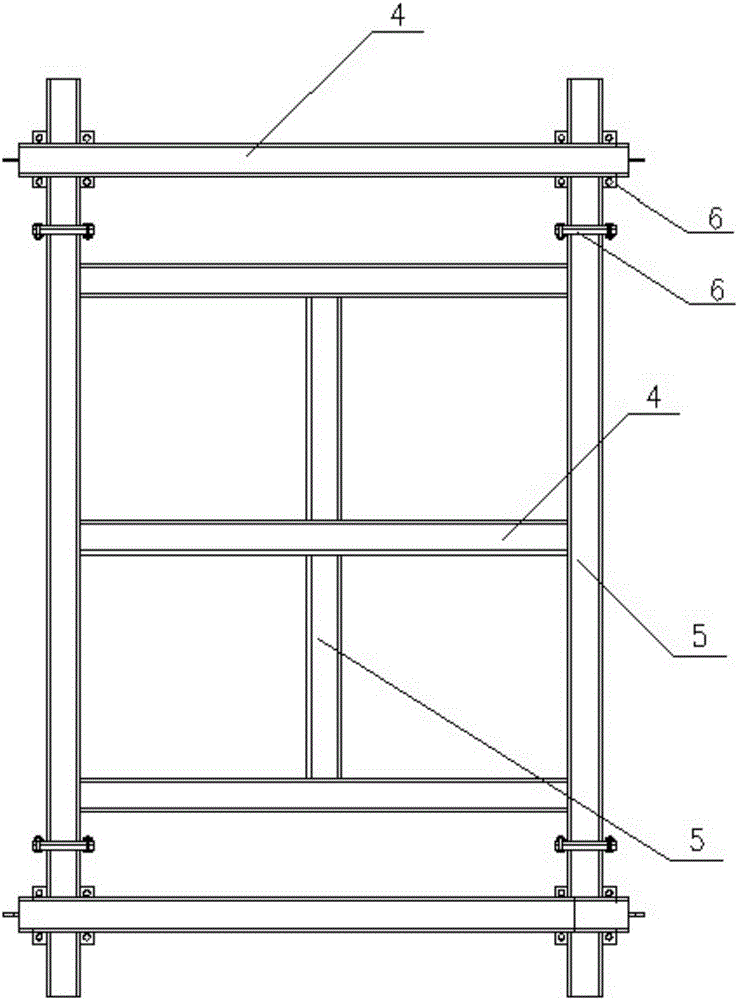

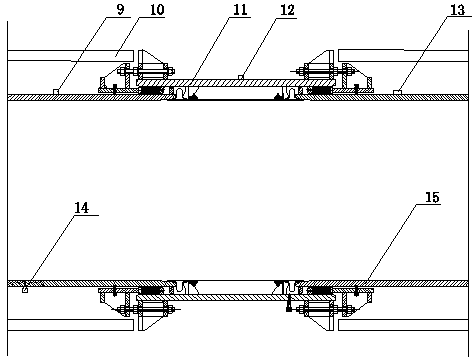

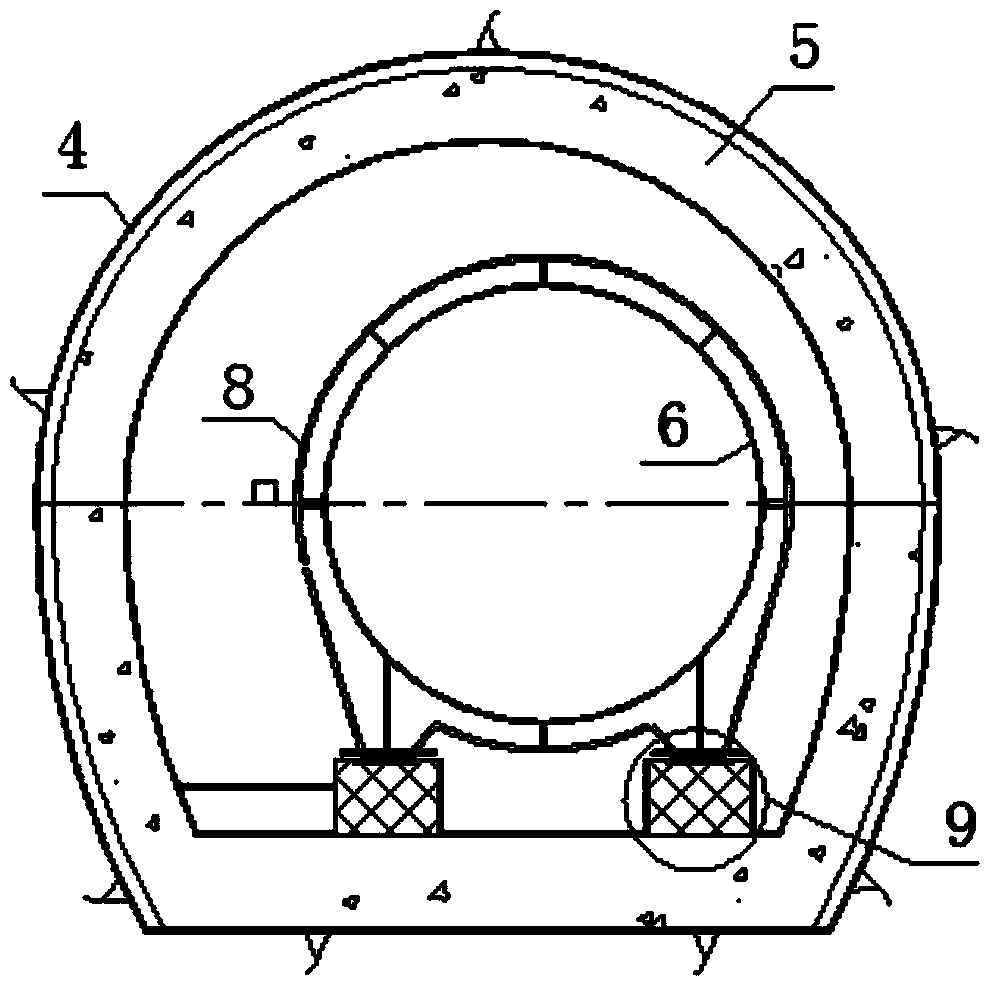

Inner support device for manufacturing penstock

The invention provides an inner support device for manufacturing a penstock. The inner support device for manufacturing the penstock is composed of two single support frames which have the totally same structure. According to each support frame, a hexagonal I-shaped steel support and penstock supports are welded together, the penstock supports are welded into a whole through angle steel connecting rods, the end of each penstock support is welded to a jack support, each jack is welded to one jack support, and the two support frames are welded into a whole through U-steel connecting rods. When being used, the inner support device for manufacturing the steel penstock is hung in the penstock, the roundness of the penstock can be accurately controlled through adjustment of the abutting deviation between the lower-layer jacks and the penstock wall, and therefore beneficial conditions are provided for follow-up operation such as welding and stiffening ring assembly alignment. The inner support device for manufacturing the steel penstock is easy to install, convenient to use, easy to disassemble, capable of enabling the roundness of the penstock and the surface quality of the penstock wall to be effectively controlled, lightening the auxiliary workload of penstock manufacturing, improving the production efficiency and saving cost, and reusable.

