Patents

Literature

63results about How to "Meet site construction requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low temperature low hydration heat cementing cement system

InactiveCN101328050AImprove performanceAvoid thermal decompositionSolid waste managementDrilling compositionSlagHydrate decomposition

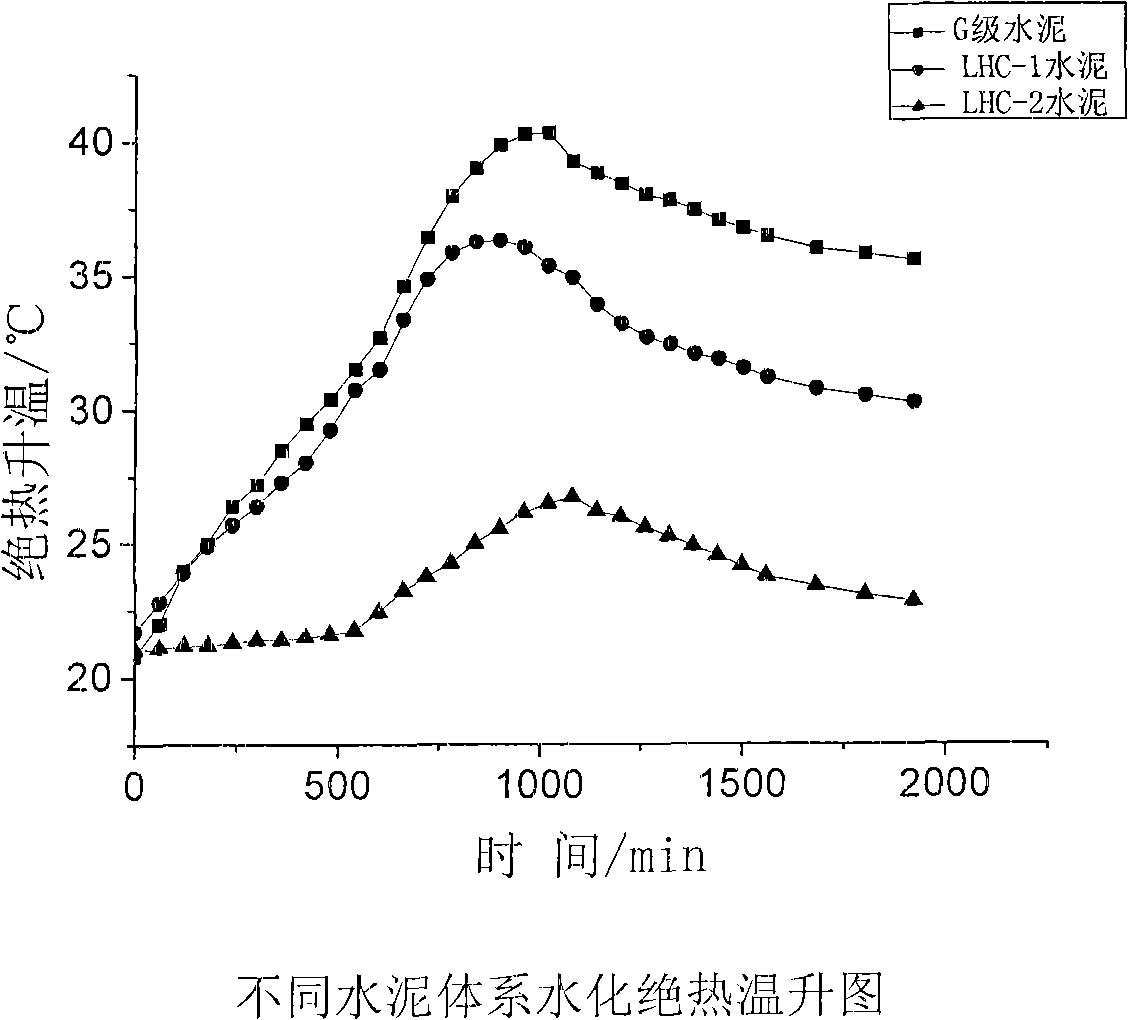

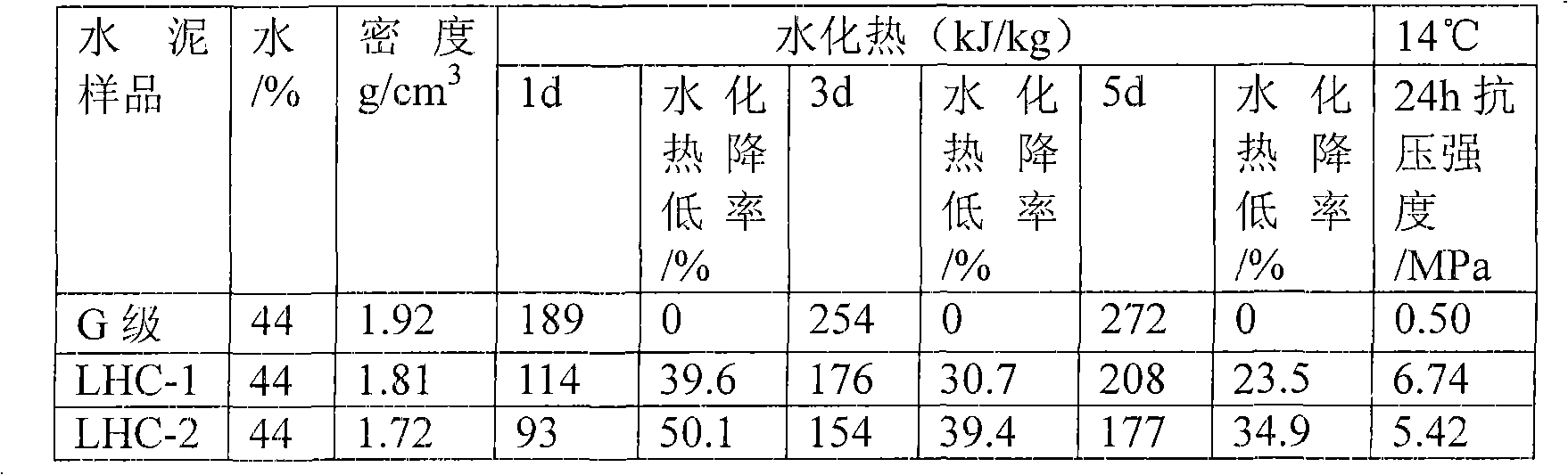

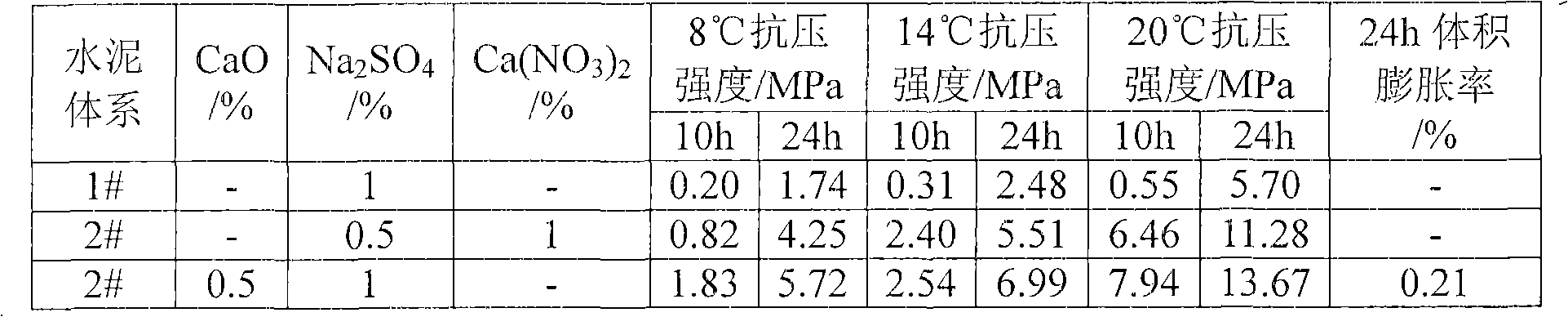

The invention relates to a low temperature and low hydration heat cementing concrete system used in the natural gas hydrate layer cementing field. The objective of the invention is to effectively reduce the heat release of the cement hydration, prevent the hydrate from decomposing because of large heat and reduce the harm of the hydrate to the cementing. The whole performance of the cement under the low heat release condition is improved by adding materials which can reduce the whole hydration heat release of the cement using G grade oil well cement as base material. (1) The proper addition of superfine slag with a specific surface area between 6000 and 12000cm2 / g can make sure the strength properties of the early and later stage of the cement. (2) The hydration heat is further reduced by adding fly ash with a lower hydration activity. (3) An amount of gypsum component is added so that the cement paste has certain expansion property at a low temperature to prevent the cement paste shrinking at a low temperature. The low temperature and low hydration heat cementing concrete provided by the invention has an obvious effect for reducing the whole cement hydration heat and a good effect for preventing the deep water hydrate decomposition.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

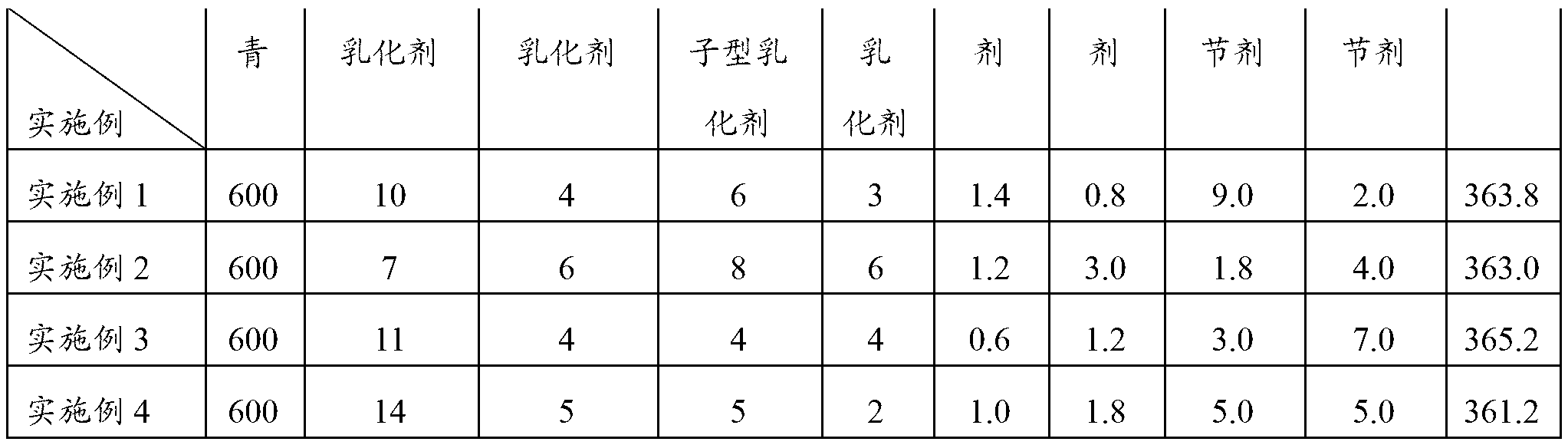

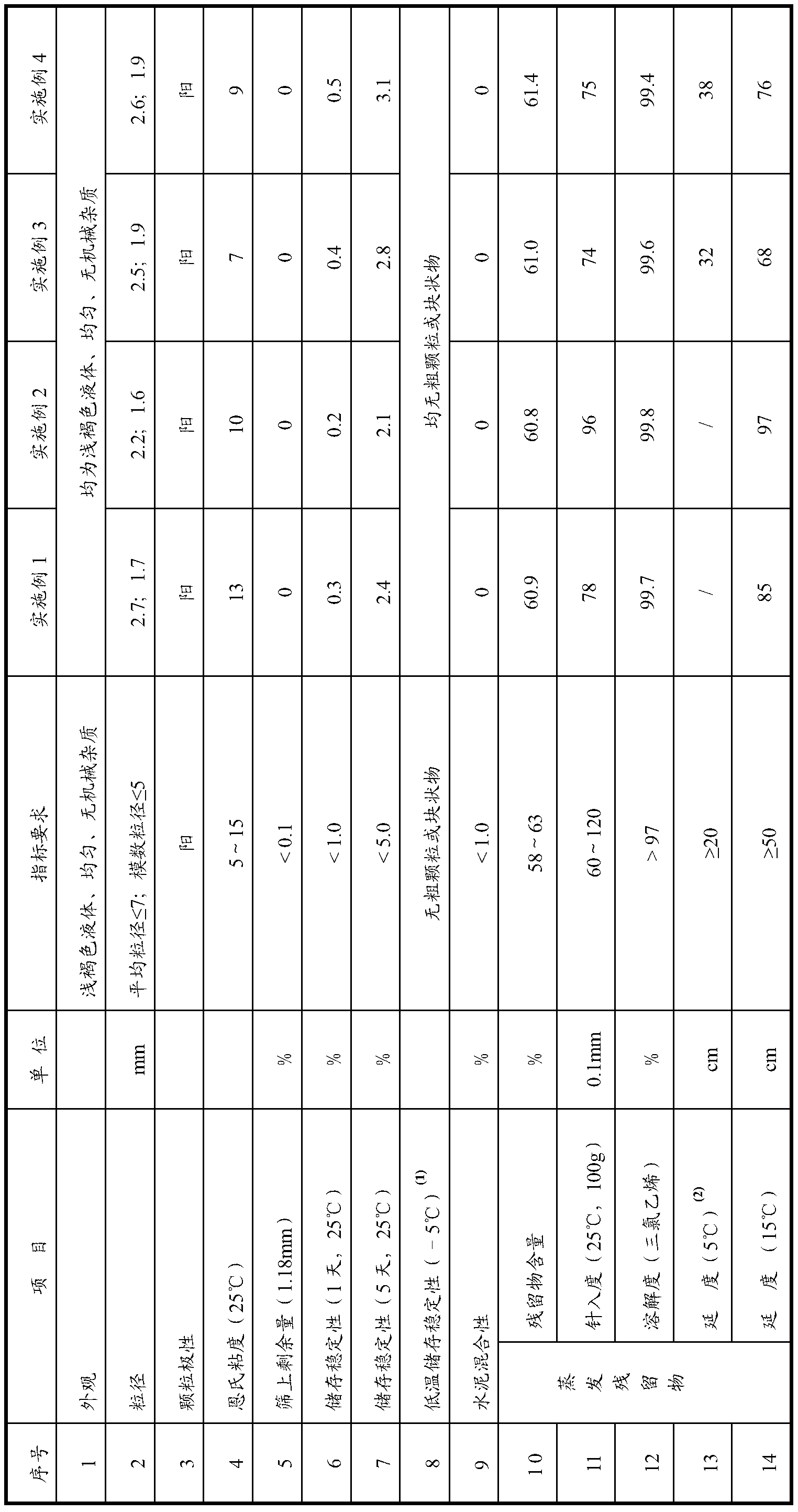

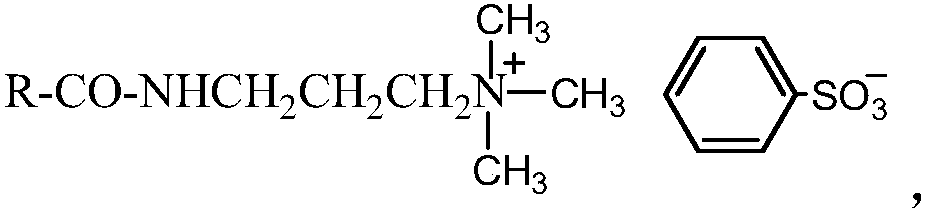

Emulsified asphalt for CRTS I and CRTS II slab ballastless tracks and preparation method of emulsified asphalt

InactiveCN103232710AImprove adaptabilityGood storage stabilityBuilding insulationsBitumen emulsionCarboxylic acid

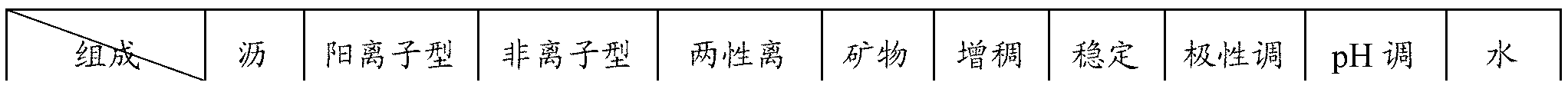

The invention provides emulsified asphalt for CRTS I and CRTS II slab ballastless tracks of high speed railways, passenger transport lines and interurban railways, and a preparation method of the emulsified asphalt. The emulsified asphalt comprises 55-65 parts of matrix asphalt or modified asphalt, 35-45 parts of water, 0.4-1.5 parts of cationic emulsifier, 0.3-1.2 parts of non-ionic emulsifier, 0.2-1.2 parts of amphoteric ionic emulsifier, 0.2-0.8 part of mineral emulsifier, 0.05-0.3 part of stabilizer, 0-0.2 part of thickener, 0-2.0 parts of pH modifier, and 0.1-1.2 parts of a polarity adjuster which is compounded of alkylamine and polycarboxylic acid surfactant. The emulsified asphalt has good storage stability and adaptability and also has the most significant characteristic that CRTS I and CRTS II cement-emulsified asphalt mortars can be prepared from the emulsified asphalt at the same time; two prepared mortars have good working performance, mechanical property and endurance quality; and the emulsified asphalt is suitable for the slab ballastless tracks, especially for the slab ballastless tracks of high speed railways, passenger transport lines and interurban railways.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

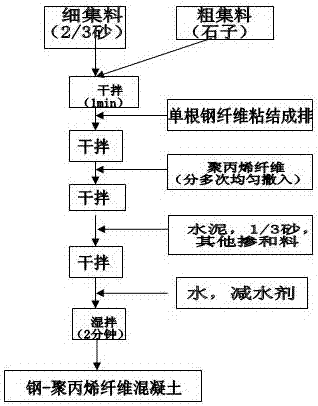

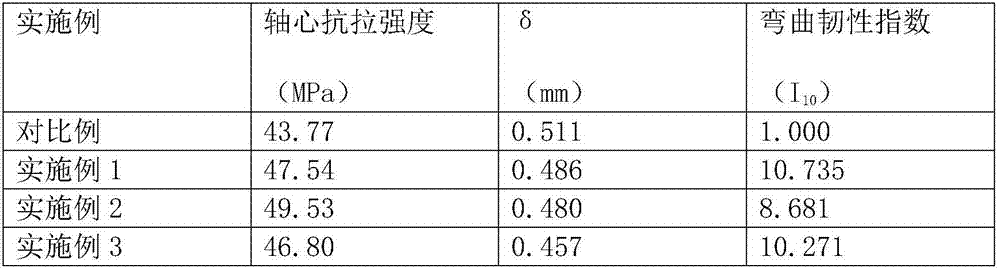

High-performance expanded hybrid fiber concrete material for wet joints, and preparation method thereof

The invention provides a high-performance expanded hybrid fiber concrete material for wet joints, and a preparation method thereof. According to the present invention, based on the practical problems of the wet joint in the whole simply supported-continuous structure system, high-strength hybrid fiber reinforced concrete is used as a joint material to provide the hybrid effect at different levels and different load applying stages so as to well inhibit and restrict the development of cracks, wherein the development of the concrete micro-crack is limited by releasing the concentrated force of the micro-crack in the concrete with Durafibers, the development of the macro-crack is limited by steel fibers, and by mixing the Durafibers and the steel fibers, a variety of mechanical properties of the whole concrete can be improved in the case of the low doping volume, such that the concrete can have characteristics of high bending resistance, high toughness, high impermeability, high fatigue resistance and the like so as to prevent the occurrence of diseases.

