Hydraulic tunnel structure spanning large-scale active fault zone

A technology for active faults and hydraulic tunnels, applied in tunnels, mining equipment, earth-moving drilling, etc., can solve problems such as failure to meet safety requirements, failure to achieve earthquake resistance and resistance to large-scale fault creep and dislocation damage. Conducive to the layout of observation facilities, significant economic and social benefits, and convenient post-maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection is not limited to the content described in this embodiment.

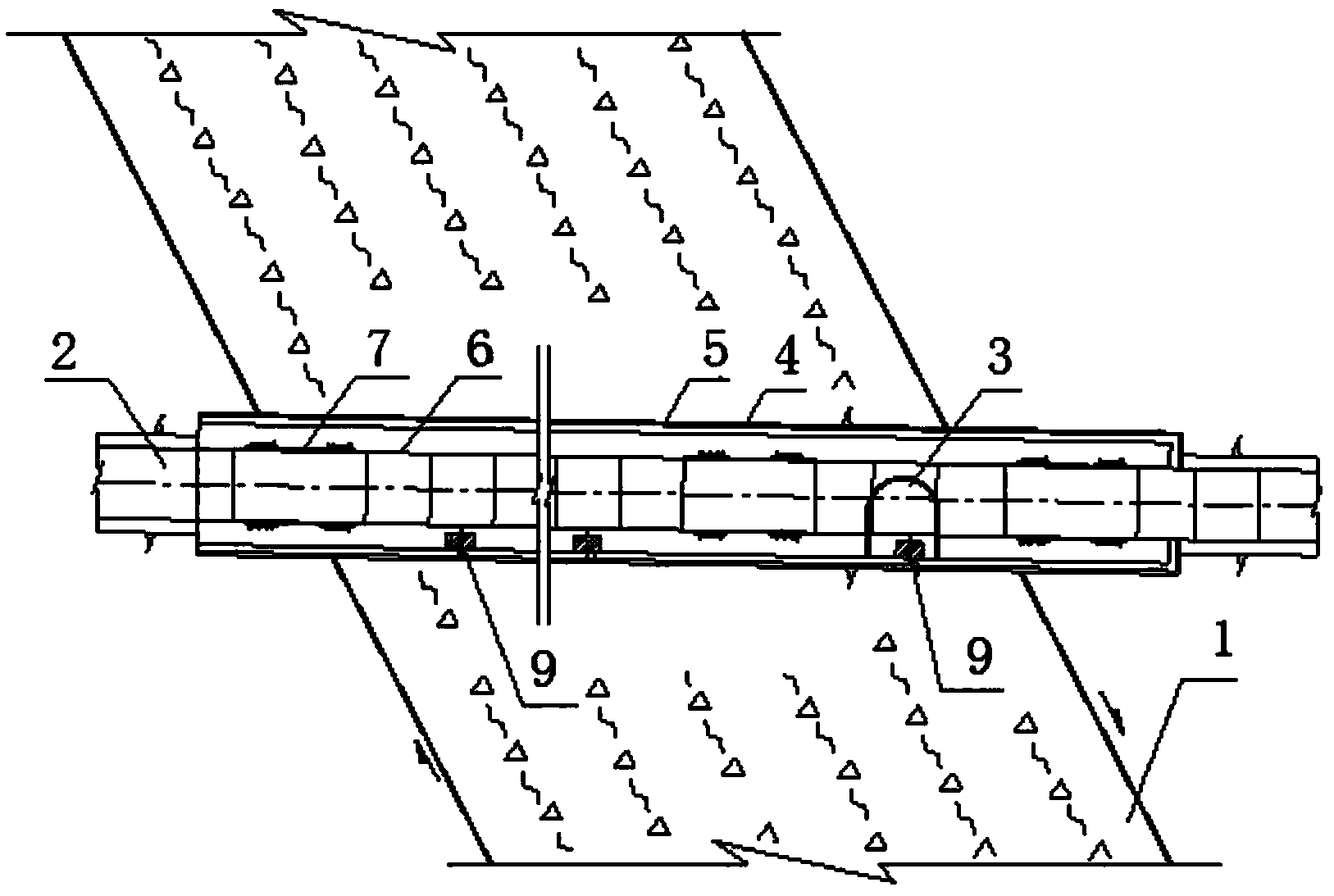

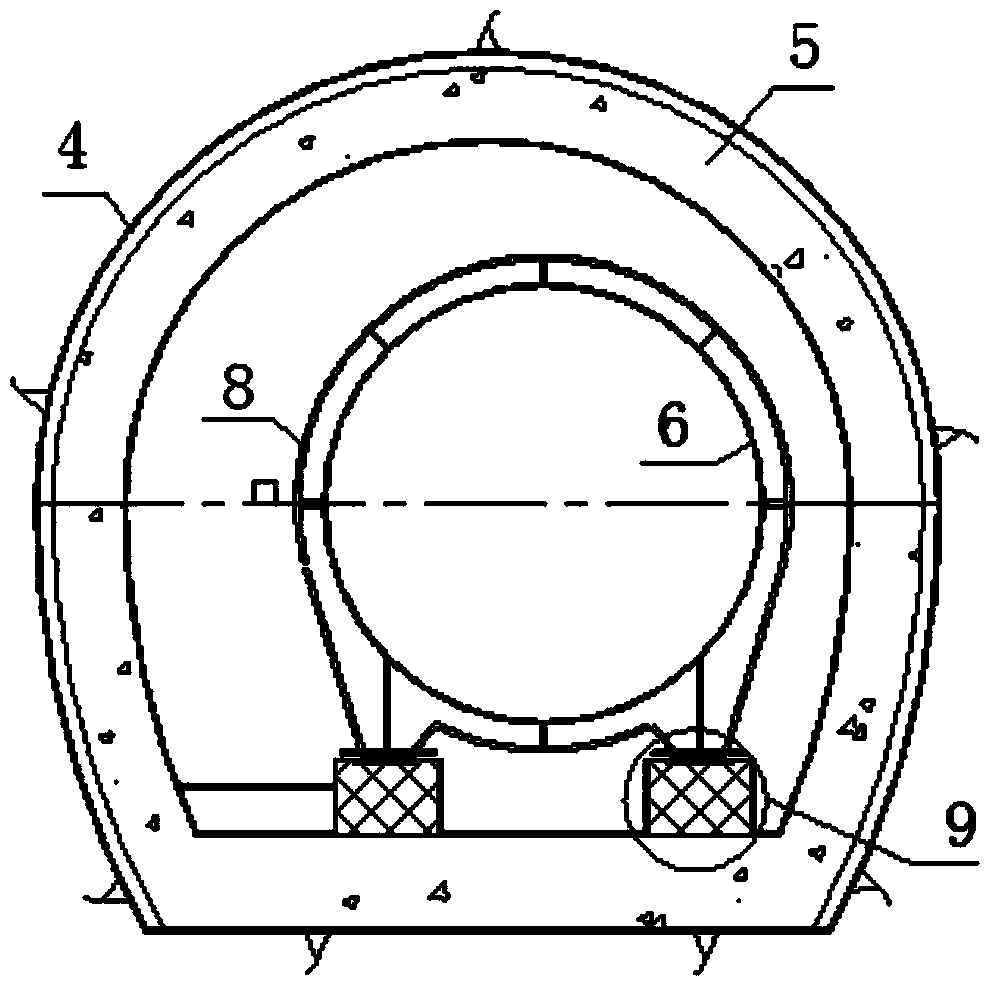

[0016] Such as figure 1 and figure 2 As shown, the present invention is a hydraulic tunnel structure spanning a large-scale active fault zone, which includes an active fault spanning section 1, a buried pressure steel pipe section 2 connected at both ends, and a bridge connected to the active fault spanning section 1 along the longitudinal direction of the tunnel. Maintenance tunnel 3, the active fault spanning section 1 adopts a composite lining structure, which consists of an outer layer structure and an inner layer structure along the radial direction of the tunnel. The outer layer structure includes the first-stage annular support 4 and the first-stage annular lining on the radially outer side 5. The first-stage annular support 4 and the first-stage an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com