Owner:SINOHYDRO BUREAU 6 CO LTD

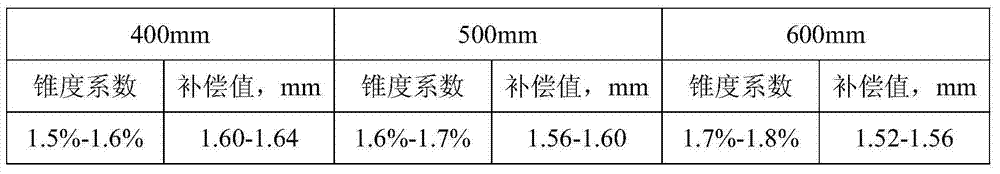

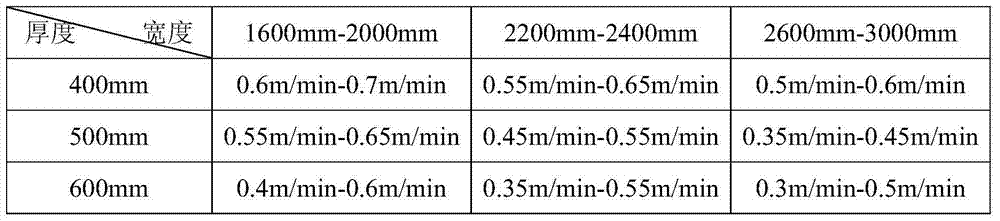

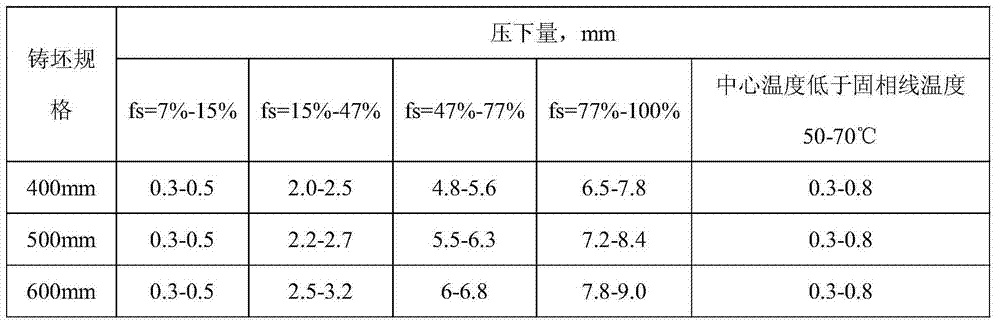

Continuous casting manufacturing process of ultra-thick slabs for hydropower station pressure vessel steel

ActiveCN103611903AThe process is easy to implementThe continuous casting production process is smoothPenstockSteelmaking continuous casting

The invention discloses a continuous casting manufacturing process of ultra-thick slabs for hydropower station pressure vessel steel, and belongs to the technical field of steelmaking-continuous casting. The process includes the steps that casting powder special for peritectic steel of which the carbon content ranges from 0.08% to 0.14% is designed according to continuous casting characteristics of the peritectic steel; taper values of hydropower station steel penstock casting blanks with different thicknesses are set according to steel type conditions. The defects of surface transverse cracks of the casting blanks and corner transverse cracks of the casting blanks are overcome by setting an ultra-thick slab continuous casting secondary cooling mode. Different pulling rates are set according to the thickness and the width of the slabs, and the problem of center segregation of the ultra-thick slabs is solved through low-pulling-rate casting. The process has the advantages that the process is simple and high in generalization performance, the applicable thickness specification range of the continuous casting slabs is from 400mm to 600mm, and the width specification range is from 1600mm to 3000mm. By utilizing the ultra-thick slabs to manufacture hydropower station steel penstocks through the process, surface indentations, surface transverse cracks and the center segregation level of the casting blanks all can be well controlled.

Owner:SHOUGANG CORPORATION

Ultra-large-diameter steel penstock installation method

InactiveCN107503333ARealize secondary assembly weldingMeet the requirements of mechanized assembly of stiffening ringsFinal product manufactureWater-power plantsProduction linePenstock

The invention discloses an ultra-large-diameter steel penstock installation construction technique. An installation method comprises the steps that ultra-large-diameter steel penstocks are coupled on site, specifically, tiles split into three flaps are rounded, single-section steel penstocks are assembled into multi-section steel penstock sets through assembling and welding, and stiffening rings are additionally welded to the multi-section steel penstock sets; the coupled steel penstock sections are transported in an adit, specifically, rails are prefabricated and paved in the adit, and the steel penstocks are transported to an installation station through a separable trolley; and the formed steel penstocks are positioned and installed, specifically, in the installation station, after steel penstock bodies are regulated to the installation height and fixed through a separable trolley jacking device, the trolley is removed, and integral installation of the multiple steel penstock sections is achieved. According to the ultra-large-diameter steel penstock installation construction technique, the operation layout of a traditional production line is effectively simplified, temporary assembling facilities inside the adit are simplified, the excavated sections of branched holes and the excavated sections of a main hole are decreased, the occupied area for steel penstock section assembling is decreased, and the requirements of a place where finished products can be stacked are eliminated; steel penstock sections are formed at a time during secondary assembling and welding, and the installation precision is improved through mechanical assembling and welding; and the installation construction technique does not rely on traditional lifting and turning modes any more, the safety risk is lowered, the installation construction period is shortened, the installation personnel number is decreased, and investment is reduced.