Owner:WUHAN UNIV OF TECH

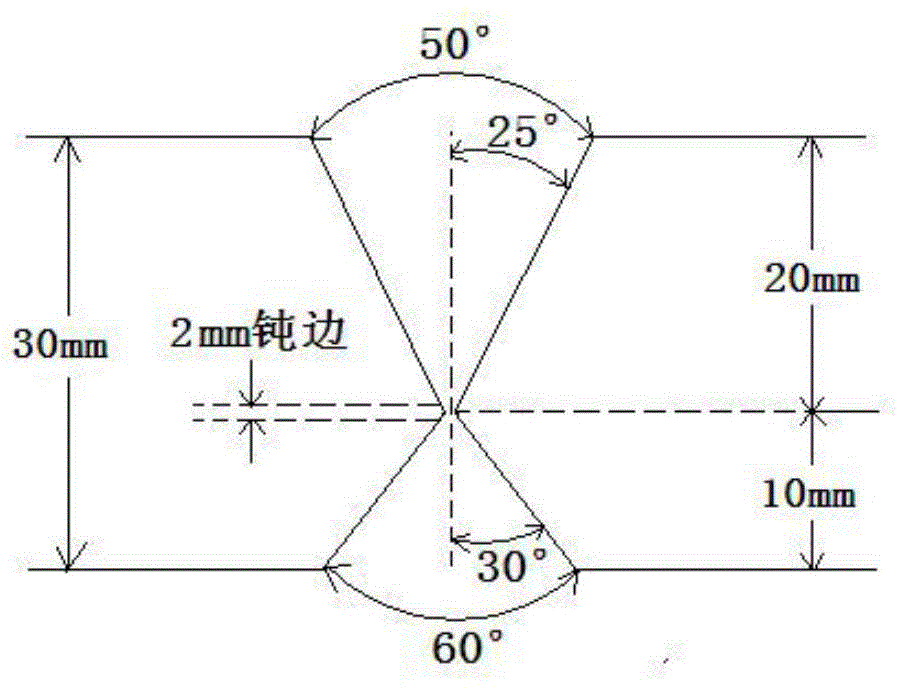

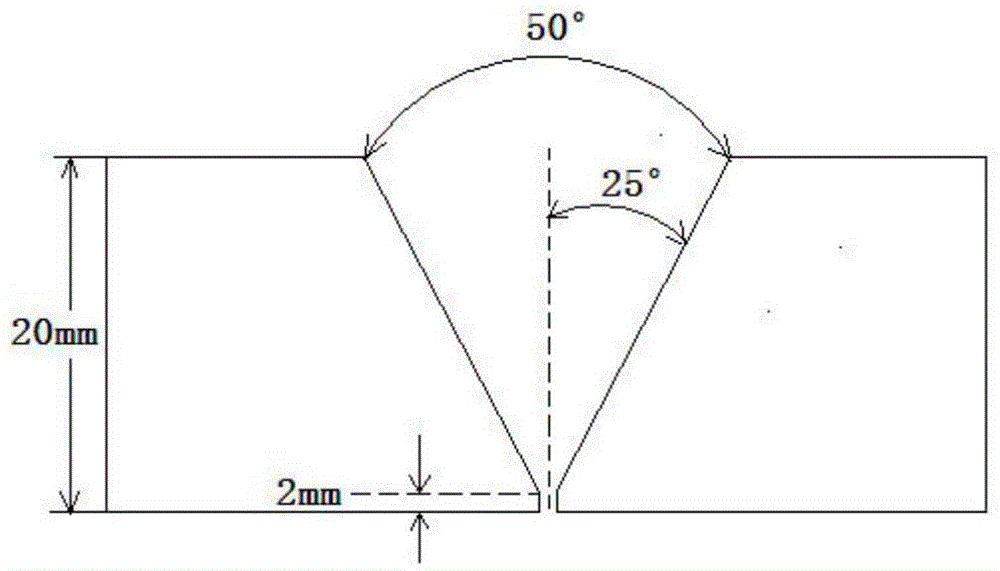

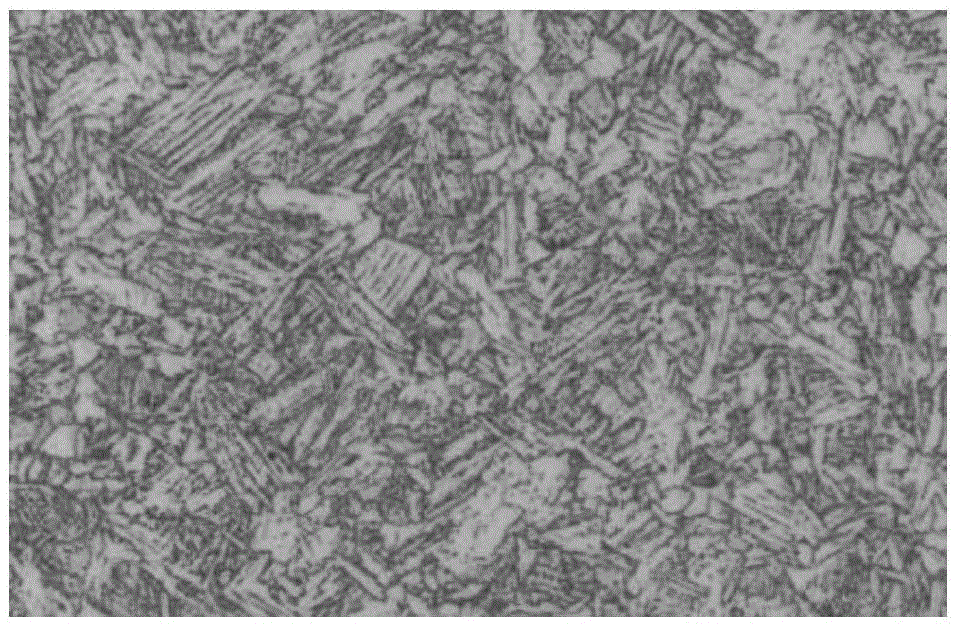

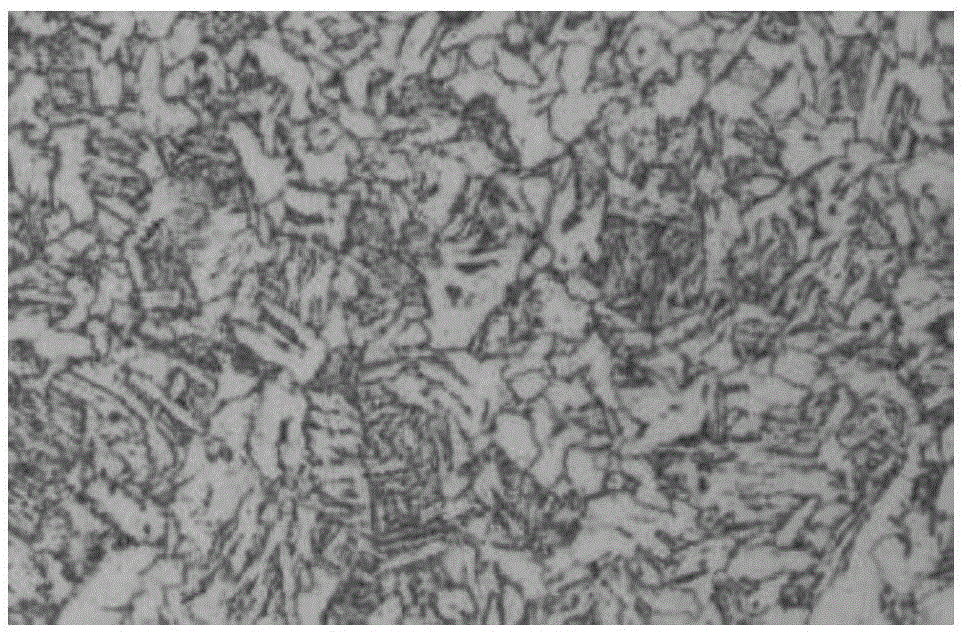

Welding wire special for high-strength steel penstock submerged-arc welding

InactiveCN104162748AEnsure safetyMeet site construction requirementsArc welding apparatusWelding/cutting media/materialsPenstockHigh strength steel

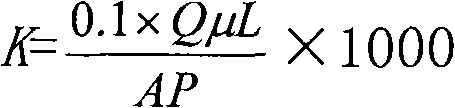

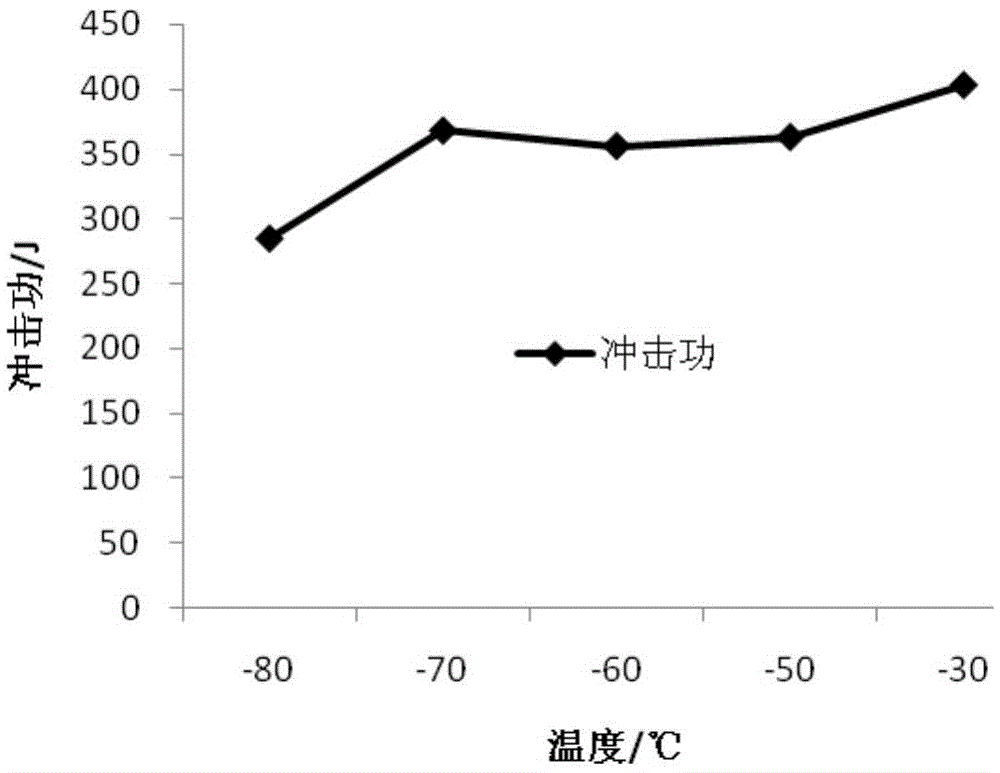

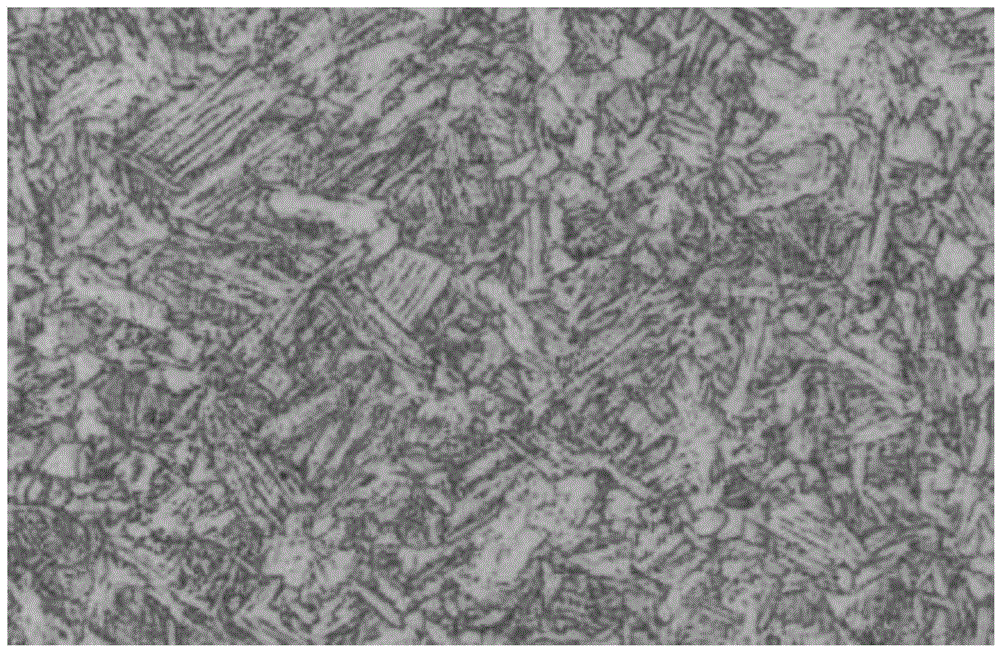

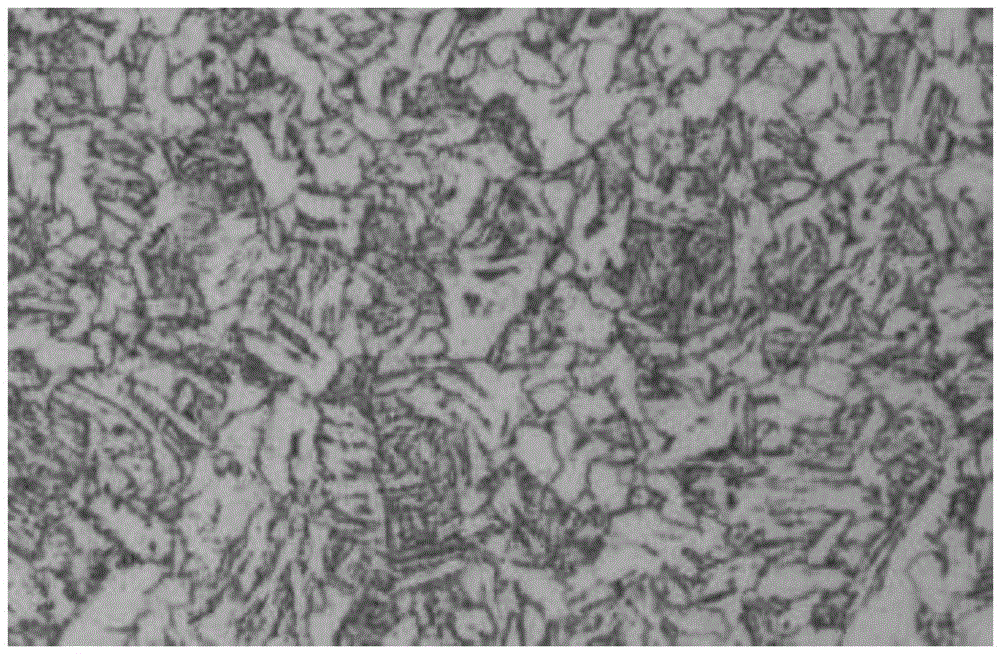

The invention discloses a welding wire special for high-strength steel penstock submerged-arc welding and belongs to the field of welding materials. The welding wire comprises, by weight, 0.08%-0.2% of C, 0.1%-0.3% of Si, 1.5%-2.5% of Mn, 1.5%-3.5% of Ni, 0%-0.5% of Cr, 0.5%-1.0% of Mo, 0%-0.05% of Al, 0%-0.2% of Nb, 0%-0.2% of V, 0%-0.2% of Ti, 0%-0.01% of B, 0%-0.005% of O, 0%-0.01% of N, 0%-0.01% of S, 0%-0.01% of P, and the balance Fe and inevitable impurity elements. The welding wire is matched with a hydroelectric steel penstock made of a 100kg-grade steel plate, and when the welding wire is matched with alkaline welding flux, the requirements of a welded joint of the hydroelectric steel penstock made of the 100kg-grade steel plate that welded joint tensile strength is higher than or equal to 950 MPa, minus 60 DEG C ballistic work is higher than or equal to 47 J and 0 DEG C ballistic work is higher than or equal to 100 J can be met.

Owner:SHOUGANG CORPORATION

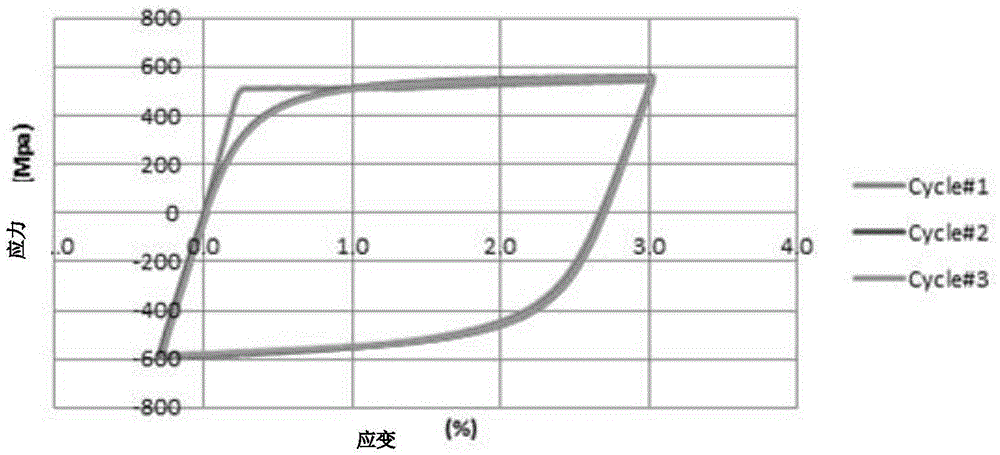

Manufacturing method for large-strain-resistant corrosion-resistant seamless line pipe for marine environment R-Lay laying

The invention relates to a manufacturing method for a large-strain-resistant corrosion-resistant seamless line pipe for marine environment R-Lay laying. The method is used for manufacturing the line pipe which is suitable for shallow sea and deep sea reelpipe manner laying and can meet the requirement that the corrosion-resistant high strength is larger than or equal to 415 MPa in an acid environment after repeated twining and straightening are carried out. The method includes the steps of burdening and pipe manufacturing, and a pipe material meeting the requirement for conveying exploited oil and gas resources in the shallow sea and deep sea R-Lay laying manner is manufactured. The manufacturing method has the beneficial effects that the seamless line pipe has the good large-strain-resistant performance, it is guaranteed that the strength is larger than 415 MPa after tension-compression cycling is carried out three times under 3% strain, and the -20 DEG C ballistic work is larger than 300 J. The good HIC and SSC resistance is achieved, the CSR is smaller than or equal to 1.5%, the crack length rate is smaller than or equal to 5%, the CTR is smaller than or equal to 3%, and breakage can be avoided when 100% loading is carried out for 96 hours in the SSCB method. The large-strain-resistant corrosion-resistant seamless line pipe is widely suitable for the shallow sea and deep sea R-Lay laying manner.

