Technique for manufacturing steel plate for 600MPa hydropower steel penstock

A pressure steel pipe and production process technology, which is applied in the production process field of steel plates for 600MPa hydraulic pressure steel pipes, can solve the problems of high cooling equipment performance requirements, inability to be widely promoted, and increased rolling load, etc., and achieve excellent low temperature impact toughness and welding performance, improving productivity, and reducing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

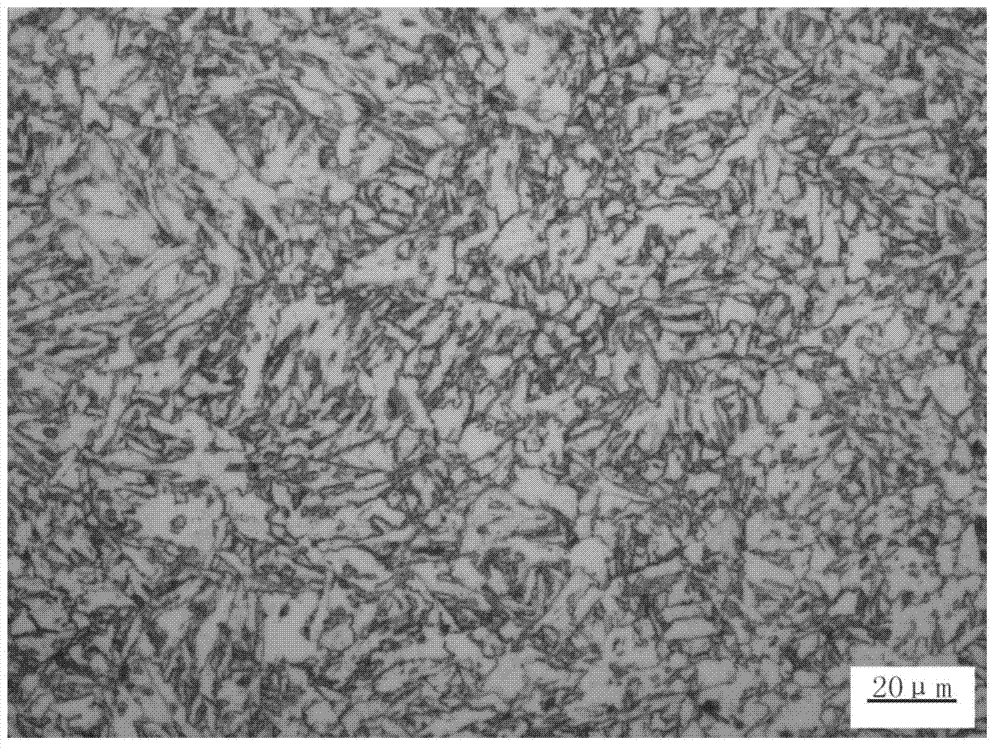

Image

Examples

Embodiment 1

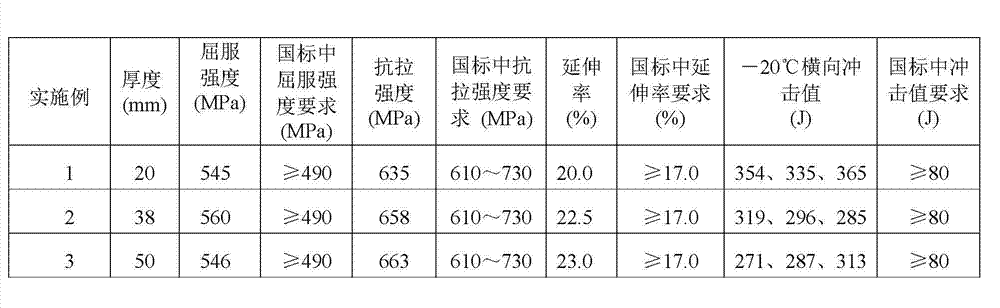

[0023] Smelt according to the chemical composition shown in Table 1, and cast into steel ingots, heat the steel ingots to 1232 ° C, keep the temperature in the furnace for 300 minutes, and carry out the first stage rolling on the experimental rolling mill, that is, rolling in the austenite recrystallization zone , the rolling start temperature is 1214°C, the reduction in the first to second passes should be greater than 10%, followed by at least 1 to 2 pass reductions controlled at 20 to 40%, when the thickness of the rolled piece is 60mm, the rolling Wait for the temperature to reach 900°C on the road, and then carry out the second stage of rolling, that is, rolling in the austenite non-recrystallized region. The final rolling temperature is 840°C, and the thickness of the finished steel plate is 20mm. After rolling, the steel plate enters the accelerated cooling (ACC) device and is cooled to 590°C at a rate of 5°C / s, and the cooling bed is cooled after the water exits. Afte...

Embodiment 2

[0025] The implementation is the same as in Example 1, wherein the heating temperature is 1240°C, the total time in the furnace is 320 minutes, the rolling start temperature of the first stage rolling is 1220°C, the thickness of the intermediate billet is 96mm, and the rolling start temperature of the second stage rolling is The temperature is 892°C, the final rolling temperature is 831°C, and the thickness of the finished steel plate is 38mm. After rolling, the steel plate enters the accelerated cooling (ACC) device and is cooled to 589°C at a rate of 5°C / s, and the cooling bed is cooled after the water exits. Afterwards, the steel plate is subjected to tempering heat treatment, the tempering temperature is 630°C, and the holding time is 20min+t×2.5min / mm, where t is the thickness of the steel plate in mm. Finally, the steel plate can be obtained

Embodiment 3

[0027] The implementation is the same as in Example 1, wherein the heating temperature is 1233°C, and the total time in the furnace is 340 minutes; the rolling start temperature of the first stage rolling is 1218°C, and the thickness of the intermediate billet is 100mm; the rolling start temperature of the second stage rolling is 892°C, the final rolling temperature is 821°C, and the thickness of the finished steel plate is 50mm; after rolling, the steel plate enters the accelerated cooling (ACC) device, and is cooled to 558°C at a rate of 5°C / s, and the cooling bed is cooled after the water exits. Afterwards, the steel plate is subjected to tempering heat treatment, the tempering temperature is 610°C, and the holding time is 20min+t×2.5min / mm, where t is the thickness of the steel plate in mm. Finally, the steel plate can be obtained

[0028] Table 1 Chemical composition (wt%) of the present invention embodiment 1~3

[0029] Example C Si mn P S Nb V Ti ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com