Owner:SINOHYDRO BUREAU 7 CO LTD

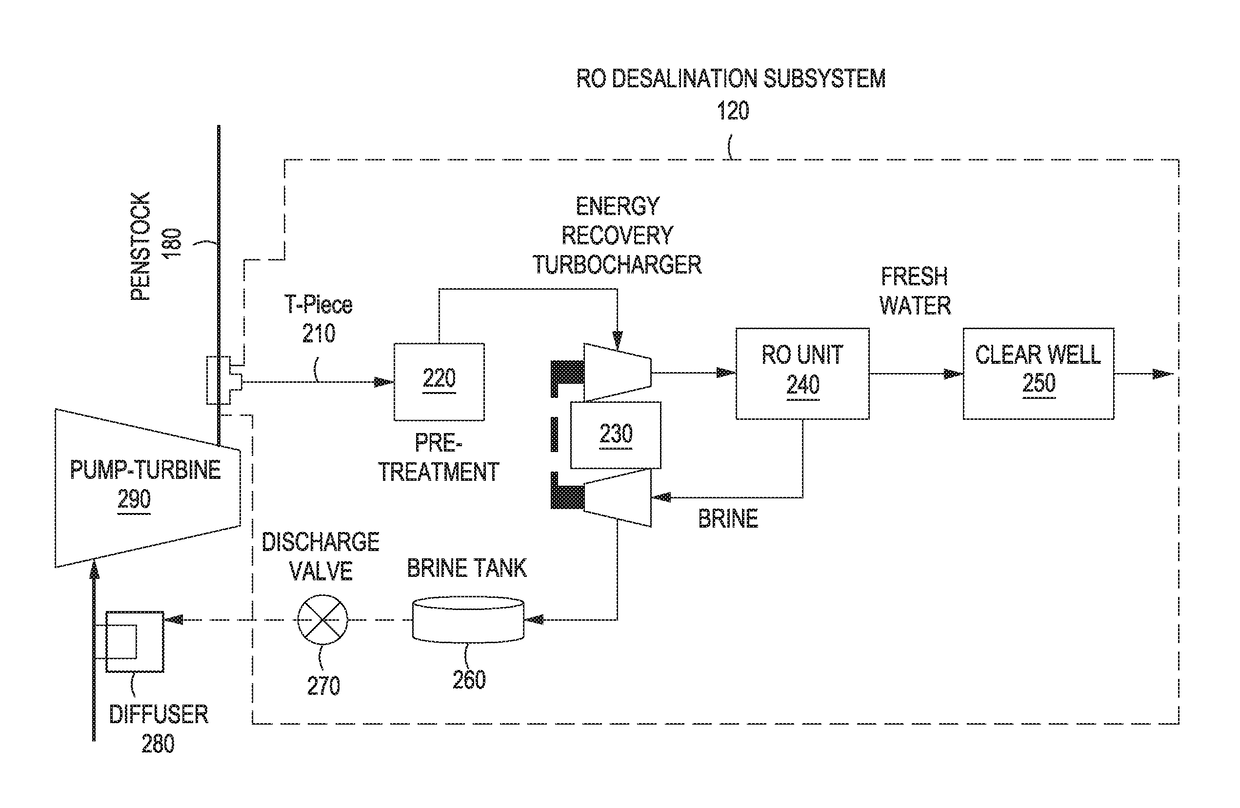

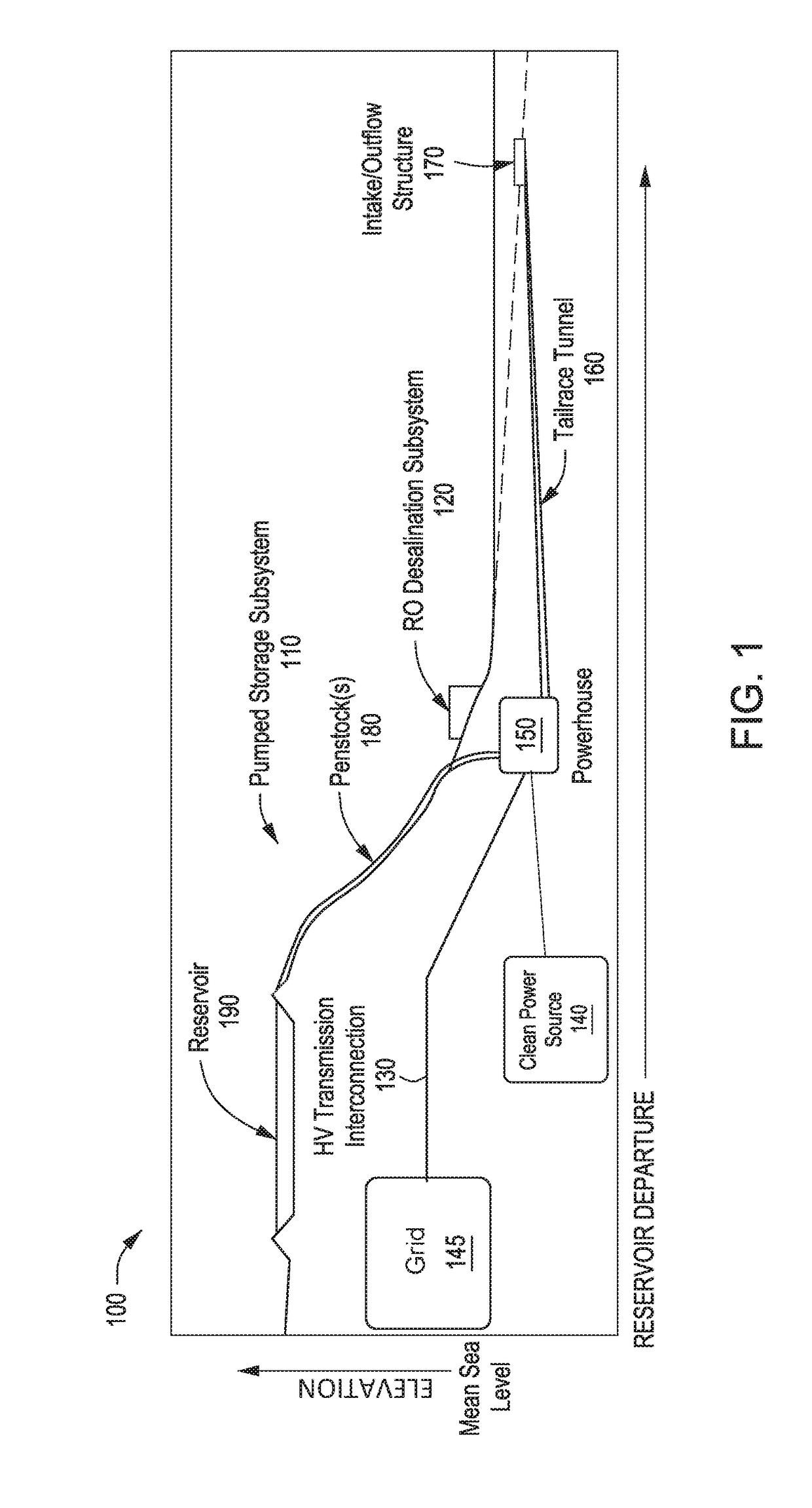

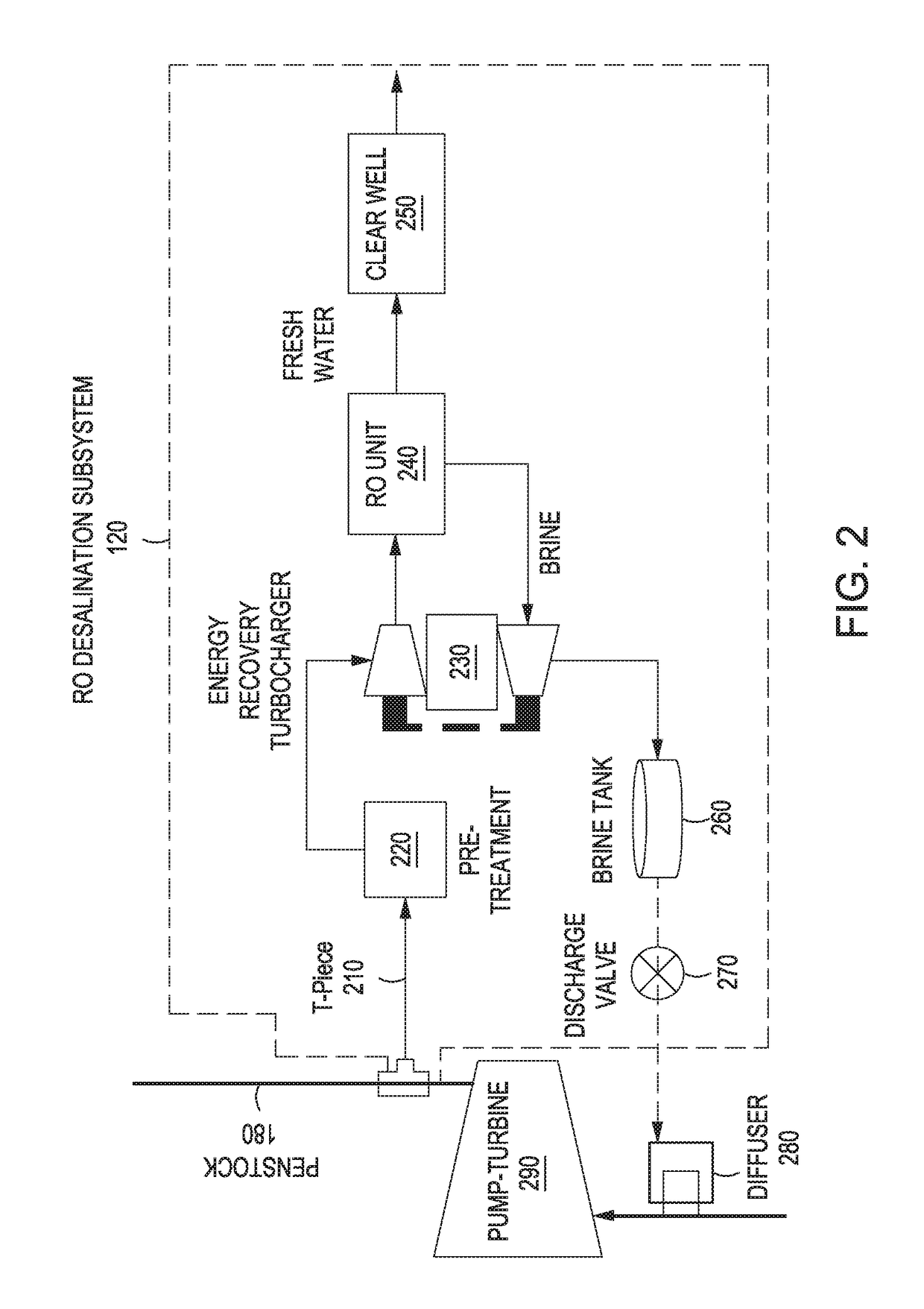

Integrated system for generating, storing and dispensing clean energy and desalinating water

ActiveUS20180290902A1Reduces net costReduce pumpingWaste water treatment from quariesGeneral water supply conservationPower stationDesalination

Embodiments of this invention provide an integrated system for clean energy generation and storage and RO desalination. The integrated system includes a first subsystem that stores hydraulic energy. The integrated system further includes a second subsystem that desalinates water. The integration system also includes a penstock that facilitates flow of the water between the first subsystem and the second subsystem. The integrated subsystem may also incorporate solar and / or wind power generation plants as a power source for the integrated system.

Owner:OCEANUS POWER & WATER LLC

Compact-sized generation of appreciable hydropower through centrifuge-induced gravity effects

A device and a method for producing hydroelectric energy. The device generates compact-scale appreciable hydroelectric energy. Utilizing centrifugal force, at least one container attached to a radial arm moves horizontally about a vertical axis. Pressurized liquid in the container flows at high speed through a penstock into, and ultimately through, a turbine to generate electricity.

Owner:IGLESIA GERALDO R

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com