Owner:TIANJIN PIPE (GROUP) CORP

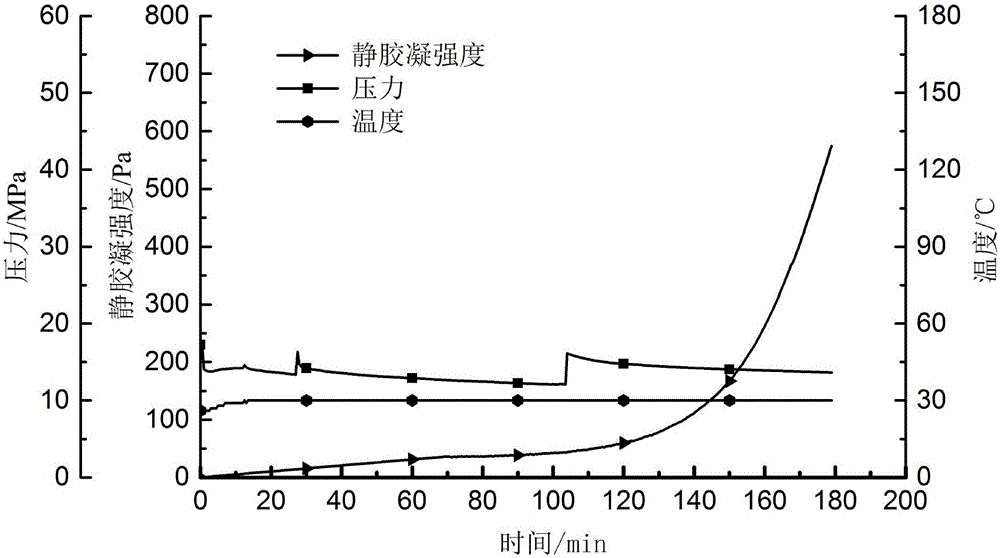

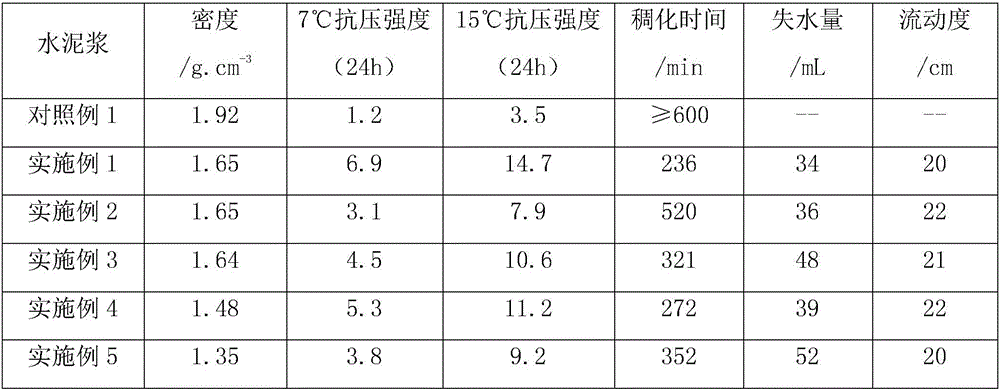

A liquid colloid filling low-temperature well-cementing cement mortar system

A liquid colloid filling low-temperature well-cementing cement mortar system is provided. The system is characterized in that the system includes 100 parts by mass of Portland cement, 80-120 parts by mass of ultrafine Portland cement, 10-30 parts by mass of hollow glass microbeads, 10-20 parts by mass of micro-silicon, 8-12 parts by mass of liquid colloid, 2-6 parts of an early strength agent, 1-2 parts by mass of drag reducer, 4-8 parts by mass of a water loss reducing agent, 1-2 parts by mass of a defoamer and 120-150 parts of water. According to the system, the density of the system is adjustable in a range of 1.35-1.65 g / cm<3>, the low-temperature early strength is high, thickening performance and fluidity are good, the water loss amount is low, and the system has excellent anti-fluid-channeling performance, can be used for well cementing for deepwater surface layer sections, can save working time and costs and can provide safe and efficient technical supports for deepwater oil and gas exploitation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

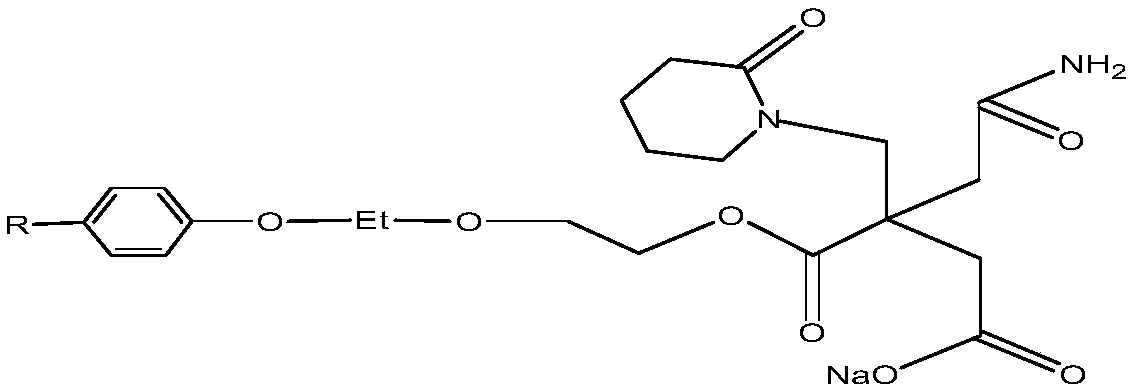

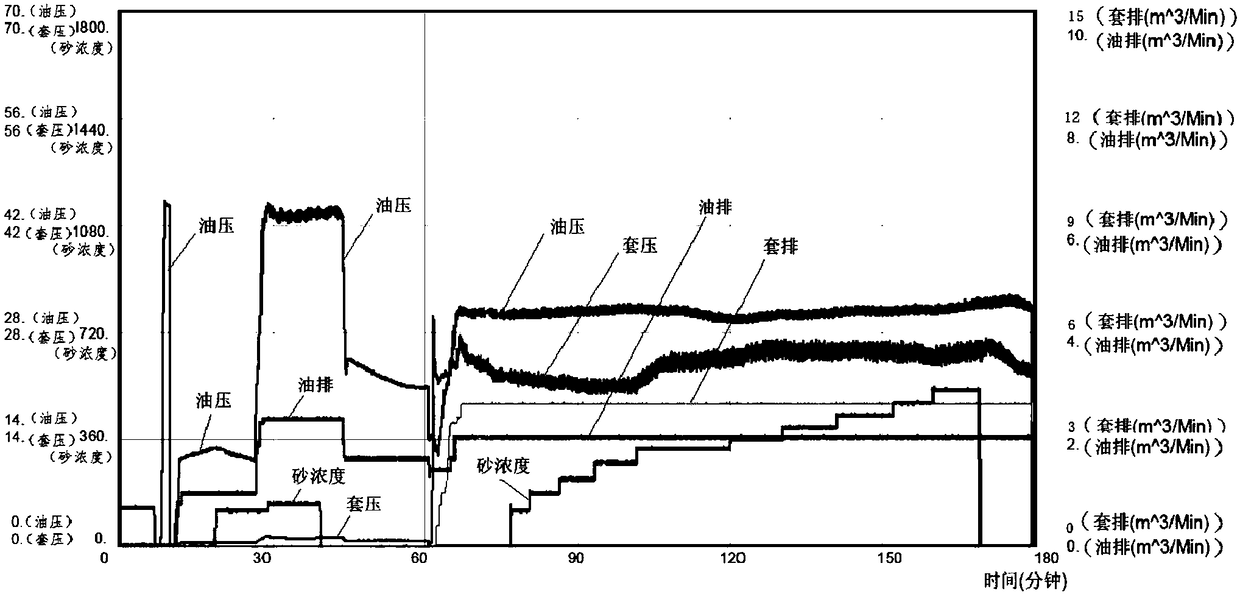

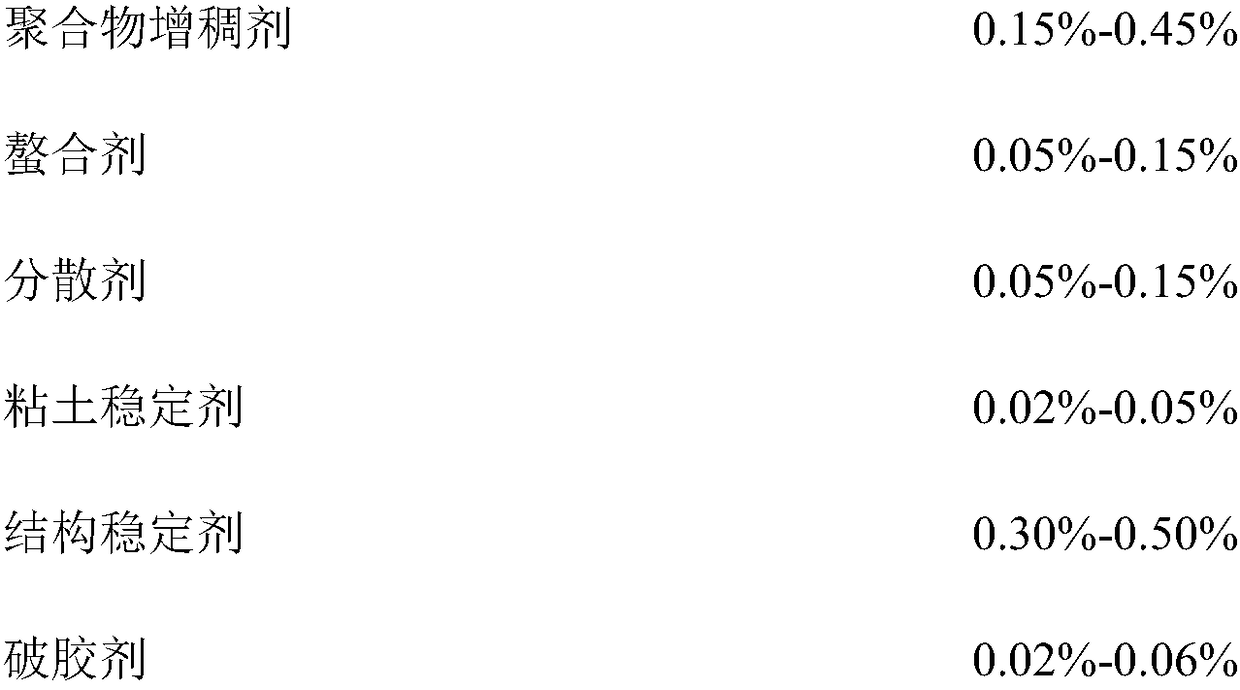

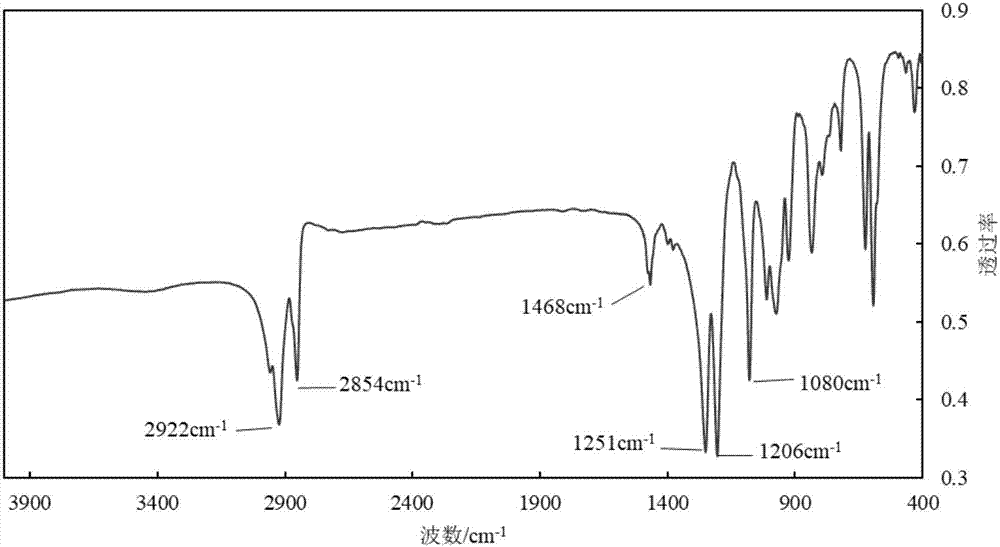

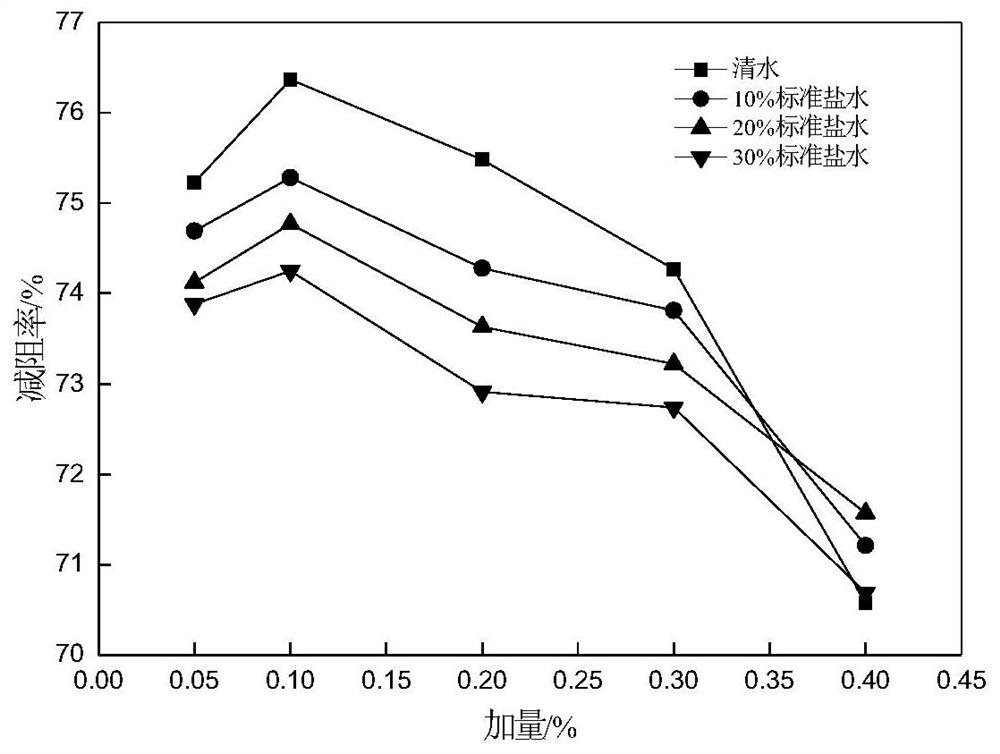

Slickwater fracturing fluid suitable for being used at hypersalinity condition

InactiveCN108559477AGood drag reduction performanceSimple processDrilling compositionSalt resistanceStabilizing Agents

Provided is a slickwater fracturing fluid suitable for being used at a hypersalinity condition. The slickwater fracturing fluid is prepared from, by mass, 0.15-0.45% of polymer viscosifier, 0.05%-0.15% of chelating agent, 0.05%-0.15% of dispersing agent, 0.02%-0.05% of clay stabilizer, 0.30%-0.50% of structure stabilizer, 0.02%-0.06% of gel breaker and the balance water. The slickwater fracturingfluid has the advantages of being low in viscosity, friction and cost and easy to recycle, easily flowing back and the like; the problems are mainly solved that at the hypersalinity condition, polymers are poor in salt resistance and sand-carrying stability and does not easily disperse; the problem can also be solved that vegetable glue fracturing fluid easily rots; after being filtered, flow-backliquid can be further directly recycled, and requirements of large-scale fracturing construction of compact oil-gas reservoirs can be effectively met.

