Welding wire special for high-strength steel penstock submerged-arc welding

A technology of submerged arc welding and high-strength pressure, applied in the direction of welding medium, welding equipment, welding equipment, etc., to achieve the effect of satisfactory welding process adaptability and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The special welding wire for high-strength pressure steel pipe submerged arc welding adopts a diameter of 4mm, and its composition: 0.11%C, 0.25%Si, 2.0%Mn, 3.0%Ni, 0.15%Cr, 0.6%Mo, 0.03%Al, 0.04%Nb, 0.04%V, 0.15% Ti, 0-0.005B, 0.0025% O, 0.004% N, 0.004% S, 0.008% P, and the rest is Fe.

[0020] Flux composition used in submerged arc welding: 10.0% CaO, 18.0% MgO, 30.0% CaF 2 ,4.0%Na 2 O, 2.0% K 2 O, 1.0% MnO, 0.4% FeO, 21% SiO 2 ,11.0%Al 2 o 3 , 1.0% TiO 2 ,0.03%ZrO 2 .

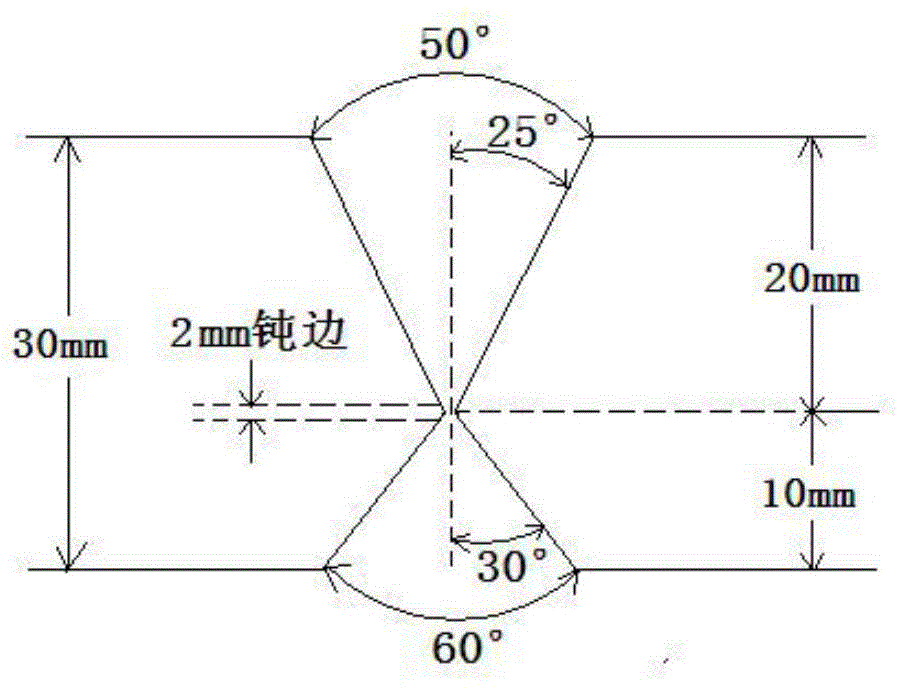

[0021] A 30mm thick Q890 steel plate is used, and the test plate is opened with an asymmetrical X-shaped groove. The groove is as follows: figure 1 As shown, the size of the steel plate is 600mm×200mm×30mm, leaving 2mm blunt edge and leaving no gap between the two plates.

[0022] The 30mm+30mm thick Q890 steel plate is preheated to 120°C before welding, and the interlayer temperature is controlled at 160-180°C. Before welding, the groove is polished with a grinder to see the light, and subm...

Embodiment 2

[0026] The special welding wire for high-strength pressure steel pipe submerged arc welding adopts a diameter of 4mm, and the welding wire composition: 0.11%C, 0.25%Si, 2.0%Mn, 3.0%Ni, 0.15%Cr, 0.6%Mo, 0.03%Al, 0.04%Nb, 0.04%V , 0.15% Ti, 0~0.005B, 0.0025% O, 0.004% N, 0.004% S, 0.008% P, and the rest is Fe.

[0027] Flux composition used in submerged arc welding: 10.0% CaO, 18.0% MgO, 30.0% CaF 2 ,4.0%Na 2 O, 2.0% K 2 O, 1.0% MnO, 0.4% FeO, 21% SiO 2 ,11.0%Al 2 o 3 ,1.0%TiO 2 ,0.03%ZrO 2 .

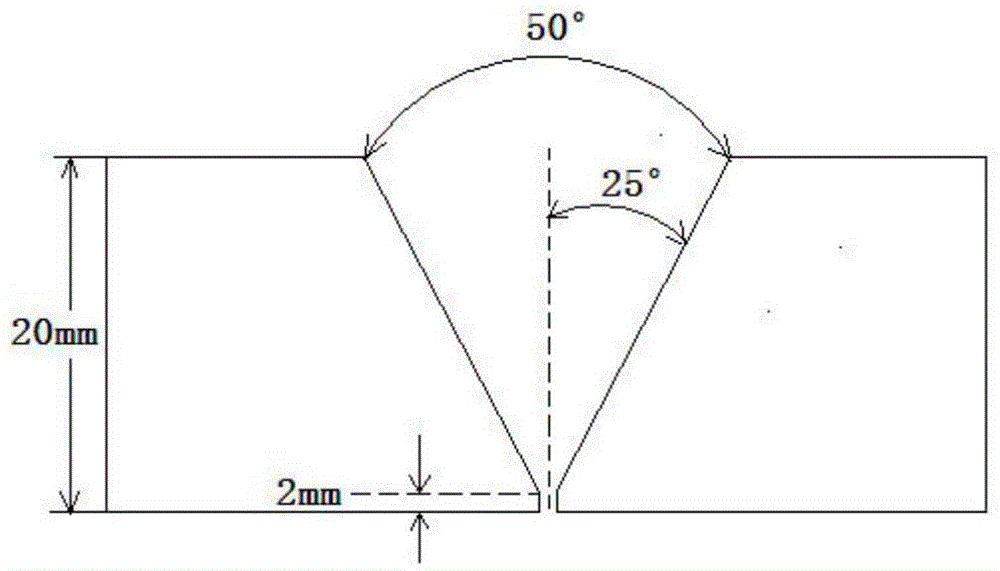

[0028] A 30mm thick Q890 steel plate is used, and the test plate is opened with a V-shaped groove. The groove is as follows: figure 2 As shown, the size of the steel plate is 600mm×200mm×20mm, leaving 2mm blunt edge and leaving no gap between the two plates.

[0029] The 20mm+20mm thick Q890 steel plate is preheated to 100°C before welding, and the interlayer temperature is controlled at 160-180°C. Before welding, the groove is polished with a grinder to see the light, and subme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com