Ultra-large-diameter steel penstock installation method

A penstock and super-diameter technology, which is applied in the field of automatic production and installation of penstocks for super-diameter hydro-generators, can solve the problems of difficult quality control, many auxiliary processes, and high safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is a further description of the present invention with the specific installation and implementation of a penstock steel pipe in a hydropower station. The description of the embodiment is only used to further illustrate the present invention and cannot be understood as limiting the scope of protection of the present invention. Those skilled in the art made it according to the content of the above-mentioned invention Some non-essential improvements and adjustments also belong to the protection scope of the present invention.

[0028] In conjunction with the accompanying drawings.

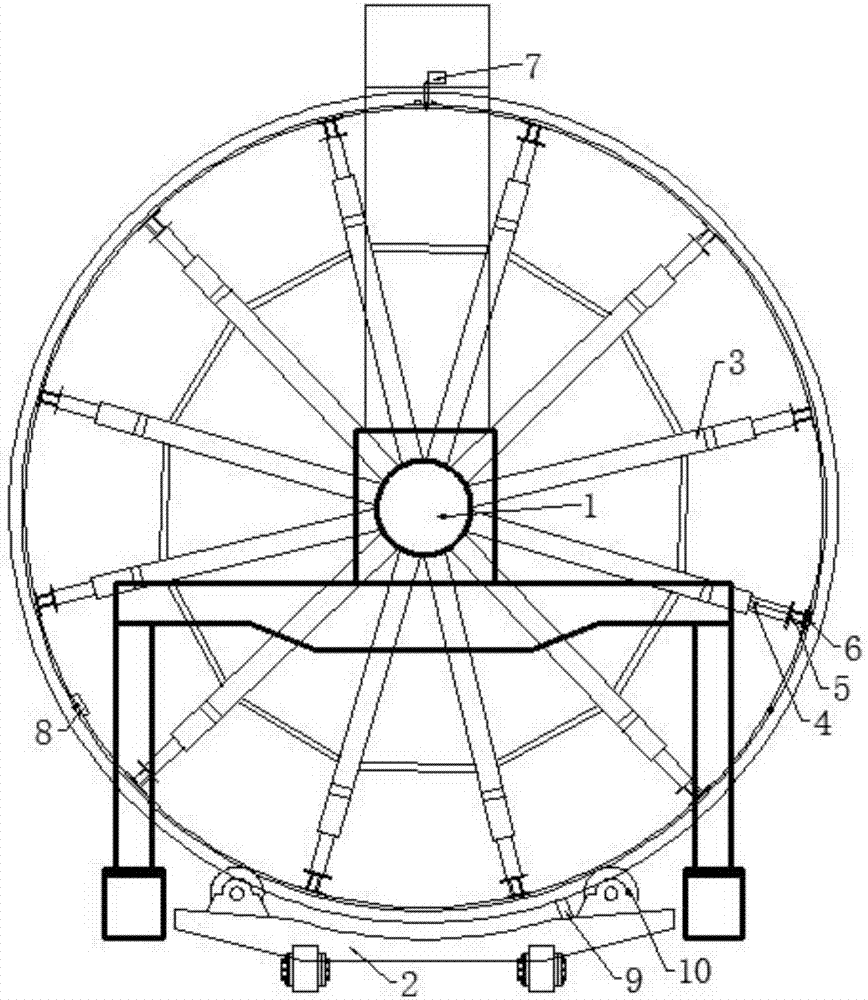

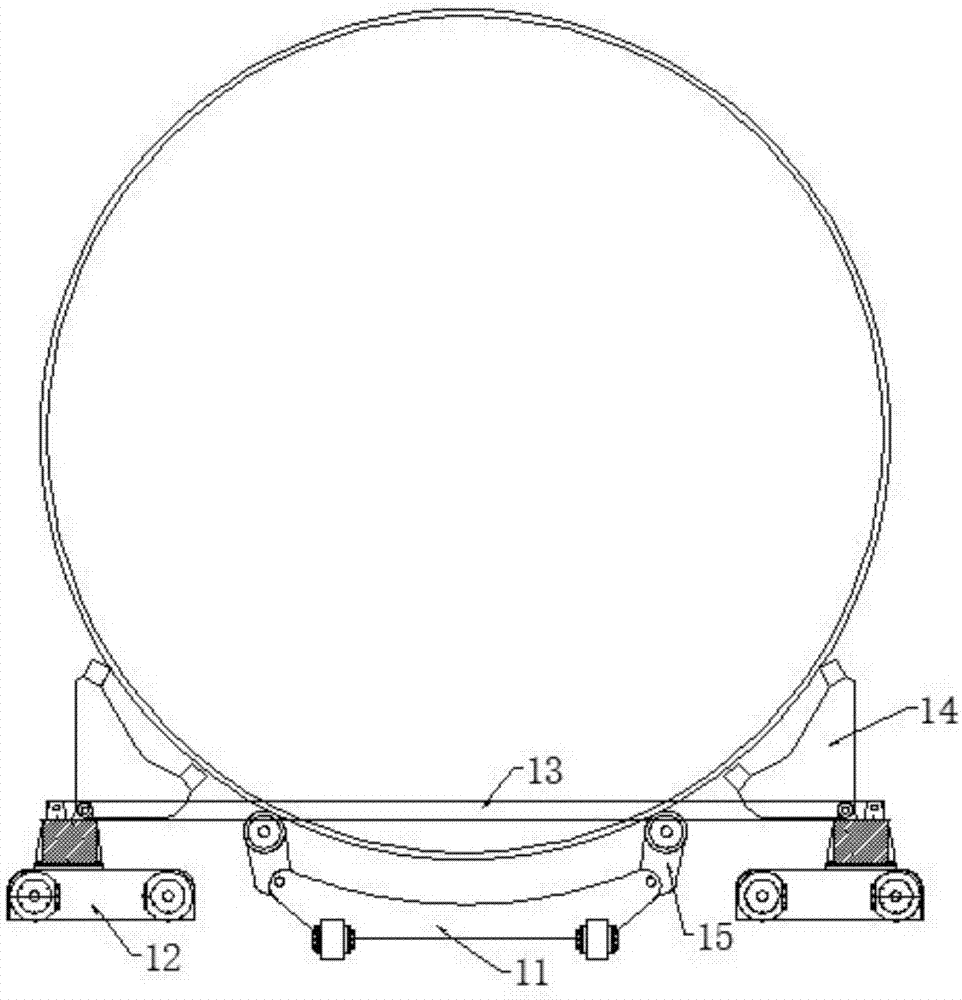

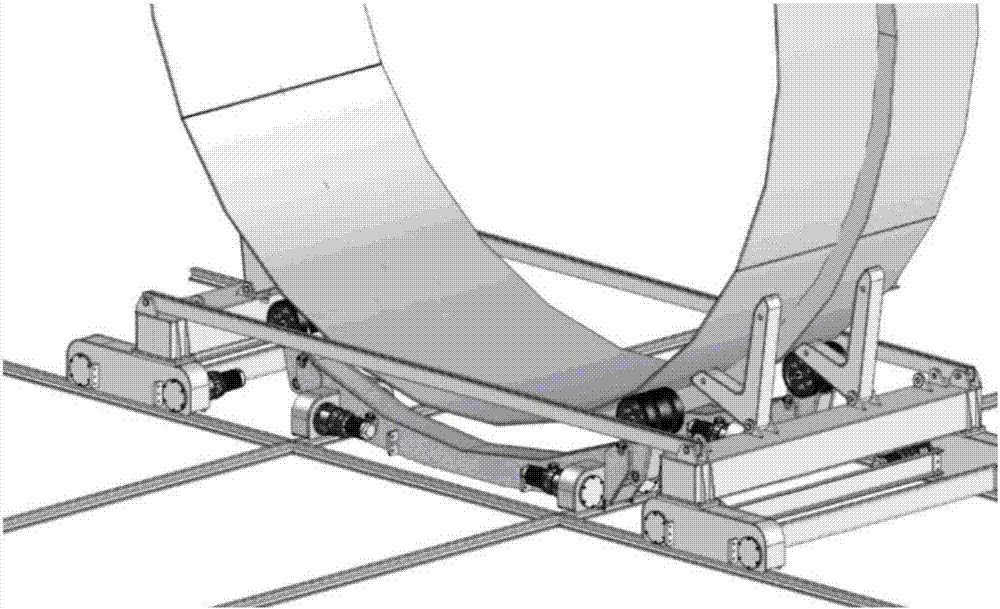

[0029] The installation method of the ultra-large-diameter pressure steel pipe of the present invention utilizes the following equipment: automatic assembly and welding equipment, transport assembly trolley 2, including a transfer trolley 12 and a detachable trolley for installing the trolley 11.

[0030] The installation method of the ultra-large-diameter pressure steel pipe of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com