Owner:PETROCHINA CO LTD

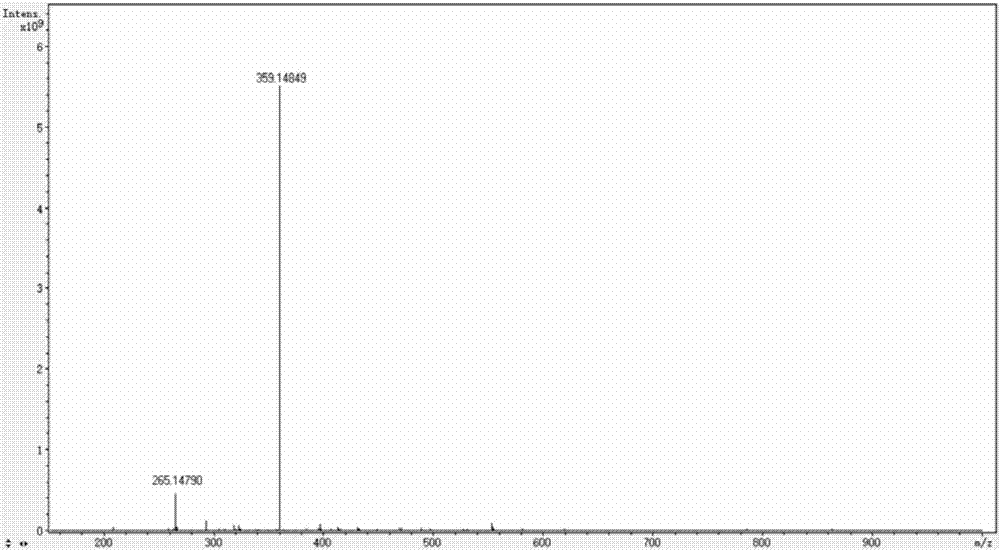

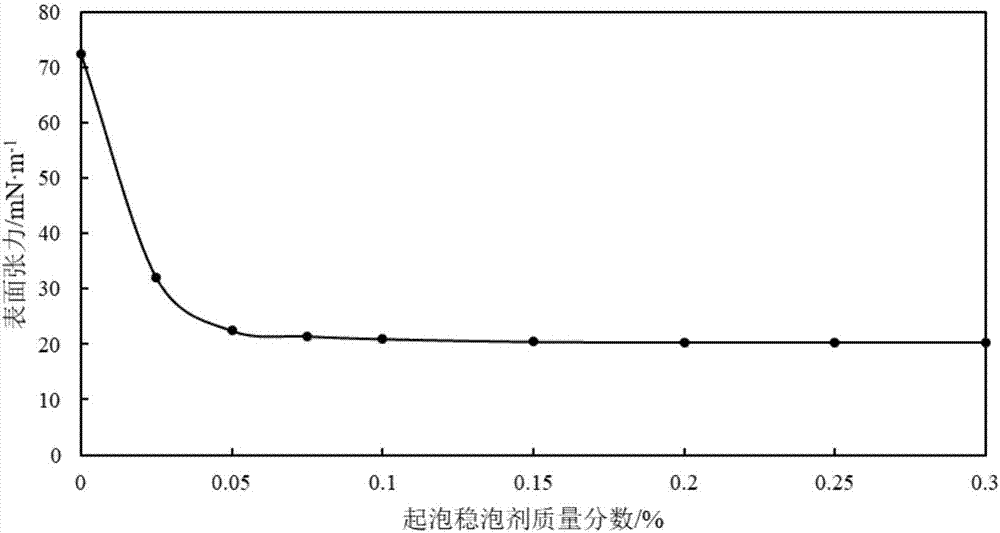

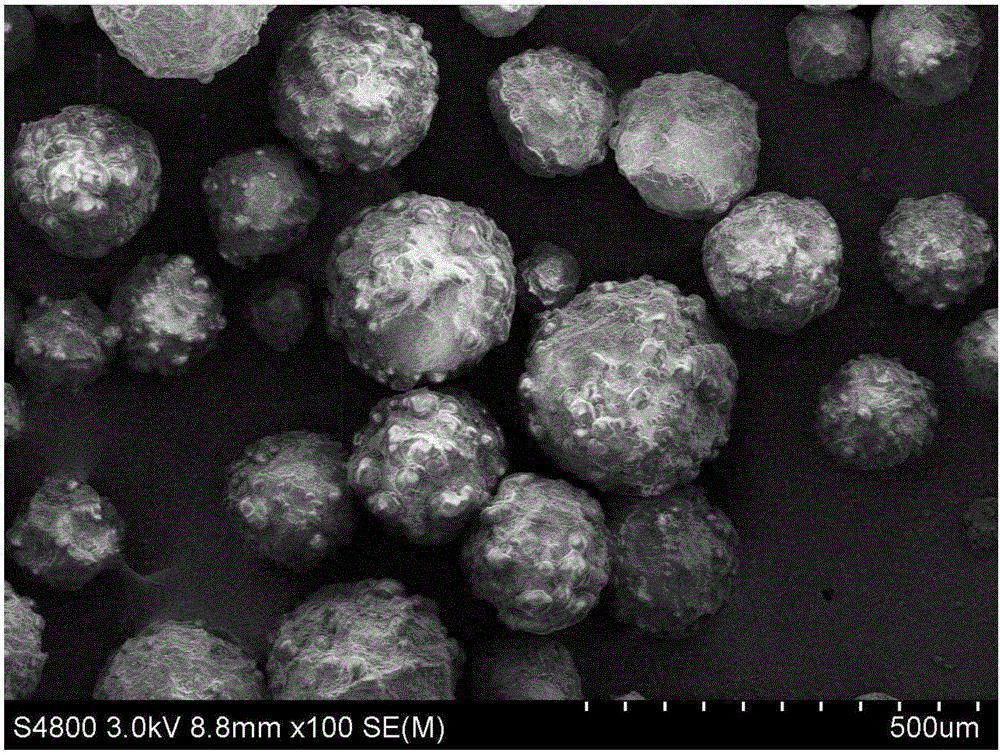

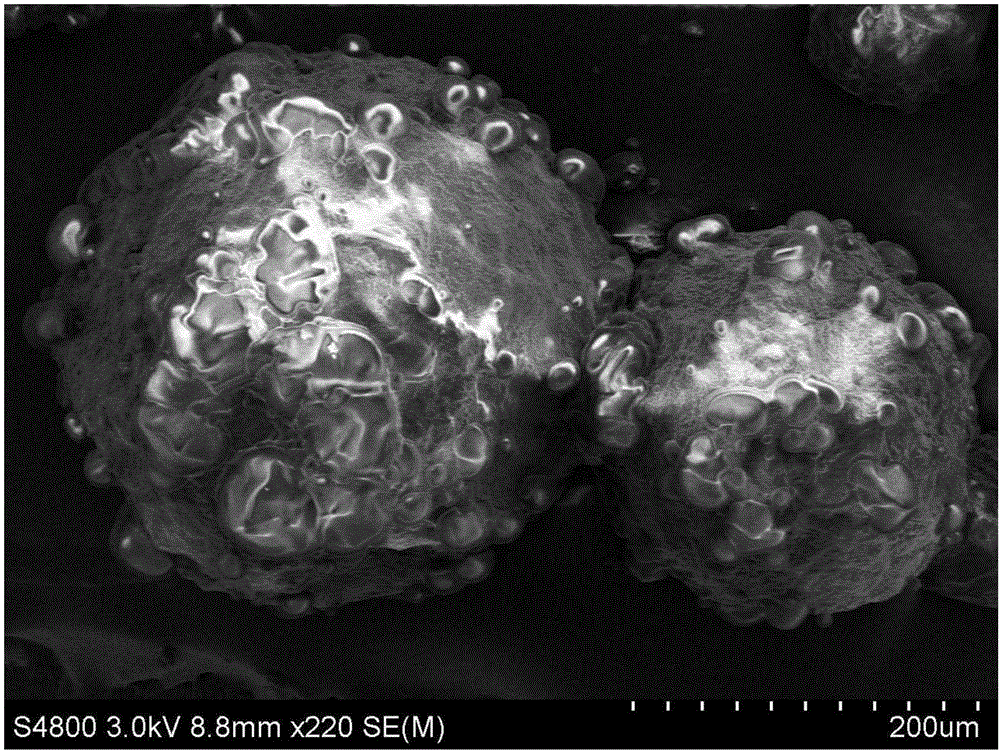

Novel foam drilling fluid system and preparation method thereof

InactiveCN107502321AFine foamImprove molecular structureDrilling compositionReduction rateFoaming agent

The invention relates to a novel foam drilling fluid system and a preparation method thereof. The novel foam drilling fluid system is developed on the basis of the development of a novel foaming foam stabilizer. The novel foaming foam stabilizer has the advantages of novel structure and excellent performance. A small amount of the foaming foam stabilizer can generate a large amount of foam, and the half-life of the foam can reach more than 3 times that of foam generated by a conventional foaming agent. A single foaming foam stabilizer can achieve the compounding effects of a plurality of foaming agents in the prior art, and the dosage is less. The novel foam drilling fluid system developed on the basis of the novel foaming foam stabilizer has a half-life up to 7.1 d when the foaming foam stabilizer is added in a small amount, the half-life of the novel foam drilling fluid system is obviously better than the half-life of a foam drilling fluid formulated by the conventional foaming agent The novel foam drilling fluid system has good performance, can resist temperature of 120 DEG C, can resist salt of 10%, and can resist rock debris pollution of 12%, shale recovery rate is 90% or more, the linear expansion reduction rate is 80% or more. The novel foam drilling fluid system is free of seepage loss in 80 / 120-mesh gravel, the seepage loss is 1.2 ml or less in 40 / 80-mesh gravel, and the novel foam drilling fluid system can effectively meet the requirements of on-site construction.

Owner:CHINA UNITED COALBED METHANE +1

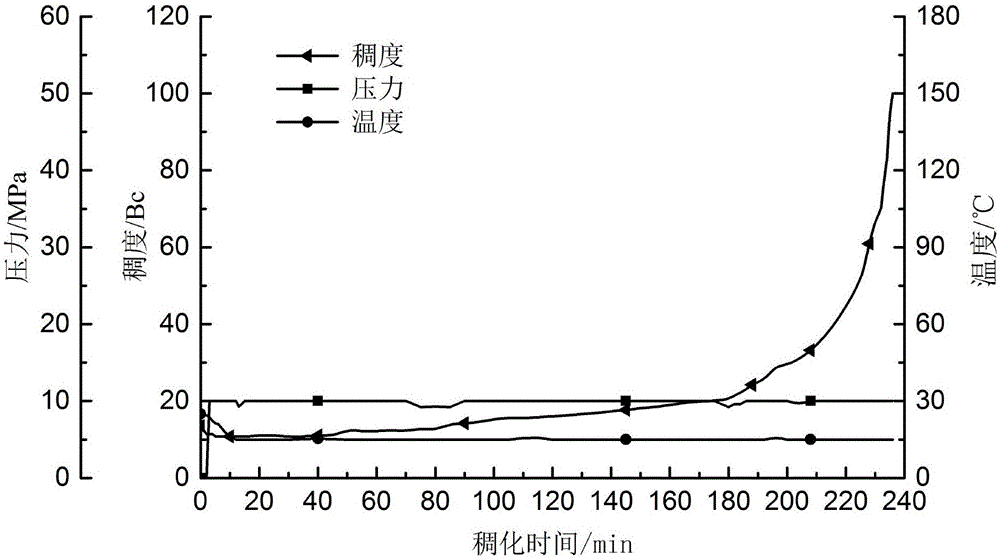

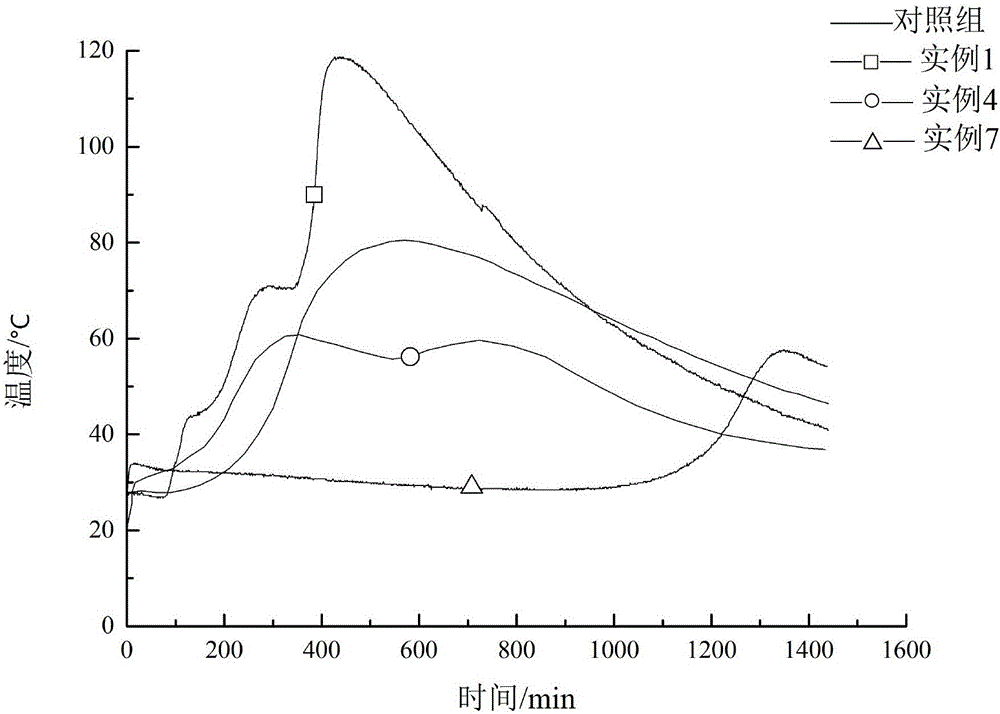

Early-strength low-hydration heat evolution cement paste system applicable to deepwater shallow cementation

The invention discloses an early-strength low-hydration heat evolution cement paste system applicable to deepwater shallow cementation. The system is prepared from 100 parts of cement, 5-10 parts of phase-change heat absorption materials, 10-30 parts of a density reducing agent, 8-15 parts of suspension materials, 0.5-1 part of a drag reducer, 0.3-0.55 part of retarder, 0.7-1 part of a fluid loss agent, 0.7-1 part of a defoaming agent, 0.06-0.1 part of an early strength agent and 68.2-82.3 parts of water. The cement paste system has the good early strength property at low temperature, is small in hydration heat evolution amount and good in thickening property, flowing property and sedimentation stability, has right-angle thickening property and small water loss, and meets on-site construction requirements. According to the system, surface cementation in the deepwater hydrate layer can be achieved, operation time and cost can be saved, and a technical support is provided for mining of oil and gas resources in the deepwater hydrate layer.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

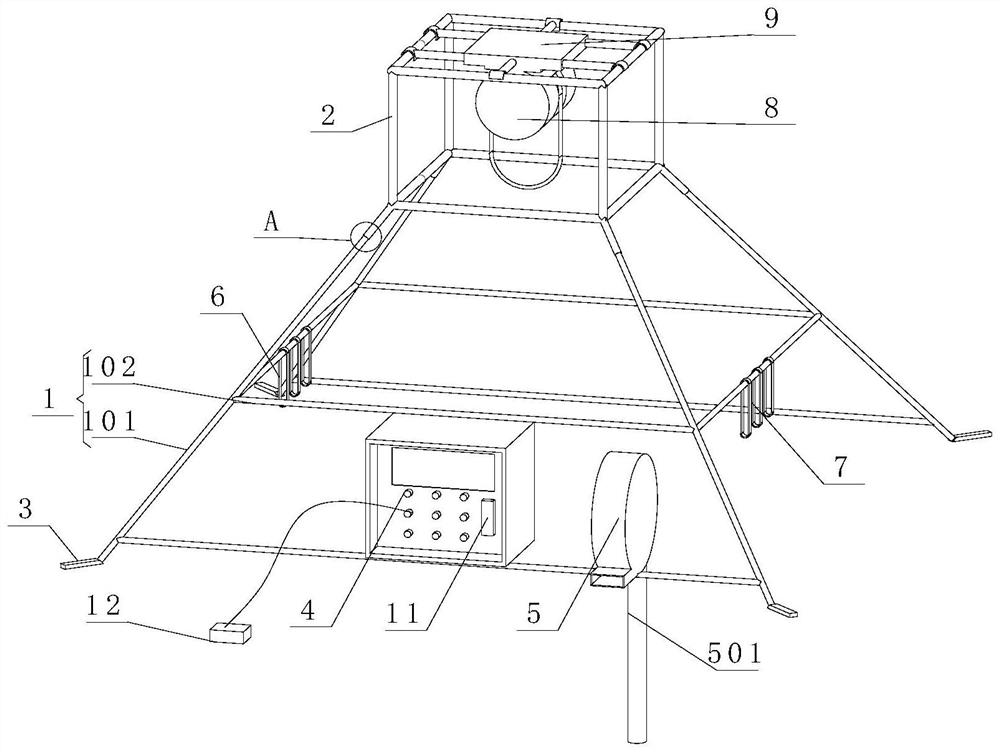

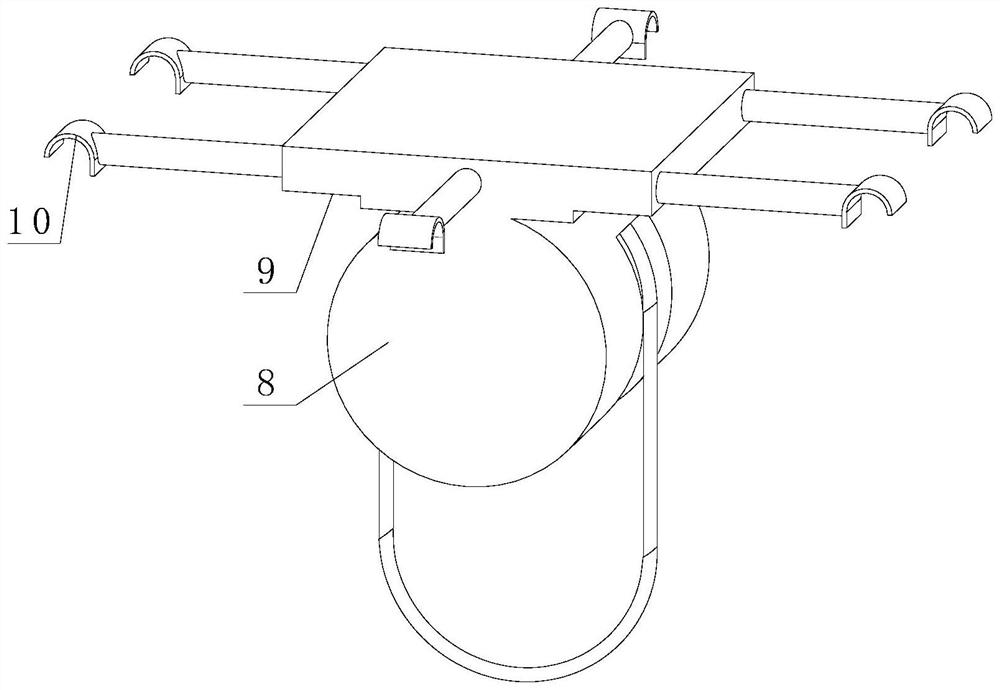

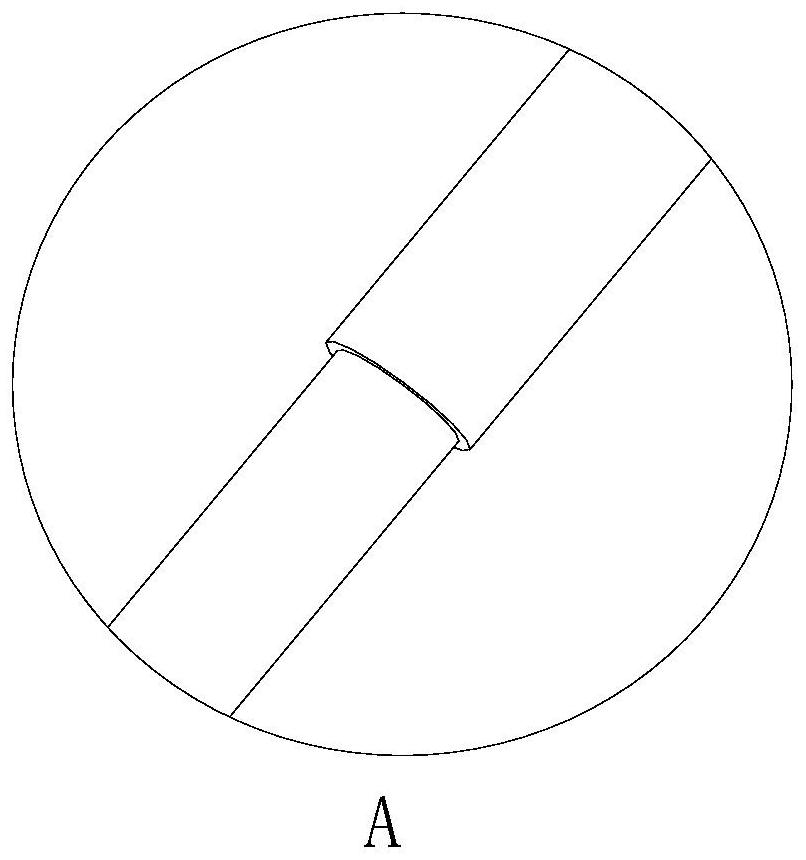

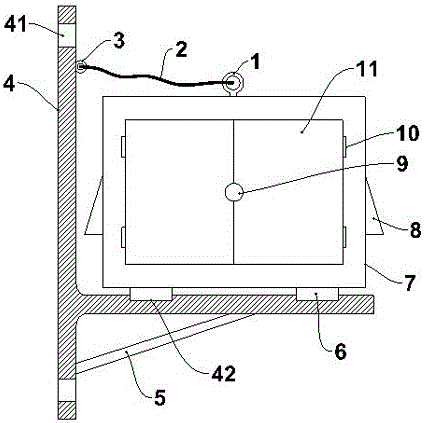

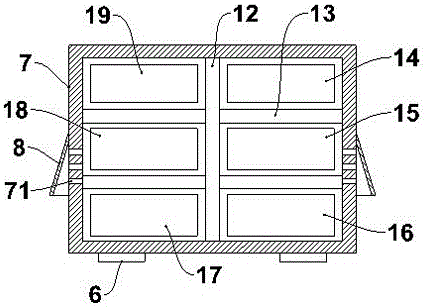

Integrated deep foundation pit operation intelligent machine

PendingCN111851511AEnsure safetyImprove securityFoundation testingExcavationsStructural engineeringMachine

The invention relates to the field of foundation pit construction equipment, in particular to an integrated deep foundation pit operation intelligent machine. The problems of high equipment carrying difficulty and low safety performance are solved. The integrated deep foundation pit operation intelligent machine comprises a plurality of pithead supports, an installation frame is arranged on the pithead supports, an electric hoist is installed on the pithead supports through the installation frame, a control instrument box and a fan are further installed on the pithead supports, and the controlinstrument box is in circuit connection with the electric hoist, the fan and a gas detection device. The device integrates multiple functions of rapid and stable material lifting, real-time gas detection, intelligent air supply, automatic sound-light alarm, emergency lifting of constructors, differential mechanism hanging points and rope ladder hanging points, the life safety of the constructorsis guaranteed, the safety and reliability of construction machines and tools are improved, and the construction efficiency is improved.

Owner:甘肃送变电工程有限公司 +2

Novel complex surface active degradation agent used for releasing the blocking of Polymer/Surfactant flooding

InactiveCN101550333AImprove protectionGood compatibilityDrilling compositionOil waterSURFACTANT BLEND

The present invention relates to a novel complex surface active degradation agent used for releasing the blocking of surfactant flooding. The invention mainly settles a problem that the well blocking of polymer / surfactant affects the recovery rate of oil accumulation. The invention is characterized in that the components and matching ratio are as follows by weight: 0.03-3.0% of surface activity degradation agent, 0.1-3.0% of weak degradation agent, and the balance of water. The complex active degradation agent is used for deblocking oil-water well of polymer / surfactant flooding in tertiary oil recovery. The oil layer can be excellently protected. Furthermore the complex surface active degradation agent used for releasing the blocking of surfactant flood further has the following advantages of good compatibility with stratum, no pollution, excellent fluidity, good safety, good environment-protecting property, long effective period and satisfaction to the field construction requirement.

