Temperature response type amphoteric polymer retarder and preparation method thereof

An amphoteric polymer, temperature-responsive technology, used in the field of oil and gas exploration and development chemicals, can solve the problems of adding amount and temperature sensitivity, unstable cement slurry, low cement stone strength, etc. Low volume sensitivity and good adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

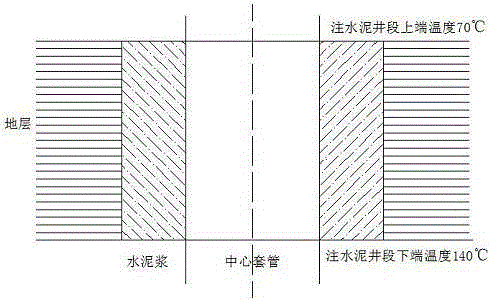

Image

Examples

example 1

[0020] (1) Weigh the corresponding monomer according to the mass percentage and dissolve it in deionized water, put the maleic anhydride solution in the reaction flask, stir and heat, and reflux the condenser tube, 2-acrylamide-2-methylpropanesulfonic acid, The mixed solution of dimethyl diallyl ammonium chloride and acrylamide is placed in the constant pressure dropping funnel;

[0021] (2), take by weighing the initiator ammonium persulfate accounting for 8% of the monomer mass and be dissolved in deionized water, and placed in the constant pressure dropping funnel;

[0022] (3) When the system temperature rises to a preset temperature of 90°C, start adding the initiator solution dropwise, as well as 2-acrylamide-2-methylpropanesulfonic acid, dimethyl diallyl ammonium chloride and acrylamide three or the mixed solution and timing;

[0023] (4) Add dropwise for 1 hour, then react at constant temperature for 4 hours, cool, purify, dry and grind the obtained solution to obtain...

example 2

[0026] The temperature-responsive amphoteric polymer retarder prepared in Example 1 was used to prepare well cement slurry, and the cement slurry consisted of the following components in parts by weight.

[0027]

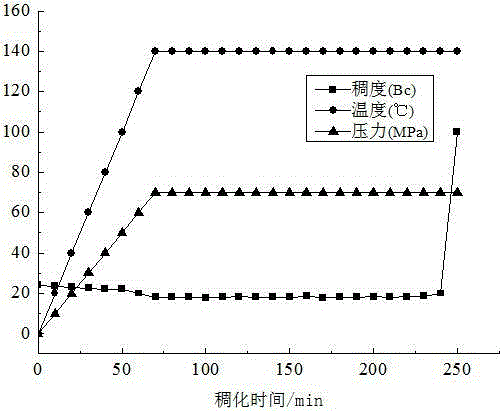

[0028] When the temperature-responsive amphoteric polymer retarder of the present invention is added in an amount of 3%, the thickening time at 135°C, 140°C and 145°C is shown in Table 1, wherein the thickening curve at 140°C and 70MPa is as follows figure 2 Shown:

[0029] Table 1 Temperature Sensitivity Experiment

[0030]

[0031] When the temperature-responsive amphoteric polymer retarder of the present invention is added in an amount of 3%, the change rate of the thickening time is within 20% for every 5°C increase in temperature, and the temperature sensitivity of the amphoteric polymer retarder is low. In addition, the related Experiments also prove that the amphoteric polymer retarder is less sensitive to dosage, and the dosage sensitivity coefficien...

example 3

[0033] The temperature-responsive amphoteric polymer retarder prepared in Example 1 was used to prepare well cement slurry, and the cement slurry consisted of the following components in parts by weight.

[0034]

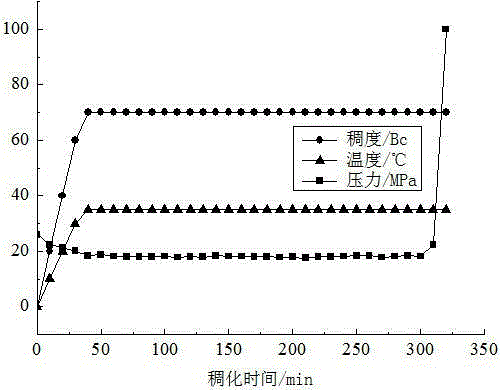

[0035] When the temperature-responsive amphoteric polymer retarder of the present invention is added in an amount of 0.2% and 0.5%, respectively at 70°C and 90°C, the compressive strength tests of cement stones maintained for 24h and 48h under normal pressure conditions are shown in Table 1. Among them, when the addition amount is 1%, the thickening curve at 70°C and 35MPa is as follows image 3 Shown:

[0036] Table 1 Cement stone compressive strength

[0037]

[0038] The temperature-responsive amphoteric polymer retarder prepared by the present invention can be used under high temperature conditions, and its strength develops well under low temperature conditions, which is far greater than SY / T5504.1-2005 "Evaluation Method for Oil Well Cement Admixture Pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com