Owner:大庆开发区东油新技术有限公司

Submarine seamless line pipe above 415SPDF steel grade having large strain resistance

The invention provides a submarine seamless line pipe above 415SPDF steel grade having large strain resistance. The submarine seamless line pipe comprises the following components, by weight, 0.05-0.11% of C, 0.20-0.40% of Si, 1.0-1.40% of Mn, less than or equal to 0.010% of P, less than or equal to 0.002% of S, 0.05-0.30% of Ni, 0.05-0.30% of Cr, 0.05-0.30% of Mo, 0.010-0.050% of Als, less than or equal to 0.010% of N, 0.010-0.050% of Nb, 0.03-0.08% of V, 0.05-0.25% of Cu, 0.008-0.030% of Ti, less than or equal to 0.020%of Pb, less than or equal to 0.020% of Sn, less than or equal to 0.030% of As, less than or equal to 0.015% of Sb, less than or equal to 0.015% of Bi, less than or equal to 0.0005% of B, less than or equal to 0.22% of carbon equivalent CEpcm, less than or equal to 0.39% of CEIIW, and less than or equal to 0.8% of a total amount of Ni, Mo, Cr and Cu that are added to Ni, Mo, Cr and Cu alloys. The submarine seamless line pipe has the benefits that after three times of pull-down circulation under 3% strain, the strength of the submarine seamless line pipe can be ensured to be greater than 415MPa, and ballistic work at minus 20 degrees of the submarine seamless line pipe can be ensured to be greater than 300J; the submarine seamless line pipe has less than or equal to 1.5% of crack sensitivity ratio (CSR), less than or equal to 5% of crack length ratio, and less than or equal to 3% of crack thickness ratio (CTR); and the submarine seamless line pipe does not break under 100% loading for 96h by an SSCB method.

Owner:TIANJIN PIPE (GROUP) CORP

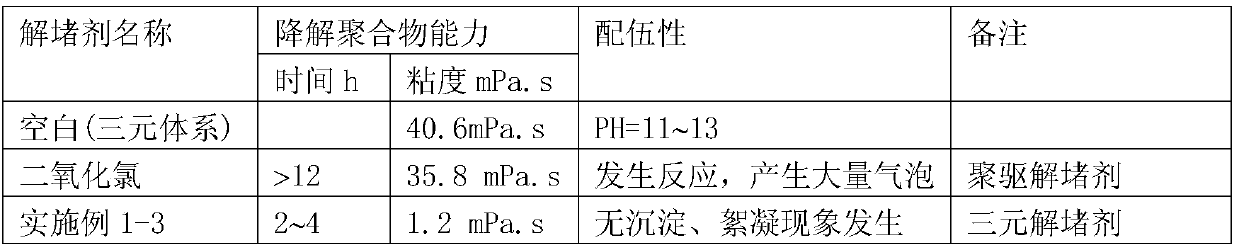

Chemical plugging remover suitable for ternary composite flooding injection well

ActiveCN109652043AIncrease the effective rangeStrong effective distanceDrilling compositionAcetic acidPolymer degradation

The invention relates to a chemical plugging remover suitable for a ternary composite flooding injection well. The method mainly solves problems of poor effect and short validity period when measuressuch as changing stratum injection fluid, acidizing and blocking removal of a common water injection well and the like are applied to a ternary compound flooding injection well. The chemical pluggingagent consists of three parts, namely a precursor, a main agent and an after agent, wherein the precursor consists of 10-15 percent of a polymer degradation agent and 90-85 percent of water; the mainagent consists of 7-10 percent of hydrochloric acid, 3-5 percent of acetic acid, 3-5 percent of ammonium fluoride, 1.0-2.0 percent of triethanolamine, 0.5-1.0 percent of an imidazoline quaternary ammonium salt corrosion inhibitor and 85.5-77 percent of water; the after agent consists of 1.0-3.0 percent of organic phosphonic acid, 0.5-1.0 percent of hexamethylene tetraammonium and 98.5-96.0 percentof water, wherein the components are measured in percentage by weight. The chemical plugging remover suitable for the ternary composite flooding injection well aims at various plugging substances such as scale, polymer, alkali and the like in the ternary composite flooding injection well, has functions of degrading polymer, dissolving scale, complexing, metal ions and the like, and has the advantages of good stability, low corrosivity and safe use.

Owner:DAQING JINGSHENG WEIYE OILFIELD TECH SERVICE +1

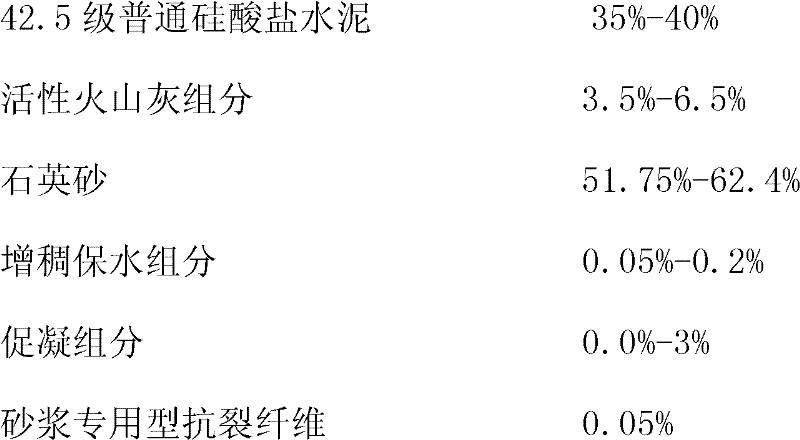

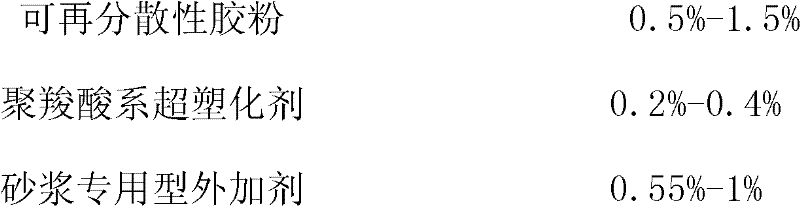

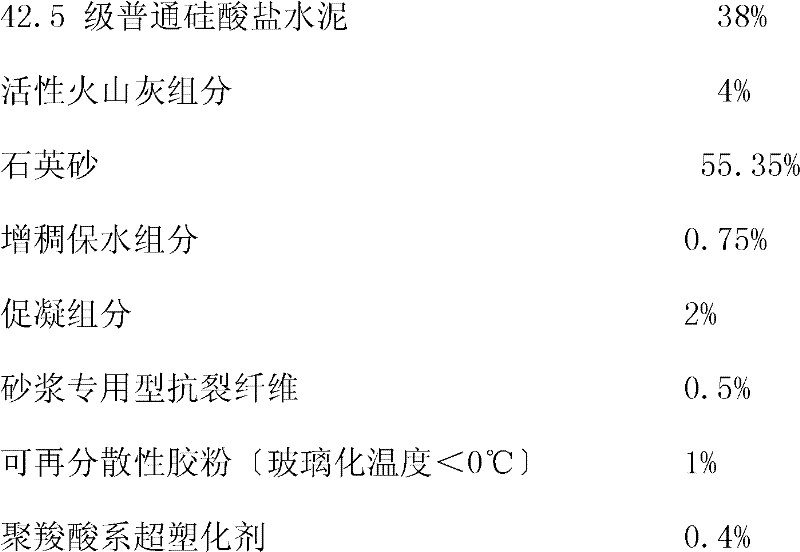

A high-performance structural reinforcement mortar composition and its preparation process

The invention discloses a high-performance structural reinforcement mortar composition, which uses 42.5-grade ordinary Portland cement and active pozzolan components as the main ingredients of the gelling material, and uses thickening and water-retaining components, polycarboxylic acid superplasticizers, It is modified by the coagulation-accelerating component, and special anti-crack fiber for mortar, quartz sand, and redispersible rubber powder are also added. The invention adopts redispersible polymer rubber powder and several kinds of active additives, which can effectively improve the durability of the mortar and the durability of the whole formed with the reinforced concrete matrix when added to the basic compound of ordinary mortar, and at the same time, it is harmful to the human body. It is not harmful to the environment and is a new type of energy-saving green building material.

Owner:上海维固工程实业有限公司

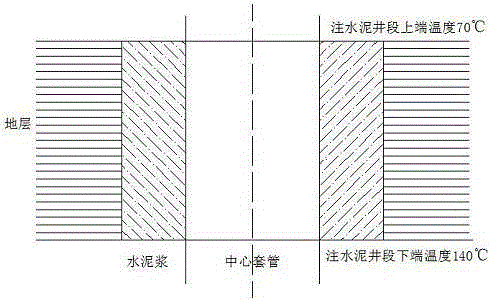

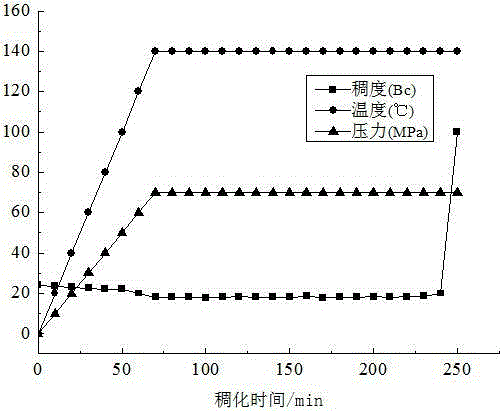

Temperature response type amphoteric polymer retarder and preparation method thereof

InactiveCN105273135AStrong retardationGood adjustabilityDrilling compositionMaleic anhydride2-Methyl propane

The invention relates to an oil well cement retarder in the field of oil gas well exploration and development and a preparation method of the oil well cement retarder. The amphoteric polymer retarder is prepared from, by mass, 10-20% of dimethyldiallylammonium chloride (DMDAAC), 20-30% of 2-acrylamide-2-methyl propane sulfonic acid (AMPS), 30-50% maleic anhydride (MA) and 10-30% of acrylic amide (AM). Due to lateral groups in an amphoteric polymer structure, a self-response type response can be made for the temperature of surroundings, and the temperature adaptability is high. The delayed coagulation of cement paste within the whole temperature region with 70 DEG C and 140 DEG C as the upper and lower end temperatures of a cementing well section is achieved, the thickening time of the cement paste and the retarder added amount are in the good linear relation, the right-angled thickening effect is obvious, the temperature and the added amount sensitivity are low, and the cement paste comprehensive performance can meet the requirement for well cementation construction; in addition, the retarder is simple in synthesis technology, low in cost, high in operability and capable of achieving large-scale production and application.

Owner:SOUTHWEST PETROLEUM UNIV

Protection drilling fluid for low-pressure reservoir

The invention discloses a protection drilling fluid for a low-pressure reservoir and relates to the technical field of drilling fluids. The formula of the protection drilling fluid comprises the following components in percentage by weight: 0.1-0.3% of high-viscosity polyanionic cellulose, 0.5-1.0% of sulfonated asphalt, 0.1-0.3% of low-viscosity polyanionic cellulose, 0.1%-0.2% of caustic soda, 1-2% of fluid loss additive, 2-3% of oil layer protection agent, 2%-3% of white clay and the balance of water. The protection drilling fluid disclosed by the invention has the characteristics of good plugging effect, smooth, dense and film-like mud cake, low harm to the low-porosity, low-permeability and low-abundance reservoir, and simplicity and easiness in formulation and operation of a pulp mixing process.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

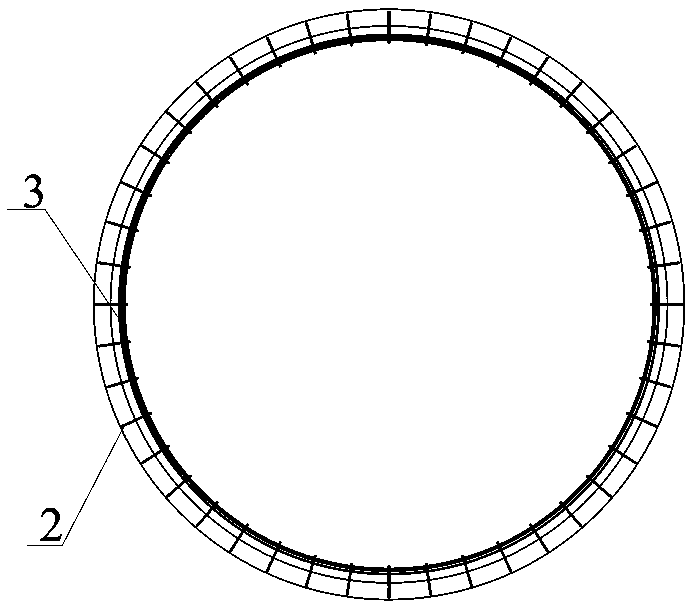

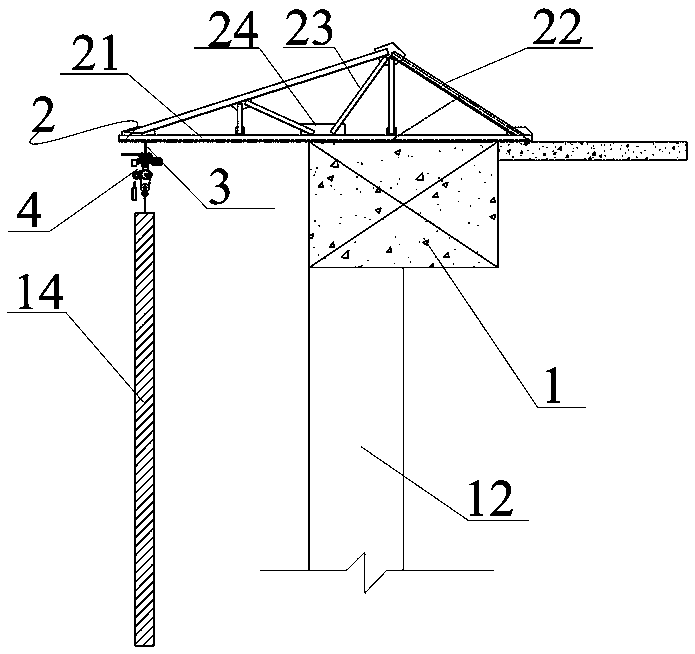

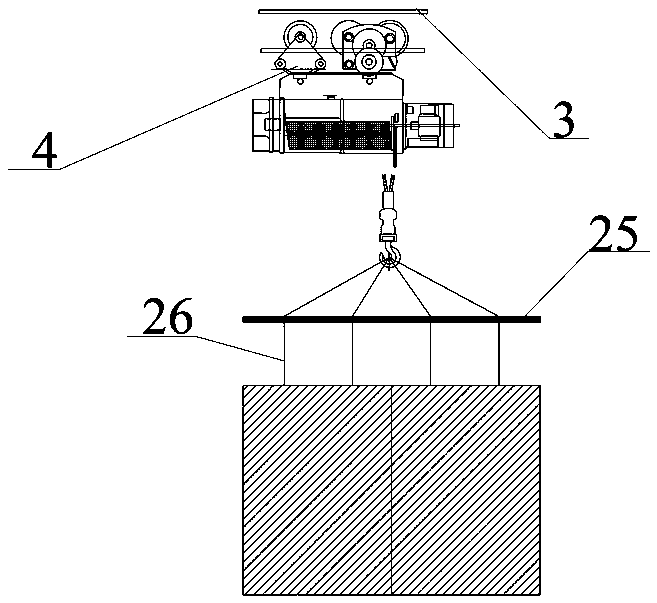

Circular foundation pit lined wall formwork construction system and construction method

PendingCN110453689ASave tower crane timesSpeed up the construction progressExcavationsBulkheads/pilesRebarEngineering

The invention relates to a circular foundation pit lined wall formwork construction system and a construction method. The circular foundation pit lined wall formwork construction system comprises a formwork hanging system and a formwork system, the formwork system comprises an end formwork, a bottom formwork and a side formwork, the formwork hanging system is fixed on a crown beam of a circular deep foundation pit, the formwork hanging system comprises vertical-directional triangular trusses arranged evenly along the crown beam, an annular rail fixed on the vertical-directional triangular trusses, and an electric hoist with a running car, and the electric hoist is fixed on the annular rail and used for hoisting the side formwork; the bottom formwork includes a molded hyperbolic steel bottom formwork and a bottom formwork cross plate support frame for supporting the molded hyperbolic steel bottom formwork; the end formwork includes an end plate, a structural steel support and reinforcement device, a wooden I-shaped beam, lined wall reserved horizontal rebar and a screw; and the side formwork includes a side formwork body, a molded large formwork hook, a steel molded pouring port, anoperation platform, a high-strength screw and a connecting rod. According to the circular foundation pit lined wall formwork construction system, the electric hoist with the running car can design the number and moving positions according to needs, after the assembly of the side formwork body is completed, hoisting to a preset position is conducted through the formwork hanging system, construction is fast, and the cost is low.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

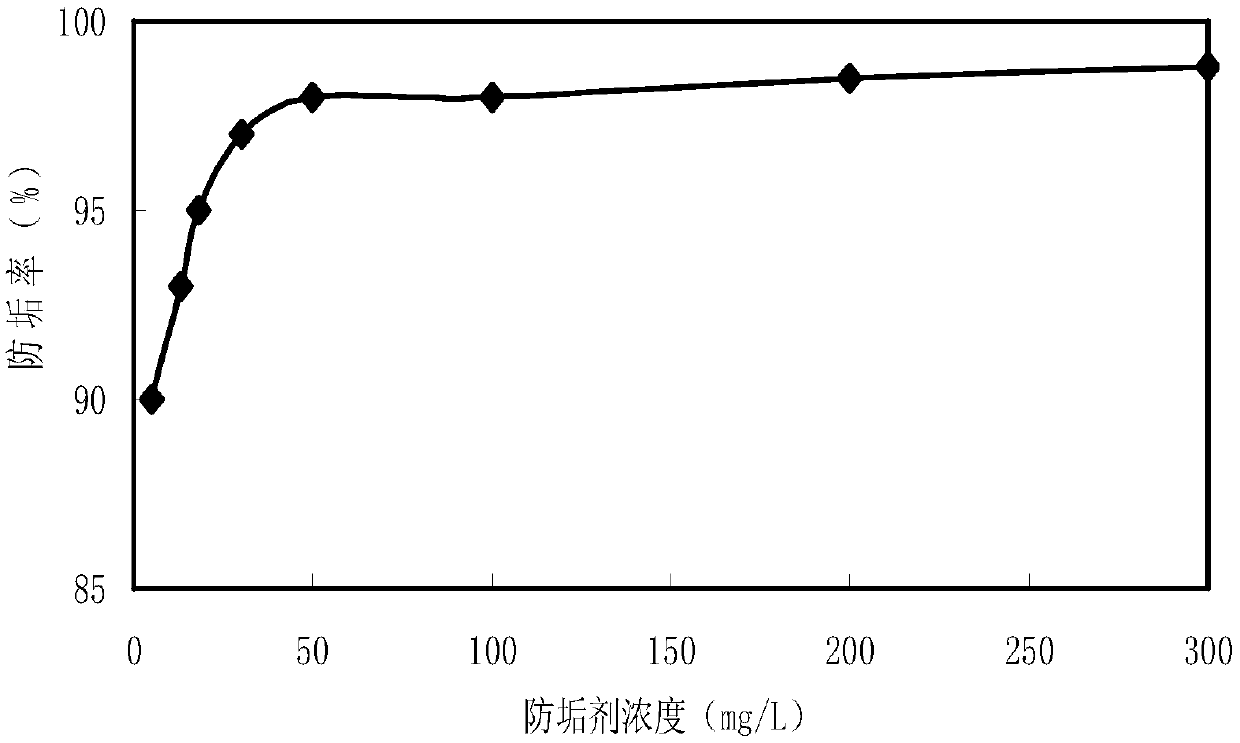

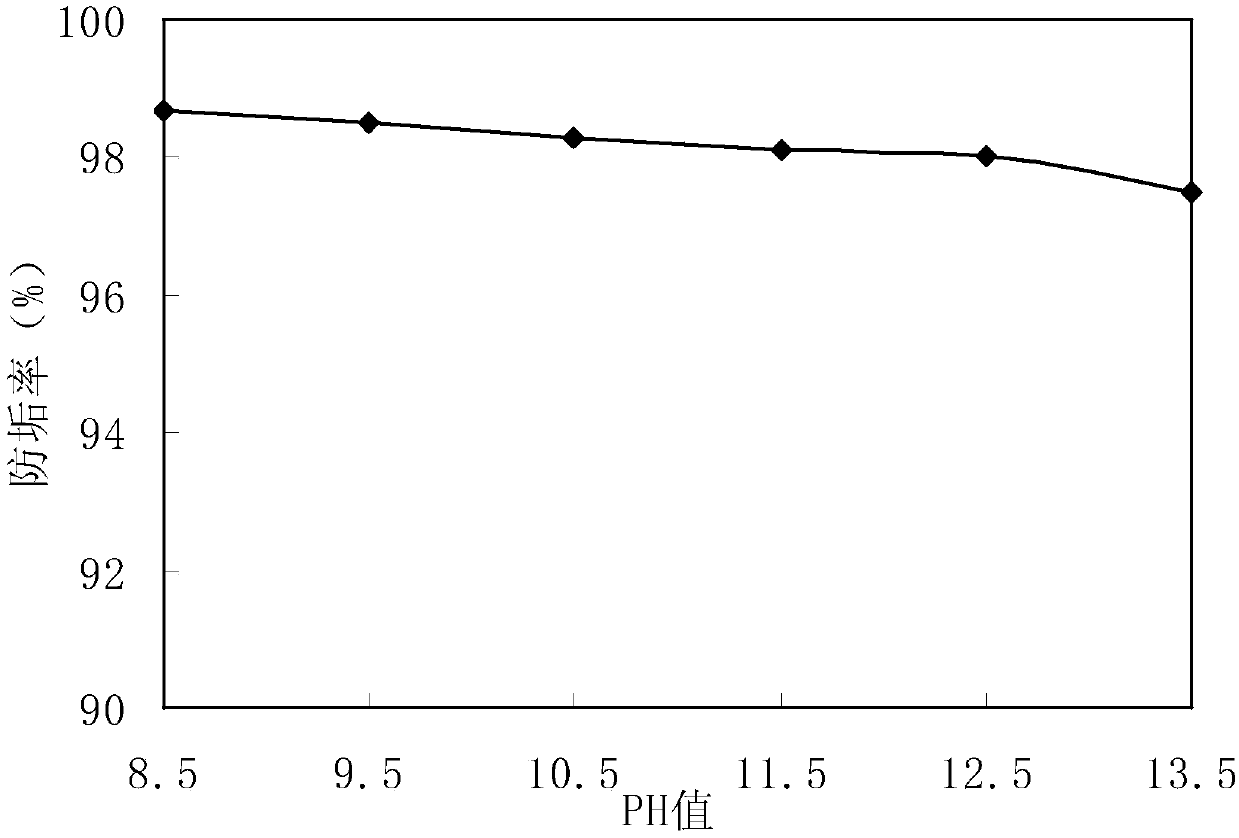

Solid free scale-preventing workover fluid suitable for sodium bicarbonate formation water

InactiveCN103923621AGood anti-scaling effectLess corrosiveDrilling compositionSodium bicarbonatePollution

The invention discloses a solid free scale-preventing workover fluid suitable for sodium bicarbonate formation water. The fluid comprises the following components in percentage by weight: 56-97% of basic liquid, 0-12% of a weighting agent, 1.2-10% of a scale-preventing agent, 1.6-10% of a corrosion inhibitor and the balance of fresh water, wherein the density of the workover fluid is 1.20-1.55g / <cm3>; the basic liquid is an industrial calcium chloride solution with the saturated density of 1.40g / <cm3>; the weighting agent is zinc chloride; the scale-preventing agent is one of glacial acetic acid and formic acid; the corrosion inhibitor is imidazoline of quaternary ammonium salt. The density of the workover liquid disclosed by the invention can be randomly adjusted in a range from 1.20g / <cm3> to 1.55g / <cm3>. The workover fluid is particularly remarkable in scale preventing effect to sodium bicarbonate formation water, low in corrosivity to a sleeve of an oil pipe, good in compatibility with formation water, low in cost, low in damage, pollution-free, solid-free and good in mobility, and can meet the field construction demand.

Owner:CNPC BOHAI DRILLING ENG

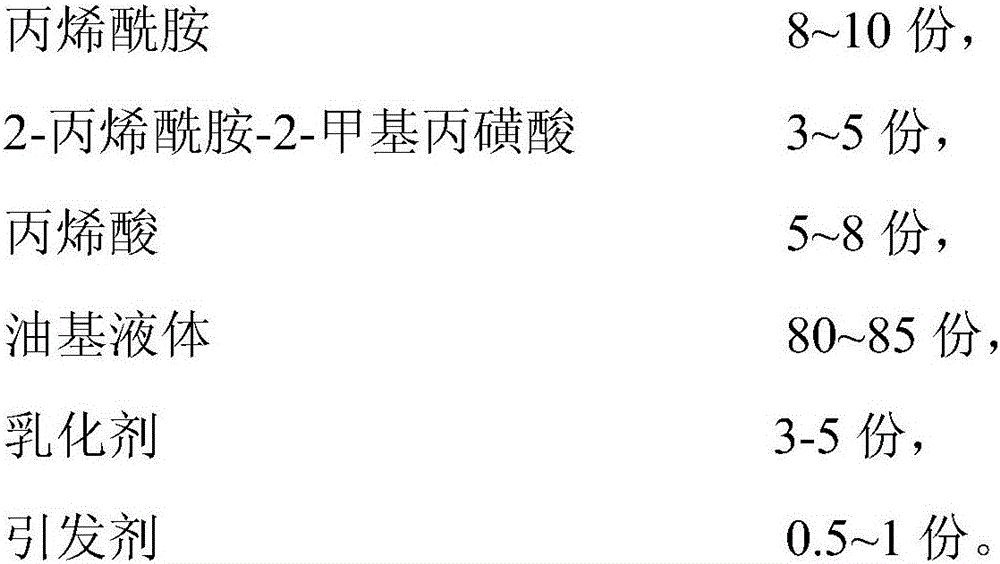

Multi-effect emulsion type thickening agent and preparation method thereof

ActiveCN113621106AReduce frictionDisperse and dissolve quicklyDrilling compositionSolventComposite material

The invention discloses a one-dose multi-effect emulsion type thickening agent and a preparation method thereof. The problems that in the prior art, liquid needs to be prepared in advance, construction is tedious, construction efficiency is affected, meanwhile, the function is single, and different construction environments cannot be met at the same time exist. According to the technical scheme, the method comprises the following steps: dissolving a water-soluble monomer in water to obtain a water phase, mixing solvent oil and an emulsifier to obtain an oil phase, stirring the mixed oil-water phase at a high speed to obtain a pre-emulsion, carrying out a reaction through inverse emulsion polymerization, and adding a phase inversion agent into the prepared emulsion to obtain the one-dose multi-effect emulsion type thickening agent. The one-dose multi-effect emulsion type thickening agent prepared by the invention is used as a fracturing fluid, and has different effects by adjusting the dosage. When a small amount of the one-dose multi-effect emulsion type thickening agent is added, the one-dose multi-effect emulsion type thickening agent can be used as a slickwater fracturing fluid and has the characteristics of low friction resistance, salt resistance and excellent dispersing and dissolving performance; and when the addition amount is large, the the one-dose multi-effect emulsion type thickening agent can be used as a high-temperature-resistant fracturing fluid and has excellent temperature resistance and shear resistance. Seamless switching between the slick water fracturing fluid and the high-temperature-resistant fracturing fluid can be achieved by controlling the adding amount of the thickening agent, and the requirement for on-line continuous mixing large-scale site construction is met.

Owner:陕西铜泽新能源科技有限公司

Steel wire rope pre-tightening device for flexible attachment of tower crane

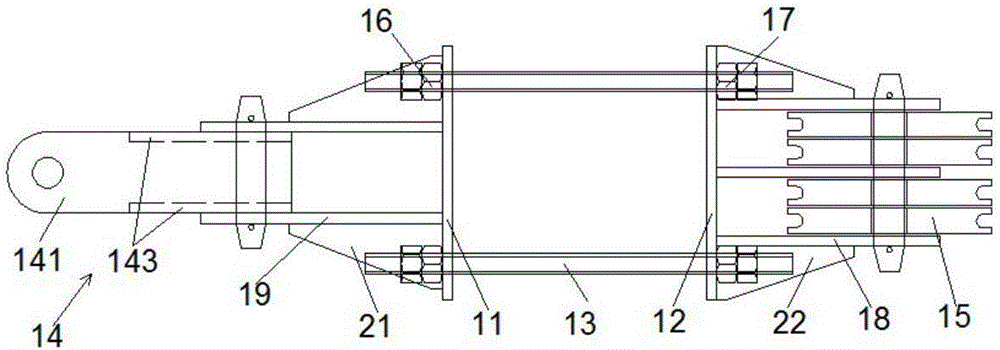

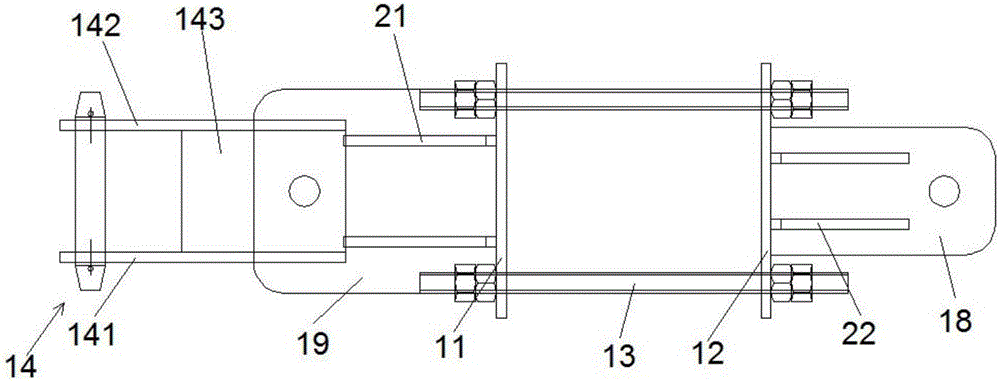

ActiveCN106185642AFlexible Attachment RealizationAdjustable preloadCranesArchitectural engineeringTower crane

The invention discloses a steel wire rope pre-tightening device for flexible attachment of a tower crane. The steel wire rope pre-tightening device comprises a first connecting plate, a second connecting plate, screws, a connector and a plurality of pulleys. The first connecting plate is in threaded connection to one end of each screw. The second connecting plate is in threaded connection to the other end of each screw. The positions, on the outer side of the first connecting plate and the outer side of the second connecting plate, of each screw are each provided with a nut. The connector comprises an upper connecting plate, a lower connecting plate and two rib plates, wherein the upper connecting plate and the lower connecting plate are parallel, and the two rib plates are fixed between the upper connecting plate and the lower connecting plate. The two rib plates are rotationally connected to the outer side of the first connecting plate. Second mounting plates perpendicular to the second connecting plate are fixed to the outer side wall of the second connecting plate. The pulleys are arranged on the second mounting plates. According to the steel wire rope pre-tightening device for flexible attachment of the tower crane, flexible attachment of the tower crane can be achieved, and for buildings and variable-section buildings with attachment points far away from a tower body, the field construction requirement is met, and safety operation, smooth mounting and smooth demounting of the tower crane are achieved.

Owner:北京庞源机械工程有限公司

Viscoelastic surfactant weighted fracture fluid, and preparation method thereof

The invention provides a viscoelastic surfactant weighted fracture fluid, and a preparation method thereof. The viscoelastic surfactant weighted fracture fluid is composed of, by mass, 2 to 5% of an isopropanol solution of a viscoelastic surfactant, 20 to 40% of a weighting agent, 0.1 to 1% of hydrochloric acid, and the balance water. The preparation method comprises following steps: an A component taking as a base solution and a B component taken as a cross-linking agent are prepared respectively, wherein the A component is composed of, by mass, 1% of the isopropanol solution of the viscoelastic surfactant, 20 to 40% of the weighting agent, 0.1 to 1% of hydrochloric acid, and the balance water, and the B component is composed of 1 to 4% of the isopropanol solution of the viscoelastic surfactant; and the A component and the B component are mixed so as to obtain a finished product. The density of the viscoelastic surfactant weighted fracture fluid ranges from 1.15 to 1.42g / cm<3>, the density is increased greatly, and fracture fluid on-site construction requirements are satisfied. The viscoelastic surfactant weighted fracture fluid is convenient to prepare, possesses instant performance, is capable of realizing construction field rapid preparation, possesses excellent temperature resistance and shearing resistance, and is capable of realizing automatic gel breaking in encounter with oil gas in stratum.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

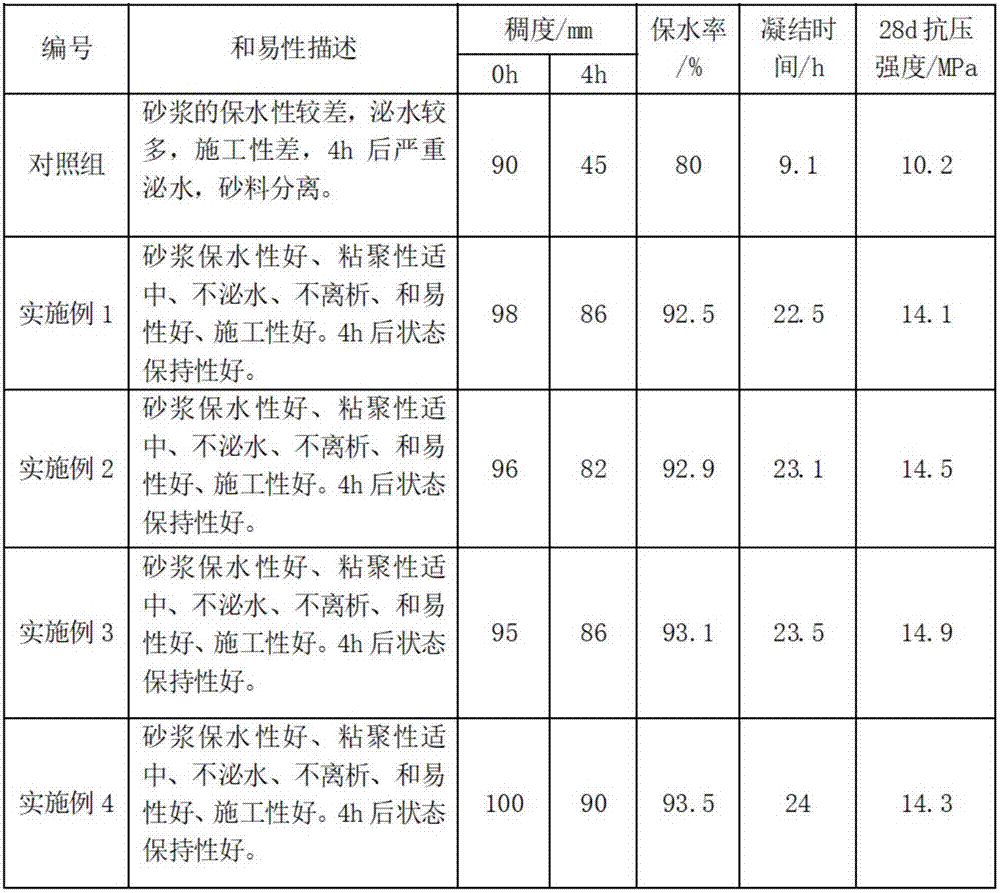

Special plastic stabilizer for machine-made sand plastering mortar

InactiveCN107973544AGood construction performanceImprove water retentionReducing agentMaterials science

The invention discloses a special plastic stabilizer for machine-made sand plastering mortar. The special plastic stabilizer is prepared from the following components in parts by mass: 52 to 56 partsof a retarder, 0.5 to 1 part of an air entraining agent, 18 to 20 parts of a water reducing agent, 18 to 25 parts of a water retaining agent, 0.5 to 1 part of a thixotropic agent and 1 to 3 parts of adispersant. The special plastic stabilizer for the machine-made sand plastering mortar disclosed by the invention is specially used for the machine-made sand plastering mortar; the constructability,the water retaining property, the cohesive performance, the thixotropic performance, the workability and the storage performance of the mortar can be improved.

Owner:FUKE TECH (SUZHOU) CO LTD

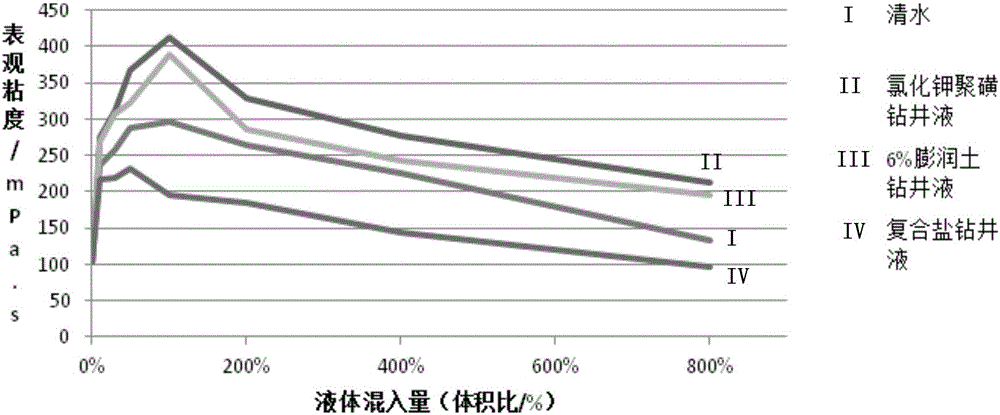

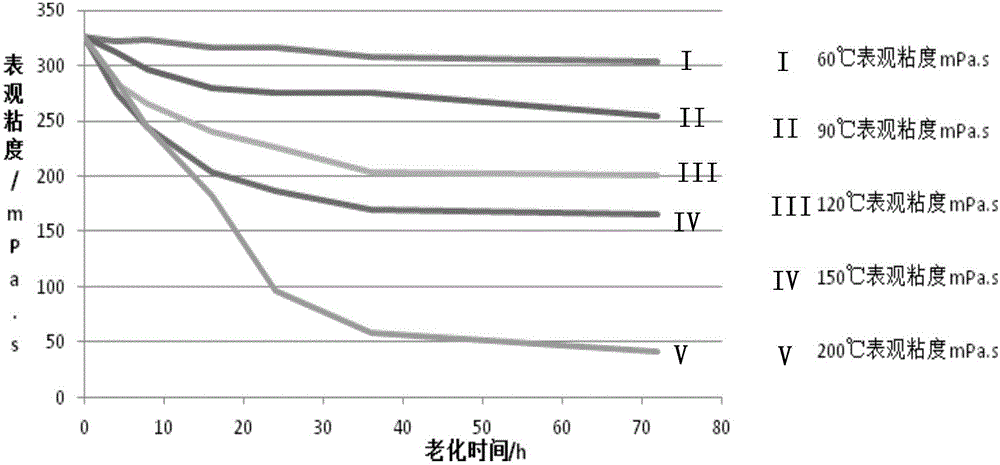

Acrylamide polymer-oil base compounded system and application thereof as cement paste supporting liquid

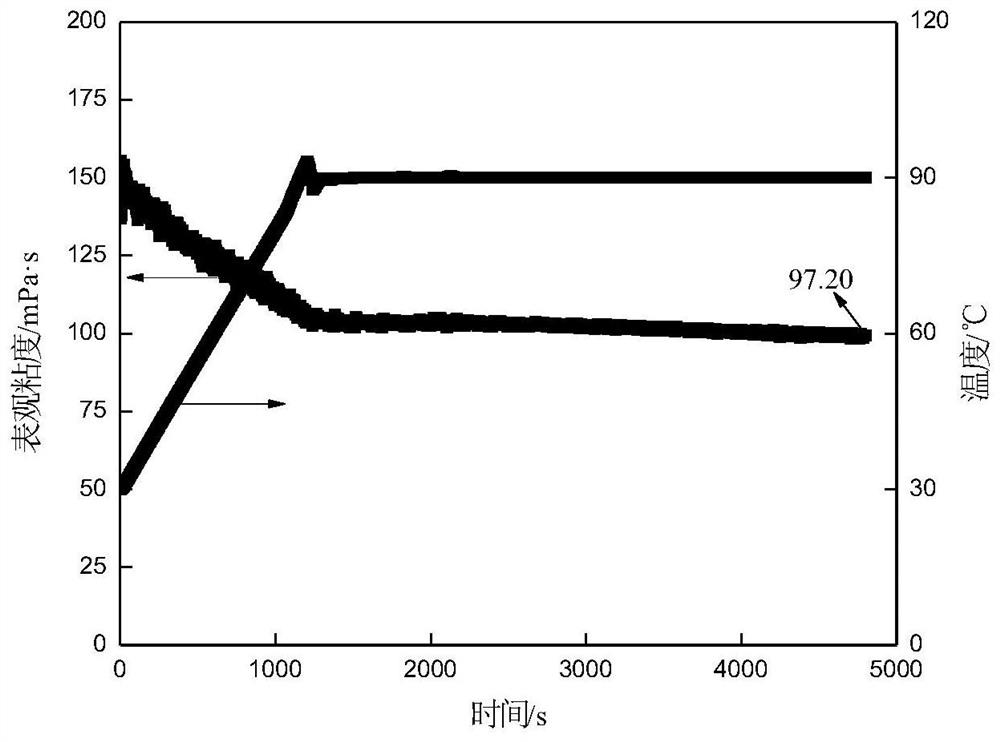

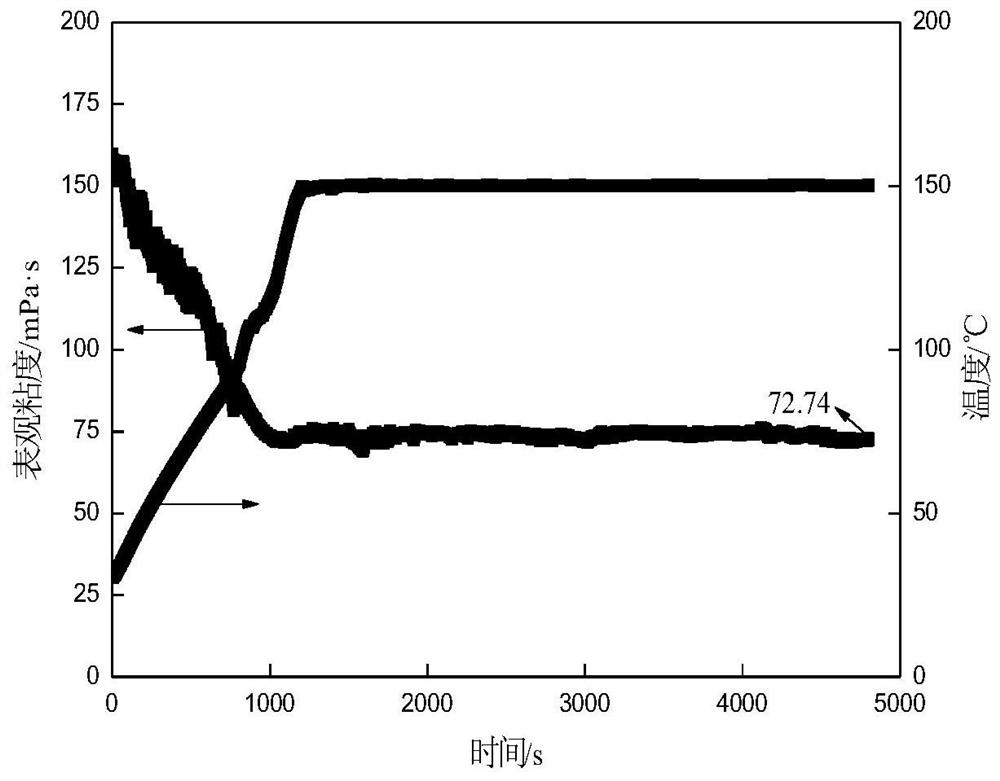

InactiveCN106350041ANo flashing phenomenonGood compatibilityDrilling compositionPolymer scienceApparent viscosity

The invention discloses an acrylamide polymer-oil base compounded system. The compounded system is formed by compounding an acrylamide polymer with the molecular weight of 4.0*10<6>-1.0*10<7> and an oil base liquid, wherein the acrylamide polymer realizes the polymerization of the acrylamide polymer and the compounding of the acrylamide polymer and the oil base liquid through adopting inverse emulsion polymerization of acrylamide, 2-acrylamide-2-methylpropanesulfonic acid and acrylic acid; the system is used as the cement paste supporting liquid which thickens in the presence of water, and the thickening has controllability and a very strong anti-dilution property; and under the condition of 150 DEG C, 72h aging continues for, the apparent viscosity does not fall dramatically, and an excellent heat-resisting property is achieved. In addition, the supporting liquid and the cement paste have excellent compatibility and avoid the flash set phenomenon of the cement paste after being mixed sufficiently, the normal-temperature flowing property and high-temperature flowing property of the mixed thick liquid are both suitable for pumping to meet the on-site operation requirement.

Owner:CNPC BOHAI DRILLING ENG

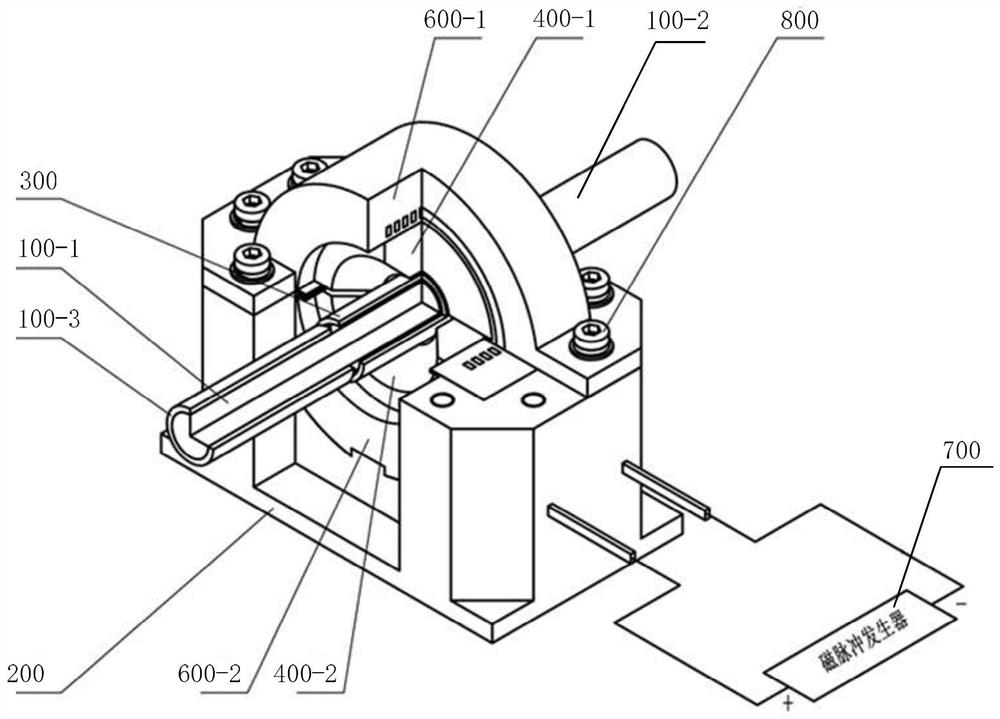

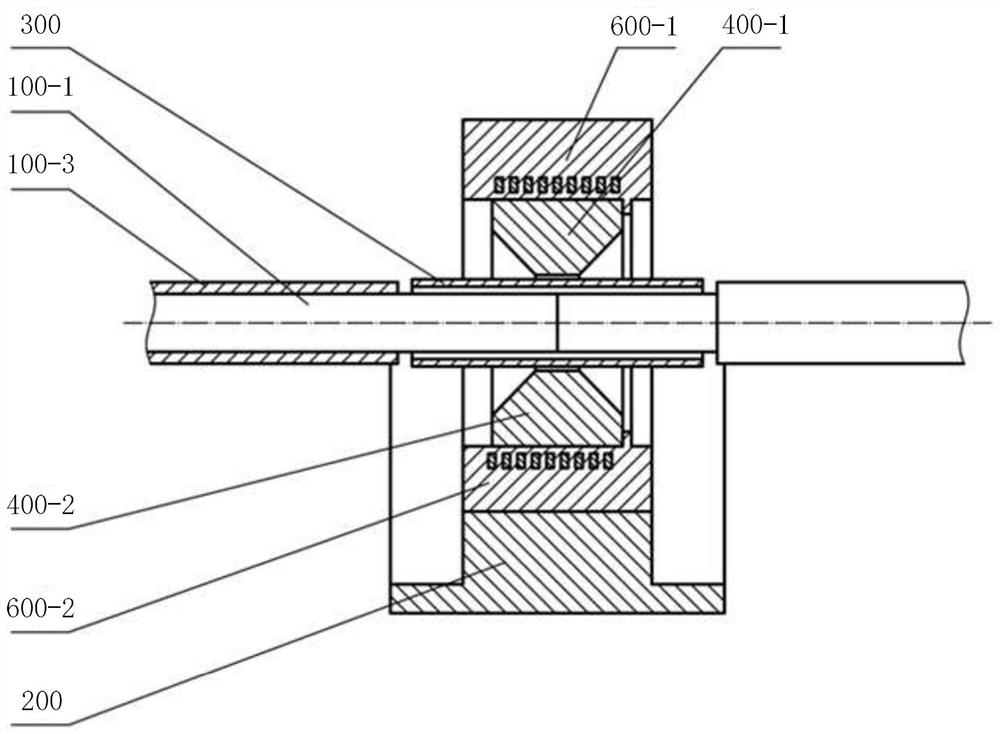

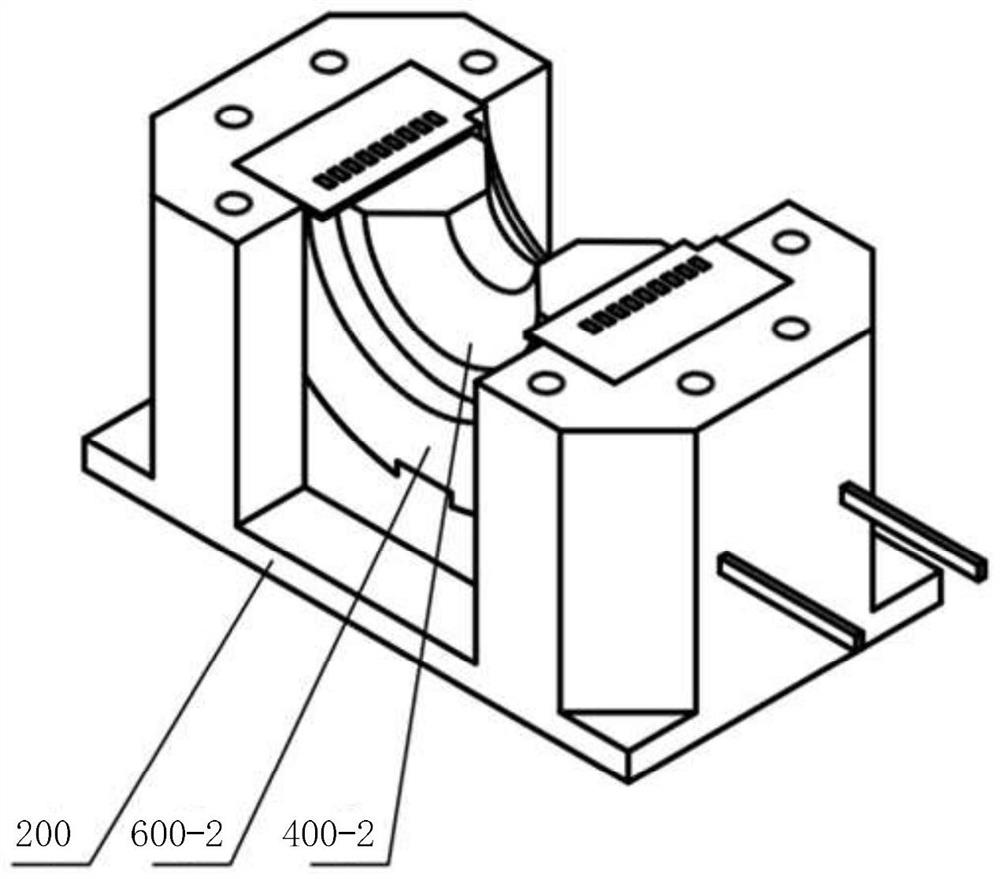

Magnetic pulse rapid connection device and method for power cable

PendingCN111613953AHigh strengthMeet the on-site construction requirements where it is not convenient to disassemble the coil axiallyLine/current collector detailsPower cableRemoving coil

The invention provides a magnetic pulse rapid connection device for a power cable. The magnetic pulse rapid connection device comprises a connection part, a supporting part and a pulse generator, andis characterized in that the connection part is integrally cylindrical and comprises a magnetic collector and a coil assembled at the outer diameter of the magnetic collector; the magnetic collector and the coil are of a split structure, the connection part is divided into an upper part and a lower part, the lower part of the connection part is assembled on the supporting part, and a fastening assembly is arranged at the joint of the upper part of the connection part and the lower part of the connection part; the coil is electrically connected to the magnetic pulse generator, an internal wirecore at the joint of two strands of power cables to be connected is arranged in a connecting pipe, and the connecting pipe is arranged between the upper part and the lower part of the connection part.Correspondingly, the invention further provides a connection method based on the above device. By adopting a split structure, the field construction requirement that the coil of the long cable is inconvenient to disassemble axially, can be met.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

Novel complex surface active degradation agent used for releasing the blocking of Polymer/Surfactant flooding

InactiveCN101550333BImprove protectionGood compatibilityDrilling compositionOil waterSURFACTANT BLEND

The present invention relates to a novel complex surface active degradation agent used for releasing the blocking of surfactant flooding. The invention mainly settles a problem that the well blocking of polymer / surfactant affects the recovery rate of oil accumulation. The invention is characterized in that the components and matching ratio are as follows by weight: 0.03-3.0% of surface activity degradation agent, 0.1-3.0% of weak degradation agent, and the balance of water. The complex active degradation agent is used for deblocking oil-water well of polymer / surfactant flooding in tertiary oilrecovery. The oil layer can be excellently protected. Furthermore the complex surface active degradation agent used for releasing the blocking of surfactant flood further has the following advantagesof good compatibility with stratum, no pollution, excellent fluidity, good safety, good environment-protecting property, long effective period and satisfaction to the field construction requirement.

Owner:大庆开发区东油新技术有限公司

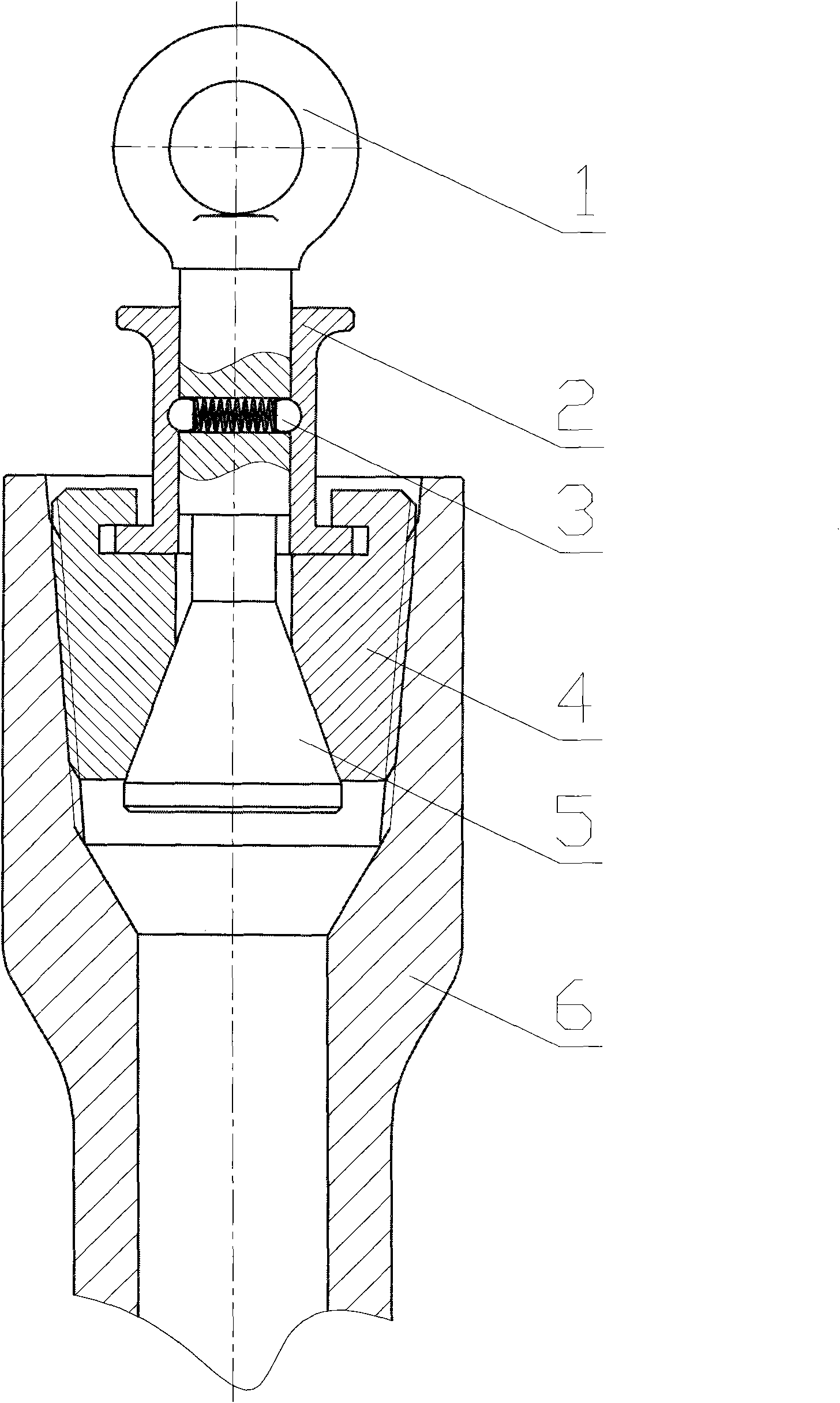

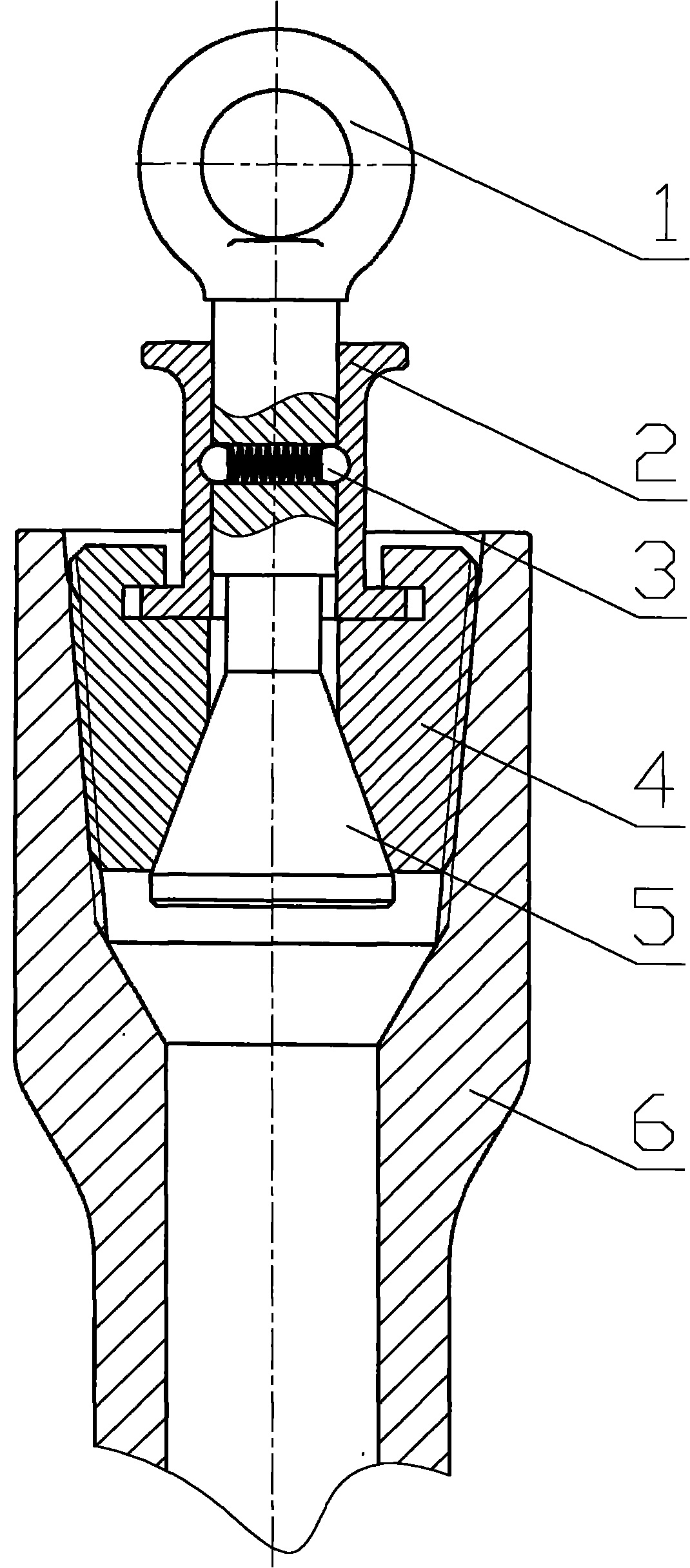

Rapid drill stem hoisting adapter

InactiveCN102134973AReduce labor intensityQuick releaseDrilling rodsDrilling casingsEconomic benefitsEngineering

The invention relates to a rapid drill stem hoisting adapter comprising a drill stem, a lifting ring, a linkage sliding sleeve, fixture blocks, and a cone. The outer walls of the fixture blocks are arc-shaped and provided with drill stem threads, and the inner walls of the fixture walls are tapered. The diameter of the lower end of each fixture block is large. A tapered body formed by a plurality of fixture blocks is suspended on the linkage sliding sleeve, the lifting ring passes through the linkage sliding sleeve, and the lower part of the lifting ring is connected with the tapered body. The tapered body with a small-diameter upper end and a large-diameter lower end is matched with the inner walls of the fixture blocks, the fixture blocks are connected with the drill stem threads, a damping lock is arranged between the lifting ring and the linkage sliding sleeve, the fixture blocks are expanded by lifting the tapered body of the lifting ring upwards so that the threads on the outer walls of the fixture blocks are connected with the threads on the inner wall of the drill stem to press the lifting ring to enable the tapered body to be apart from the fixture blocks, the fixture blocks are retracted, and the threads on the outer walls of the fixture blocks are separated apart from the threads on the inner wall of the drill stem. Therefore, the rapid drill stem hoisting adapter can be rapidly connected with and separated from the fixture blocks, and has advantages of easiness and convenience for hoisting of the drill stem, high operation efficiency, and low labor intensity of workers. The invention can meet requirements of on-site construction, and has obvious economic benefits.

Owner:DONGYING ZHICHENG TECH

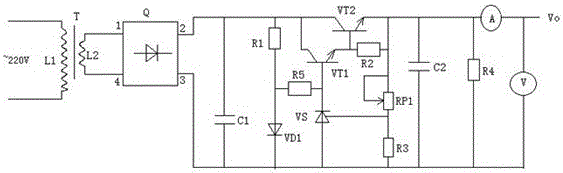

DC power supply and control circuit thereof

InactiveCN106332495AImprove stabilityEasy to hang and moveAc-dc conversionCasings/cabinets/drawers detailsPower flowVoltage source

The invention discloses a DC power supply and a control circuit thereof, comprising a power supply body and a T-shaped bracket, wherein the upper side of the horizontal part of the T-shaped bracket is provided with a power supply body, and the lower end of a vertical part of the bracket is equipped with a supporting rod, one end of which is fixed on the lower side of the horizontal part of the bracket. The top of the power supply body is fitted with a hanging ring, and there is a rope connecting the hanging ring and the suspension loop. The middle part of the left and right sides of the power supply body is mounted with a plurality of through-holes for heat dissipation. The upper part of the through-hole is provided with a rain shield, and the front side of the power supply body is equipped with a hinge-connected door that can open and close. The device can adjust DC voltage of the DC power supply from 3V to 15V continuously, with a maximum current up to 10A. The device has temperature compensation characteristics, and adopts high-precision standard voltage source integrated circuit TL431, enabling a higher stabilized voltage precision.

Owner:桂林大创科技有限公司

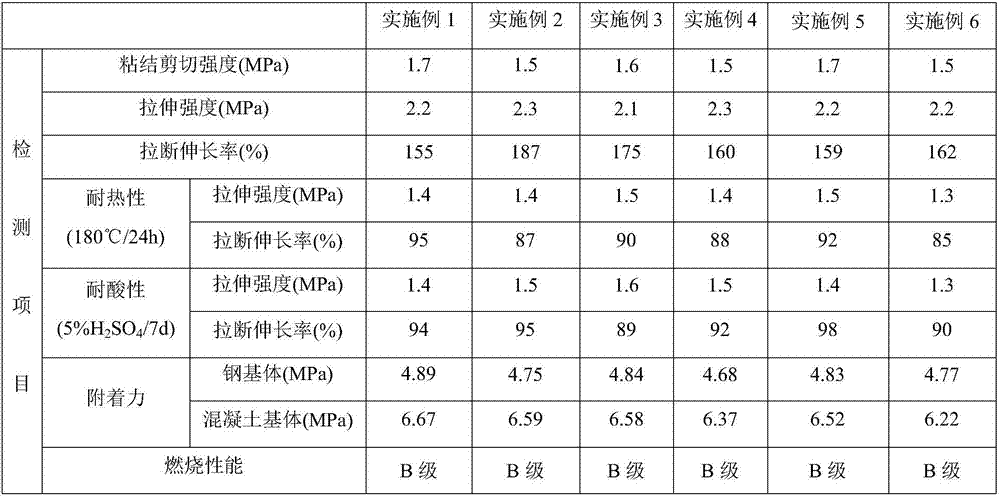

Preparation method for flame-retardant heatproof corrosion-resistant adhesive

ActiveCN106939152AImprove adhesionHigh nitrogen contentNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveSolvent

The invention provides a preparation method for a flame-retardant heatproof corrosion-resistant adhesive, belonging to the technical field of chemical adhesives. The preparation method comprises the following steps: 1) preparation of a component A: adding hydroxyl-terminated polydimethylsiloxane, an antifoaming agent, flame-retardant polyether polyol, a coupling agent and a solvent into a reaction vessel, successively carrying out heating and stirring, then successively adding an inorganic filling material and a fire retardant, carrying out vacuum-pumping for 10 to 30 min under stirring, and carrying out cooling and filtering after uniform mixing so as to obtain the component A; 2) preparation of a component B: mixing a semi-closed isocyanate curing agent, a catalyst and a solvent at room temperature under stirring so as to obtain the component B; and 3) preparation of the adhesive: mixing the component A with the component B under stirring so as to obtain the flame-retardant heatproof corrosion-resistant adhesive. According to the invention, flame-retardant polyether polyol is added, so the nitrogen content of a molecular chain is increased, and thermal stability of a paint is enhanced; a combustion product is low in smoke and free of toxicity; and the flame-retardant heatproof corrosion-resistant adhesive overcomes the defects of conventional adhesives, meets demands of on-site construction and improves the competitiveness of an enterprise.

Owner:CHENGDU LONGZHIQUAN SCI & TECH +1

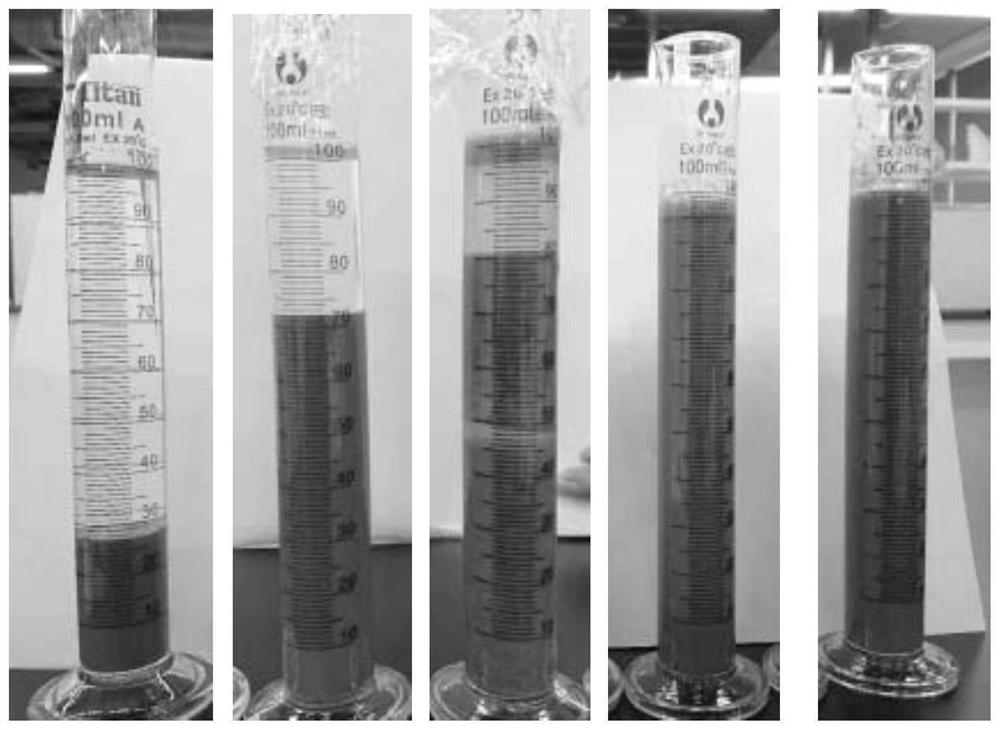

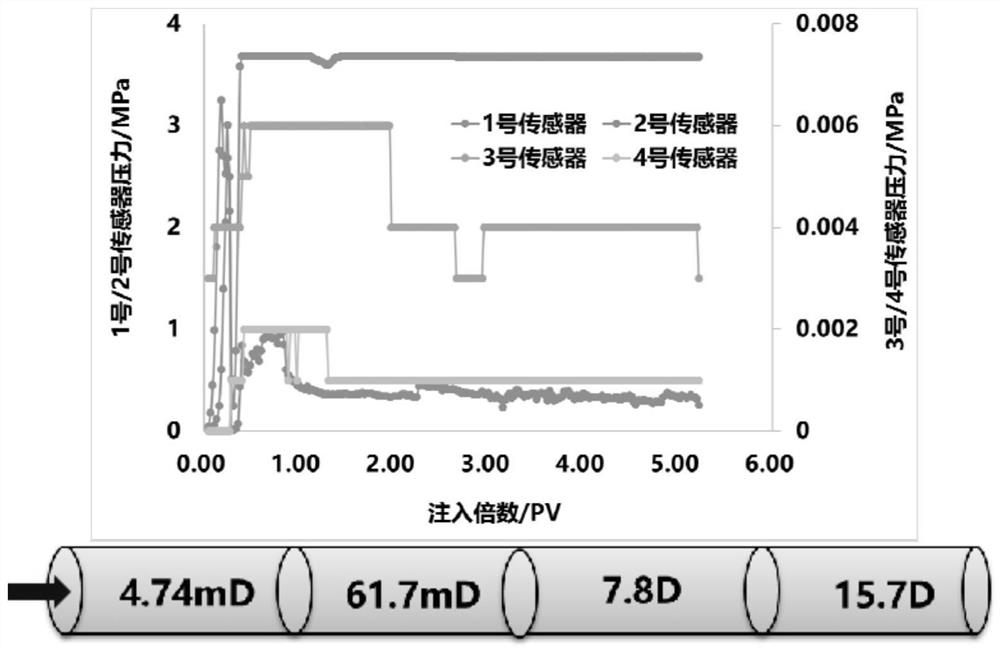

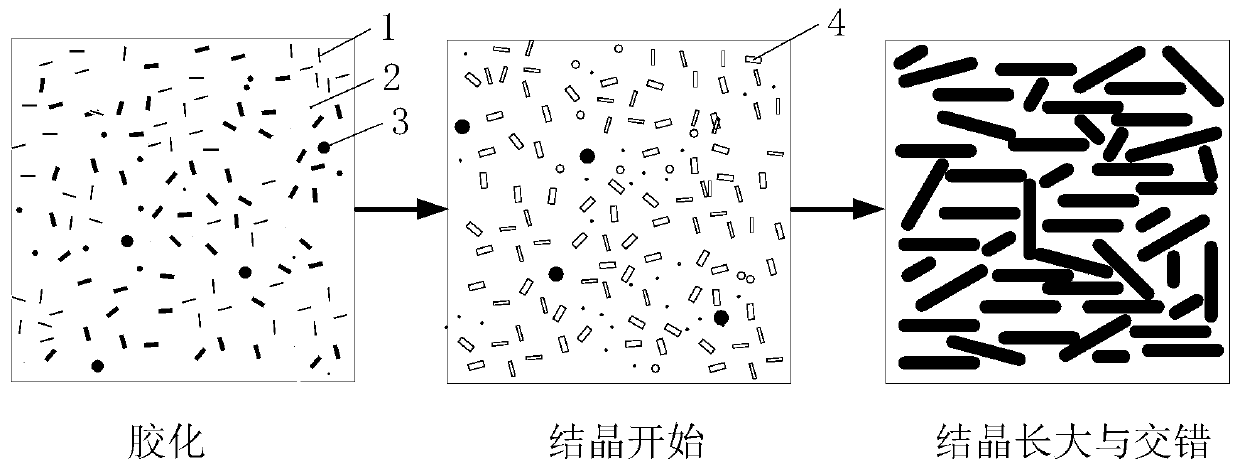

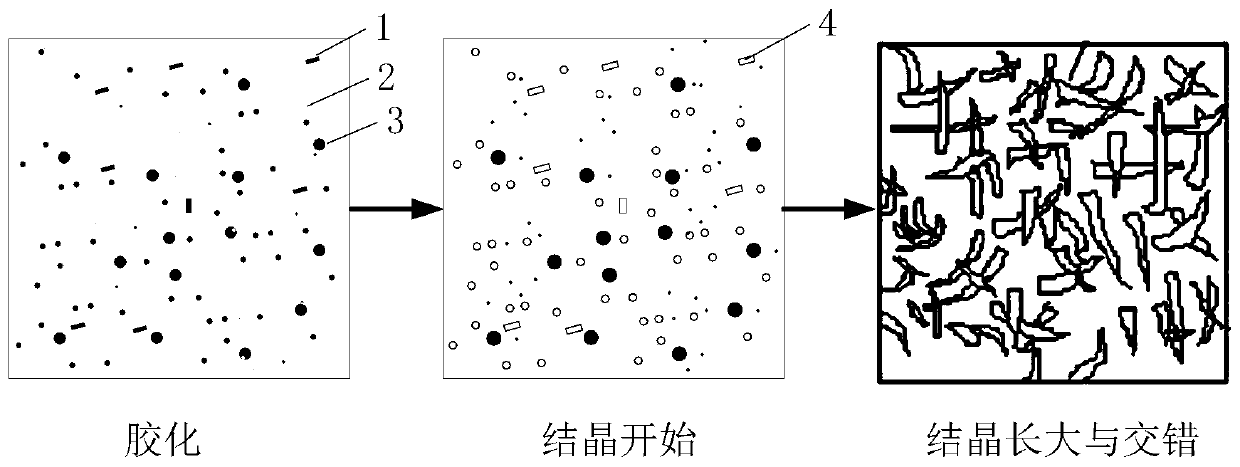

Weak consolidation large pore channel treatment system as well as preparation method and application thereof

PendingCN114736661AImprove seal strengthWith placeholder functionSolid waste managementFluid removalSoil scienceOil field

The invention discloses a weak-consolidation large-pore-channel treatment system as well as a preparation method and application thereof, and belongs to the technical field of agents for profile control and water shutoff of oil fields. The weak-consolidation large-pore-channel treatment system is prepared from the following raw materials in percentage by mass: 1%-5% of a proppant, 0.2%-0.8% of a support enhancer, 2%-20% of a curing agent, 0%-0.5% of a tackifier and the balance of oilfield production sewage. Compared with an organic gel system, the weak-consolidation large-pore-channel treatment system has the advantages that the plugging strength is higher, and a certain space occupying function is achieved; and compared with a cement inorganic solidification system, the risk of blocking or polluting a production layer is reduced.

Owner:CHINA NATIONAL OFFSHORE OIL (CHINA) CO LTD +1

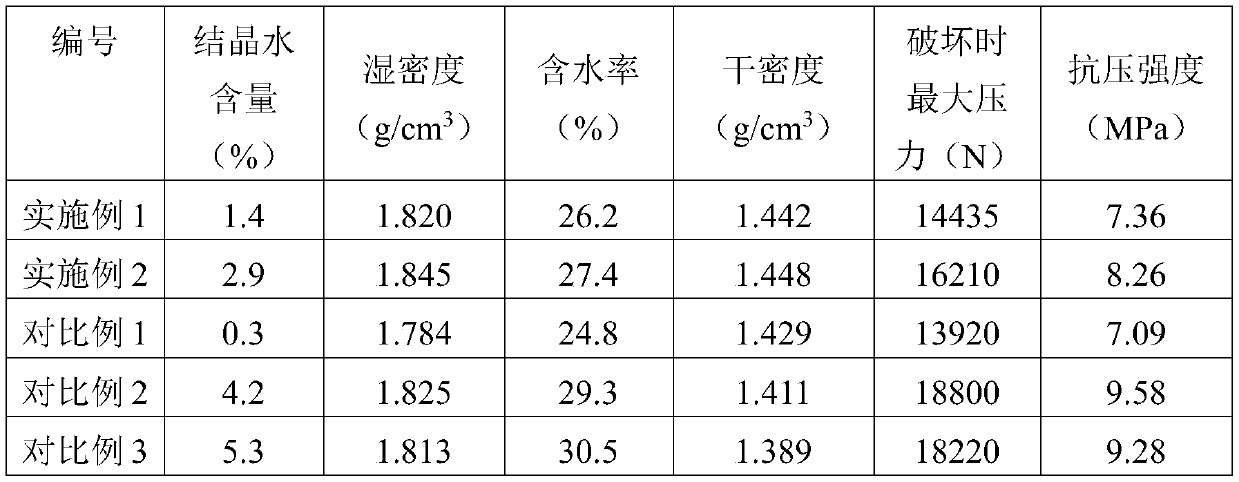

High-strength self-waterproof phosphogypsum roadbed material and preparation method thereof

ActiveCN111320446AHigh strengthImprove waterproof performanceSolid waste managementPhysical chemistryEnvironmental engineering

The invention discloses a high-strength self-waterproof phosphogypsum roadbed material. The ardealite raw material is calcined to obtain modified ardealite powder for preparing an ardealite roadbed material. In the process of converting calcium sulfate dihydrate into hemihydrate gypsum through dehydration, generation of alpha-hemihydrate gypsum is effectively promoted by further regulating and controlling the water content and the input amount of the ardealite raw material in a closed calcining environment, so that the mechanical property and the waterproof property of the obtained ardealite roadbed material are remarkably improved. The modification method provided by the invention is extremely simple and convenient to operate, can realize 100% recycling of phosphogypsum waste, has important economic and environmental benefits, and is suitable for popularization and application.

Owner:HUBEI PROVINCIAL CENT FOR QUALITY SUPERVISION AD TEST OF CONSTR ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com